Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68 results about "Amplitude amplification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

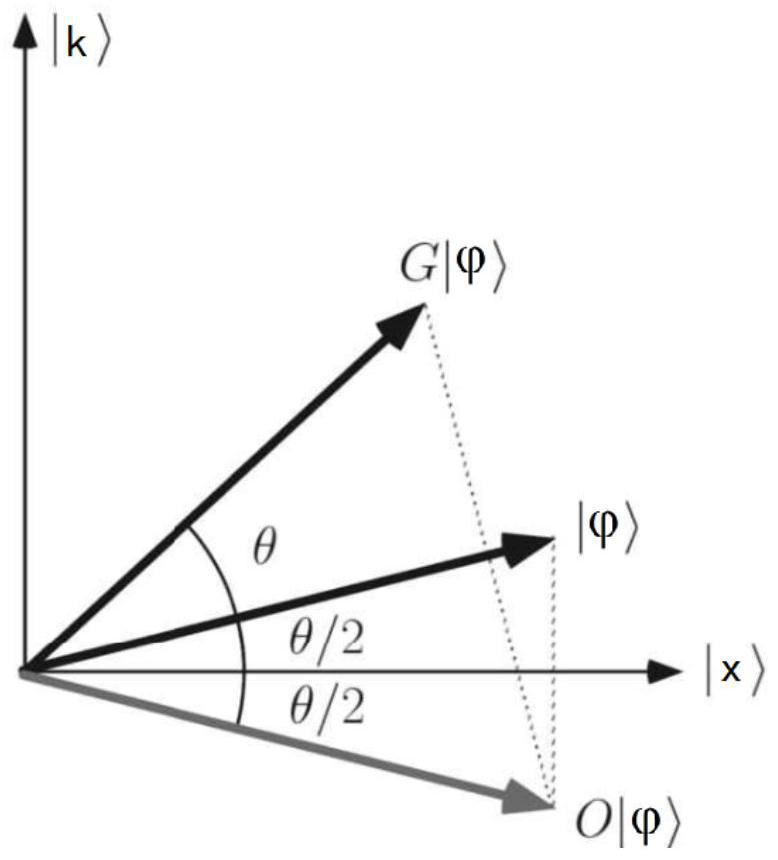

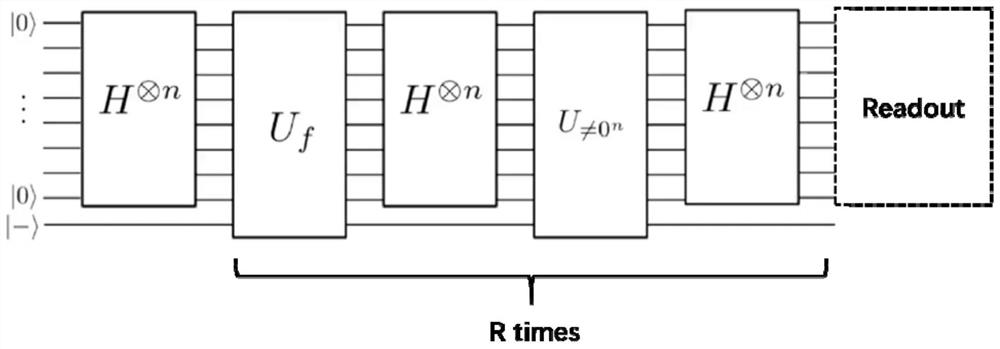

Amplitude amplification is a technique in quantum computing which generalizes the idea behind the Grover's search algorithm, and gives rise to a family of quantum algorithms. It was discovered by Gilles Brassard and Peter Høyer in 1997, and independently rediscovered by Lov Grover in 1998.

Transmitter

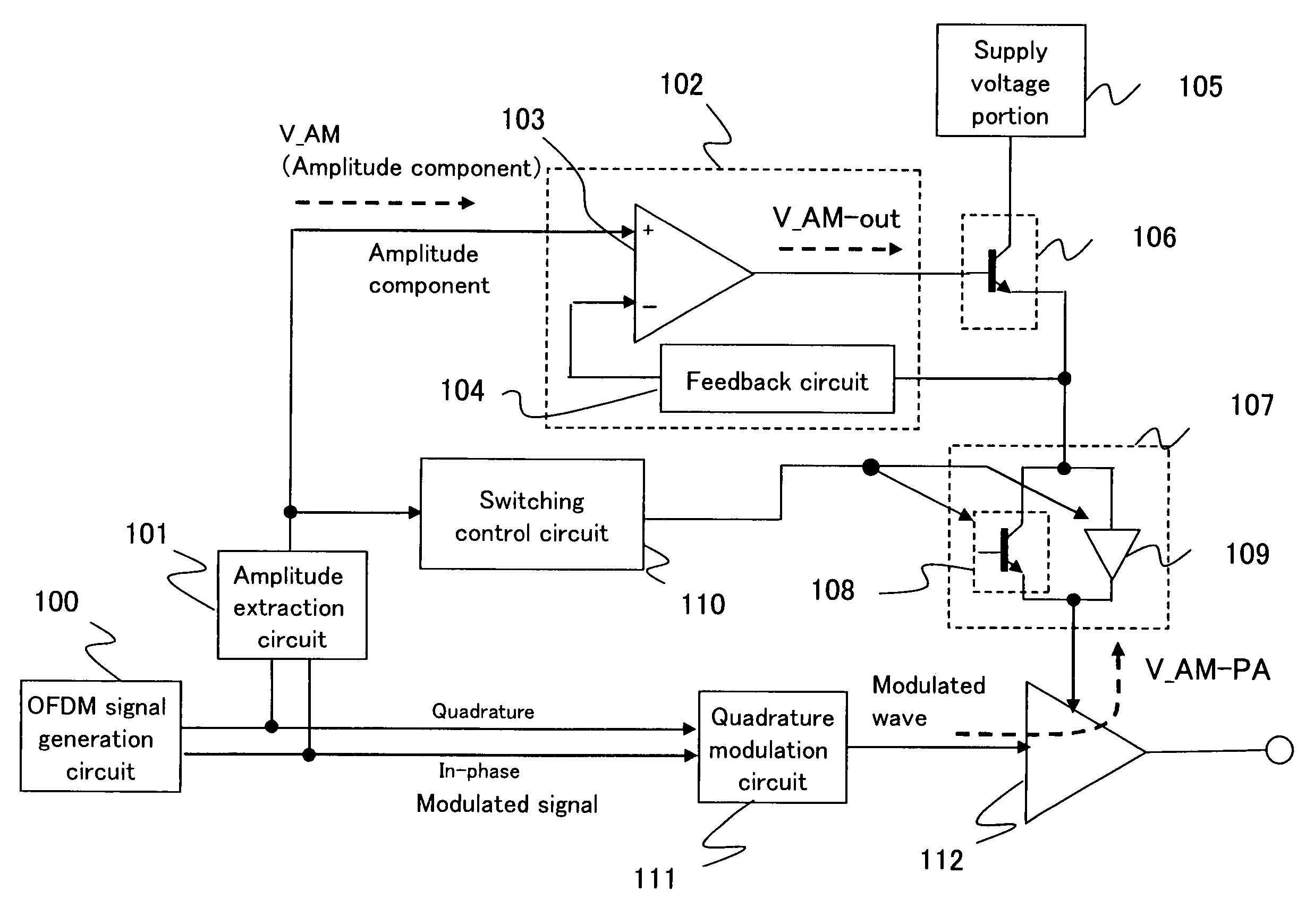

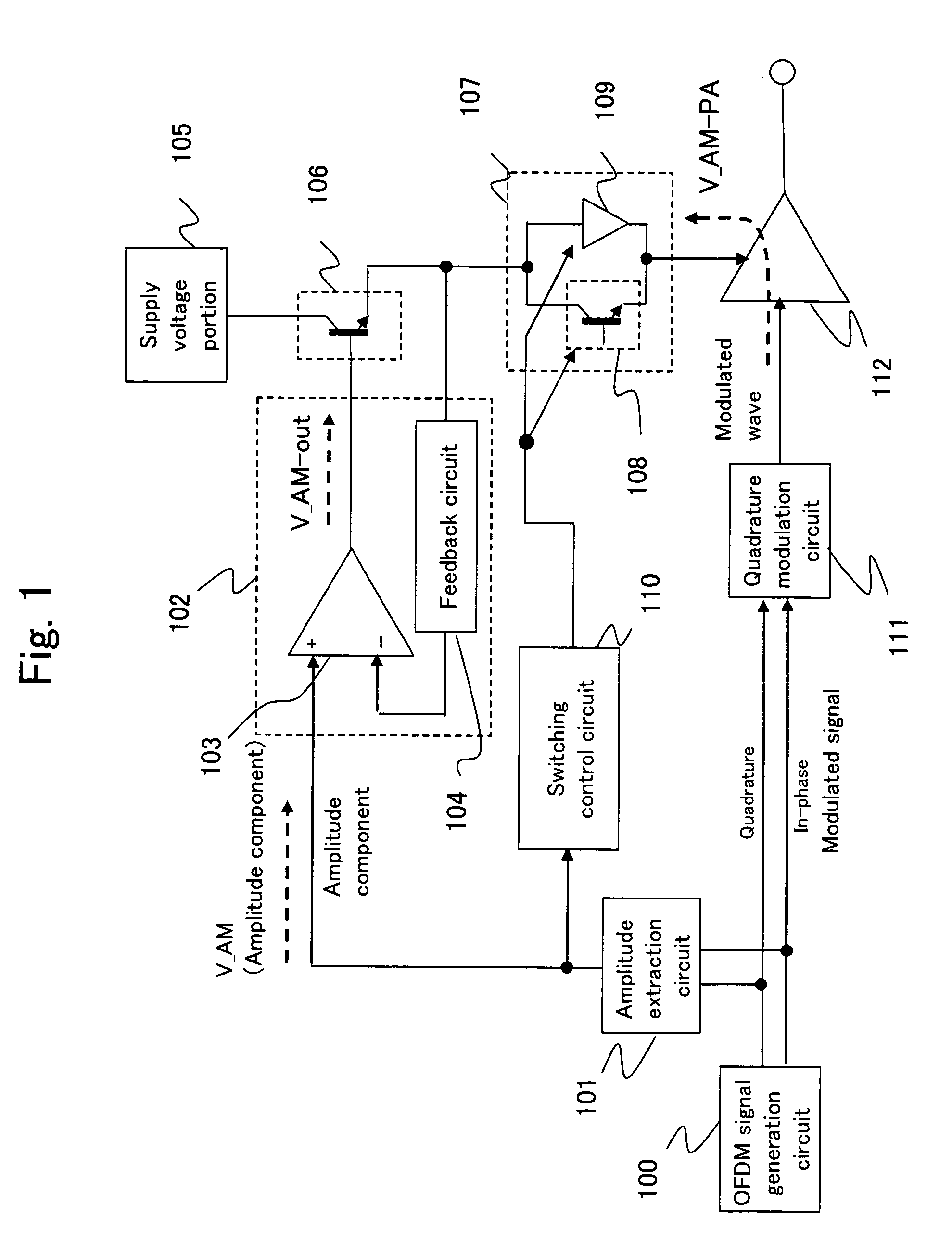

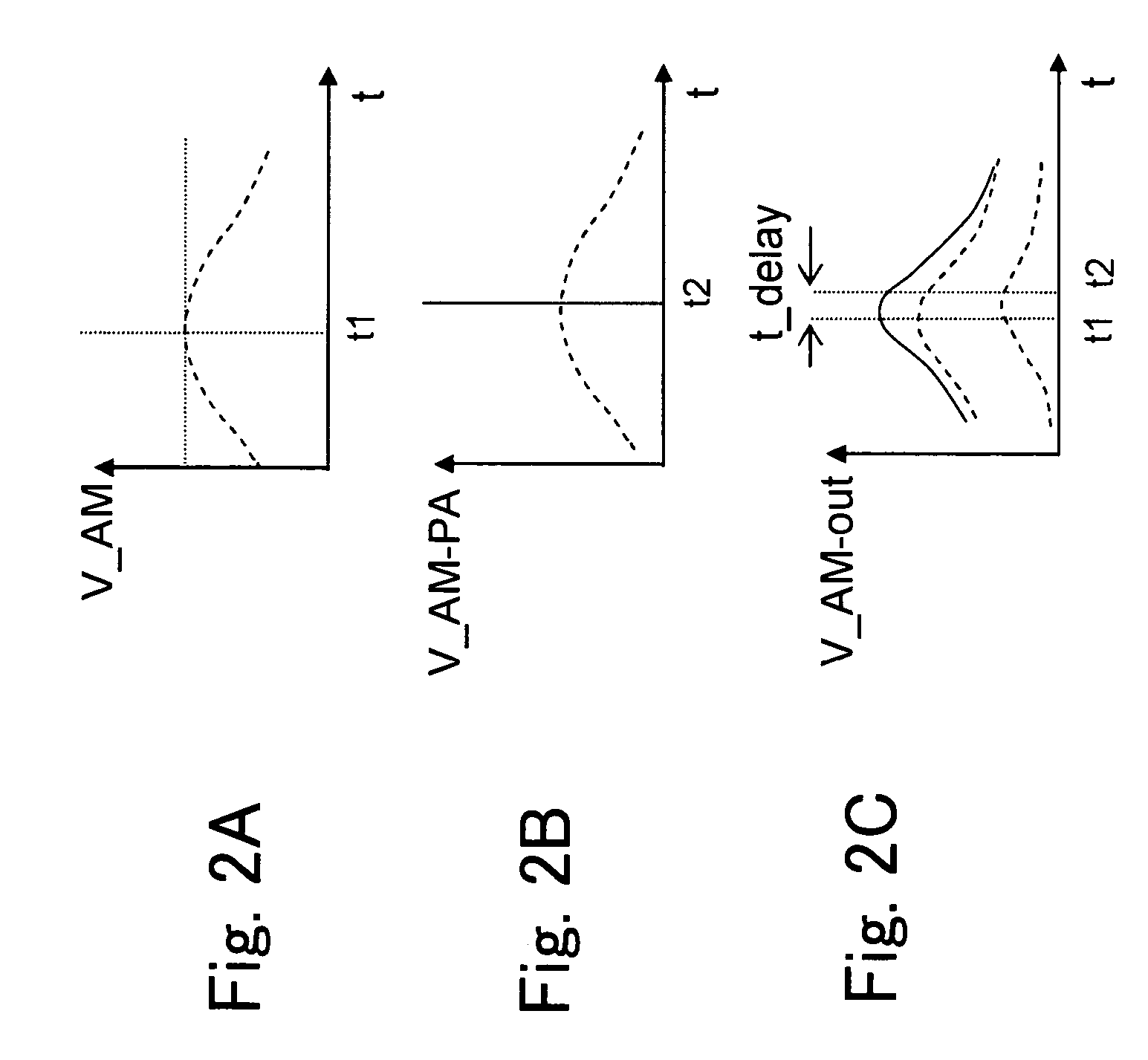

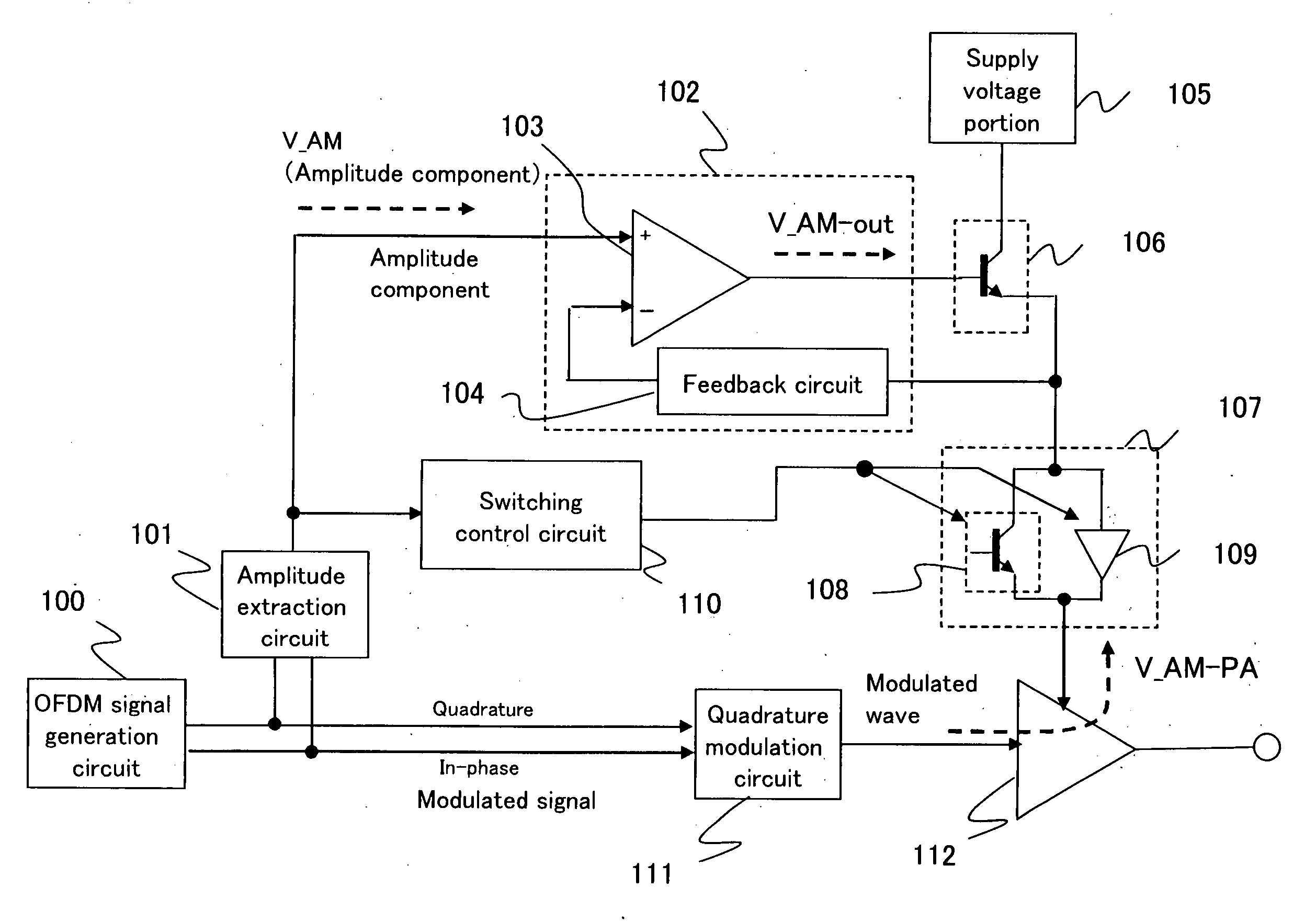

InactiveUS7395039B2Highly efficient EERSimultaneous amplitude and angle modulationResonant long antennasVoltage regulationFeedback circuits

Owner:COLLABO INNOVATIONS INC

Transmitter

InactiveUS20060111057A1Group delay can be reducedHighly efficient EERSimultaneous amplitude and angle modulationResonant long antennasVoltage regulationFeedback circuits

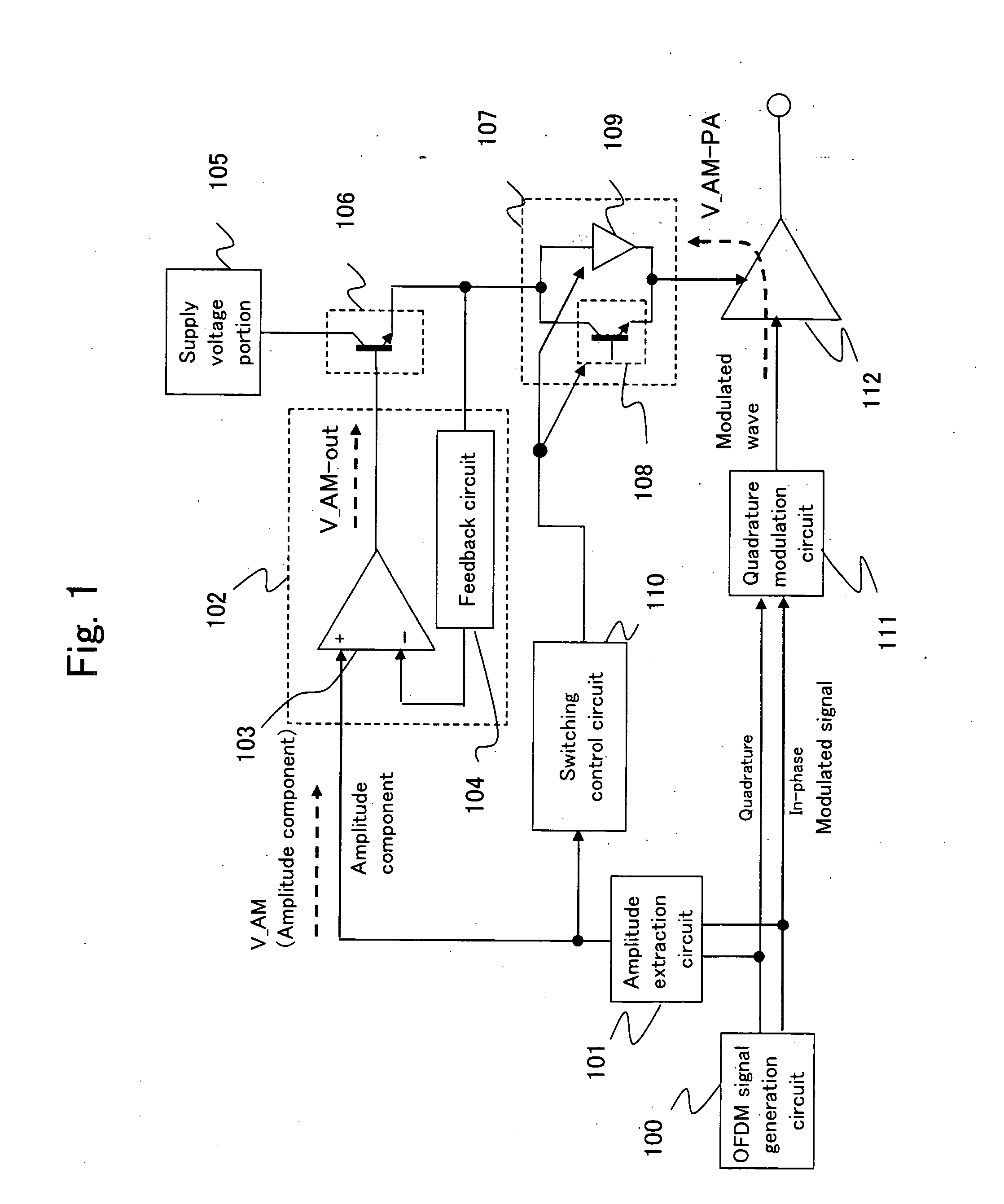

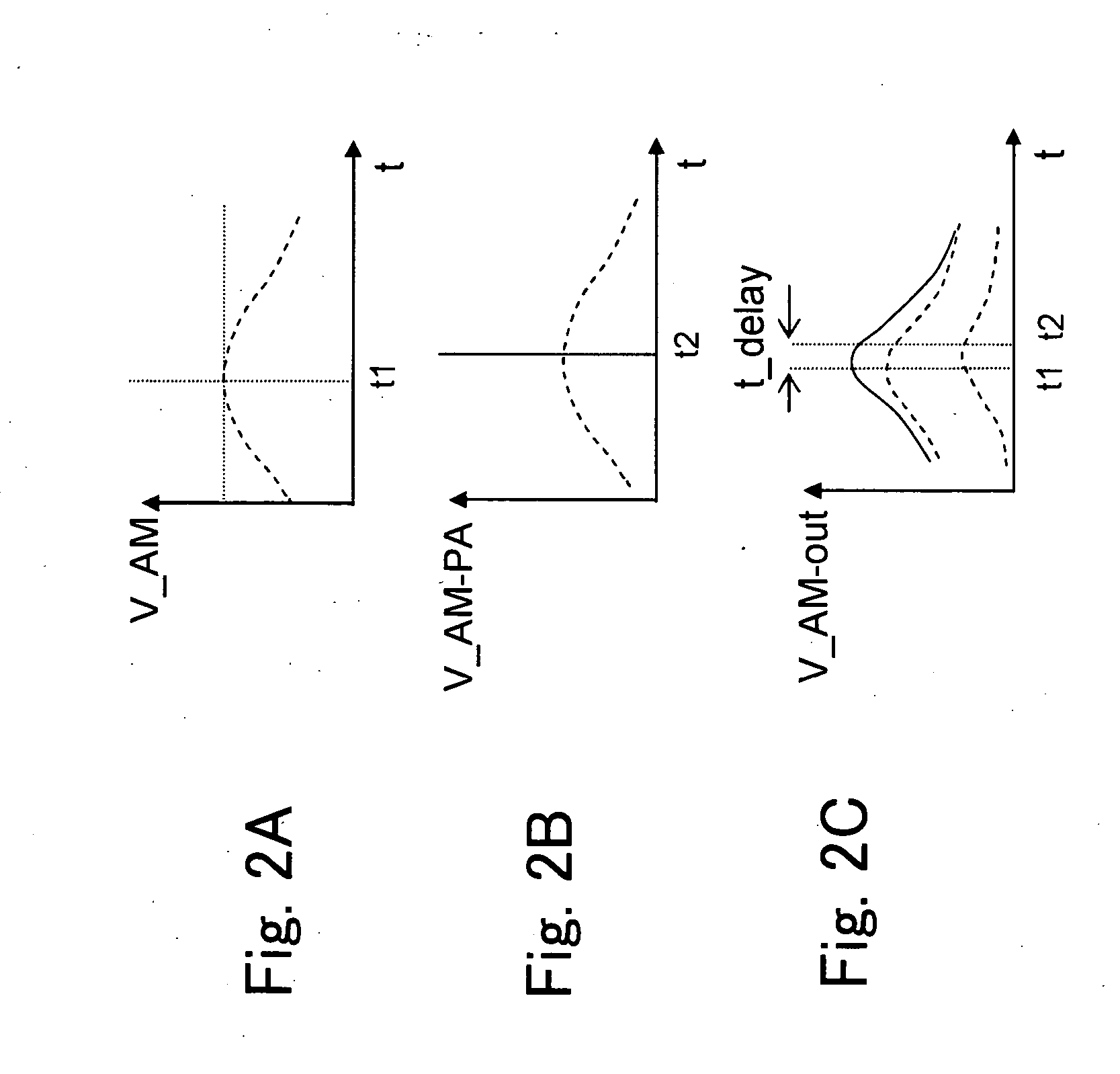

In a transmitter of the present invention, a modulated signal is separated into an amplitude component and a phase component which are inputted to a radio-frequency modulated signal input terminal and a supply voltage terminal of a radio-frequency power amplifier. A voltage adjustment circuit is provided between an output terminal of the radio-frequency power amplifier and an amplitude amplification circuit having a feedback circuit. The voltage adjustment circuit changes the amount of isolation in accordance with the voltage level of the amplitude component. By this, the amplitude component of the radio-frequency modulated wave attenuates the level inputted to the feedback circuit of the amplitude amplification circuit through the supply voltage terminal of the radio-frequency power amplifier.

