Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

82 results about "Charcoal preparations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnesium salt modified charcoal and application thereof

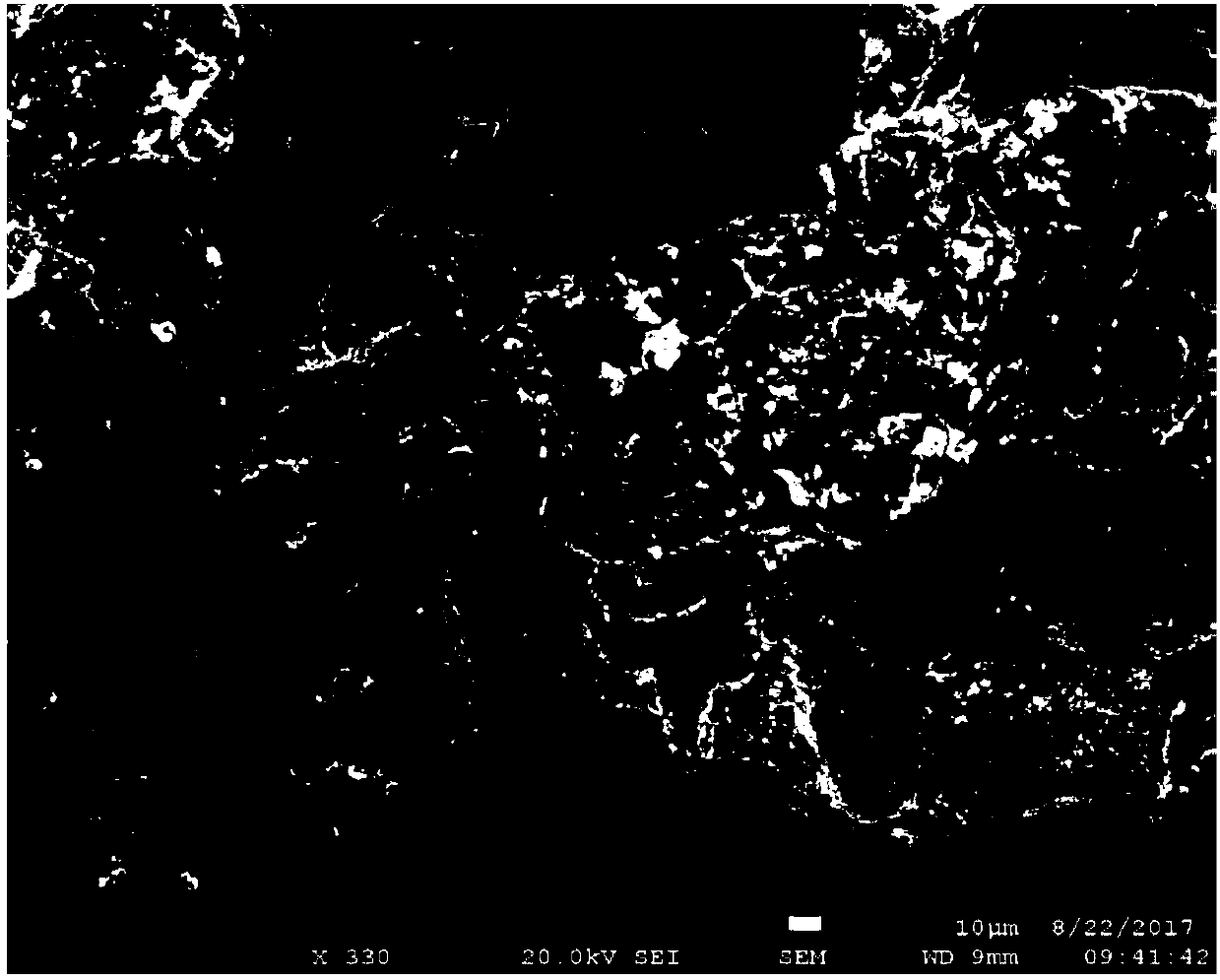

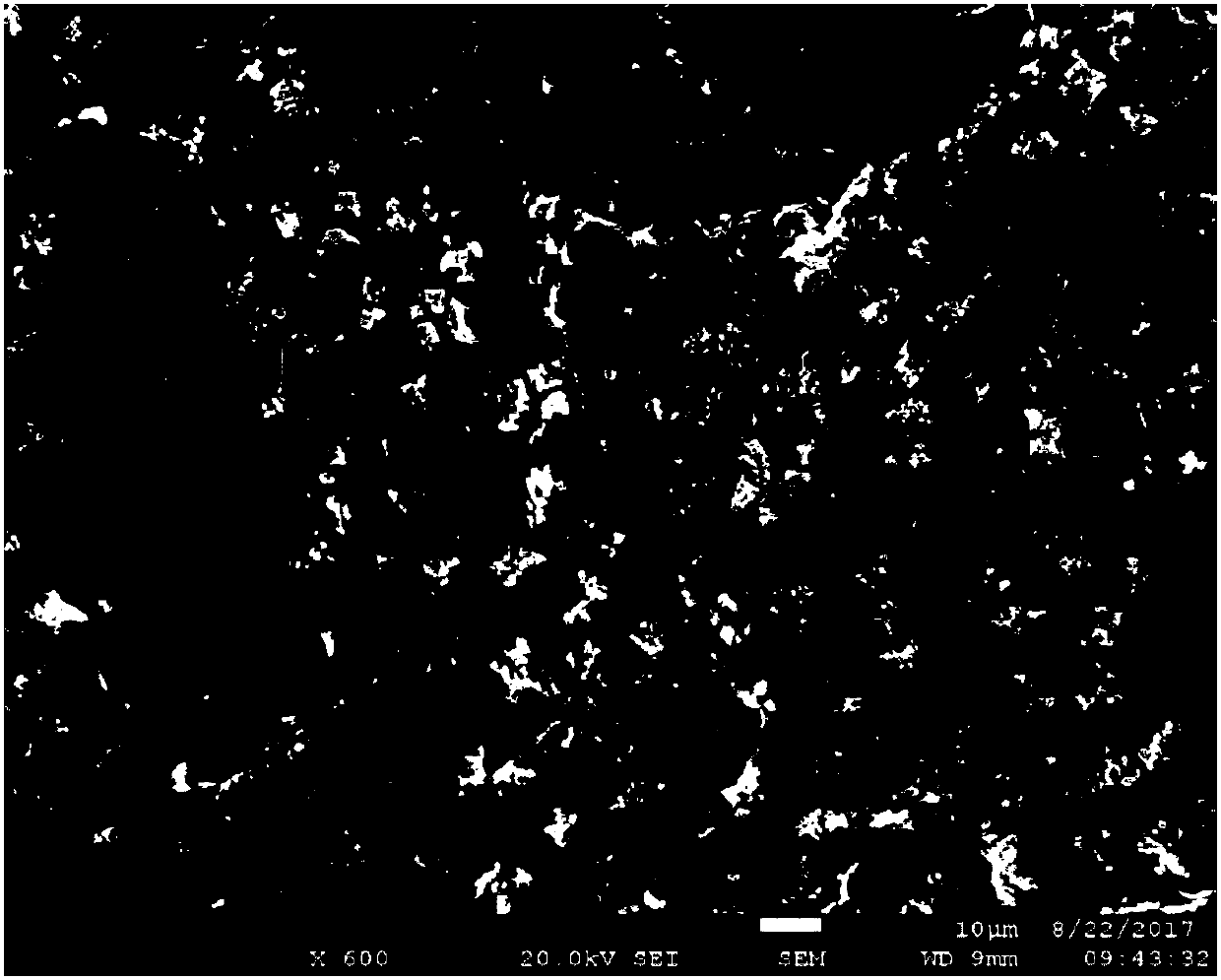

PendingCN108786738AImprove adsorption efficiencyRelieve stressOther chemical processesWater contaminantsMagnesium saltNitrogen atmosphere

The invention belongs to the technical field of biological environment protection, and particularly relates to magnesium salt modified charcoal and an application thereof. The magnesium salt modifiedcharcoal is simple to operate and low in manufacture cost, large-scale industrialization production can be achieved, and water environment pollution is managed and controlled. A preparation method ofthe magnesium salt modified charcoal includes the steps: 1) pretreating raw materials, selecting agricultural and forest residues, placing the agricultural and forest residues into sodium hydroxide solution to soak the agricultural and forest residues, washing the agricultural and forest residues by distilled water until the agricultural and forest residues reach neutral, drying the washed agricultural and forest residues at the temperature of 80-105 DEG C, crushing the dried agricultural and forest residues, and enabling the particle diameter of the crushed agricultural and forest residues tobe smaller than 2mm; 2) magnesium salt modified charcoal preparation: soaking a product acquired in the step 1) into magnesium chloride solution for 1-12h, performing ultrasound on mixture for 0.5-1h, drying the mixture at the temperature of 80-105 DEG C; 3) performing pyrolysis on a product acquired in the step 2) in nitrogen atmosphere to prepare the magnesium salt modified charcoal. The mass volume ratio of the product to the magnesium chloride solution is 1:15-1:25g / ml.

Owner:NORTHWEST A & F UNIV

Domestic sludge-based charcoal preparation method, and application of charcoal

InactiveCN105126749AEfficient removalMaterials are readily availableOther chemical processesWater/sewage treatment by sorptionMuffle furnaceCharcoal preparations

The invention relates to a domestic sludge-based charcoal preparation method, and an application of charcoal, and belongs to the technical field of environment restoration. The method comprises the following steps: air-drying domestic sludge, grinding to obtain a raw material with the particle size of 60 meshes, sealing the raw material in a crucible, placing the crucible in a muffle furnace, roasting at 300-500DEG C, cooling to room temperature, and taking out sludge charcoal from the crucible. A difficultly-soluble, stable and highly-aromatize solid substance rich in carbon is obtained through the method, and test confirms that the substance can be used to adsorb heavy metal pollutants in environment as an environment restoration material, and can efficiently remove heavy metal (such as Pb and Cd) pollutants in water and soil.

Owner:YANGZHOU UNIV

Preparation method for rice straw carbon-based fertilizer for reducing rice field greenhouse gas emissions

InactiveCN105315098AFacilitate mass adoptionEasy to operateBio-organic fraction processingOrganic fertilisersHydrothermal carbonizationGreenhouse gas reduction

The invention belongs to the technical field of biomass charcoal preparation and particularly relates to a preparation method for rice straw carbon-based fertilizer for reducing rice field greenhouse gas emissions. The rice straw carbon-based fertilizer for reducing greenhouse gas emissions is prepared through hydrothermal carbonization and assimilation of CO2.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Triarrhena lutarioriparia based modified charcoal preparation method, triarrhena lutarioriparia based modified charcoal and application

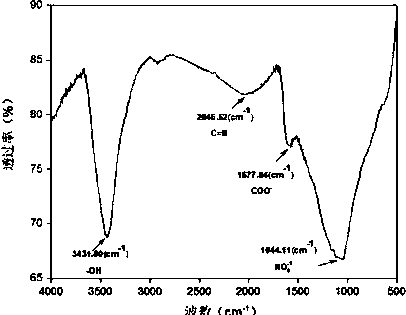

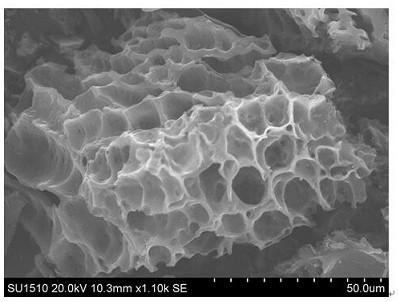

InactiveCN107321305AExpand application channelsRich pore structureOther chemical processesContaminated soil reclamationPotassium hydroxideTriarrhena lutarioriparia

The invention discloses a triarrhena lutarioriparia based modified charcoal preparation method. According to the preparation method, Hunan endemic species triarrhena lutarioriparia is utilized as a raw material to prepare the triarrhena lutarioriparia based charcoal, and the triarrhena lutarioriparia based charcoal is treated by potassium hydroxide and hydrochloric acid to prepare a triarrhena lutarioriparia based modified charcoal material. The invention further discloses the triarrhena lutarioriparia based modified charcoal prepared by the preparation method and application of the triarrhena lutarioriparia based modified charcoal. The triarrhena lutarioriparia based modified charcoal has rich pore structures; meanwhile pore transport channels of the triarrhena lutarioriparia plants for conveying nutrients and water are kept and used for adsorbing heavy metal cadmium; an application way of the fast-growing grass triarrhena lutarioriparia is fully widened; the triarrhena lutarioriparia has the advantages of low cost, easiness in obtaining and extreme potency in environmental pollution treatment.

Owner:HUNAN AGRICULTURAL UNIV

Charcoal preparation method and application thereof

InactiveCN107915215ARich pore sizeImprove stabilityGas treatmentDispersed particle filtrationParticulatesFreeze-drying

The invention discloses a charcoal preparation method and an application thereof and belongs to the field of biological material preparation. The method specifically comprises the following steps: firstly, soaking cleaned banana peel in a solution with a pore forming agent, performing freeze-drying, calcining in an inert atmosphere, performing ball-milling in a nitrogen-containing atmosphere, screening, and finally performing acid pickling, water washing and centrifugal collection, thereby obtaining charcoal. As the pore forming agent is used before the banana peel is carbonized, a carbonizedmaterial is relatively rich in pore; the carbonized material is further subjected to ball milling in the presence of a nitrogen-containing gas, so that not only is the specific surface area of the carbonized material increased, but also a nitrogen source is introduced into the charcoal; the prepared charcoal material is good in stability, can be applied to filtration of granules and organic matters in the atmosphere and adsorption of organic matters in water, can be used as a supercapacitor electrode material, and in addition can be repeatedly used.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

