Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Enhanced transmission signal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

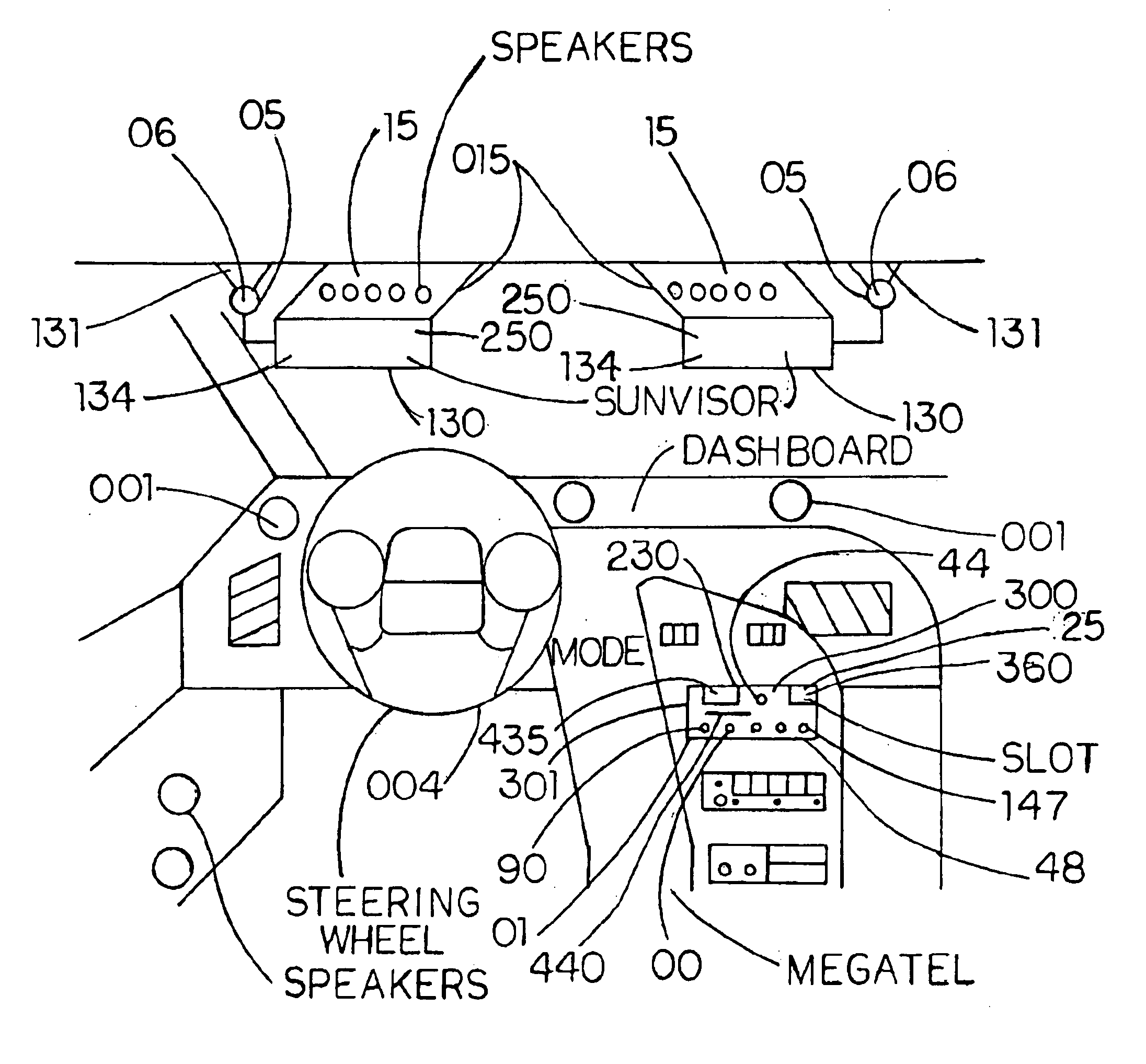

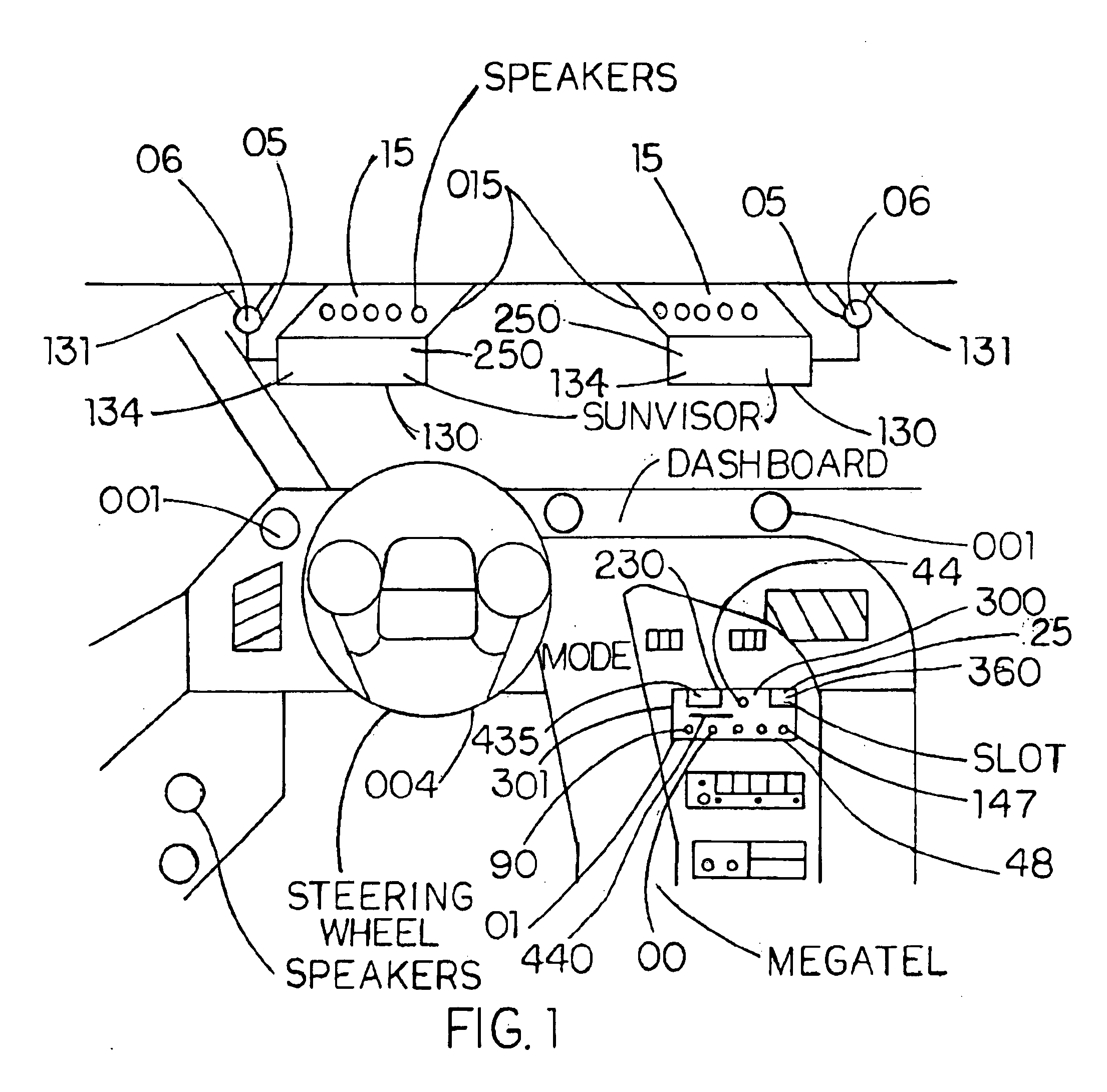

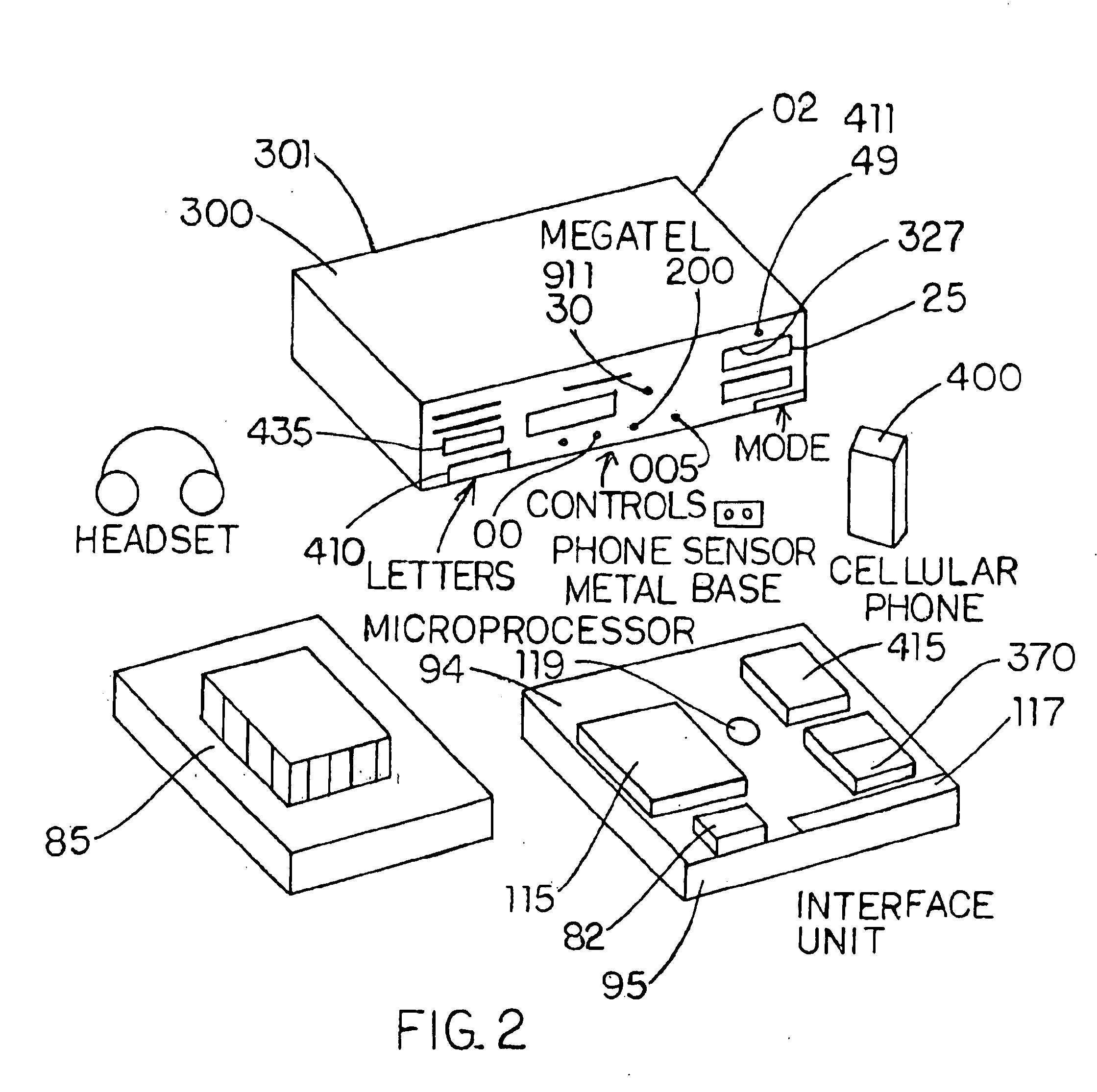

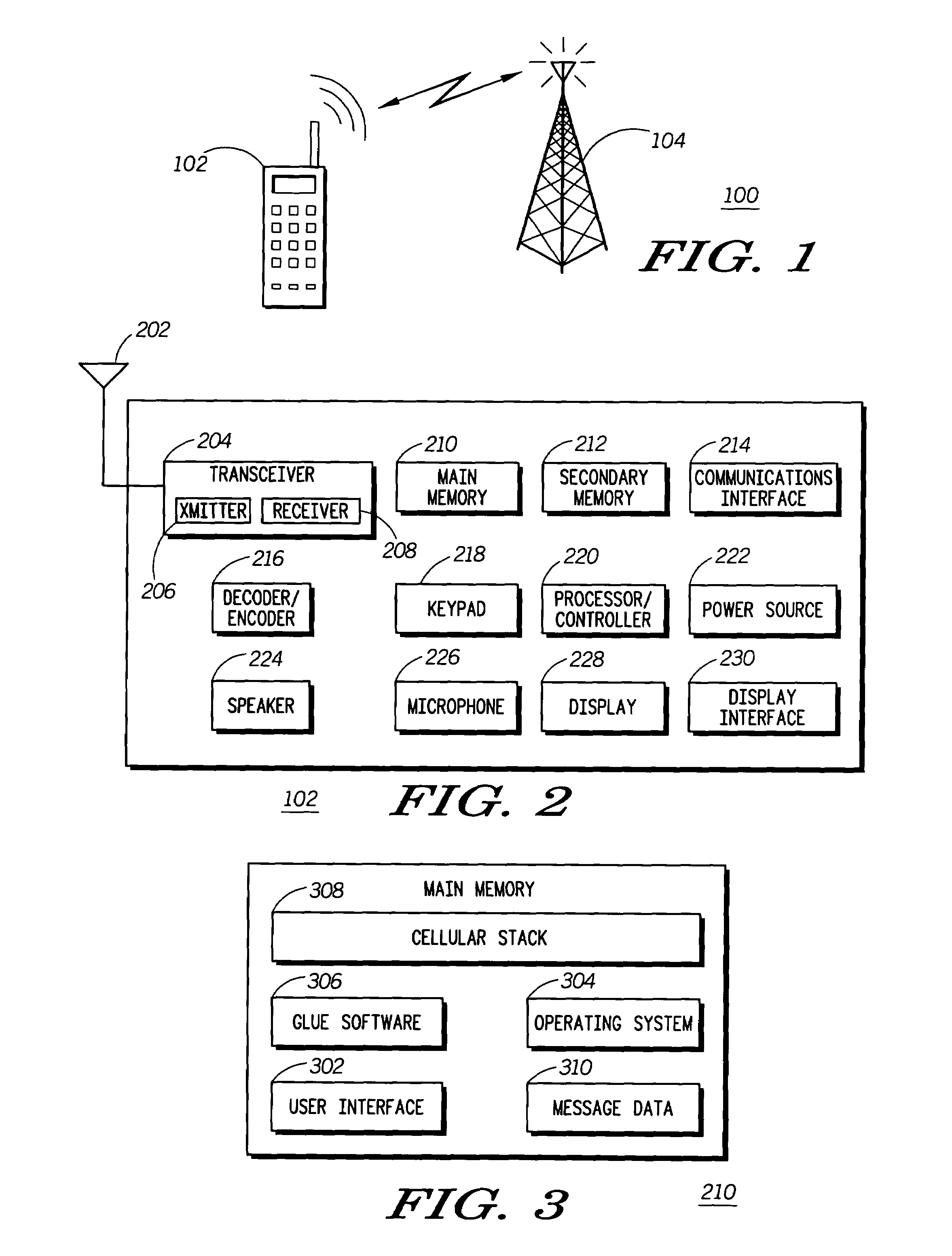

Megatel communication information system

InactiveUS6782240B1Reduction of pressure effectEnhanced informationSubstation speech amplifiersRadio transmissionThe InternetHands free

An entertainment device for vehicles adaptable to include various telecommunication and Internet applications, a sunviser monitoring screen for viewing, with an electronic screen protector for protecting the screen. The device, which is referred to as megatel, incorporates receivers and transmitters to enable cell phone and Internet transmission via the radio wave of an entertainment device radiated towards the antenna to the megatel body and output to the CPU. The signal to the CPU is controlled by the controller so that transmissions for the radio, the cell phone, and the Internet is separated and output to the monitoring screen and the speakers of the entertainment device so as to allow hands free communication while driving.

Owner:TABE JOSEPH A

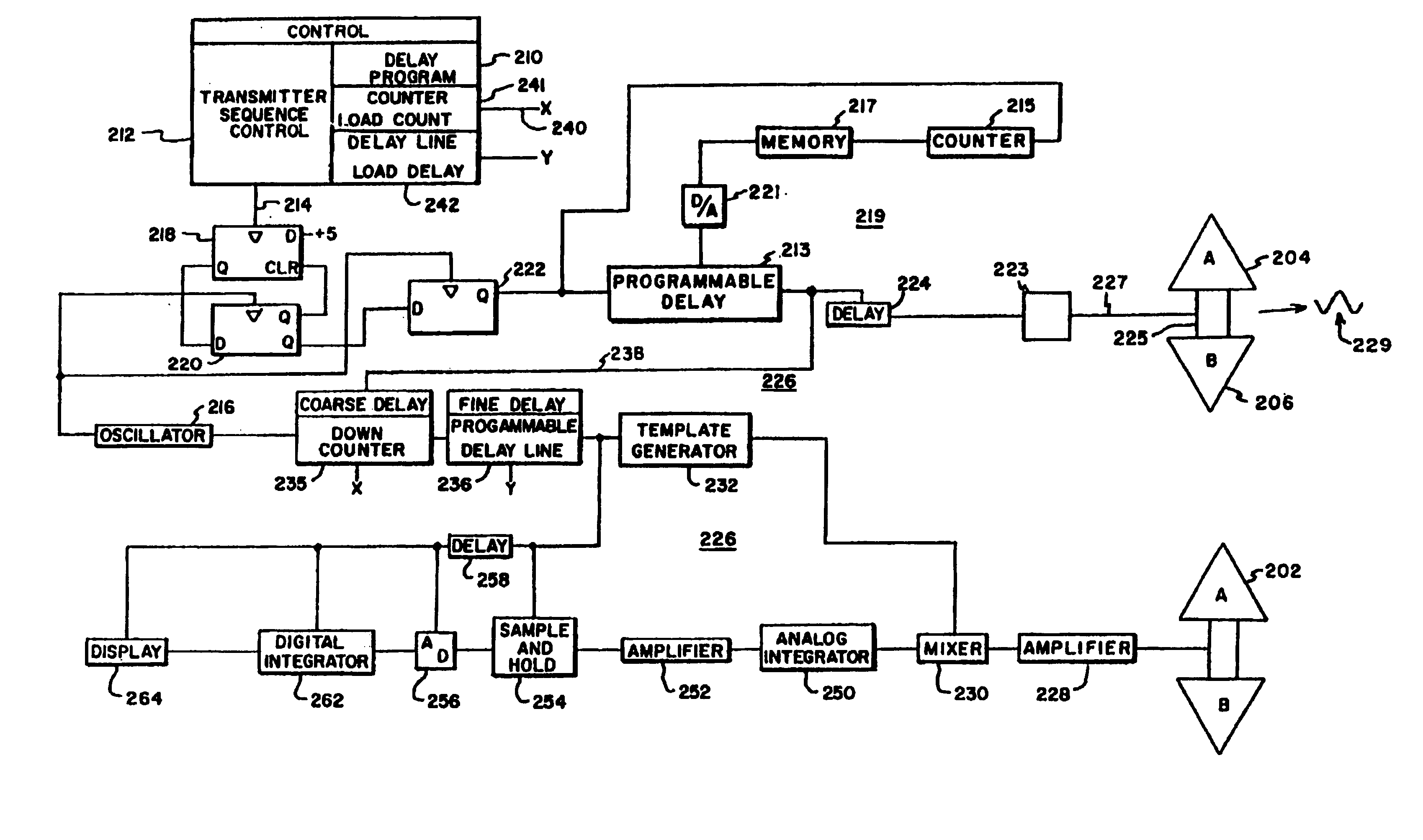

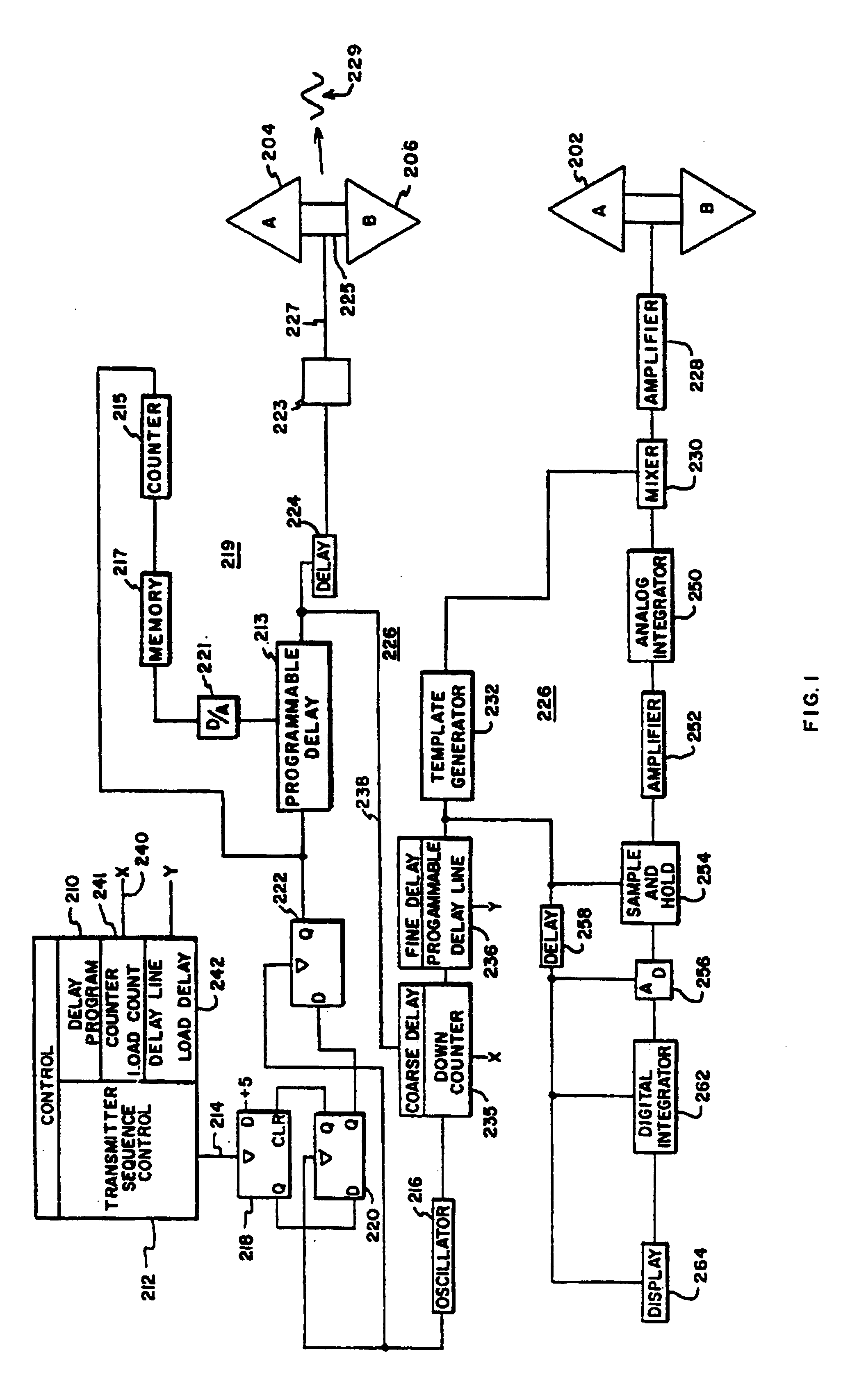

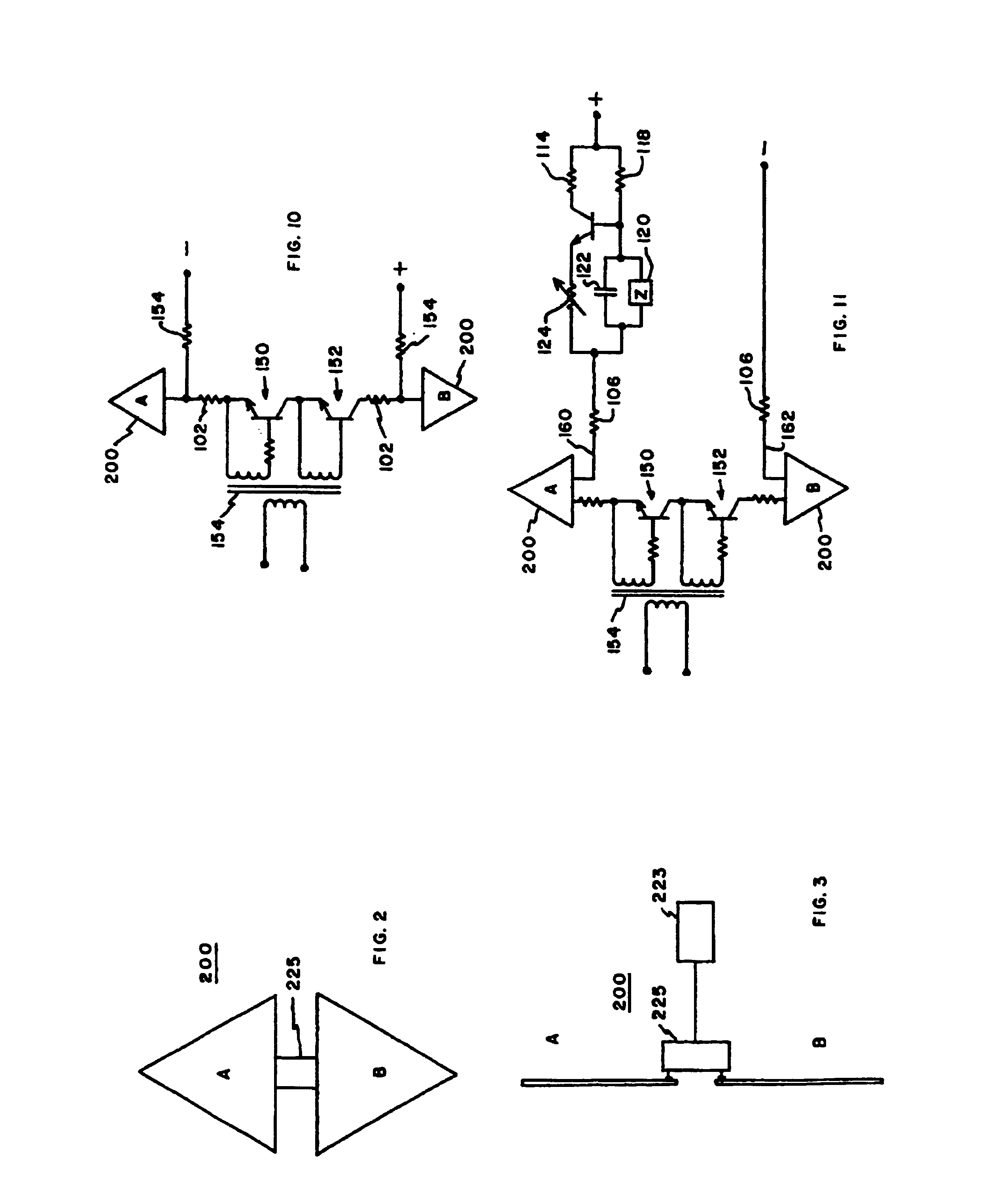

Time domain radio transmission system

InactiveUSRE39759E1Conveniently frequency modulationEliminate the effects ofSecret communicationIndividually energised antenna arraysTime domainCommunications system

A time domain communications system wherein a broadband of time-spaced signals, essentially monocycle-like signals, are derived from applying stepped-in-amplitude signals to a broadband antenna, in this case, a reverse bicone antenna. When received, the thus transmitted signals are multiplied by a D.C. replica of each transmitted signal, and thereafter, they are, successively, short time and long time integrated to achieve detection.