Owner:COLLABO INNOVATIONS INC

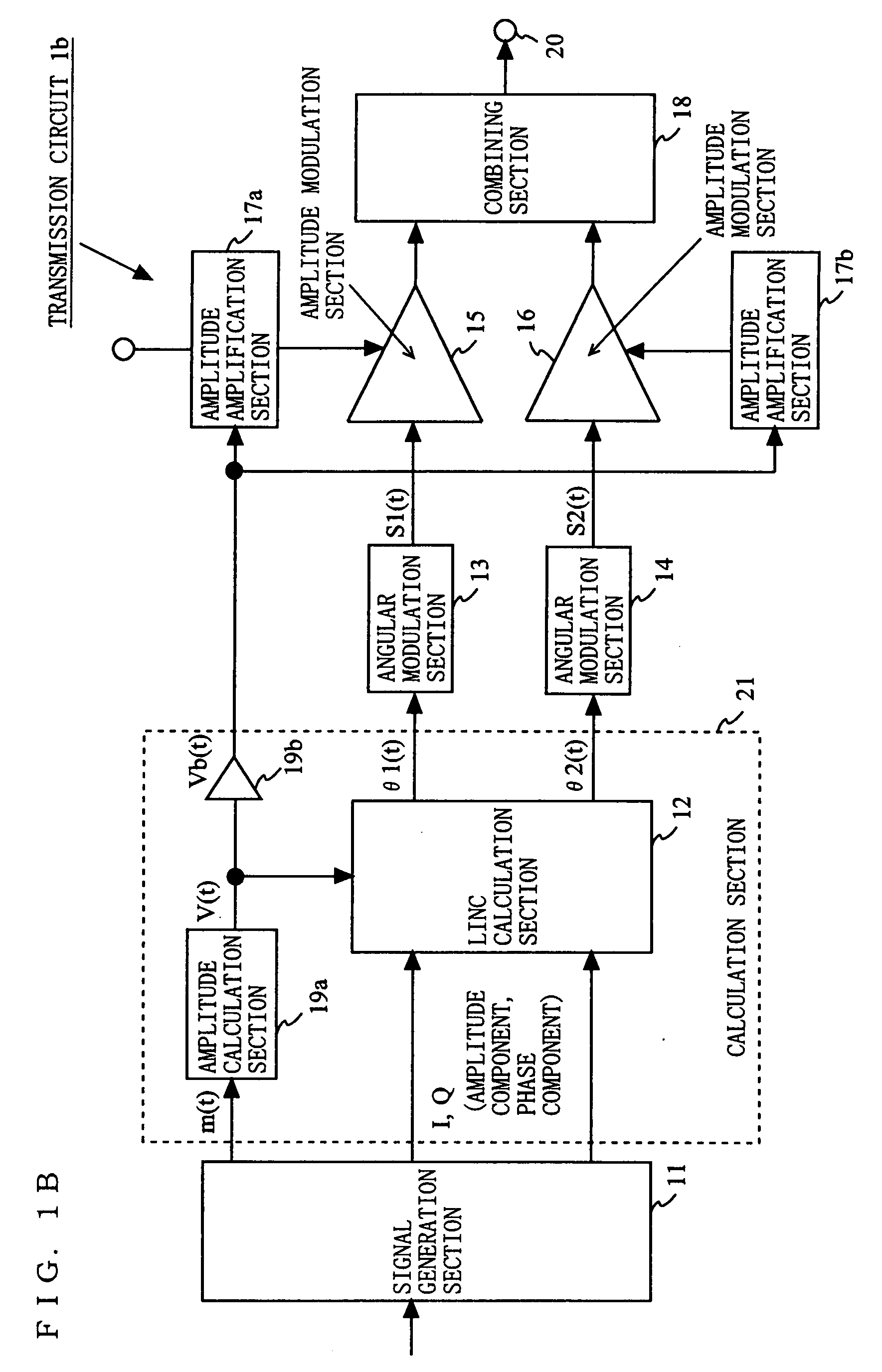

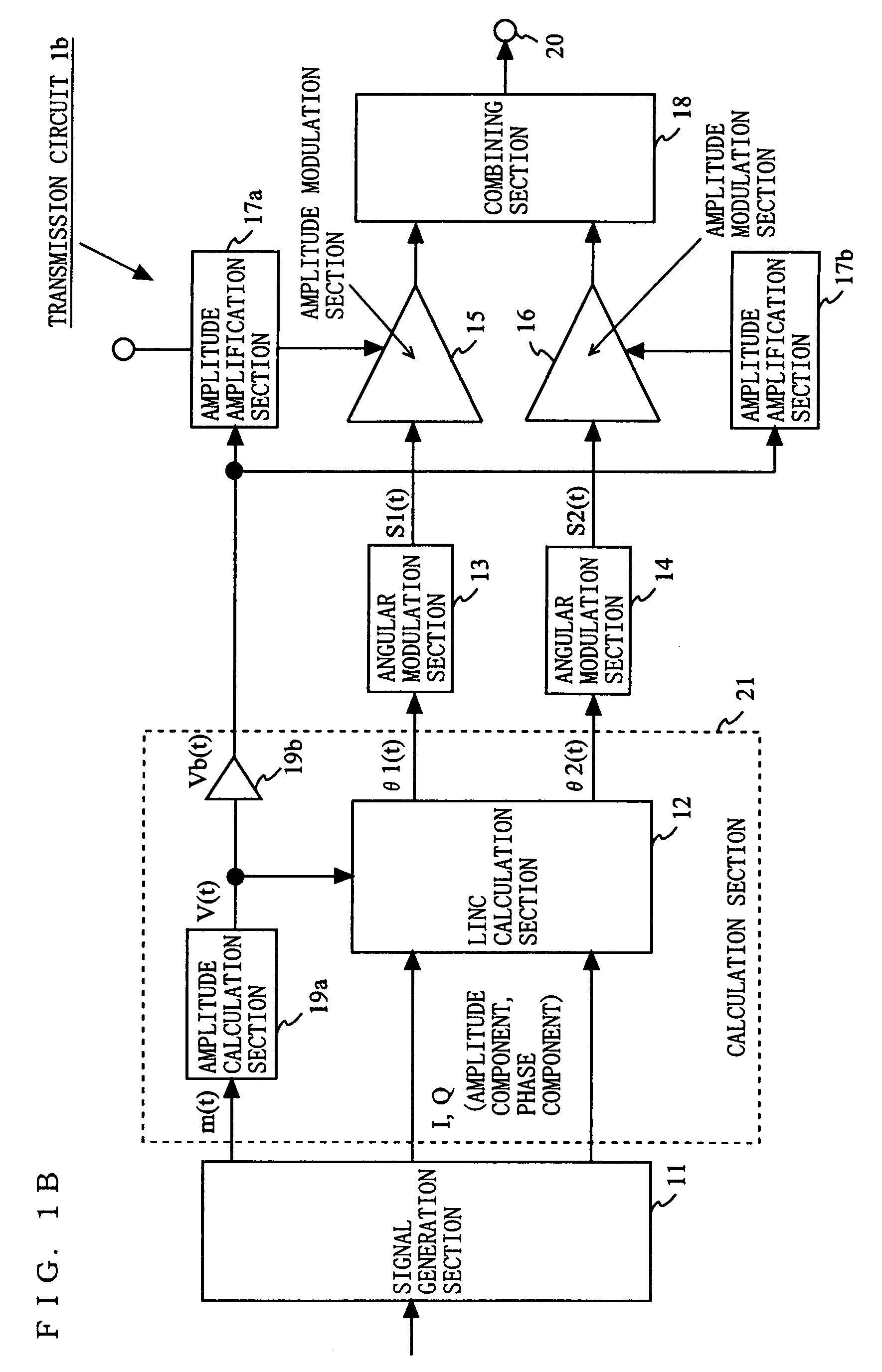

Transmission circuit, and communication apparatus using the same

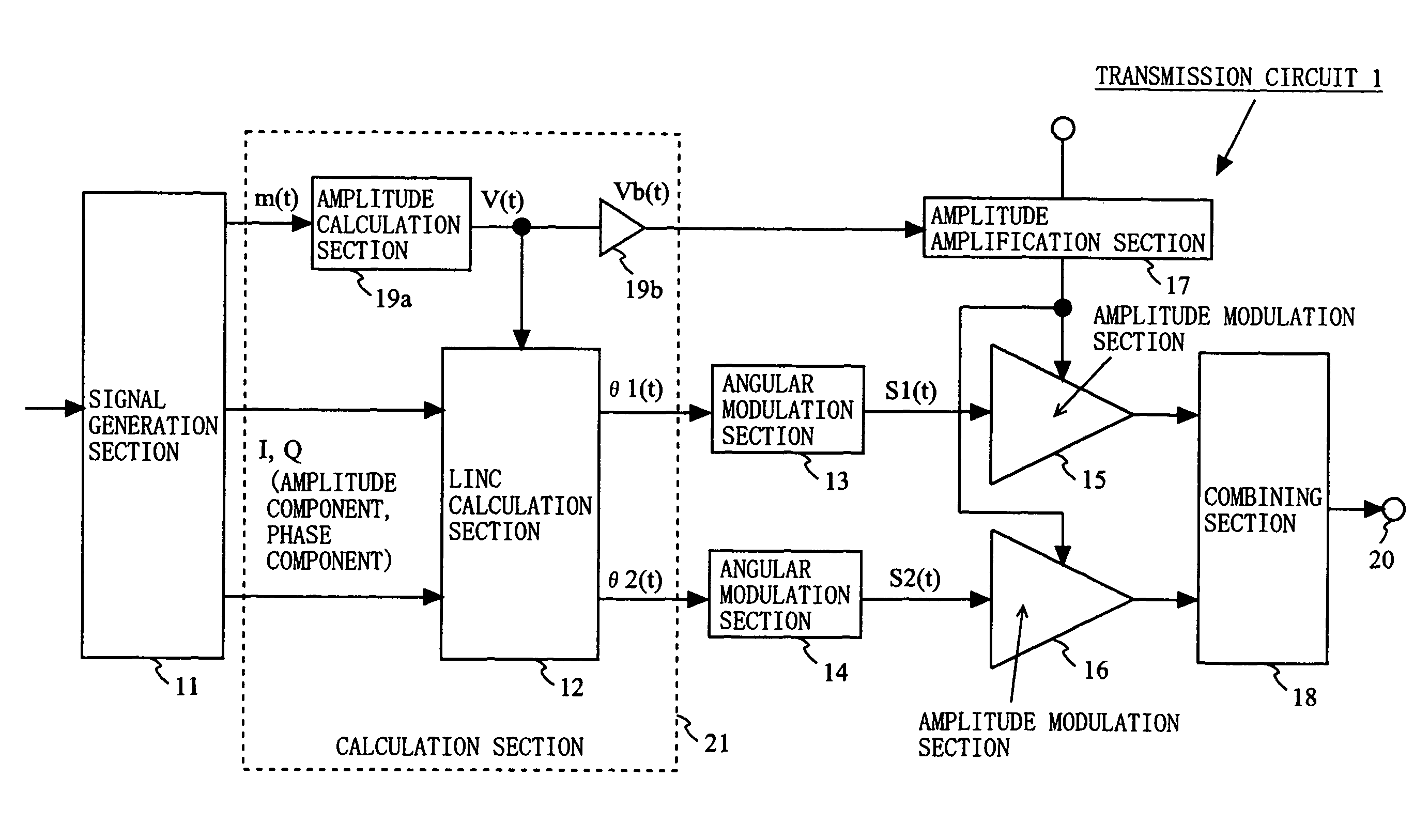

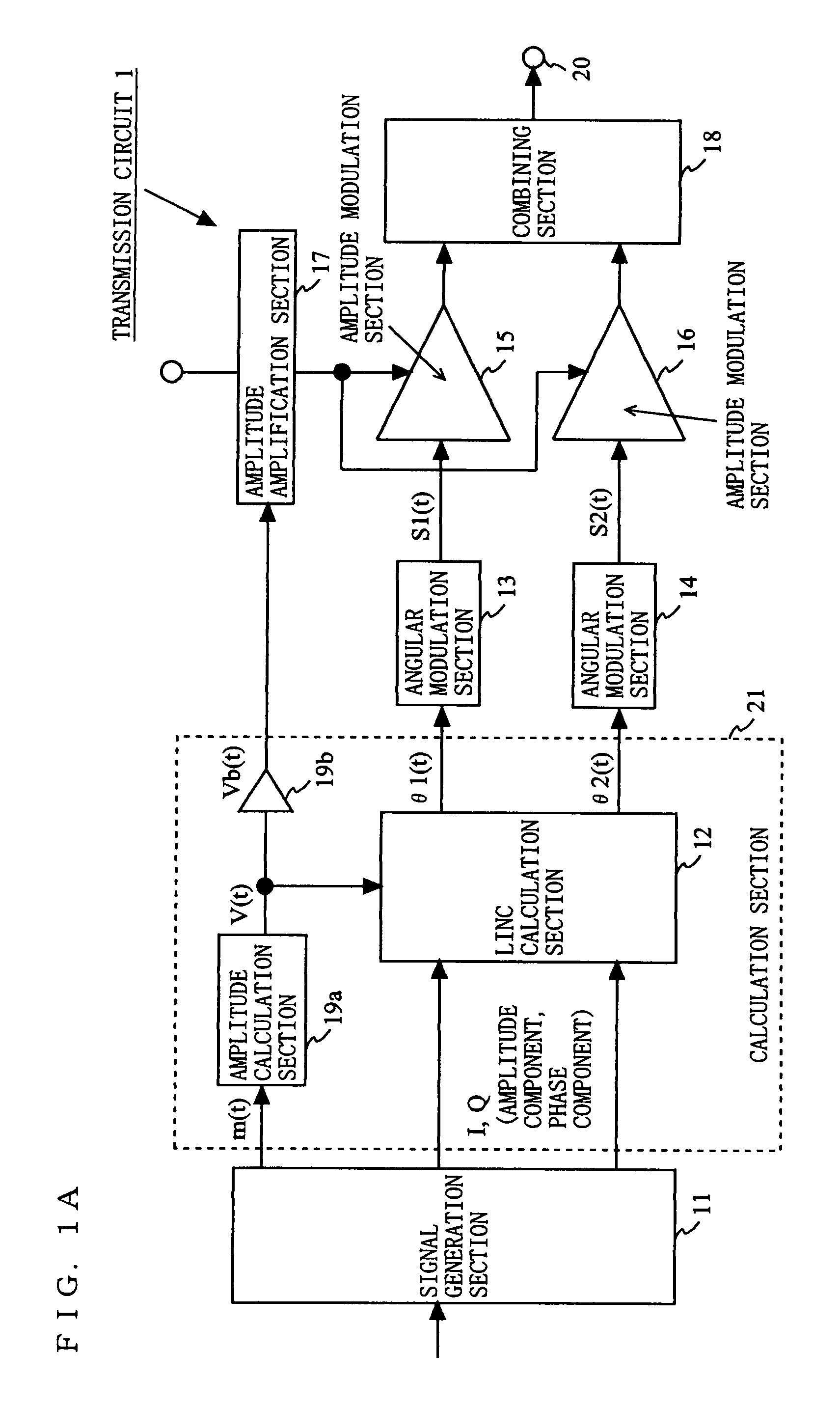

InactiveUS20070254622A1Improve efficiencyEnhanced transmission signalModulation with suppressed carrierTelephonic communicationAngle modulationEngineering

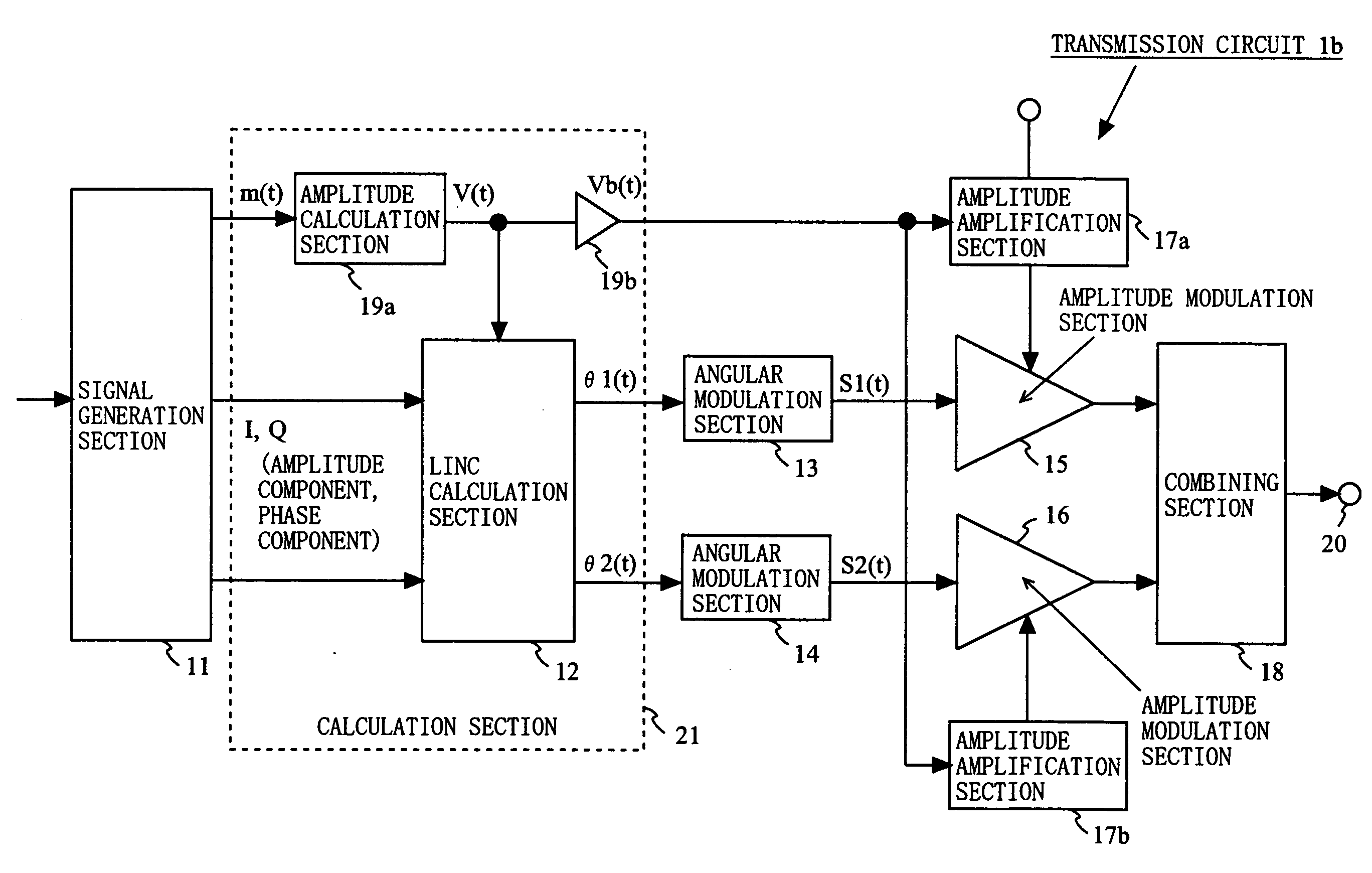

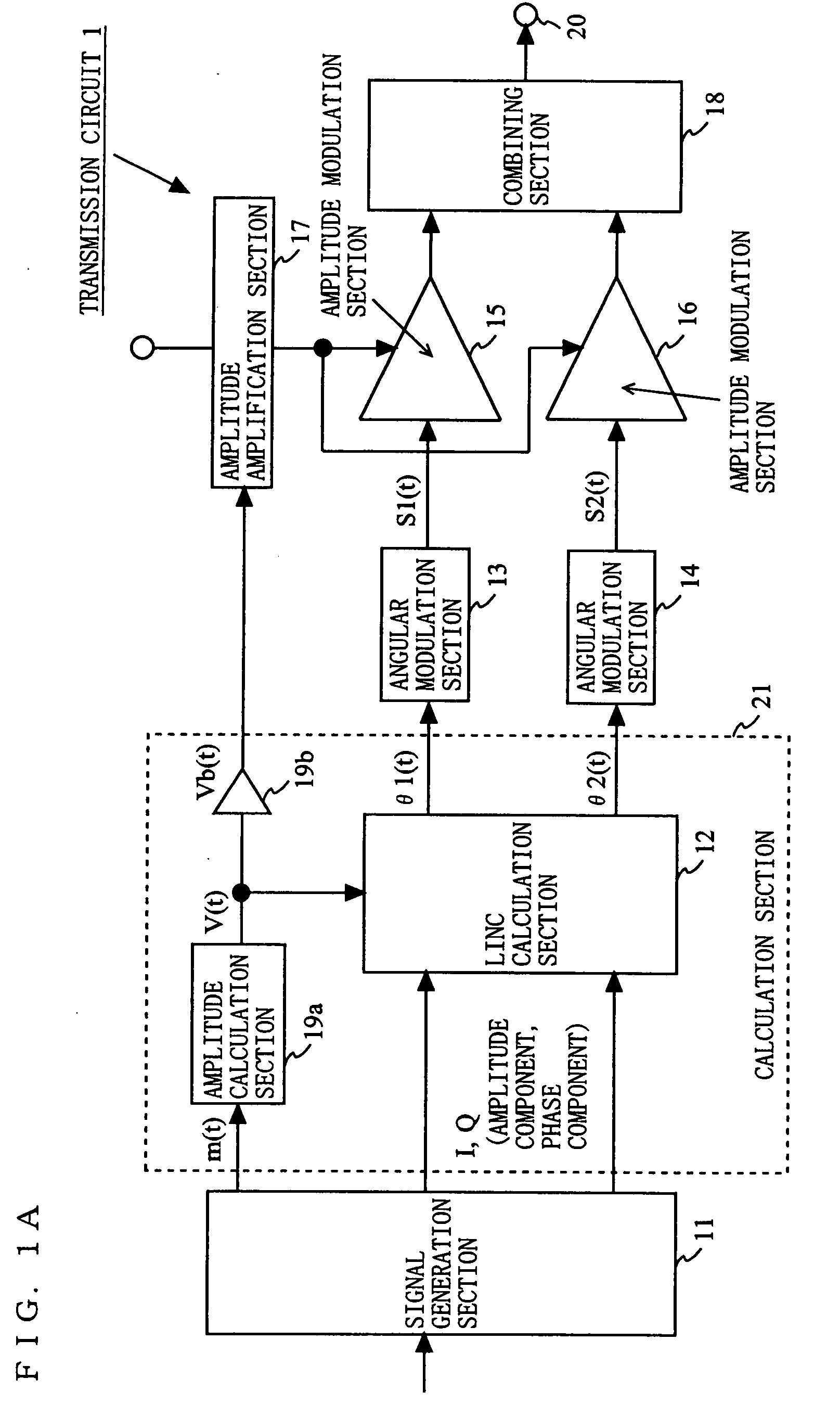

A compact transmission circuit for outputting a highly linear transmission signal regardless of the output power level and operating at a high efficiency is provided. A signal generation section 11 generates an amplitude signal and quadrature data based on input data. A calculation section 21 calculates using the amplitude signal and the quadrature data to output a discrete value having a level discrete at every predetermine time period, and first and second phase signals. An amplitude amplification section 17 outputs a voltage controlled in accordance with the discrete value. Angular modulation sections 13 and 14 angular-modulate the phase signals and output first and second angle-modulated signals. Amplitude modulation sections 15 and 16 amplitude-modulate the angle-modulated signals with the voltage from the amplitude amplification section 17 and output first and second modulated signals. A combining section 18 combines the first and second modulated signals and outputs a transmission signal.

Owner:PANASONIC CORP

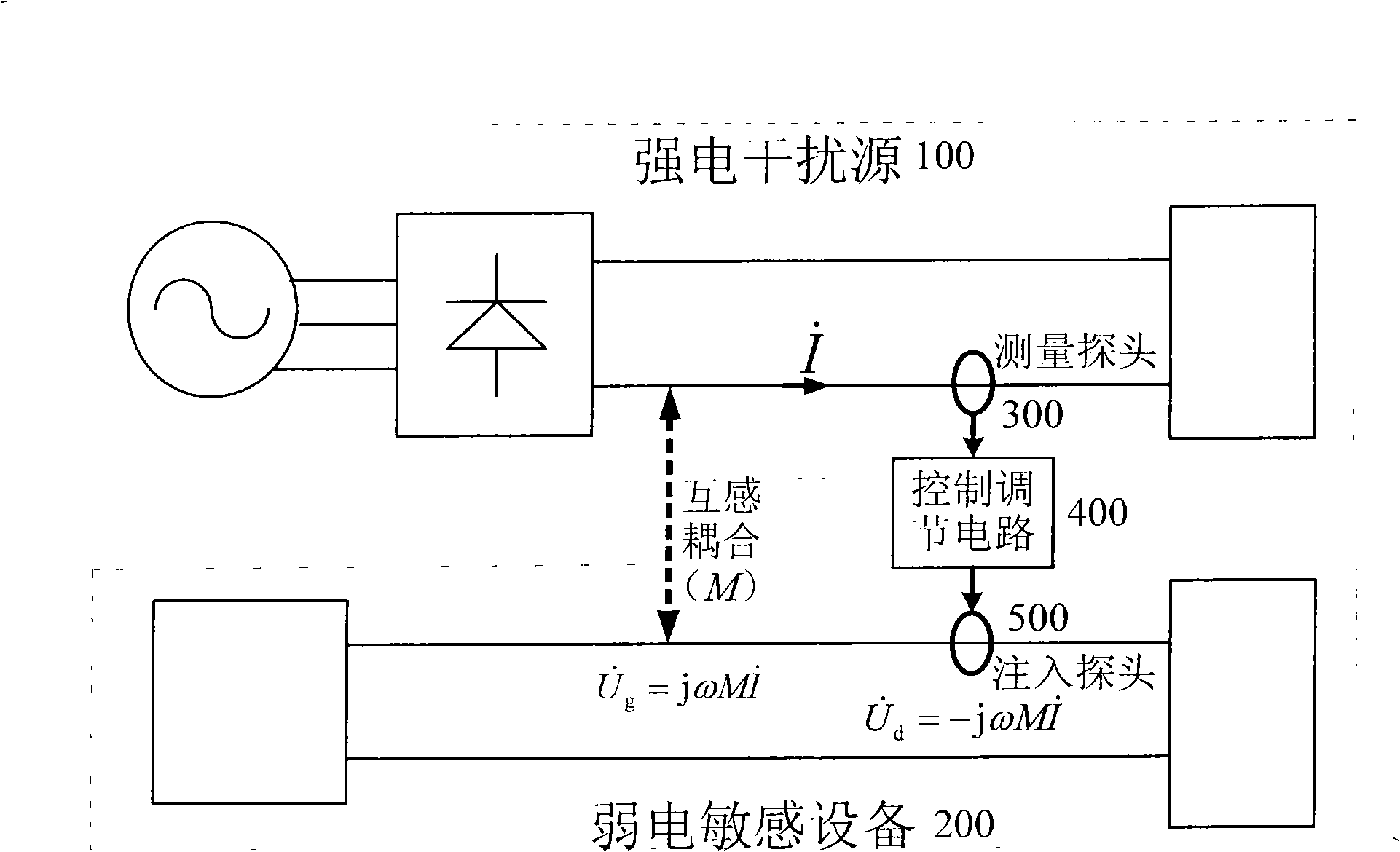

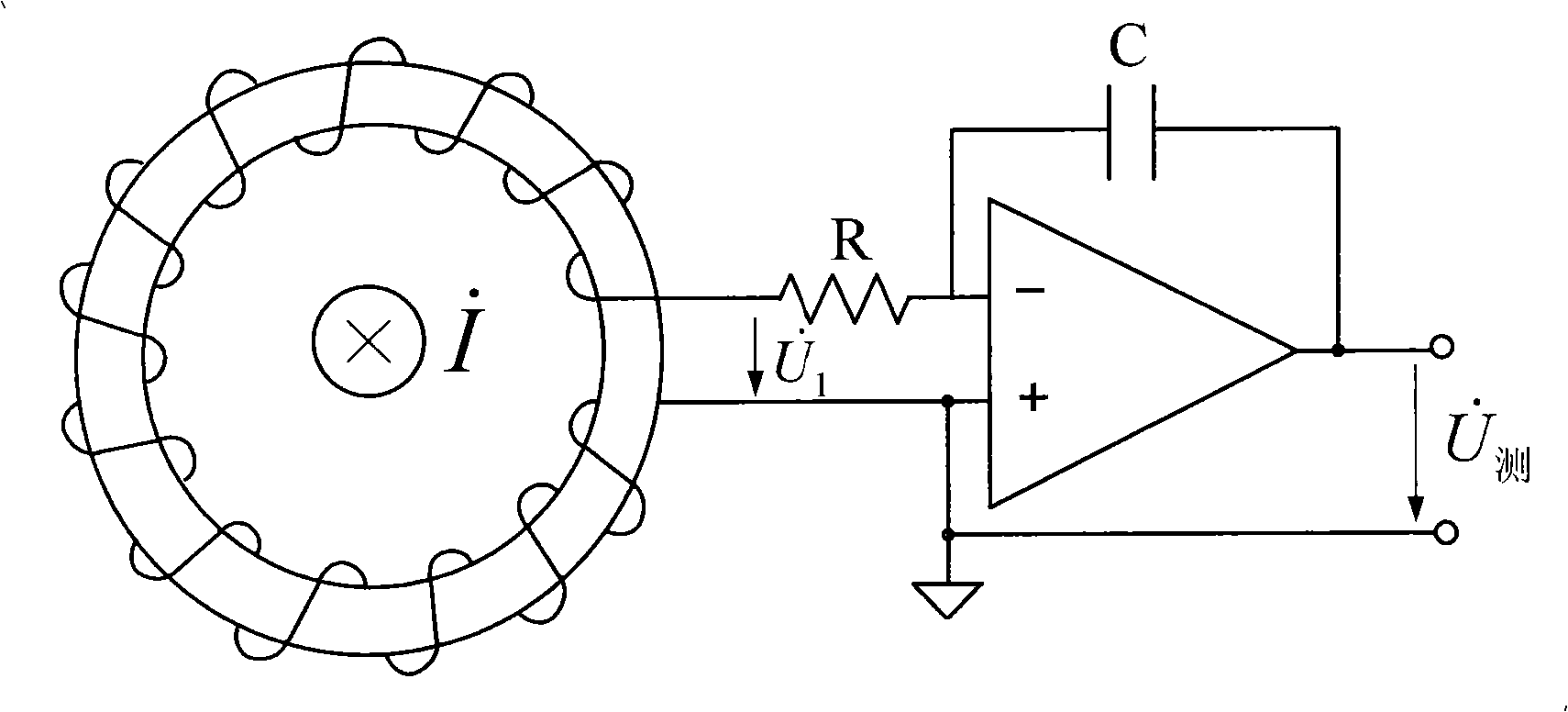

Method and device for eliminating mutual inductance coupling electromagnetic interference

ActiveCN101295924ASolve the shortcomings of not being able to filter out co-channel interference signalsOvercome the disadvantage of not being able to filter out co-channel interference signalsElectric signal transmission systemsCurrent interference reductionDisturbance voltageSignal on

The invention discloses a method and device for eliminating mutual inductance coupling electromagnetic interference; the method of the invention comprises the steps that: after a current signal on the power line of a strong current interference source system is detected and converted into a voltage signal, amplitude amplification is carried out to the normal phase or the reversed phase of the measuring conversion voltage signal and the voltage signal is converted into an output current signal, the value of which is not affected by the load; then the output current signal is converted into an offsetting signal which is equal to an interfering signal in amplitude and contrary to the interfering signal in phase; and the offsetting signal is injected into the loop of a weak current device to offset the interfering voltage inducted by the strong current interference source system to the loop of the weak current device by inductance coupling. The method of the invention dexterously brings in a voltage / current switching circuit, thereby overcoming the influence of the loop impedance of the weak current device on the offsetting effects and enlarging the application scope of the mutual inductance coupling offsetting method. The method and the device of the invention has low power consumption and cost, overcomes the defect that EMI filtering can not remove the interfering signals with the same frequency; compared with a shielding method, hardware devices required by the invention has smaller volume and lighter weight, thus not increasing the difficulty of system layout.