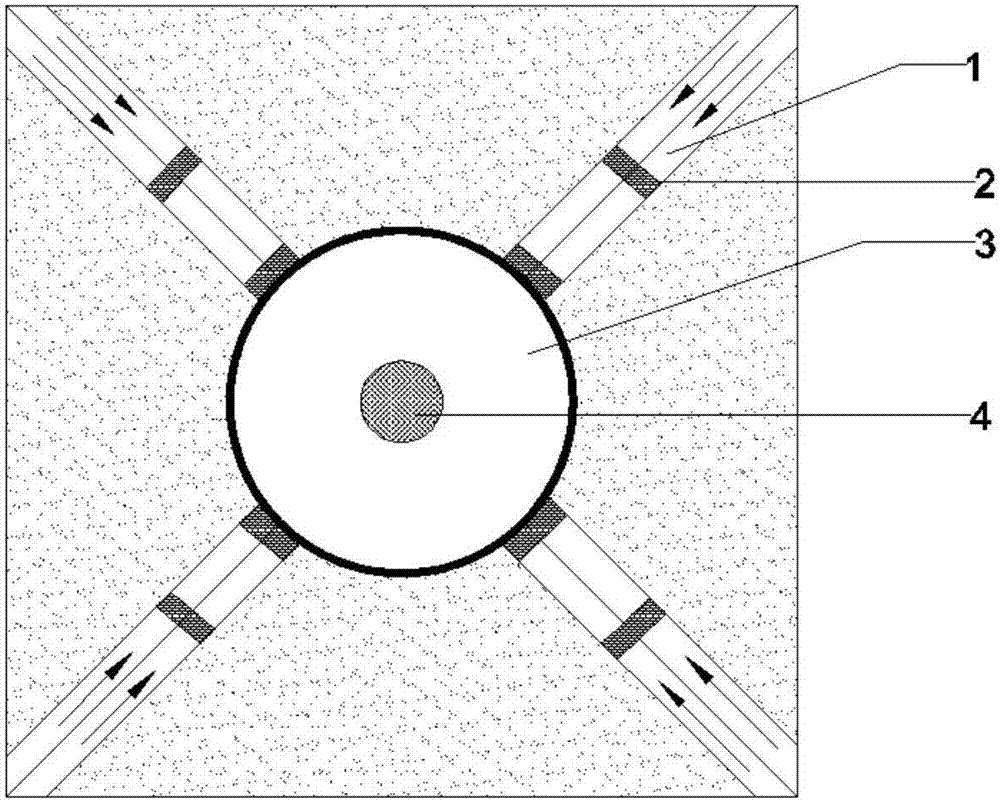

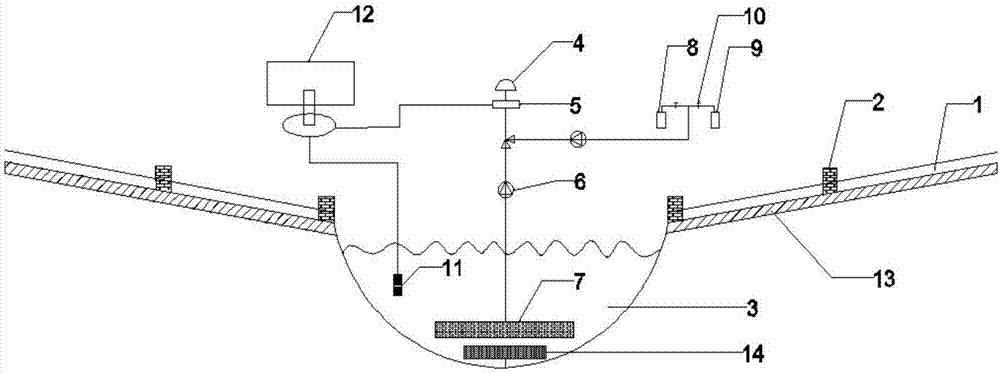

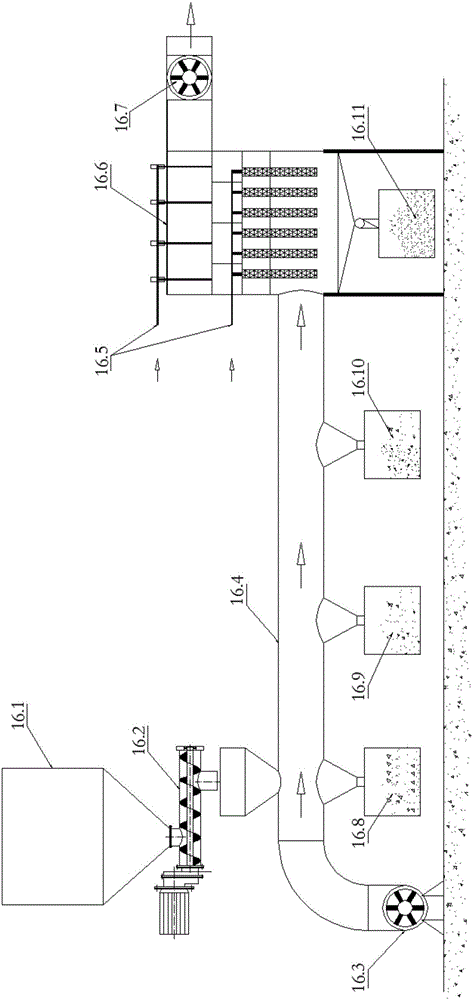

Method for remedying polluted soil through multi-pond-alga water circulation irrigation system

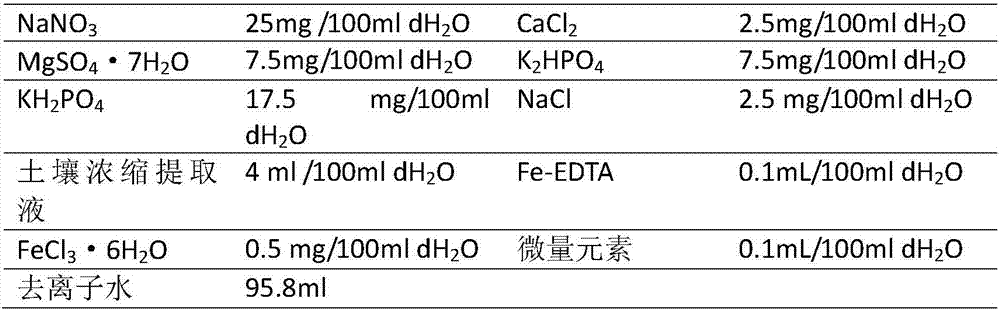

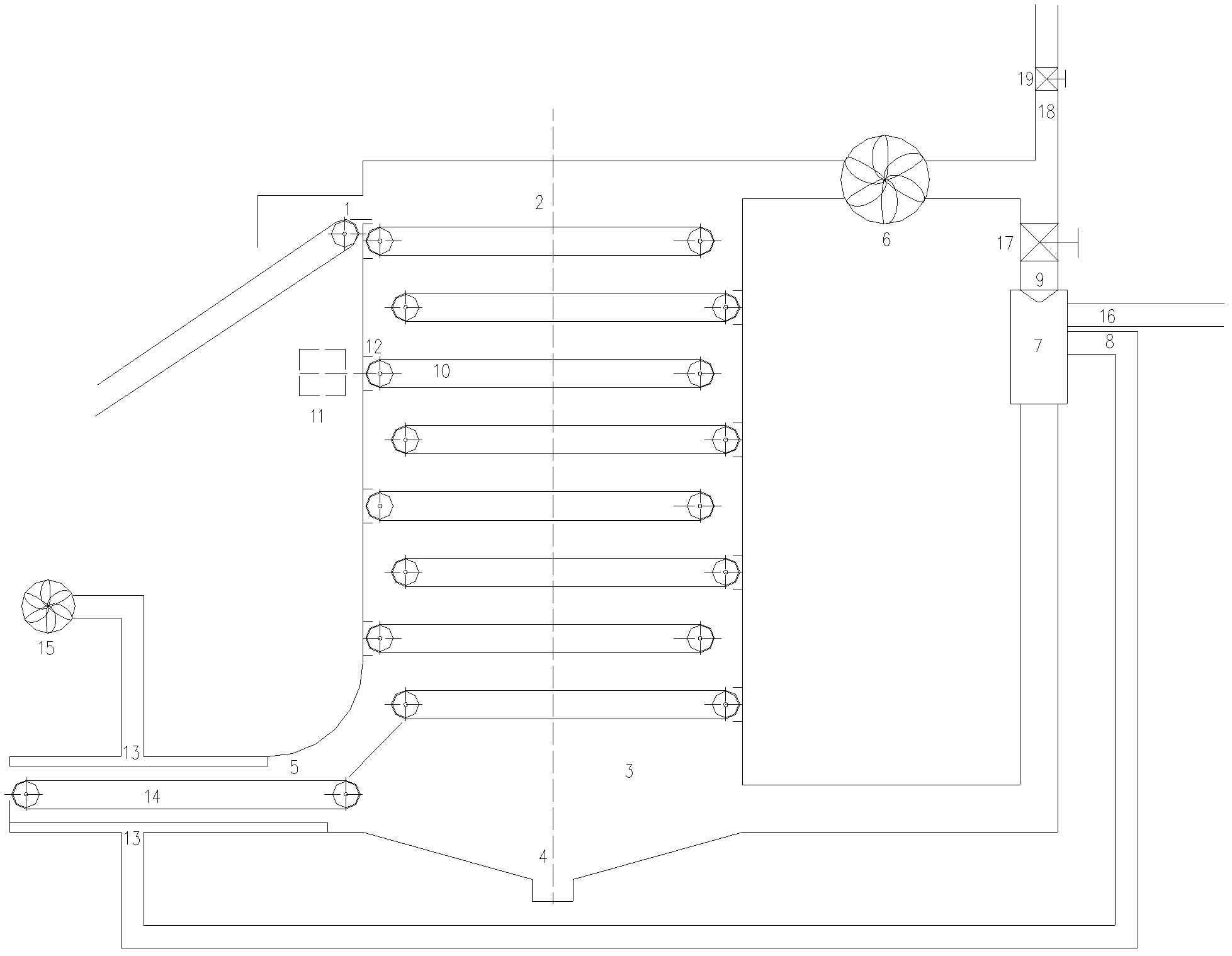

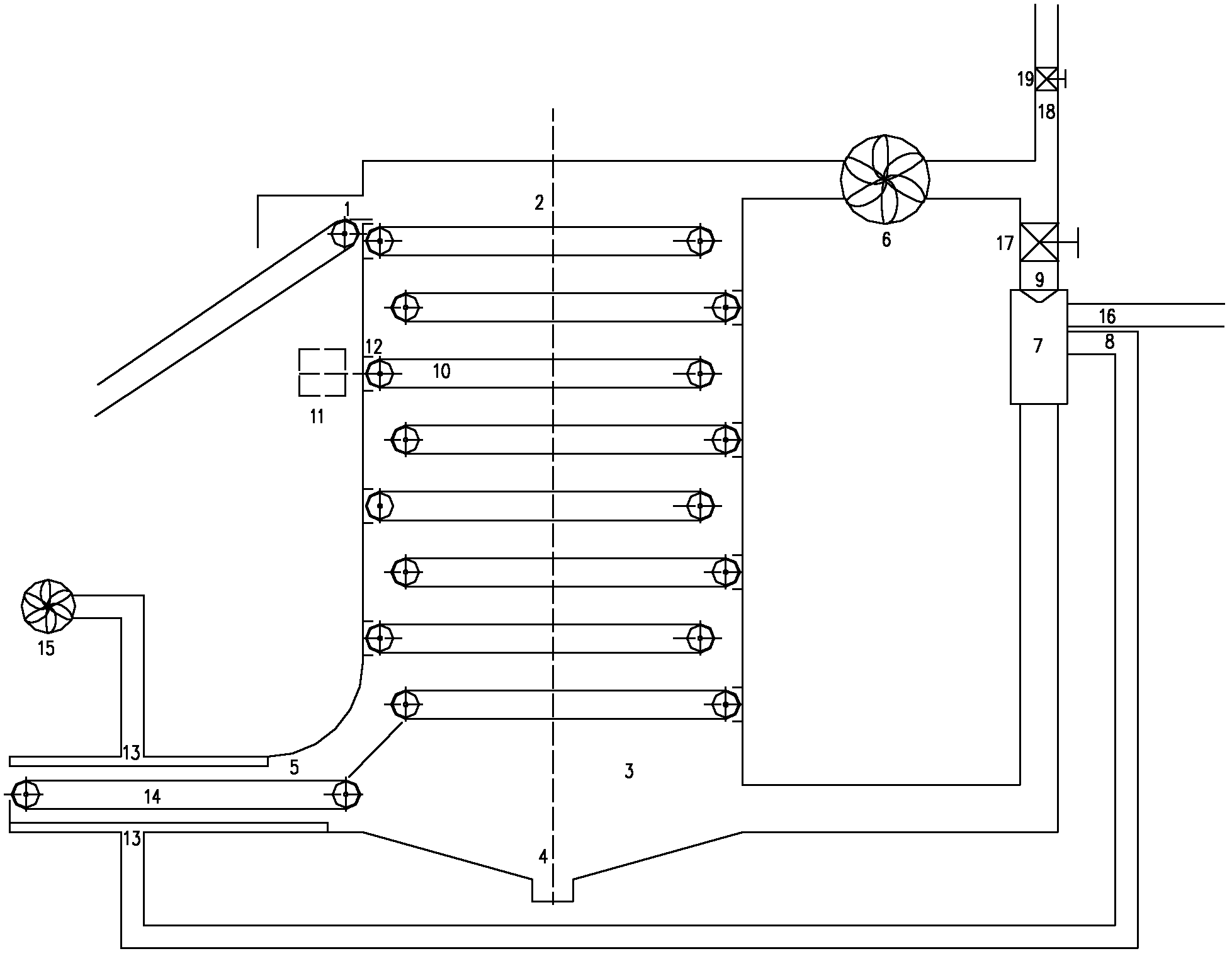

ActiveCN107971334ASolve the problem of repairing high water consumptionImprove fertilityContaminated soil reclamationSoil-working methodsAutomatic controlAdditive ingredient

The invention provides a method for remedying soil heavy metal pollution, improving saline and alkaline land and recycling microalgae for resource utilization through a multi-pond-alga water circulation irrigation system, and belongs to the field of soil remediation and resource utilization. Through the interaction of man-made ponds, microalgae and soil, a pond-microalga combined remediation system is adopted as the core, the soil is prepared and domesticated to remedy the microalgae, the multiple ponds are used for collecting rainwater, the microalgae are cultivated and subjected to expandingpropagation, and the microalgae are sprayed to the field; through circulation irrigation, multi-time spraying and alga water recycling, heavy metal in the polluted soil is taken away, the salinity ofthe soil is reduced, the nutritional ingredients of the soil are improved, and the soil fertility is restored; the microalgae are harvested through the method of pond enrichment and flocculation andaeration, the alga charcoal preparation process is utilized through combination, and resource utilization is achieved; and the system achieves automatic control through a sensor, a PC and a control component. The remediation method comprises a heavy metal / saline and alkaline land remediation microalga cultivation system, a water collection system, an intelligent spray irrigation unit, a microalgarecycling system and a microalga resource utilization system.

