Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

81 results about "Cycloheptene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cycloheptene is a 7-membered cycloalkene with a flash point of −6.7 °C. It is a raw material in organic chemistry and a monomer in polymer synthesis. Cycloheptene can exist as either the cis- or the trans-isomer.

Amino substituted diaryl[a,d]cycloheptene analogs as muscarinic agonists and methods of treatment of neuropsychiatric disorders

Disclosed herein are analogs of clozapine and pharmaceutically acceptable salts, esters, amides, or prodrugs thereof; methods of synthesizing the analogs; and methods of using the analogs for treating neuorpsychiatric disorders. In some embodiments, the analogs are amino substituted diaryl[a,d]cycloheptenes.

Owner:ACADIA PHARMA INC

Amino substituted diaryl[a,d]cycloheptene analogs as muscarinic agonists and methods of treatment of neuropsychiatric disorders

Disclosed herein are analogs of clozapine and pharmaceutically acceptable salts, esters, amides, or prodrugs thereof; methods of synthesizing the analogs; and methods of using the analogs for treating neuorpsychiatric disorders. In some embodiments, the analogs are amino substituted diaryl[a,d]cycloheptenes.

Owner:ACADIA PHARMA INC

Amino bustituted diaryl[a,d]cycloheptene analogs as muscarinic agonists and methods of treatment of neuropsychiatric disorders

Disclosed herein are analogs of clozapine and pharmaceutically acceptable salts, esters, amides, or prodrugs thereof; methods of synthesizing the analogs; and methods of using the analogs for treating neuorpsychiatric disorders. In some embodiments, the analogs are amino substituted diaryl[a,d]cycloheptenes.

Owner:ACADIA PHARMA INC

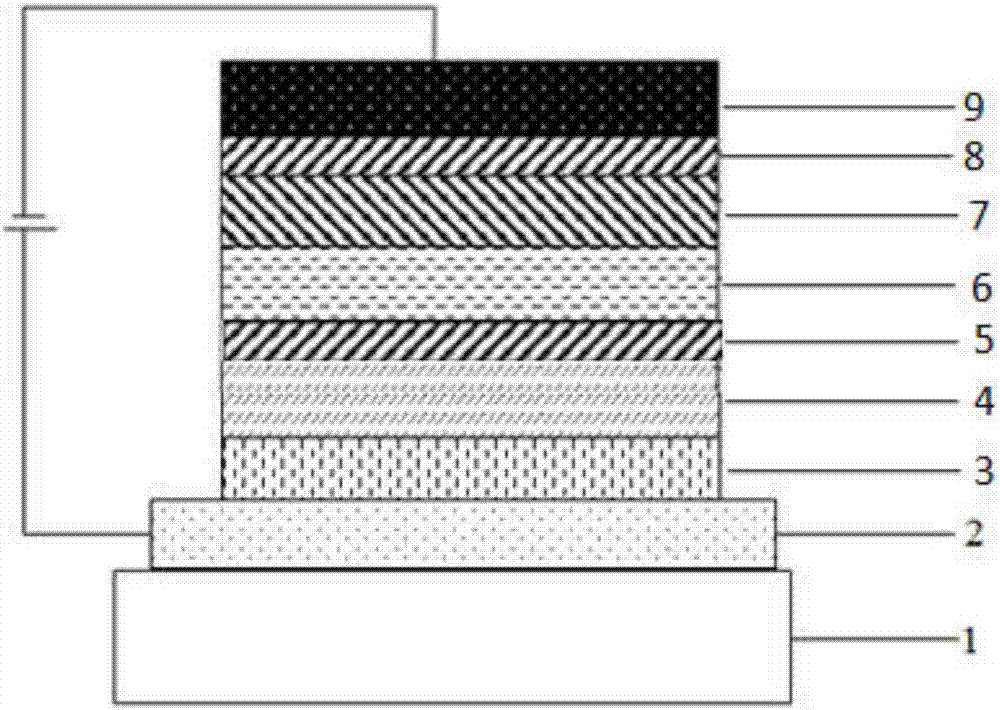

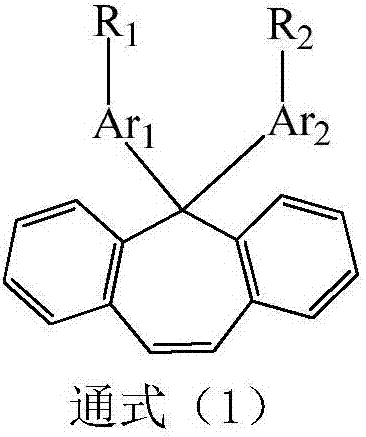

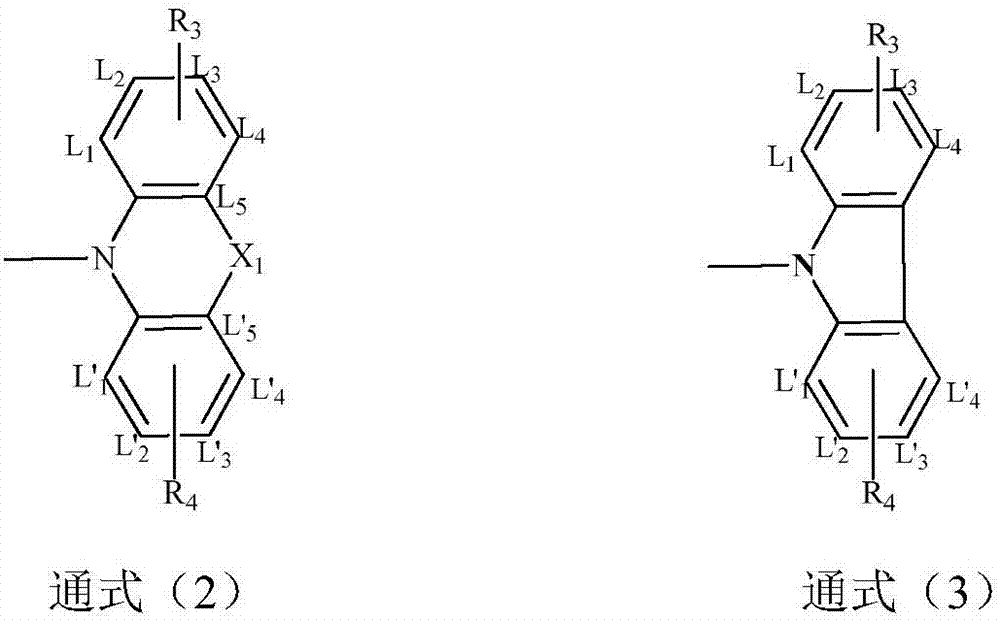

Compounds with 5H-dibenzo[a,d]cycloheptene as cores and application of compounds

ActiveCN107602397AImprove hole transport abilityHigh refractive indexOrganic compound preparationSolid-state devicesBenzeneNitrogen

The invention discloses compounds with 5H-dibenzo[a,d]cycloheptene as cores and an application of the compounds to OLED (organic light-emitting diode) devices. The compounds with 5H-dibenzo[a,d]cycloheptene as the cores are characterized in that central position of a heptyl ring of each compound is linked with a nitrogen-containing branch chain through phenyl, biphenyl or naphthyl. The compounds are not prone to crystallization and have good film forming property and heat stability as well as proper HOMO and LUMO energy level, by means of structure optimization of the devices, photoelectric property of the OLED devices can be improved effectively, and the service life of the OLED devices can be prolonged effectively.