Owner:NAVAL UNIV OF ENG PLA

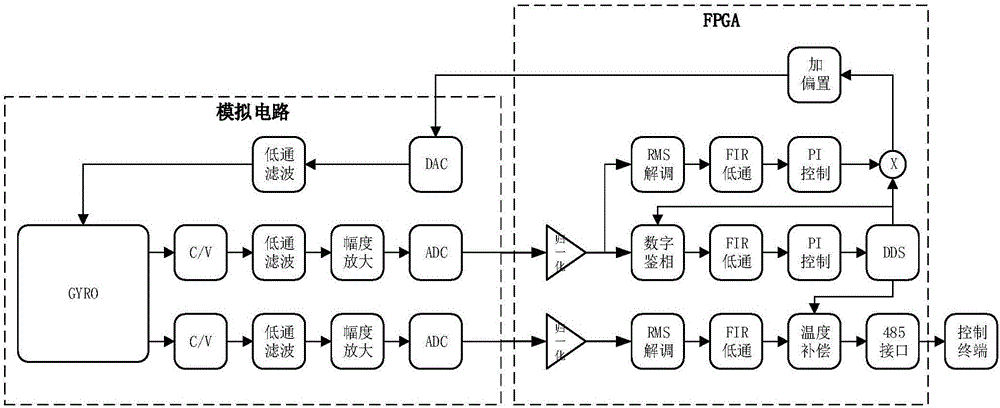

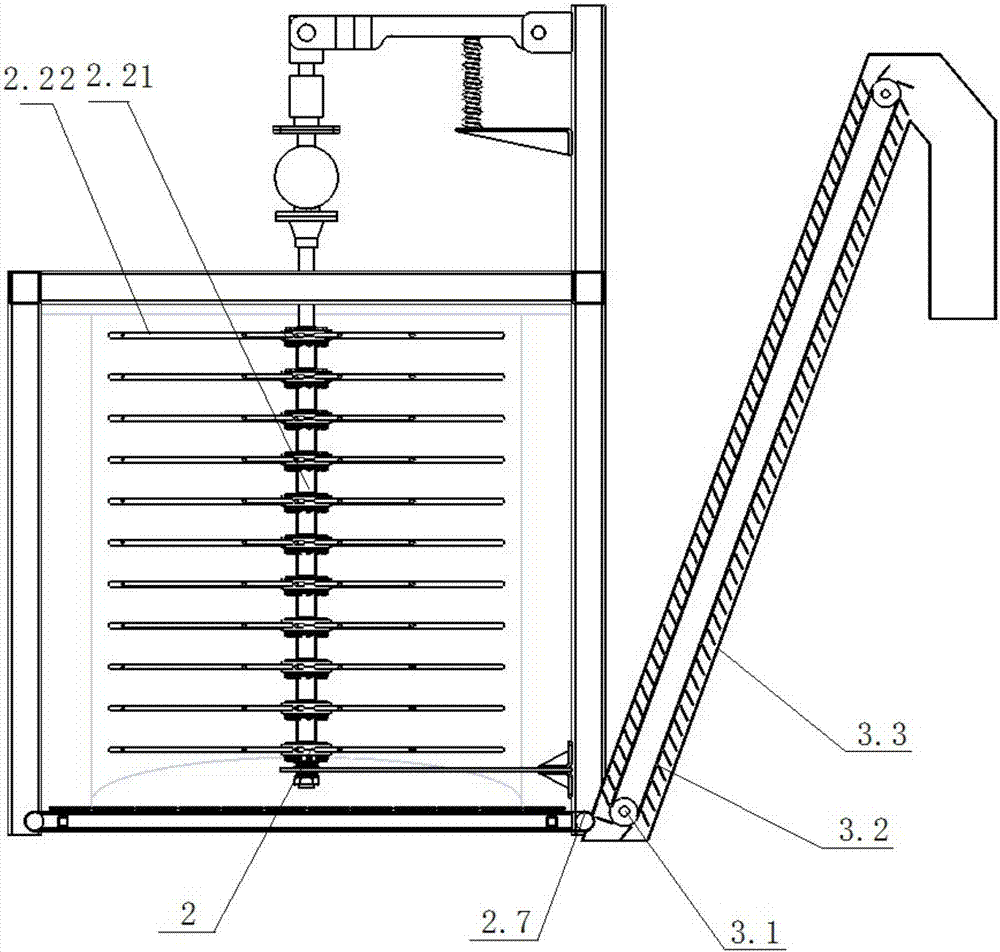

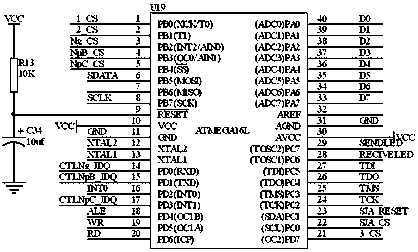

Silicon micro-machined gyroscope digital driving closed loop control system

ActiveCN105892293AEasy to integrateReduce noiseSpeed measurement using gyroscopic effectsAdaptive controlCapacitanceGyroscope

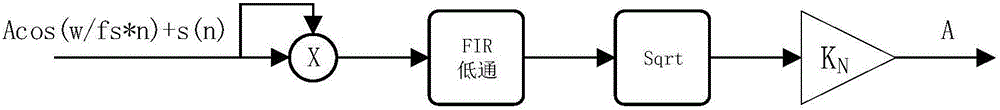

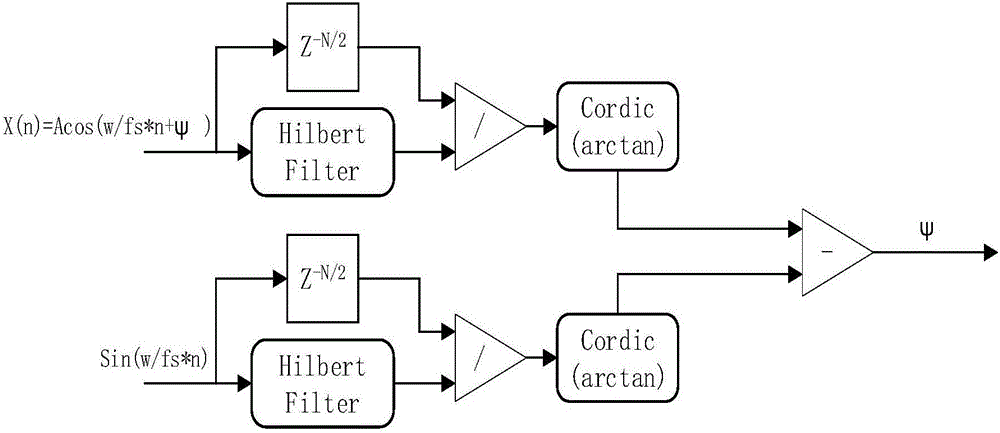

The present invention relates to a silicon micro-machined gyroscope digital driving closed loop control system with temperature compensation based on an FPGA. The silicon micro-machined gyroscope digital driving closed loop control system is characterized in that after the charge amplification, low-pass filtering, amplitude amplification and quantification operations are carried out on a silicon micro-machined gyroscope sensitive detection capacitance signal, the driving closed loop control and the temperature compensation functions are realized by the FPGA; a driving closed loop realizes an amplitude stabilization function by the root-mean-square (RMS) demodulation, the low-pass filtering and the PI control; a phase tracking function is realized by the Hilbert discrimination, the low-pass filtering, the PI control and a Cordic algorithm; a temperature compensation function of the angular velocity signal output is realized by a linear relationship of a resonant frequency and a temperature signal. The silicon micro-machined gyroscope digital driving closed loop control system of the present invention overcomes the problems, such as complicated analog circuit structure, large noise, temperature drift, etc., and has the advantages of being flexible, convenient and transplantable, being low in noise, being able to realize the temperature compensation, and being easy to realize a monolithic application specific integrated circuit (ASIC).

Owner:SUZHOU UNIV

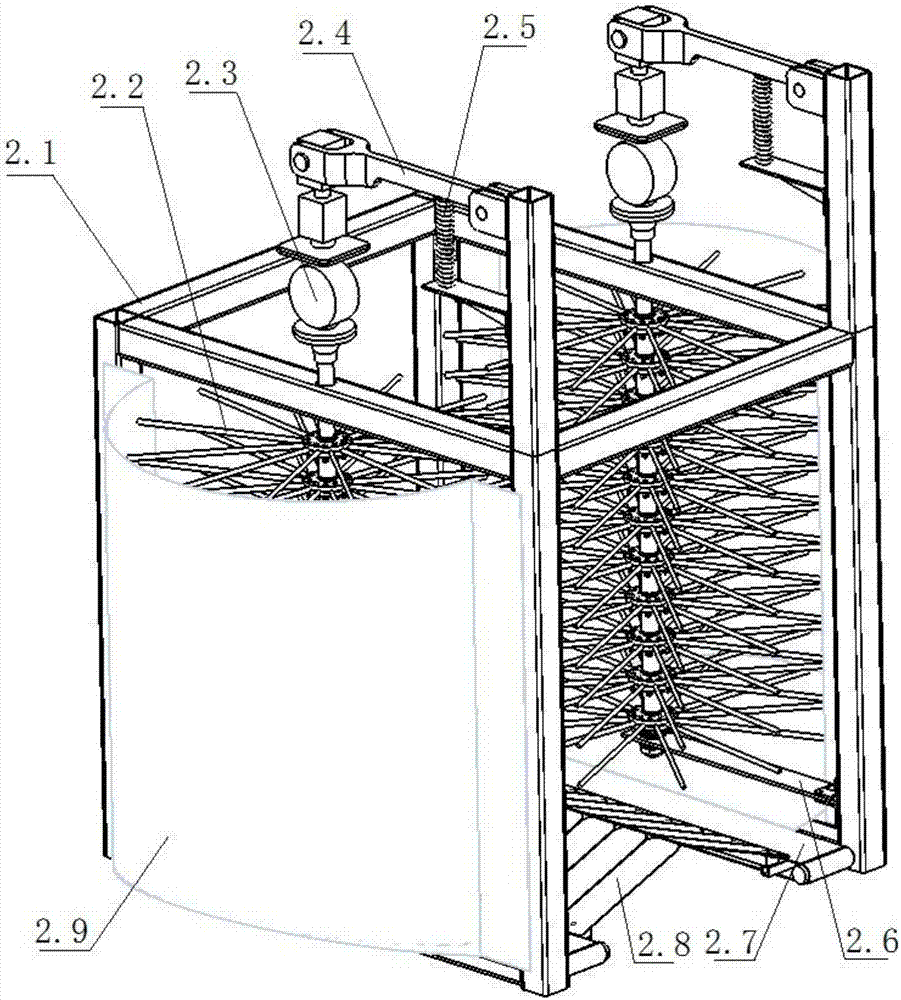

Vertical double-cylinder harvesting machinery capable of performing continuous harvesting work

InactiveCN106856841ALarge amplitudeGuaranteed continuous outputPicking devicesElectric machineryEngineering

The invention relates to the technical field of fruit picking and in particular to picking of forest fruits and berries. According to the technical scheme, vertical double-cylinder harvesting machinery capable of performing continuous harvesting work comprises a mounting frame, a shaking picking roller, a vibrating motor, a fixed arm, a steel plate spring, a collecting plate and a collecting belt; the vibrating motor serves as a vibrating source to provide an exciting force so as to generate up-and-down high frequency vibration; the fixed arm, the spring and the steel plate spring jointly form an integrated system integrating fixing, restoring and amplitude amplification, so that the vibrating amplitude generated by the vibrating motor can be amplified as required, and the vibrating force can be continuously output; and the vibrating picking roller colliding with branches can rotate automatically so as to defuse the resistance generated by the branches, thus realizing continuous harvesting.

Owner:CSIC ZHONGNAN EQUIP

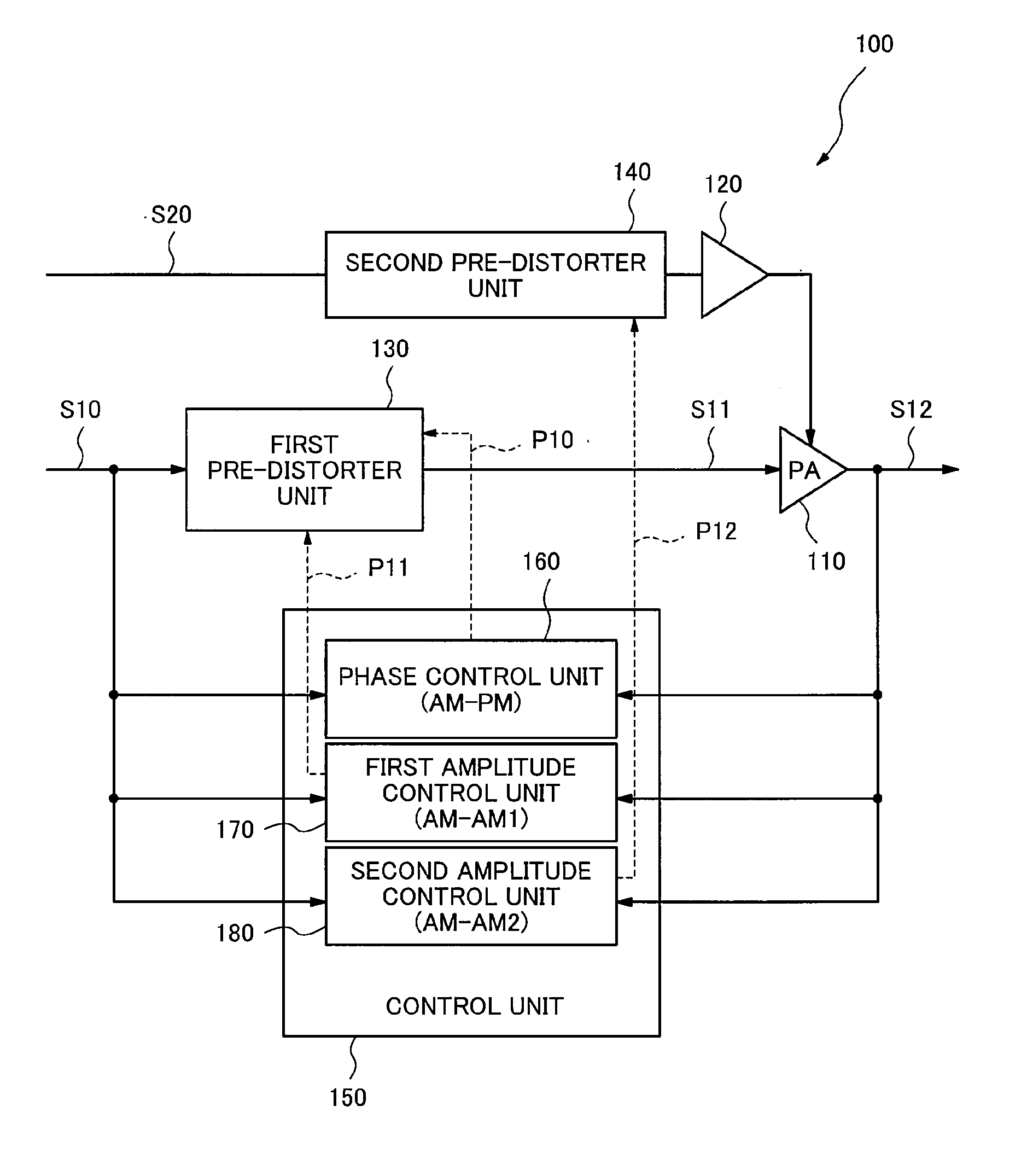

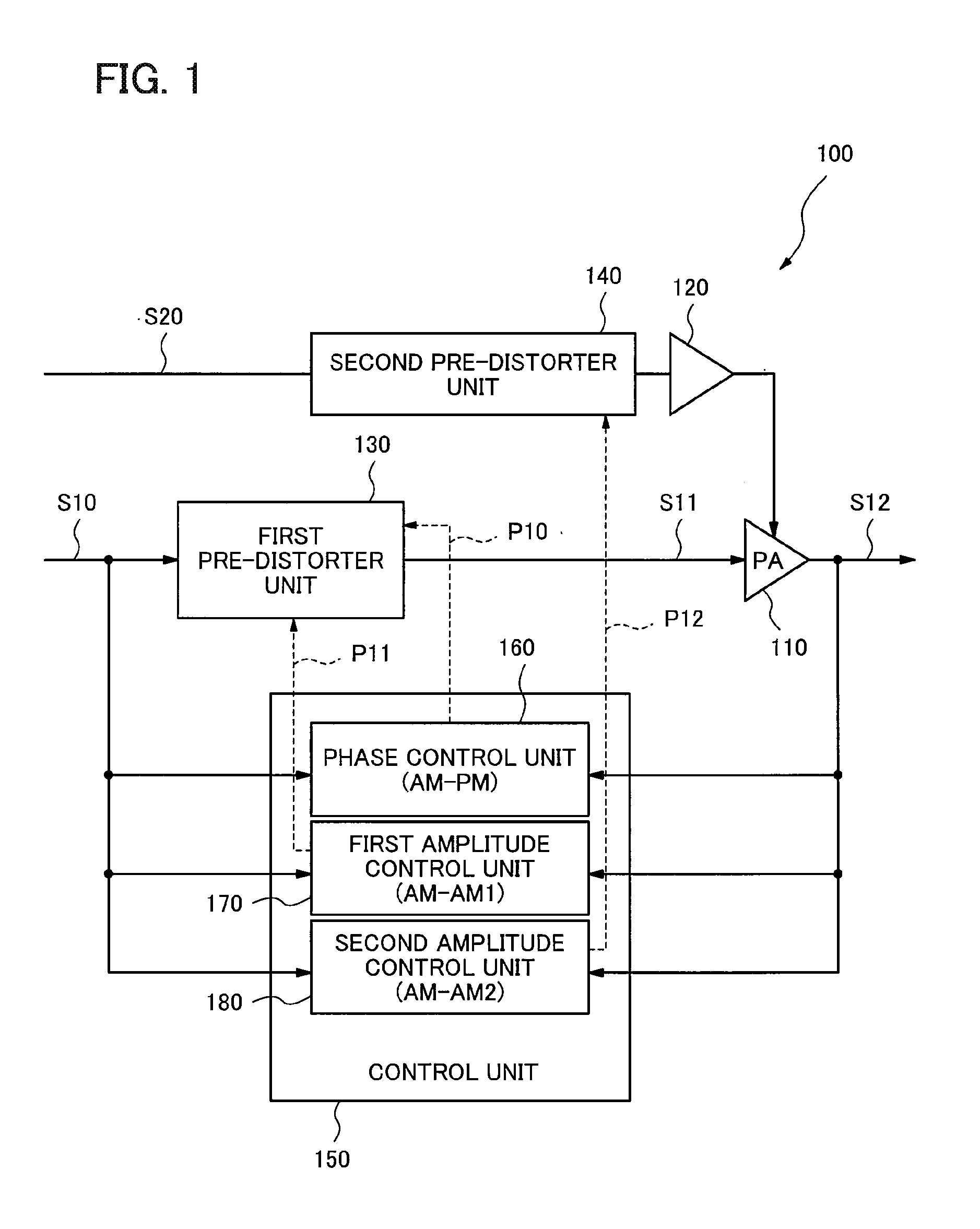

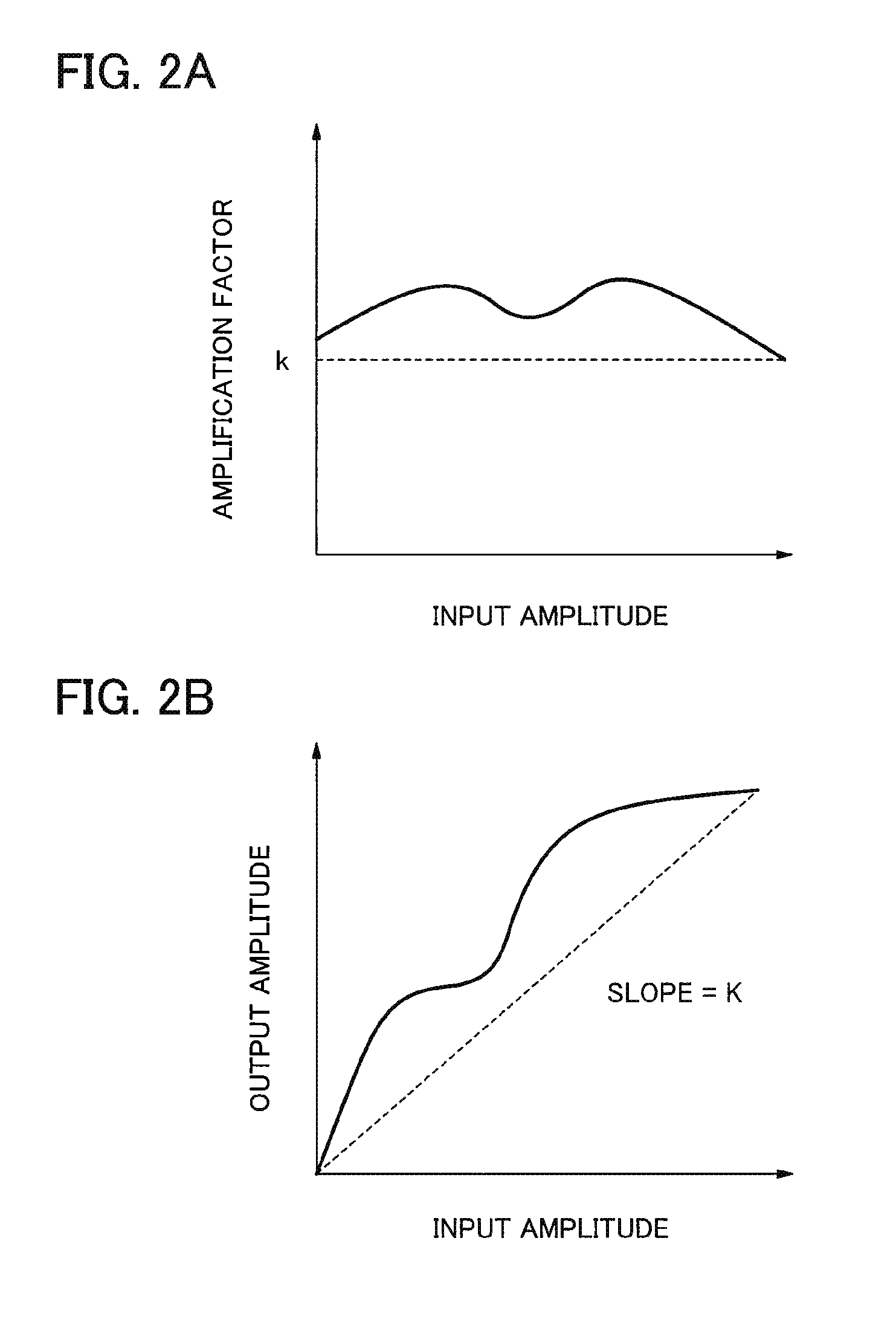

Amplifying device and method for controlling the same

ActiveUS20130257531A1Low distortion characteristicGuaranteed uptimeAmplifier modifications to reduce non-linear distortionAmplifier modifications to reduce noise influenceInformation controlLow distortion

It is difficult to realize the low distortion characteristics and the highly-efficient operation of the amplifying device simultaneously, therefore, an amplifying device according to an exemplary aspect of the invention includes a first pre-distorter unit outputting a modulated signal obtained by adding a phase compensation amount and an amplitude adjustment amount to an input signal; a power amplifier inputting the modulated signal and outputting an output signal obtained by amplifying the modulated signal; a power supply voltage modulation unit modulating a power supply voltage of the power amplifier; a second pre-distorter unit controlling the power supply voltage modulation unit on the basis of amplitude information on the input signal; and a control unit controlling an operation of the first pre-distorter unit and the second pre-distorter unit; wherein the control unit includes a phase control unit controlling the phase compensation amount by using a phase coefficient, a first amplitude control unit controlling the amplitude adjustment amount by using a first amplitude coefficient, and a second amplitude control unit controlling the operation of the second pre-distorter unit by using a second amplitude coefficient; and wherein the first amplitude control unit cooperates with the second amplitude control unit so that an amplitude amplification factor may become constant which is a ratio of an amplitude of the output signal to an amplitude of the input signal.

Owner:NEC CORP

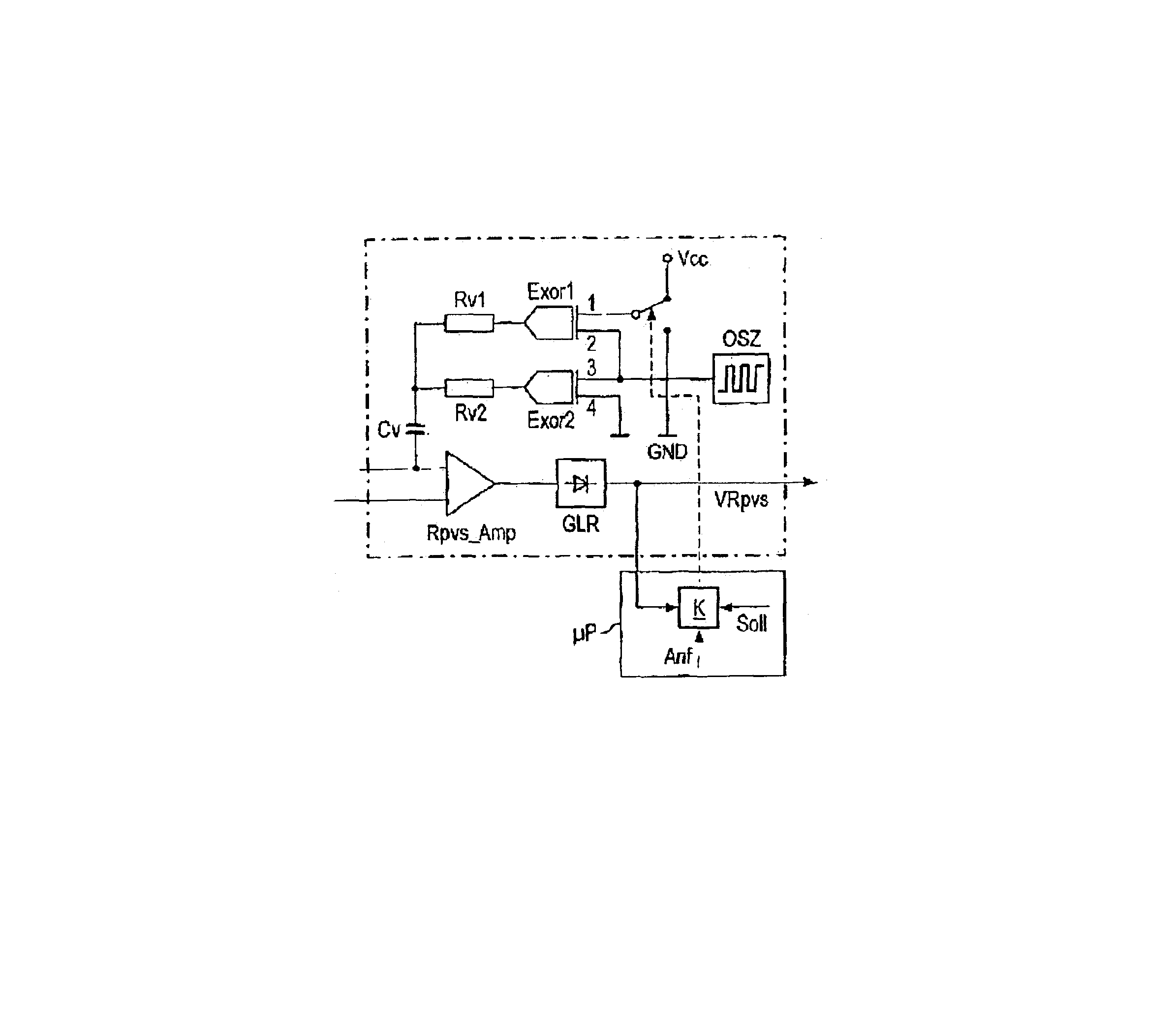

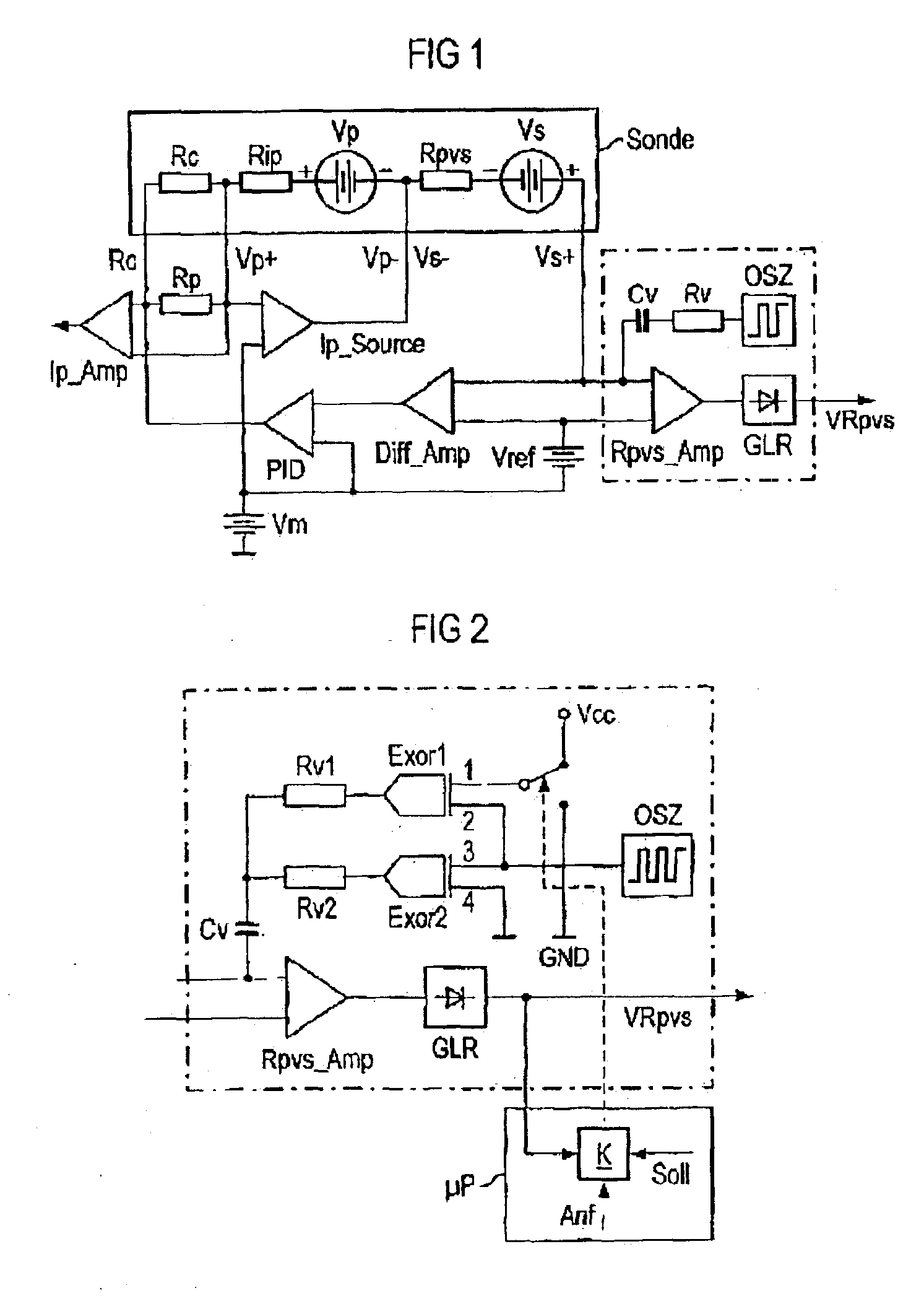

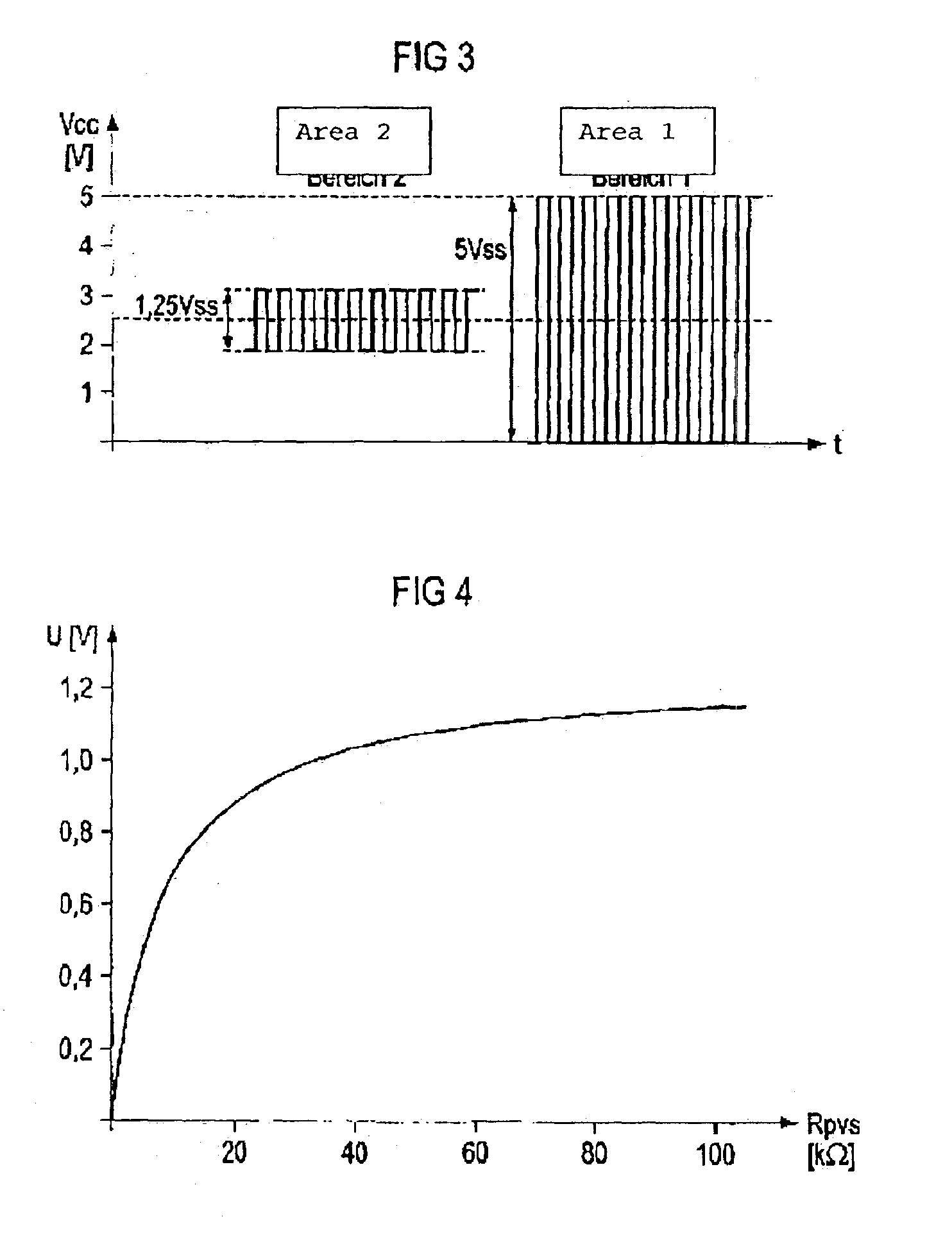

Device for determining the internal resistance of a linear oxygen probe

InactiveUS6868713B2Resistance/reactance/impedenceEngine testingElectrical resistance and conductanceInternal resistance

The device comprises a voltage divider (Rv1, Rv2) to whose two terminals the oscillator signal with a phase position that is mutually opposed is supplied until, in the instance of a switched-on probe heating, the voltage (VRpvs) that is proportional to the probe internal resistance (Rpvs) falls below a predetermined set value (set), whereby, at this point in time, the output signal of the oscillator (SZ) is supplied to both terminals of the voltage divider (Rv1, Rv2) with the same phase position (area 1) thus effecting an amplitude change-over (amplitude amplification).