Owner:TIME DOMAIN

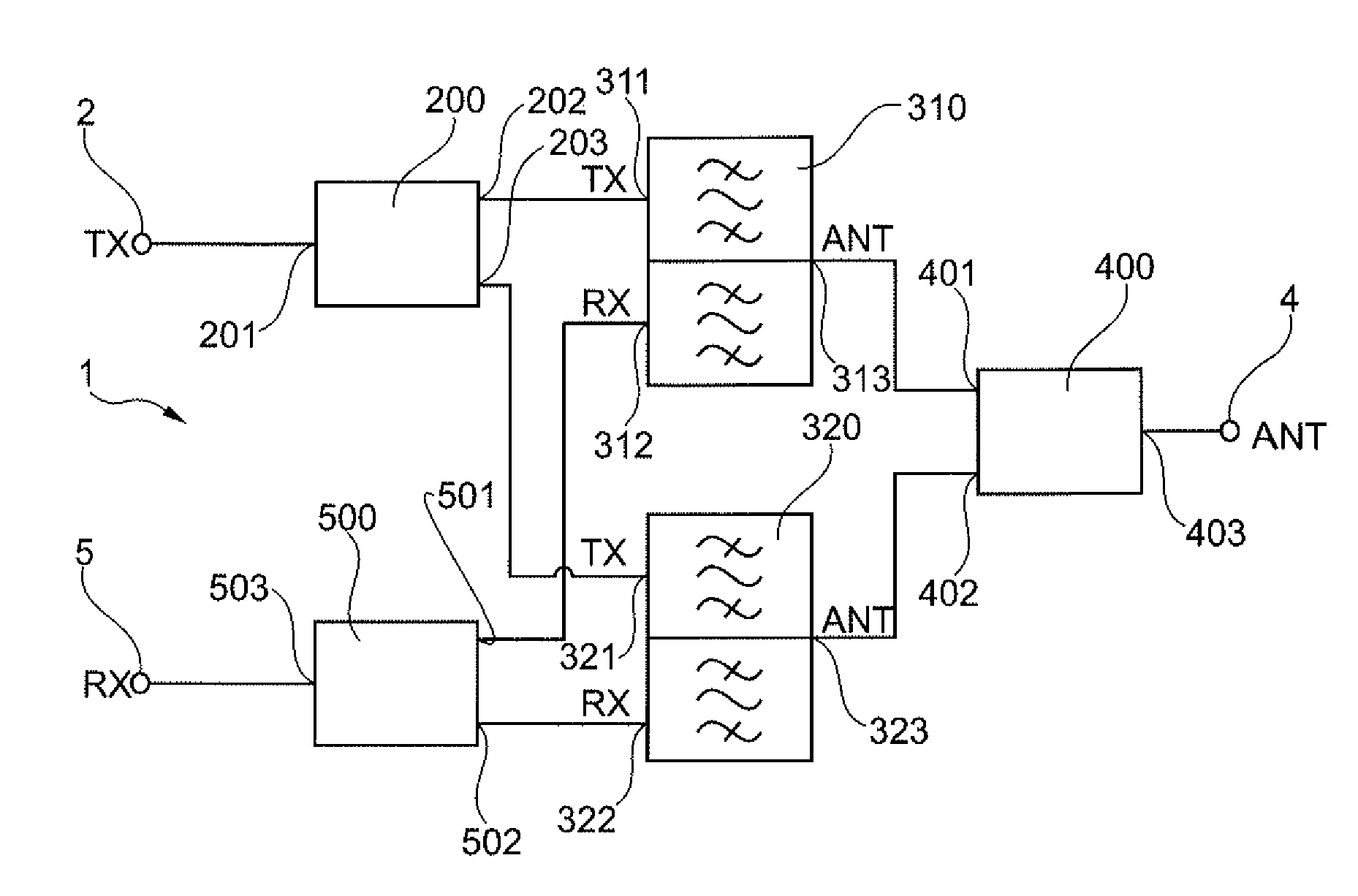

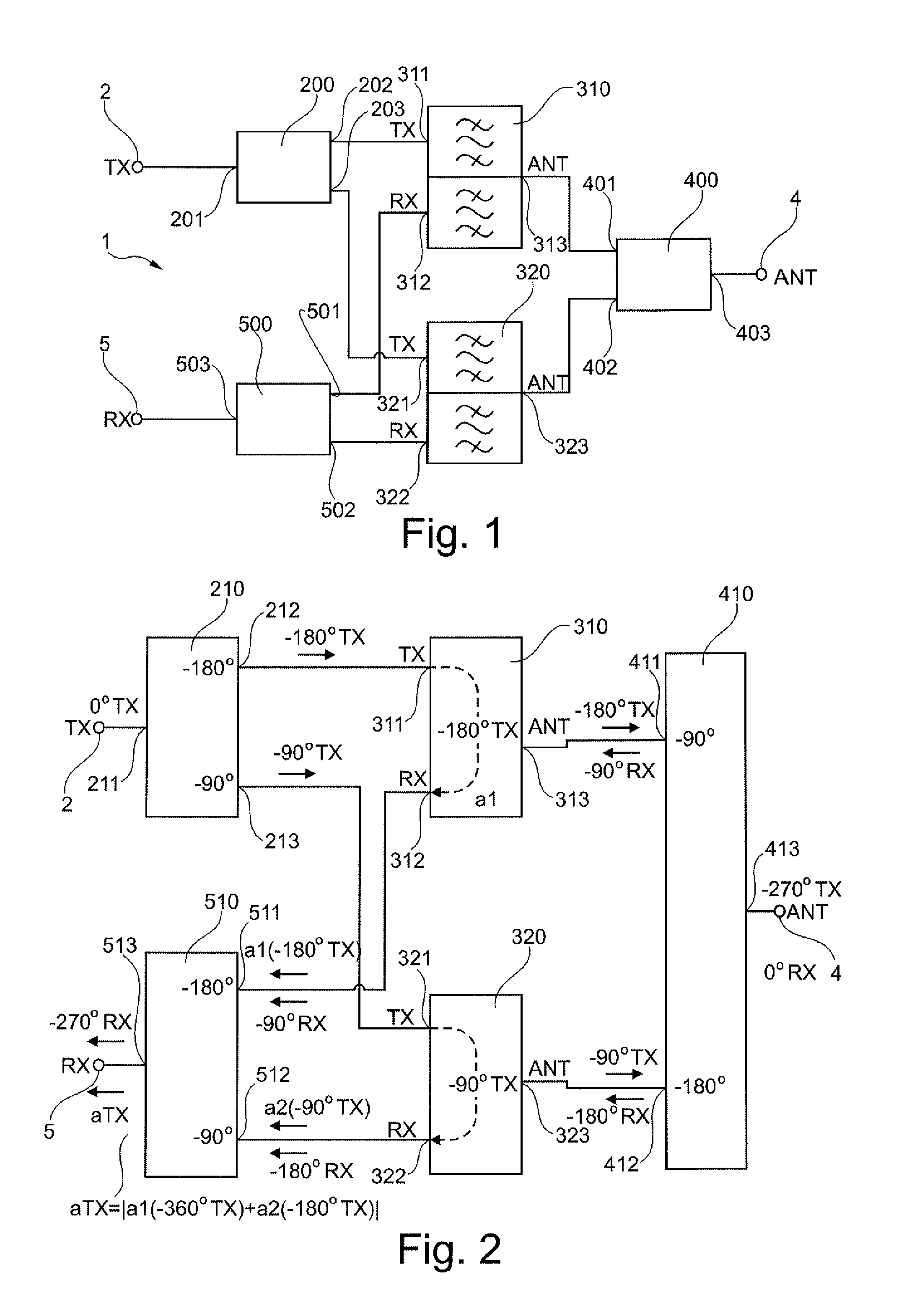

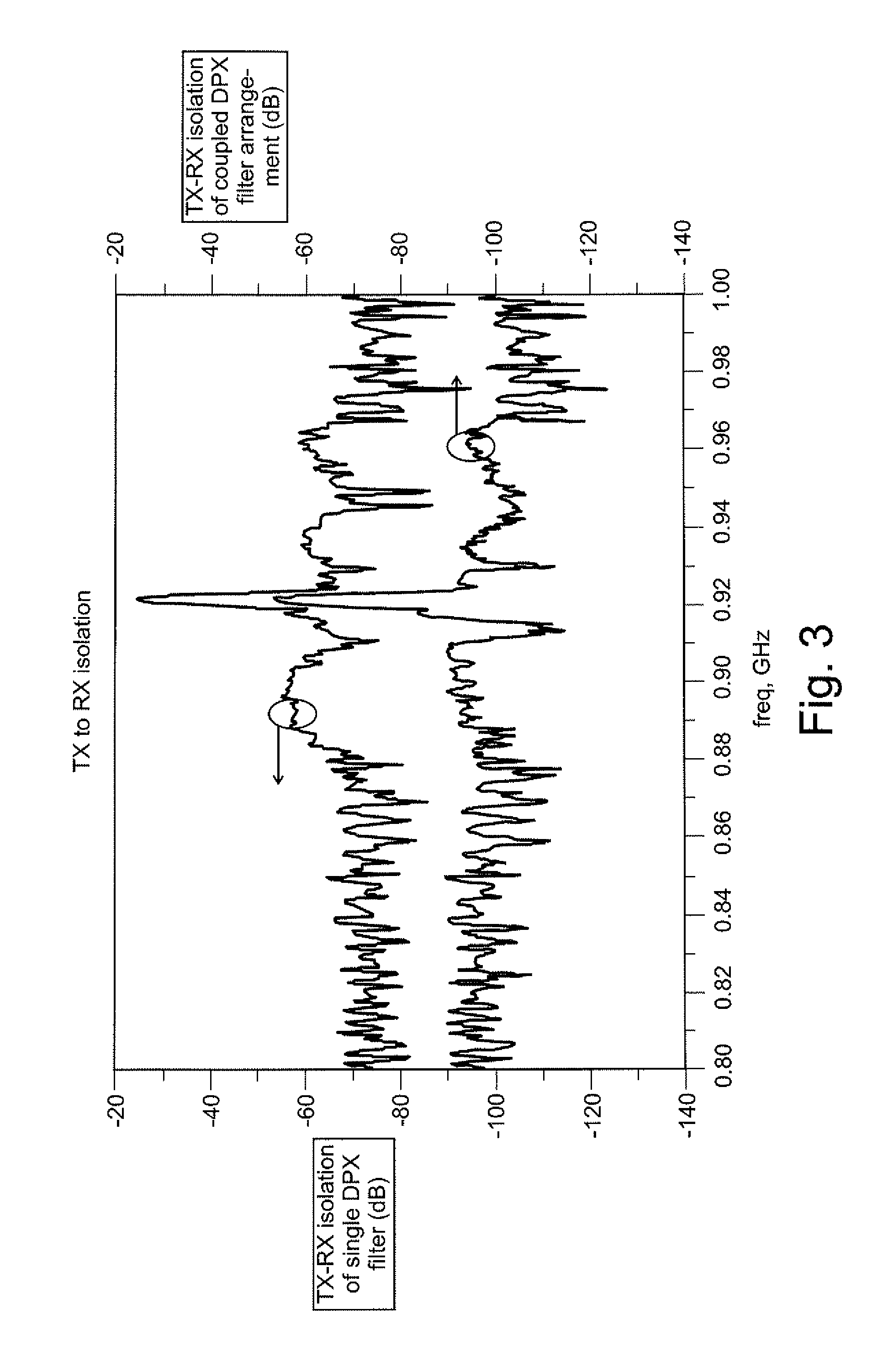

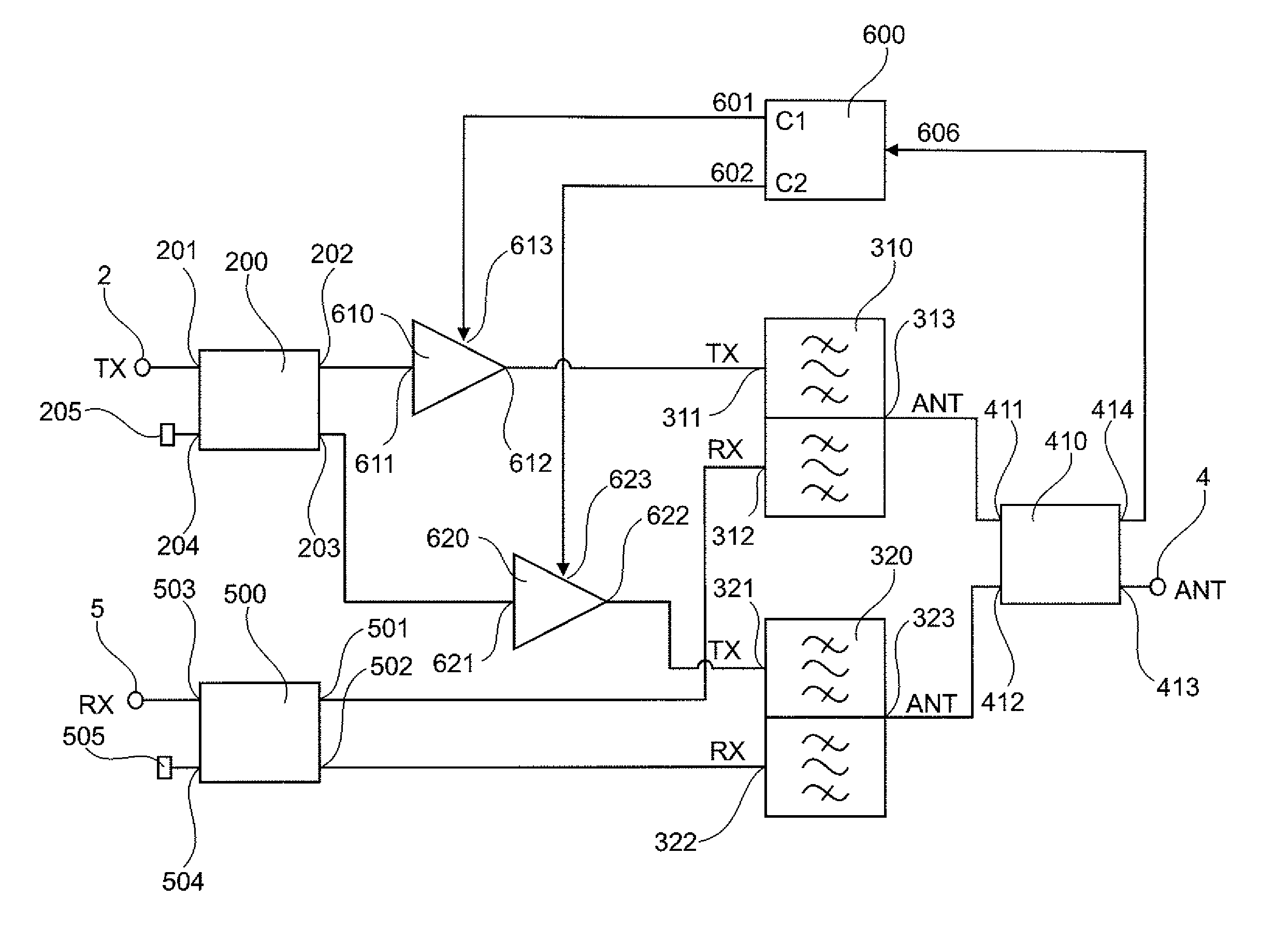

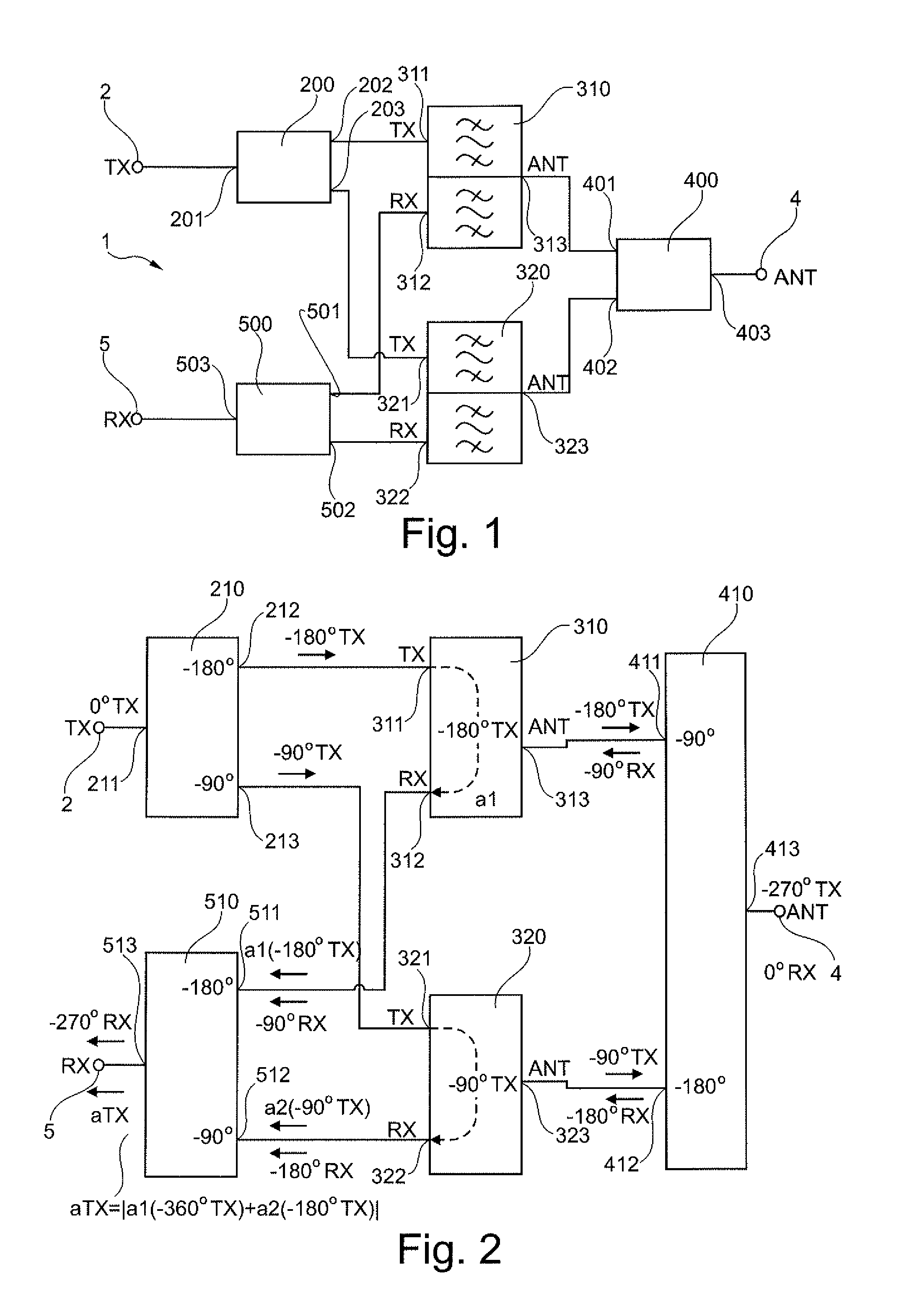

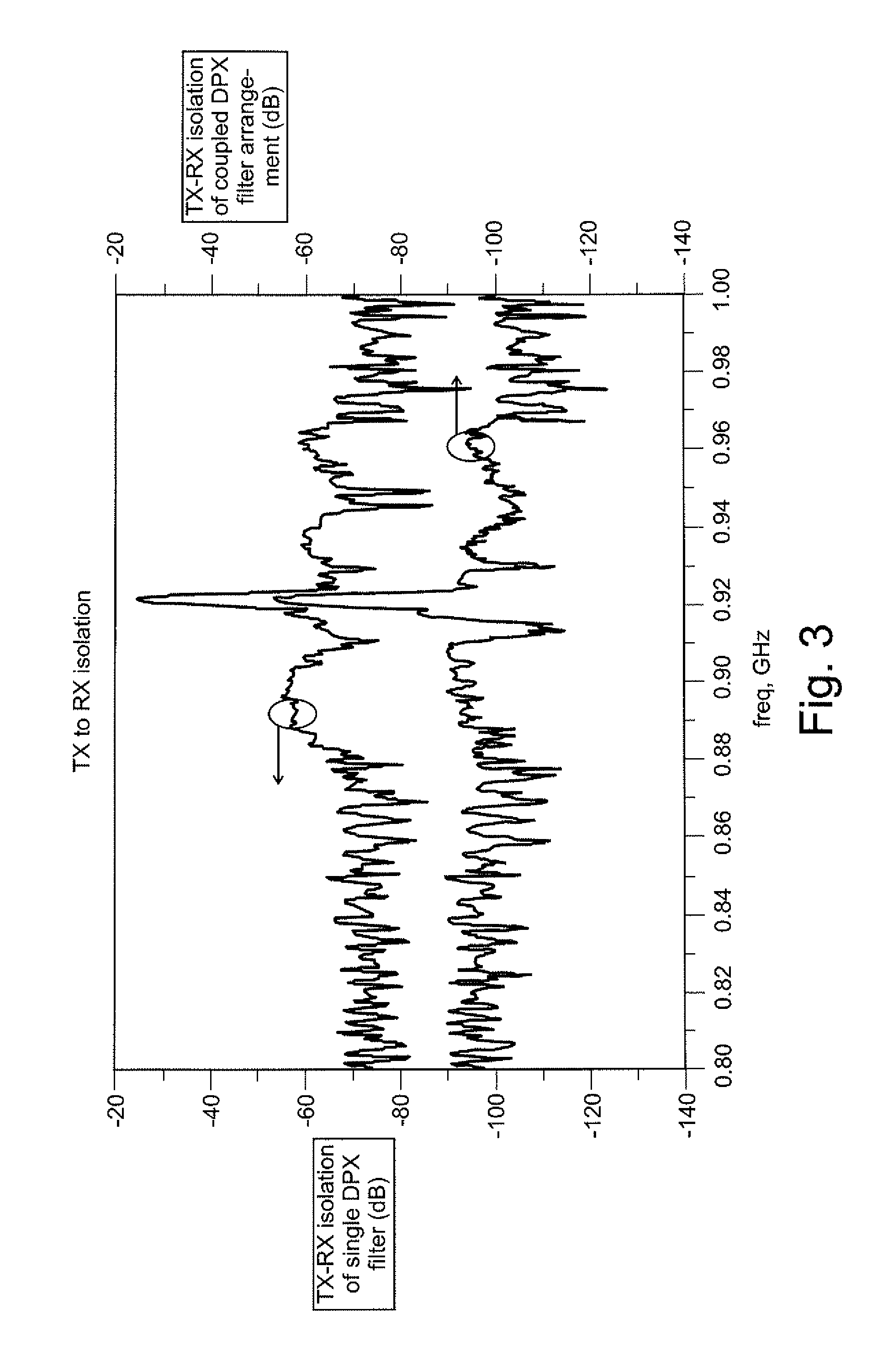

Filter arrangement

ActiveUS20120230227A1Easy to optimizeEnhanced transmission signalMultiple-port networksRadio transmissionRadio receptionTransmitter

A filter arrangement for filtering a radio transmit signal and radio receive signal, comprising a first duplex filter and a second duplex filter, a signal divider for splitting a transmit input signal into a first transmitter signal portion and a second transmitter signal portion, the first transmitter signal portion being passed to the a transmit port of the first duplex-filter, and a second signal portion being passed to the second transmitter port of the second duplex filter. The filter arrangement further comprising a signal combiner / divider for combining a first filtered transmit portion signal and a second filtered transmit portion signal into a single filtered transmit signal. The filter arrangement further comprising a signal combiner for combining a first filtered receive signal portion and a second filtered receive signal portion into a single filtered receive signal, which is provided at a third output of the signal combiner. With such a filter arrangement the suppression of noise from the transmit signal in the receive signal is improved.