Owner:JIANGSU SUNERA TECH CO LTD

Preparation method of macromolecule packaging material

The invention relates to a preparation method of a macromolecule packaging material. The preparation method comprises the following steps: (1) opening a reaction kettle, adding alkyd resin, polychloroprene and polycarbonate into the reaction kettle, heating and mixing until the mixture is mixed uniformly; (2) after temperature preservation, increasing the temperature of the reaction kettle, then adding cycloheptene, cellulose acetate butyrate, ethylene glycol, silicon dioxide and butyl rubber after temperature stabilization, then mixing again until all components are dispersed uniformly, thereby obtaining the uniform mixed packaging material; (3) then carrying out extrusion molding on the mixed packaging material; (4) cooling the extruded material, arranging the material rapidly at 3-6 DEG C, and cooling; (5) after cooling, heating the macromolecule packaging material to be 130 DEG C, and stretching after temperature preservation; and (6) packaging the packaging material so as to obtain the prepared macromolecule packaging material.

Owner:FUJIAN NANWANG ENVIRONMENTAL PROTECTION TECH CO LTD

Cycloolefin addition copolymer and optical transparent material

The present invention provides a cyclic olefin addition copolymer composed of endo-tricyclo[4.3.0.1 2,5 ]dec-3,7-diene, endo-tricyclo[4.3.0.1 2,5 ] Cyclic olefin compounds with branched chain substituents such as dec-3-ene and other cyclic olefin compounds such as bicyclo[2.2.1]hept-2-ene, and cyclic olefin compounds with hydrolyzable silyl groups when necessary A cyclic olefin addition copolymer obtained by copolymerization or hydrogenation of a olefin compound after copolymerization; and a crosslinking composition in which a specific crosslinking agent is added to the copolymer, and the crosslinked product formed by crosslinking the composition contains The optical material of its copolymer, composition or cross-linked product, and the production method of the copolymer by addition polymerization using a specific nickel catalyst.

Owner:JSR CORPORATIOON

Method for preparing intermediate of colchicine derivatives

ActiveCN102603556AMild reaction conditionsSimple processOrganic compound preparationCarboxylic acid amides preparationBenzeneColchicine derivatives

The invention discloses a method for preparing an intermediate of colchicine derivatives, namely (5S)-N-(3-amino-9,10,11-trimethoxy-6,7-dihydro-5H-dibenzo [a, c] cycloheptene-5-yl) acetamide. The method comprises the steps of rearranging colchicine under the action of sodium methylate to generate allo-colchicine, hydrolyzing the allo-colchicine under alkaline conditions to obtain colchicinic acid and carrying out Schmidt rearrangement on the colchicinic acid and an azide reagent under the catalysis of polyphosphoric acid to obtain the intermediate of the colchicine derivatives, namely the (5S)-N-(3-amino-9,10,11-trimethoxy-6,7-dihydro-5H-dibenzo[a,c]cycloheptene-5-yl)acetamide. The method has the advantages that the polyphosphoric acid is adopted to catalyze the Schmidt rearrangement; the reaction condition is mild; the process is simple; the product purification is easy; the yield is high; and large-scale industrial production is easy to realize.

Owner:ZHEJIANG UNIV

Low-temperature-resistant packaging material and preparation method therefor

The invention discloses a low-temperature-resistant packaging material. The packaging material contains the following raw materials in parts by weight: 15-30 parts of polyimide, 10-15 parts of polytetrafluoroethylene, 10-15 parts of polytrifluorochloroethylene, 5-10 parts of butyronitrile, 2-5 parts of polysulfone, 2-5 parts of silicon rubber, 5-10 parts of methylphenylvinyl silicone, 10-20 parts of organic silicone gel, 5-15 parts of asbestos, 5-10 parts of polyester, 5-10 parts of epoxy resin, 5-15 parts of polycarbonate, 5-10 parts of cycloheptene, 2-5 parts of aziridine, 5-10 parts of an emulsifier and 5-10 parts of an accelerant. Meanwhile, the invention discloses a preparation method for the low-temperature-resistant packaging material.

Owner:SUZHOU JIN TENG ELECTRONICS TECH

Process for producing epsilon-caprolactam

A process for producing epsilon -caprolactam, characterized by subjecting cyclohexanone oxime to the vapor-phase Beckmann rearrangement reaction in the presence of an alcohol using a solid catalyst and treating the resultant reaction product containing a 1-aza-2-alkoxy-1-cycloheptene with water to remove the 1-aza-2-alkoxy-1-cycloheptene from the reaction product. The thus-obtained epsilon -caprolactam has a 1-aza-2-alkoxy-1-cycloheptene content of generally 100 ppm or lower, desirably 25 ppm or lower, preferably 10 ppm or lower. It hence has a low basicity with respect to free bases and is of desirable quality.

Owner:SUMITOMO CHEM CO LTD

Oxabicycloheptanes and oxabicycloheptenes for the treatment of reperfusion injury

A method of reducing reperfusion injury in mammalian tissue comprising contacting the tissue with a protein phosphatase 2A (PP2A) inhibitor having the structure.