Owner:CONTINENTAL AUTOMOTIVE GMBH

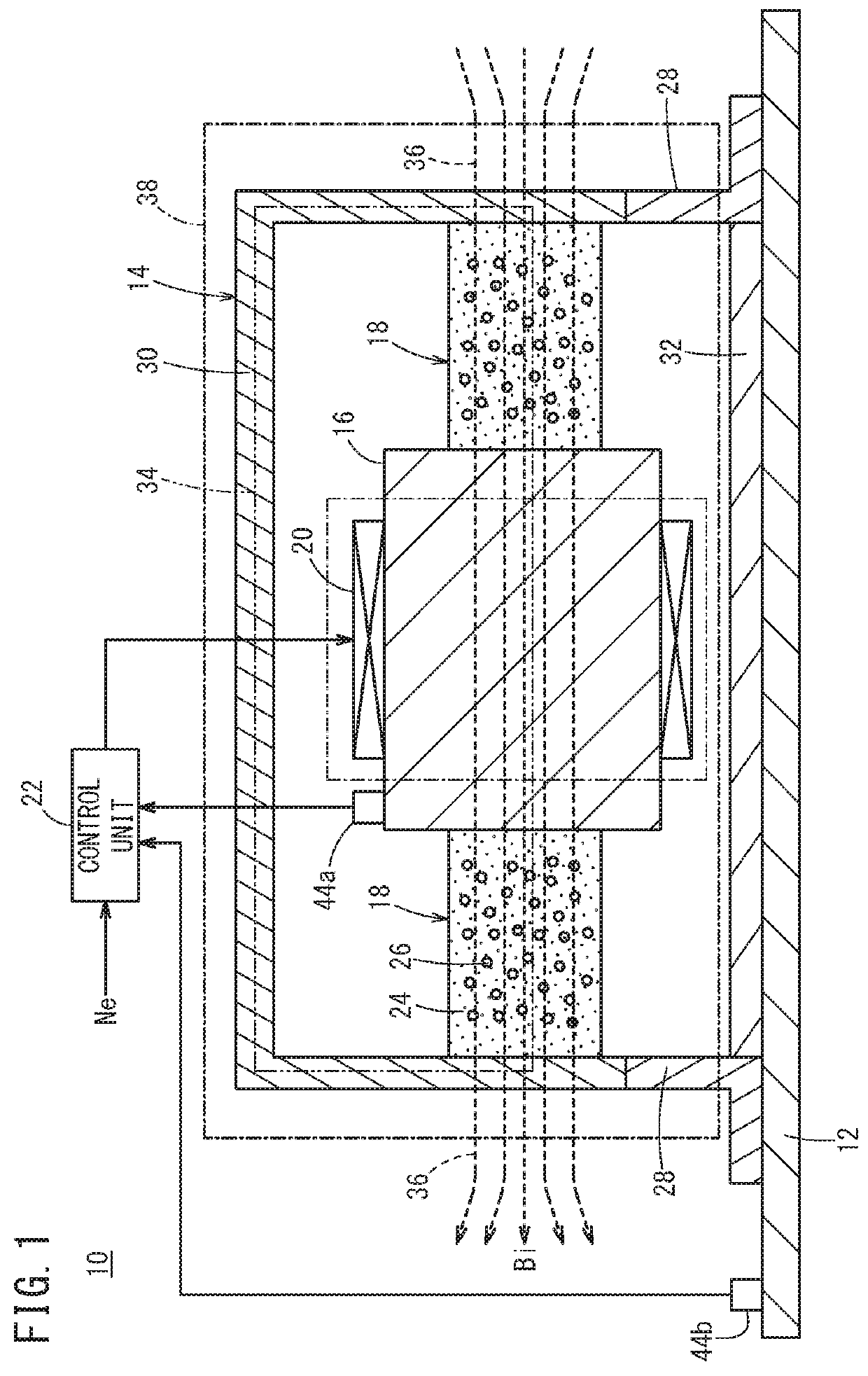

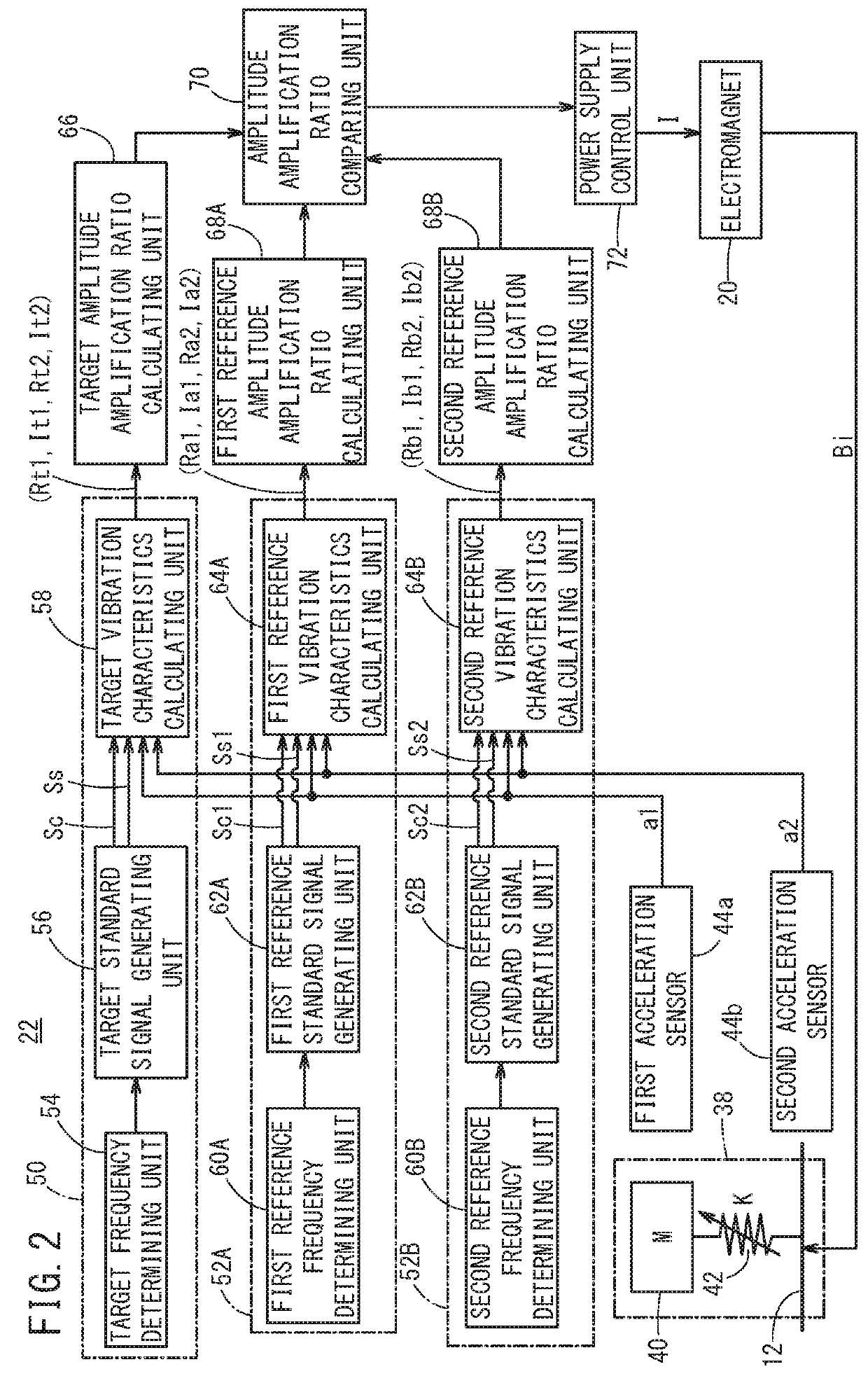

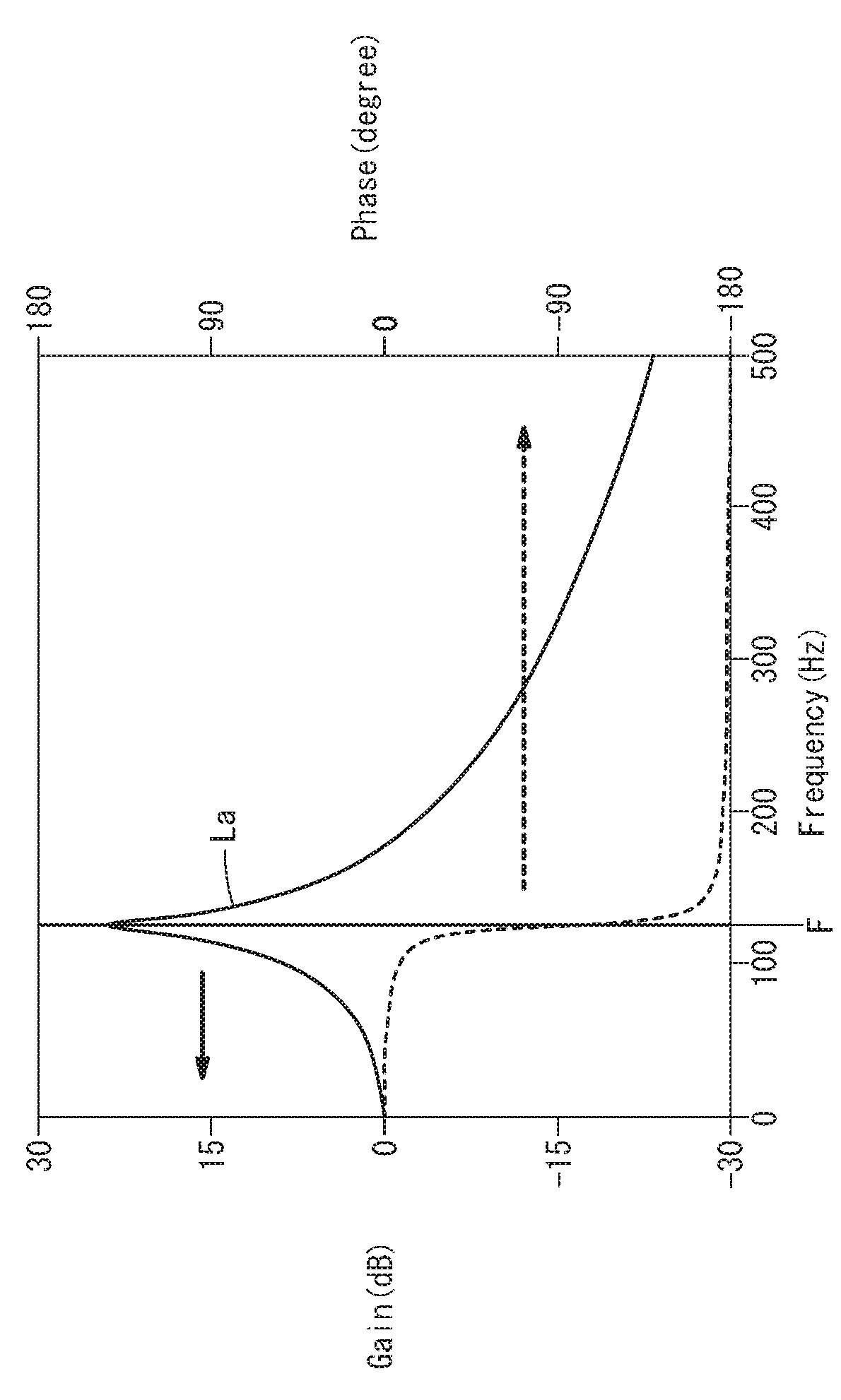

Dynamic damper control device

ActiveUS20180180131A1Low costNon-rotating vibration suppressionSprings/dampers functional characteristicsVibration controlEngineering

The present invention relates to a dynamic damper control device. A control unit includes a first acceleration sensor configured to obtain a first acceleration of a mass member, a second acceleration sensor configured to obtain a second acceleration of a vibration control target member, and a target amplitude amplification ratio calculating unit configured to calculate a target amplitude amplification ratio of the mass member and the vibration control target member based on the first acceleration and the second acceleration, and is configured to change a magnetic force produced from an electromagnet based on the target amplitude amplification ratio.

Owner:HONDA MOTOR CO LTD

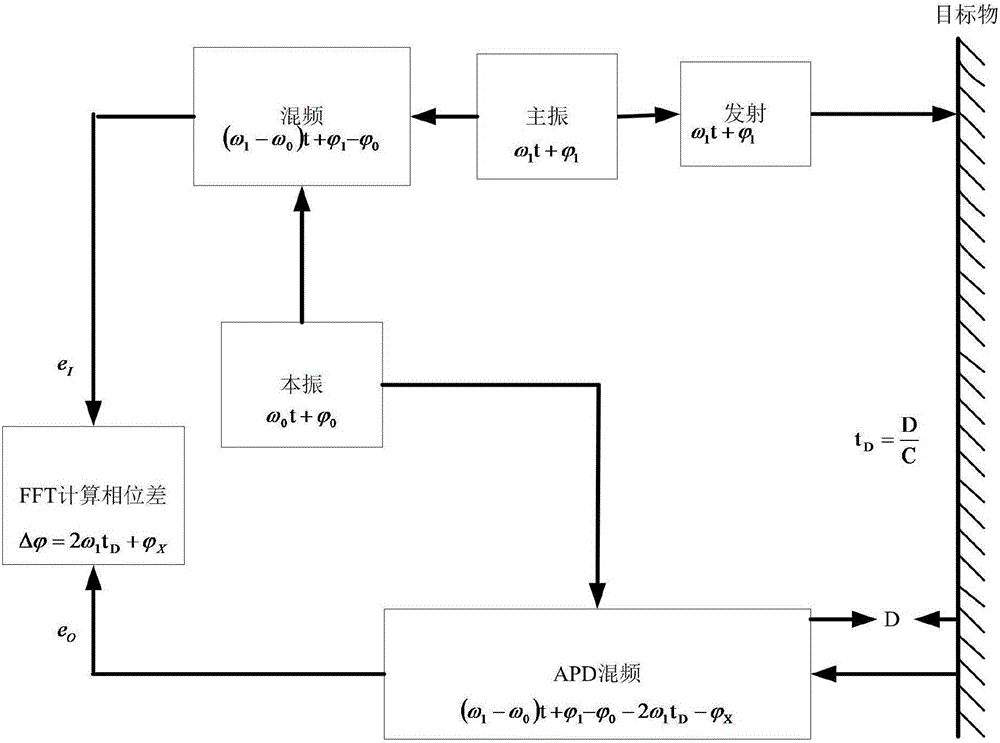

Laser phase range finding method

ActiveCN105824028AEliminate Phase ErrorImprove stabilityElectromagnetic wave reradiationBandpass filteringSignal-to-noise ratio (imaging)

A laser phase range finding method disclosed by the present invention comprises the steps of dividing the laser emitted out by a spectroscope into the inner light path laser and the outer light path laser; using an inner / outer light path APD mixer circuit to carry out the mixing processing on the inner light path laser and the outer light path laser separately, using a second-order band-pass filtering amplifying circuit to carry out the signal amplifying and filtering processing on the inner light path laser and the outer light path laser after the mixing processing in a time sharing manner, using an AGC circuit to carry out the amplitude amplification processing on the inner light path laser and the outer light path laser after the amplification and filtering processing separately, using an MCU to obtain the phase difference of the inner light path laser and the outer light path laser after the amplitude amplification processing, and obtaining the measurement distance corresponding to the outer light path laser after the range finding according to the phase difference of the inner and outer light paths. The beneficial effects of the present invention are that a total phase error caused under different environments is eliminated real-timely, so that the range finding stability and precision are improved; the AGC circuit and the second-order band-pass filtering amplifying circuit are utilized simultaneously to improve the amplitude and the signal to noise ratio of a signal, so that the phase difference operation is more accurate.

Owner:SHENZHEN WEIRUI JINGKE ELECTRONICS

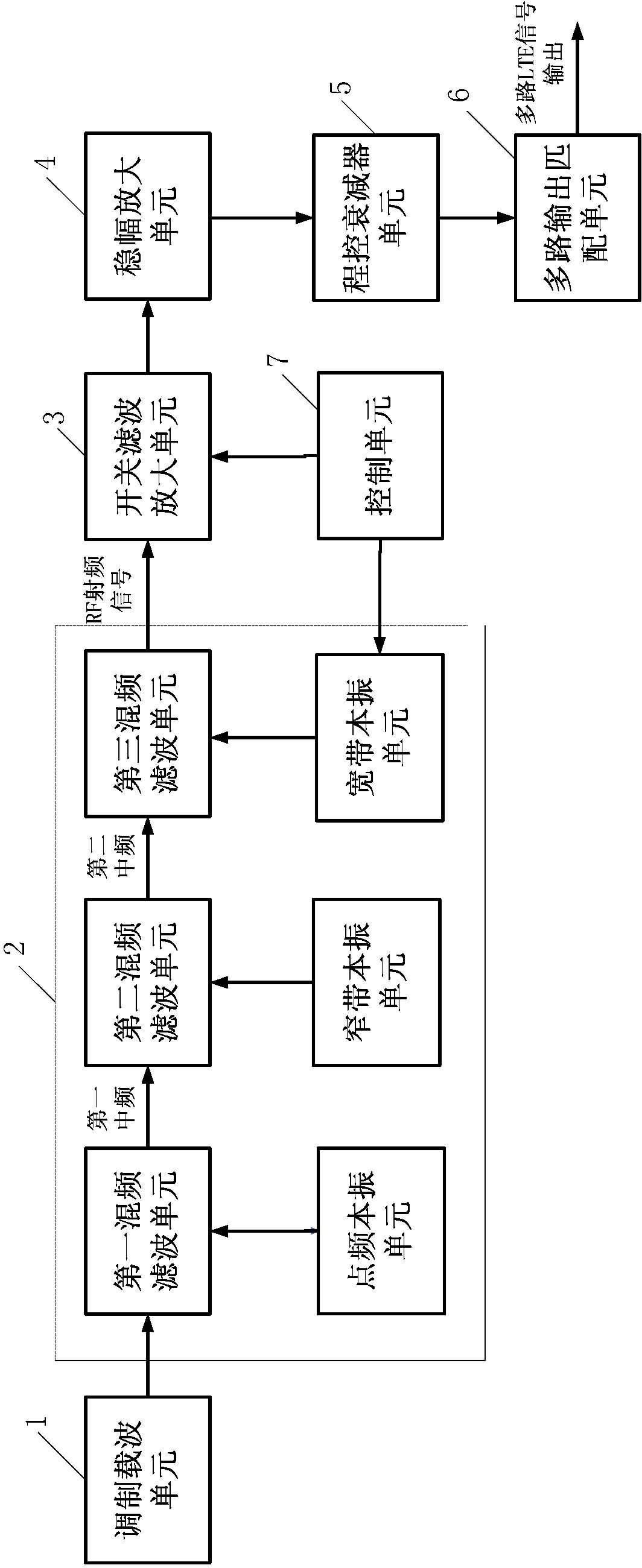

Network end signal emitting device of time division-long term evolution (TD-LTE) system

InactiveCN102684714AMeet frequency range requirementsMeet low spurious requirementsTransmitters monitoringCarrier signalEngineering

The invention relates to a network end signal emitting device of a time division-long term evolution (TD-LTE) system. The network end signal emitting device comprises a modulation carrier wave unit used for generating TD-LTE modulation carrier wave signals, wherein the output end of the modulation carrier wave unit is connected with the input end of a frequency mixing filtering unit used for generating radio frequency (RF) signals, the output end of the frequency mixing filtering unit is connected with the input end of a switch filtering amplification unit, the output end of the switch filtering amplification unit is connected with the input end of a program control attenuator unit through a fixed amplitude amplifying unit, and the output end of the program control attenuator unit is connected with the input end of a multi-path output matching unit used for outputting multiple paths of LTE signals. The multi-time frequency conversion can meet the output frequency range requirement of the signal output, the switch filter and the frequency fixing filtering are utilized, the low stray requirements of output signals are met, high-accuracy requirements of the signal output power can be met through a fixed amplitude loop, the signal output maximum power requirement is met through multi-stage amplification, and the low-power step and large-dynamic-range requirements are realized through the combination of the fixed amplitude amplification unit and the program control attenuator.

Owner:CHINA ELECTRONIS TECH INSTR CO LTD

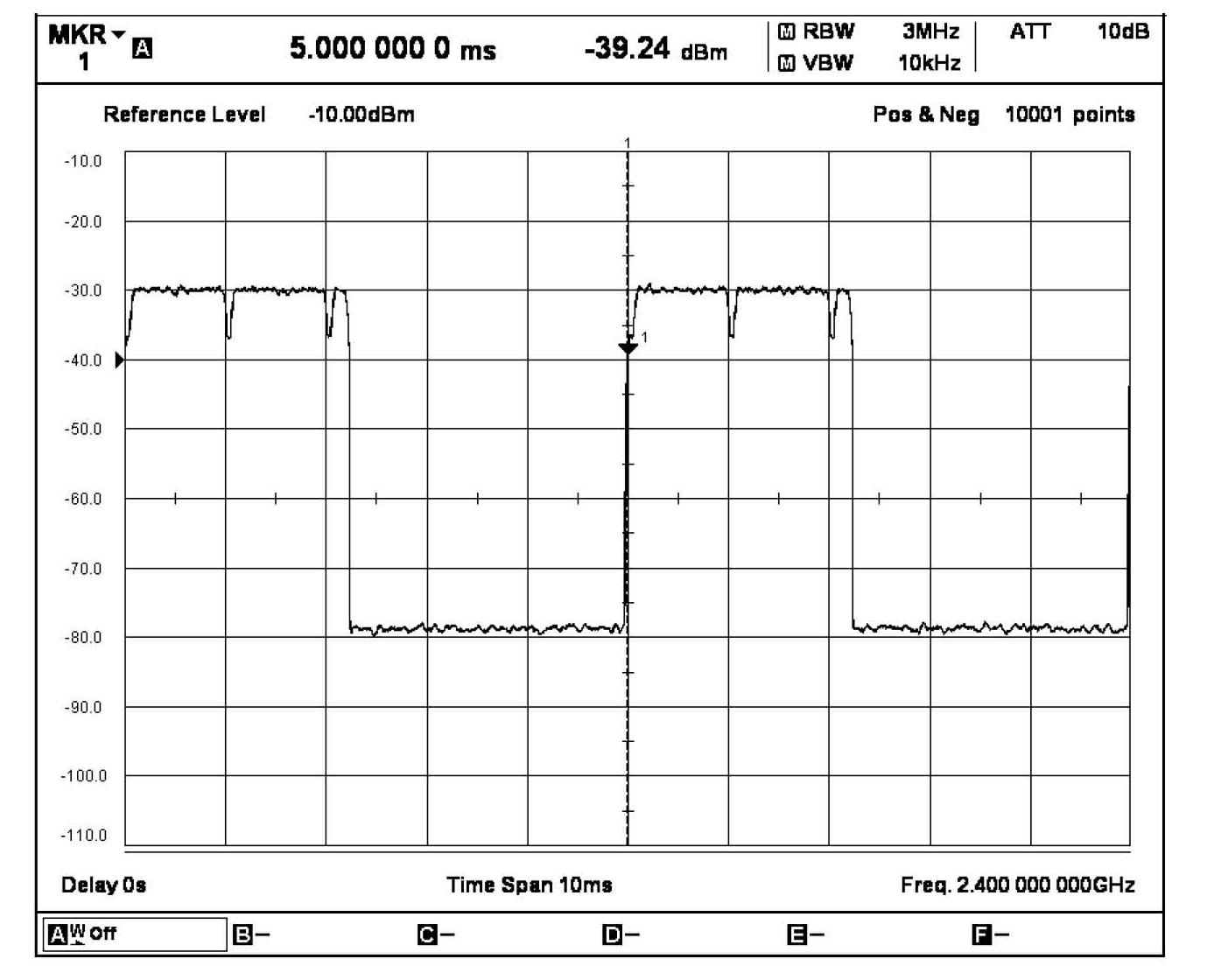

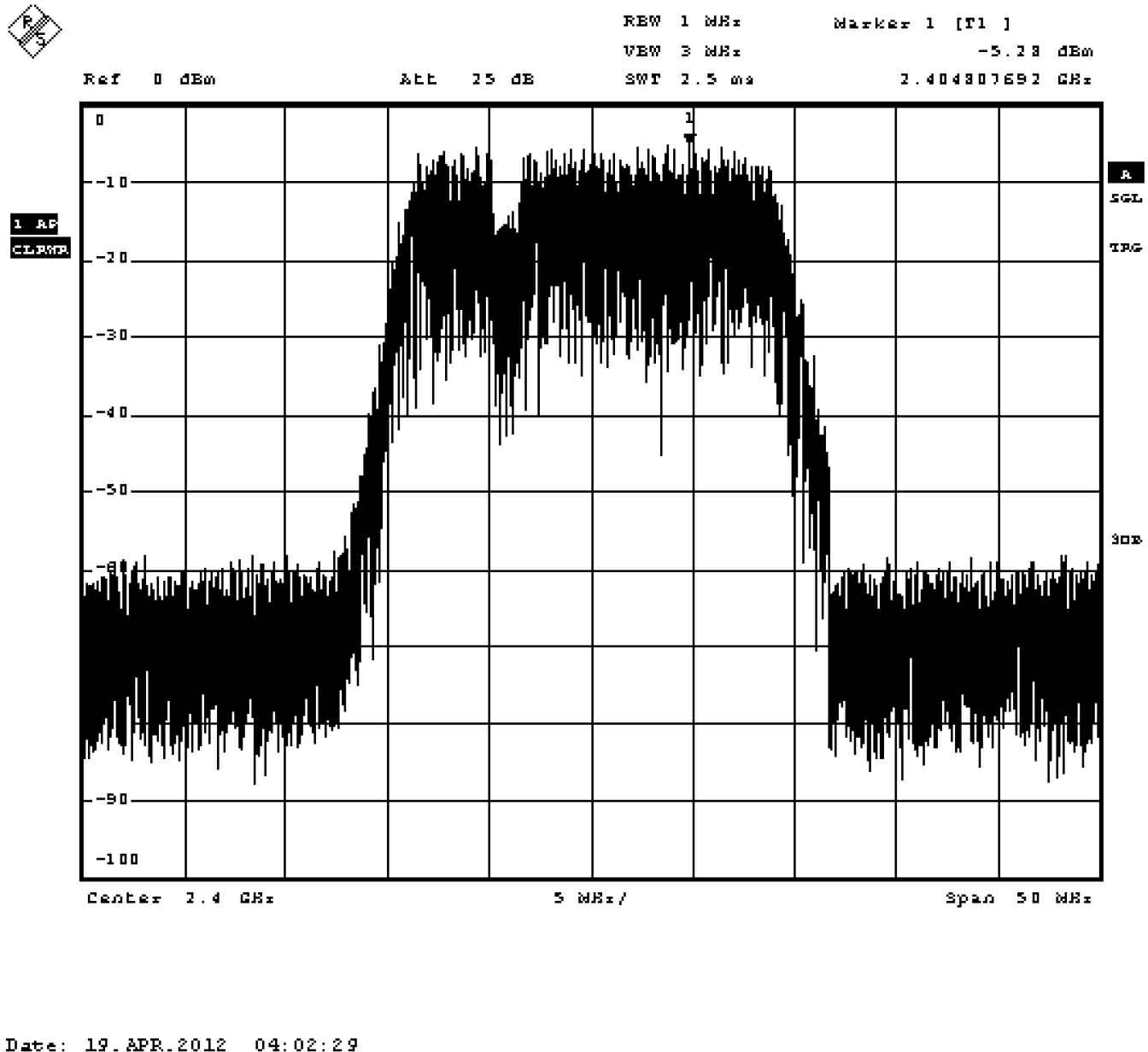

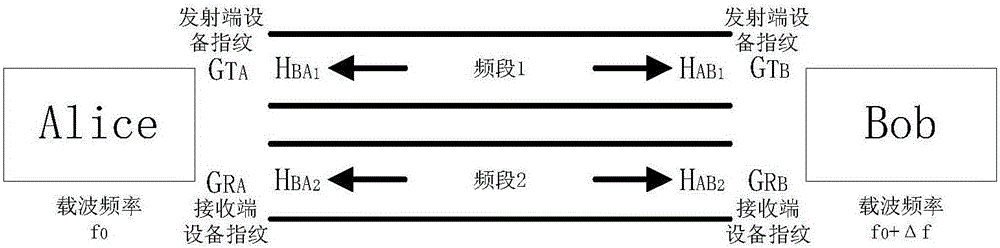

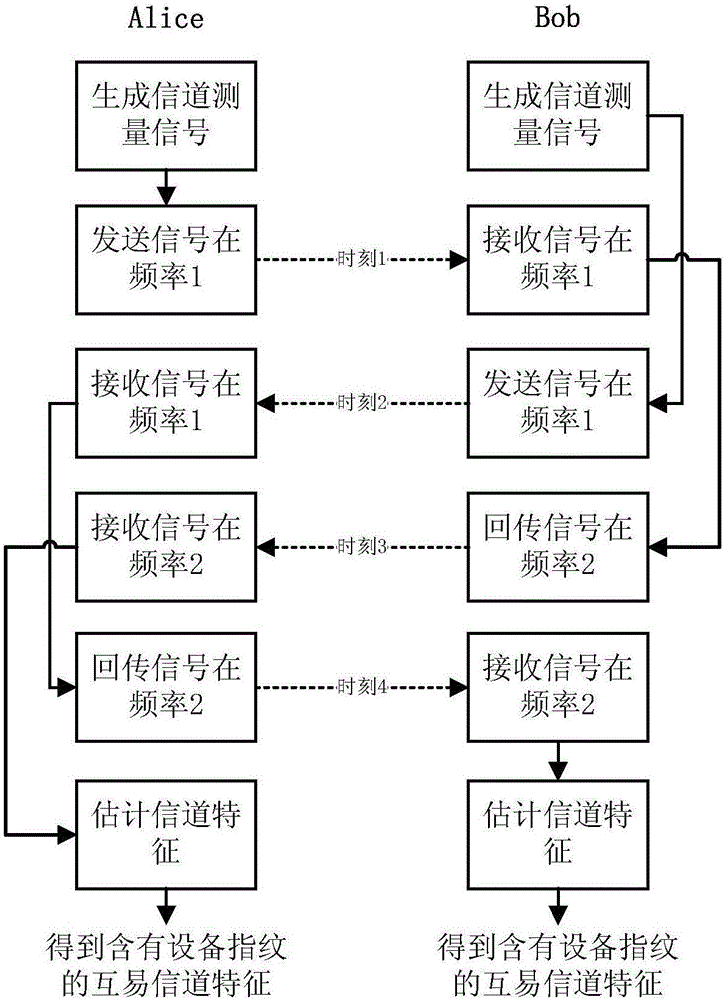

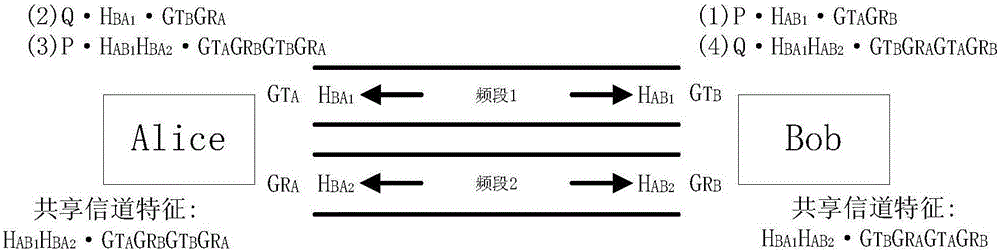

Joint time-frequency duplex shared channel characteristic obtaining method

ActiveCN105099640AQuick implementationImprove reciprocitySignal allocationChannel estimationThird partyCommunications system

The invention discloses a joint time-frequency duplex shared channel characteristic obtaining method. Two parties of communication obtain channel characteristics using two frequency bands. The two parties of communication send channel measurement signals to each other at different moments firstly using the first frequency band, and then return the received signals to the opposite parties at different moments using the other frequency band without processing or only simple processing such as signal amplitude amplification. According to the method, the two parties of communication can obtain highly consistent shared channel characteristics in case of different device fingerprints. Besides, the method is capable of ensuring that the channel characteristics obtained by the two legal parties of communication cannot be broken by a third-party wiretapper after the whole information exchange process is wiretapped, thereby ensuring the security of obtaining the shared channel characteristics. The method joint time-frequency duplex shared channel characteristic obtaining method can be applied to a wireless communication system or to a wired communication system and an optical fiber communication system.