Owner:KATHREIN SE

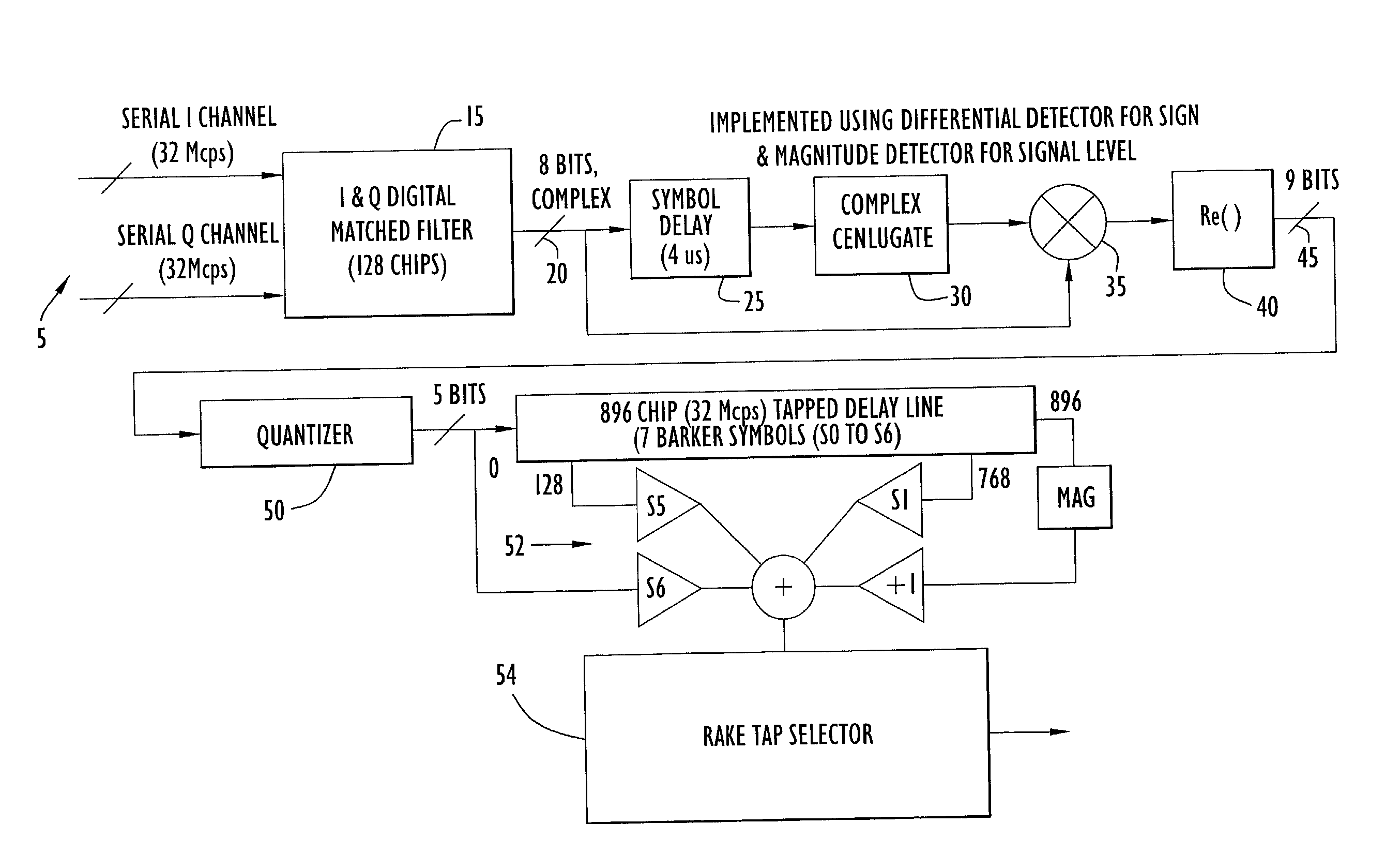

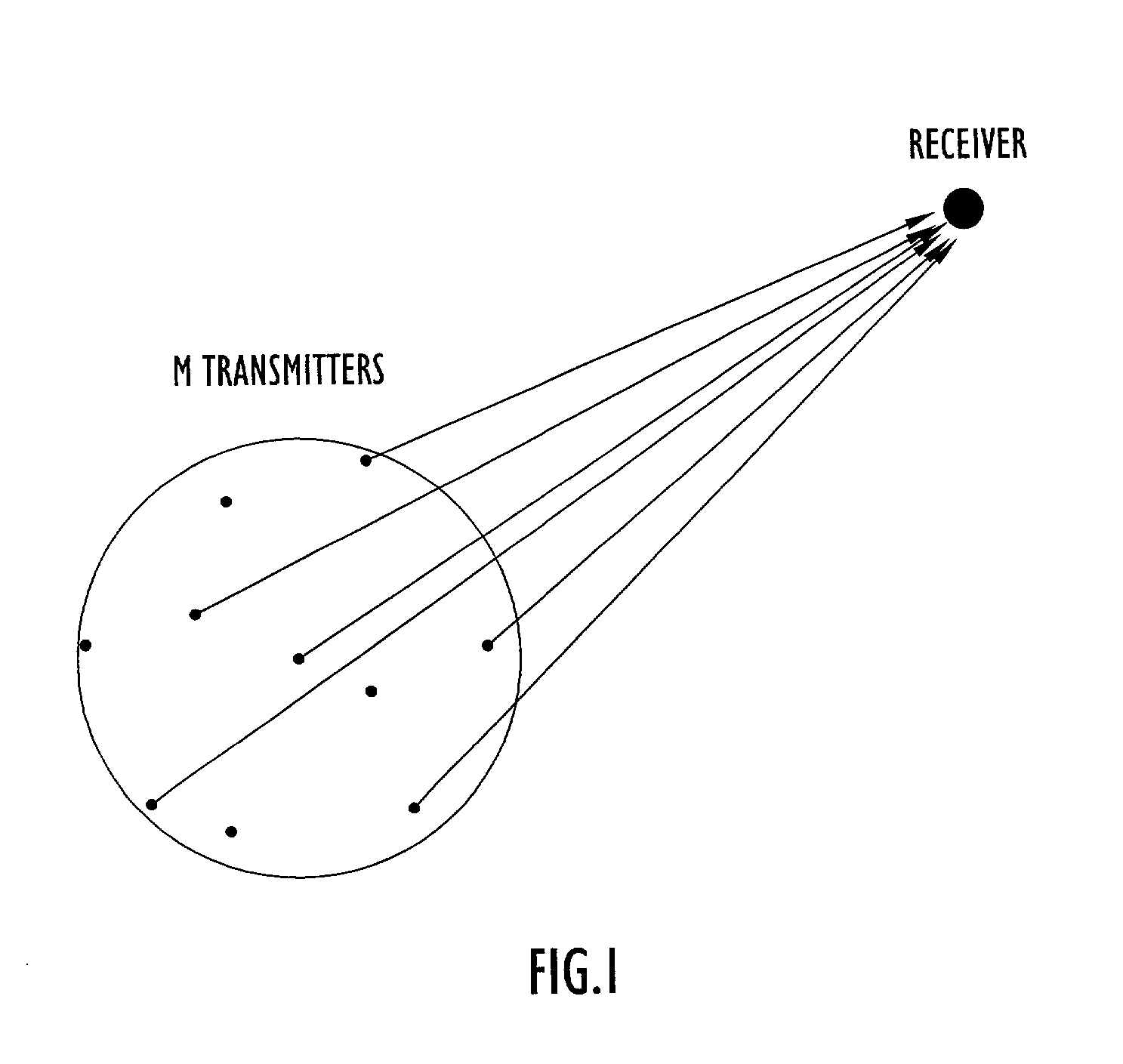

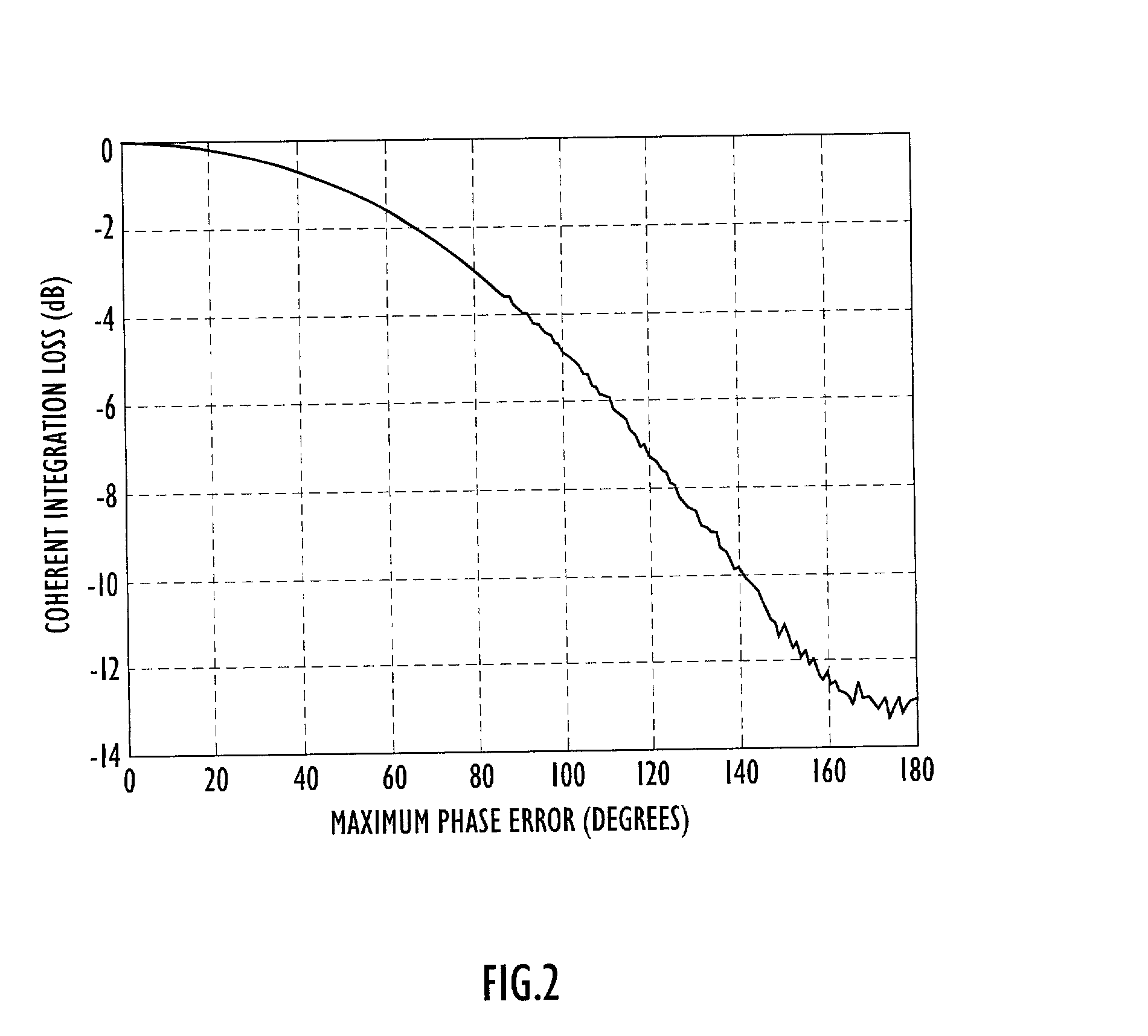

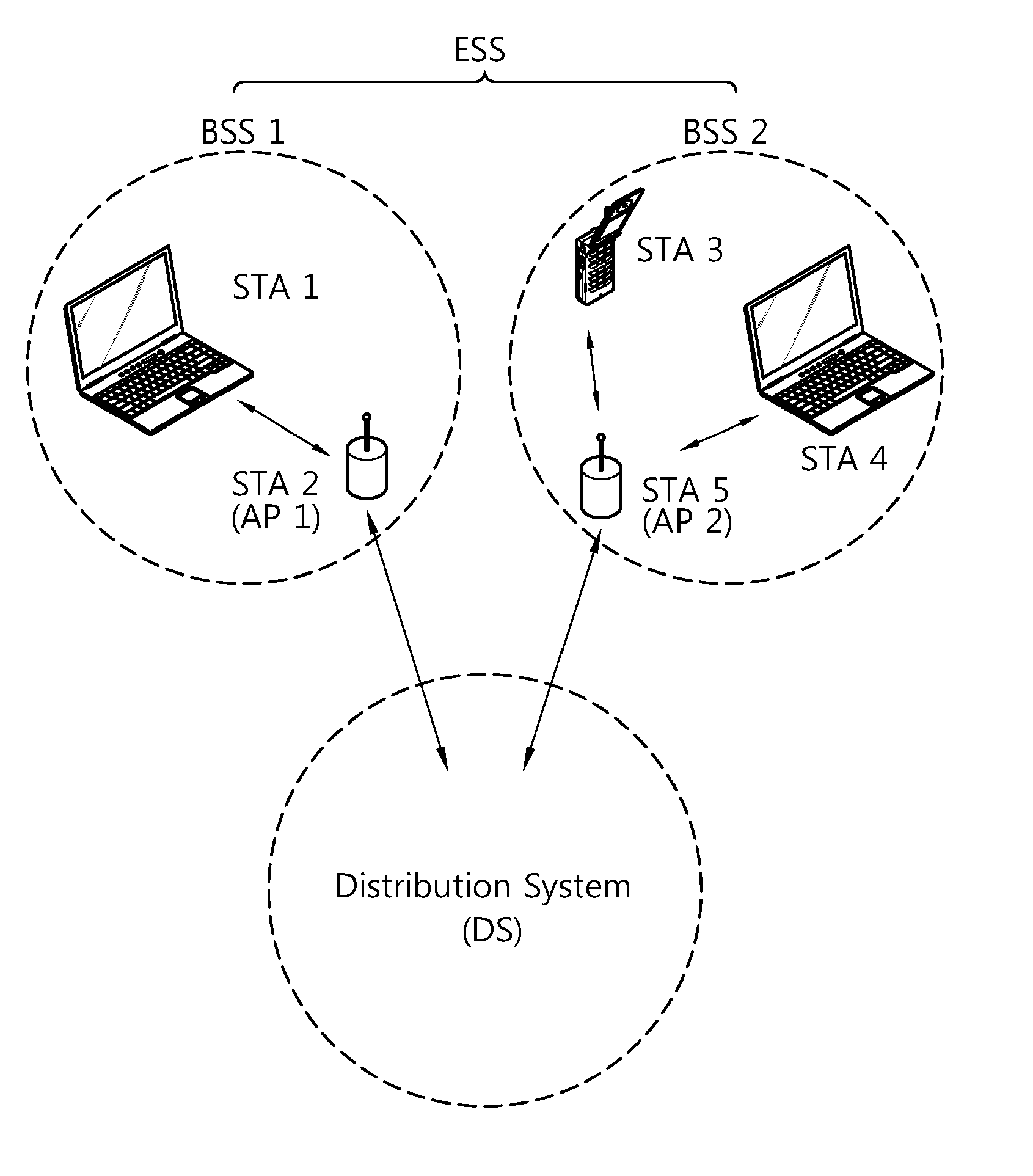

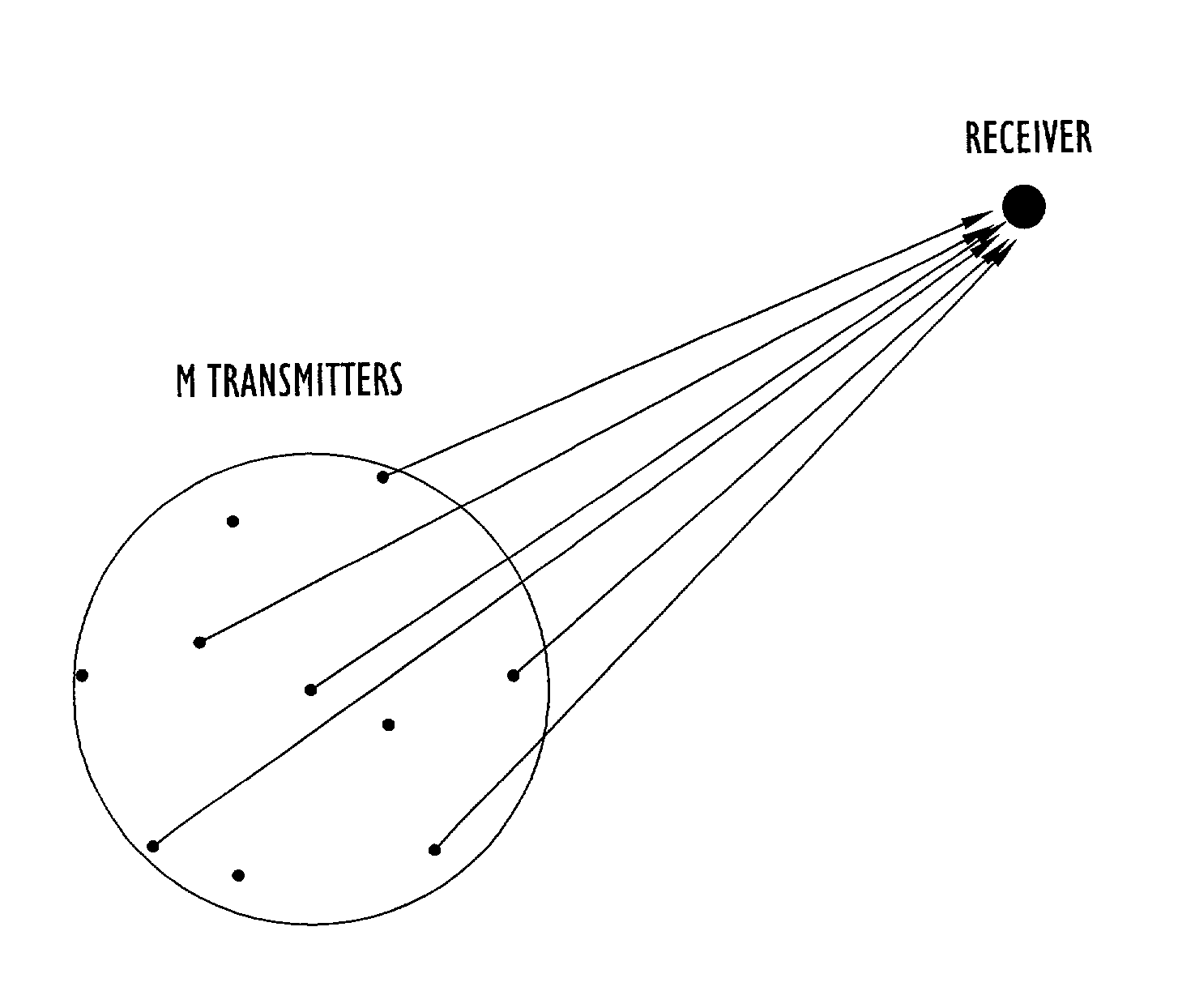

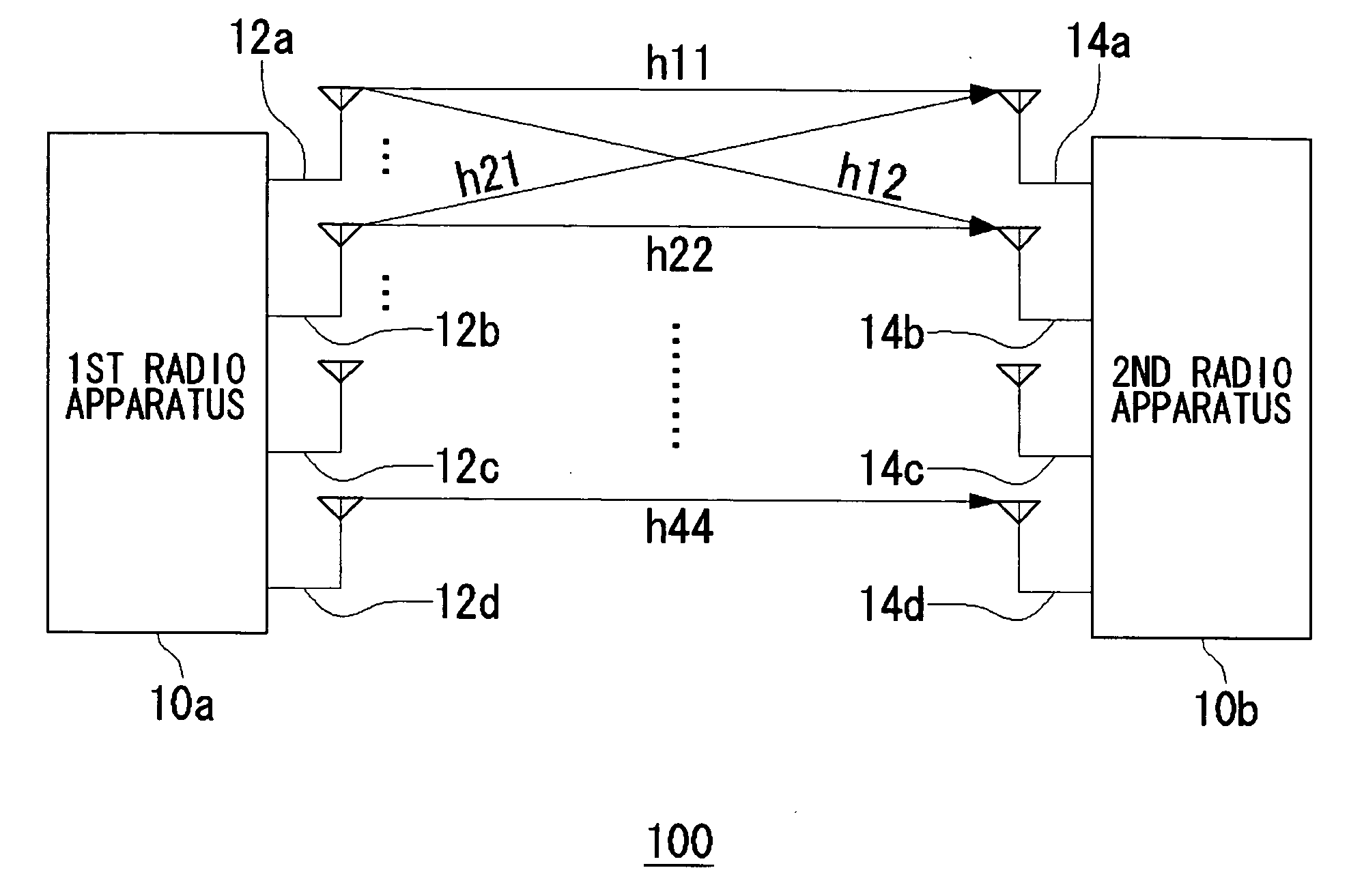

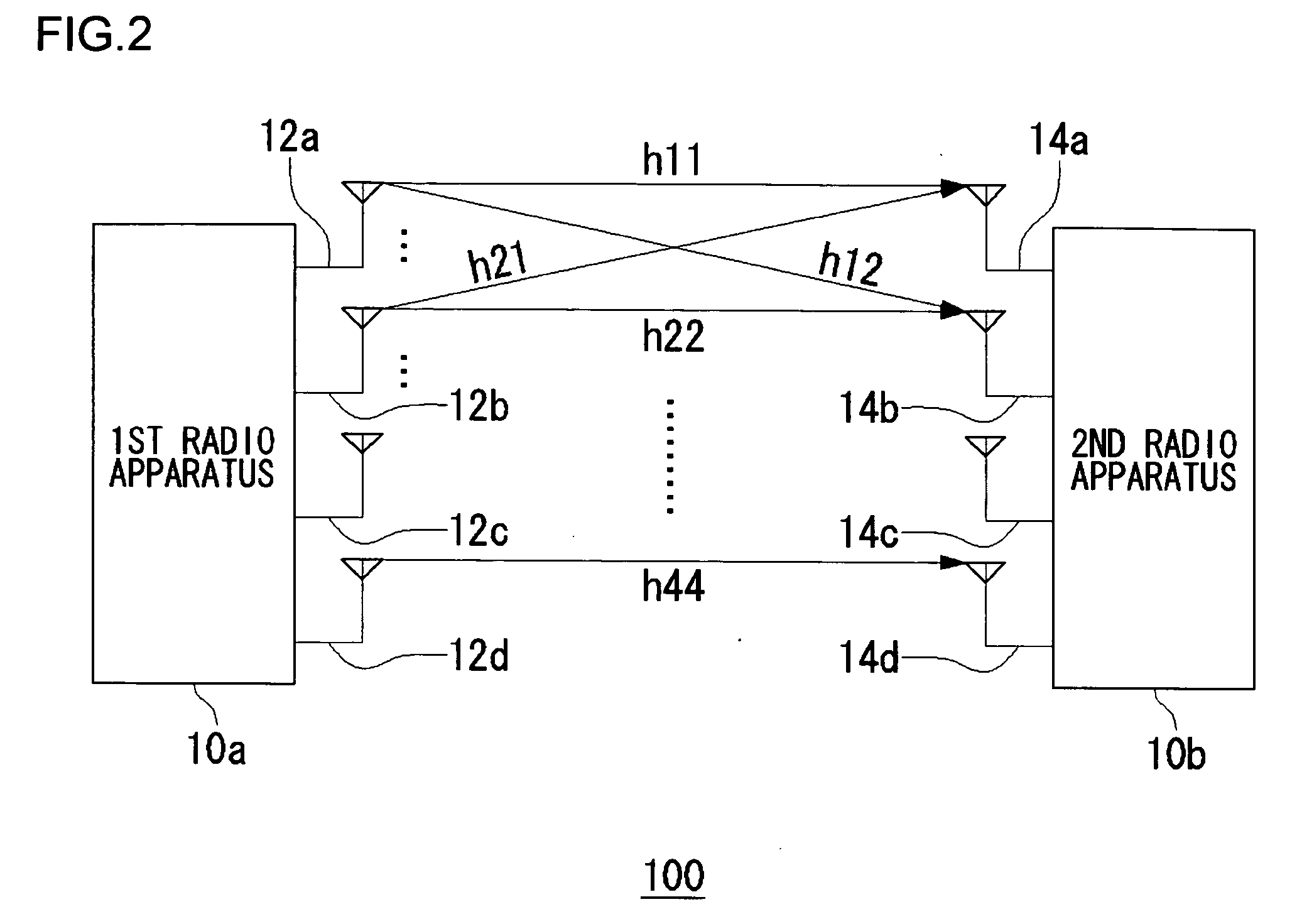

Methods and apparatus for synchronously combining signals from plural transmitters

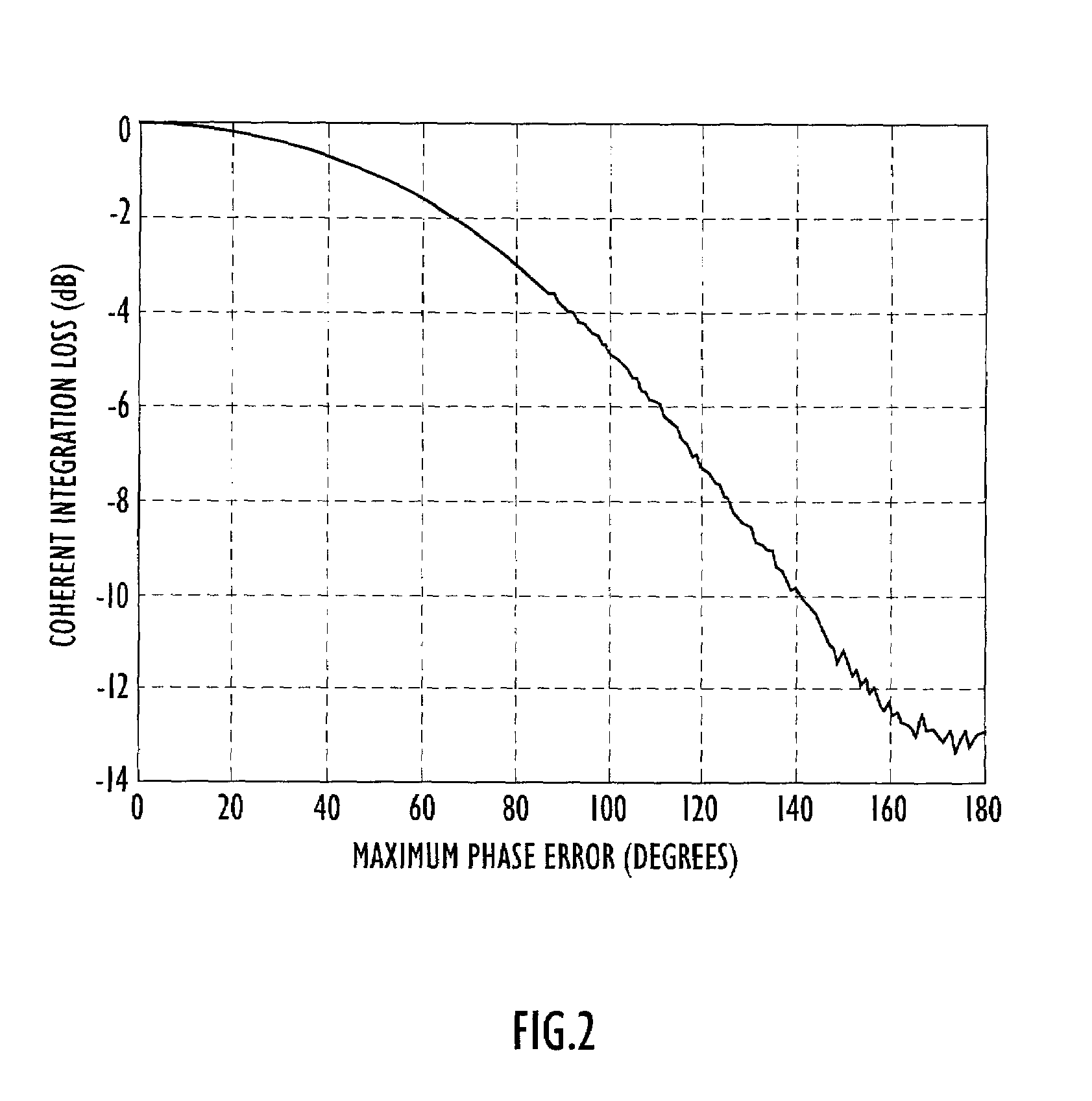

ActiveUS20050031045A1Improve ranging abilityReduce transmit powerSite diversitySpatial transmit diversitySignal onSignal-to-noise ratio (imaging)

Enhanced reception of transmitted signals in a communication system is achieved by synchronously combining transmissions from a cluster of transmitters at a distant receiver. The transmitters coordinate transmissions such that each substantially simultaneously transmits the same signal on the same communication channel. As a consequence of the spatial diversity of the transmitters, the transmitted signals arrive at the receiver at different times. The receiver essentially treats the different transmitted signals as though they were different multipath signals from a single transmitter. A multipath equalizer or combiner is used to determine timing offsets among the received signals, and the received signals are time aligned by phase rotating the signals in accordance with the estimated timing offsets. The time-aligned signals are then coherently combined and detected. The combined signal has a greater signal-to-noise ratio than the individual received signals, permitting detection at a greater range or with a lower bit error rate.

Owner:STINGRAY IP SOLUTIONS LLC

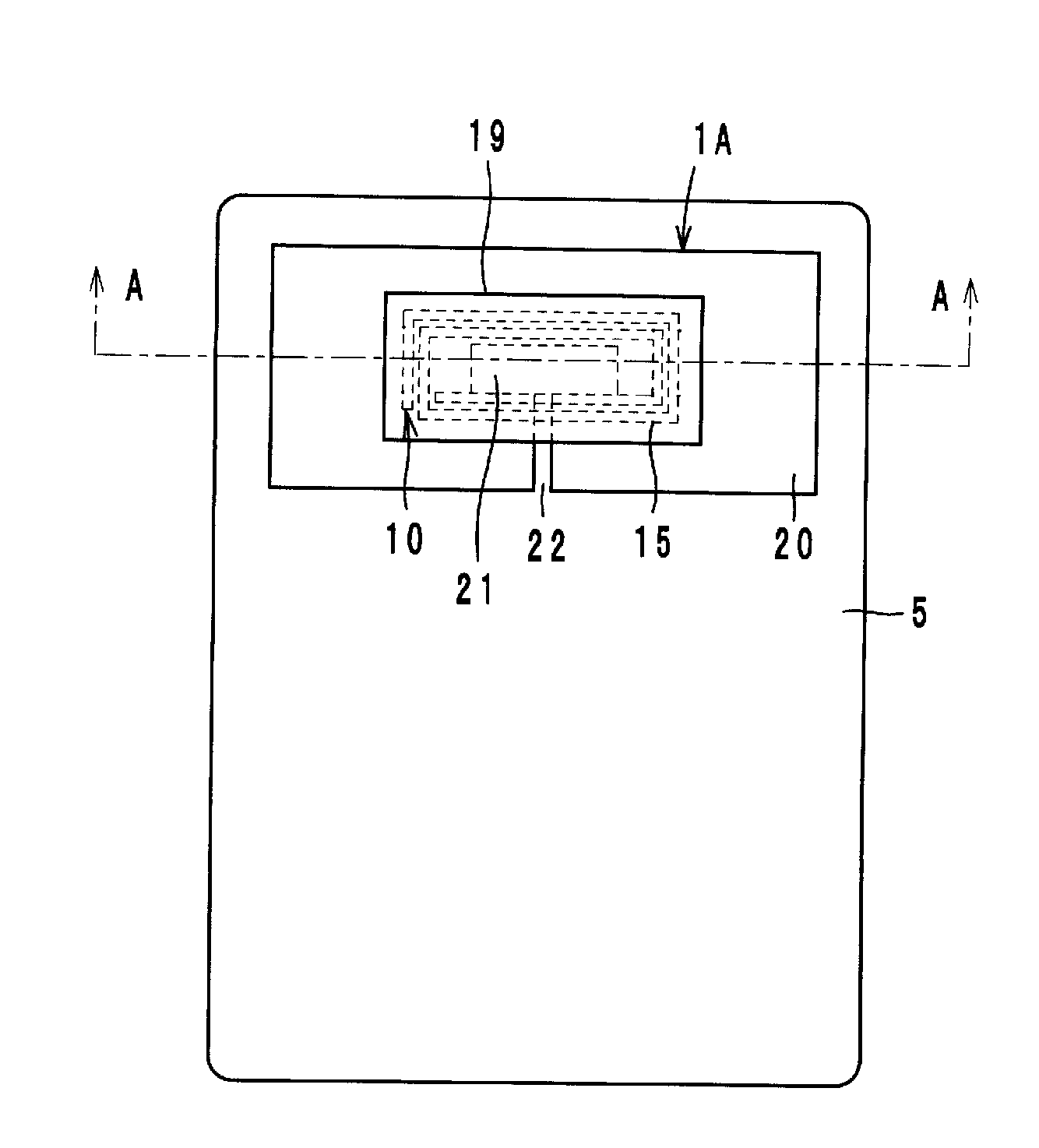

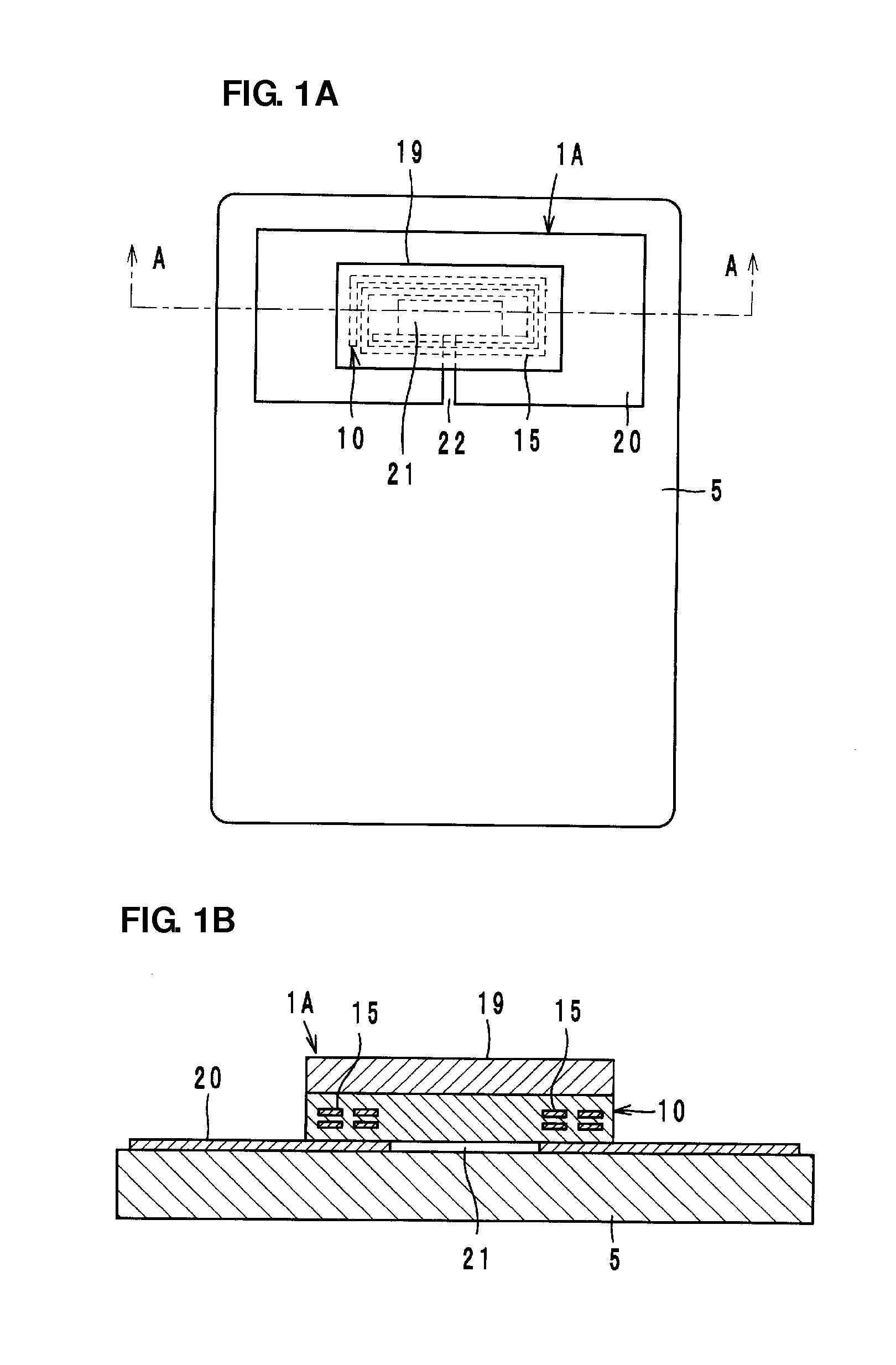

Antenna device and mobile communication terminal

ActiveUS20120176282A1High gainImprove communication distanceNear-field transmissionAntenna supports/mountingsConductor CoilElectrical and Electronics engineering

An antenna device includes a feeding member including a coil pattern and an emitting member to emit a transmit signal supplied from the feeding member and to receive a receive signal and supplying it to the feeding member. The emitting member includes an opening portion and a slit portion communicating with the opening portion. When seen in plan view from the direction of the winding axis of the coil pattern, the opening portion of the emitting member and the inner region of the coil pattern overlap each other, and the emitting member and the coil pattern overlap each other at least partially.