Owner:江苏氿官资源环境研究院有限公司

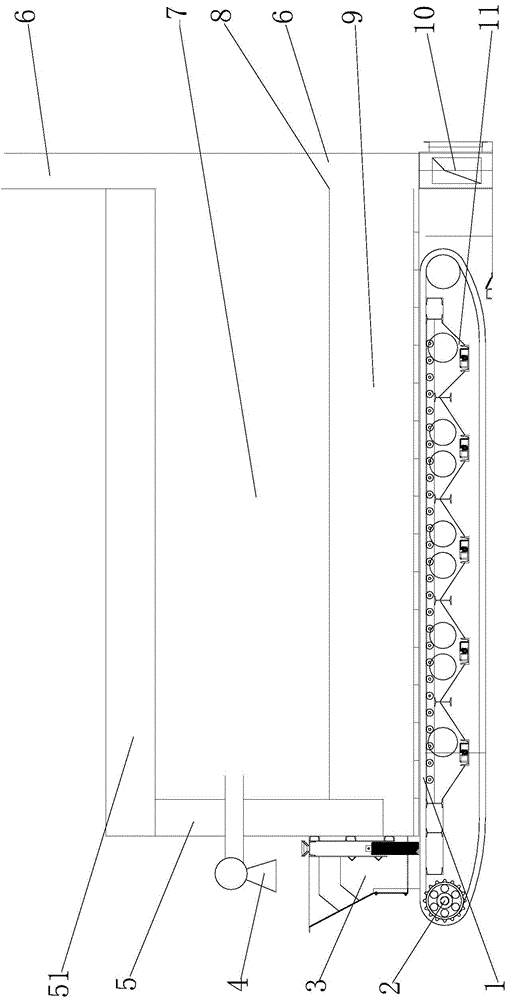

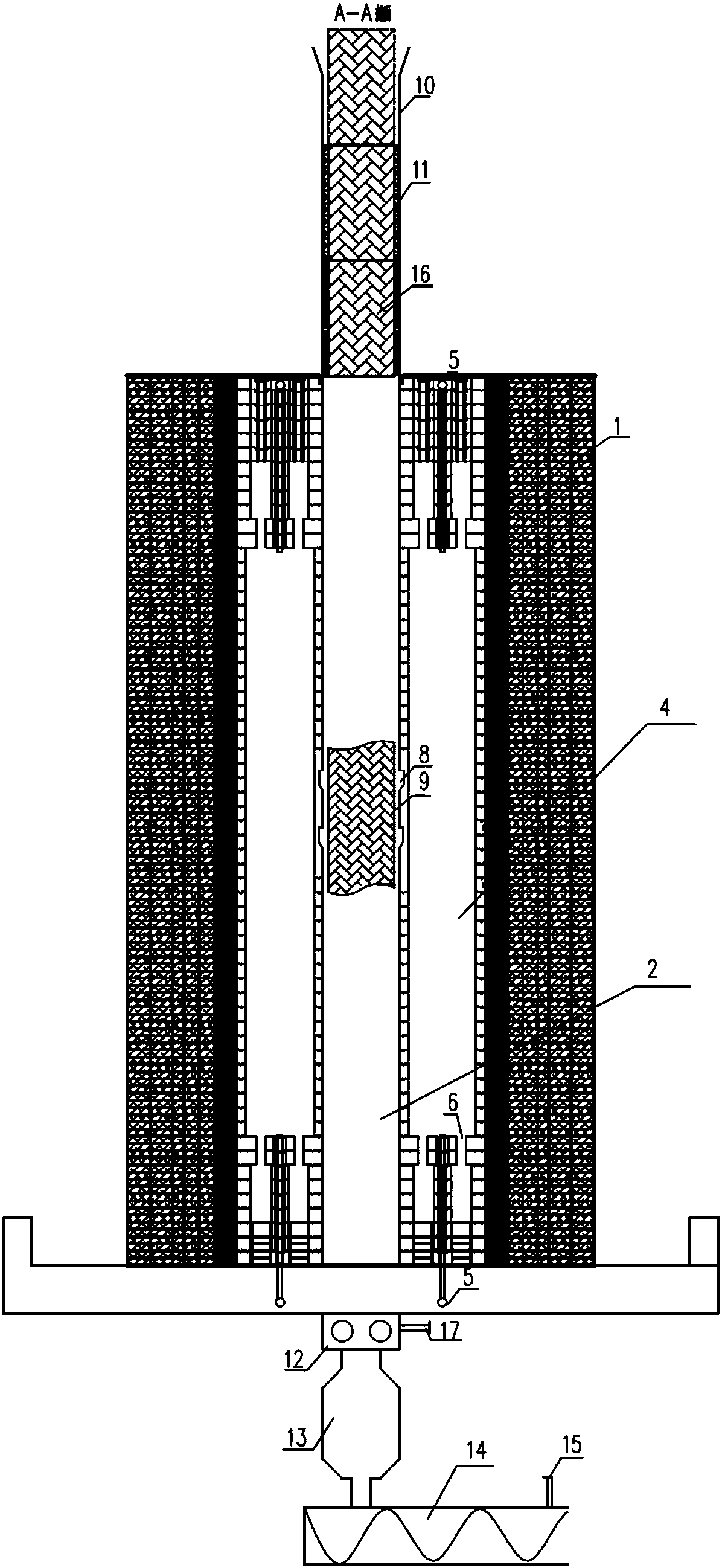

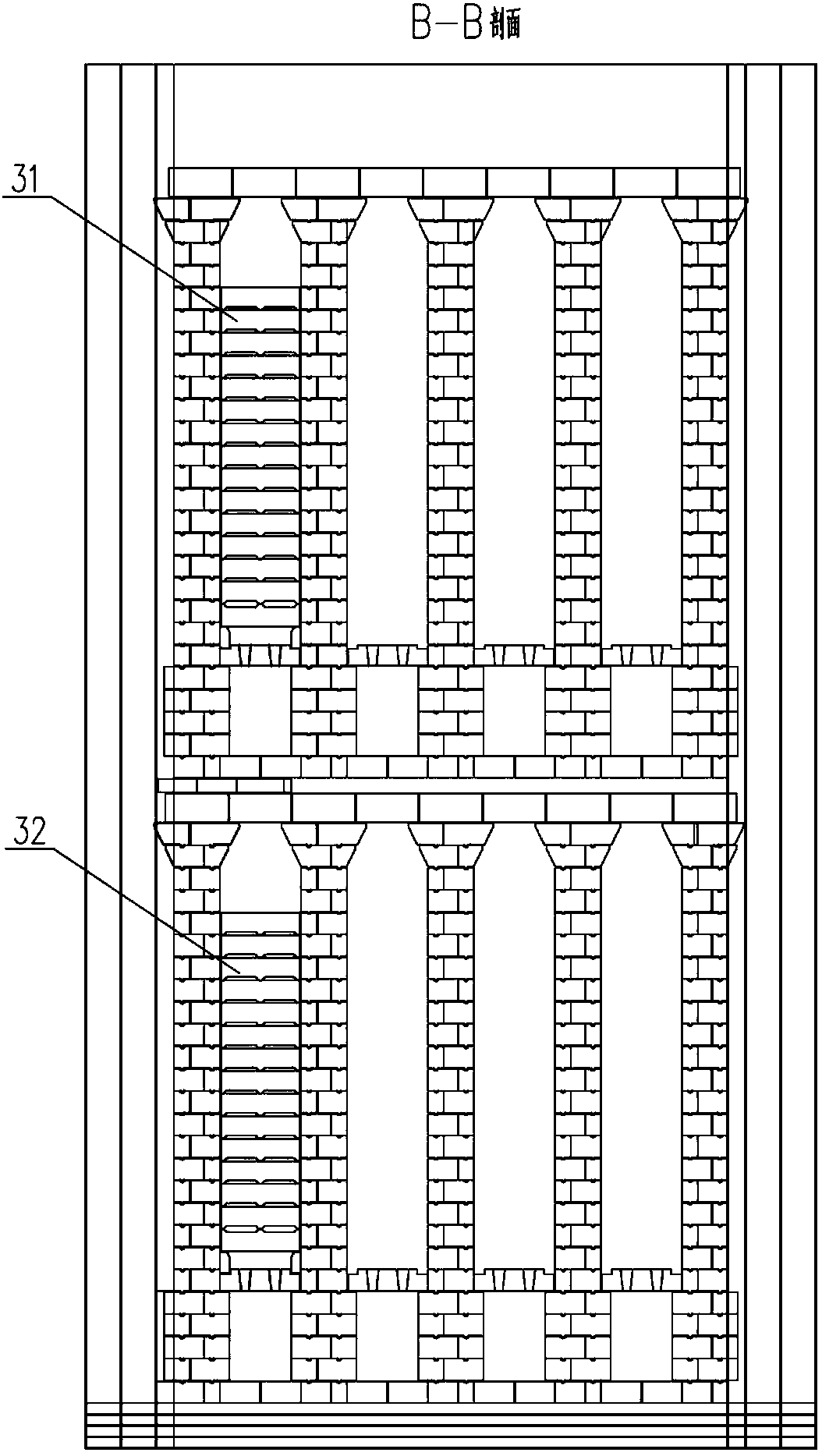

Preparation device of charcoal with biomass as raw material

InactiveCN102634356AFiring Technology ScienceGood energy saving effectBiofuelsSpecial form destructive distillationTunnel kilnEnvironmental resistance

The invention belongs to the technical field of equipment manufacture in energy engineering and relates to a preparation device of charcoal with biomass as a raw material. The preparation device belongs to a vertical kiln, which can realize continuous production and has a multi-level chain belt structure. Multilevel fire grates of the preparation device are classified up and down, and pyrolysis gas is introduced to a combustion chamber arranged outside a vertical furnace and is used for firing and releasing heat in a high-temperature environment of gas combustion; and the cascade utilization of heat energy of heat source smoke is realized when the heat source smoke flows by charcoal preparation fuel on each level of heated fire grate, and inhalable particles, tar particles and the like contained in the heat source smoke are filtered by each fuel layer. A tunnel charcoal burner of the vertical furnace has higher thermal efficiency, meets the requirement of environment friendliness, is adjustable in production capacity and can replace small-and-medium-sized periodic-production charcoal burners and large-scale tunnel kilns, thus having good application prospect and environmental benefits; and according to the preparation device, the integral structure is reasonable, the operation and use are simple, the charcoal firing process is scientific, the energy conservation property is good, the quality of fired charcoal is good, the performance is good, and the economic benefits are obvious.

Owner:QINGDAO UNIV

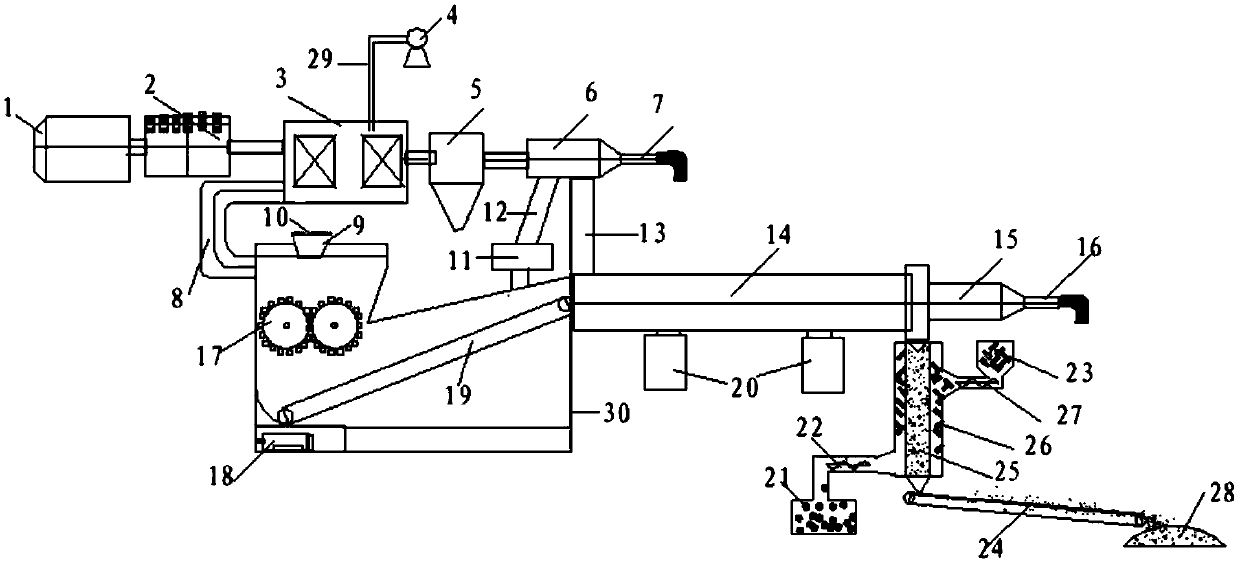

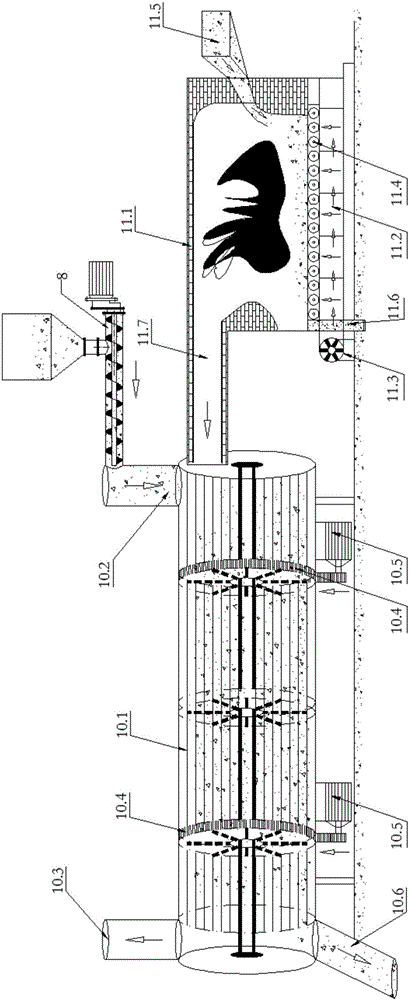

Environment-friendly organic polluted soil thermal desorption remediation system

The invention provides an environment-friendly organic polluted soil thermal desorption remediation system. The system comprises an integrated feeding and crushing mechanism, a thermal desorption mechanism, a flue gas dust removal mechanism and a charcoal preparation mechanism, wherein the integrated feeding and crushing mechanism is used for crushing and drying organic polluted soil; the thermaldesorption mechanism is used for carrying out thermal desorption treatment on the crushed and dried organic polluted soil; the flue gas dust removal mechanism is used for carrying out harmless treatment on harmful gas and flue gas tail gas generated by crushing and drying and thermal desorption treatment of the organic polluted soil; the charcoal preparation mechanism is used for preparing charcoal by utilizing high-temperature waste heat generated after the soil is subjected to the thermal desorption treatment; and the four mechanisms cooperatively work to remediate and treat the organic polluted soil. The system is simple in structure, the organic polluted soil is treated, no toxic gas is generated, the charcoal can be prepared by the waste heat generated by heat desorption of the soil,so that the system is very environment-friendly and energy-saving.

Owner:GEZHOUBA ZHONGGU TECH CO LTD

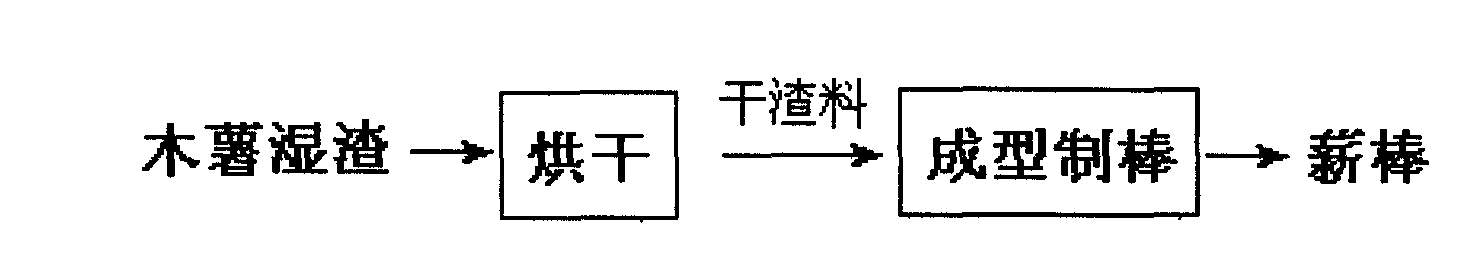

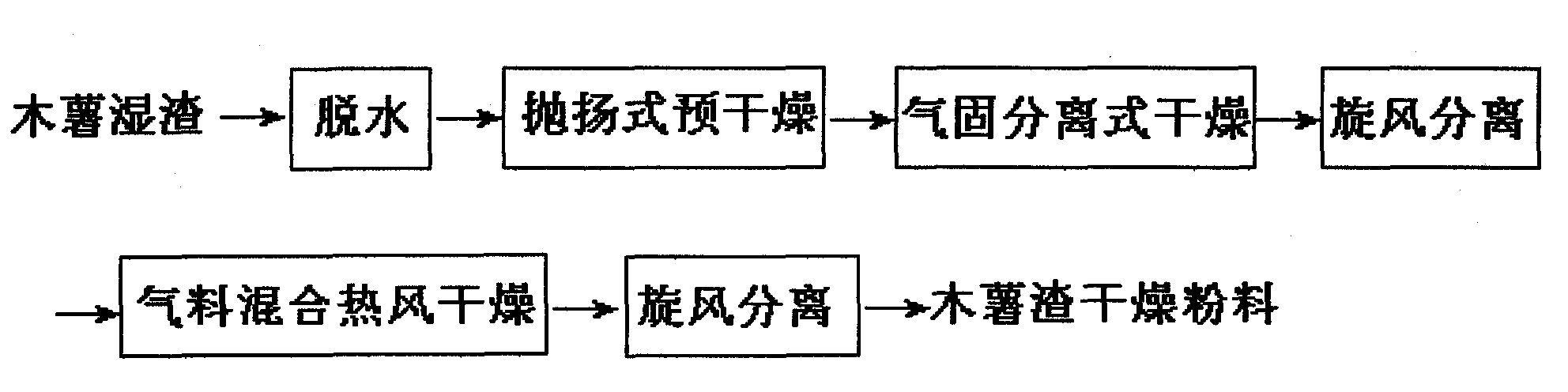

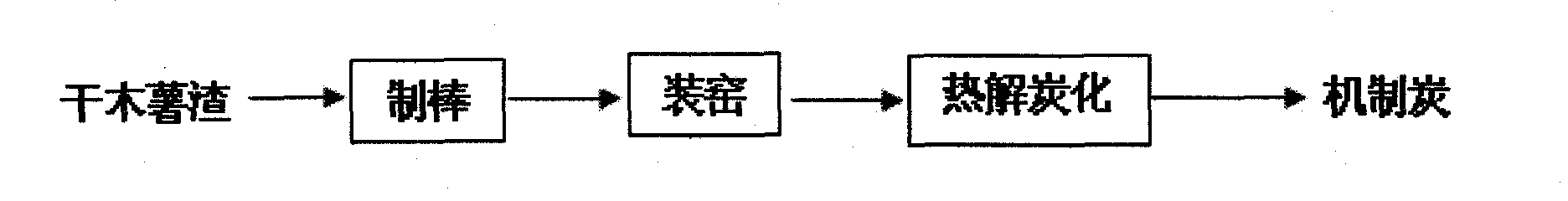

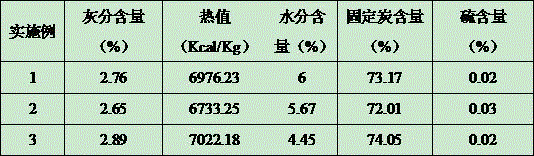

Method for preparing firewood sticks by waste cassava residues and application on charcoal preparation

InactiveCN102220178AIncrease added valueAvoid pollutionBiofuelsSolid fuelsEngineeringManihot esculenta

The invention discloses a method for preparing firewood sticks by waste cassava residues and application on charcoal preparation. The method comprises the following steps of taking the waste cassava residues produced in the production process of cassava starch as raw materials, drying the waste cassava residues to obtain dried residues, and preparing the formed firewood sticks by the dried residues, wherein after the waste cassava residues are dried, the water content rate of the dried residues is controlled to range from 10% to 15%, and the temperature of a mold for preparing the formed firewood sticks by the dried residues is controlled to be 230-280 DEG C. The firewood sticks prepared by the method are further baked into charcoal products which have the advantages of low ash content, low sulphur content, charcoal content, high heat productivity and the like, and are high-quality biomass energy. By the method, the waste cassava residues can be subject to industrial processing to form three levels of products (the dried residues, the firewood sticks and charcoal), so that circulated economic ecological chain of 'cassava-starch-cassava residues-biomass energy' can be formed, simultaneously, the risk that the waste cassava residues pollute environments can be eliminated, the direct energy-saving benefit is obvious, and the indirect emission reduction economic benefit is remarkable.