Owner:SOUTHEAST UNIV

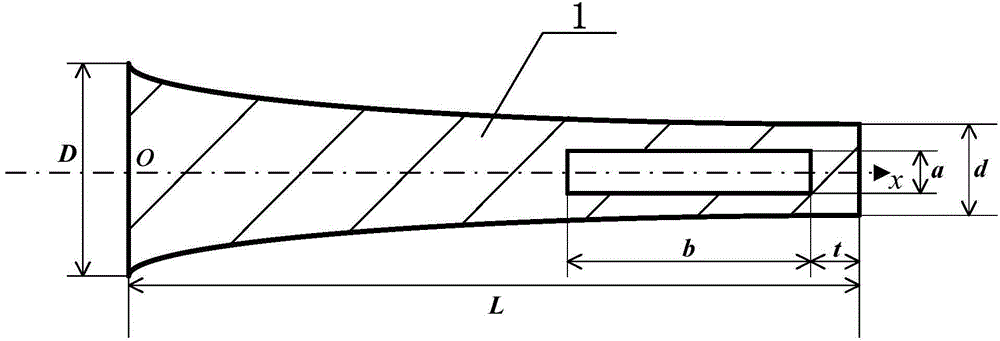

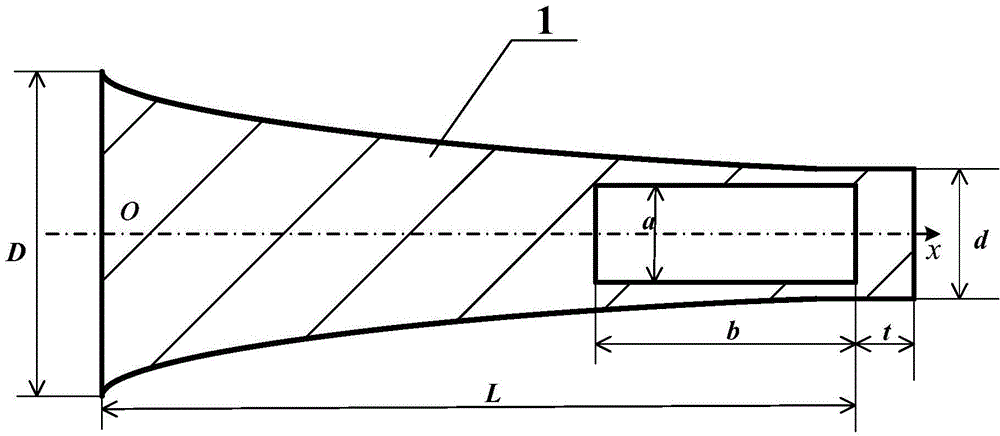

Catenary suspension linear ultrasound longitudinal vibration amplitude-change bar with hole formed in axial direction of output end

InactiveCN104785430AIncreased amplitude amplification factorImprove work efficiencyMechanical vibrations separationEngineeringLongitudinal vibration

Provided is a catenary suspension linear ultrasound longitudinal vibration amplitude-change bar with a hole formed in the axial direction of the output end. The rectangular through hole is machined in the inner side of the small end in the axial direction of the center line of the amplitude-change bar, the distance t between the outer wall of the rectangular through hole and the small end is 2 mm-0.18 mm, the length of the amplitude-change bar is L, and according to the geometric shape, the amplitude-change bar is a rod-like body with the two end faces being parallel planes perpendicular to the center line and the side face being a hyperbolic cosine revolution surface. Because the rectangular through hole is formed in the position, away from the output end by a certain distance, in the axial direction of the center line of the catenary suspension linear amplitude-change bar, when the amplitude-change bar works at a longitudinal vibration resonant frequency position, the output end further has excited bending vibration components besides longitudinal vibration components of the amplitude-change bar; due to the superposition of the longitudinal vibration components and the bending vibration components, the amplitude amplification coefficient of the holed conical amplitude-change bar is increased by 1.68-3.3 times compared with that of a solid conical amplitude-change bar, and working efficiency is greatly improved.

Owner:SHAANXI NORMAL UNIV

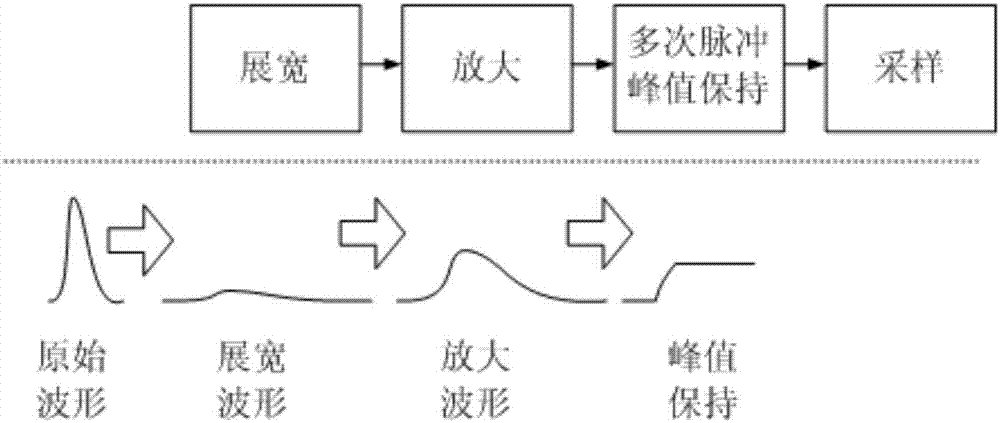

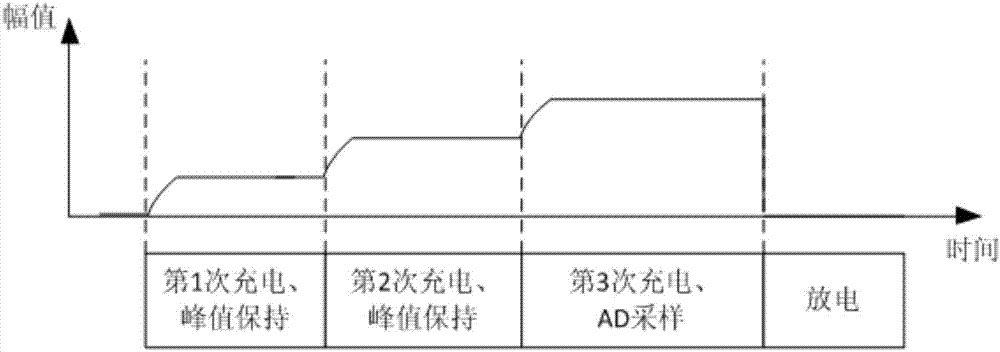

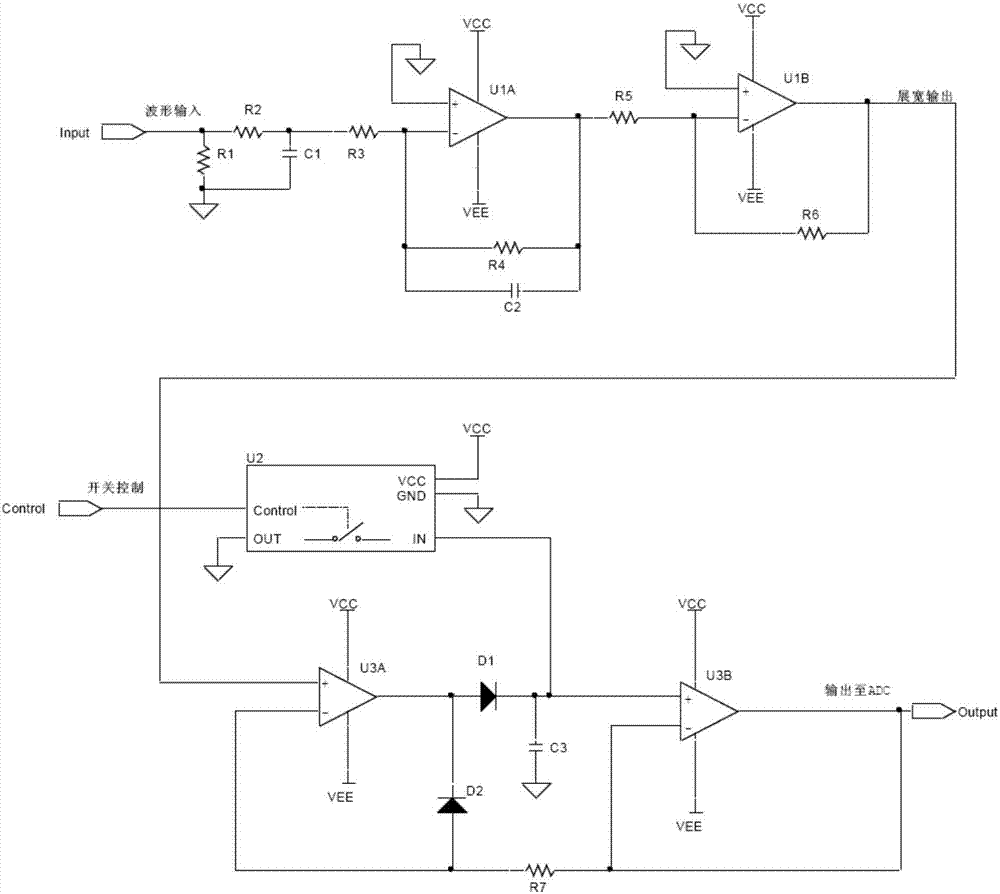

Short pulse amplitude measurement method based on multiple times of pulse peak keeping, and implementation circuit

ActiveCN107276569ASolve the lack of wideningSNRPulse shapingCapacitanceSignal-to-noise ratio (imaging)

The invention relates to a short pulse amplitude measurement method based on multiple times of pulse peak keeping, and an implementation circuit. The method comprises the following steps: 1) performing pulse width expansion on a measured nanosecond level narrow pulse; 2) performing amplitude amplification on the expanded pulse signal; and 3) charging an energy storage capacitor for multiple times by using a waveform after the multiple times of pulse peak keeping to obtain the amplitude information of the nanosecond level narrow pulse. According to the short pulse amplitude measurement method, the energy storage capacitor is charged for multiple times by using multiple expanded and amplified signals, the pulse peak keeping is performed, which is equivalent to amplifying the energy of the measured nanosecond level narrow pulse, the noise of echo can also be avoided, the problems of insufficient nanosecond level narrow expansion and low signal to noise ratio are solved, and the short pulse amplitude measurement method can be widely used in the nanosecond narrow pulse peak keep.

Owner:TANWAY TECH (BEIJING) CO LTD

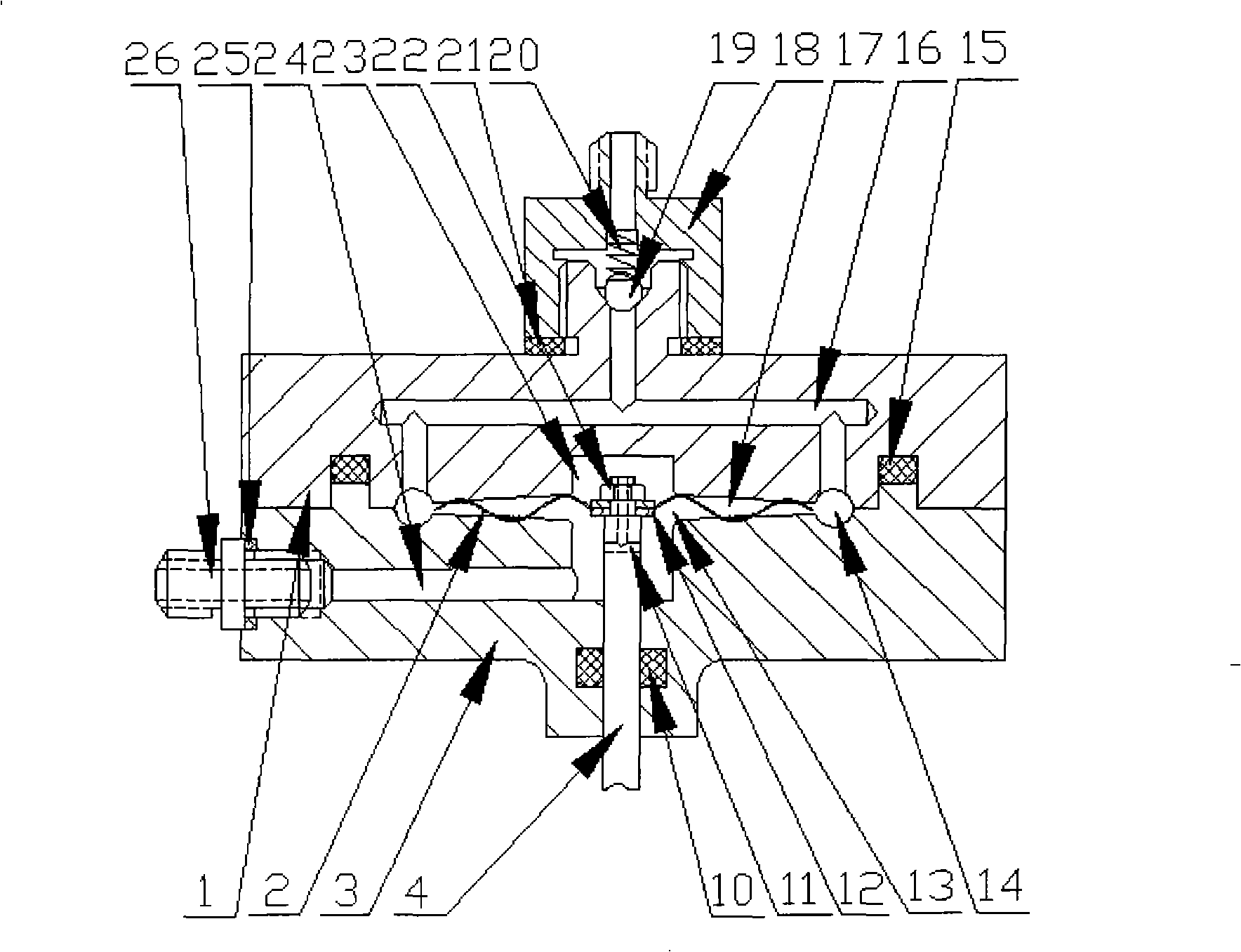

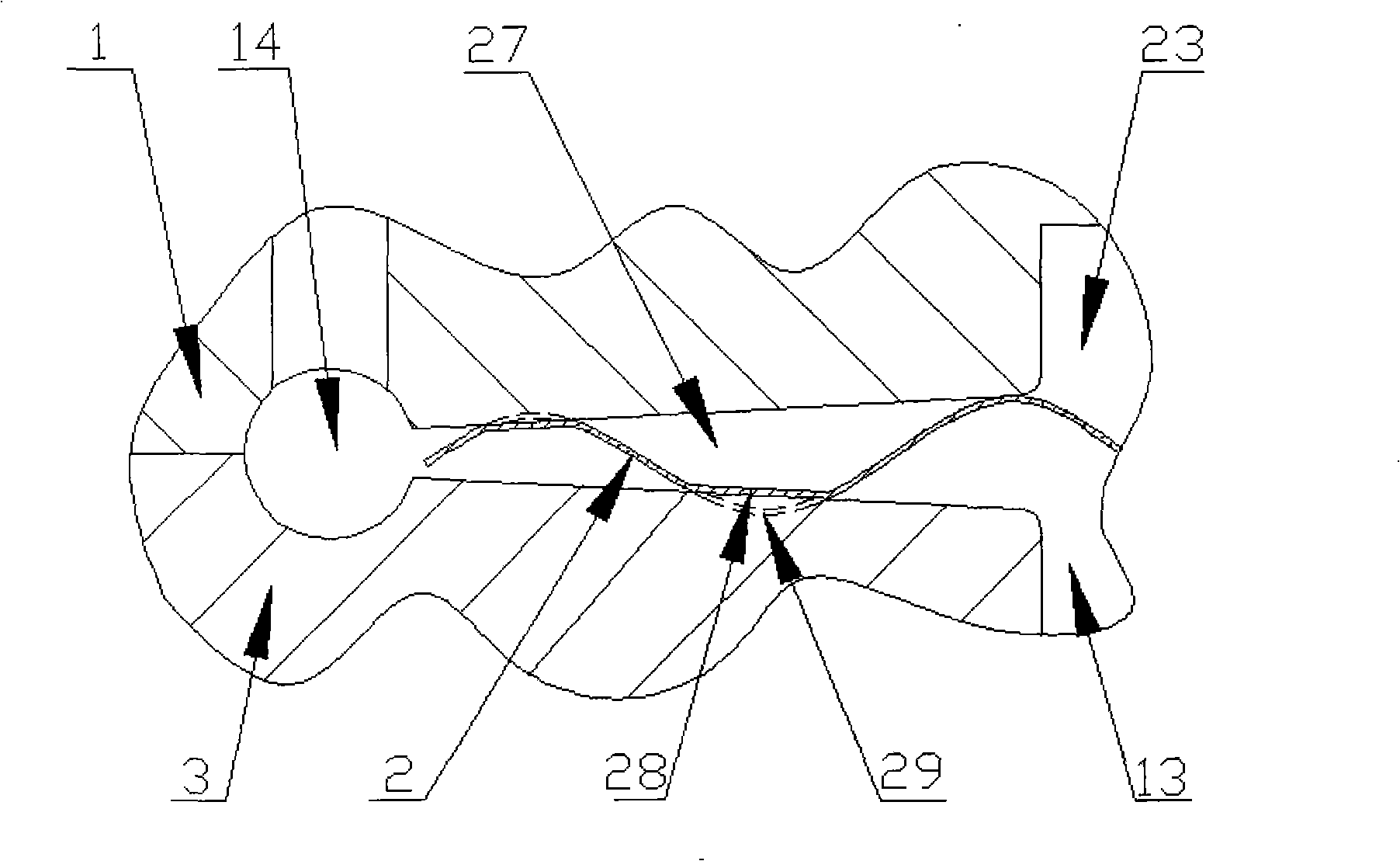

High-frequency valveless pump on the basis of intelligent material

InactiveCN101275549AGood for high-frequency characteristicsIncrease energy densityFlexible member pumpsPositive-displacement liquid enginesManufacturing technologyHydraulic pump

The invention belongs to a hydraulic pump manufacturing technology, and relates to the improvement on the working principle of a traditional hydraulic pump. The new type pump mainly comprises an intelligent material driving magnifying mechanism, a metal diaphragm vibration boosting mechanism, an oil absorption circuit and an oil drain non-return circuit. The intelligent material driving magnifying mechanism performs amplitude amplification on the high frequency vibration energy outputted by intelligent material through an arc type flexible hinge, and drives the metal diaphragm vibration boosting mechanism, the middle part of a circular metal diaphragm in forced vibration generates a ring-shaped transverse wave diffusing outwards, the upper and lower surfaces of the metal diaphragm and the upper and lower dish-shaped surfaces of a pump cavity form two groups of closed chambers moving outwards, the closed chambers forces oil continuously from a low pressure cavity to a high pressure cavity, thus realizing oil pumping. When a traditional reciprocating pump pumps oil in each vibration cycle, a hydraulic valve changes the direction of the oil circuits, resulting the bottleneck that working frequency can not be too high, if the structure is employed, the bottleneck can be avoided, the high frequency characteristic of the intelligent material can be fully applied to the manufacture field of hydraulic pumps.

Owner:BEIHANG UNIV

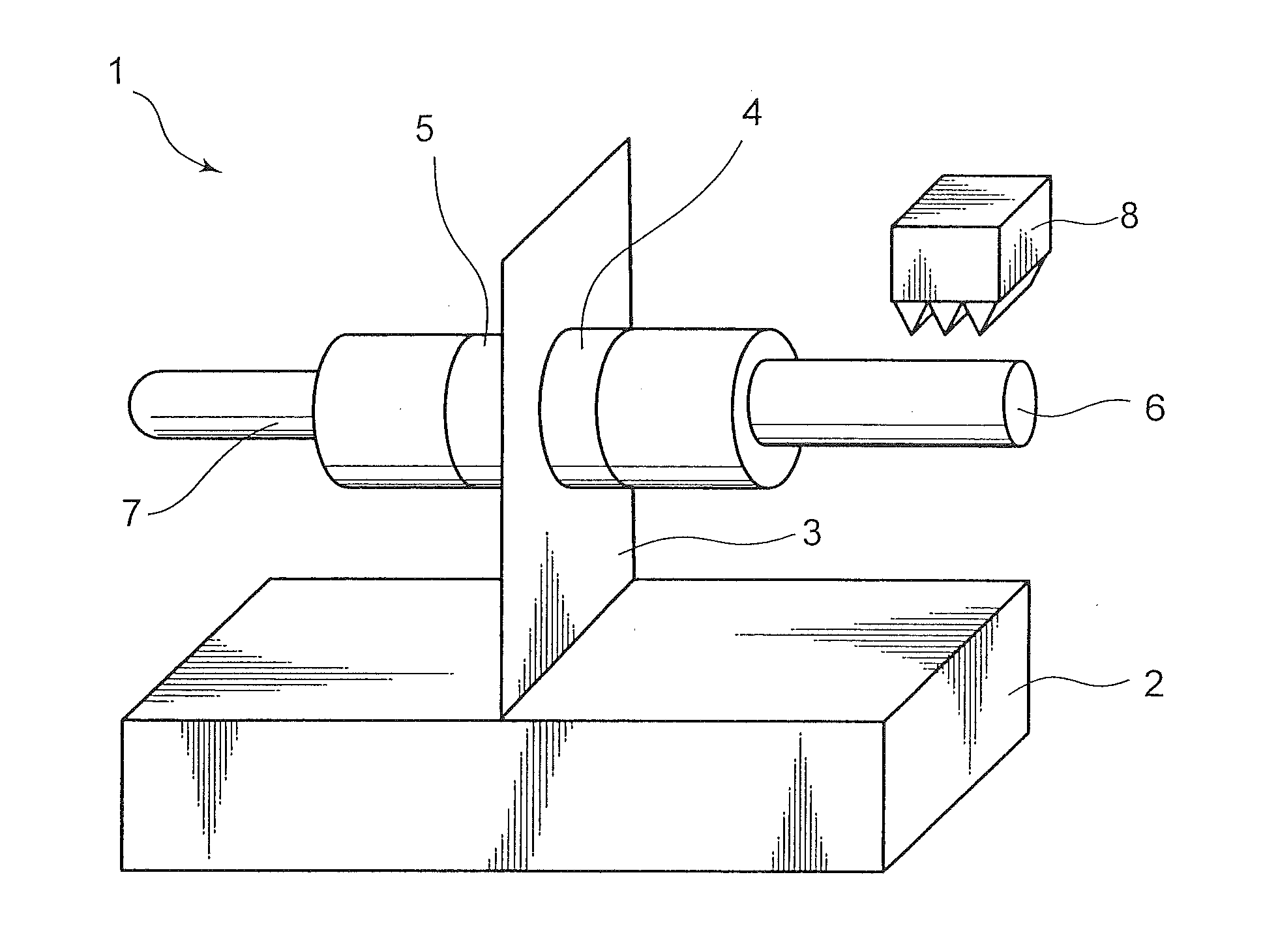

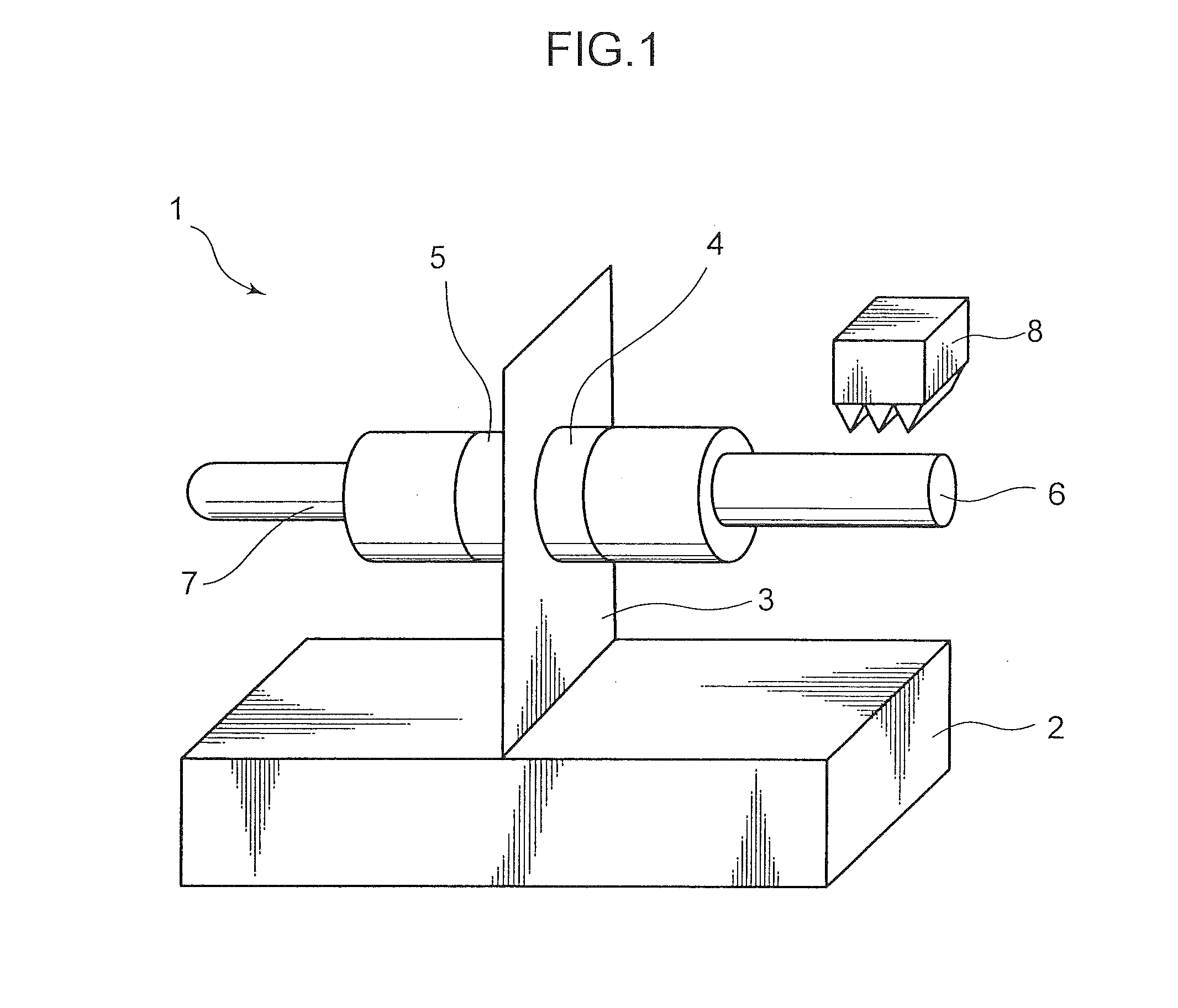

Drive device

InactiveUS20120299442A1Increase vibrationIncrease movement speedPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesElectricityResonance

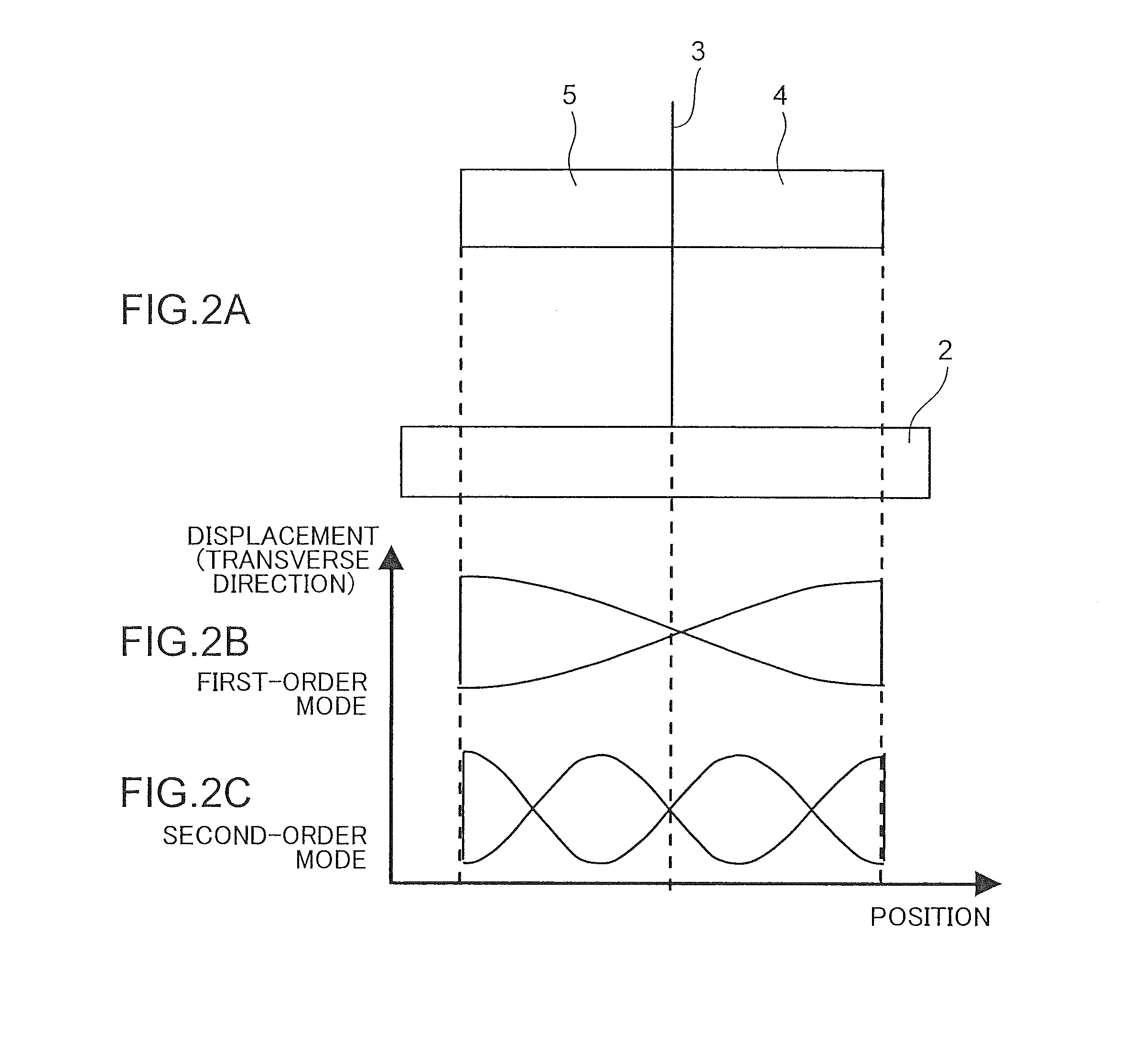

Disclosed is a drive device 1 which is adapted to move a driven member used on a speed difference between during extending and during contracting in a course of vibration of a vibrator. The vibrator, e.g., a piezoelectric element 4, 5, is formed in a structure which has two resonance modes identical in terms of a vibration direction, and allows a ratio between resonance frequencies of the two resonance modes to become approximately 2. A drive signal to be given to the vibrator is configured to approximately conform to the two resonance modes. The drive device 1 having the above configuration makes it possible to generate pseudo-sawtooth displacement vibration multiplied by an amplitude amplification factor Q through resonance, thereby improving a movement speed, and allow a larger part of input energy to be used for mechanical vibration, thereby improving energy efficiency.