Owner:MURATA MFG CO LTD

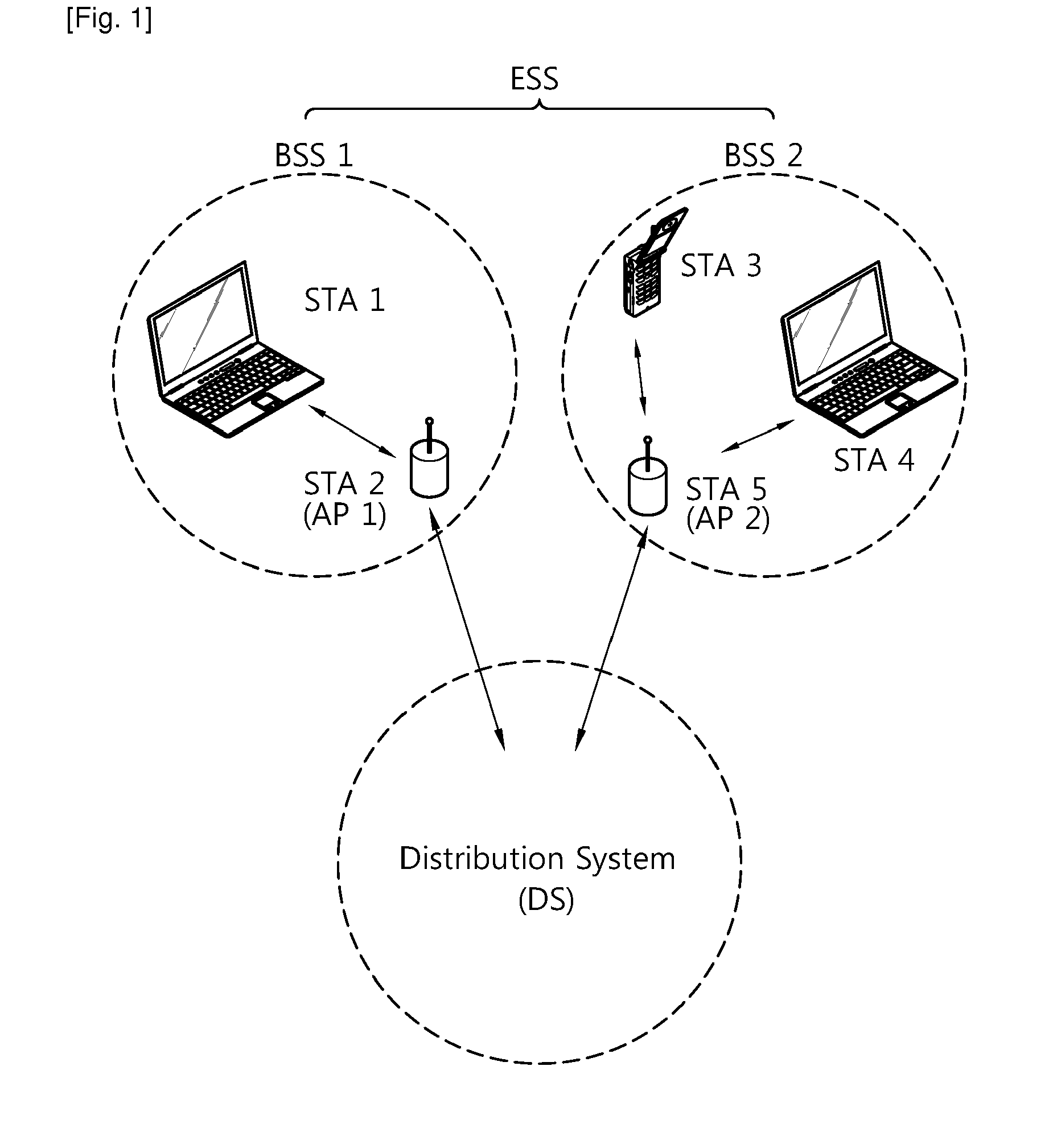

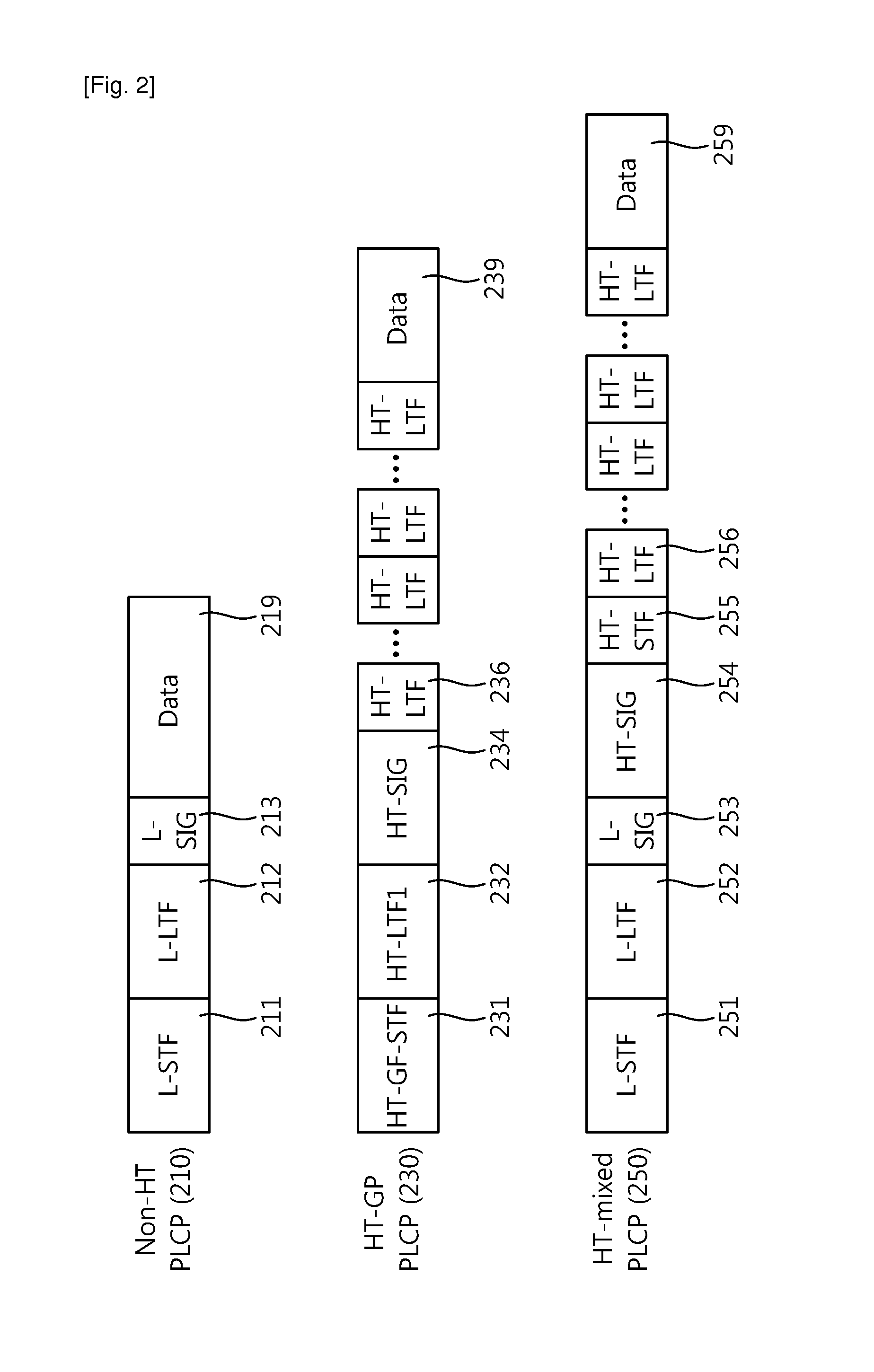

Method and apparatus for transmitting data in WLAN system

ActiveUS20120224570A1Reduce complexityEnhanced transmission signalModulated-carrier systemsNetwork topologiesDemodulationInformation field

A method of transmitting data in a WLAN system using a transmission frequency band including a plurality of frequency blocks includes generating a transmission information field, including at least one of information for timing acquisition of a frame, channel estimation information, and information for demodulation and decoding of the data, generating a plurality of transformed transmission information fields by multiplying the transmission information field by a transform sequence, and transmitting the plurality of transformed transmission information fields through the plurality of respective frequency blocks. The transform sequence comprises a plurality of transform values, and the plurality of transformed transmission information fields is generated by multiplying transmission information field by each of a plurality of transform values.

Owner:LG ELECTRONICS INC

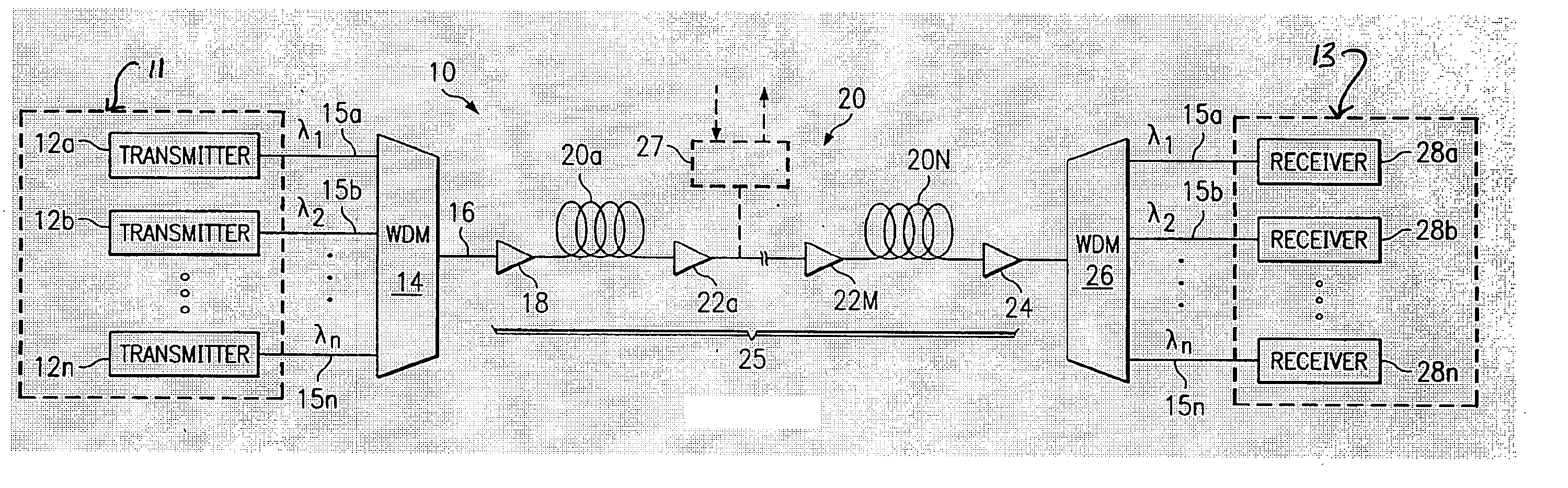

Methods and apparatus for synchronously combining signals from plural transmitters

ActiveUS7218682B2Improve ranging abilityReduce transmit powerSite diversitySpatial transmit diversitySignal-to-noise ratio (imaging)Communications system

Enhanced reception of transmitted signals in a communication system is achieved by synchronously combining transmissions from a cluster of transmitters at a distant receiver. The transmitters coordinate transmissions such that each substantially simultaneously transmits the same signal on the same communication channel. As a consequence of the spatial diversity of the transmitters, the transmitted signals arrive at the receiver at different times. The receiver essentially treats the different transmitted signals as though they were different multipath signals from a single transmitter. A multipath equalizer or combiner is used to determine timing offsets among the received signals, and the received signals are time aligned by phase rotating the signals in accordance with the estimated timing offsets. The time-aligned signals are then coherently combined and detected. The combined signal has a greater signal-to-noise ratio than the individual received signals, permitting detection at a greater range or with a lower bit error rate.