Owner:里克思特生物技术有限公司

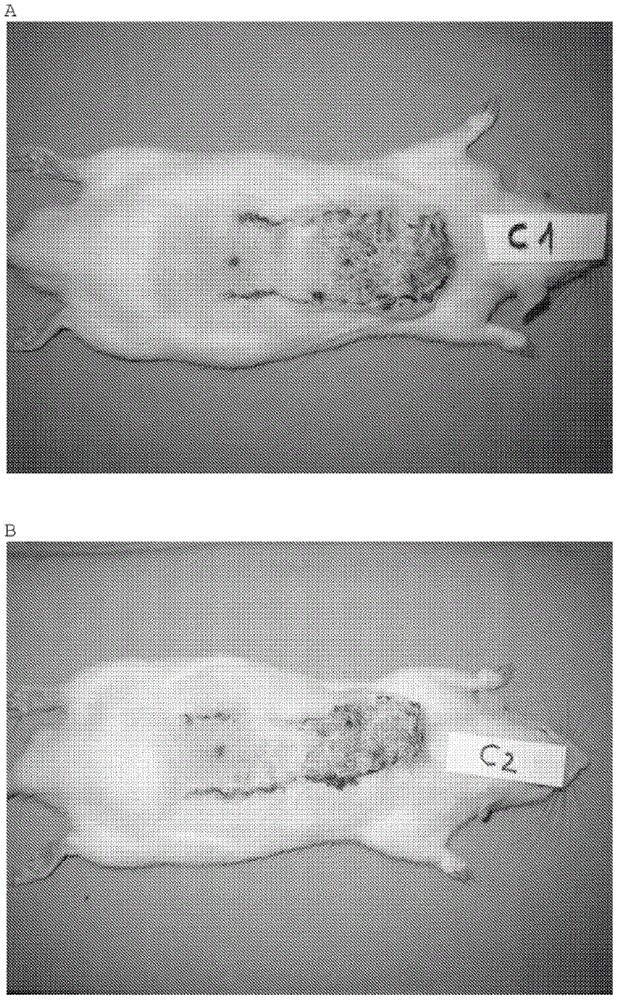

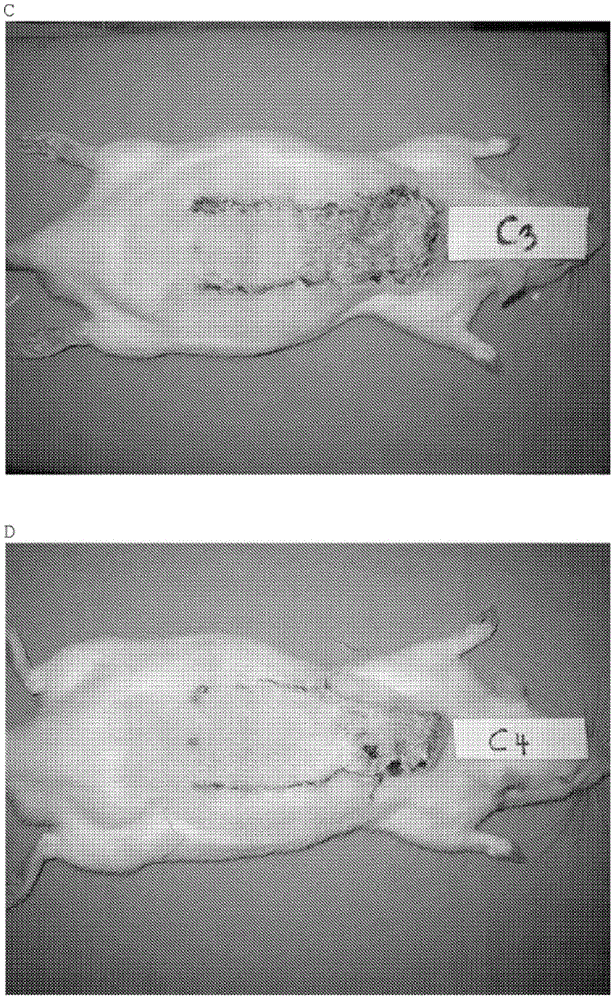

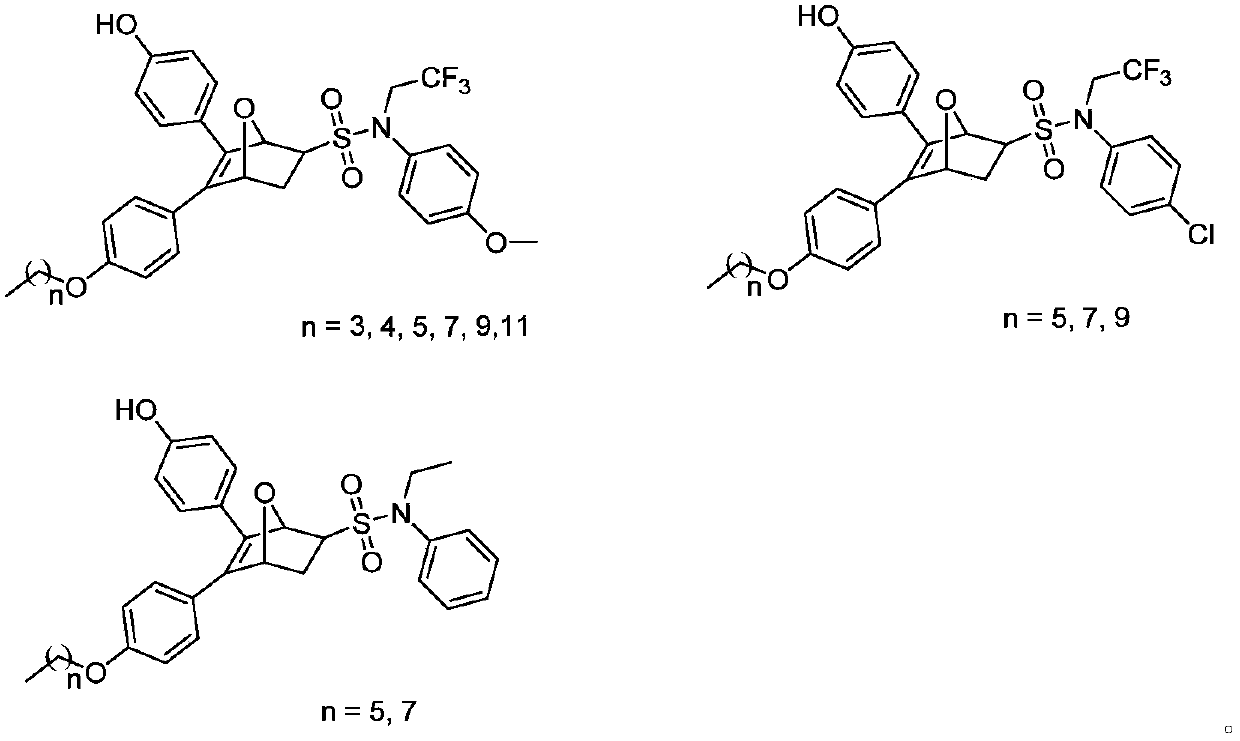

Oxo-bridged bicyclo-heptylene sulfonamides compound containing different alkyl chain lengths, as well as preparation method and application thereof

The invention discloses an oxo-bridged bicyclo-heptylene sulfonamides compound containing different alkyl chain lengths, as well as a preparation method and application thereof, and belongs to the technical field of medicines. 3-(4-hydroxycyclohexyl phenyl)-4-(4-alkoxy phenyl)-furan and a phenylethylene sulfonamide derivative are adopted as raw materials, no catalyst is needed, the raw materials are reacted at 90 DEG C for 8 hours, and the oxo-bridged bicyclo-heptylene sulfonamides compound containing the different alkyl chain lengths is obtained through one-step preparation. The action mode of the oxo-bridged bicyclo-heptylene sulfonamides compound is different from the action mode of existing anti-breast cancer drug tamoxifen, and the compound not only can be used for effectively inhibiting the growth of a breast cancer cell MCF-7, but also has favorable estrogen receptor alpha down-regulation activity equivalent to fulvestrant, and shows an application prospect of the compound in breast cancer therapy.

Owner:WUHAN UNIV

Process for producing dicyanonorbornane and zerovalent-nickel complex catalyst

ActiveCN101443308AVolume suppressionOrganic compound preparationOrganic chemistry methodsArylPtru catalyst

The present invention is to provide a process for producing dicyanonorbornane characterized by causing hydrogen cyanide to undergo addition reaction with cyanonorbornene (bicyclo[2.2.1]-5-heptene-2-carbonitrile) in the presence of a zerovalent nickel complex catalyst which is produced by using a phosphite represented by P (x) (y) (z) (wherein P is a phosphorus atom, and x, y and z are each OR, where R represents an aryl group having not more than 18 carbon atoms) as a ligand to reduce a nickel halide with at least one metal selected among zinc, cadmium, beryllium, aluminum, iron and cobalt, wherein the phosphite is one which has a phosphate content of 1.0 weight % or lower based on the whole phosphitem to produce the zerovalent nickel complex catalyst.

Owner:MITSUI CHEM INC

Compound taking diphenyl cycloheptene as core and application thereof in organic light-emitting device

ActiveCN107216279AEasy injectionImprove transmission performanceOrganic chemistrySolid-state devicesOrganic light emitting deviceNitrogen

The invention discloses a compound taking diphenyl cycloheptene as a core and an application thereof in an organic light-emitting device. The diphenyl cycloheptene is used as a mother core of the organic compound and is connected with a triarylamine group or a nitrogenous poly-heterocyclic aromatic base through a phenyl group, a biphenyl group or a naphthyl group. The compound disclosed by the invention has higher glass transition temperature and molecular thermal stability, is suitable for HOMO and LUMO energy levels and is higher in Eg. Through the optimization for the device structure, the photoelectric property of an OLED device can be effectively promoted, and the service life of the OLED device can be effectively prolonged.