Owner:KONICA MINOLTA INC +1

Method for realizing reverberant field focusing by using random array

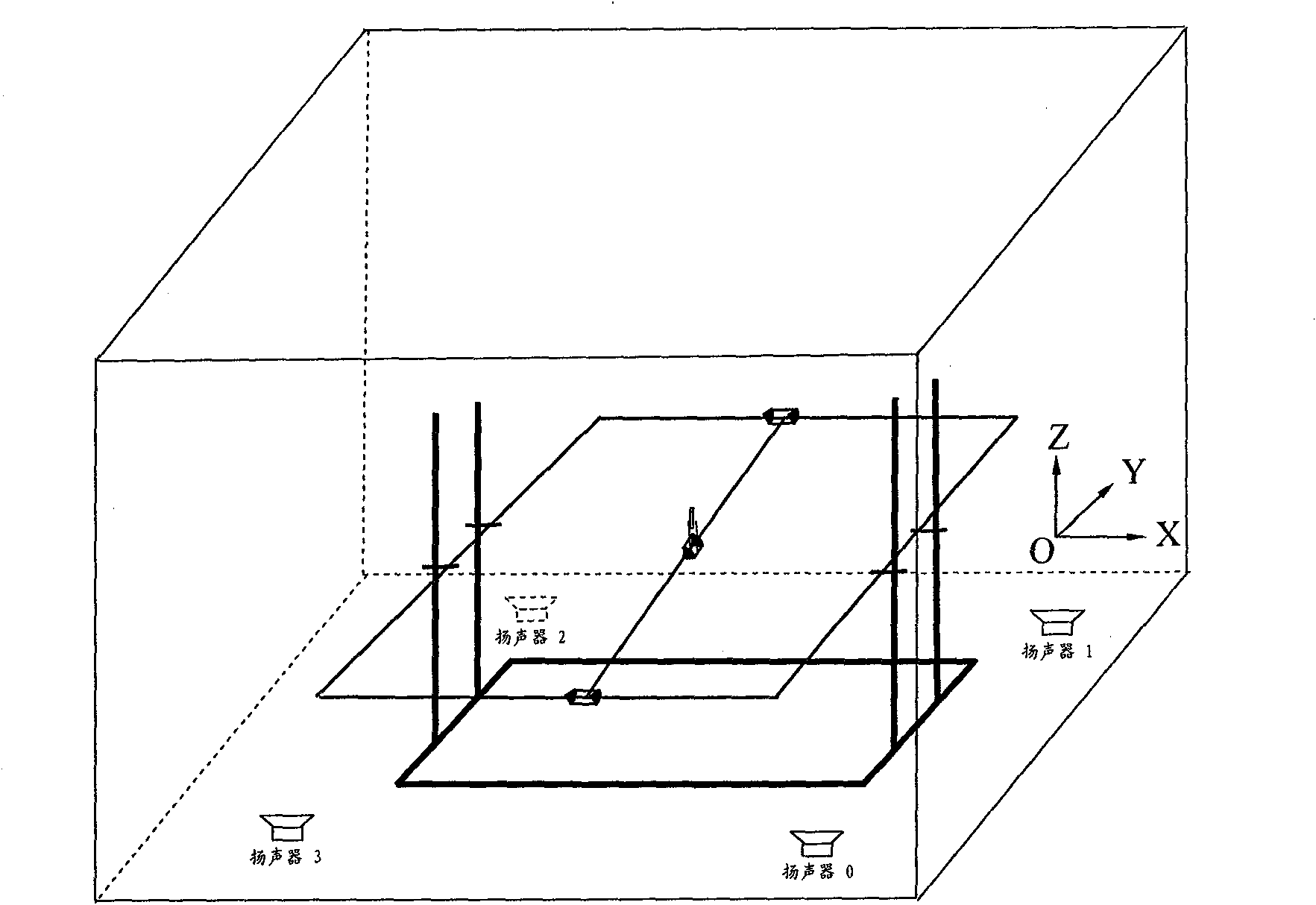

ActiveCN101615392ARealize the focus of the reverberant sound fieldAchieve sound field focusSound producing devicesTime domainPhase difference

The invention relates to a method for realizing reverberant field focusing by using a random array. The method comprises the following steps: 1) when the random array synchronously transmits same source signals under a reverberant environment, recording receiving signals acquired by a microphone at an expected position; 2) processing the recorded receiving signals by time domain inversion and amplitude amplification; and 3) transmitting the time domain inversion signals amplified in step 2) by the random array so as to generate sound focusing at the expected position. The method has the advantages that array elements can be randomly placed; focusing blur produced by phase difference among the array elements can be fully eliminated; a Green's function between a source point and an expected focusing point is solved by adopting an experimental measurement method instead of the prior calculation or estimation method, and the calculation burden is removed; the array element distance breaks through the limitation of half wavelength; and under the condition that the array element numbers are the same, the space domain resolution focused by the random array is slightly greater than the space domain resolution focused by a linear array.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

Transmission circuit, and communication apparatus using the same

InactiveUS7742541B2Enhanced transmission signalImprove efficiencyTelephonic communicationModulation with suppressed carrierTime segmentAngle modulation

A compact transmission circuit for outputting a highly linear transmission signal regardless of the output power level and operating at a high efficiency is provided. A signal generation section 11 generates an amplitude signal and quadrature data based on input data. A calculation section 21 calculates using the amplitude signal and the quadrature data to output a discrete value having a level discrete at every predetermine time period, and first and second phase signals. An amplitude amplification section 17 outputs a voltage controlled in accordance with the discrete value. Angular modulation sections 13 and 14 angular-modulate the phase signals and output first and second angle-modulated signals. Amplitude modulation sections 15 and 16 amplitude-modulate the angle-modulated signals with the voltage from the amplitude amplification section 17 and output first and second modulated signals. A combining section 18 combines the first and second modulated signals and outputs a transmission signal.

Owner:PANASONIC CORP

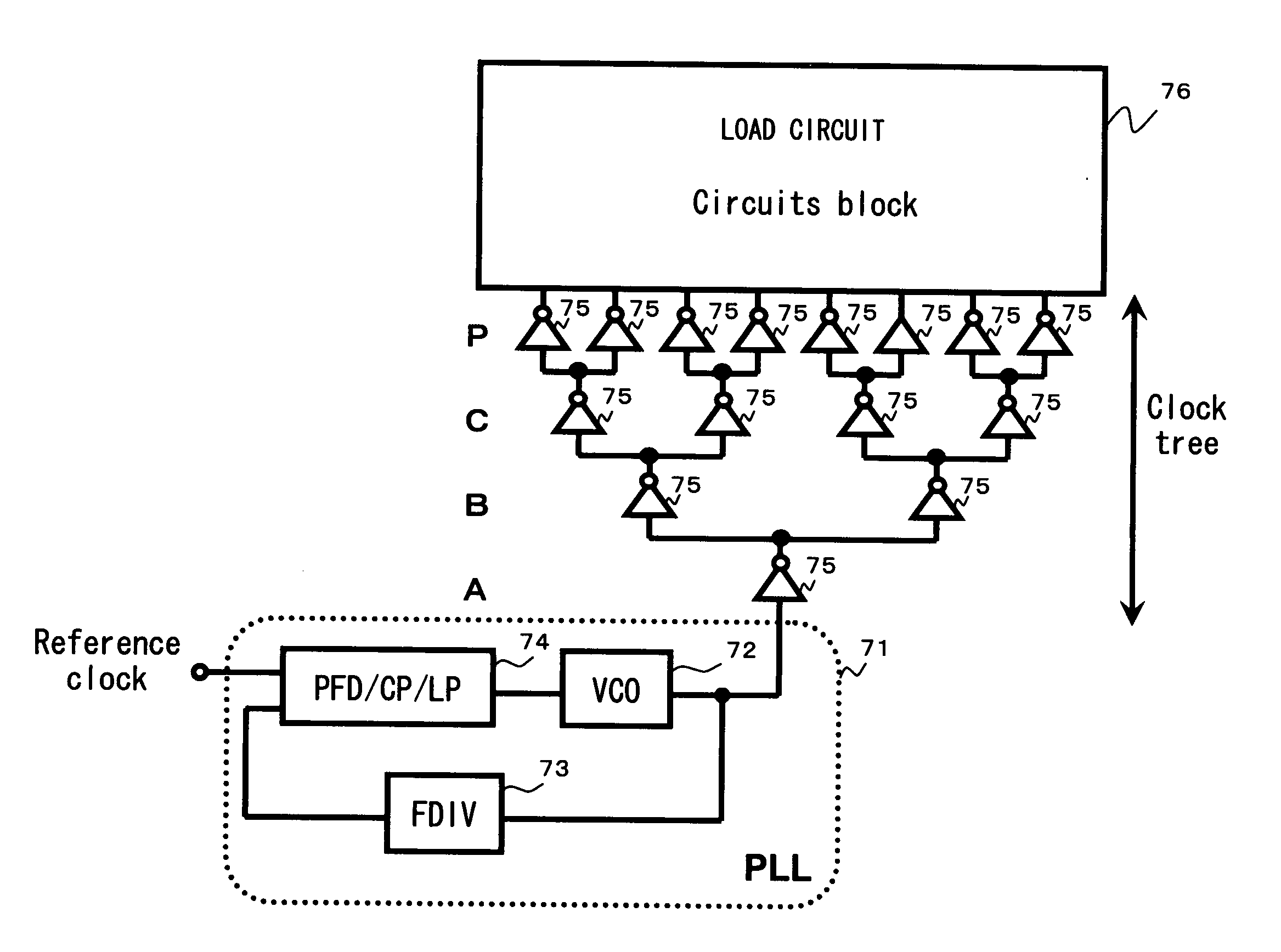

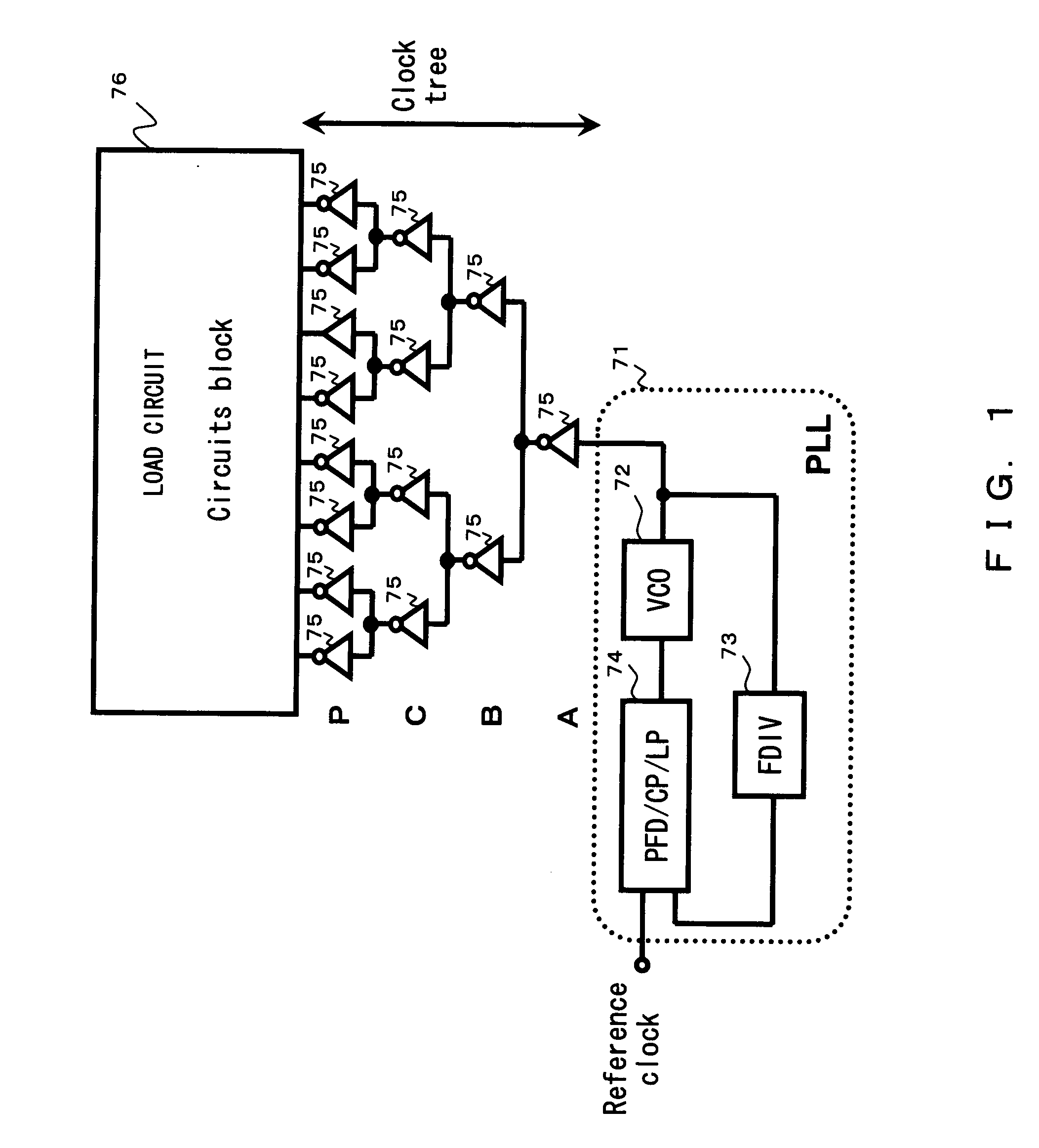

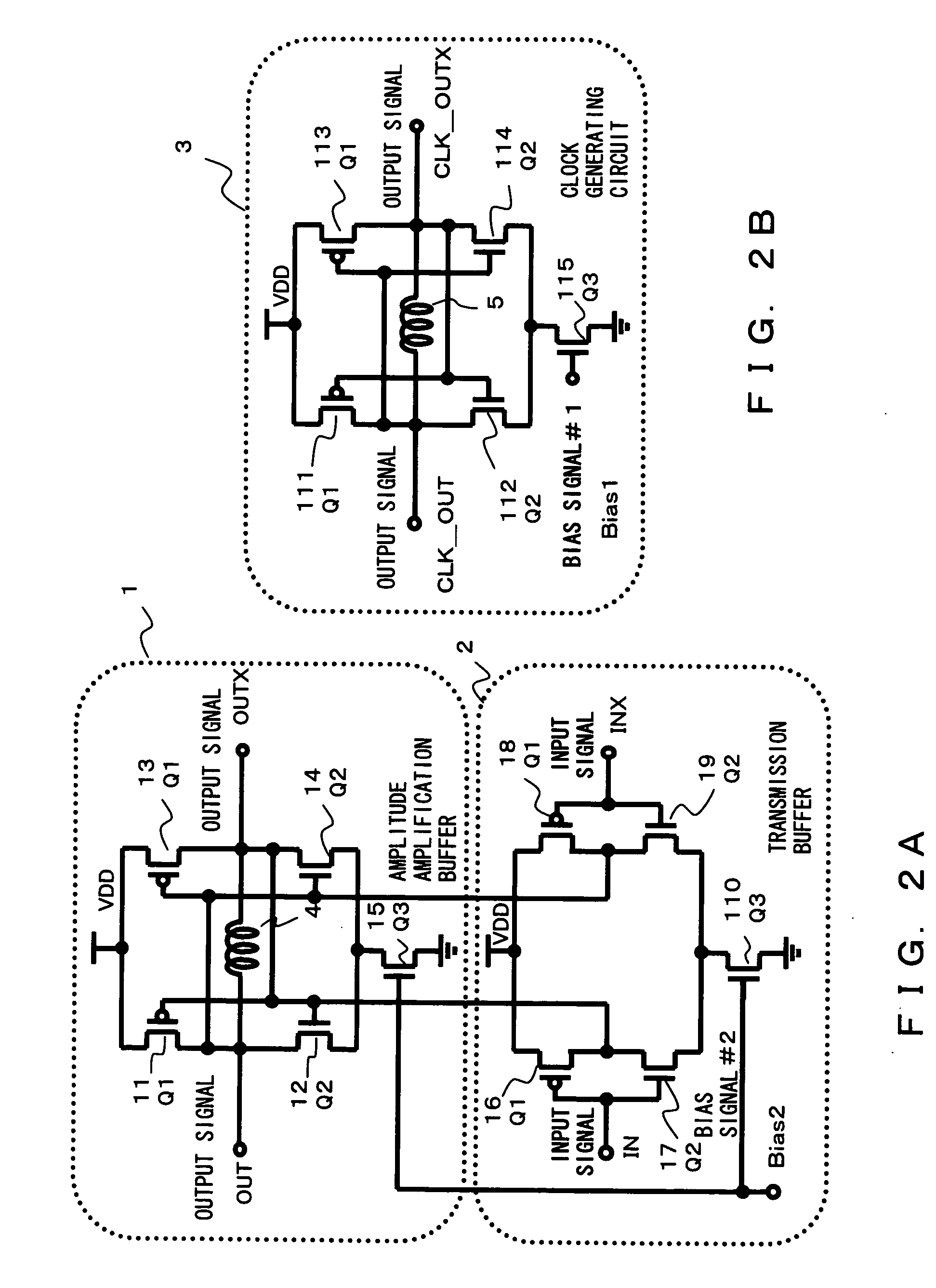

Clock distribution circuit

ActiveUS20070063751A1Stable supplySuitable for operationElectric pulse generatorPulse shapingCouplingEngineering

A clock distribution circuit for suitably generating, transmitting, and receiving clock signals used in circuits that are configured with the same circuit topology is provided. The clock distribution circuit has a transmission buffer circuit that transmits a clock signal and an amplitude amplification buffer circuit that amplifies the amplitude of cross-coupling connections inserted in parallel with the transmission buffer circuit on a transmission path for the clock signal. Wherein the number of transistors having the same conductivity type as the transistors of a differing conductivity type of the transmission buffer circuit and that of the transistors of a differing conductivity type of the amplitude amplification buffer circuit are the same. At least one transistor is provided as a bias adjustment transistor for adjusting bias in each of the transmission buffer circuit and the amplitude amplification buffer circuit, respectively, and bias adjustments are made simultaneously.

Owner:FUJITSU LTD

Index type ultrasound longitudinal vibration amplitude-change bar with hole formed in axial direction of output end

InactiveCN104785432AIncreased amplitude amplification factorImprove work efficiencyMechanical vibrations separationVibration amplitudeLongitudinal vibration

Provided is an index type ultrasound longitudinal vibration amplitude-change bar with a hole formed in the axial direction of the output end. The rectangular through hole is machined in the inner side of the small end in the axial direction of the center line of the amplitude-change bar, the distance t between the outer wall of the rectangular through hole and the small end is 2 mm-0.18 mm, the length of the amplitude-change bar is L, and according to the geometric shape, the amplitude-change bar is a rod-like body with the two end faces being parallel planes perpendicular to the center line and the side face being an index revolution surface. Because the rectangular through hole is formed in the position, away from the output end by a certain distance, in the axial direction of the center line of the index type amplitude-change bar, when the amplitude-change bar works at a longitudinal vibration resonant frequency position, the output end further has excited bending vibration components besides longitudinal vibration components of the amplitude-change bar; due to the superposition of the longitudinal vibration components and the bending vibration components, the amplitude amplification coefficient of the holed index amplitude-change bar is increased by 1.8-4.8 times compared with that of a solid index type amplitude-change bar the same as the holed index amplitude-change bar in shape and material, and working efficiency is greatly improved.

Owner:SHAANXI NORMAL UNIV

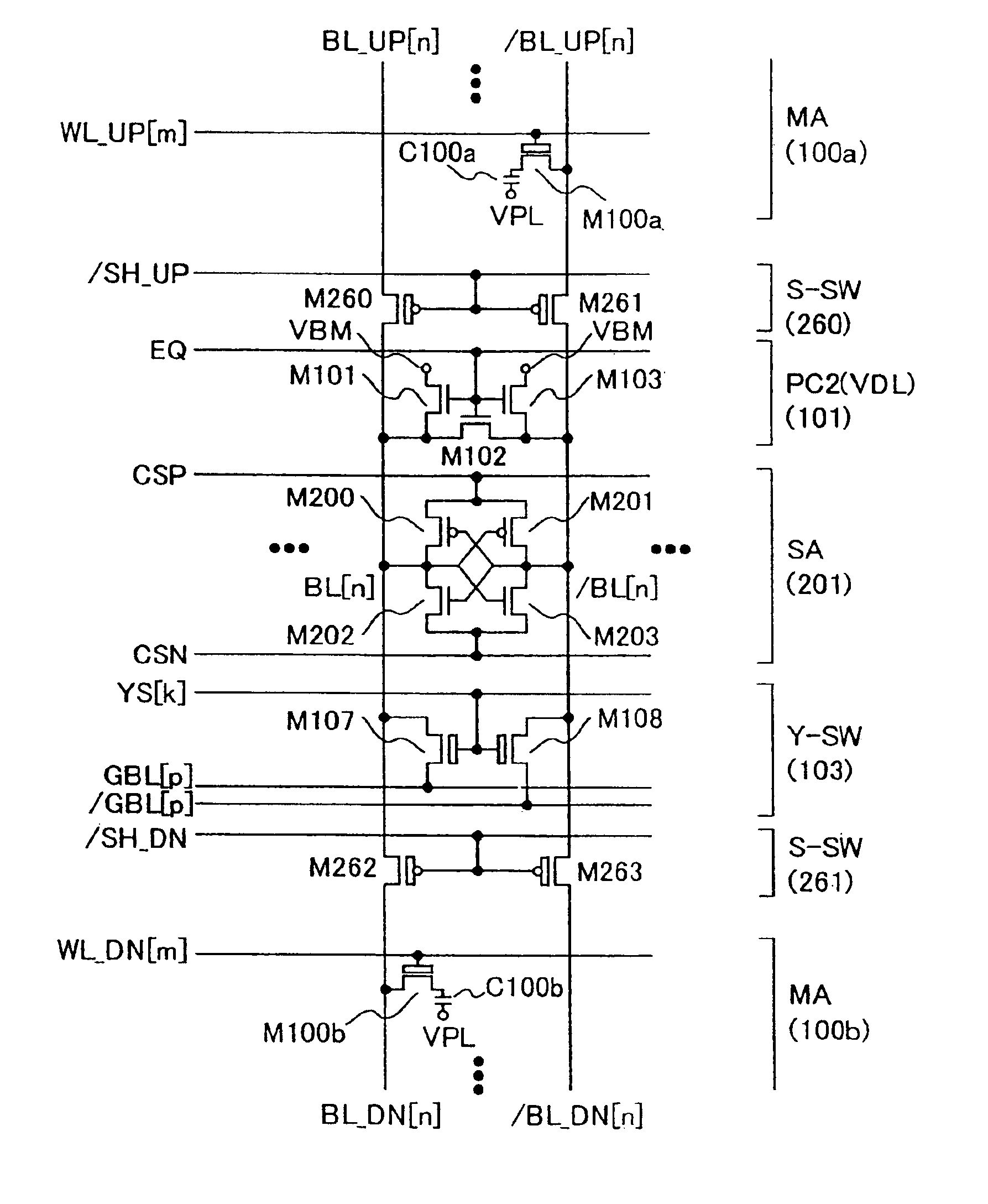

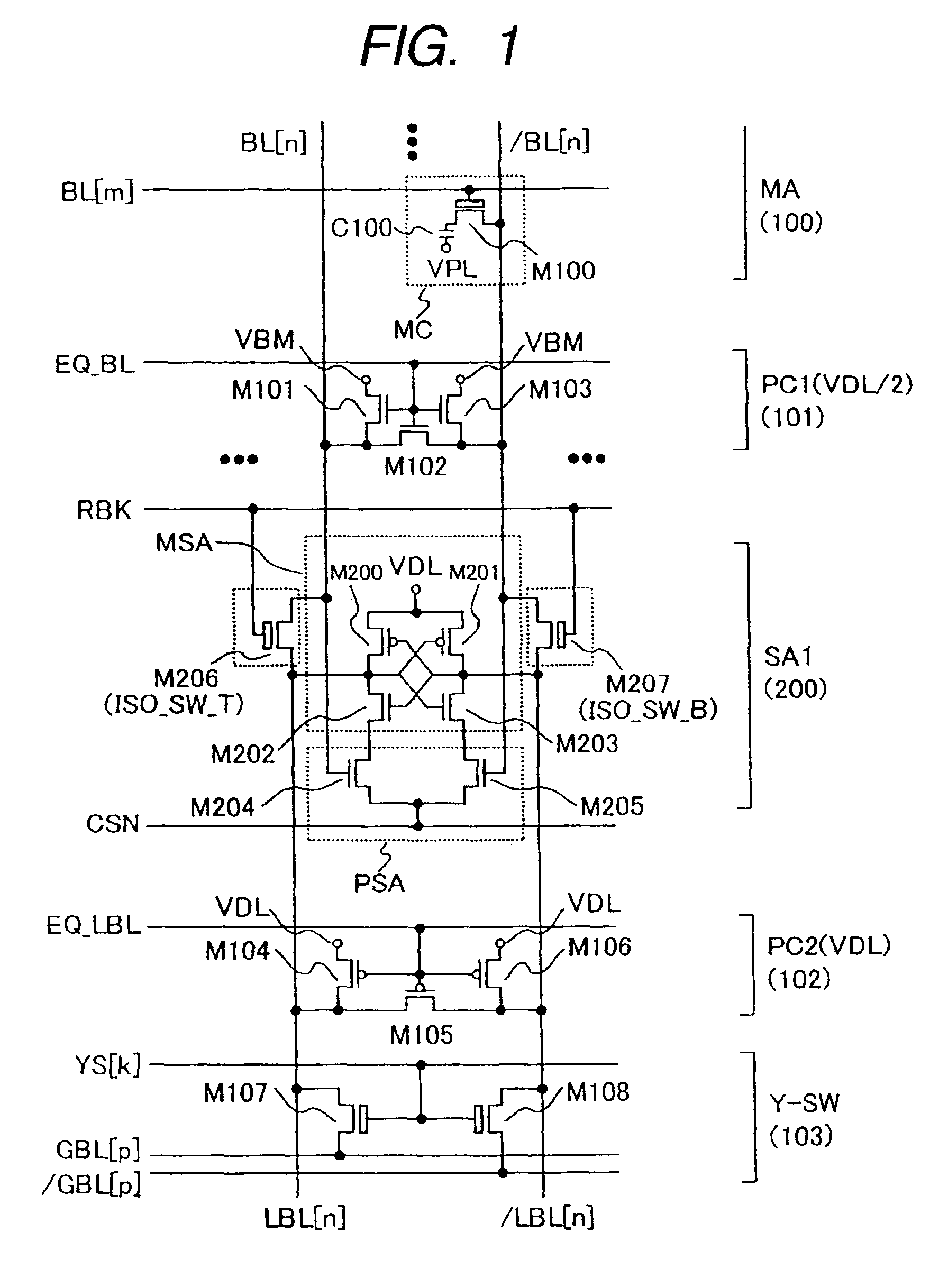

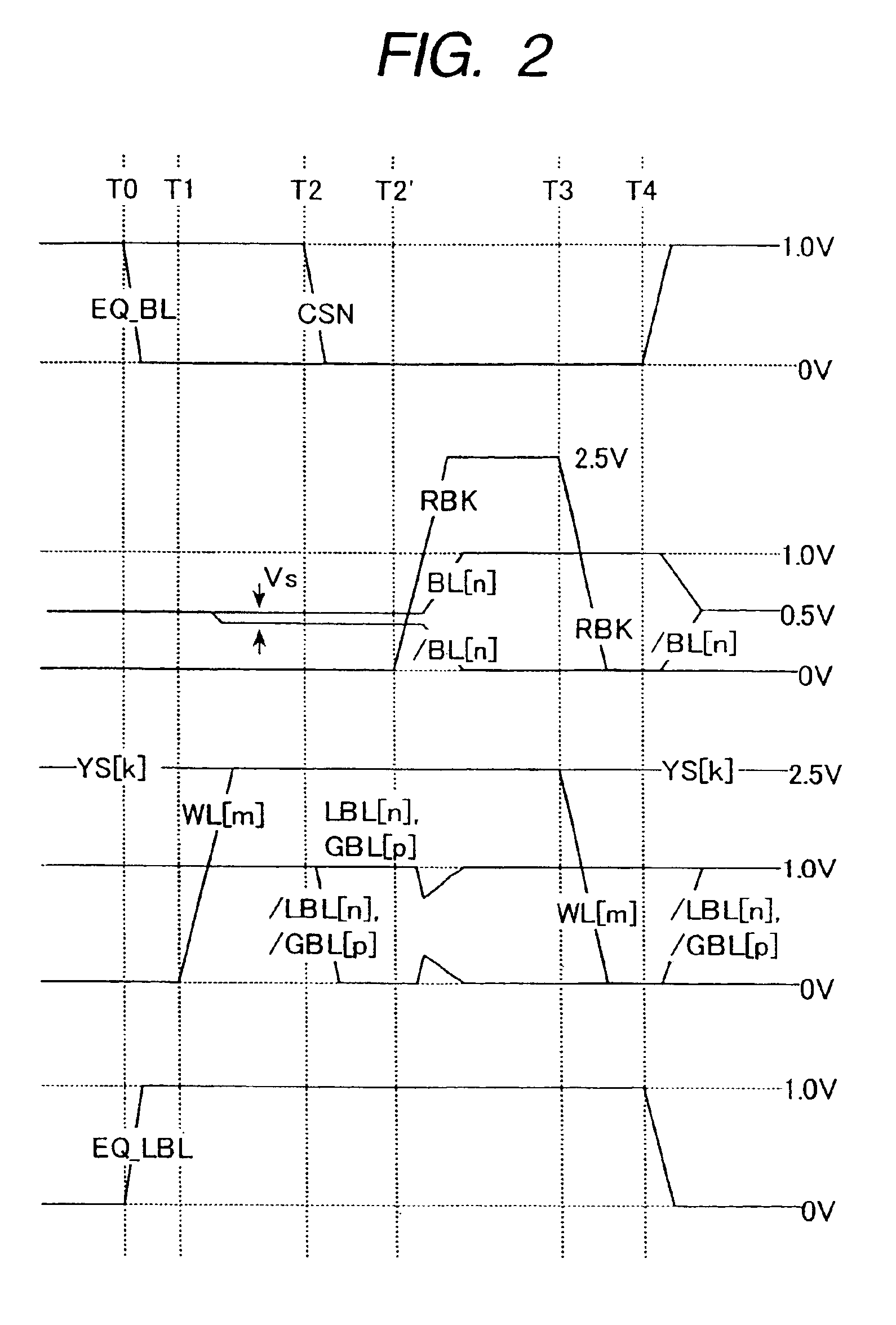

Semiconductor device

The present invention provides a sense circuit for DRAM memory cell to cover the events that a sense time becomes remarkably longer when a power source voltage is lowered, a sense time under the low voltage condition becomes shorter when temperature rises and a sense time changes to a large extent for fluctuation of processes. The present invention provides the following typical effects. A switch means is provided between the bit line BL and local bit line LBL connected to the memory cells for isolation and coupling of these bit lines. The bit line BL is precharged to the voltage of VDL / 2, while the local bit line LBL is precharged to the voltage of VDL. The VDL is the maximum amplitude voltage of the bit line BL. A sense amplifier SA comprises a first circuit including a differential MOS pair having the gate connected to the bit line BL and a second circuit connected to the local bit line LBL for full amplitude amplification and for holding the data. When the bit line BL and local bit line LBL are capacitance-coupled via a capacitor, it is recommended to use a latch type sense amplifier SA connected to the local bit line LBL.