Owner:STINGRAY IP SOLUTIONS LLC

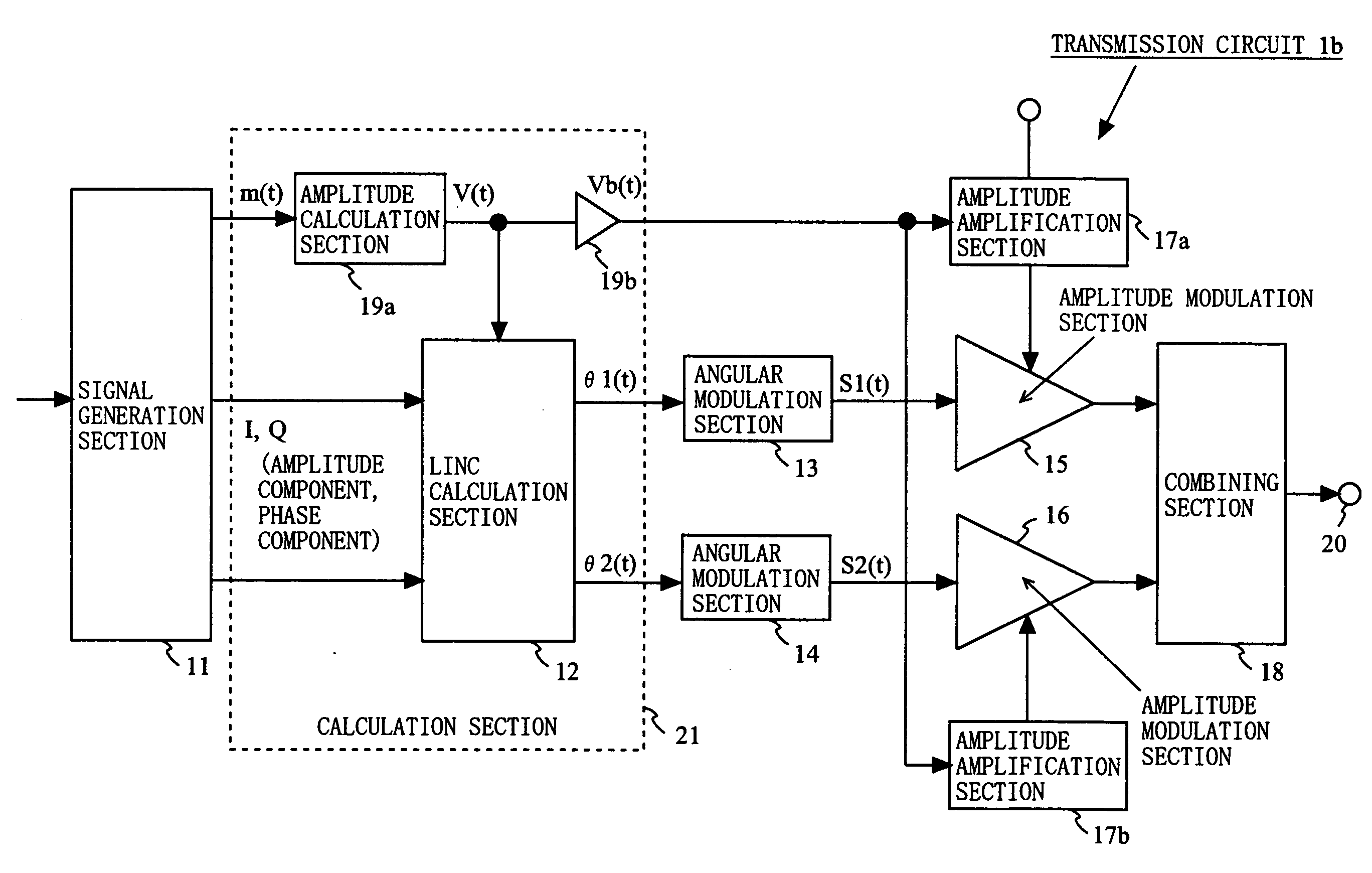

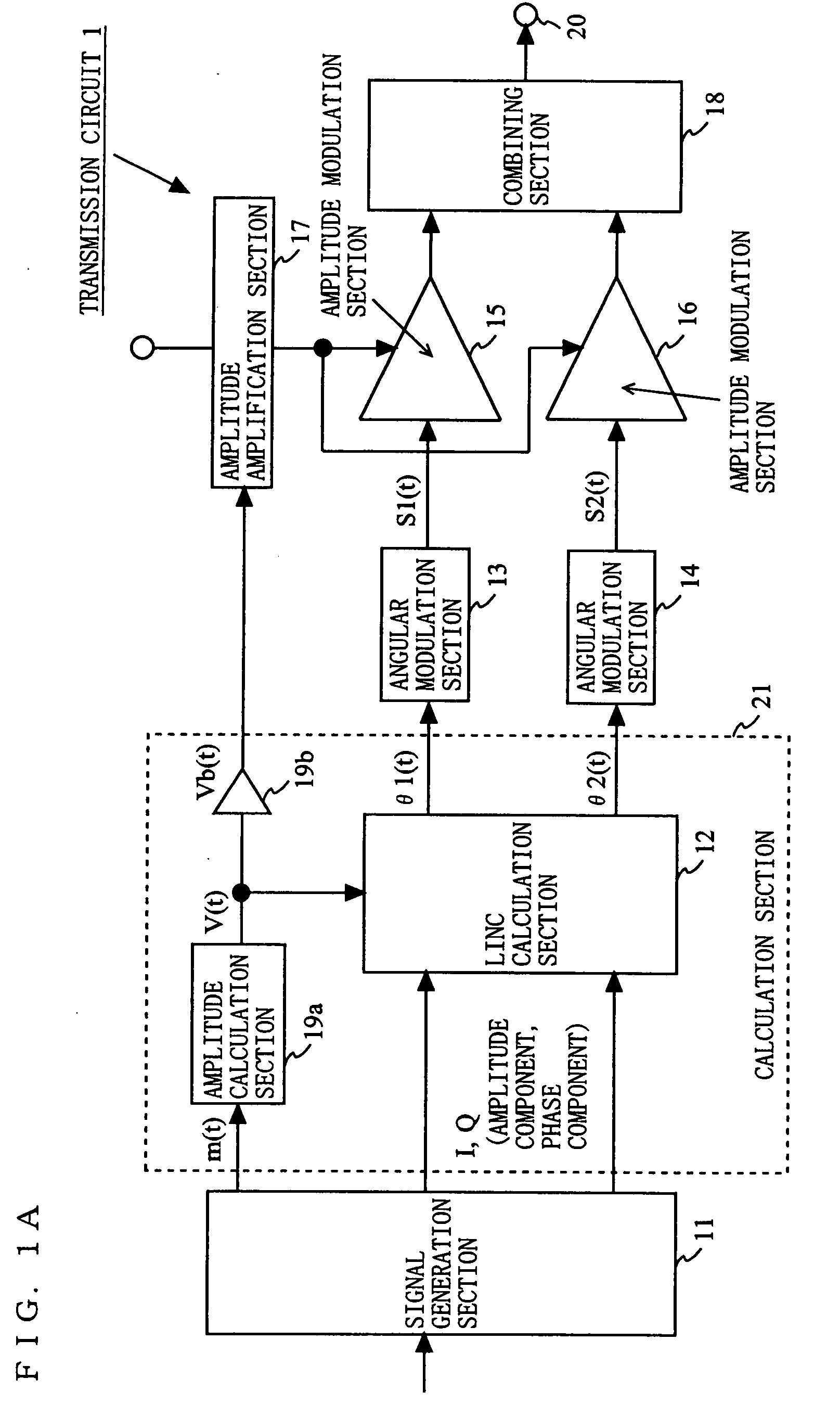

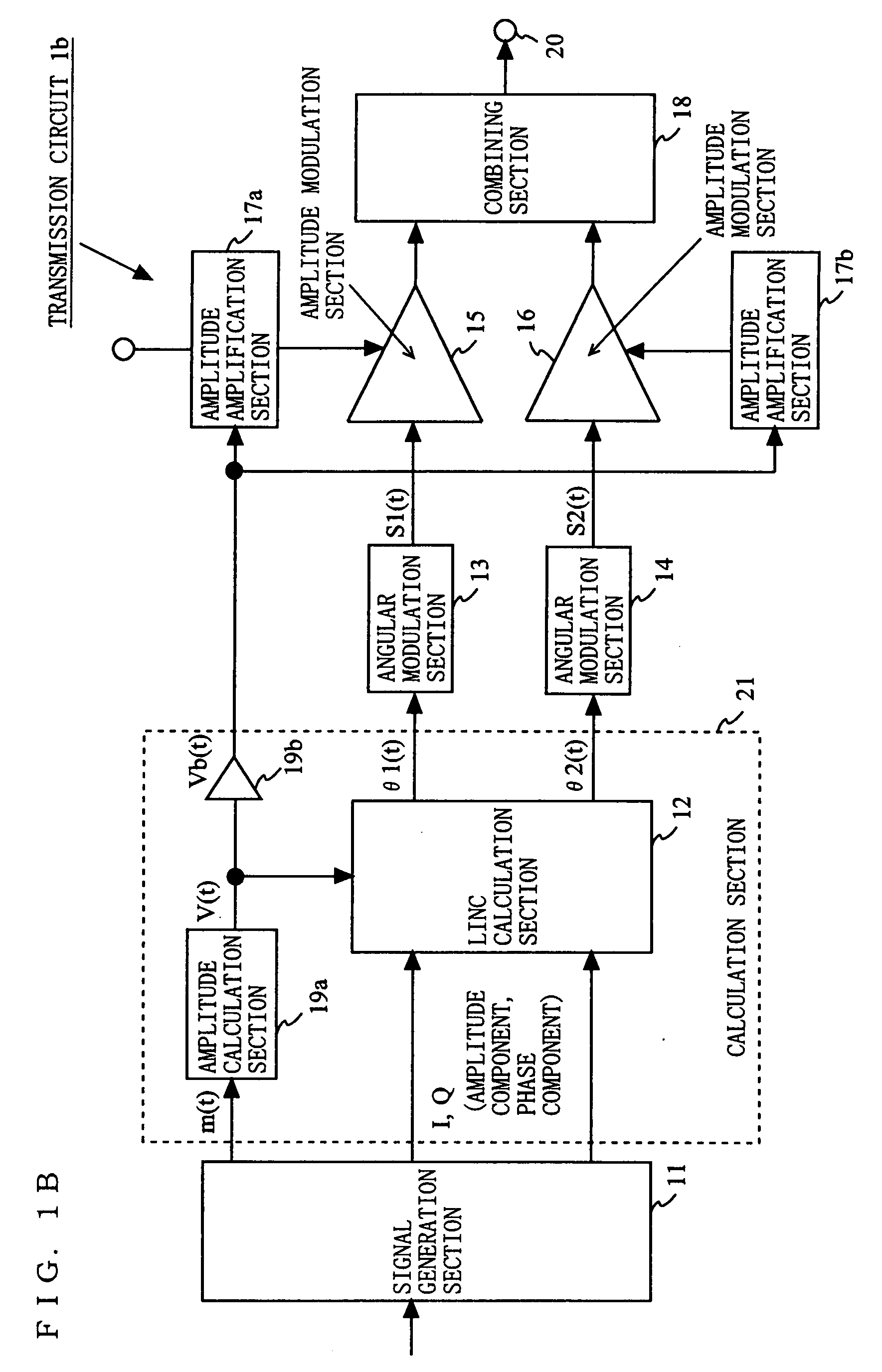

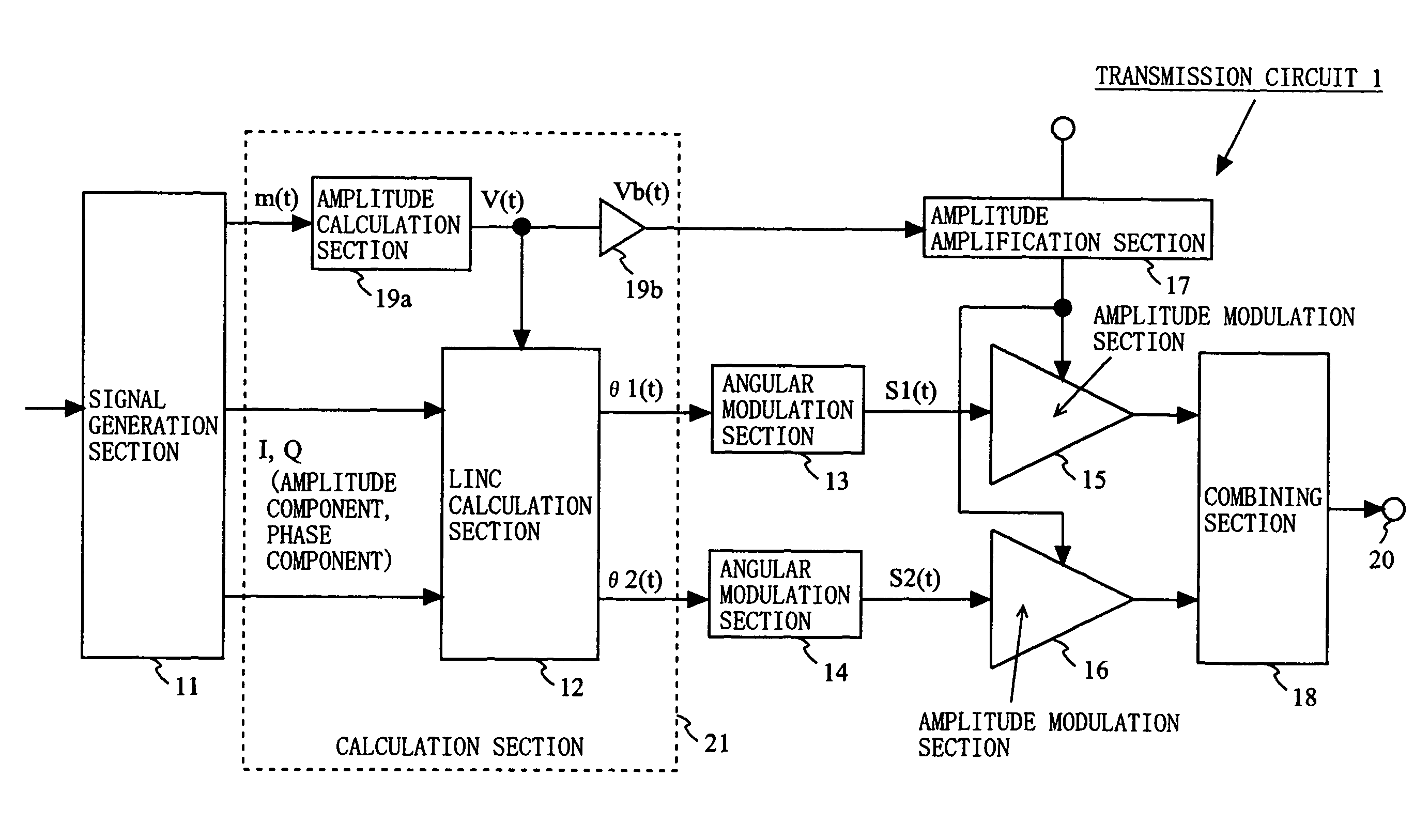

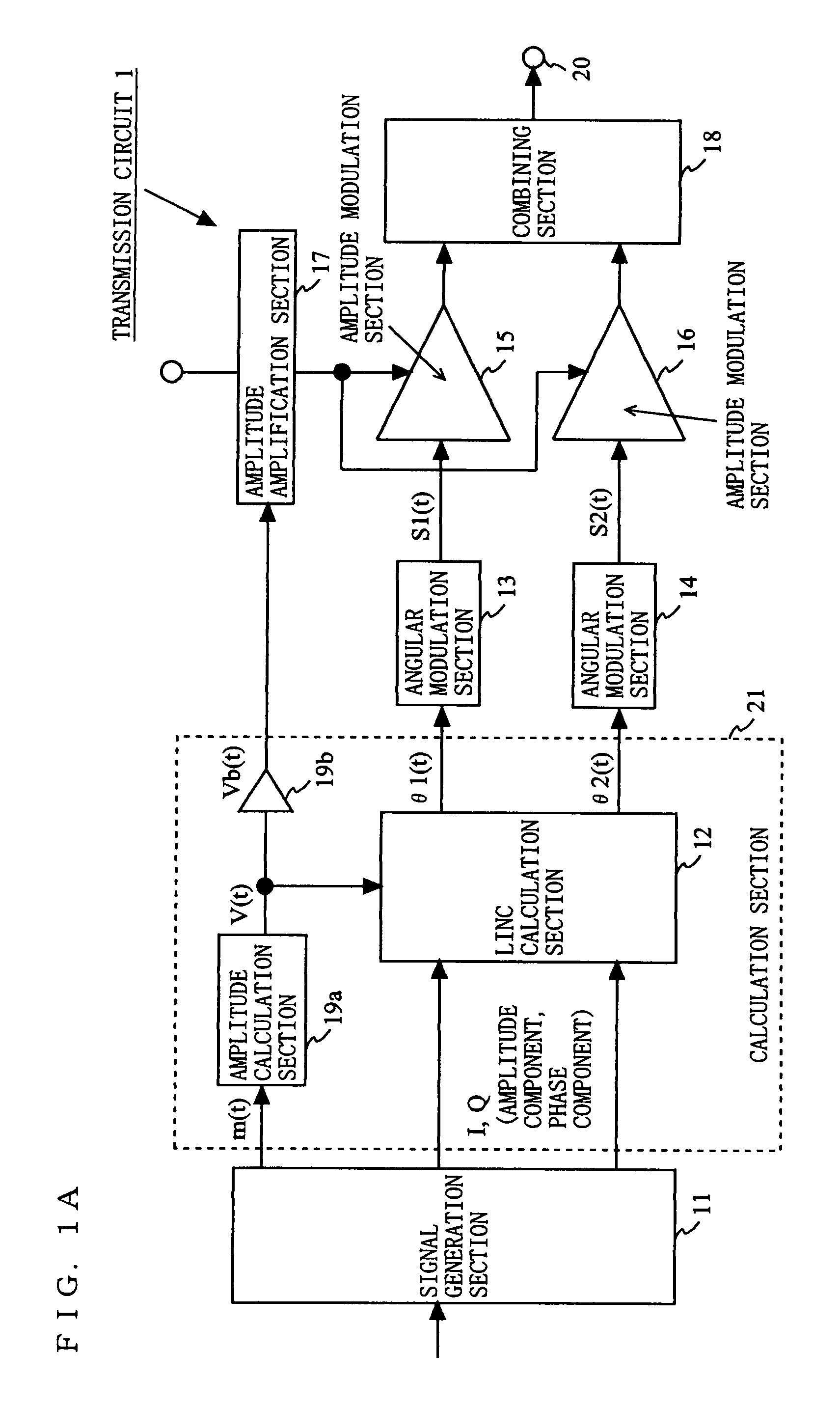

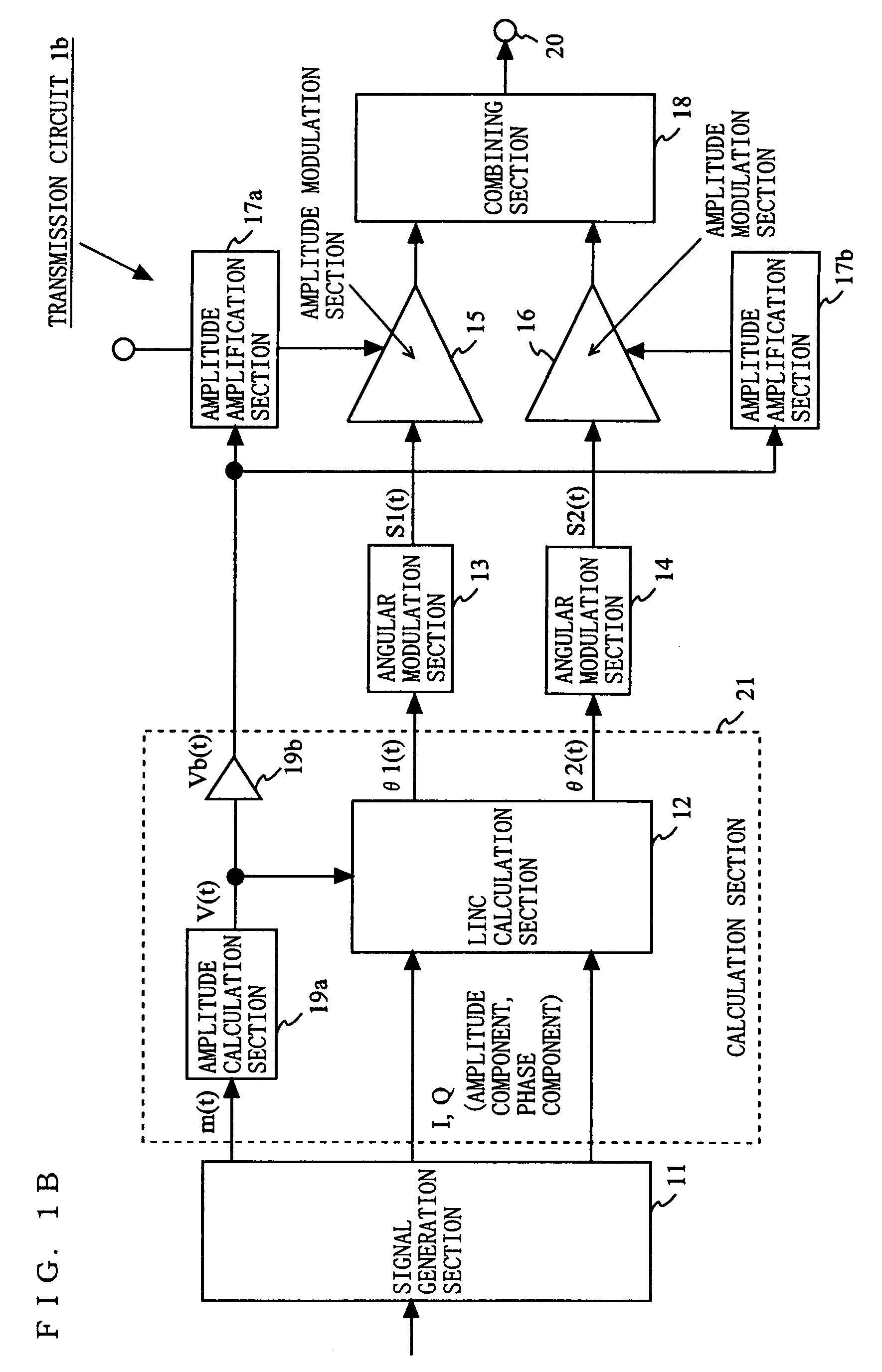

Transmission circuit, and communication apparatus using the same

InactiveUS20070254622A1Improve efficiencyEnhanced transmission signalModulation with suppressed carrierTelephonic communicationAngle modulationEngineering

A compact transmission circuit for outputting a highly linear transmission signal regardless of the output power level and operating at a high efficiency is provided. A signal generation section 11 generates an amplitude signal and quadrature data based on input data. A calculation section 21 calculates using the amplitude signal and the quadrature data to output a discrete value having a level discrete at every predetermine time period, and first and second phase signals. An amplitude amplification section 17 outputs a voltage controlled in accordance with the discrete value. Angular modulation sections 13 and 14 angular-modulate the phase signals and output first and second angle-modulated signals. Amplitude modulation sections 15 and 16 amplitude-modulate the angle-modulated signals with the voltage from the amplitude amplification section 17 and output first and second modulated signals. A combining section 18 combines the first and second modulated signals and outputs a transmission signal.

Owner:PANASONIC CORP

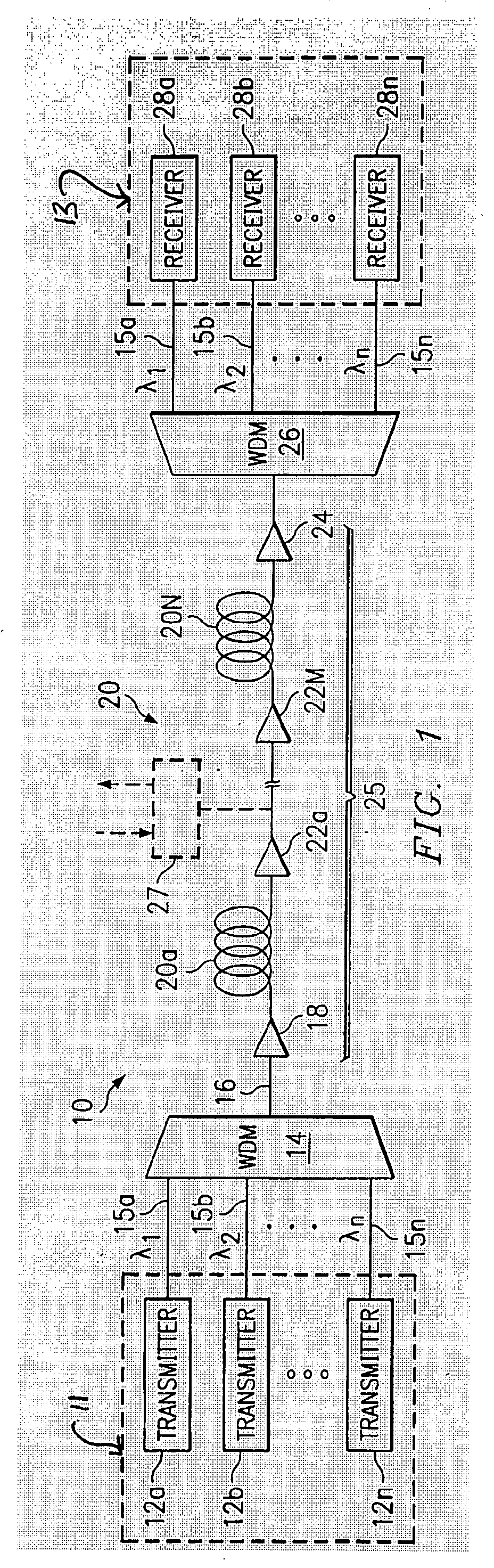

System and method for suppression of stimulated Brillouin scattering in optical transmission communications

InactiveUS20060188267A1Reduce the impactIncreases power thresholdElectromagnetic transmittersFrequency spectrumLength wave

An optical transmitter includes a light source and an SBS suppression circuit coupled to the light source. The light source is operable to generate an optical signal having one or more wavelengths. The optical signal has a signal spectrum having an upper band limit and a lower band limit. The SBS suppression circuit is operable to communicate a noise current for receipt by the light source. The noise current is operable to broaden the signal spectrum of the optical signal. The light source operates to convert the noise current into a noise component of the signal spectrum that resides between the upper band limit and the lower band limit.

Owner:XTERA COMM

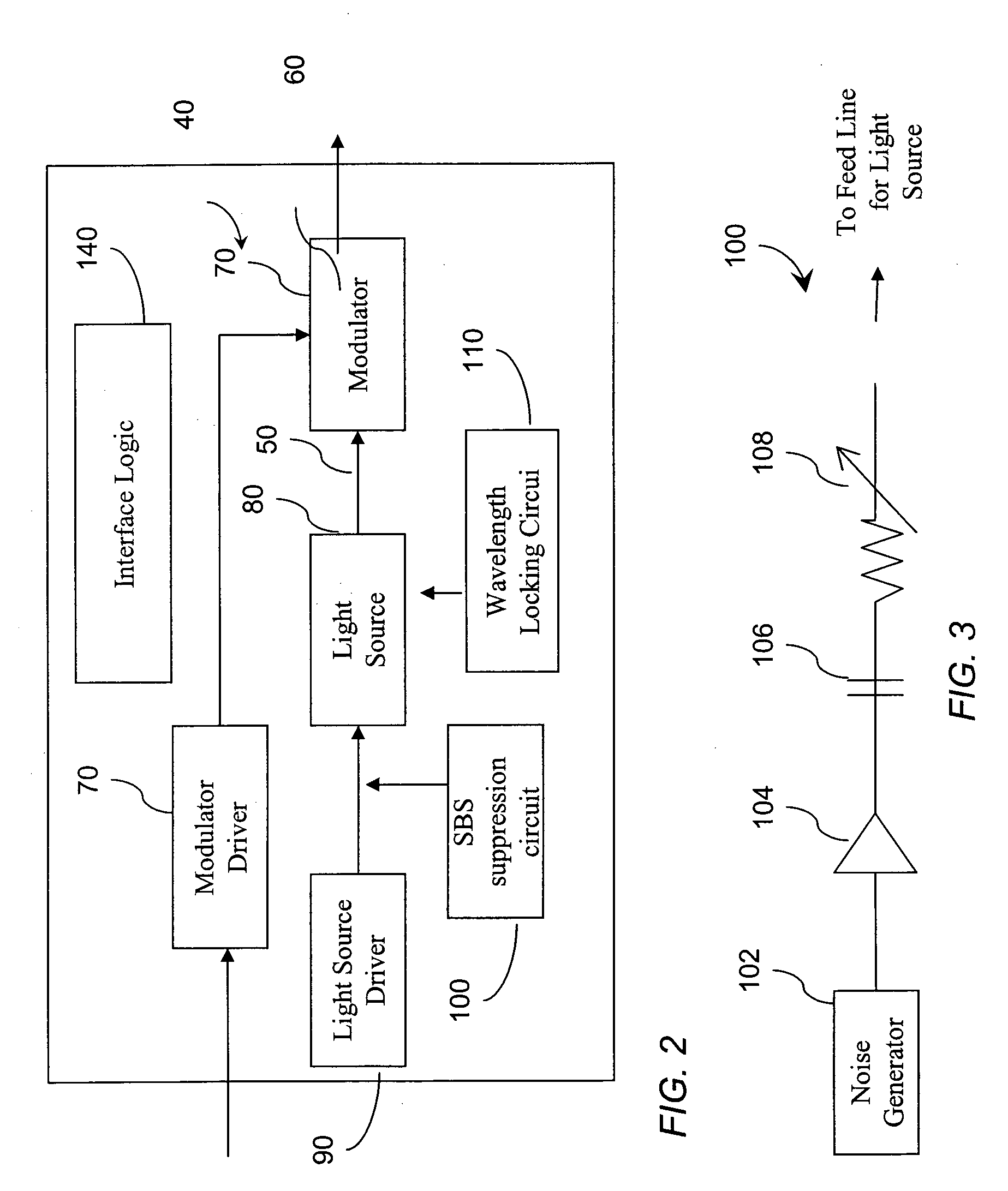

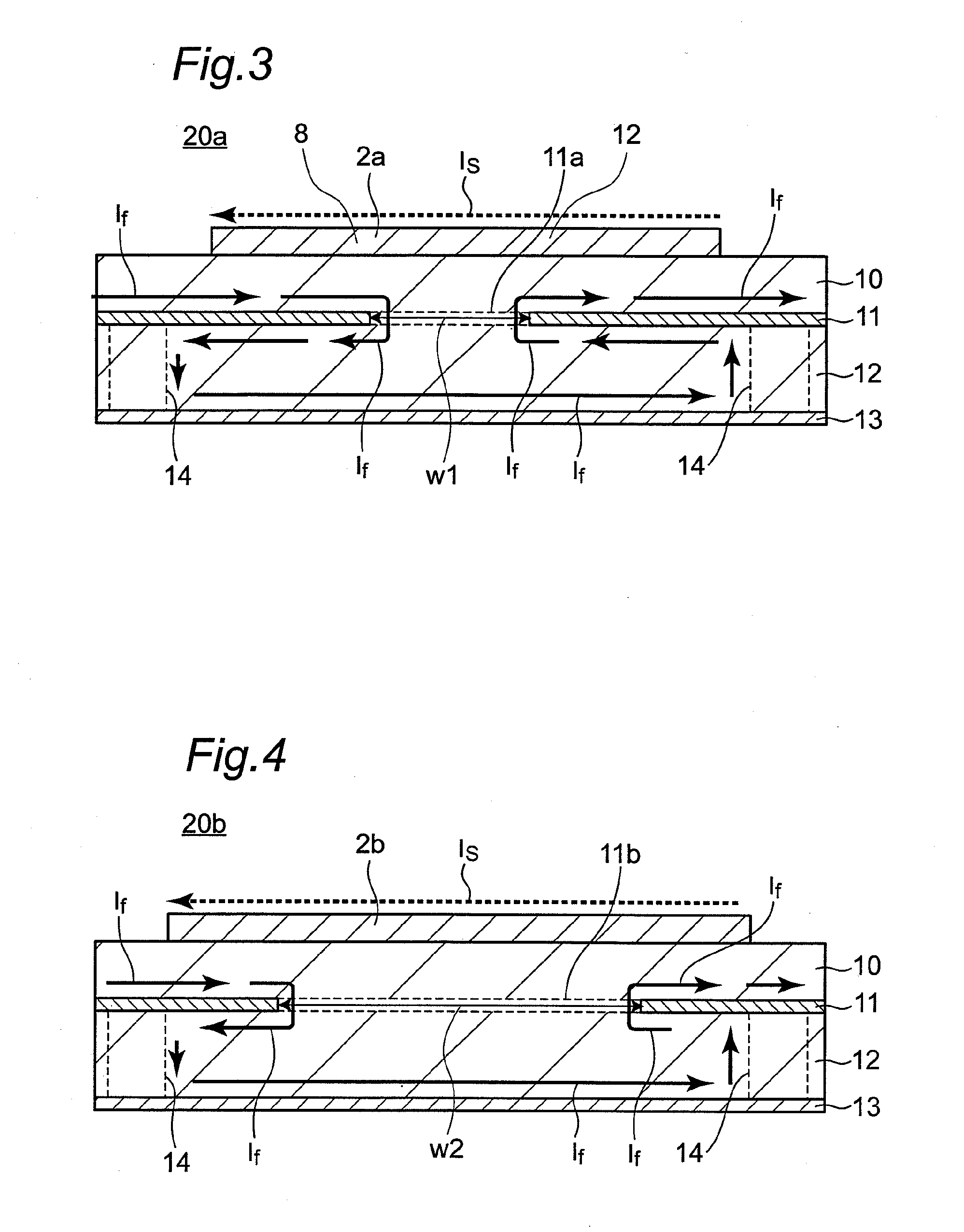

Parallel differential transmission lines having an opposing grounding conductor separated into two parts by a slot therein

InactiveUS8040200B2Reduce amountLow costMultiple-port networksWaveguidesElectrical conductorDifferential transmission

In a differential transmission line, a substrate has first and second surfaces parallel to each other, and a first grounding conductor is formed on the second surface of the substrate. A dielectric layer is formed on the first grounding conductor, and a second grounding conductor is formed on the dielectric layer. First and the second signal conductors are formed to be parallel to each other on the first surface of the substrate. The first signal conductor and the first and second grounding conductors constitute a first transmission line, and the second signal conductor and the first and second grounding conductors constitute a second transmission line. A slot is formed in the first grounding conductor to three-dimensionally intersect with the first and second signal conductors and to be orthogonal to a longitudinal direction thereof, and a connecting conductor is formed for connecting the first grounding conductor with the second grounding conductor.

Owner:PANASONIC CORP

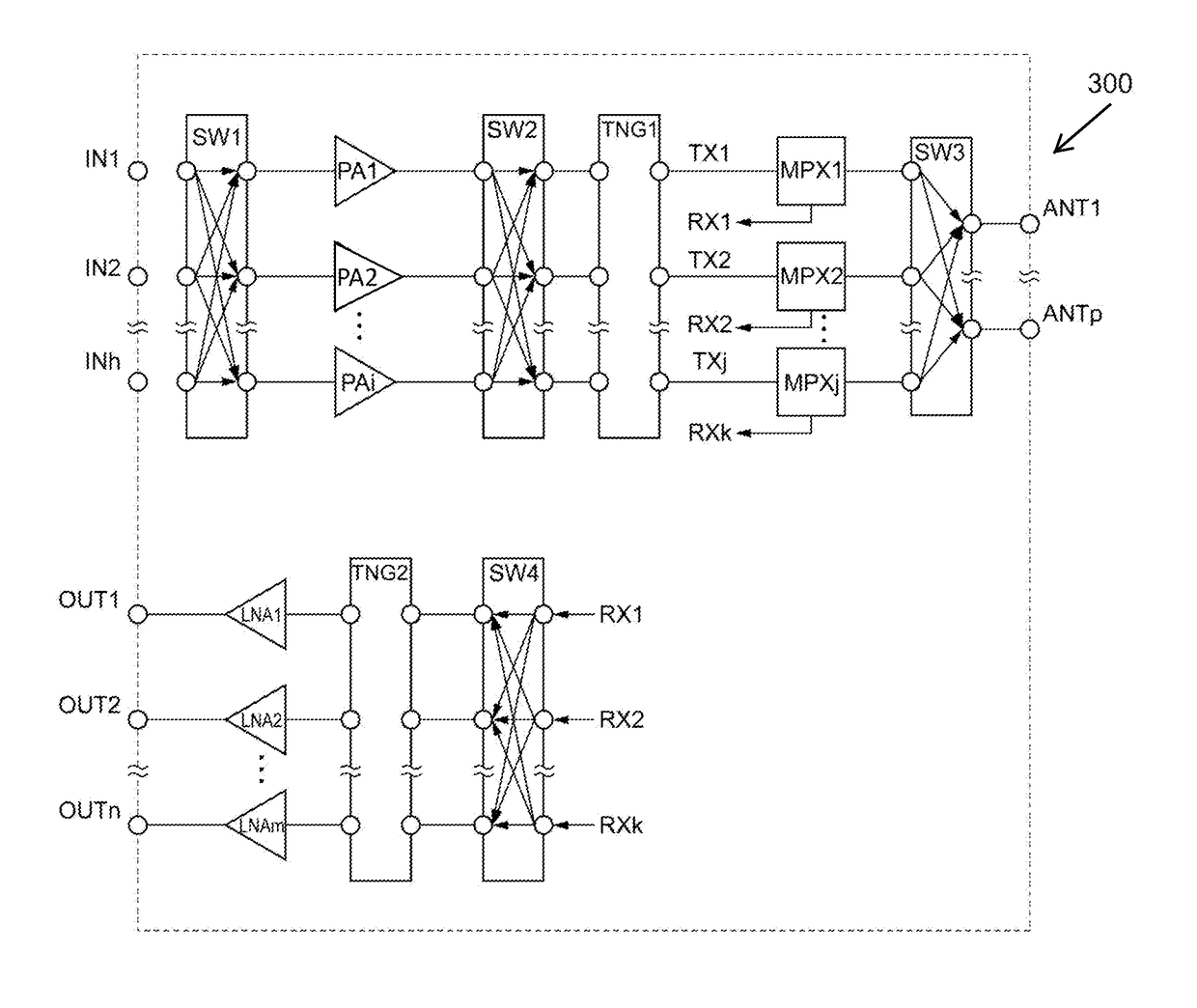

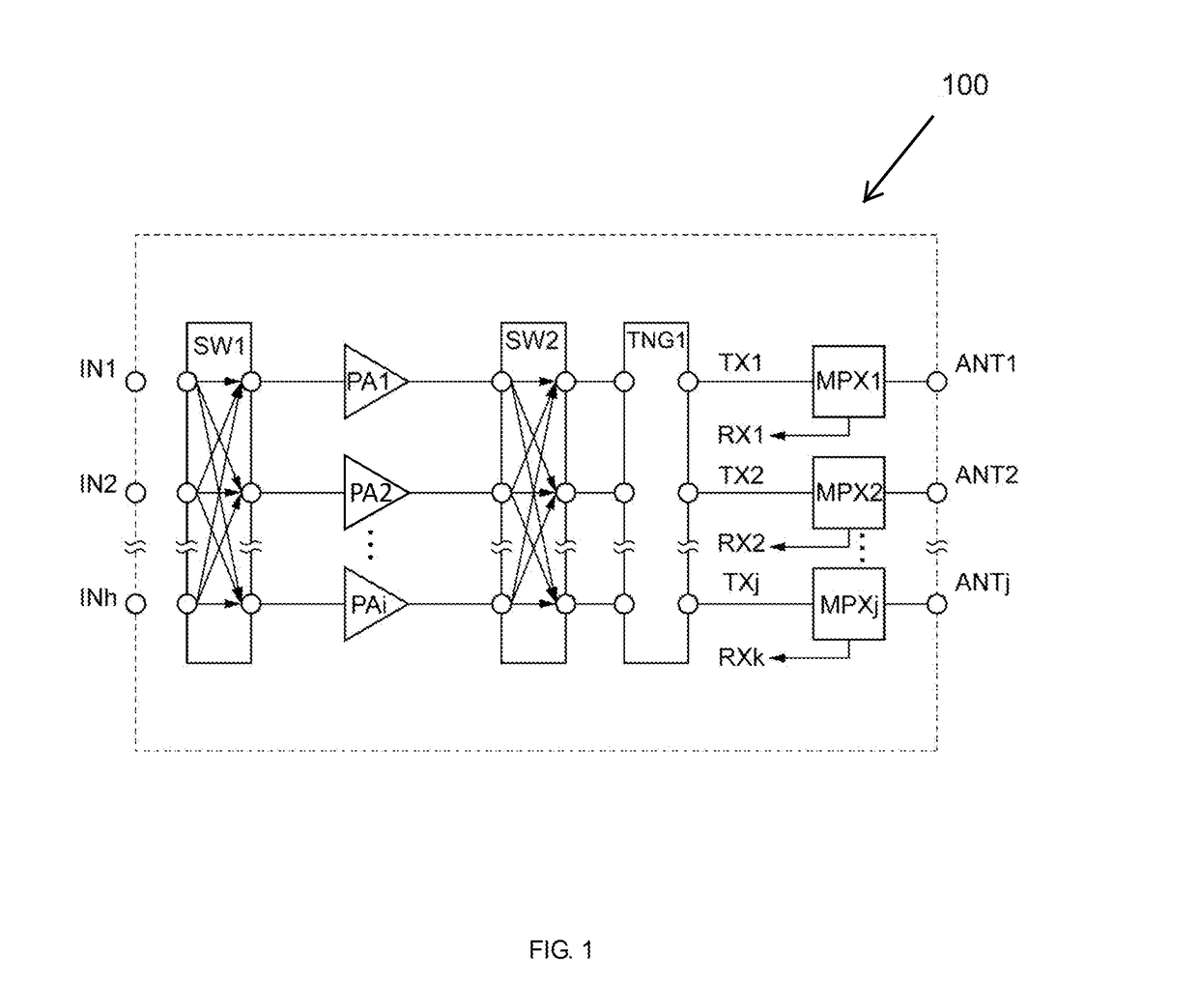

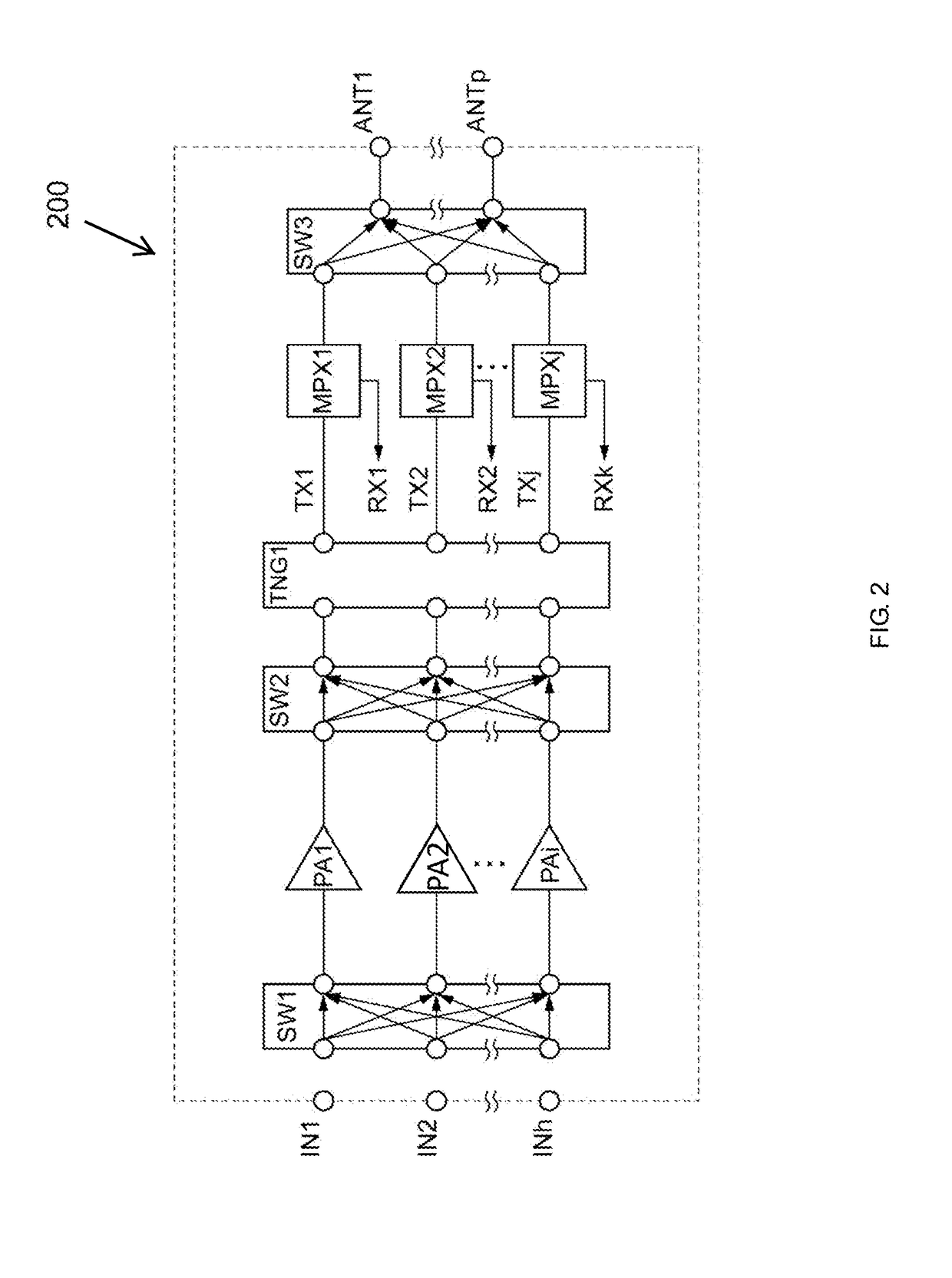

Multi-band power amplifier module

ActiveUS20180337643A1Facilitate communicationIncrease speedHigh frequency amplifiersGated amplifiersVIT signalsEngineering

A multi-band power amplifier module includes at least one transmission input terminal, at least one power amplifier circuit that receives a first transmission signal and a second transmission signal through the at least one transmission input terminal, a first filter circuit that allows the first transmission signal to pass therethrough, a second filter circuit that allows the second transmission signal to pass therethrough, at least one transmission output terminal through which the first and second transmission signals output from the first and second filter circuits are output, a transmission output switch that outputs each of the first and second transmission signals output from the at least one power amplifier circuit to the first filter circuit or the second filter circuit, and a first tuning circuit that adjusts impedance matching between the at least one power amplifier circuit and the at least one transmission output terminal.