Owner:南宁市环境保护科学研究所

Preparation method of biomass-based active carbon

InactiveCN109179410ALarge specific surface areaHigh removal rateCarbon compoundsEnvironmental resistancePotassium hydroxide

The invention relates to a preparation method of biomass-based active carbon used for absorbing volatile organic pollutants and organic pollutants in waste water. The preparation method comprises following steps: 1, rice husk pretreatment, wherein rice husk is washed and dried; 2, rice husk pyrolysis charcoal preparation, wherein, clean rice husk is subjected to primary pyrolysis at 450 DEG C so as to obtain rice husk pyrolysis charcoal; and 3, the rice husk pyrolysis charcoal is mixed with potassium hydroxide at an alkali to charcoal ratio of 3:1, an obtained mixture is heated to 400 DEG C ina tubular furnace, the temperature is controlled to be constant for a certain period of time, and is increased to 750 DEG C for constant temperature treatment. The raw materials are widely available,are cheap, and are friendly to the environment; the whole reaction process conditions are mile; operation is simple, and is convenient to control. The raw materials are nontoxic and harmless, are friendly to the environment, are high in safety, are low in equipment requirement, and are beneficial for large scale production. The specific surface area of the obtained rice husk based active carbon is as high as 2094.15m<2> / g, the surface of the active carbon possesses abundant porous structures; the rice husk active carbon is used for adsorption removing of benzene series, and the removing rateis as high as 80.2%.

Owner:南京天博环境检测技术有限公司

Sulfur-loaded cocoanut active charcoal flue gas demercuration adsorbent and preparation method

InactiveCN107224960AImprove efficiencyHigh porosityGas treatmentOther chemical processesFlue gasPhysical chemistry

The invention discloses a sulfur-loaded cocoanut active charcoal flue gas demercuration adsorbent and a preparation method. According to the sulfur-loaded cocoanut active charcoal flue gas demercuration adsorbent disclosed by the invention, waste coconut shell is utilized as a raw material, a full-novel thermal energy heating technology of microwave heating is utilized to enable dipolar molecules in the material to move in high frequency, and meanwhile, the inside and the outside of the material are heated and charred to obtain cocoanut active charcoal; compared with a traditional heating method, the active charcoal preparation method disclosed by the invention has quick speed, low energy consumption and high efficiency; then the prepared active charcoal and sulfur are activated and modified by microwave; on one hand, elemental sulfur can be loaded on the active surface; on the other hand, after microwave heating, the surface is rough and in a convex-concave shape, holes become slits extending inwards, and flue gas adsorption is greatly facilitated. The demercuration adsorbent prepared by the preparation method disclosed by the invention has high porosity and strong adsorption, not only has stronger removing effect on mercury in the flue gas, but also has better removing and adsorbing effects on heavy metal of Pb, cadmium and the like in the flue gas.

Owner:ANHUI HANSHAN COUNTY TIANSHUN ENVIRONMENTAL PROTECTION EQUIP

Biomass organic charcoal preparation method

InactiveCN104910934AImprove use valueControllableBiofuelsWaste based fuelPellet fuelCleaner production

The invention provides a biomass organic charcoal preparation method, and relates to the technical field of biomass charring. The method adopts a kettle type charring furnace thermal conversion technology, and concretely comprises the following steps: 1, carrying out preprocessing compaction on a biomass raw material to mold a granular fuel; 2, adding the preprocessed biomass molded granular fuel into a charring furnace body, adding a catalyst, and fully mixing the catalyst with the biomass molded particle; and 3, introducing a heating carrier into a tubular heat exchanger in the charring furnace and a jacket on the external surface of the charring furnace, allowing the heating carrier to transmit heat to the biomass molded particles through the heat exchanger and the jacket, and controlling the heat conversion temperature and the conversion time through controlling the pressure and the temperature of the heating carrier. The method has the advantages of simplicity, high efficiency, easy operation control, improvement of the utilization values of biomass energy, realization of clean production of biomass organic charcoal, and improvement of the charcoal yield of the biomass organic charcoal, and allows the biomass organic charcoal product with excellent performances to be prepared.

Owner:邢献军

Biomass dry distillation furnace and charcoal preparation method

ActiveCN107779216AHigh recovery rateGuaranteed qualityCoke quenchingSpecial form destructive distillationCollection systemProcess engineering

The invention relates to the field of comprehensive utilization of biomass energy and discloses a biomass dry distillation furnace and a charcoal preparation method. The biomass dry distillation furnace comprises a biomass loading system, a dry distillation system, a retorting gas collection system and a charcoal discharge system, wherein a first humidifying apparatus is arranged in the charcoal discharge system; the charcoal enters the charcoal discharge system; the first humidifying apparatus sprays a humidifying medium; the humidifying medium reacts with the charcoal to produce water gas while cooling the charcoal. According to the biomass dry distillation furnace disclosed by the invention, high-efficiency externally-heated biomass dry distillation equipment can realize batch feeding,continuous dry distillation and continuous discharging of biomass blocks, has loading and closing functions and also has retorting gas collection and maximum heat reutilization functions. Moreover, the invention further provides a high-quality charcoal preparation method.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

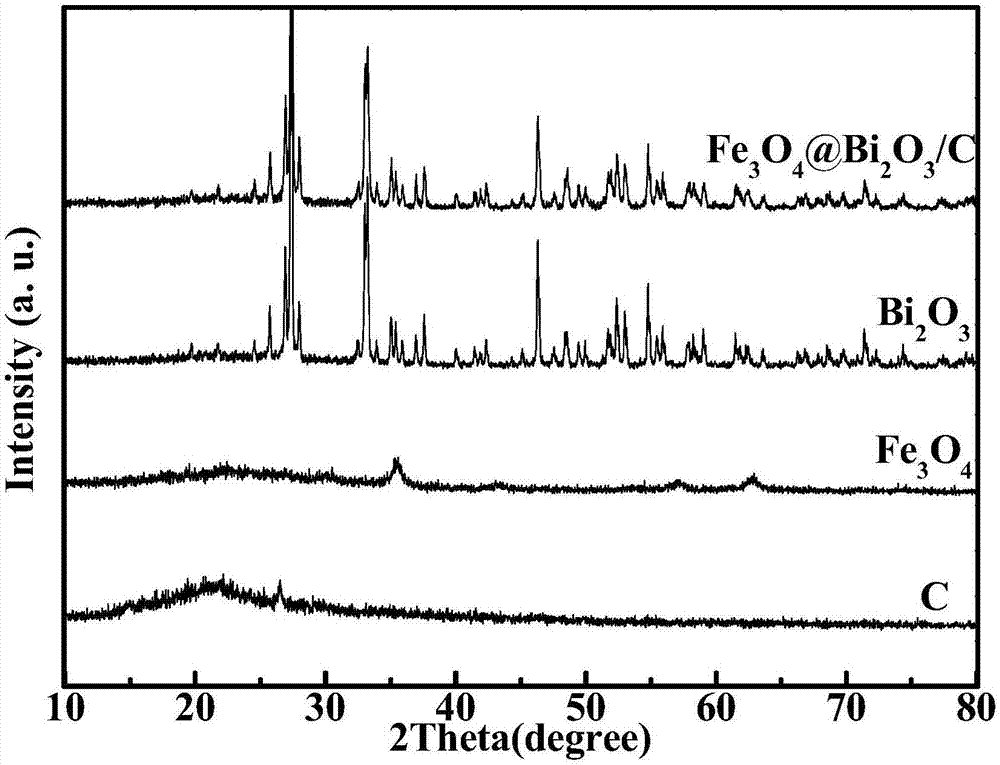

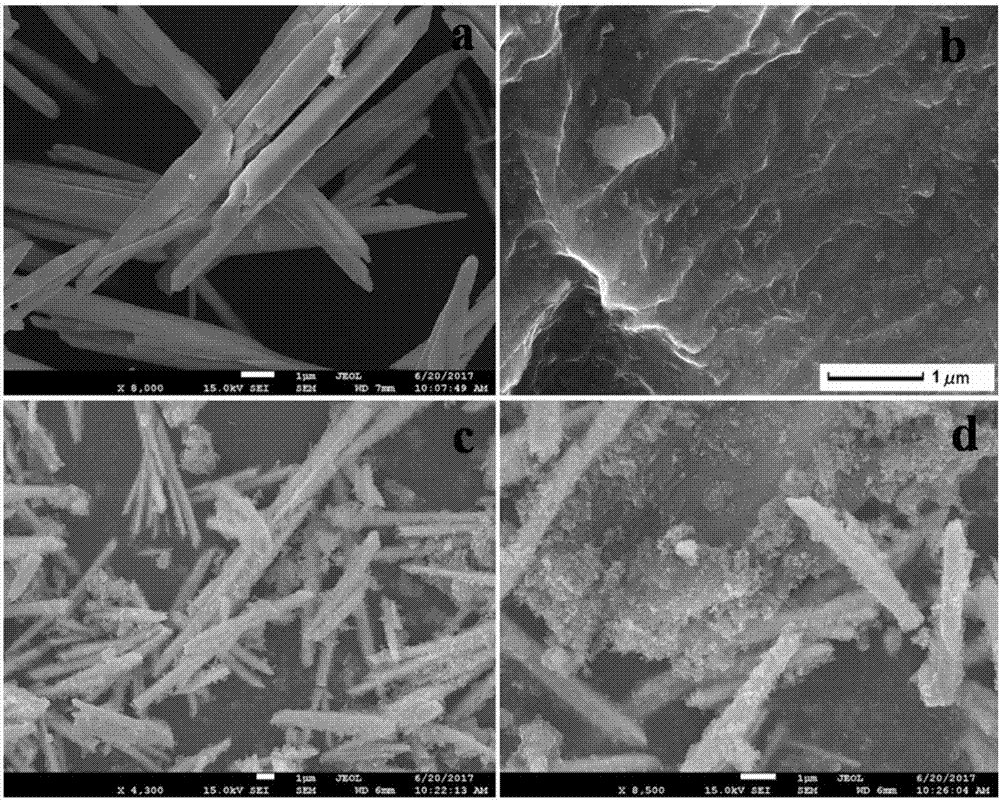

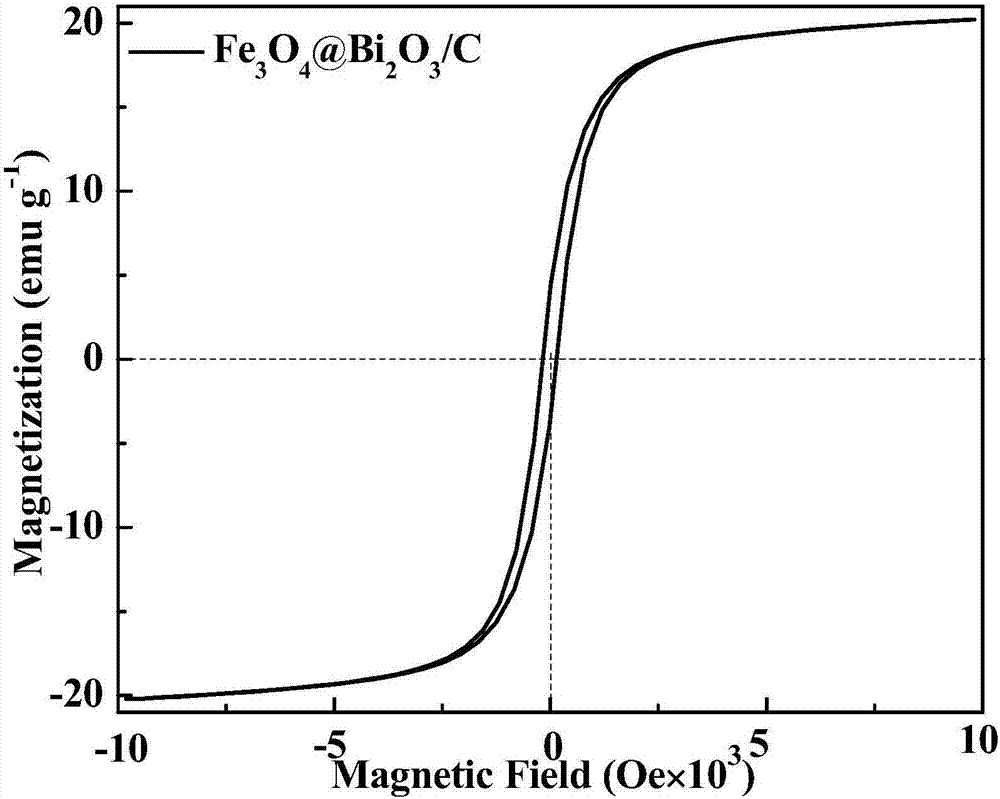

Biomass charcoal based magnetic bismuth oxide composite photocatalyst preparation method and application

InactiveCN107362805AEasy to recycleImprove circulation utilizationWater/sewage treatment by irradiationWater treatment compoundsMaterials preparationOxide composite

The invention belongs to the technical field of environmental material preparation and provides a biomass charcoal based magnetic bismuth oxide composite photocatalyst Fe3O4@Bi2O3 / C preparation method and application. The technical scheme includes steps: step 1, Bi2O3 preparation; step 2, biomass charcoal preparation; step 3, Fe3O4@Bi2O3 preparation; step 4, Fe3O4@Bi2O3 / C preparation. The prepared Fe3O4@Bi2O3 / C composite photocatalyst is convenient, quick and efficient in separation and recovery and is high in photocatalytic activity and stability; by adoption of biomass withered peach blossom petals as a carbon source, reasonable utilization of wastes is realized, and resources are saved.

Owner:JIANGSU UNIV

Method for preparing methane and barbecue charcoal from rhizoma curcumae dregs

InactiveCN106085541AImprove conversion rateNothing producedBiofuelsSolid fuelsCompression moldingResource utilization

The invention discloses a method for preparing methane and barbecue charcoal from rhizoma curcumae dregs, and belongs to the technical field of biomass energy. The methane and barbecue charcoal prepared from the rhizoma curcumae dregs is prepared through the steps of rhizoma curcumae dreg drying, smashing, fermentation, biogas residue drying and smashing, gasification, carbonization, compression molding and the like. By means of the method for preparing the methane and barbecue charcoal from the rhizoma curcumae dregs, the rhizoma curcumae dregs are utilized to the maximum extent, full resource utilization purposes of methane preparation through rhizoma curcumae dreg biological fermentation and barbecue charcoal preparation through fermentation residue pyrolysis are achieved, the production cost can be greatly reduced, environmental pollution can be reduced, resource can be saved, resource recycling utilization is promoted, good economic benefit and environmental benefit are achieved, a scientific basis is provided for resource utilization of similar lignocellulose waste, and a wide market prospect is achieved.