Owner:JIANGSU SUNERA TECH CO LTD

Process for preparing bicylo[2.2.1] heptane derivatives

InactiveUS6841713B2Hydrocarbon by isomerisationPhysical/chemical process catalystsIsomerizationBase oil

The invention relates to economical and efficient methods for producing 2-methylene-3-methylbicyclo[2,2,1]heptane, 2,3-dimethylbicyclo[2.2.1]hept-2-ene and the like that are useful for materials of producing base oil of traction drive fluid for traction drive lubricating oil. The methods comprise reacting one or more C3-4 acyclic olefins with cyclopentadiene and isomerizing the resulting bicyclo[2.2.1]heptene derivatives in the presence of an isomerization catalyst to give one or more bicyclo[2.2.1]heptane derivatives.

Owner:IDEMITSU KOSAN CO LTD

Method for removing ethanol, isopropanol and octyl alcohol from amino resin workshop wastewater

InactiveCN105084495AStrong complexing abilityFast precipitationWater contaminantsNature of treatment waterOctanolAcetophenone

The invention relates to a method for removing ethanol, isopropanol and octyl alcohol from amino resin workshop wastewater. The components adopted by the method comprises 1,3,3-trimethyl-2-oxabicyclo[2.2.2]octane, 1,8-dihydroxy-3-methoxy-6-methylanthraquinone, S(-)-2-amino-6-n-propyle-4,5,6,7-tetrahydrobenzothiazole dihydrochloride, 4-octylphenol ethoxylate, 3',4'-dihydoxy-2-(methylamino)acetophenone hydrochloride, 4-acetoxy-3-methoxy-(2-propenyl) benzene, 4-methoxybenzyl acetate, 6,6,10-trimethyl bicyclo-3,1,1-hept-2-ene, and 2-[[1-(3-acetylthio-2-methylpropionyl)pyrrolidine-2-formyl]amino]-3-phenylpropionic acid. The components adopted by the method have strong complexing capability with target substances, high speed of forming complex precipitates, and high removal rate up to 99.9%.

Owner:李海兰

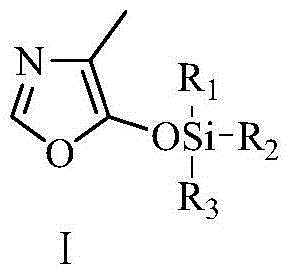

Vitamin B6 intermediate 4-methyl-5-alkylsiloxane oxazole, preparation method thereof as well as method for preparing vitamin B6

The invention relates to a vitamin B6 intermediate 4-methyl-5-alkylsiloxane oxazole, a preparation method thereof as well as a method for preparing the vitamin B6. 4-methyl-5-alkylsiloxane oxazole has the structure shown as the formula I. 2-alanine and formaldehyde or paraformaldehyde are subjected to N-hydroxymethylation and lactonization in a solvent under the action of an acid catalyst to obtain 4-methyl-tetrahydro-oxazole-5-ketone (II), the ketone is not separated and is directly subjected to chloro substitution, silicon etherification and an elimination reaction in the presence of an acid-binding agent to generate 4-methyl-5-alkylsiloxane oxazole (I). 4-methyl-5-alkylsiloxane oxazole and 2-n-propyl-1,3-dioxo-5-cycloheptene are subjected to addition and hydrolysis to prepare the vitamin B6. The process is short, the operation is easy, little wastewater is produced, safety and environmental protection are realized, the reaction selectivity is good, a product is low in cost and high in purity, and industrial production is facilitated better.

Owner:XINFA PHARMA

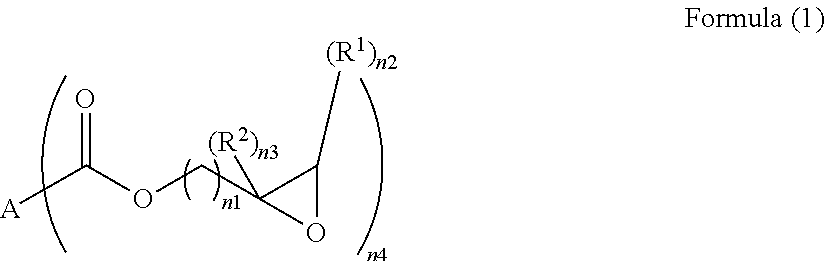

Polyfunctional epoxy compound

InactiveUS20130274433A1Increase freedomImprove curing effectOrganic chemistrySemiconductor/solid-state device detailsEpoxyCyclobutane

There is provided an epoxy resin composition having low viscosity and a high cationic curing property. An epoxy compound of Formula (1):(in Formula (1), A is an (n4)-valent C4-20 linear hydrocarbon group optionally containing an epoxy group, an (n4)-valent C4-20 cyclic hydrocarbon group optionally containing an epoxy group, or an (n4)-valent group of a combination of the linear hydrocarbon group and the cyclic hydrocarbon group; R1 and R2 are each independently a hydrogen atom or a C1-10 alkyl group; n1 is an integer of 2 to 6; n2 is an integer of 2; n3 is an integer of 1; and n4 is an integer of 3 to 8). For example, A is an (n4)-valent organic group formed by removing (n4) hydrogen atoms from butane, pentane, or hexane, or an (n4)-valent organic group formed by removing (n4) hydrogen atoms from cyclobutane, cyclopentane, cyclohexane, epoxycyclohexane, alkyl-substituted epoxycyclohexane, bicycloheptene, or bicyclooctene.

Owner:NISSAN CHEM IND LTD

Preparation method of (R,S)-2-[[5-(9-fluorenemethoxycarbonylamino)dibenzo[A,D]cycloheptane-2-yl]oxyl]acetic acid

ActiveCN104761470AEasy post-processingReduce manufacturing costCarbamic acid derivatives preparationOrganic compound preparationBenzoic acidEvaporation

The invention relates to a preparation method of Ramage linker and mainly solves problems of long processes, complex post-treatment, much waste water, waste gas and solid waste, and high cost in a conventional synthetic method. The preparation method includes following steps: (A) carrying out a reaction to 2-carboxybenzaldehyde and m-methoxyphenylacetic acid to obtain an intermediate 2-(3-methoxylstyryl)benzoic acid, dissolving the intermediate with a solvent, performing hydrogenation reduction, and performing post-treatment crystallization to obtain a compound R-1; (B) carrying out a reaction to the R-1 with SOCl2 or POCl3 to obtain 2-methoxyl-10,11-dihydro-5H-dibenzo[a,d]cycloheptene-5-one, performing negative-pressure evaporation to remove the SOCl2 or the POCl3, dissolving the 2-methoxyl-10,11-dihydro-5H-dibenzo[a,d]cycloheptene-5-one in benzene, methylbenzene or 1,2-dichloroethane, performing a catalytic reaction with anhydrous AlCl3 and performing post-treatment crystallization to obtain a compound R-2; (C) carrying out a reaction to the R-2 with benzyl bromoacetate in DMF or an acetone / K2CO3 solution to obtain a compound R-3; (D) performing hydrogenation reduction to the R-3 to obtain a compound R-4; and (E) adding a catalyic amount of PTS to the R-4 in DMF and carrying out a reaction to the R-4 with Fmoc-NH2 to obtain the Ramage linker, which is an effective C-terminal linker in solid-phase synthesis.