Owner:MURATA MFG CO LTD

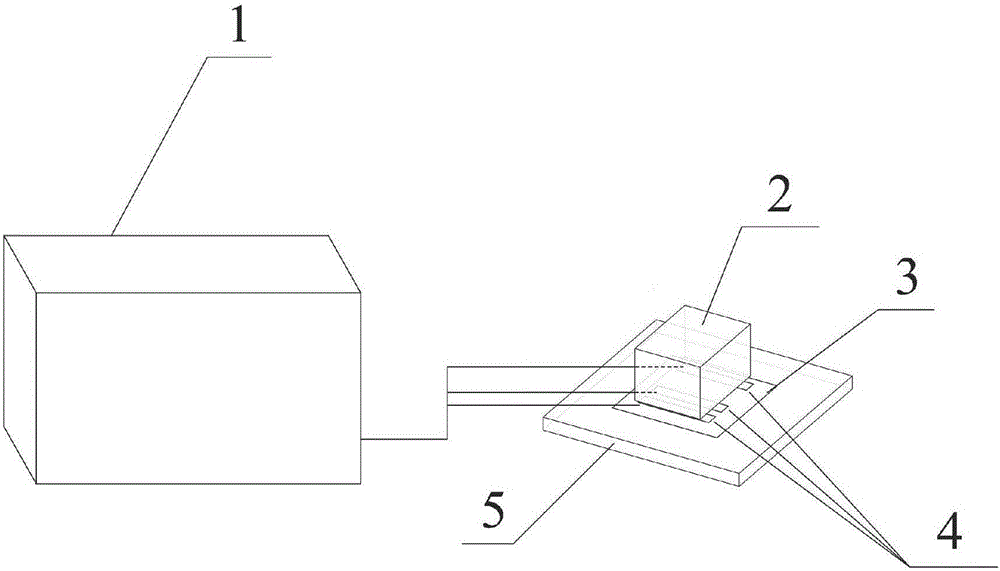

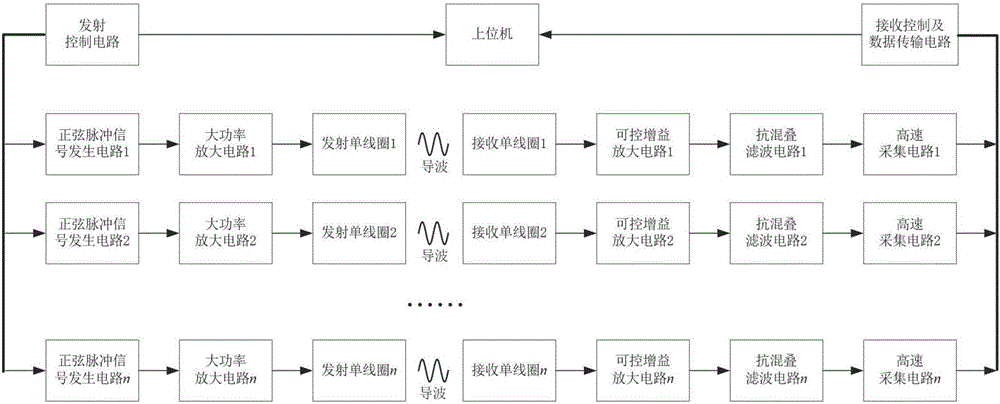

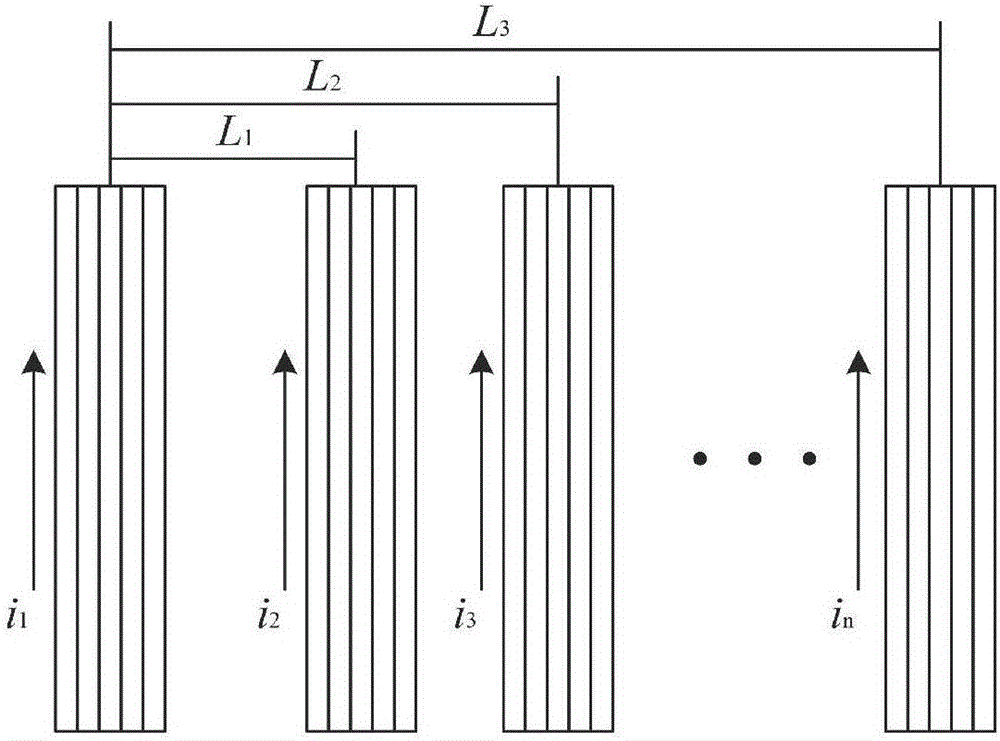

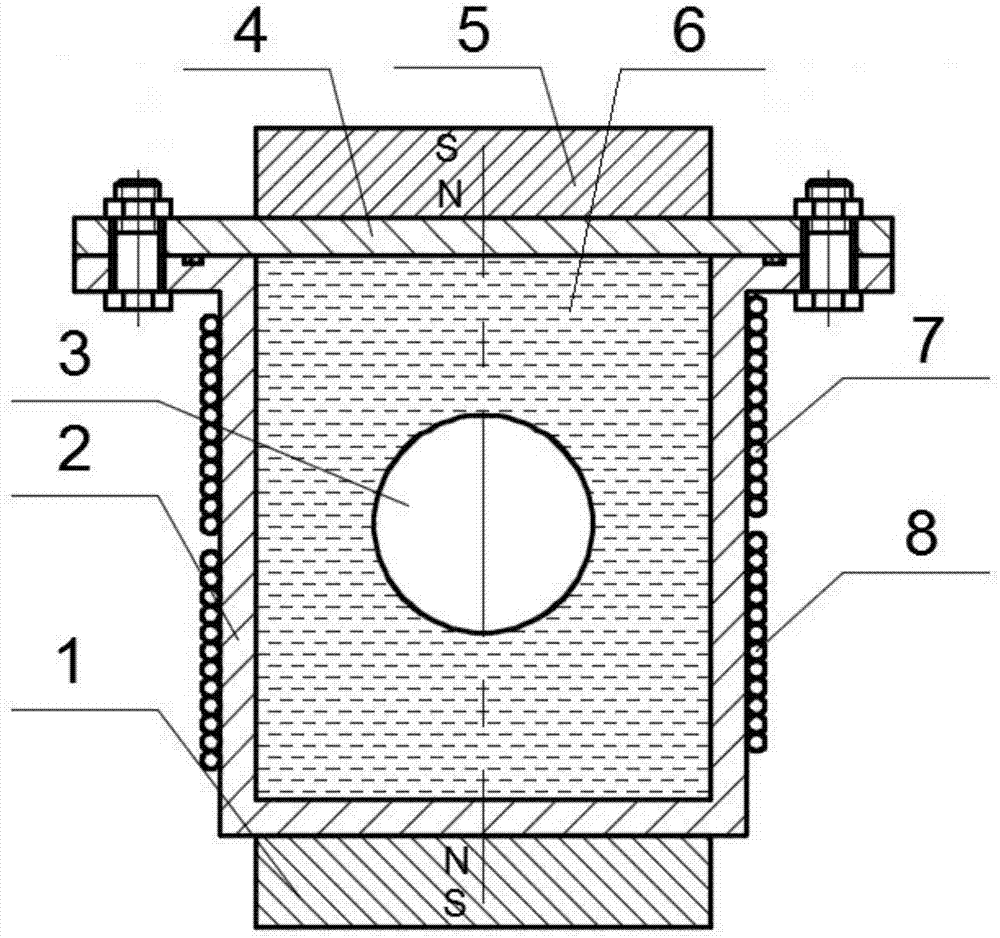

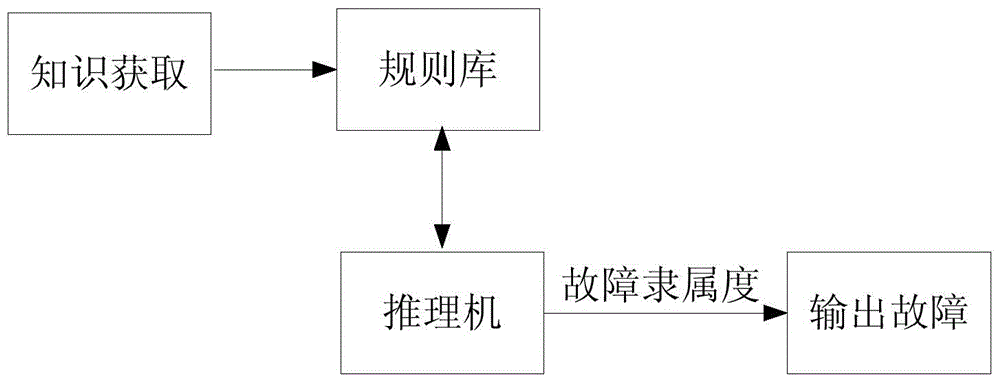

Multicoil ultrasonic guided-wave device of arbitrary frequency, and guided wave excitation method and receiving method thereof

InactiveCN106568847AEnhanced transmission signalUltrasonic/sonic/infrasonic wave generationResponse signal detectionPhase shiftedExcitation current

The invention belongs to the technical field of nondestructive test, and more specifically relates to a multicoil ultrasonic guided-wave device of arbitrary frequency, and a guided wave excitation method and a guided wave receiving method thereof. The multicoil ultrasonic guided-wave device is used for nondestructive test of metal sheets and pipes, and comprises a multichannel excitation and receiving circuit device, a magnet, a magnetic induced contraction band, and a multicoil subassembly. The guided wave excitation method comprises following steps: 1, the arrangement manner of the transmitting multicoil subassembly is determined; 2, the type of guided wave is selected; 3, the frequency dispersion curve of guided wave in a piece to be tested is calculated; 4, guided wave mode and working points thereof are selected; 5, the phase difference of excitation current in the coils are calculated; 6, drive pulse is generated based on calculate results obtained in step 4, and ultrasonic guided-wave is transmitted. The guided wave receiving method comprise following steps: 1, the combination arrangement manner of the receiving multicoil is determined; 2, the type of guided wave is selected; 3, the frequency dispersion curve of guided wave in the piece to be tested is calculated; 4, the type, mode, and working points of guided wave are selected; 5, the phase difference of each coil in signal receiving is calculated; and 6, phase shift and superposition of the receiving signals of the coils are realized.

Owner:哈尔滨零声科技有限公司

Magnetic fluid acceleration sensor based on first-order buoyancy principle

InactiveCN104849495ASolve mobility problemsSolve the problem that injection is difficult or even impossible to fillAcceleration measurementMagnetic liquidsAcceleration Unit

A magnetic fluid acceleration sensor based on a first-order buoyancy principle belongs to the field of mechanical engineering measurement. The problem that the existing magnetic fluid acceleration sensor cannot be applied in engineering practice due to a variety of structure problems is solved successfully. The device comprises a first permanent magnet (1), a shell (2), a mass block (3), an end cover (4), a second permanent magnet (5), magnetic liquid (6), an upper coil (7), and a lower coil (8). When acceleration is produced outside, the nonmagnetic mass block moves in a cavity, the volume distribution of the magnetic liquid (6) in the shell (2) changes, a signal is output, and first-order buoyancy formed by the first permanent magnet (1) and the second permanent magnet (5) inside the magnetic liquid (6) causes frequency difference between the mass block (3) and the shell (2). Thus, the sensitivity of the sensor is improved.