Owner:广西南宁荣威德新能源科技有限公司

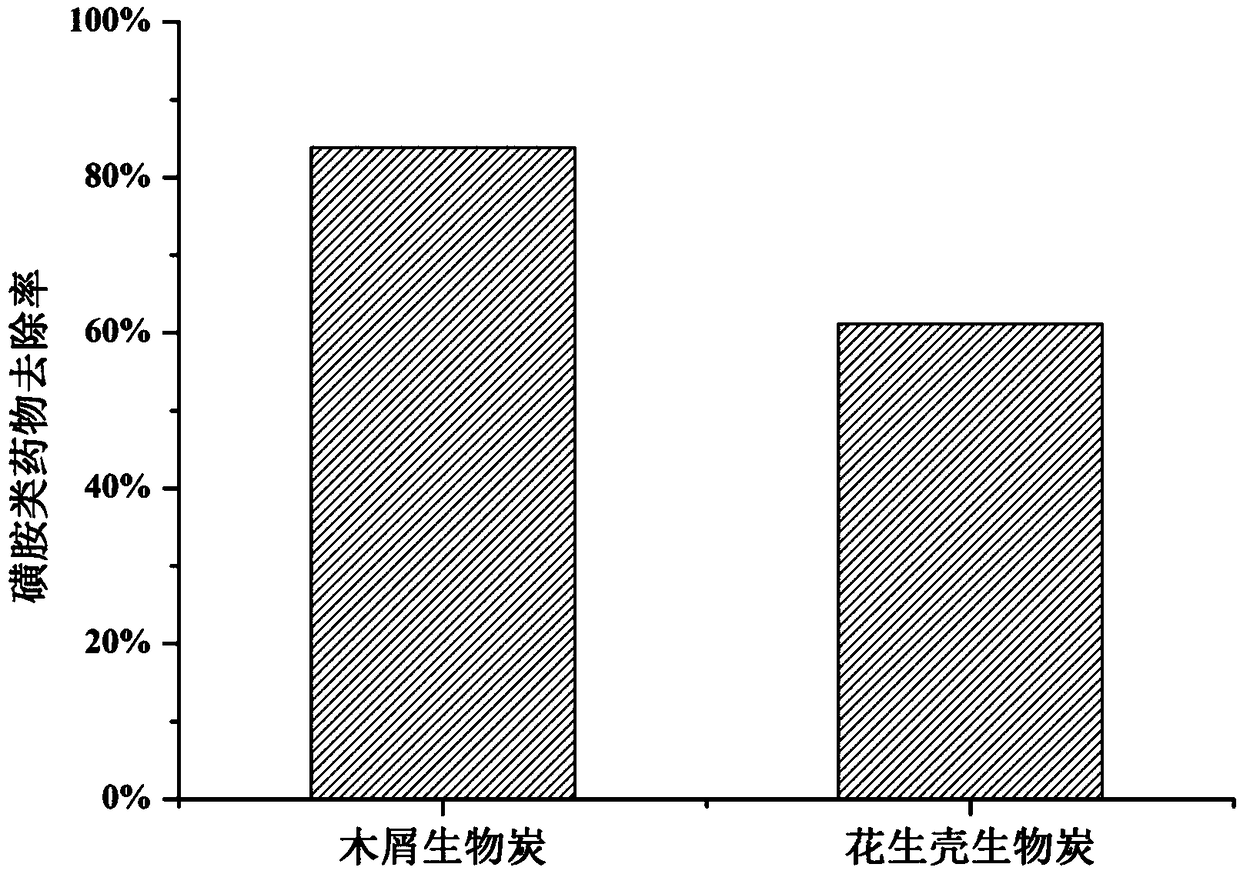

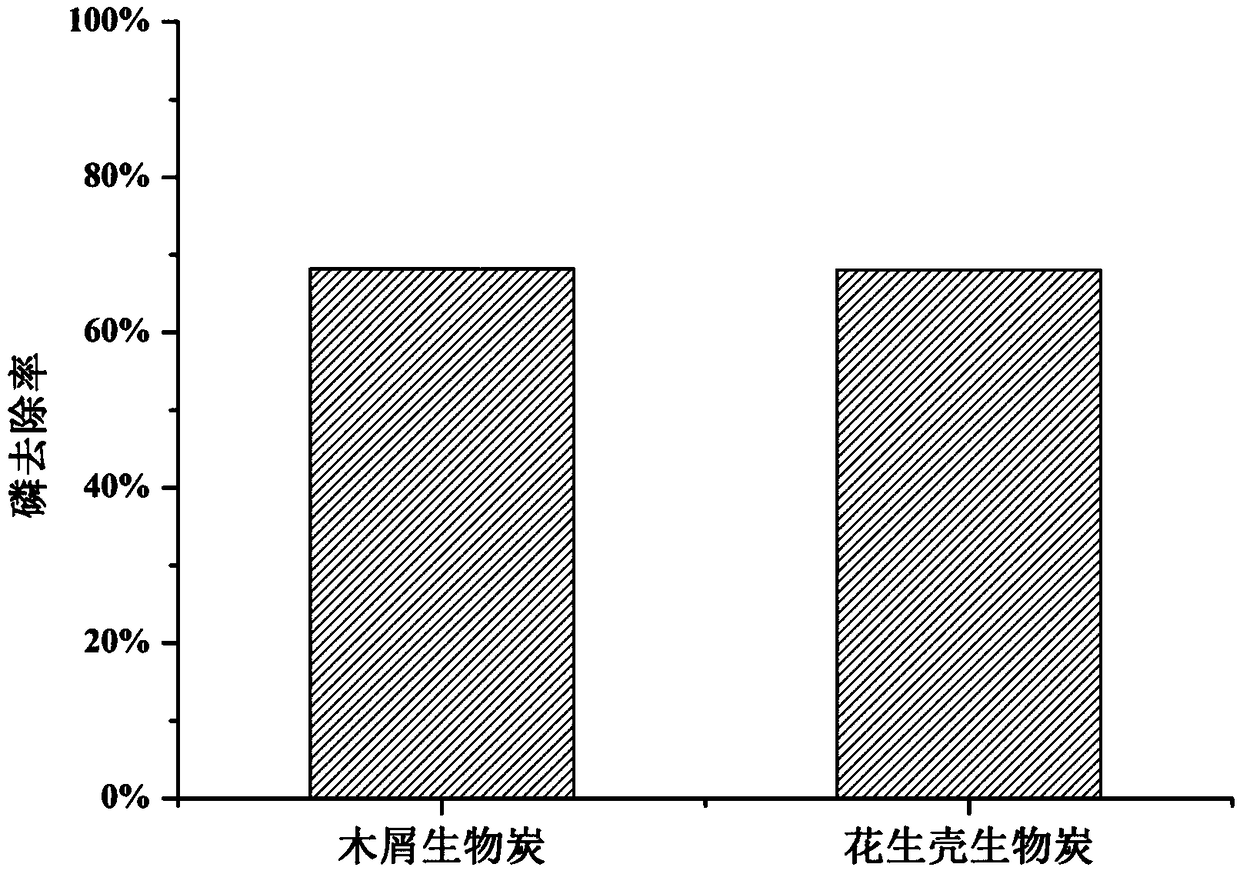

Method for resourcezation treatment on urea wastewater

InactiveCN109160571AImprove fertilityImprove the situationOther chemical processesWater contaminantsSulfur drugFiltration

The invention relates to a method for resourcezation treatment on urea wastewater. The method comprises the following steps: selecting a charcoal preparation material, treating the preparation material, preparing charcoal, and combining the charcoal with calcium peroxide e. By adopting the method, resourcezation treatment on urea wastewater is implemented, on one hand, the charcoal self has a goodadsorption capability and is capable of effectively adsorbing pollutant substances in wastewater, such as sulfonamides, the pollutant substances can be removed by means of filtration and the like, and the treated urea wastewater can be used as a liquid fertilizer; on the other hand, due to addition of the calcium peroxide, a phosphorus resource in the urea wastewater can be effectively recycled,calcium ions can be reacted with phosphorus in the urea wastewater to generate calcium phosphate (Ca3(PO4)2), in addition, the charcoal is mostly prepared from waste biomass, and the preparation and utilization process self belongs to resource circulation and utilization, so that the technique has very good effects on both urea wastewater treatment and resource recycling and utilization.

Owner:TIANJIN UNIV

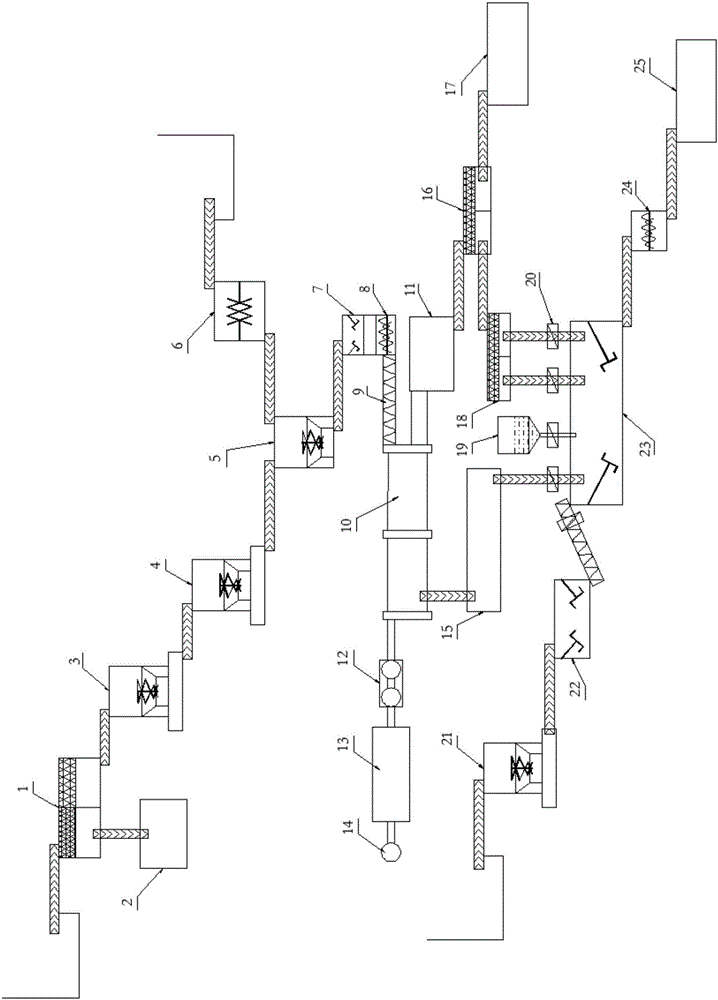

Soil restoration agent preparation system

InactiveCN106238442AAchieve recyclingAchieve self-sufficiencySolid waste disposalContaminated soil reclamationFiberResource utilization

The invention discloses a soil restoration agent preparation system. The soil restoration agent preparation system comprises a biomass charcoal preparation subsystem, a waste gas treatment subsystem, a carbon residue sorting subsystem and a soil restoration agent preparation subsystem. The biomass charcoal preparation subsystem is used for smashing and mixing organic fiber matter in household rubbish screen underflow and agricultural straw waste to produce biomass combustible charcoal. The waste gas treatment subsystem is used for purification treatment of odors produced in the carbonization treatment process of the biomass charcoal preparation subsystem. The carbon residue sorting subsystem is used for sorting carbon residues produced by burning the biomass combustible charcoal in the biomass charcoal preparation subsystem to remove remaining inorganic substances. The soil restoration agent preparation subsystem is used for preparing a soil restoration agent finished product under the action of adhesives by using the biomass combustible charcoal and the carbon residues as raw materials. The soil restoration agent preparation system has the remarkable effects that the troubling problem that the household rubbish and agricultural straw waste can cause secondary pollution for ages is solved; and moreover, no emission is generated in the production process, and full resource utilization and harmless treatment of the household rubbish are realized.

Owner:重庆以法莲实业有限公司

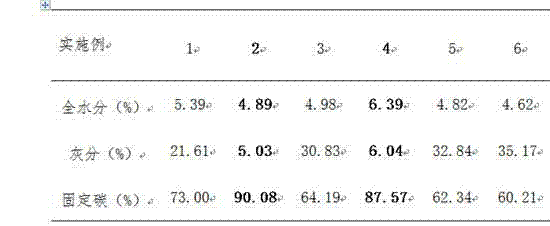

Method for preparing spicy carbon by utilizing semi-coke

The invention belongs to the technical field of wood charcoal preparation, and particularly relates to a method for preparing spicy carbon by utilizing semi-coke. The method comprises the following steps: uniformly mixing the semi-coke powder with the coke powder; and adding a forming adhesive to the mixture and forming to obtain the spicy carbon, wherein in the mixture of the semi-coke powder and the coke powder, the semi-coke powder is 70%-80% (in percentage by mass), the coke powder is 20%-30%, and the content of fixed carbon in the coke is not lower than 80%. The spicy carbon obtained by the method disclosed by the invention is excellent in quality, not only can be used for replacing the wood charcoal to reduce the tension in wood charcoal supply, but also can be used for improving the additional value and the efficient utilization of the semi-coke.

Owner:三门峡中兴煤炭综合利用研究开发中心

Environment-friendly barbecue charcoal and preparation method thereof

InactiveCN107129847AObvious deashingExtended burn timeSolid fuelsFuel additivesAdhesiveCharcoal preparations

The invention belongs to the technical field of barbecue charcoal preparation, particularly relates to environment-friendly barbecue charcoal and a preparation method thereof and mainly solves technical problems of short combustion time, high consumption and proneness to generation of a great quantity of harmful gases in a charring process of existing barbecue charcoal. The environment-friendly barbecue charcoal is prepared from, by weight, 45-50 parts of a first raw material, 45-50 parts of a second raw material, 1-3 parts of an adhesive, 2-5 parts of sodium humate, 0.5-3 parts of calcium sulfate and 0-3 parts of calcium oxide, wherein the first raw material refers to anthracite or smoke-free decomposed coal, and the second raw material refers to smoke-free decomposed coal or charcoal particles. Production steps of the environment-friendly barbecue charcoal include 1) raw material pretreatment; 2) mixing and stirring; 3) extrusion moulding; 4) heating and drying. The environment-friendly barbecue charcoal has advantages of long combustion time, low consumption, freeness of charring, easiness in processing, freeness of smoke and odor and the like.

Owner:李永庆

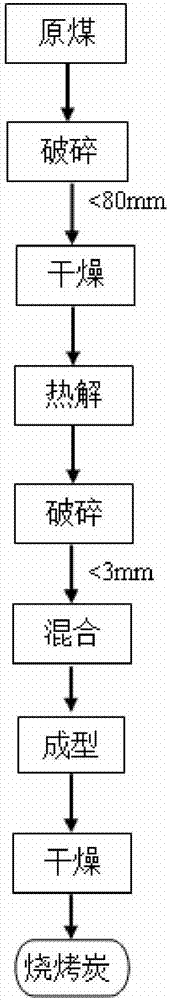

Preparation method of clean lignite-based semicoke barbeque charcoal

InactiveCN107083250ALower ignition pointReduce manufacturing costSolid fuelsSpecial form destructive distillationSulfurCrusher

The invention discloses a preparation method of clean lignite-based semicoke barbeque charcoal, and belongs to the technical field of barbeque charcoal preparation by lignite-based semicoke. The barbeque charcoal is prepared from the lignite-based semicoke, binder and water. Lignite is crushed below 80 mm by crushing, the crushed lignite is subjected to drying in a drying machine and a pyrolitic reaction in a pyrolizing furnace in sequence, the solid lignite semicoke is produced, and after being crushed below 3 mm by a crusher, the lignite semicoke is sent for subsequent blending and stirring; solid semicoke powder, the binder, sulfur fixing agent and the like are subjected to stirring and blending treatment through a blender, and a blended material and the water are sent into an edge mill for grinding and secondary blending for formed mixture preparation; the mixture is conveyed to a forming machine through a conveyor, and barbeque charcoal products in different shapes are prepared through the forming machine; the wet formed barbeque charcoal is conveyed to a mesh-belt dryer for drying treatment. According to the method, the lignite semicoke is adopted as a raw material, so that the ignition point and the production cost of the barbeque charcoal are effectively lowered, which are beneficial to use and popularization of the barbeque charcoal.