Owner:江苏吉泰肽业科技有限公司

Polyelectrolyte material for new energy automobile fuel cell and preparation method of polyelectrolyte material

The invention discloses a preparation method of a polyelectrolyte material for a new energy automobile fuel cell. The preparation method is characterized by comprising the steps of S1, preparing polymerizable cyclohexyl imidazole salt; S2, carrying out copolymerization and pouring on the basis of a polymerizable type cyclohexyl imidazolium salt, N-(4-cyano-3-trifluoromethylphenyl) methacrylamide, tris (2-acryloyloxyethyl) isocyanurate and 5-vinyl bicyclo [2.2. 1] heptyl-2-ene so as to obtain a copolymer membrane; and S3, carrying out ion exchange. The invention also discloses a polyelectrolyte material, which is prepared according to the preparation method of the polyelectrolyte material for the new energy automobile fuel cell, for the new energy automobile fuel cell. The polyelectrolyte material for the new energy automobile fuel cell, disclosed by the invention, is good in comprehensive performance and performance stability, high in ionic conductivity and mechanical strength, good in alkali resistance and oxidation resistance, long in service life and safe and environment-friendly to use.

Owner:邓文辉

Preparation method of hydrochloric acid cyclobenzaprine

Owner:佛山市隆信医药科技有限公司

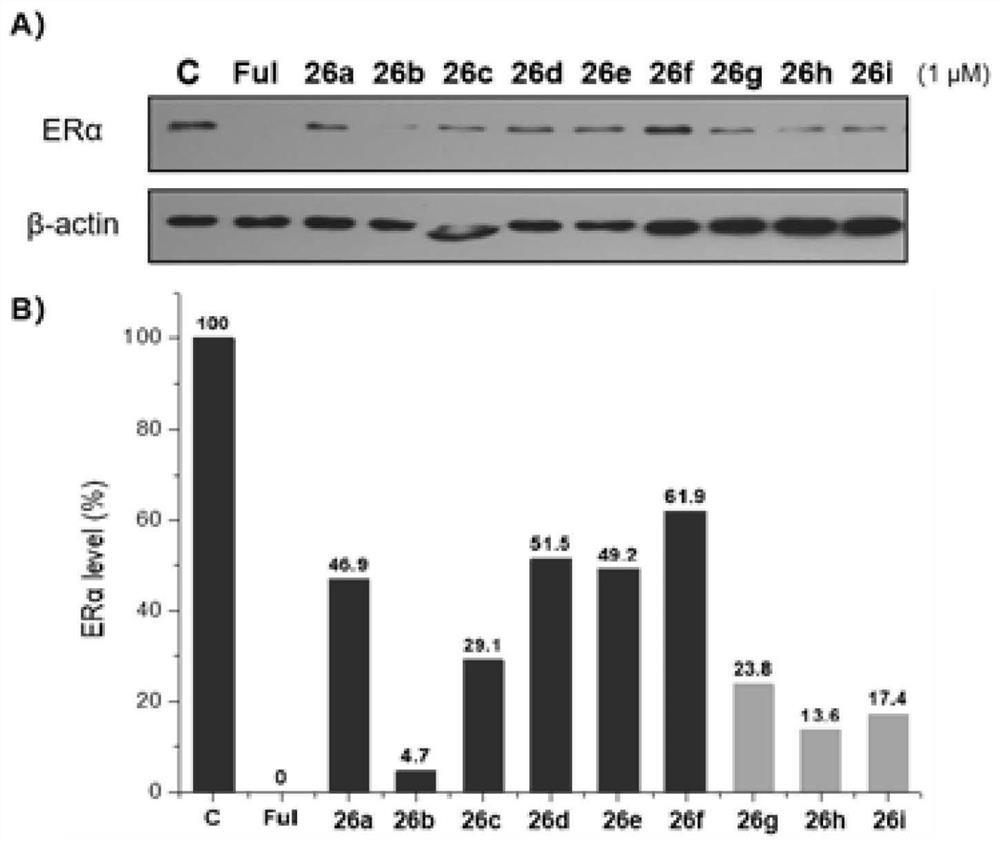

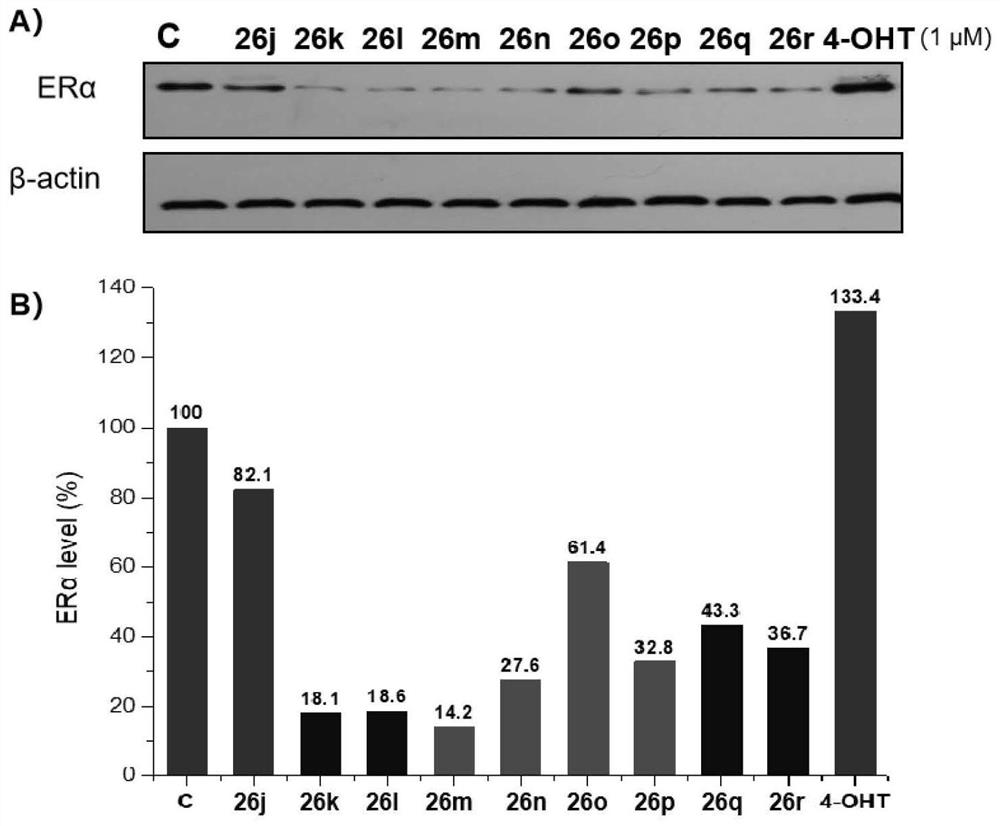

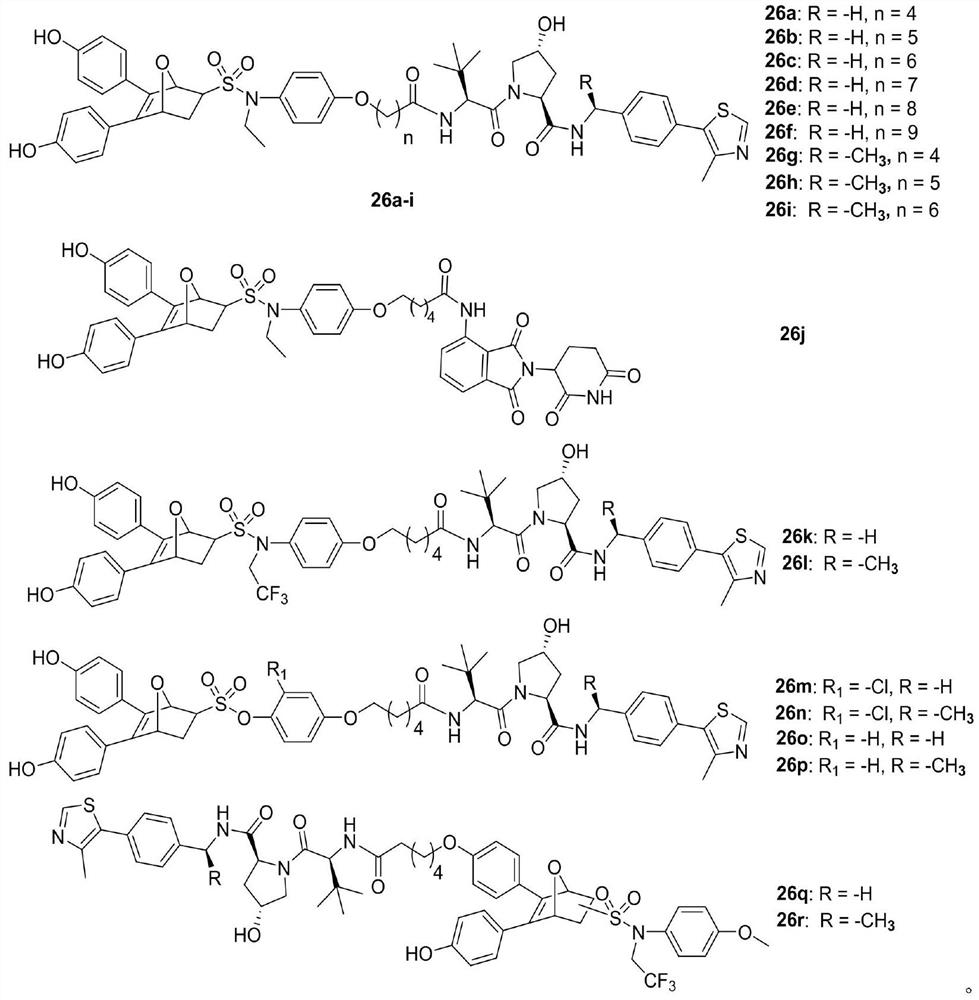

Proteolytic targeted chimeric compound taking oxygen bridge bicycloheptene compound as estrogen receptor ligand as well as preparation method and application

The invention discloses a proteolytic targeted chimeric compound taking an oxygen bridge bicycloheptene compound as an estrogen receptor ligand as well as a preparation method and an application. Tworeasonable synthesis modes are adopted, a VHL ligand or a CRBN ligand serves as an E3 ligase ligand part, oxygen bridge bicycloheptene sulfonate or sulfonamide estrogen receptor ligands are connectedthrough alkyl side chains with different lengths, and a series of target product Protac molecules are obtained through synthesis. An action mode of the Protac molecules is different from that of an existing anti-breast cancer drug tamoxifen, and the Protac molecules are targeted estrogen down-regulators. The compound not only retains a certain estrogen receptor binding capacity, but also has goodestrogen receptor alpha down-regulation activity equivalent to that of fulvestrant, can realize event-driven targeted estrogen receptor degradation, and is expected to overcome drug resistance causedby traditional endocrine treatment of the ER positive breast cancer through the method.

Owner:WUHAN UNIV

AMINO SUBSTITUTED DIARYL[a,d]CYCLOHEPTENE ANALOGS AS MUSCARINIC AGONISTS AND METHODS OF TREATMENT OF NEUROPSYCHIATRIC DISORDERS

Disclosed herein are analogs of clozapine and pharmaceutically acceptable salts, esters, amides, or prodrugs thereof; methods of synthesizing the analogs; and methods of using the analogs for treating neuorpsychiatric disorders. In some embodiments, the analogs are amino substituted diaryl[a,d]cycloheptenes.

Owner:ACADIA PHARMA INC

Bicyclo[4.1.0]heptane nitrosourea derivative for biological orthogonal reaction, and preparation method and application thereof

