Methane production system based on recyclable composite mediator enhanced anaerobic digestion

A technology of anaerobic digestion and composite media, which is applied in the direction of gas production bioreactors, special-purpose bioreactors/fermenters, biochemical instruments, etc., and can solve the problems of difficult enrichment of AQS, secondary pollution, loss of environment, etc. , to achieve the effects of reducing energy consumption, saving costs, and enriching the preparation materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

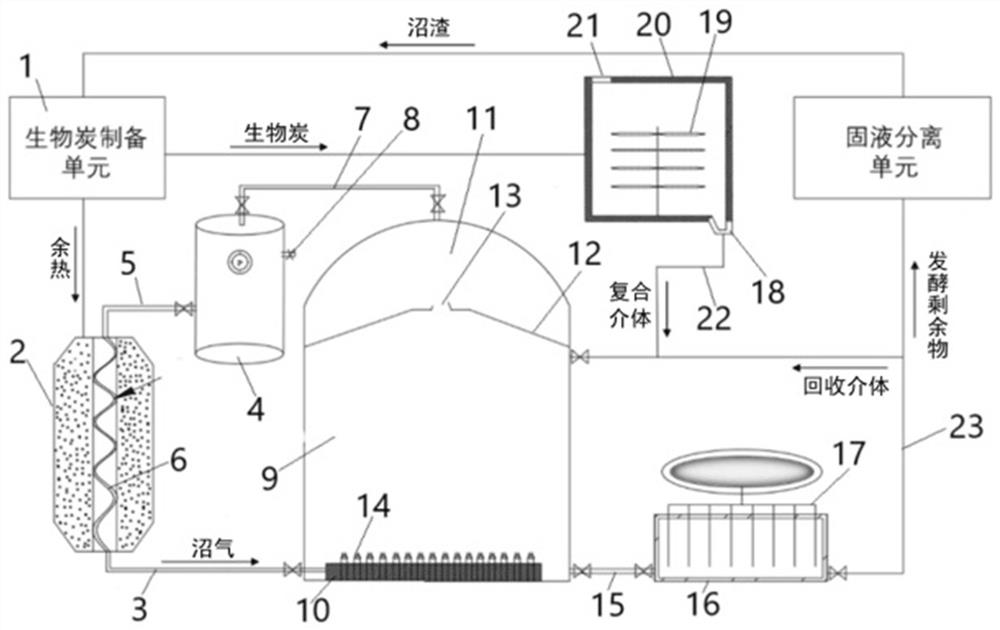

[0023] as attached figure 1 A methane production system based on enhanced anaerobic digestion of recyclable composite mediators is shown, including a biochar preparation unit 1 for producing biochar and an impregnation device 20 connected to the biochar preparation unit 1, and the biochar preparation unit 1 Biochar is prepared by high-temperature pyrolysis, and the pyrolysis temperature is between 500 °C and 600 °C. The raw materials of biochar can be selected from agricultural wastes such as crop straw, and the biogas residue treated by the solid-liquid separation unit in this scheme. The waste is fully utilized, and the biochar prepared by the biochar preparation unit 1 is sent to the impregnation device 20 for mediator loading, and the pyrolysis waste heat is stored in the heat storage device 2 . The biochar preparation unit 1 transports the prepared biochar into the impregnation device 20 through a transport pipe.

[0024] The top of the dipping device 20 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com