Owner:RENESAS ELECTRONICS CORP

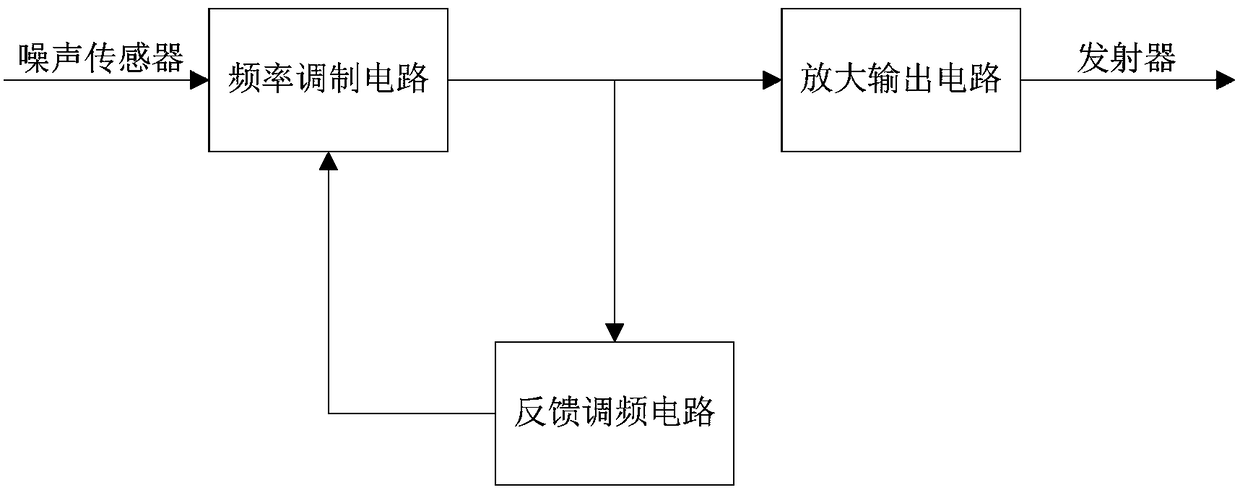

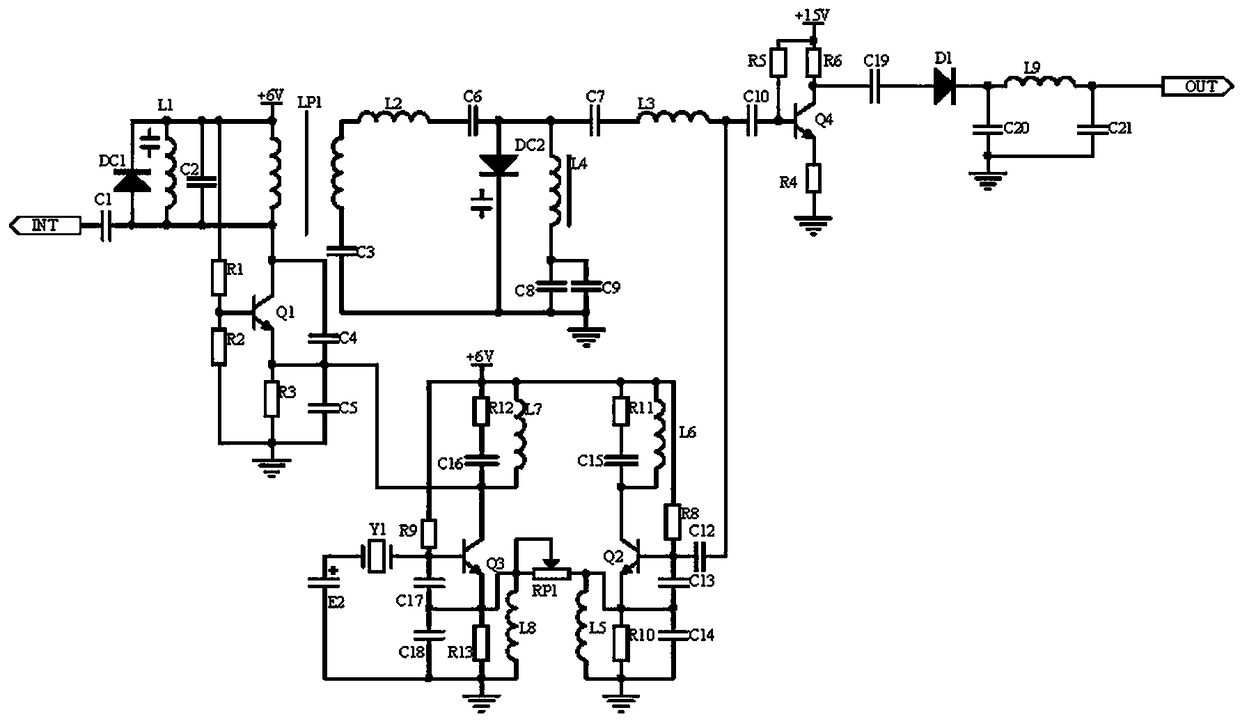

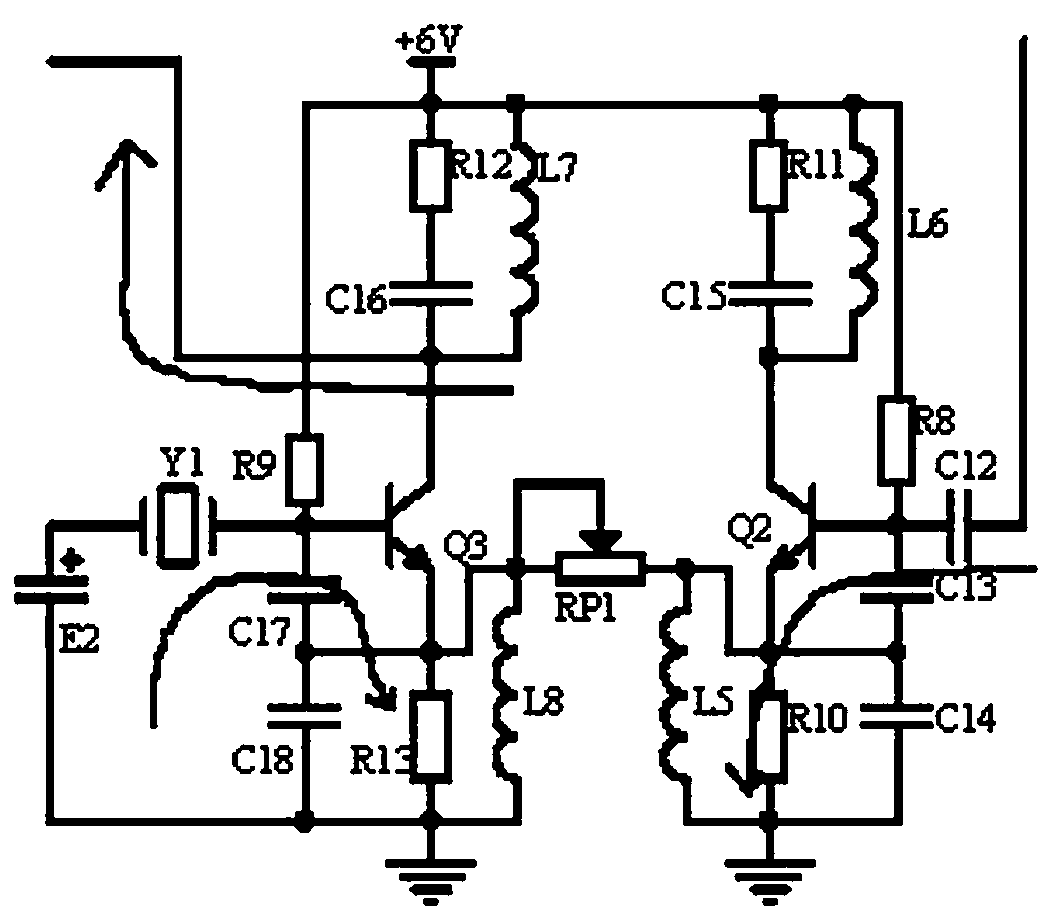

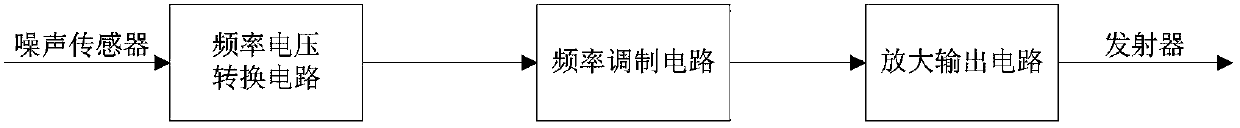

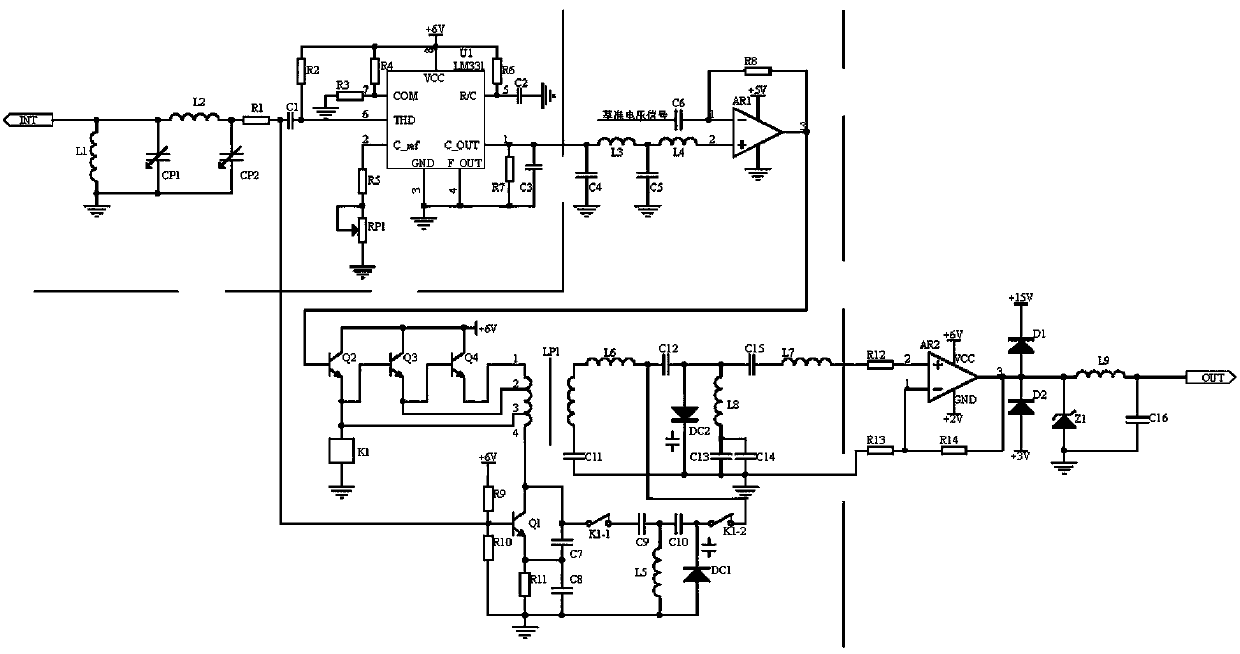

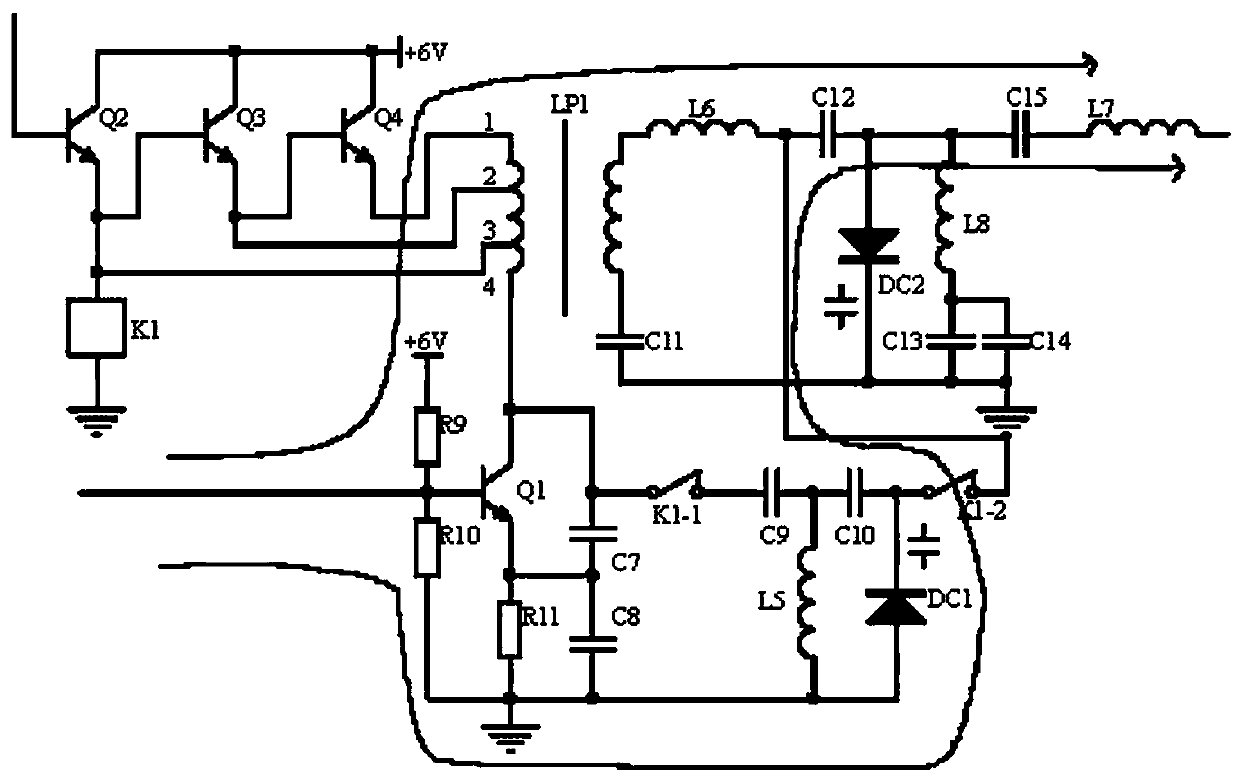

Real-time transmission device for noise measurement data

ActiveCN109443520AGuaranteed stabilityReduced susceptibility to electromagnetic noiseSubsonic/sonic/ultrasonic wave measurementUsing electrical meansLow frequency bandFrequency multiplier

The invention discloses a real-time transmission device for noise measurement data. A frequency modulation circuit resonates with a received 200-1000Hz frequency signal output by a noise sensor with amodel GSD130 through a resonance circuit to generate a resonance frequency. Then the device obtains a frequency signal corresponding to measurement noise and modulates the 450MHz oscillation frequency generated by an LC oscillator with a transistor Q1 and an oscillation coil LP1 as the core. Then the modulated signal is multiplied by two times through a frequency multiplier, and one path of the modulated signal enters the feedback frequency modulation circuit and the frequency offset signal of the resonant frequency of the output signal and the resonant frequency of the reference frequency signal is multiplied back to the LC oscillator by the differential circuit of the transistor Q2 and Q3 as the core, so that the modulated frequency signal is tailored to the best mine transmission frequency-900MH. The other path enters the amplification output circuit and is processed by amplitude amplification, unidirectional conduction, and pi-type filter circuit, and then applied to the transmitter. The real-time transmission device for noise measurement data effectively solves the problems that the transmitter is easy to be interfered and attenuated by electromagnetic noise in the processesof low-frequency band transmission and signal transmission of the transmitter.

Owner:河南鑫安利职业健康科技有限公司

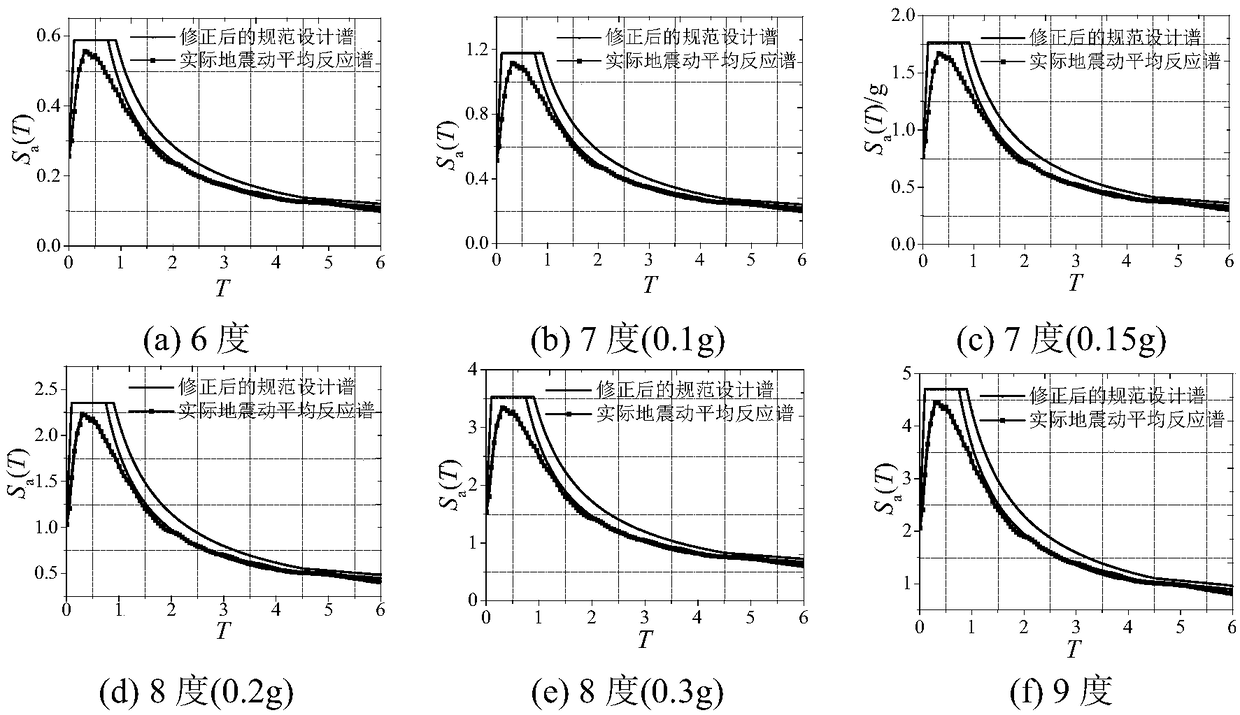

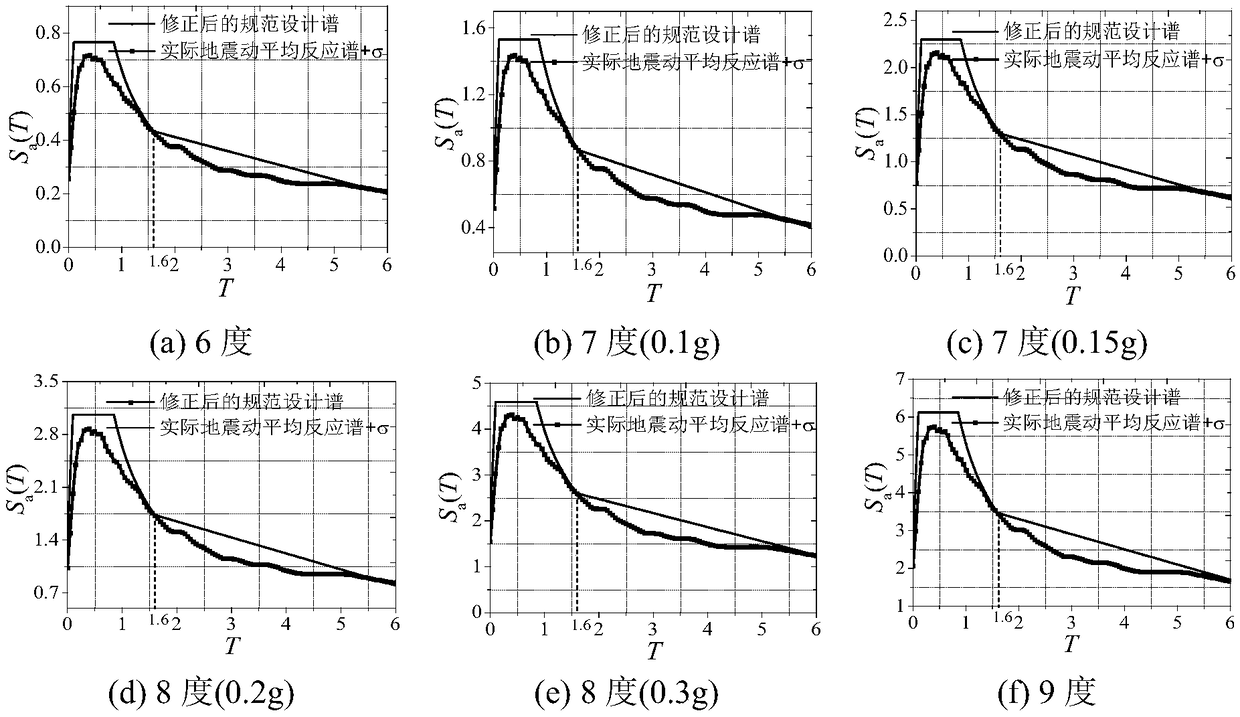

Near-fault aseismic design spectrum correcting method based on China seismic code

ActiveCN108256236AEasy to acceptEasy to useGeometric CADSpecial data processing applicationsComputer architectureNear fault

The invention discloses a near-fault aseismic design spectrum correcting method based on the China seismic code, and relates to the field of building structure aseismic design. In order to solve the problem that an aseismic design spectrum in the China current 'code for seismic design of building' (GB50011-2010) does not consider the near-fault effect insufficiently, correction considering the near-fault effect on the basis of the code for the aseismic design spectrum is put forward. Code aseismic design spectrum control parameters corresponding to frequent earthquakes are corrected; the obtained code design spectrum amplitude is multiplied by the spectrum amplitude amplification coefficient, the obtained characteristic period Tg of the code design spectrum is adjusted to a characteristicperiod Tg limit; adjusting coefficients for the 50% assurance rate and the 84% assurance rate are put forward, and adjustment is performed on the basis of the seismic code design spectrum. The application range is the aseismic design of the near-fault region building structure.

Owner:HARBIN INST OF TECH

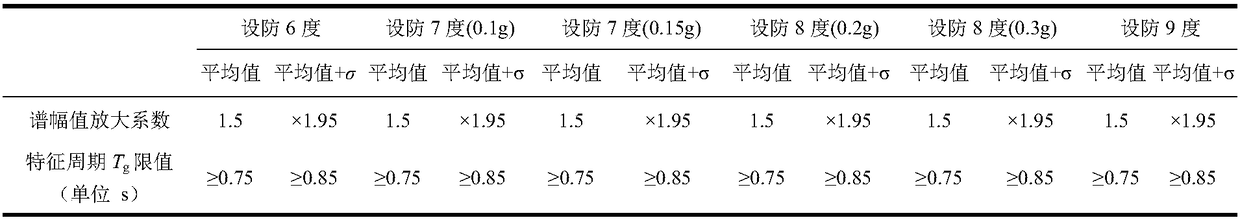

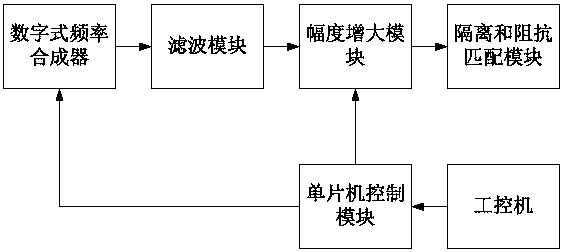

DDS-based aero-engine rotation speed sensor simulation device and method

InactiveCN108414790ASimple structureEasy to operateEngine testingTesting/calibration of speed/acceleration/shock measurement devicesMicrocontrollerAviation

The invention discloses a DDS-based aero-engine rotation speed sensor simulation device and method. The device comprises an industrial personal computer, a digital frequency synthesizer, a filter module, an amplitude amplification module, an isolation and impedance matching module and a single chip control module. The digital frequency synthesizer, the filter module, the amplitude amplification module and the isolation and impedance matching module are sequentially connected. The single chip control module is connected with the digital frequency synthesizer, the amplitude amplification moduleand the industrial personal computer. The invention further discloses the steps of the use method of the device. The device and method have the advantages of simple structure and convenient operation,and can overcome the disadvantages of inconsistency between amplitude generated by a standard signal generator and a real engine rotation speed signal, common difference between output impedance anda real sensor, poor flexibility, compatibility and impedance matching and difficult program control and system integration.

Owner:四川海特亚美航空技术有限公司

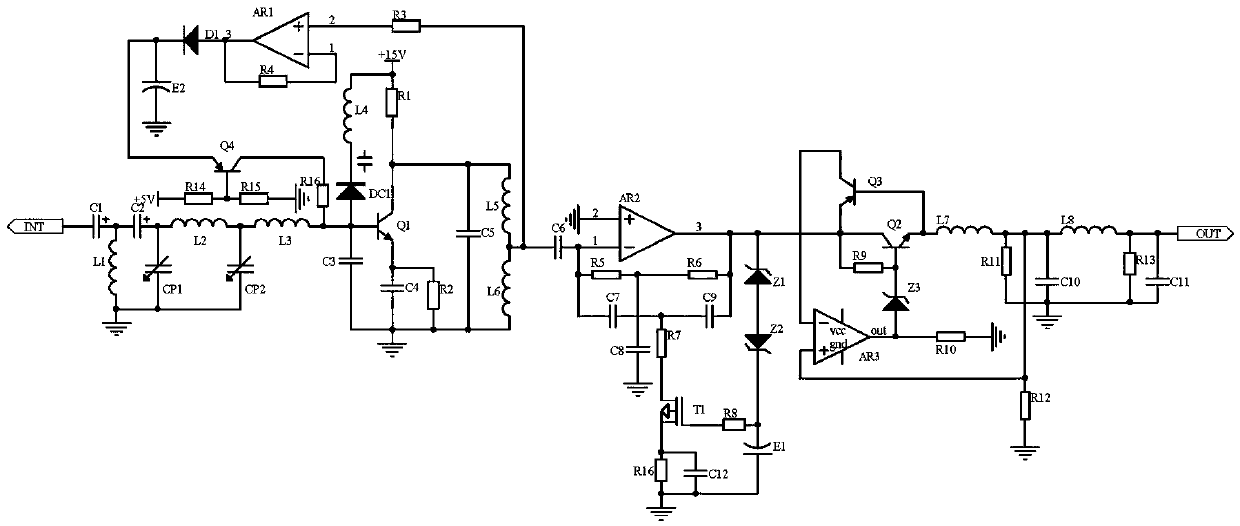

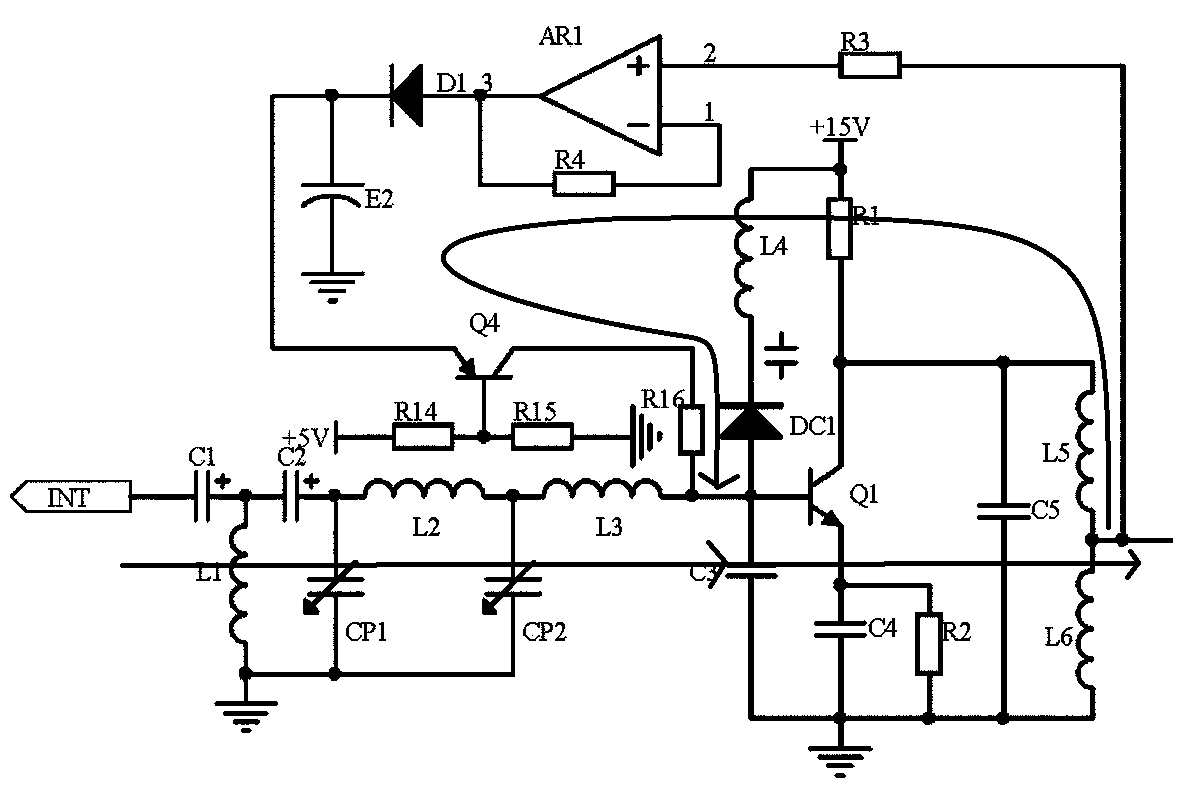

Monitoring device for real-time feedback of body indexes of special operation personnel

ActiveCN109512400AImprove stabilityHigh precisionDiagnostic recording/measuringSensorsPeak valueImpedance matching

The invention discloses a monitoring device for real-time feedback of the body indexes of special operation personnel. A first-stage amplitude modulation circuit receives weak body index signals of special operation personnel transmitted by a network signal transmission channel, and by means of an oscillator with triode Q1 as the core, the received weak signal positive feedback is subjected to primary amplitude amplification, wherein peak detection circuit feedback is applied to ensure the signal subjected to primary amplification meets the requirements of a post-stage circuit amplitude, and then the signal enters a second-stage amplitude modulation circuit, a double-T frequency selection network is employed as the feedback resistance of an operational amplifier AR2 for amplified amplitudemodulation of the signal, the feedback depth is adjusted by an MOS transistor T1, and the signal meeting the requirement of a body index monitoring server for a signal amplitude ranging from 0V to +5V is output, finally the signal enter an amplitude stabilized output circuit, through voltage stabilization by a feedback voltage stabilizing circuit and filtering by LC, an impedance matching circuitand a transmission line connected to the monitoring server achieve impedance matching, and the signal is transmitted to the monitoring server without attenuation. The monitoring device effectively solves the problem of imprecision of signal received by the monitoring server.

