Preparation method of biomass-based active carbon

A technology based on activated carbon and biomass, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of shrinking sources of wood and charcoal, limitations of activated carbon raw materials, price increases, etc., to achieve large-scale production and equipment requirements Low, easy-to-operate controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

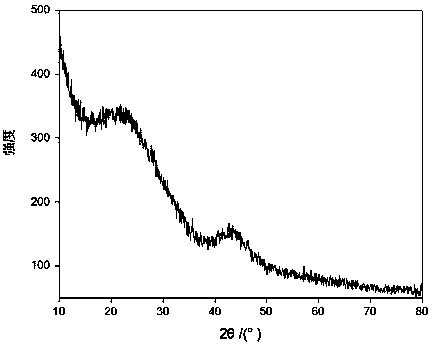

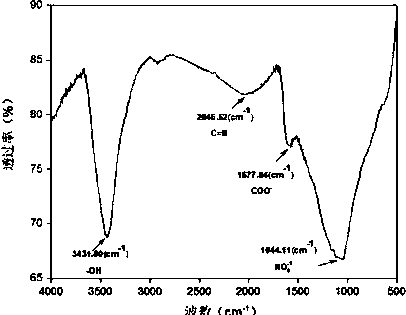

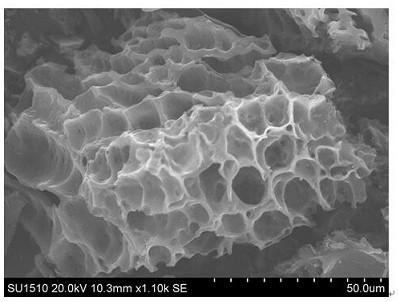

Image

Examples

Embodiment 1

[0020] Take rice husk as an example.

[0021] The first step: rice husk pretreatment.

[0022] Wash and dry the rice husk. The specific steps are: ①Put 10 g of rice husk into a 500 mL beaker, add 400 mL of tap water to rinse twice, and filter off the tap water after rinsing; ②Put 400 mL of ultrapure water into the beaker, place a 35 mm straight tube Stir bar, stir with a magnetic stirrer for five minutes, after settling for five minutes, filter the supernatant. Repeat this step three times; ③Vacuum, filter, and dry in an oven. When the temperature rises to 105°C, keep the temperature constant for 10 hours. Take it out after cooling naturally.

[0023] The second step: preparation of rice husk pyrolysis carbon.

[0024] The clean rice husk was initially pyrolyzed at 450 ℃ to obtain rice husk pyrolytic charcoal. The specific steps are: ①weigh 5 g of dry and clean rice husks, put them into ceramic ark crucible, and distribute them evenly; ②put the crucible into the high-temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com