ActiveCN111138337ARelease irreversibleImprove practicalityOrganic chemistryFluorescence/phosphorescenceNitrosoNitrourea

The invention discloses a bicyclo[4.1.0]heptane nitrosourea derivative for a biological orthogonal reaction, and a preparation method and an application thereof. The structural formula of the bicyclo[4.1.0]heptane nitrosourea derivative is represented by formula I; and in the formula I, R represents an alkyl group with the carbon atom number of 1-15, an aryl group with the carbon atom number of 6-15 or H, X represents O or N, and n is a natural number between 1 and 10. A pH-initiated IEDDA reaction of trans-cycloheptene and tetrazine is provided for the first time, and can be used as a biological orthogonal reaction. A bicyclonitrosourea derivative (BNU)-bicyclo[4.1.0]heptane nitrosourea derivative is introduced as a precursor for storing and releasing trans-cycloheptene, so that the highactivity of the trans-cycloheptene is utilized, and the instability of the trans-cycloheptene is avoided as much as possible. The pH-initiated biological orthogonal reaction can be applied to in-vitroprotein labeling, living cell imaging and tissue pre-labeling imaging, and can also be applied to living animal tumor pre-labeling imaging. The novel biological orthogonal reaction has a wide application prospect.

Owner:TSINGHUA UNIV

Amorphous olefin co/ter-polymers

PCT No. PCT / FI96 / 00253 Sec. 371 Date Jun. 26, 1998 Sec. 102(e) Date Jun. 26, 1998 PCT Filed May 7, 1996 PCT Pub. No. WO96 / 35730 PCT Pub. Date Nov. 14, 1996Amorphous and impact resistant co / ter-polymer made from olefins and aryl-substituted cyclic monomers by polymerizing using a catalyst, wherein the substituent is a phenyl- or indanyl-group and the catalyst is a metallocene-catalyst. Preferably said aryl-substituted cyclic monomer is phenyl-norbomene (5-phenyl-bicylo-2,2,1-hept-2-ene) or indanyl-norbomene (1,4-methano-1,4,4a,9a-tetrahydrofluorence).

Owner:OPTATECH CORP

Cephalotaxus fortunei norditerpenoid compounds as well as pharmaceutical composition and application to pharmacy thereof

InactiveCN106674241AOrganic active ingredientsCarboxylic acid esters separation/purificationIn vivoCephalotaxus

The invention relates to cephalotaxus fortunei norditerpenoid compounds expressed as formula (I), pharmacologically acceptable salts thereof, a pharmaceutical composition taking the cephalotaxus fortunei norditerpenoid compounds as active components and application of the cephalotaxus fortunei norditerpenoid compounds to preparation of anti-tumor medicines. A series of novel cephalotaxus fortunei norditerpenoid compounds are discovered in cephalotaxus plants; extracorporeal activity screening shows that the compounds has significant cytotoxic activity and anti-inflammatory activity; mechanism research shows that the cephalotaxus fortunei norditerpenoid compounds are different from colchicines containing cycloheptenone, have no influence on microtubule polymerization and are relevant with inhibition of NF-kB signal channels; in-vivo transplantation tumor activity evaluation shows that the cephalotaxus fortunei norditerpenoid compounds have significant anti-tumor activity and have good pharmacy prospects.