Owner:霍林郭勒市嘉华能源技术开发有限公司

Method for preparing charcoal by applying rice straw

InactiveCN109775684ALow modification costReduce manufacturing costBiofuelsCarbon preparation/purificationProcess engineeringAssembly line

The invention discloses a method for preparing charcoal by applying rice straw. The method comprises the following steps of selecting straw, wherein harvested straw is selected, and stacked airing isperformed. The straw with the low cost is adopted as raw materials of charcoal, the straw is smashed and dried in advance, then, the straw is incinerated through a dry distillation type carbonizing furnace, a conveying device and a cooling device are matched with the carbonizing furnace so that the straw can be incinerated and cooled, assembly line operation can be formed, then, pyrolygneous and pure water generated by incineration straw are diluted proportionally, a modified solution is formed, the charcoal modification cost is greatly lowered, finally, charcoal is screened, the charcoal reaches the specified grain size, the method is simple in technological process, the price of the production raw materials and a modified solution is low, the production cost of charcoal is greatly lowered, the method is worthy of being used and popularized, and meanwhile the problems that an existing charcoal preparation method is complex in technological process and the production raw materials areexpensive are solved.

Owner:天津市实验林场

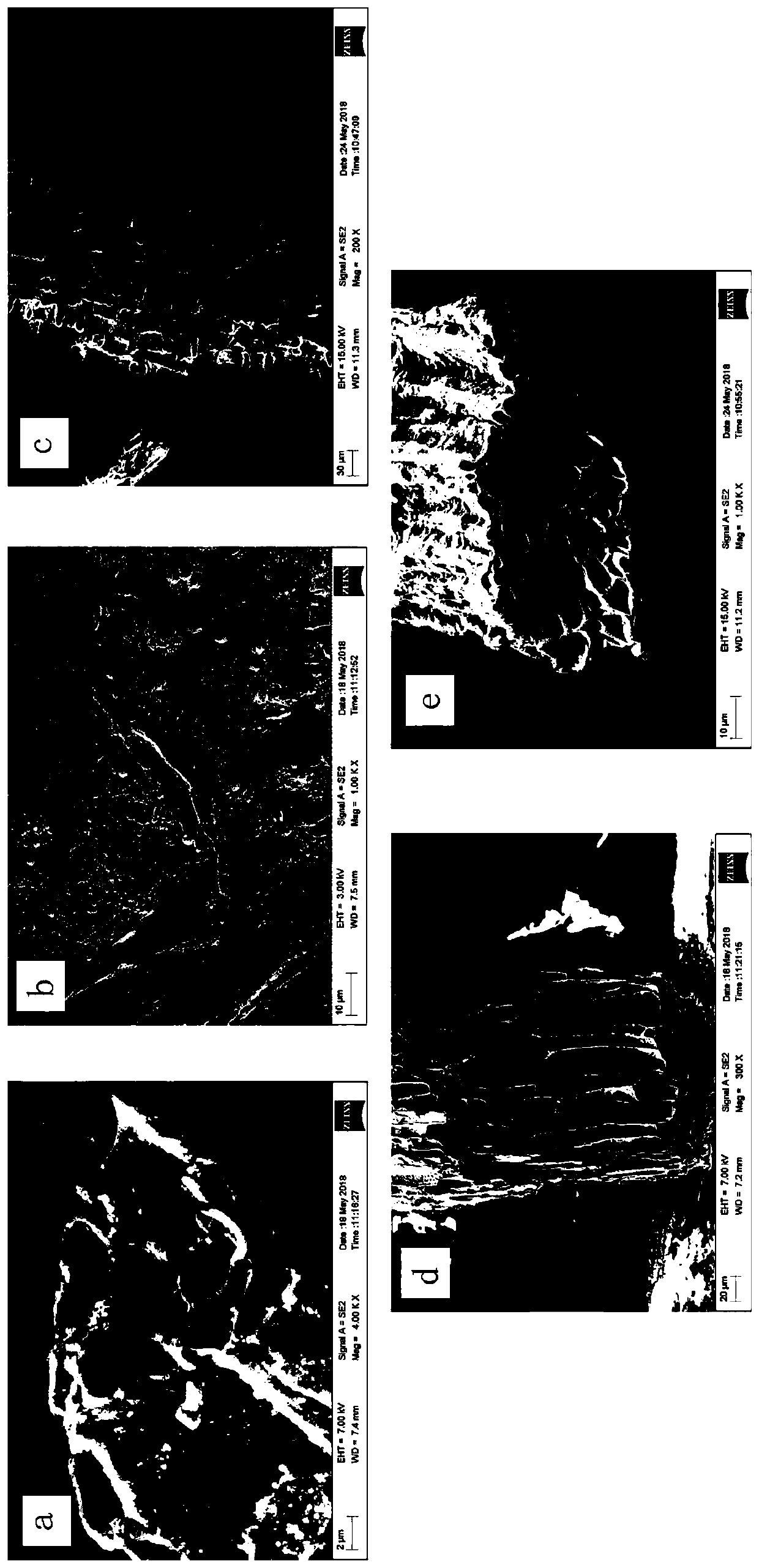

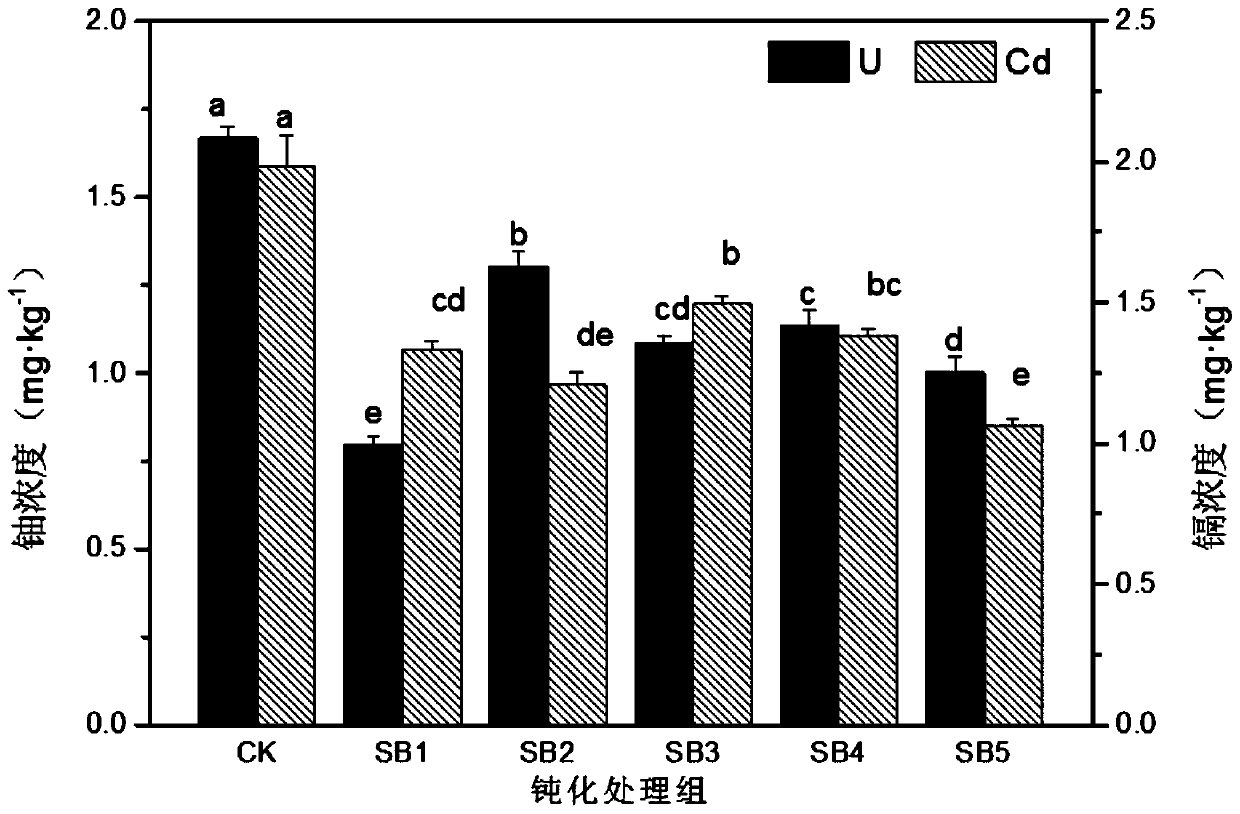

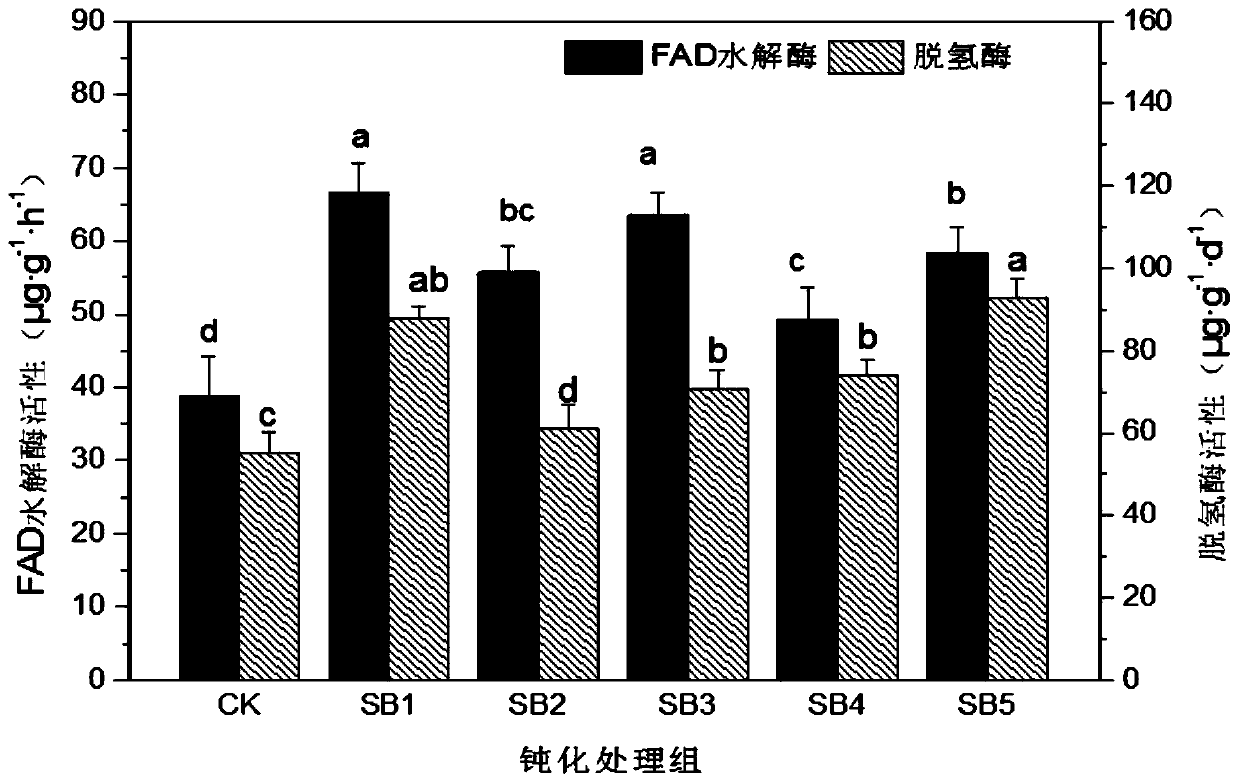

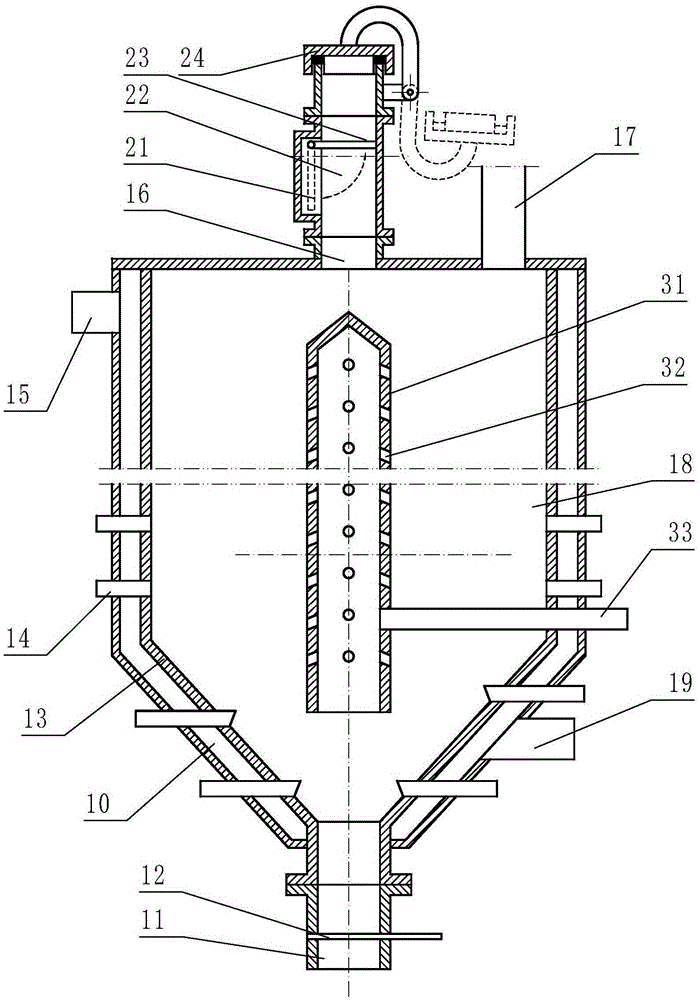

Passivation remediation method for uranium-cadmium composite contaminated soil

PendingCN110877046ARealize resource utilizationGuaranteed use valueContaminated soil reclamationSoil scienceSoil remediation

The invention discloses a passivation remediation method for uranium-cadmium composite contaminated soil, and belongs to the field of soil remediation. The method realizes effective remediation of thecadmium-uranium composite contaminated soil, and has the advantage of good remediation effect. The method comprises the steps of charcoal preparation and soil remediation. Agricultural wastes are used as a raw material, the method has the advantages of simplicity, convenience in operation, low cost, meeting of large-scale remediation requirements of the uranium-cadmium composite contaminated soil, effectiveness in soil improvement, high application values and good application prospect. The method can further realize in-situ passivation, is simple and quick, makes the soil continuously utilized after being repaired, effectively ensures the utilization values of the soil and the economic benefits of farmers, and reduces the economic loss caused by plowing-stopping remediation. An application of the remediation method, especially an application of planting leaf vegetables in the remediated soil, is also protected in the invention. The method can significantly reduce the content of uranium and cadmium in the leaf vegetables, and has high practical values.