Owner:BEIJING JIAOTONG UNIV

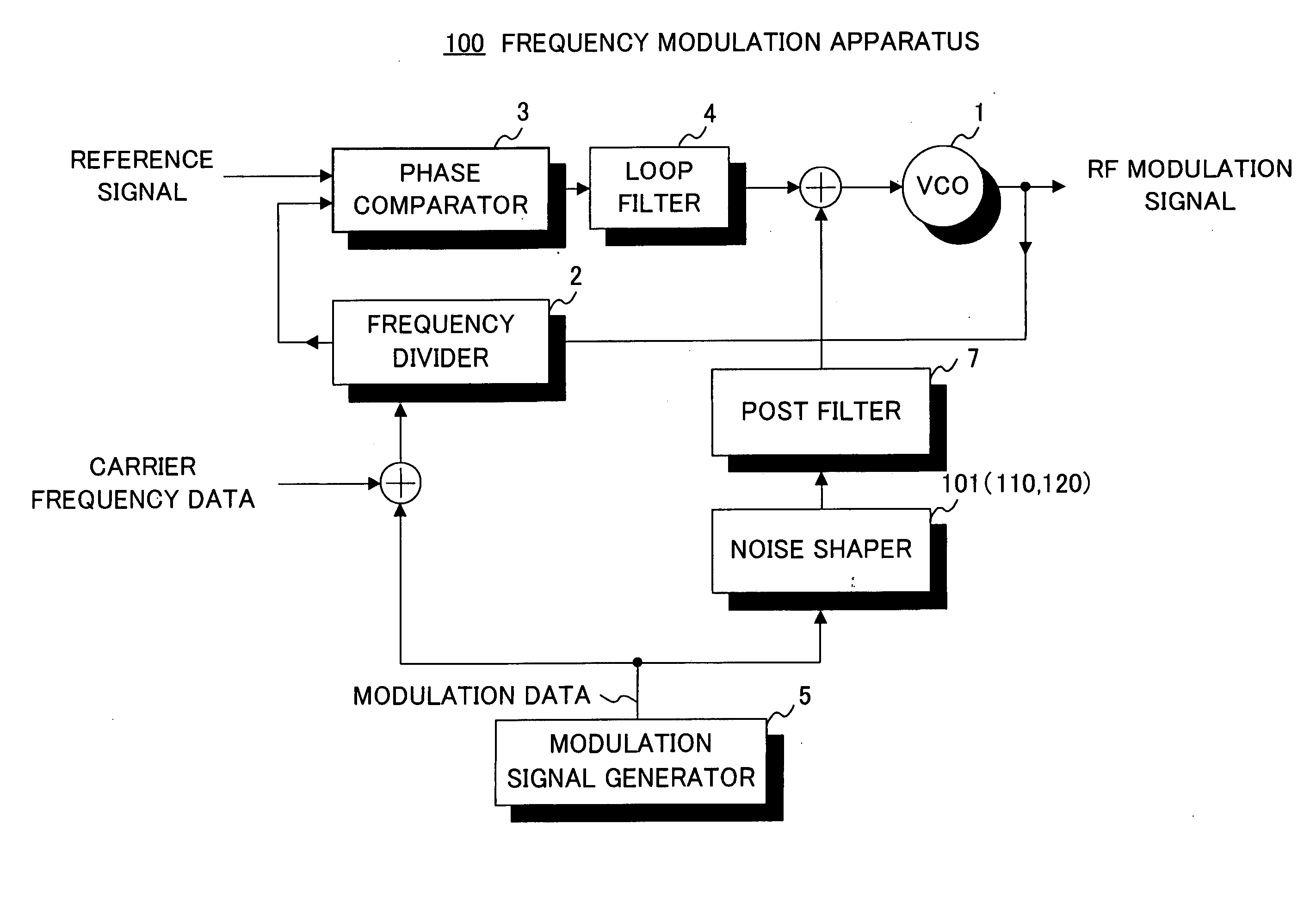

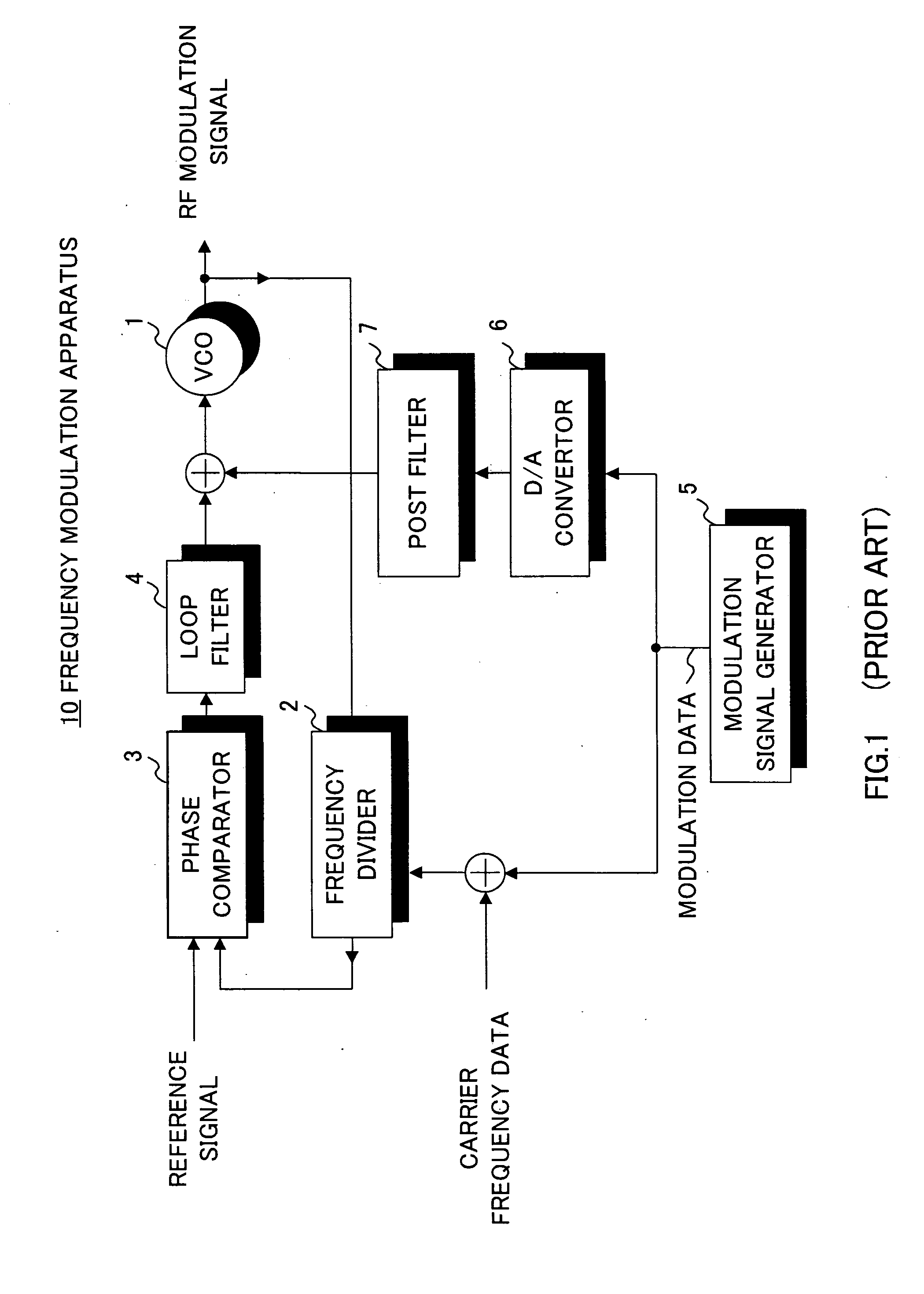

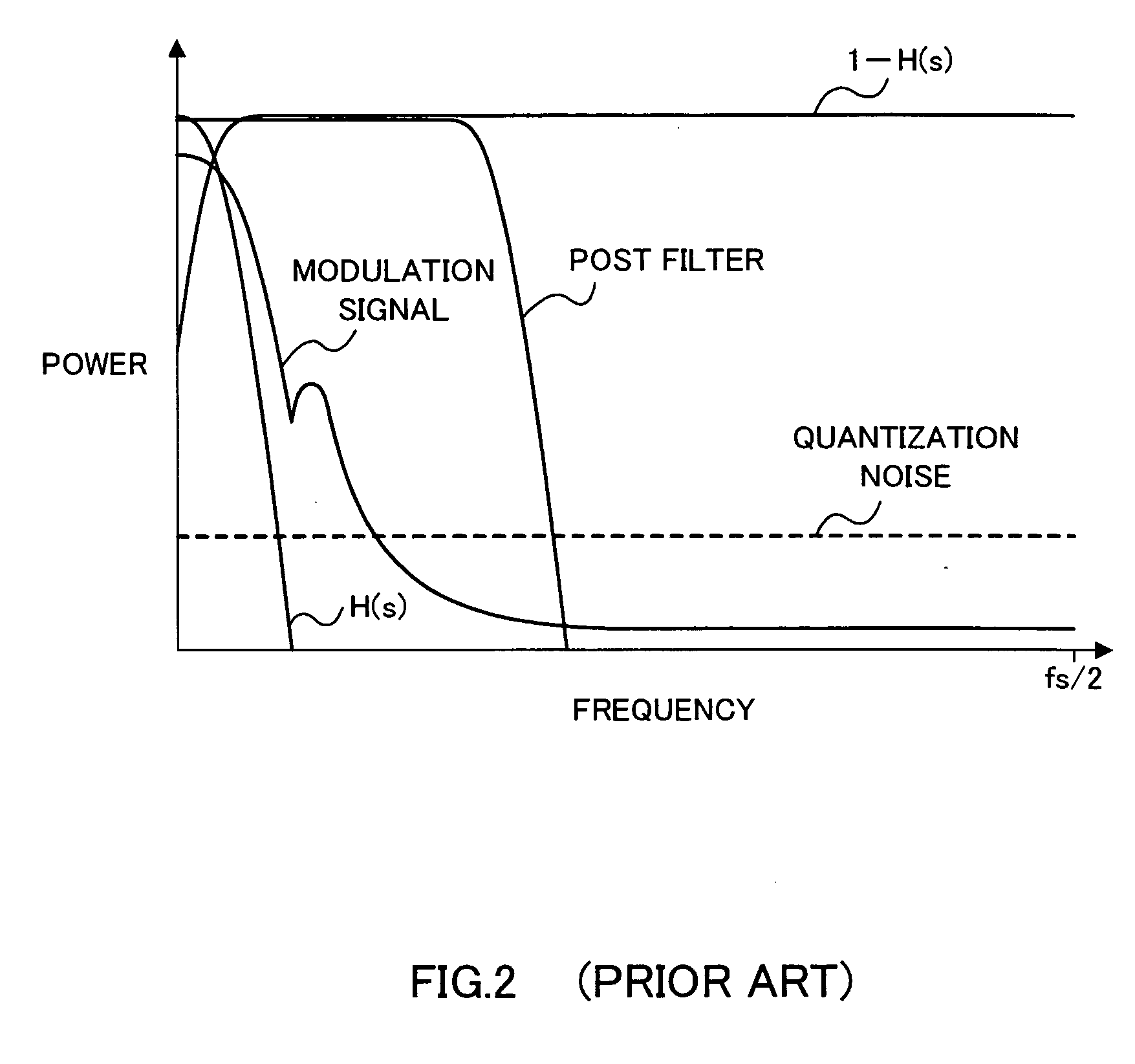

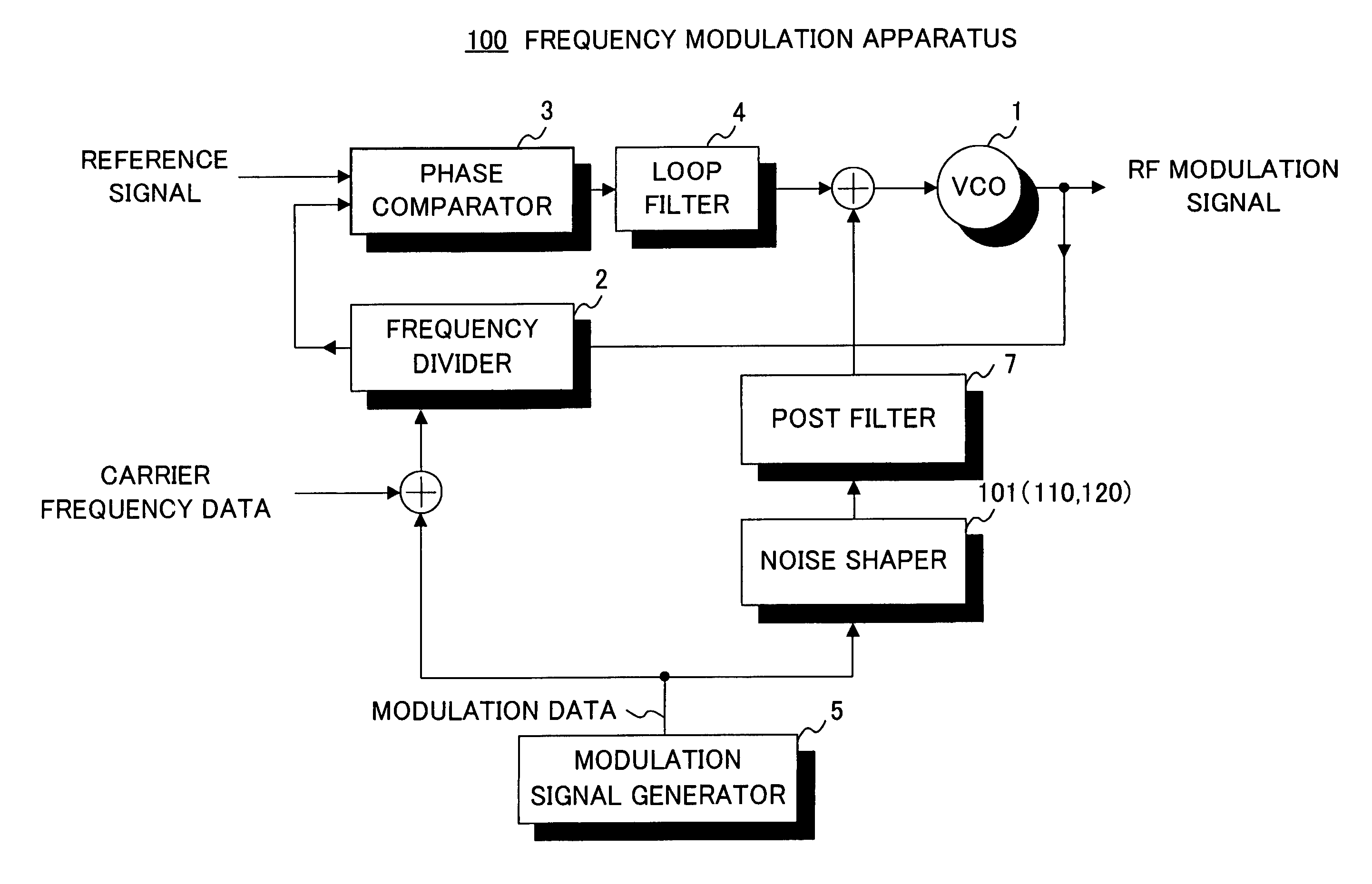

Apparatus

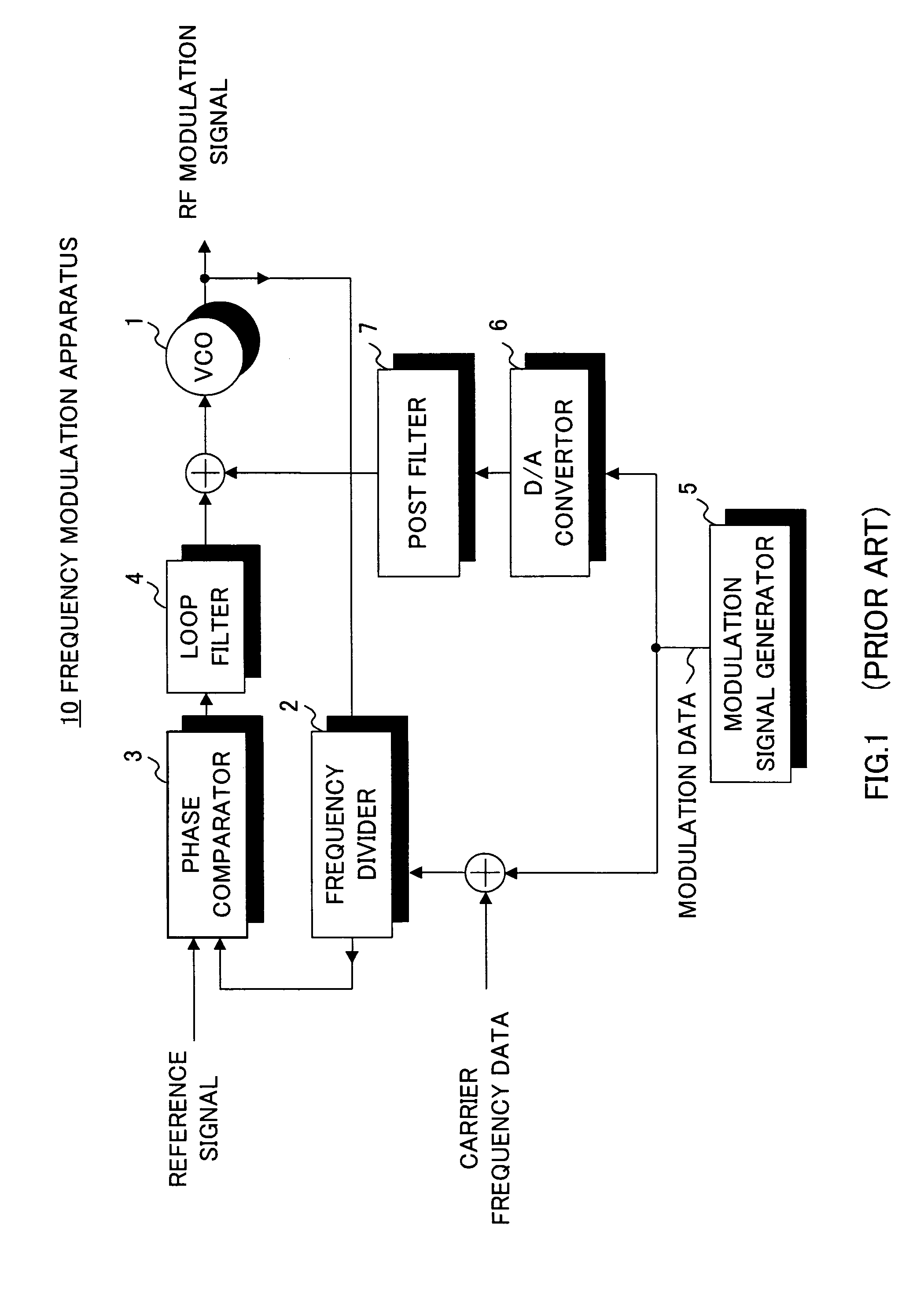

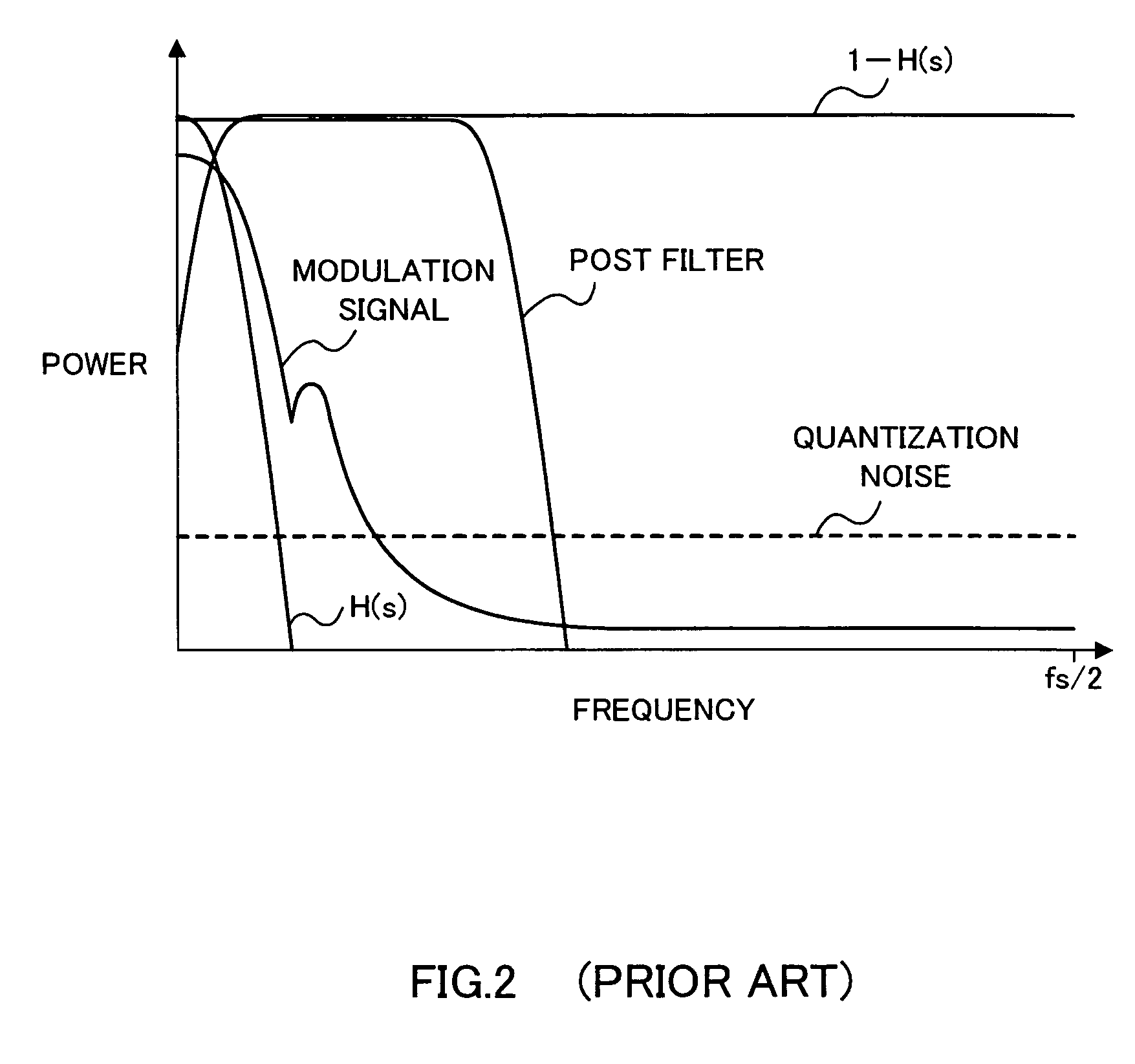

ActiveUS20050237121A1High quality transmission signalSuppress interferencePulse automatic controlAngle modulation detailsFrequency spectrumNoise shaping

A two-point frequency modulation apparatus is proposed whereby the spectrum of transmission waves is kept within the spectrum mask. Voltage is supplied to the control voltage terminal of VCO 1 in accordance with modulation data via noise shaper 101 that has operating characteristics of attenuating more noise at higher frequencies. As a result, by virtue of the working of noise shaper 101, the signal level outputted from the PLL circuit combining the modulation signal and the quantization noise decreases in proportion to the distance form the central frequency, so that two-point frequency modulation apparatus 100 is made possible whereby the spectrum of an RF modulation signal is kept within the spectrum mask.

Owner:PANASONIC CORP

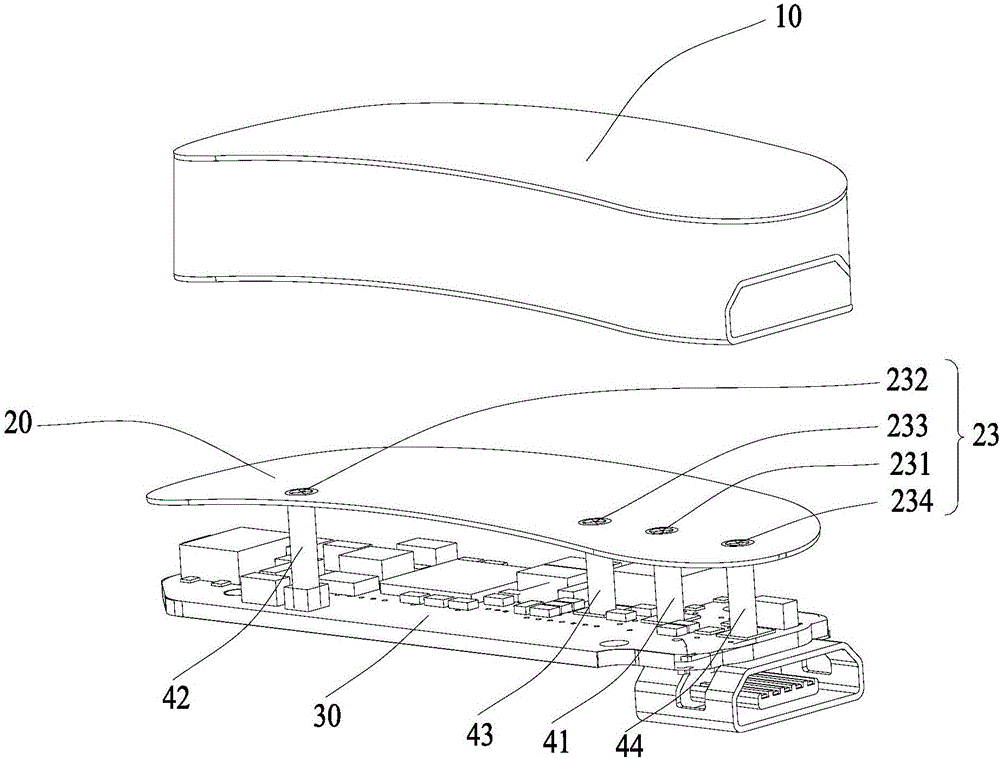

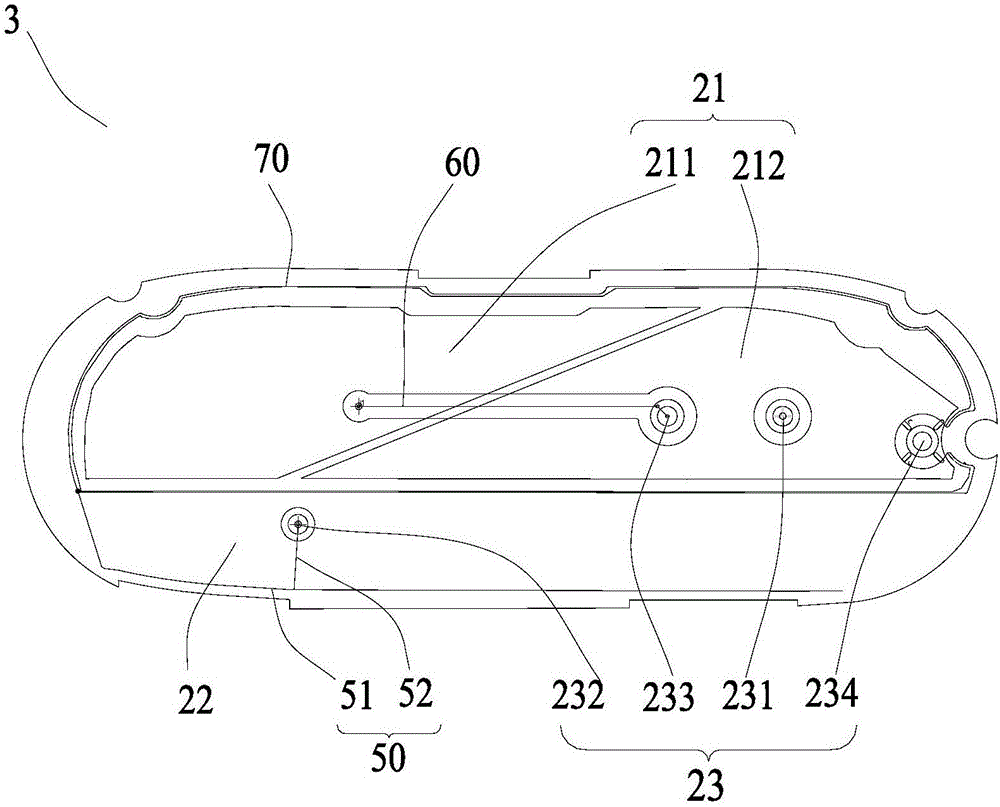

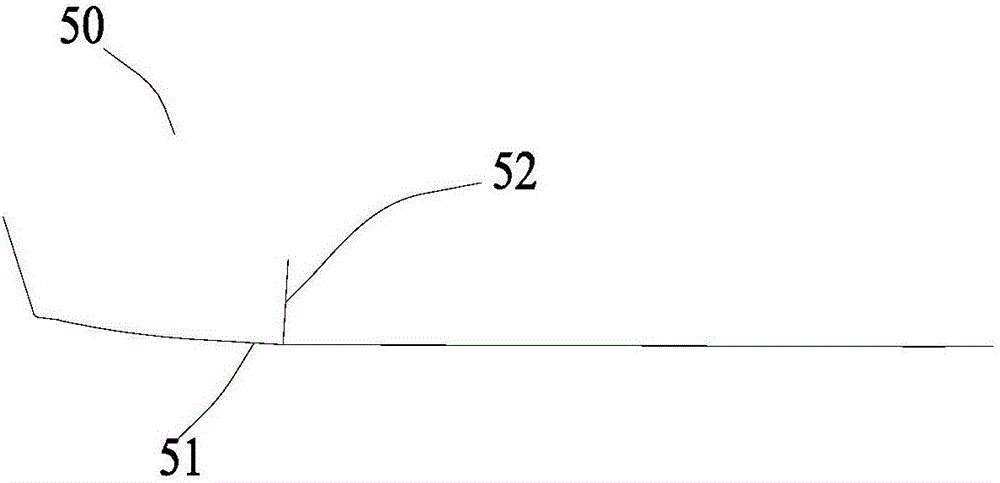

Touch Bluetooth headset

ActiveCN106060698AEnhanced transmission signalTakes up little space inside the headsetHeadphones for stereophonic communicationNetwork topologiesTouchpadElectromagnetic shielding

The invention is applicable to the technical field of headsets, and relates to a touch Bluetooth headset. The touch Bluetooth headset comprises a shell, a touchpad, a mainboard, a Bluetooth antenna, a first ejector pin and a second ejector pin; the touchpad is a flexible touchpad; the mainboard and the flexible touchpad are fixed on the shell oppositely; the flexible touchpad is provided with a plurality of metal contacts; one end of each of the first ejector pin and the second ejector pin is fixed with the mainboard, and the other end of each of the first ejector pin and the second ejector pin extends towards the flexible touchpad and leans against the metal contacts; and the Bluetooth antenna is laid on the flexible touchpad and connected with the metal contacts. According to the touch Bluetooth headset provided by the invention, the touchpad is set as the flexible touchpad and installed close to an inner wall of the headset shell, so that the headset can be designed to be more miniatured; and besides, the Bluetooth antenna is additionally installed in the flexible touchpad, and the ejector pins are used for jacking up the Bluetooth antenna, so that electromagnetic shielding can be reduced, thus a miniature Bluetooth headset can have a better signal transmission distance.

Owner:SHENZHEN GRANDSUN ELECTRONICS CO LTD

Two-point frequency modulation apparatus

ActiveUS7706495B2Suppress interferenceImprove accuracyPulse automatic controlAngle modulation detailsFrequency spectrumNoise shaping

A two-point frequency modulation apparatus is proposed whereby the spectrum of transmission waves is kept within the spectrum mask. Voltage is supplied to the control voltage terminal of VCO 1 in accordance with modulation data via noise shaper 101 that has operating characteristics of attenuating more noise at higher frequencies. As a result, by virtue of the working of noise shaper 101, the signal level outputted from the PLL circuit combining the modulation signal and the quantization noise decreases in proportion to the distance form the central frequency, so that two-point frequency modulation apparatus 100 is made possible whereby the spectrum of an RF modulation signal is kept within the spectrum mask.

Owner:PANASONIC CORP

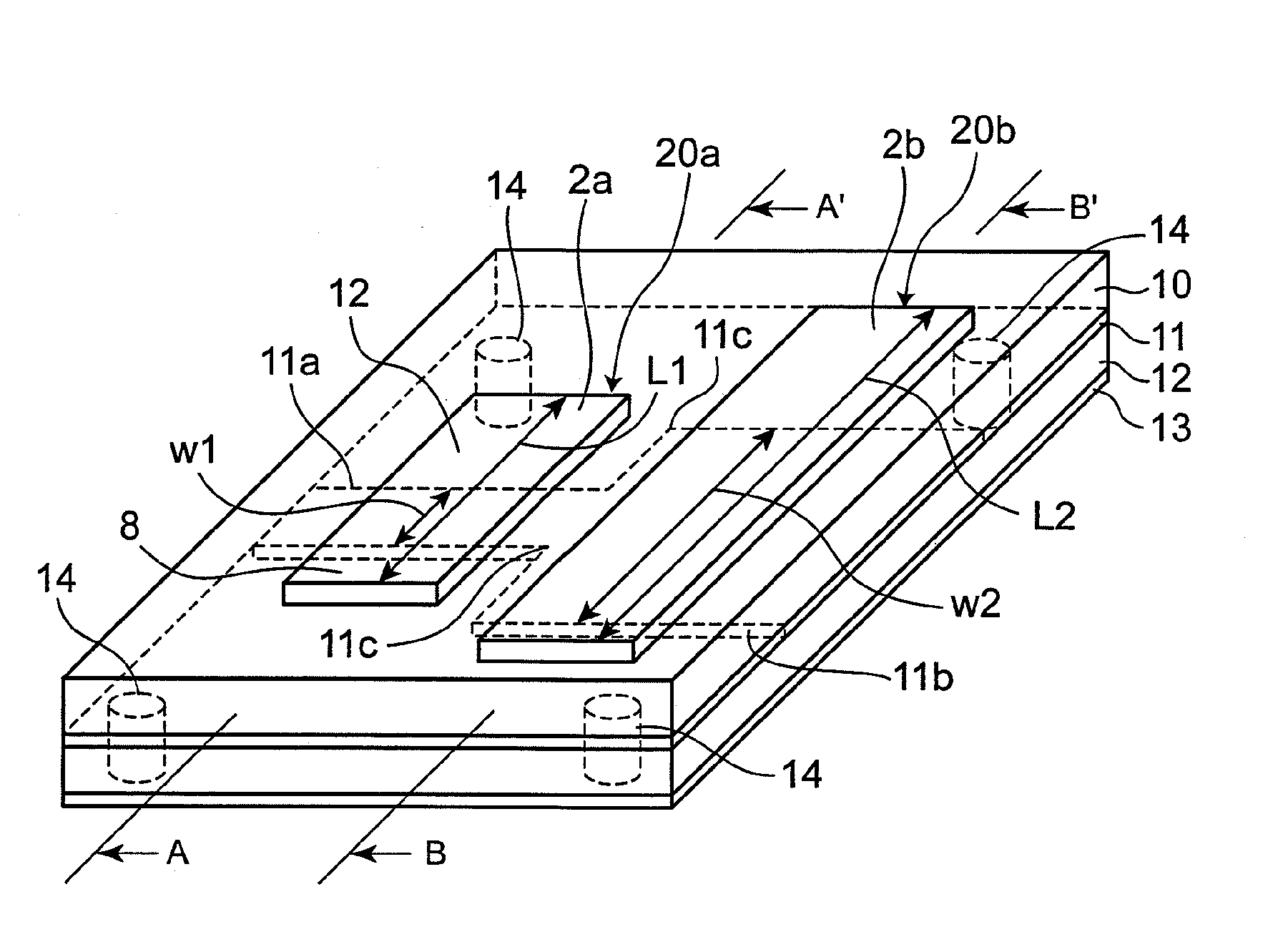

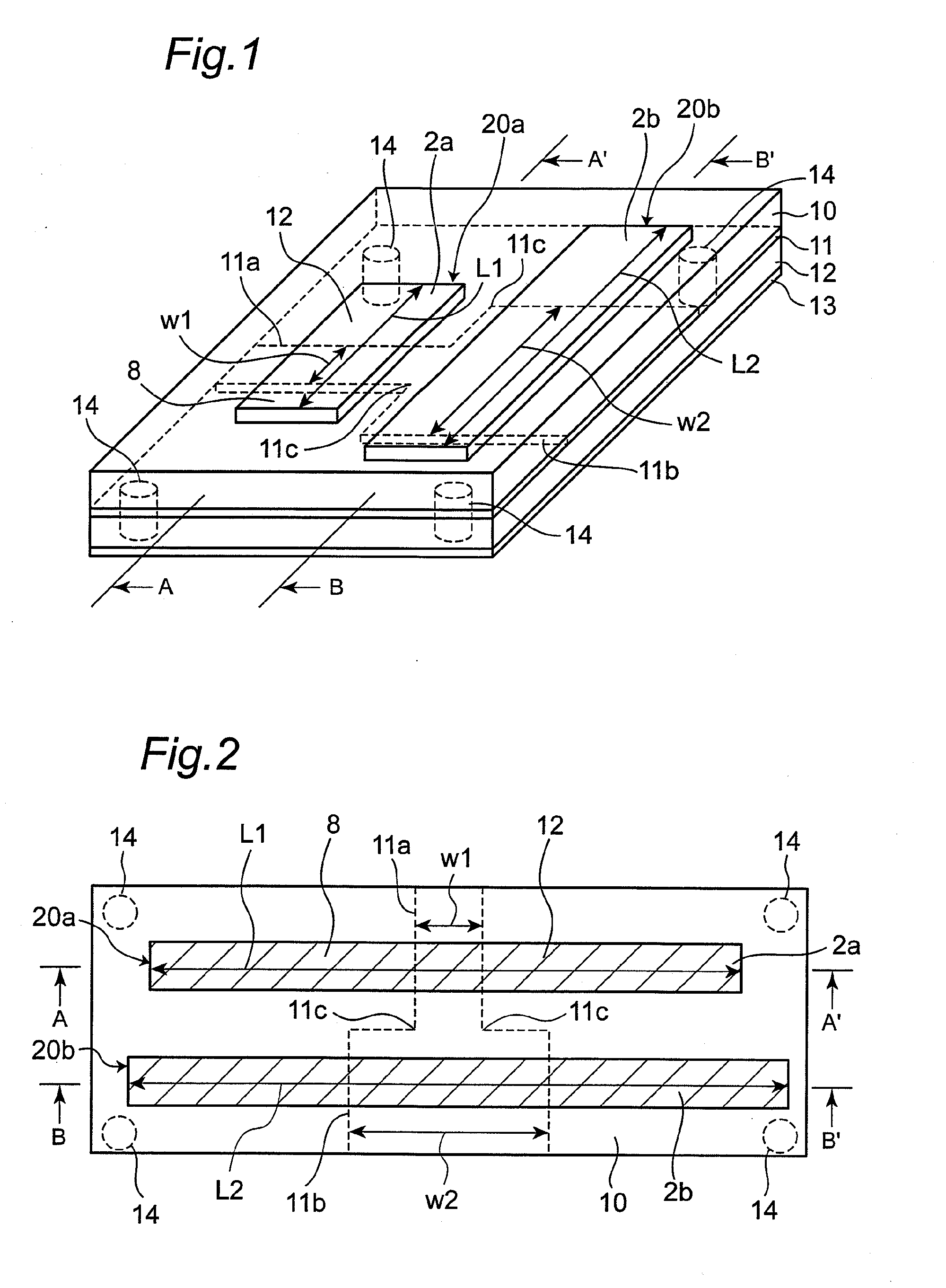

Differential transmission line including two transmission lines parallel to each other

ActiveUS20090315649A1Cost reductionReduce occupation areaMultiple-port networksWaveguidesTransmission lineEngineering

In a differential transmission line, a substrate has first and second surfaces parallel to each other, and a first grounding conductor is formed on the second surface of the substrate. A dielectric layer is formed on the first grounding conductor, and a second grounding conductor is formed on the dielectric layer. First and the second signal conductors are formed to be parallel to each other on the first surface of the substrate. The first signal conductor and the first and second grounding conductors constitutes a first transmission line, and the second signal conductor and the first and second grounding conductors constitutes a second transmission line. A slot is formed in the first grounding conductor to sterically intersect with the first and second signal conductors and to be orthogonal to a longitudinal direction thereof, and a connecting conductor is formed for connecting the first grounding conductor with the second grounding conductor.