Owner:KUNMING INST OF BOTANY - CHINESE ACAD OF SCI

Method for removing methanol, n-butanol and isobutanol from wastewater of amino resin workshop

InactiveCN105060442AStrong complexing abilityFast precipitationWater contaminantsNature of treatment waterIsobutanolN-Butanol

The invention relates to a method for removing methanol, n-butanol and isobutanol from wastewater of an amino resin workshop. The method comprises the steps of adding 1,3,3-trimethyl-2-oxa bicyclo[2.2.2]octane, flavanone glycoside, S(-)-2-amino-6-n-propyl amino-4,5,6,7-tetrahydro benzothiazole di-hydrochloride, 4-octyl phenol ethoxylate, 3',4'-dihydroxy-2-(methyl amino)acetophenone hydrochloride, 4-acetyloxy-3-methoxy-(2-propenyl)benzene, acet-4-methoxy-benzyl ester, 6,6,10-trimethyl bicyclo-3,1,1-heptyl-2-alkene, 2-[[1-(3-acetylthio-2-methyl propionyl)pyrrolidine-2-formyl]amino]-3- phenylpropionic acid and the like. The method has the advantages that complex capabilities to target objects are high; the deposition velocities of complex compounds are fast; the removal rate can reach 99.9 percent; the dose is low; hazard to a water body is avoided.

Owner:李海兰

Synthesis method of Euphorbiaceae diterpene Peplanol A

PendingCN114560760ASimple and fast operationMild conditionsGroup 4/14 element organic compoundsOrganic compound preparationOrganic synthesisChemical compound

The invention discloses a synthesis method of Euphorbiaceae diterpene Peplanol A. The synthesis method belongs to the field of organic synthesis, and comprises the following steps: by taking a cycloheptenone derivative 2 as a reaction raw material, constructing a key tricyclic skeleton through key steps of Negishi coupling reaction, Diels-Alder reaction, series cyclization reaction catalyzed by titanium free radicals and the like; finally, the target product Euphorbiaceae diterpene Pepluanol A is obtained through later functional group conversion. The synthesis method disclosed by the invention is simple and convenient to operate, the product is synthesized by 17 steps, the condition is mild, and the total yield reaches 2.5% by controlling the reaction condition. The synthesis route is novel in design thought, the raw materials are cheap and easy to obtain, the compatibility of each important functional group is strong, a plurality of Euphorbiaceae diterpene structure derivatives containing the same 5 / 6 / 7 fused ring skeleton can be conveniently synthesized, and a foundation is laid for the structure-function relationship research of the compounds.

Owner:ZHEJIANG UNIV HANGZHOU GLOBAL SCI & TECH INNOVATION CENT

Method for continuously producing imidacloprid intermediate cycloheptene-2-aldehyde-5-alkene

InactiveCN102040493AHigh selectivityHigh yieldOrganic compound preparationCarbonyl compound preparationChemical synthesisReaction temperature

The invention relates to a method for producing pesticides, in particular to a method for continuously producing imidacloprid intermediate cycloheptene-2-aldehyde-5-alkene. The method comprises the following steps of: conveying cyclopentadiene and acrolein according to the volume ratio of the cyclopentadiene to the acrolein of 1.1-1.5:1 to a tube type mixed reaction condenser by using a metering pump to react; performing continuous reactions in a tubular reactor, a tubular reactor, a residence kettle and an acceptance kettle sequentially in an overflow mode; and separating in a distilling kettle, wherein the reaction temperature is between 30 and 60 DEG C. The method overcomes the defects that power consumption of a batch reaction is large, materials are mixed non-uniformly, temperature is difficult to control and blanking accidents are easy to occur and has the advantages of short reaction time, high selectivity of a chemical synthetic reaction and high yield, wherein the yield is increased from 93 percent to 97 percent. On the basis of stabilizing the yield, the consumption of raw material acrolein is reduced from 900 kilograms per ton to 780 kilograms per ton.

Owner:荆州沙隆达控股有限公司

Rectoscope washing agent

InactiveCN104031779AKeep clean and safeGood stain removalSurface-active non-soap compounds and soap mixture detergentsPropanoic acidBenzylamine hydrochloride

The invention relates to a gastroendoscope cleaning product and in particular relates to a rectoscope washing agent. The rectoscope washing agent comprises the following raw materials: water, 2-hydracrylic acid, methacrolein, (2-hydroxyethyl)diisopropyl methylammonium bromide xanthene-9-carboxylic ester, 2,3,4,5,6-pentahydroxy-2-hexenoic acid-4-lactone, cetyl trimethyl ammonium bromide, bicyclo[2.2.1]heptyl-5-allyl-2-carbonitrile, N-(1-methyl-2-phenoxyethyl)-N-(2-chloroethyl)benzylamine hydrochloride, 3-[4,5-dihydro-1H-imidazole-2-ylmethyl-(4-methylphenyl)amino]phenol. The washing agent has a good and remarkable dirt removal effect, especially has a relatively good sterilizing effect while removing dirt generated in a rectal examination process and especially has a remarkable removal effect on three types of bacteria existent in rectums, so that the cleanness and the safety of a rectoscope are ensured on aspects of dirt removal and sterilization.

Owner:安徽斯迈特新材料股份有限公司

Prepn process of 9,10-dibromo-9,10-dihydro-4H-benzo-[4,5]-suberene-[1,2-b]-thienyl-4-one

The present invention relates to preparation process of 9,10-dibromo-9,10-dihydro-4-H-benzo-[4,5]-suberene-[1,2-b]-thienyl-4-one. The preparation process includes reaction between 9,10-dihydro-4-H-benzo- [4,5]-suberene- [1,2-b]-thienyl-4-one and brominating agent in aprotic solvent at the temperature from 0 deg.c to reflux temperature, and the post-treatment. The said aprotic solvent is C5-C14 alkane, C5-C14 cycloparaffin or their mixture. The preparation process has high selectivity and less side products.

Owner:ZHEJIANG HUAHAI PHARMACEUTICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Amino substituted diaryl[a,d]cycloheptene analogs as muscarinic agonists and methods of treatment of neuropsychiatric disorders Amino substituted diaryl[a,d]cycloheptene analogs as muscarinic agonists and methods of treatment of neuropsychiatric disorders](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/c39d20f2-03bd-480c-bd6a-a01e1d9720ef/US20050192268A1-20050901-C00001.png)

![Amino substituted diaryl[a,d]cycloheptene analogs as muscarinic agonists and methods of treatment of neuropsychiatric disorders Amino substituted diaryl[a,d]cycloheptene analogs as muscarinic agonists and methods of treatment of neuropsychiatric disorders](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/c39d20f2-03bd-480c-bd6a-a01e1d9720ef/US20050192268A1-20050901-C00002.png)

![Amino substituted diaryl[a,d]cycloheptene analogs as muscarinic agonists and methods of treatment of neuropsychiatric disorders Amino substituted diaryl[a,d]cycloheptene analogs as muscarinic agonists and methods of treatment of neuropsychiatric disorders](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/c39d20f2-03bd-480c-bd6a-a01e1d9720ef/US20050192268A1-20050901-C00003.png)

![Amino substituted diaryl[a,d]cycloheptene analogs as muscarinic agonists and methods of treatment of neuropsychiatric disorders Amino substituted diaryl[a,d]cycloheptene analogs as muscarinic agonists and methods of treatment of neuropsychiatric disorders](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/47854f59-05d8-419f-8cc7-8fcf2ee494c1/US20060194784A1-20060831-C00001.png)