Owner:SOUTHWEAT UNIV OF SCI & TECH +1

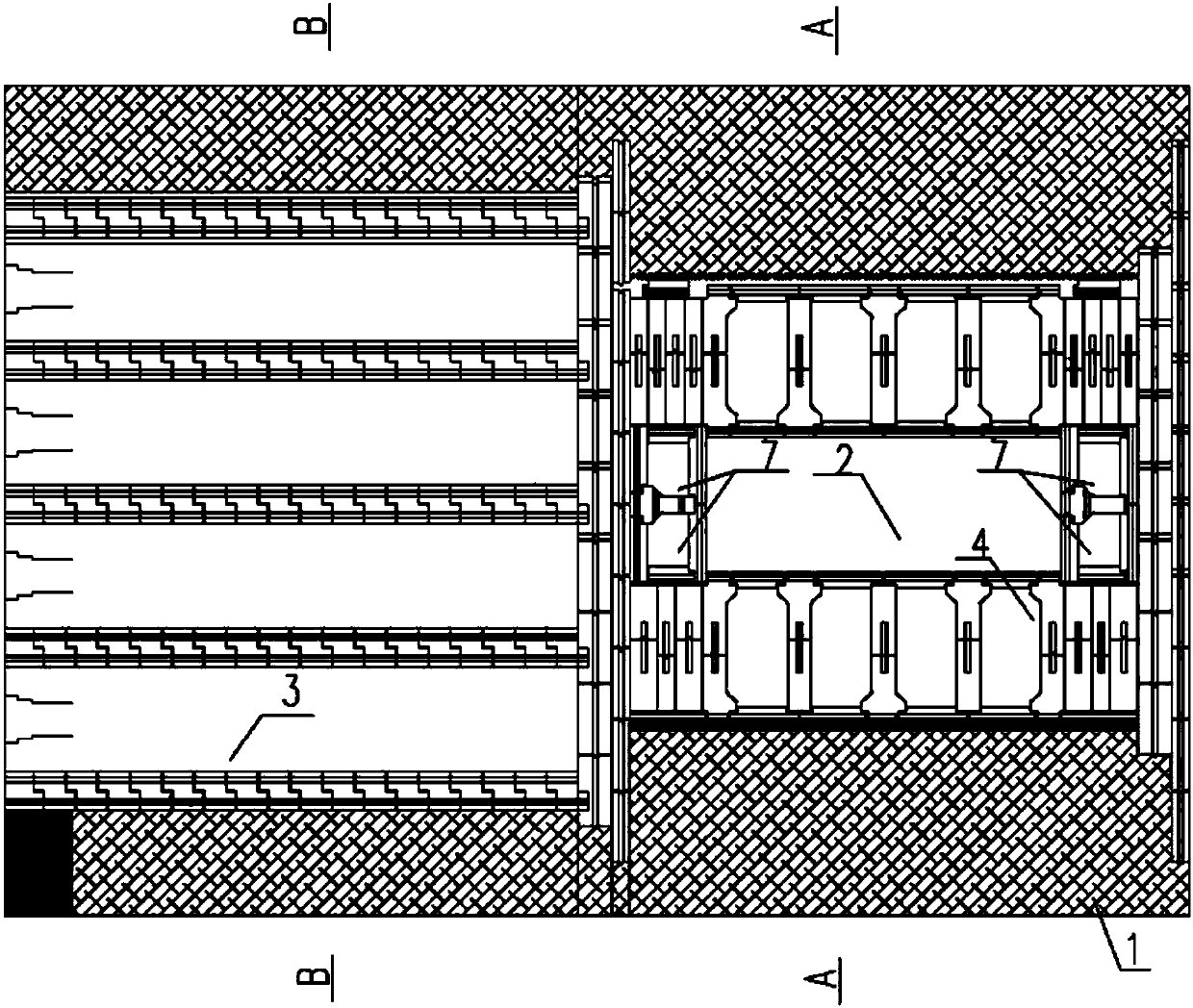

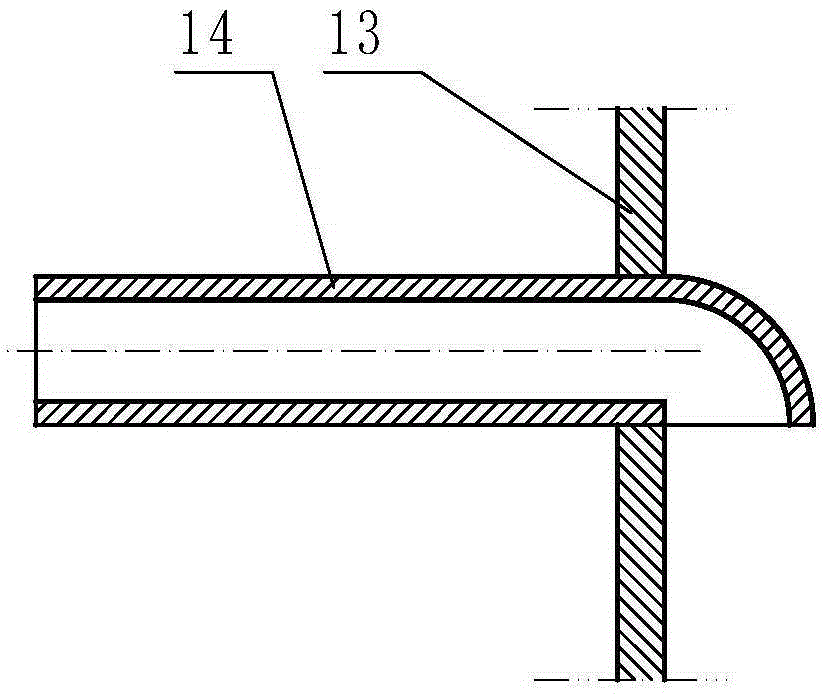

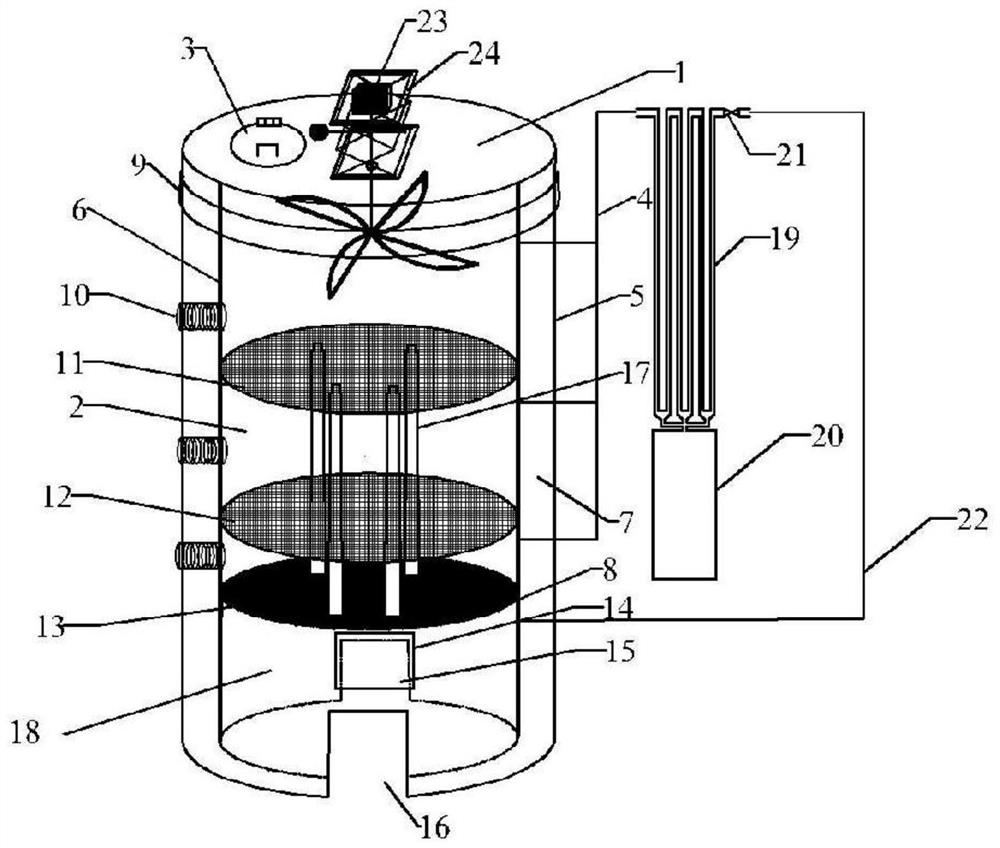

Charcoal preparation method and special charcoal preparation drying device during carbon disulfide production

InactiveCN105318675AReduce consumptionDrying gas arrangementsDrying solid materialsCarbon disulfideRaw material

The invention discloses a charcoal preparation method and a special charcoal preparation drying device during carbon disulfide production. The charcoal preparation method and the special charcoal preparation drying device during carbon disulfide production are characterized in that black charcoal or semi-coke serves as raw materials, and the raw materials are dried at the temperature of 350-450 DEG C; the charcoal preparation drying device comprises a drying chamber (18) composed of a shell (13); a heating interlayer (10) is arranged on the periphery of the shell (13); a central drying air inlet mechanism is arranged in the center of the drying chamber. Compared with the prior art, the raw material consumption can be greatly reduced, and especially energy saving and environmental friendliness are further achieved.

Owner:濮阳天泓实业有限公司

Closed charcoal preparation apparatus

InactiveCN104910932AImprove production efficiencyImprove productivityBiofuelsRetortsProduction rateRoom temperature

The invention relates to a charcoal preparation apparatus, and especially relates to a closed charcoal preparation apparatus. A technical scheme is characterized in that the apparatus comprises a temperature controller (1), a heater box (2) and a pyrolysis tank (9), and when charcoal is prepared, organic matters enter the pyrolysis tank (9), a lid (8) at the upper portion of the pyrolysis tank (9) is screwed up, the pyrolysis tank (9) is put in the heater box (2), and heating pyrolysis is carried out. The heater box is opened after the pyrolysis reaction, the pyrolysis tank (9) is cooled to room temperature, and then the prepared charcoal is taken out. The apparatus has the characteristics of ingenious conception, reasonable design, and realizes reduction of the pyrolysis temperature, shortening of the organic matter pyrolysis time and increase of the charcoal preparation efficiency by preparing charcoal through pyrolysis of organic substances in closed environment; and the apparatus can ensure anaerobic environment and improve the charcoal production rate through pyrolysis of the organic matters in a closed tank.

Owner:CHONGQING UNIV OF ARTS & SCI

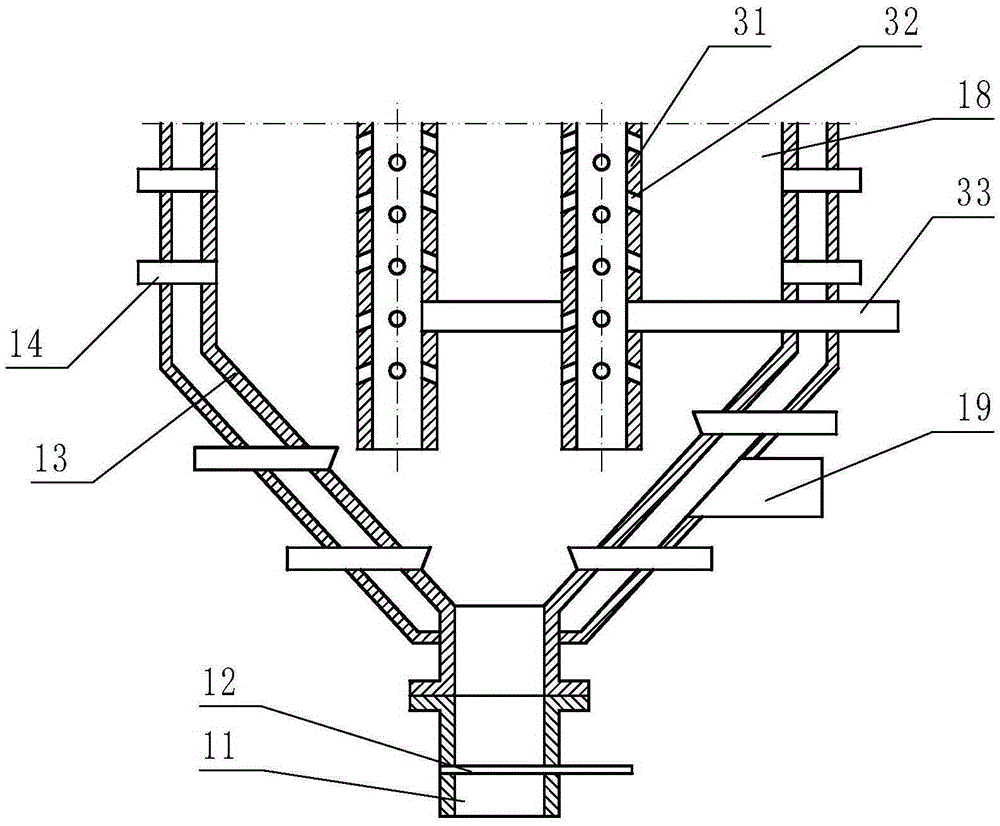

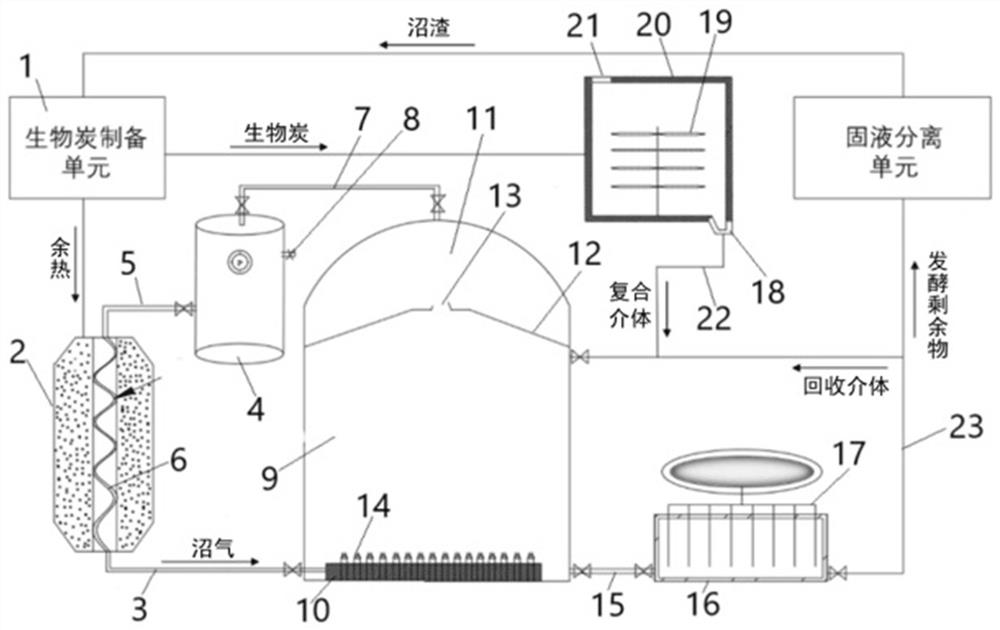

Methane production system based on recyclable composite mediator enhanced anaerobic digestion

InactiveCN114686344AInterspecies electron transferPromote degradationBioreactor/fermenter combinationsBiological substance pretreatmentsAnthraquinonesSulfonate

The invention discloses a methane production system based on recyclable composite mediator enhanced anaerobic digestion, and particularly relates to the technical field of biological fermentation. Comprising a charcoal preparation unit and an impregnation device, a stirring device is arranged in the impregnation device, an impregnation solution is an anthraquinone-2-sodium sulfonate solution, an anaerobic digester is connected to the impregnation device, a partition plate with a gas inlet is arranged in the anaerobic digester, the anaerobic digester is connected with a gas collection pressure regulating tank located above the gas inlet, and the gas collection pressure regulating tank is connected with a gas storage tank located above the gas inlet. The gas collection pressure regulating tank is communicated with a biogas preheating pipe, a heat storage device is coated outside the biogas preheating pipe, the biogas preheating pipe is connected with a pneumatic stirring device positioned in the anaerobic digester through a gas guide pipe, and the pneumatic stirring device consists of a gas channel and a plurality of one-way gas nozzles arranged on the gas channel at intervals; and the side wall of the lower part of the anaerobic digester is connected with a magnetic recovery device. By adopting the technical scheme of the invention, the problems that AQS is difficult to enrich and is easy to lose along with wastewater to cause secondary pollution to the environment are solved, and reutilization of resources can be realized.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