Owner:河南鑫安利职业健康科技有限公司

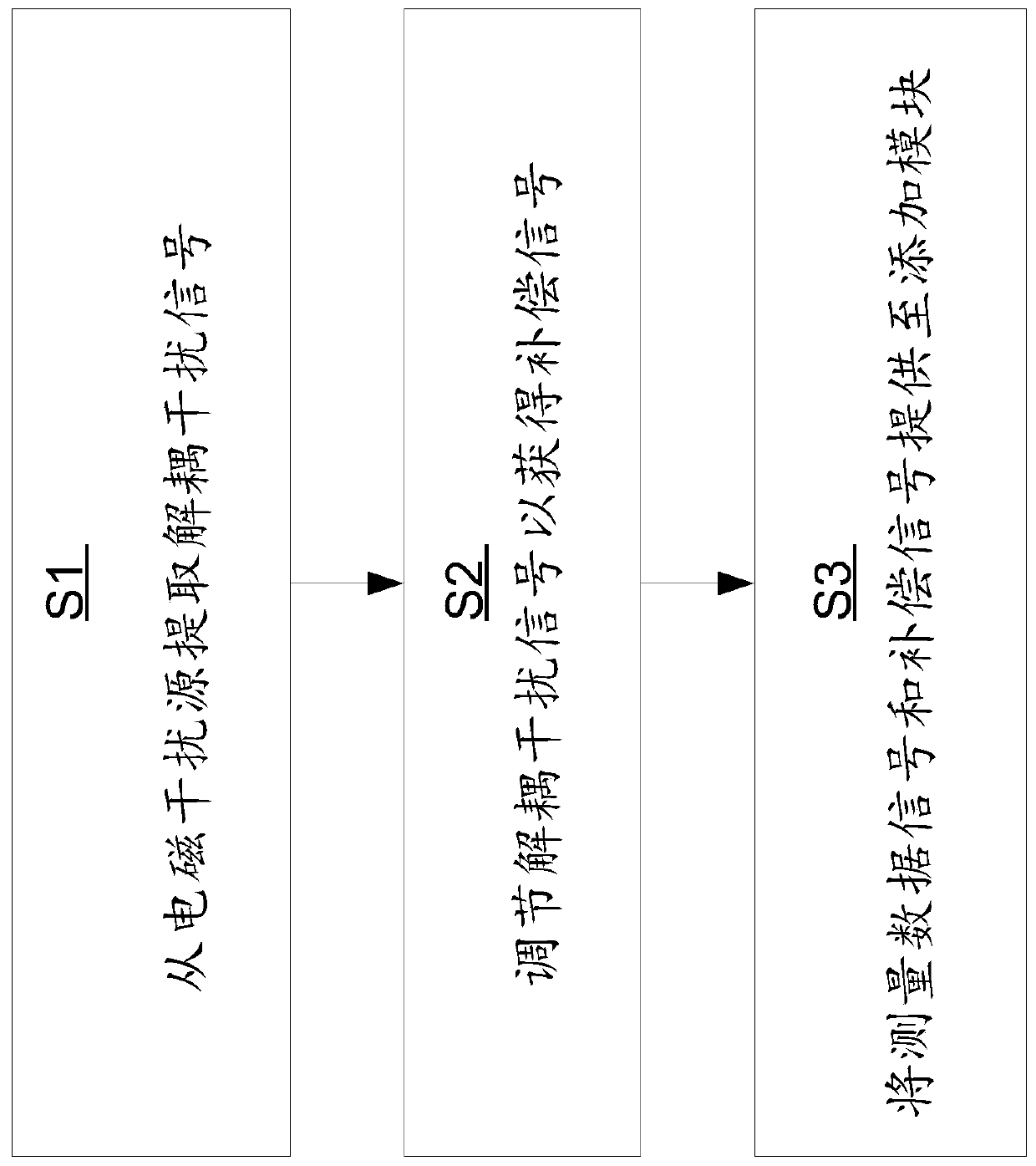

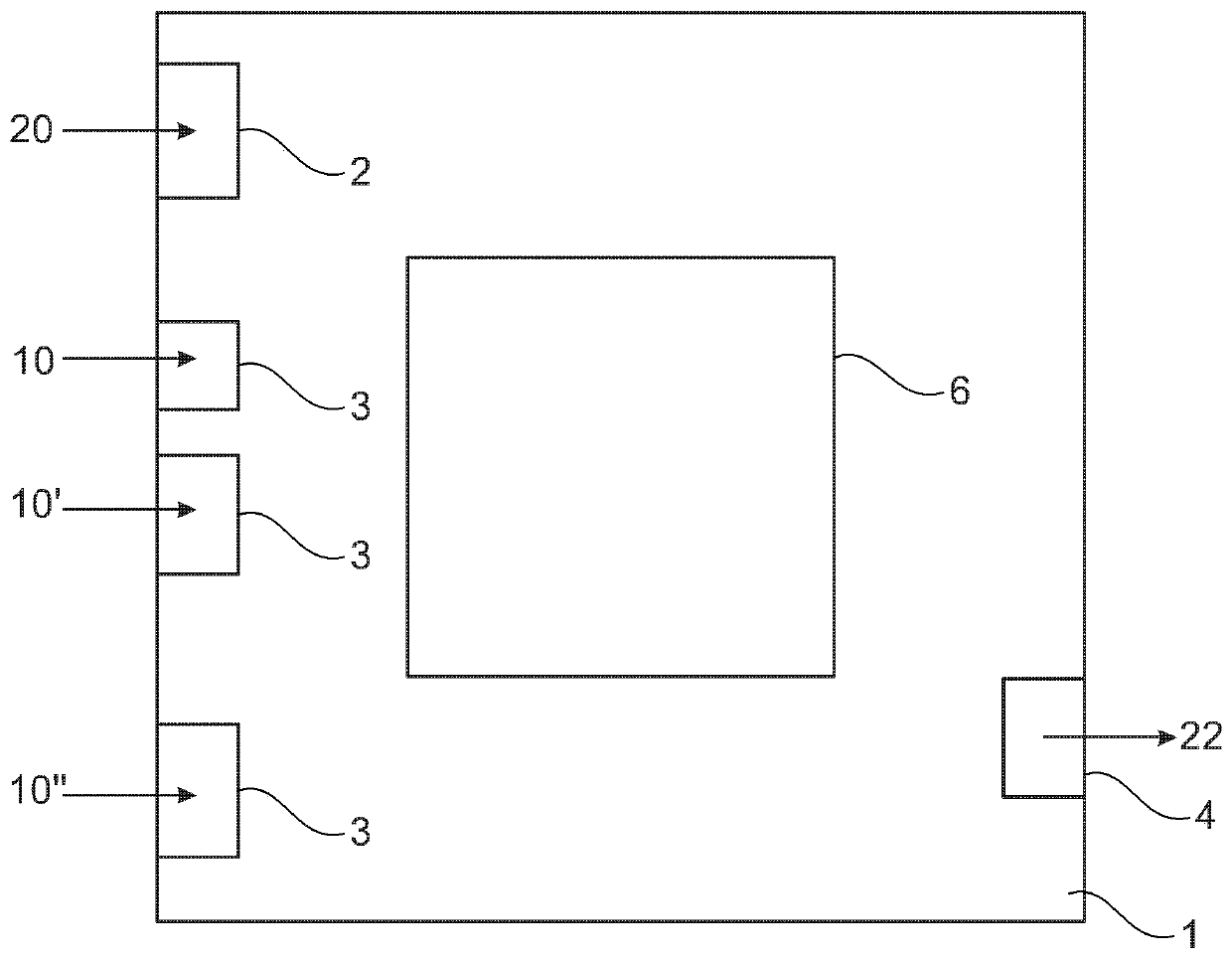

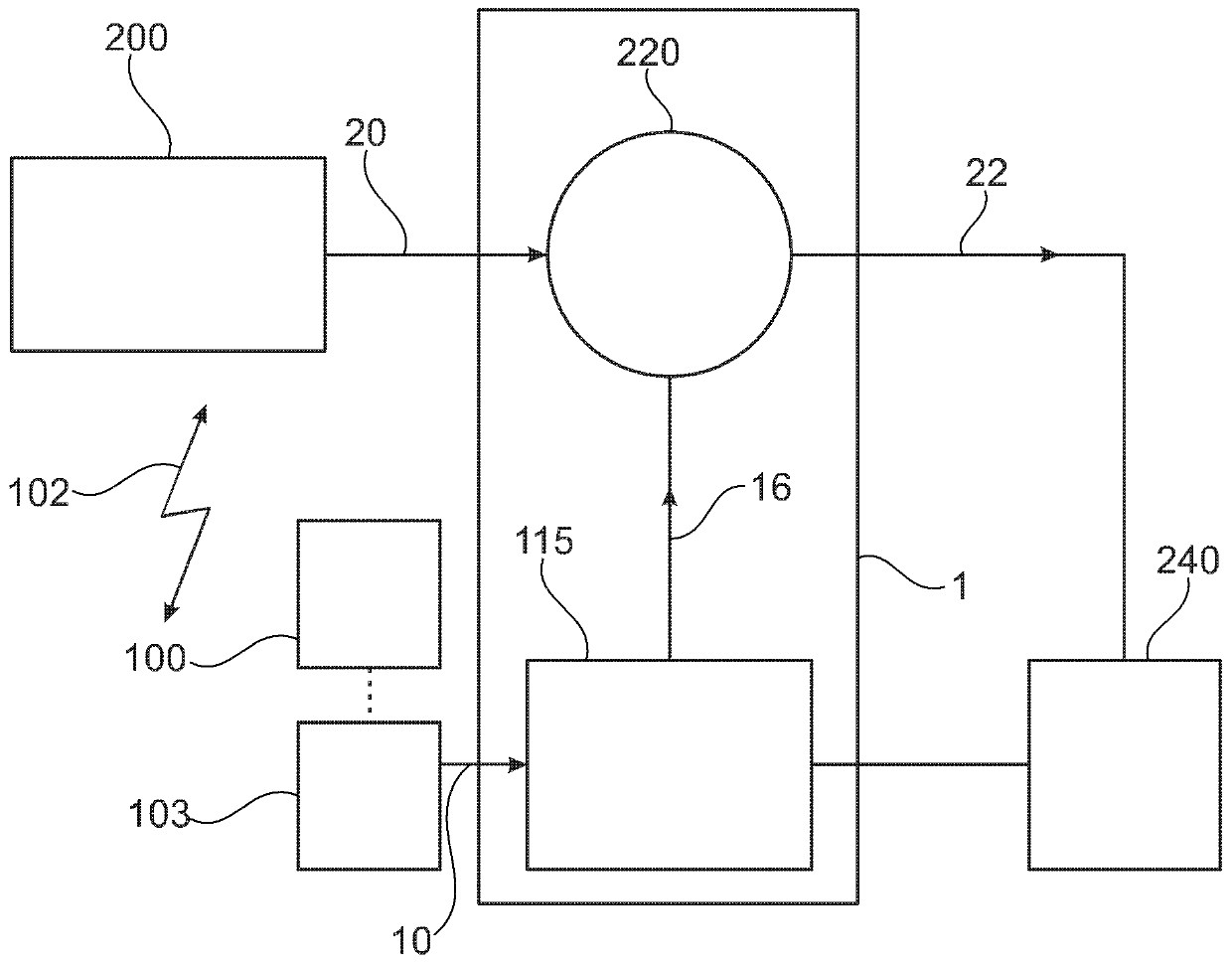

Method and device for crosstalk compensation

ActiveCN109962004AStability-of-path spectrometersSpectrometer detectorsTransformerFourier transform on finite groups

The invention discloses a method for eliminating an added crosstalk signal 102 from a measured data signal 20 which is generated by an image current, preferably in a Fourier transform mass spectrometer. The method comprises: extracting a decoupled disturbance signal 10 from the source 100 of electromagnetic disturbance which is inducing the added crosstalk signal; conditioning the disturbance signal by applying one or more phase shifts and / or amplitude amplifications so as to obtain a compensation signal 16 that essentially corresponds to an inverted signal of the added crosstalk signal; and providing the measured data signal and the compensation signal to an adding module 220 in which said signals are superimposed. The extraction device 103 for extracting the decoupled disturbance signalmay be an impedance component such as an antenna or an additional winding of a transformer.

Owner:THERMO FISHER SCI BREMEN

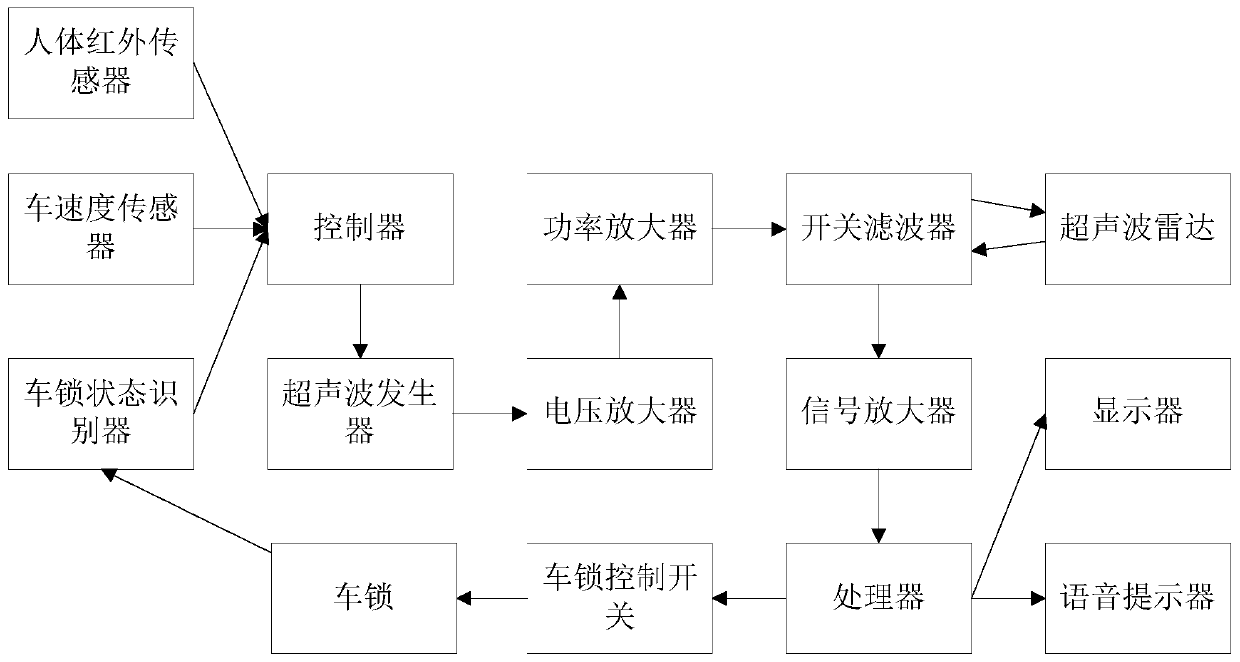

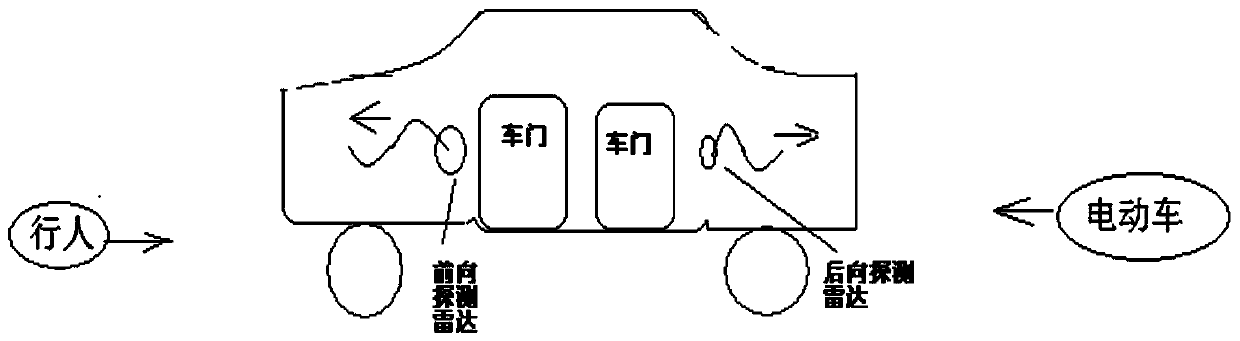

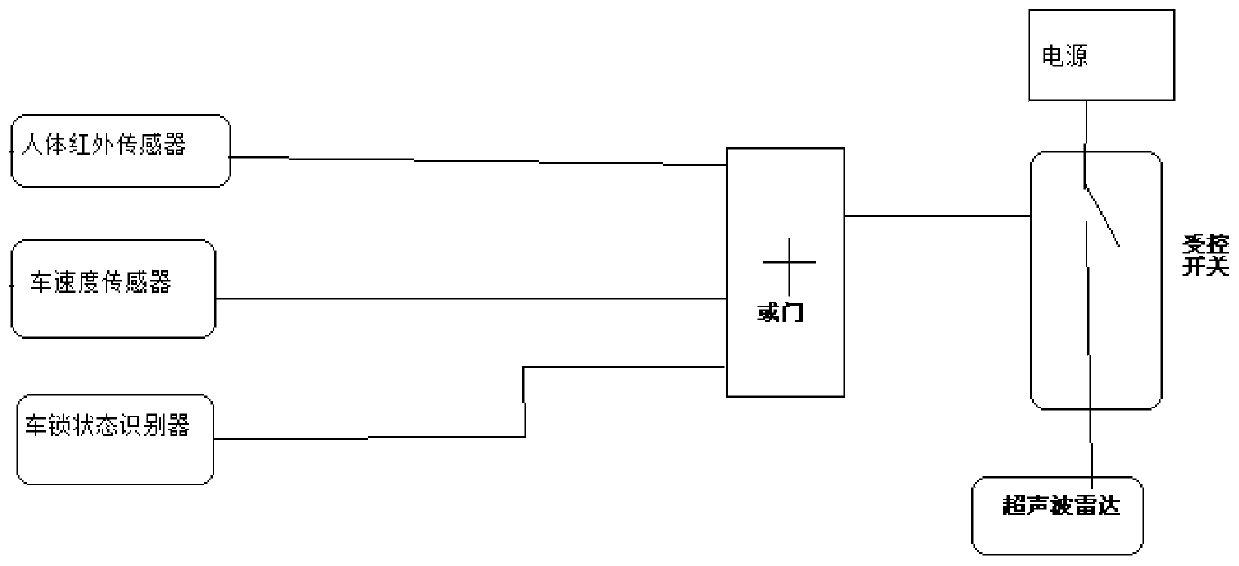

Vehicle door opening auxiliary monitoring system and method based on ultrasonic radar

InactiveCN109835249AAvoid traffic accidentsReduce traffic accidentsSignalling/lighting devicesAcoustic wave reradiationDisplay deviceEngineering

The invention discloses a vehicle door opening auxiliary monitoring system and method based on ultrasonic radar. When a human body infrared sensor detects that a human body signal exists in a vehicleand a vehicle speed sensor detects that the vehicle speed is zero or a vehicle lock state recognizer detects that a vehicle lock is in an open state, a controller sends a starting instruction to an ultrasonic generator; the ultrasonic generator starts to send an ultrasonic signal after receiving the starting instruction, and the ultrasonic signal is subjected to amplitude amplification through a voltage amplifier; the current is amplified by a power amplifier, and is finally sent to the ultrasonic radar by a switch filter, and the ultrasonic radar sends out the signal; meanwhile, the ultrasonic radar receives a feedback signal, the feedback signal is amplified through a signal amplifier, the amplified signal is sent to a processor for signal processing, and the processing result is displayed to people in the vehicle through the display; the people in the vehicle are reminded to notice the dynamic states of pedestrians and vehicles around the current vehicle body through a voice prompter.

Owner:SHANDONG NORMAL UNIV

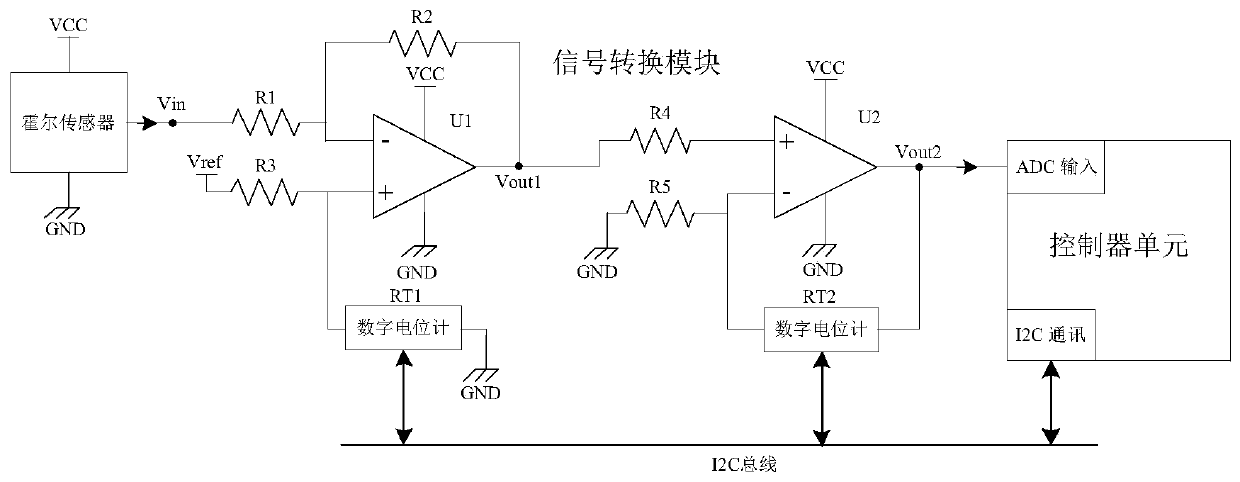

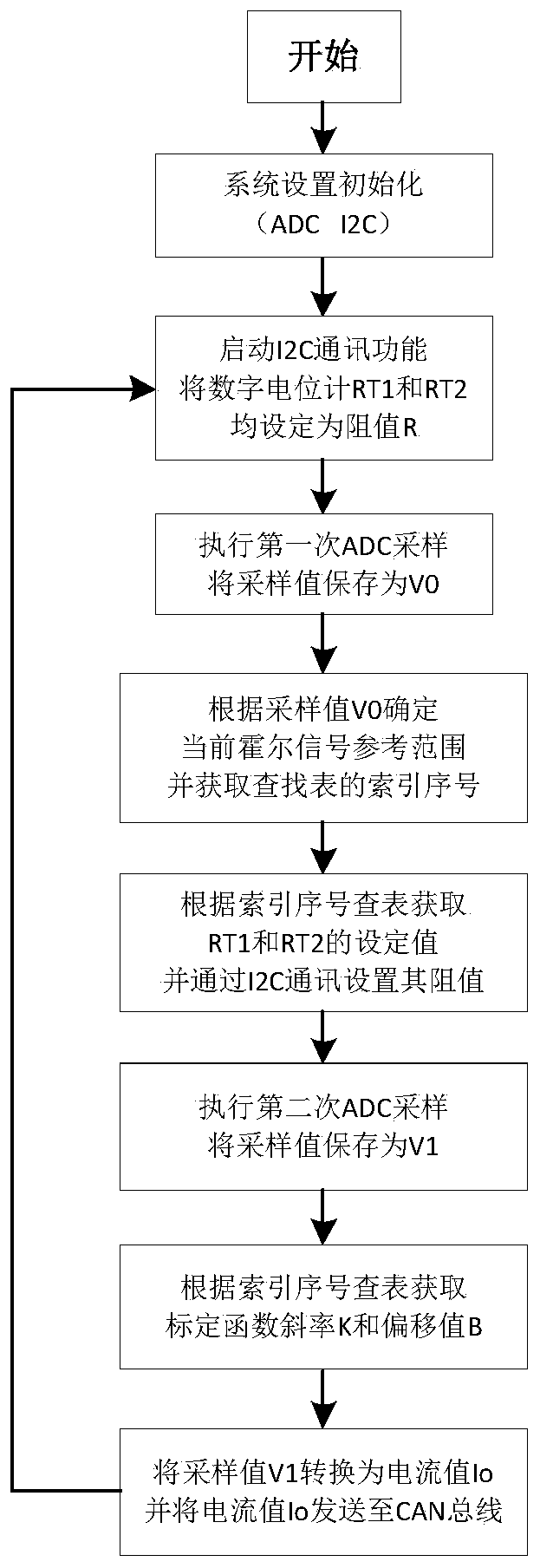

Hall signal measuring device and method with automatically adjustable detection range

ActiveCN109884377AHigh measurement accuracyResistance/reactance/impedenceElectrical testingCurrent sensorGain coefficient

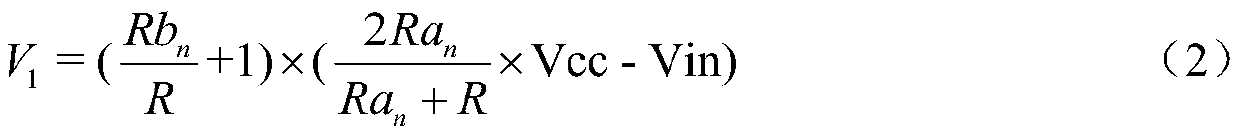

The invention provides a Hall signal measuring device with an automatically adjustable detection range. The Hall signal measuring device comprises a signal conversion module and a controller unit, wherein the signal conversion module is used for adjusting and outputting a signal measured by a Hall sensor, and the controller unit is used for determining the current value of the Hall sensor by adjusting the reference voltage and gain changes of the signal conversion module; the signal conversion module comprises a zero adjustment circuit and an amplitude amplification circuit which are connected, wherein the controller unit controls the reference voltage in the zero adjustment circuit to adjust the zero bias voltage of the output signal of the Hall sensor, the controller unit controls the gain coefficient of the amplitude amplification circuit to adjust the magnitude of the output signal of the Hall sensor; and the Hall sensor is a voltage output type Hall current sensor.

Owner:常州是为电子有限公司

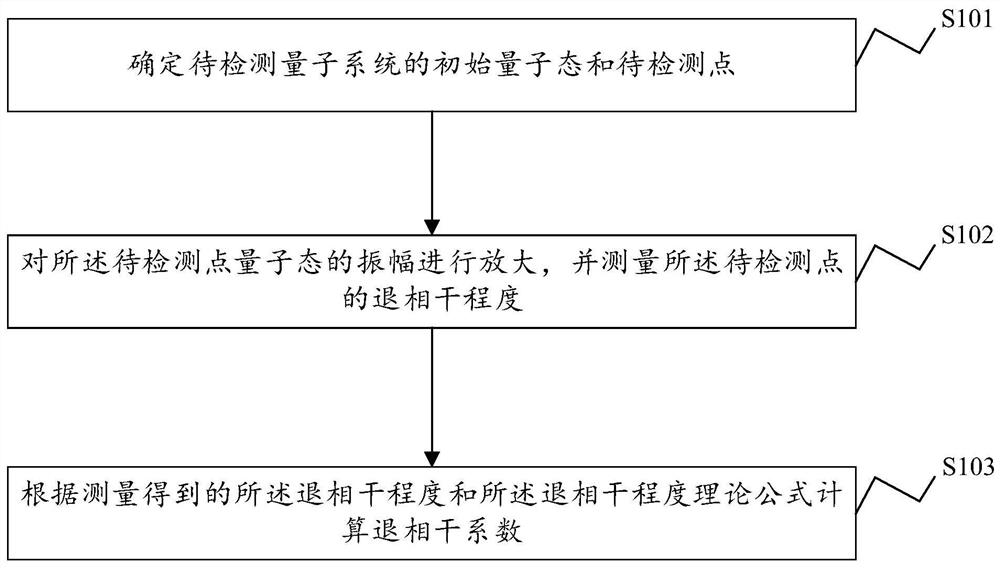

Quantum decoherence degree detection method and device, electronic equipment and storage medium

ActiveCN112270411AEfficient decoherence analysis methodQuantum computersParticle physicsCoherence analysis

The invention discloses a quantum decoherence degree detection method and device, electronic equipment and a computer readable storage medium. The method comprises the steps of determining an initialquantum state and a to-be-detected point of a to-be-detected quantum system; amplifying the amplitude of the quantum state of the to-be-detected point, and measuring the decoherence degree of the to-be-detected point; and calculating a decoherence coefficient of the to-be-detected quantum system according to the decoherence degree. According to the quantum decoherence degree detection method provided by the invention, the amplitude of the quantum state of the to-be-detected point in the to-be-detected quantum system is amplified, and the probability of the amplitude is measured to measure thedecoherence degree of the to-be-detected point. Meanwhile, the decoherence coefficient of the to-be-detected quantum system can be quantitatively calculated according to the measured decoherence degree. Therefore, the quantum decoherence degree detection method provided by the invention provides an effective quantum system decoherence analysis method.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

Transmitter modulation device for real-time transmission of noise measurement data

ActiveCN109639295AHigh precisionGuaranteed stabilityTransmissionFrequency multiplierLow frequency band

The invention discloses a transmitter modulation device for real-time transmission of noise measurement data. A frequency-voltage conversion circuit resonates with a 200-1000 Hz frequency signal outputted by a received noise sensor via a resonance circuit to obtain a frequency signal corresponding to the measurement noise, then the frequency signal is converted by a frequency-voltage converter into a 2V-6V voltage signal, a frequency modulation circuit receives the frequency signal generated by the resonant circuit and obtains the undamped 2V-6V voltage signal through an impedance matching circuit, the 2V-6V voltage signal is input to an adder to obtain a frequency deviation signal, modulation is performed through 450MHz oscillation frequency or the modulation is performed through adjustable oscillation frequency, the accuracy of frequency modulation is improved, the modulated signal is multiplied by a frequency multiplier by 2 times and is finally modulated to optimal transmission frequency 900 MHz of a coal mine for transmission to finally enter an amplification output circuit, and the frequency signal is is added to transmitter after amplitude amplification, amplitude limiting,voltage stabilization and filtering. The problem that during the low frequency band transmission of the transmitter, a signal transmission process is susceptible to electromagnetic noise interferenceand attenuation is solved.

Owner:山东省安正安全咨询服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com