![Amino substituted diaryl[a,d]cycloheptene analogs as muscarinic agonists and methods of treatment of neuropsychiatric disorders Amino substituted diaryl[a,d]cycloheptene analogs as muscarinic agonists and methods of treatment of neuropsychiatric disorders](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/47854f59-05d8-419f-8cc7-8fcf2ee494c1/US20060194784A1-20060831-C00002.png)

![Amino substituted diaryl[a,d]cycloheptene analogs as muscarinic agonists and methods of treatment of neuropsychiatric disorders Amino substituted diaryl[a,d]cycloheptene analogs as muscarinic agonists and methods of treatment of neuropsychiatric disorders](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/47854f59-05d8-419f-8cc7-8fcf2ee494c1/US20060194784A1-20060831-C00003.png)

![Amino bustituted diaryl[a,d]cycloheptene analogs as muscarinic agonists and methods of treatment of neuropsychiatric disorders Amino bustituted diaryl[a,d]cycloheptene analogs as muscarinic agonists and methods of treatment of neuropsychiatric disorders](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/0ab87a8e-7835-451b-8770-82c470c97c6a/US20060199798A1-20060907-C00001.png)

![Amino bustituted diaryl[a,d]cycloheptene analogs as muscarinic agonists and methods of treatment of neuropsychiatric disorders Amino bustituted diaryl[a,d]cycloheptene analogs as muscarinic agonists and methods of treatment of neuropsychiatric disorders](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/0ab87a8e-7835-451b-8770-82c470c97c6a/US20060199798A1-20060907-C00002.png)

![Amino bustituted diaryl[a,d]cycloheptene analogs as muscarinic agonists and methods of treatment of neuropsychiatric disorders Amino bustituted diaryl[a,d]cycloheptene analogs as muscarinic agonists and methods of treatment of neuropsychiatric disorders](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/0ab87a8e-7835-451b-8770-82c470c97c6a/US20060199798A1-20060907-C00003.png)

![Compounds with 5H-dibenzo[a,d]cycloheptene as cores and application of compounds Compounds with 5H-dibenzo[a,d]cycloheptene as cores and application of compounds](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/131513fa-de36-421b-88f8-80686f6d1f96/HDA0001424432000000011.png)

![Compounds with 5H-dibenzo[a,d]cycloheptene as cores and application of compounds Compounds with 5H-dibenzo[a,d]cycloheptene as cores and application of compounds](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/131513fa-de36-421b-88f8-80686f6d1f96/HDA0001424432000000012.png)

![Compounds with 5H-dibenzo[a,d]cycloheptene as cores and application of compounds Compounds with 5H-dibenzo[a,d]cycloheptene as cores and application of compounds](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/131513fa-de36-421b-88f8-80686f6d1f96/FDA0001424431980000011.png)

![Process for preparing bicylo[2.2.1] heptane derivatives Process for preparing bicylo[2.2.1] heptane derivatives](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/246113bd-e140-47c7-b382-8d854786024c/US06841713-20050111-C00001.png)

![Process for preparing bicylo[2.2.1] heptane derivatives Process for preparing bicylo[2.2.1] heptane derivatives](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/246113bd-e140-47c7-b382-8d854786024c/US06841713-20050111-C00002.png)

![Process for preparing bicylo[2.2.1] heptane derivatives Process for preparing bicylo[2.2.1] heptane derivatives](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/246113bd-e140-47c7-b382-8d854786024c/US06841713-20050111-C00003.png)

![AMINO SUBSTITUTED DIARYL[a,d]CYCLOHEPTENE ANALOGS AS MUSCARINIC AGONISTS AND METHODS OF TREATMENT OF NEUROPSYCHIATRIC DISORDERS AMINO SUBSTITUTED DIARYL[a,d]CYCLOHEPTENE ANALOGS AS MUSCARINIC AGONISTS AND METHODS OF TREATMENT OF NEUROPSYCHIATRIC DISORDERS](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/7f27281b-69f2-4cd4-961f-24f48a5deff4/US20090239840A1-20090924-D00001.png)

![AMINO SUBSTITUTED DIARYL[a,d]CYCLOHEPTENE ANALOGS AS MUSCARINIC AGONISTS AND METHODS OF TREATMENT OF NEUROPSYCHIATRIC DISORDERS AMINO SUBSTITUTED DIARYL[a,d]CYCLOHEPTENE ANALOGS AS MUSCARINIC AGONISTS AND METHODS OF TREATMENT OF NEUROPSYCHIATRIC DISORDERS](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/7f27281b-69f2-4cd4-961f-24f48a5deff4/US20090239840A1-20090924-C00001.png)

![AMINO SUBSTITUTED DIARYL[a,d]CYCLOHEPTENE ANALOGS AS MUSCARINIC AGONISTS AND METHODS OF TREATMENT OF NEUROPSYCHIATRIC DISORDERS AMINO SUBSTITUTED DIARYL[a,d]CYCLOHEPTENE ANALOGS AS MUSCARINIC AGONISTS AND METHODS OF TREATMENT OF NEUROPSYCHIATRIC DISORDERS](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/7f27281b-69f2-4cd4-961f-24f48a5deff4/US20090239840A1-20090924-C00002.png)

![Bicyclo[4.1.0]heptane nitrosourea derivative for biological orthogonal reaction, and preparation method and application thereof Bicyclo[4.1.0]heptane nitrosourea derivative for biological orthogonal reaction, and preparation method and application thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/9202d0a4-7654-4e1d-9590-0509d00a81f7/HDA0002337889110000011.png)

![Bicyclo[4.1.0]heptane nitrosourea derivative for biological orthogonal reaction, and preparation method and application thereof Bicyclo[4.1.0]heptane nitrosourea derivative for biological orthogonal reaction, and preparation method and application thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/9202d0a4-7654-4e1d-9590-0509d00a81f7/HDA0002337889110000021.png)

![Bicyclo[4.1.0]heptane nitrosourea derivative for biological orthogonal reaction, and preparation method and application thereof Bicyclo[4.1.0]heptane nitrosourea derivative for biological orthogonal reaction, and preparation method and application thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/9202d0a4-7654-4e1d-9590-0509d00a81f7/HDA0002337889110000022.png)

![Prepn process of 9,10-dibromo-9,10-dihydro-4H-benzo-[4,5]-suberene-[1,2-b]-thienyl-4-one Prepn process of 9,10-dibromo-9,10-dihydro-4H-benzo-[4,5]-suberene-[1,2-b]-thienyl-4-one](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/d033510c-12dd-4e67-8884-1e27a06f052d/A2005100495620002C1.PNG)

![Prepn process of 9,10-dibromo-9,10-dihydro-4H-benzo-[4,5]-suberene-[1,2-b]-thienyl-4-one Prepn process of 9,10-dibromo-9,10-dihydro-4H-benzo-[4,5]-suberene-[1,2-b]-thienyl-4-one](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/d033510c-12dd-4e67-8884-1e27a06f052d/A20051004956200041.PNG)

![Prepn process of 9,10-dibromo-9,10-dihydro-4H-benzo-[4,5]-suberene-[1,2-b]-thienyl-4-one Prepn process of 9,10-dibromo-9,10-dihydro-4H-benzo-[4,5]-suberene-[1,2-b]-thienyl-4-one](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/d033510c-12dd-4e67-8884-1e27a06f052d/A20051004956200051.PNG)