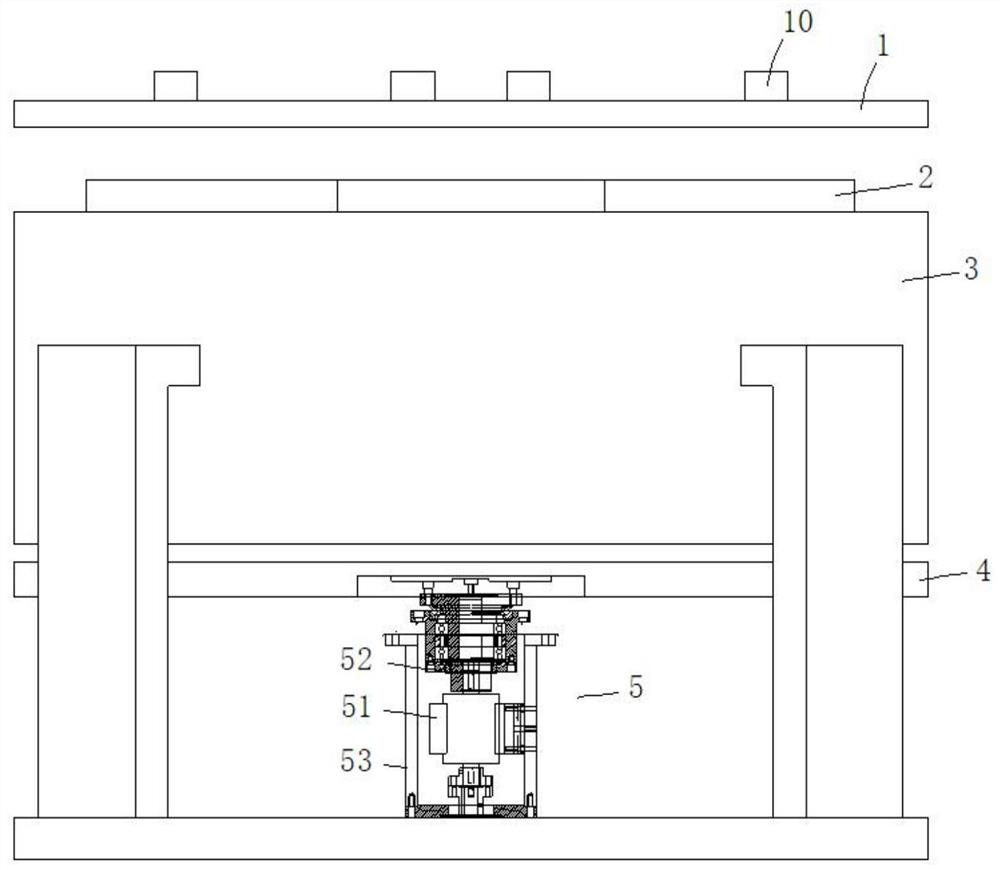

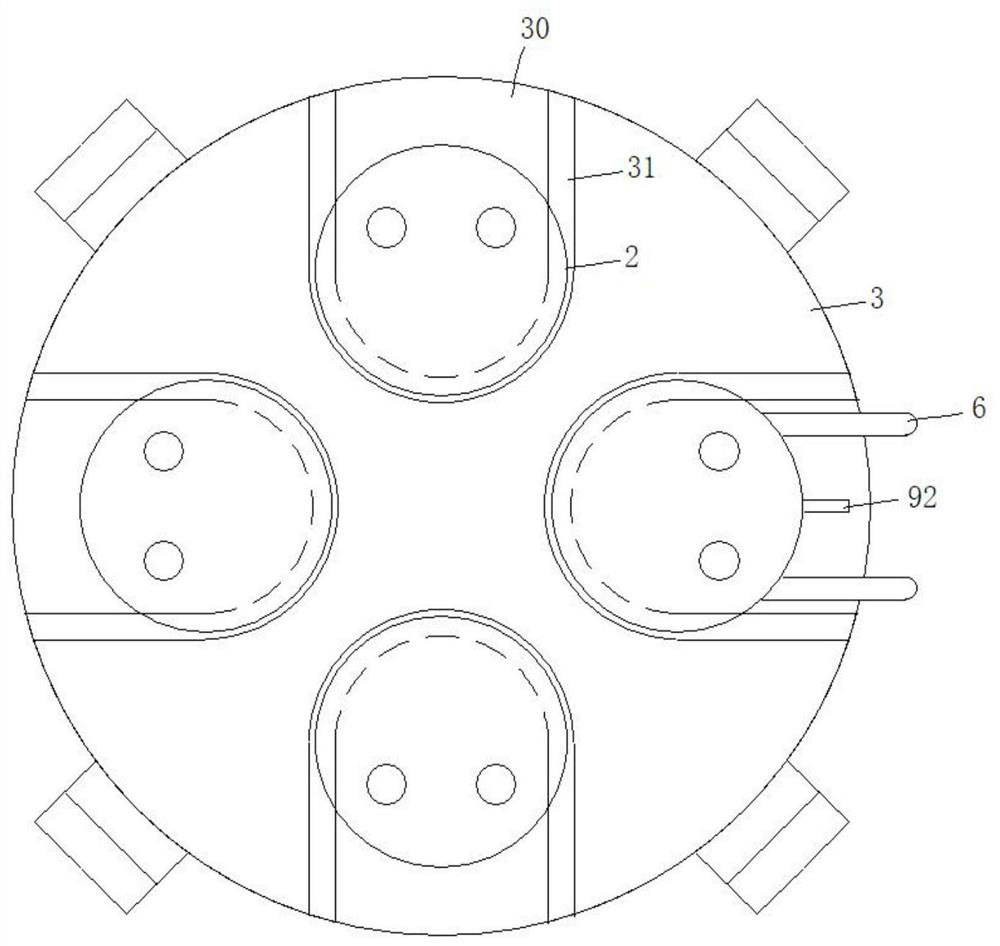

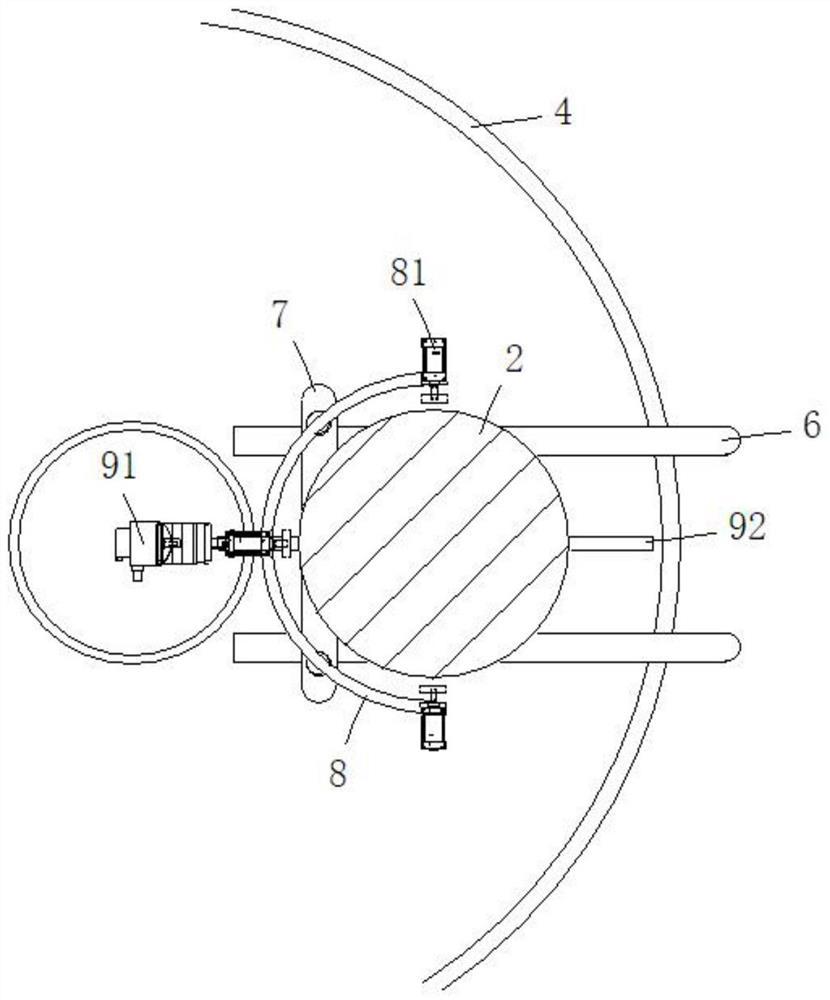

Biochar preparation equipment

ActiveCN112342043APrecise dockingIncrease flexibilityBiofuelsSpecial form destructive distillationStructural engineeringMechanical engineering

The invention discloses charcoal preparation equipment. The equipment of the invention comprises a container body and a supporting base; the container body is movably connected with the supporting base; the supporting base comprises a cover plate, a fixed base and a movable base; the cover plate is detachably connected to the top of the fixed base; the movable base is rotatably connected to the bottom of the fixed base; the movable base is connected with a first driving part; a mounting groove is formed in the fixed base; the container body is slidably connected with the mounting groove; the movable base is fixedly connected with a first support; the first support is slidably connected with a second support; the second support is connected with a second driving part; the second support isconnected with a first air cylinder; the first air cylinder is connected with a third support; the third support is connected with a second air cylinder. A carbon kettle is moved away by adopting a movable structure through an iron basket, the kettle is replaced again, so that work can be continued; such a process is unstable, the carbon kettle is prone to shaking and even colliding in the movingprocess, and biomass in the carbon kettle and the structure of the carbon kettle are damaged. With the charcoal preparation equipment of the invention adopted, the above problems can be solved.

Owner:ANHUI SCI & TECH UNIV

Charcoal preparation method based on mattress fermented feed and application thereof

InactiveCN104998615AEfficient removalEfficient recyclingOther chemical processesWater/sewage treatment by sorptionCrucibleEngineering

Charcoal preparation method based on mattress fermented feed and application thereof belong to the field of environmental restoration technologies. The mattress fermented feed is grinded after air drying, to obtain a raw material with the diameter of 60 meshes. The raw material is sealed in a crucible, the crucible is put in a muffle furnace, and after calcination of 300 to 500 DEG C and cool to ambient temperature, bedding biochar inside the crucible is taken out. Advantages of the invention lie in that: materials are easy to get, costs are low, a preparation process is simple, and an effect of processing heavy metal pollutants in waste water is obvious. Further, organic wastes such as waste padding are also recycled.

Owner:YANGZHOU UNIV

Method for preparing charcoal from sheep manure and wood dust

InactiveCN104498066ASolve processingReduce deforestationBiofuelsSpecial form destructive distillationAgricultural engineeringPulp and paper industry

The invention discloses a method for preparing wood charcoal from sheep manure and wood dust, which comprises the following steps: a. evenly mixing 50-100 parts of cleaned, air-dried and roll-pulverized sheep manure and 0-50 parts of wood dust, then feeding into a drying machine, and drying, wherein the temperature of the drying machine is 160-250 DEG C, and the drying time is such that the water content of the raw materials at the outlet of the drying machine is 8-12%; b. feeding the raw materials obtained in the step a into a rod-making machine, and pressing through the rod-making machine at 260-320 DEG C to obtain a rod-like semi-finished product for later use; and c. carbonizing the rod-like semi-finished product obtained in the step b in a carbonizing kiln, burning for 3-4 days, sealing the kiln when the temperature reaches 500-800 DEG C, and naturally cooling to obtain the wood charcoal finished product, wherein the fixed carbon content of the wood charcoal finished product meets the national hard broad-leaved wood charcoal superior quality standard (the fixed carbon content is no less than 85%). According to the invention, the problem that sheep manure is difficult to treat or is low in productive value after treatment can be effectively solved; and cutting of wood resulting from wood charcoal preparation can be reduced.

Owner:贵阳市农村能源环保办公室

Method for preparing machine-made charcoal from needle mushroom residues

The invention discloses a method for preparing machine-made charcoal from needle mushroom residues and relates to the technical field of machine-made charcoal preparation. The method comprises the following steps: (1) dissolving mushroom residues left after cultivated needle mushroom is mature into an acid liquid, carrying out ultrasonic stirring at 45-55 DEG C, after ultrasonic stirring treatment, cleaning with deionized water till a solution is neutral, further dissolving into a 8-10% sodium bicarbonate solution, carrying out ultrasonic stirring, and after stirring, cleaning with deionized water till the solution is neutral; (2) uniformly mixing the needle mushroom residues after acid liquid treatment with proteasem, amylase and cellulase to carry out a reaction; (3) carrying out carbonization treatment on the reacted product in a carbonization furnace, thereby obtaining the machine-made charcoal. The waste needle mushroom residues are turned into wealth, and not only is repeated useof resources achieved, but also the prepared machine-made charcoal product is high in yield, high in fixed carbon content and high in heat radiation.

Owner:和县伊迈炭业有限责任公司

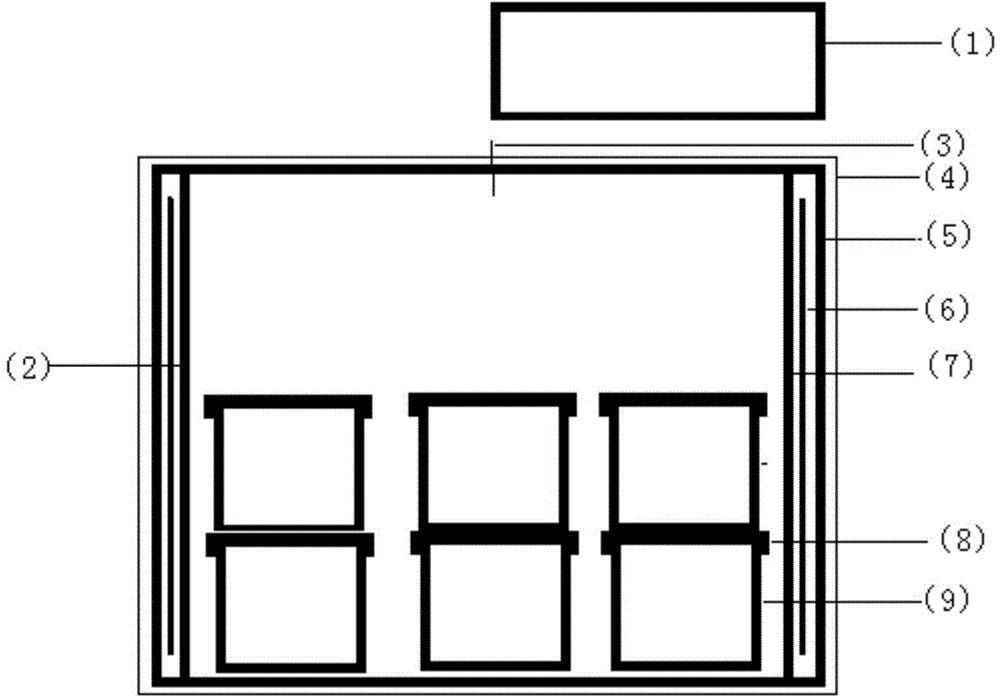

Field portable carbonization furnace for in-situ resource utilization of agricultural waste and graded preparation of biochar

PendingCN111635768AMobilityPortableCombustible gas coke oven heatingBiofuelsInsulation layerCarbonization

The invention discloses a field portable carbonization furnace for in-situ resource utilization of agricultural waste and graded preparation of biochar. The field portable carbonization furnace comprises a cover, a furnace body, a material inlet, a smoke exhaust pipe, a stainless steel outer layer, a carbonization area, a heat insulation layer, a heating partition plate, an airflow limiting sliding cover, a ventilation opening, a feeding opening, three or more heat conduction pipes, a heating area, a condensation pipe, a waste gas collection chamber, a one-way ventilation valve, a tail gas guide pipe and one or more sieve meshes. According to the invention, the product disclosed by the invention has the characteristics of mobility, portability, simple operability and the like, is suitablefor being used in special environments such as fields, mountainous regions and the like, and particularly has outstanding functions aiming at the generation of a large amount of waste agricultural biochar after autumn harvest; and the carbonization furnace disclosed by the invention is reliable and safe in charcoal preparation process, high in preparation efficiency, low in cost, small in occupiedarea and portable, and can meet the requirement of field in-situ preparation of charcoal.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com