Owner:PANASONIC CORP

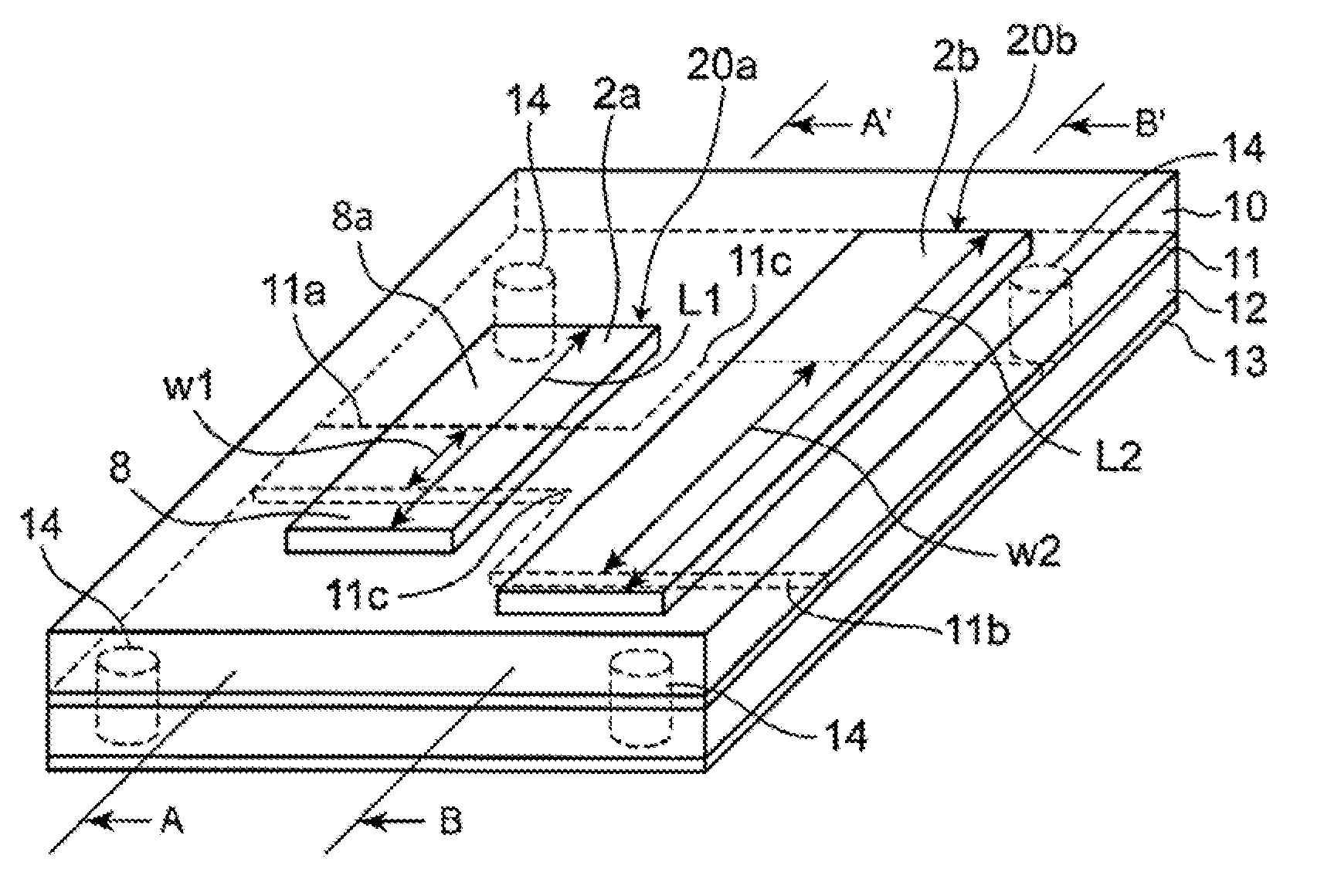

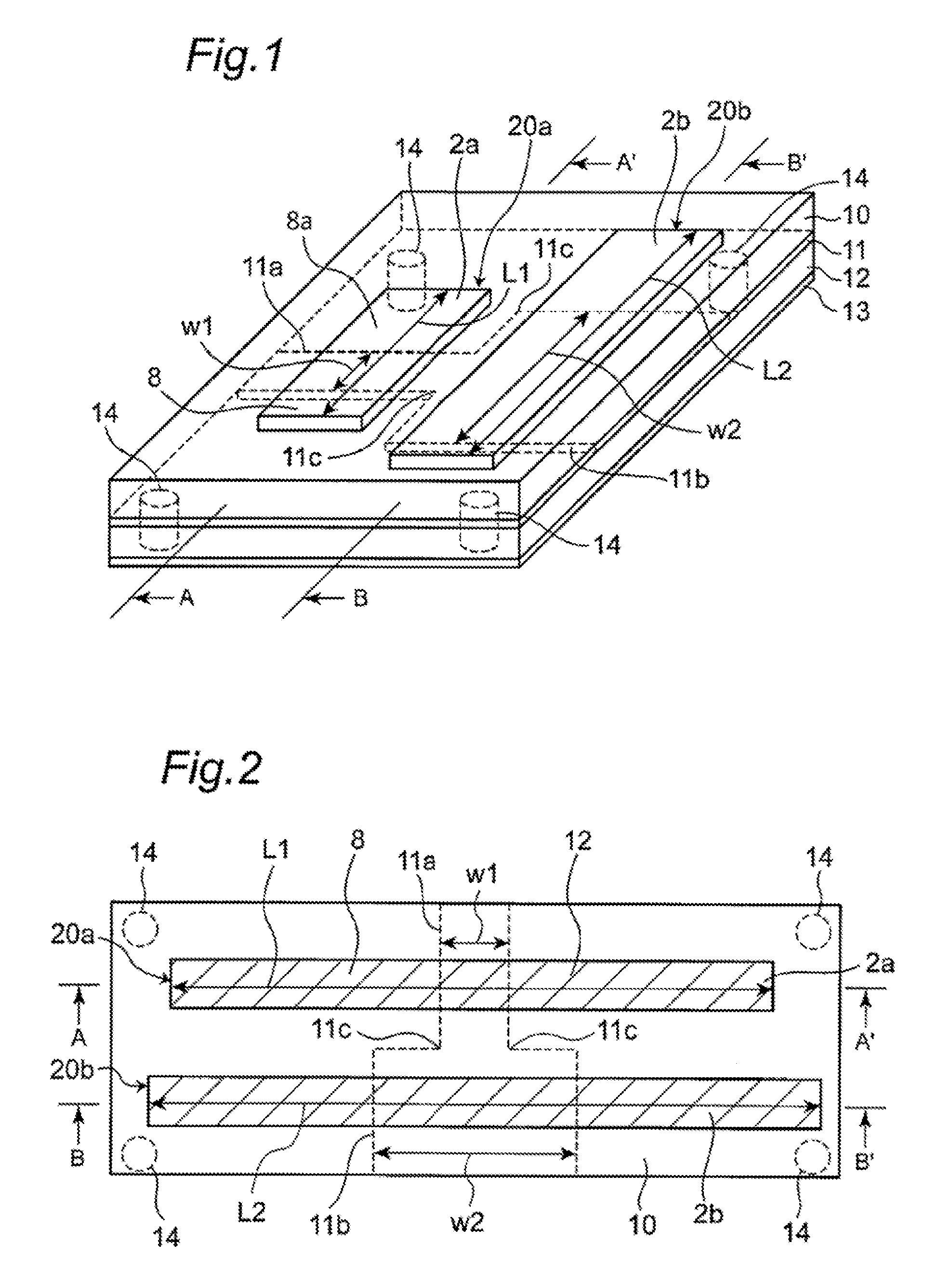

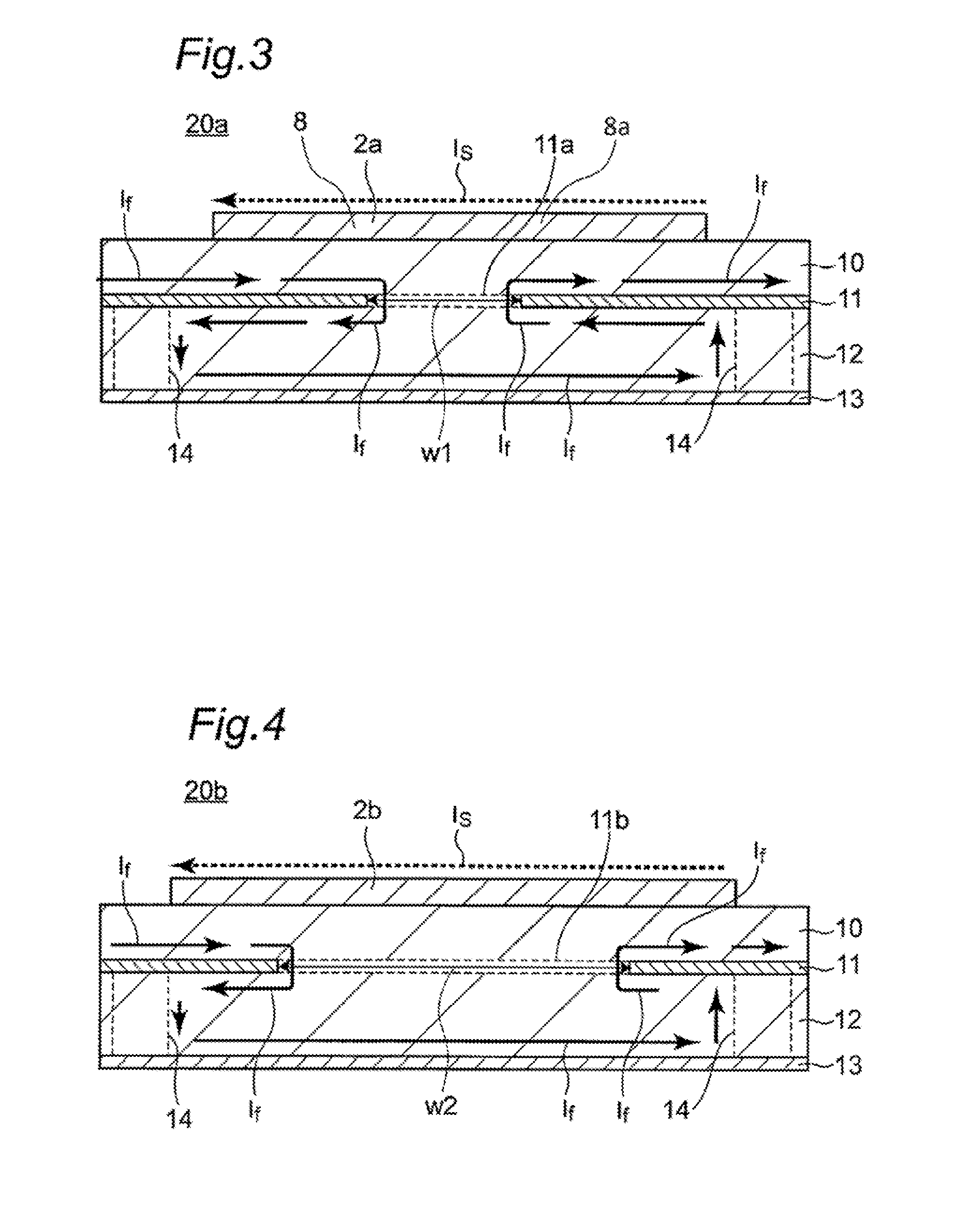

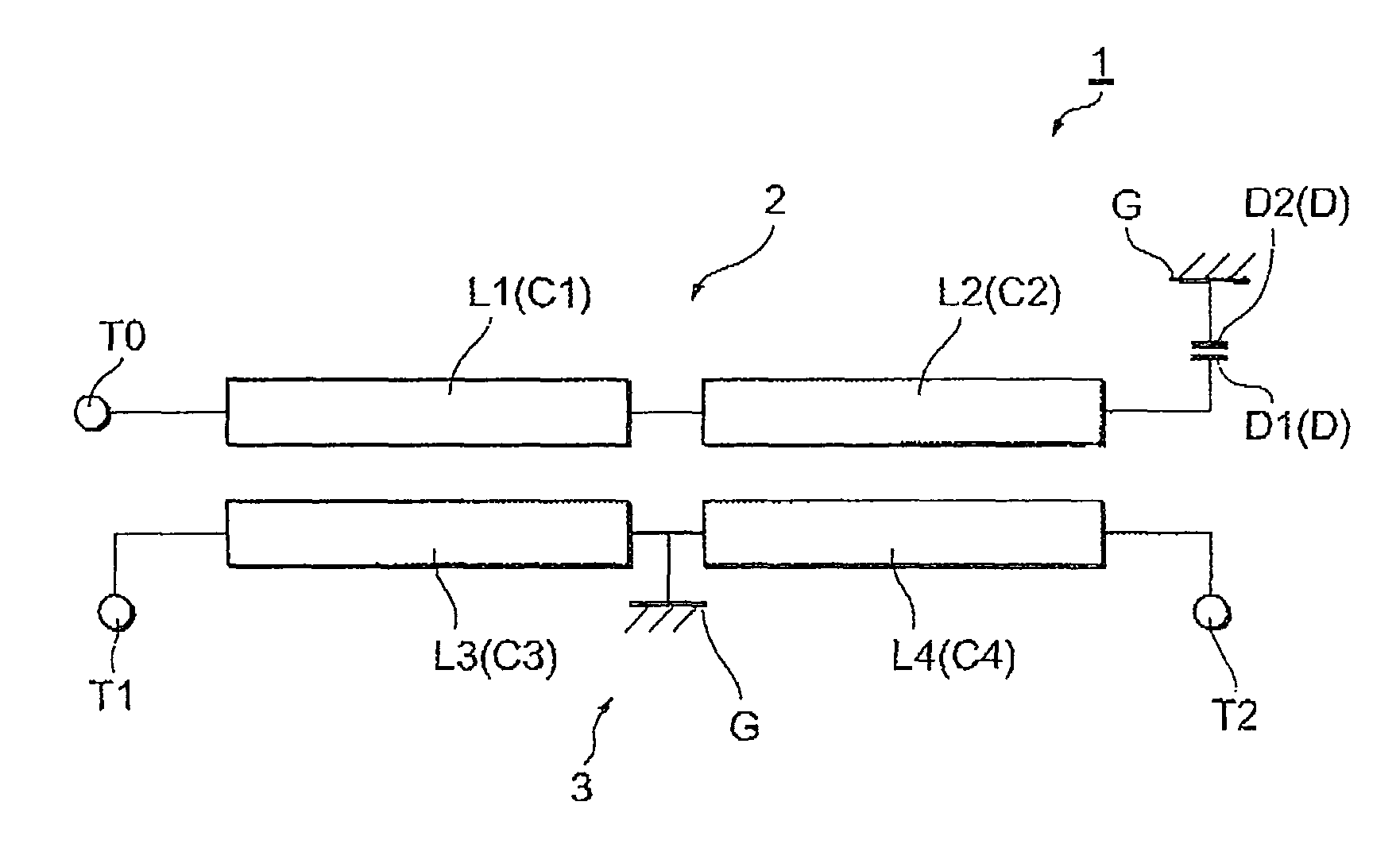

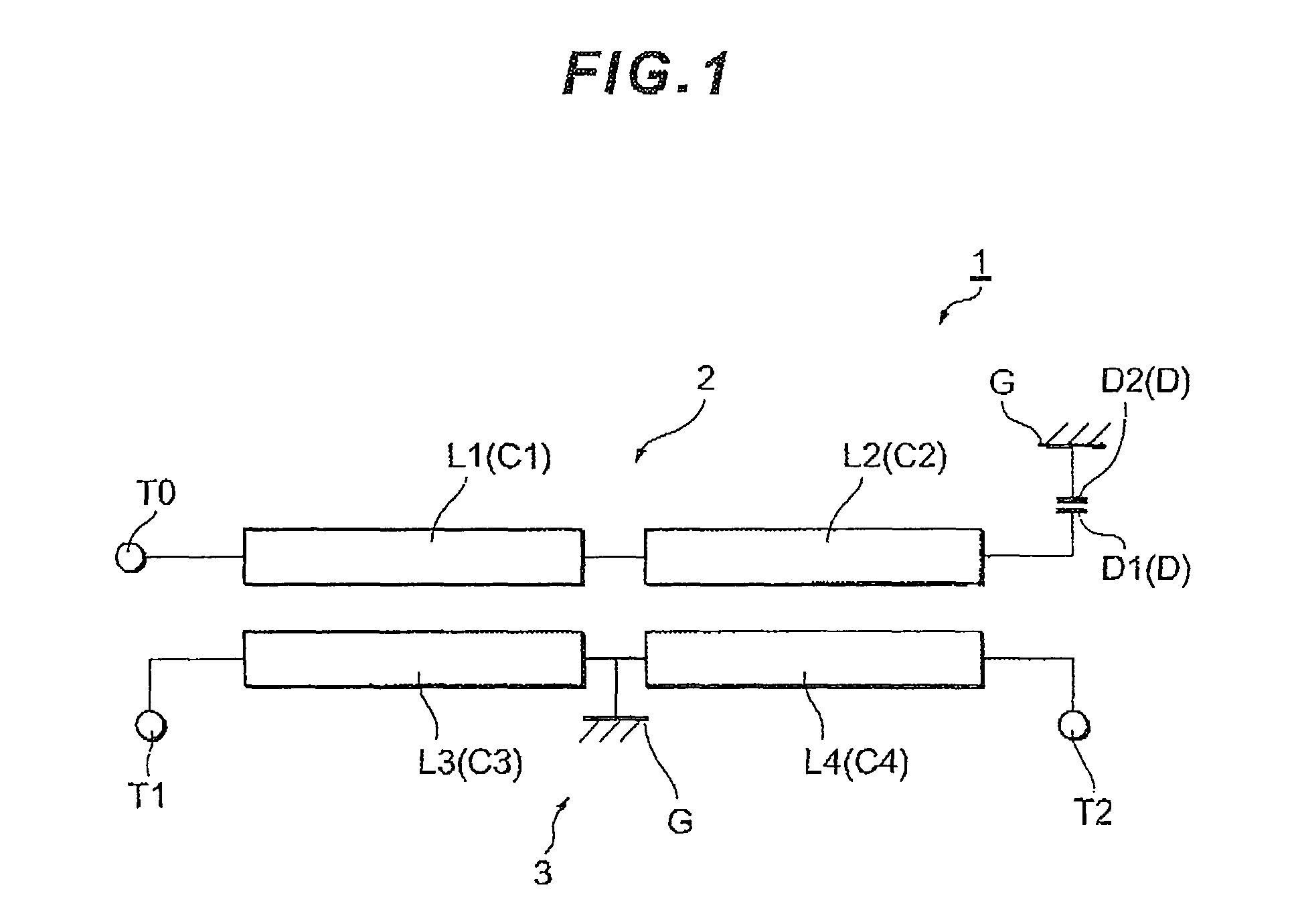

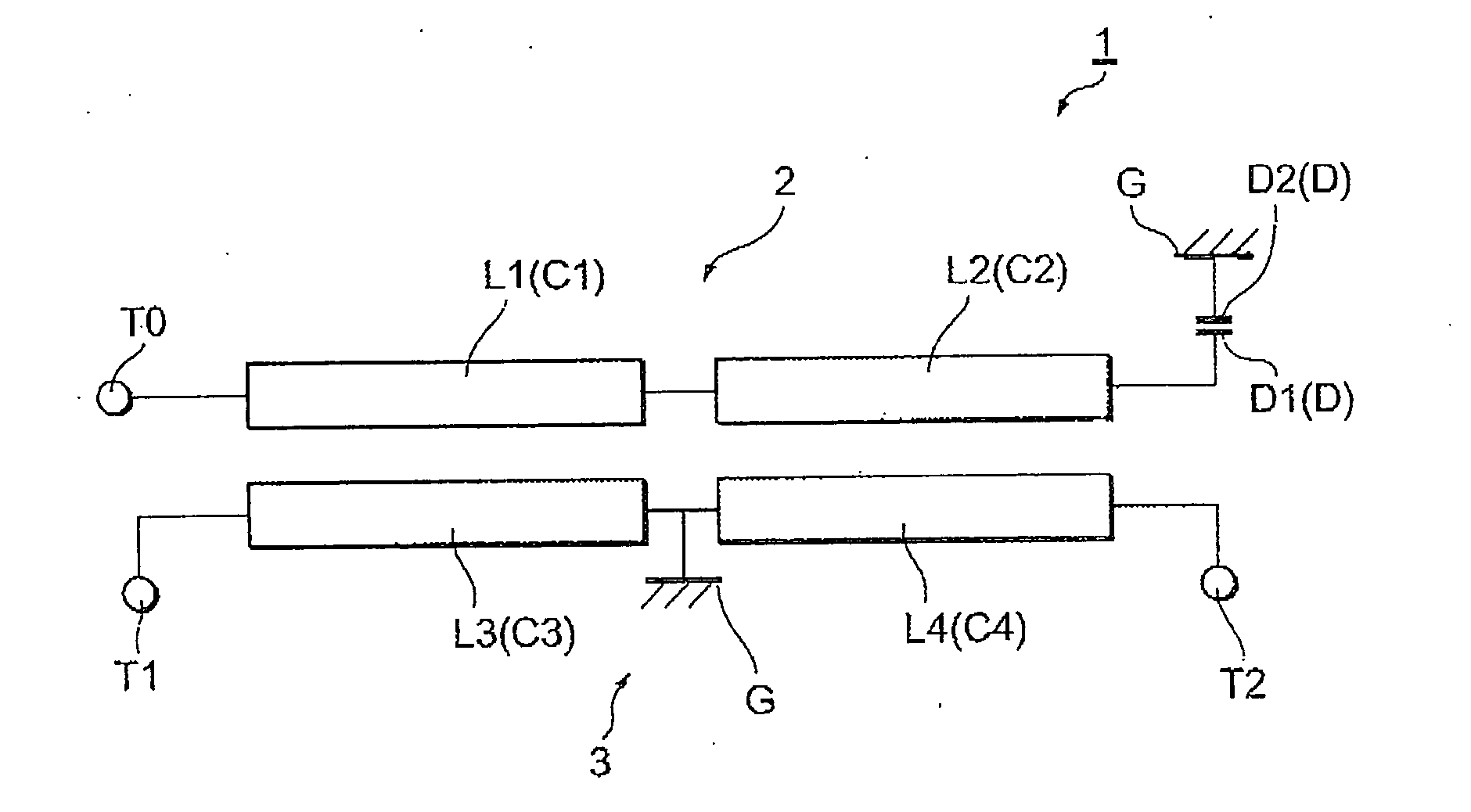

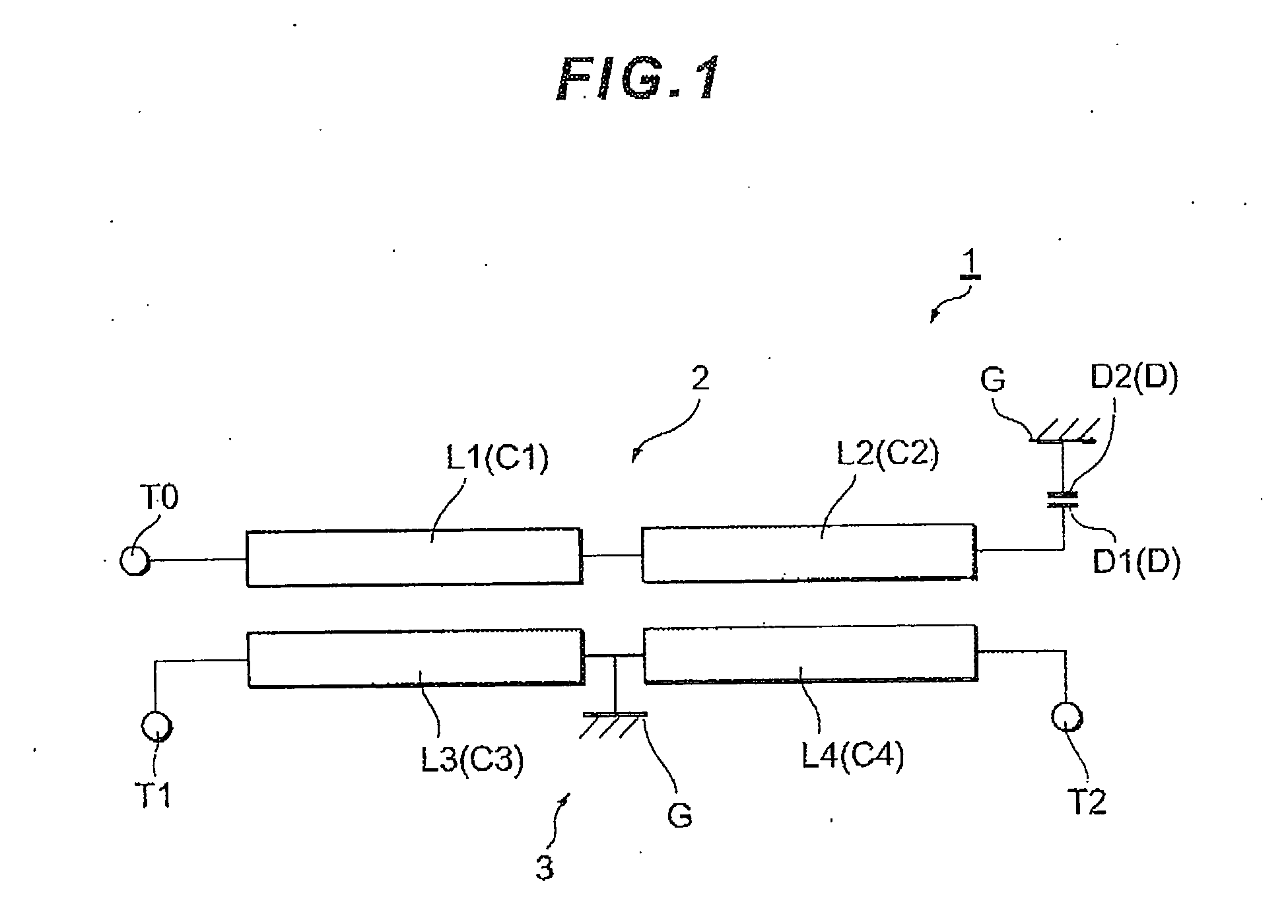

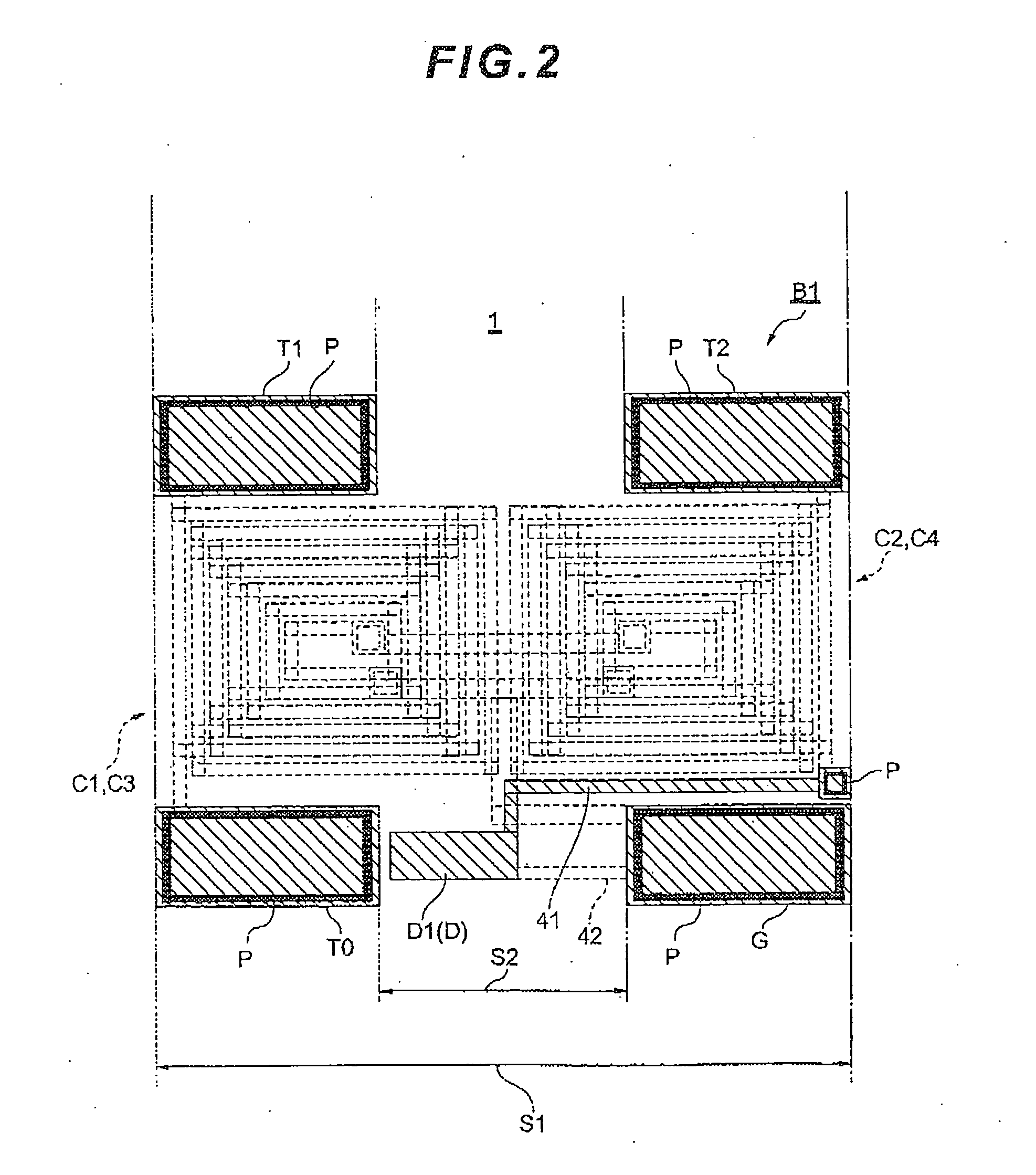

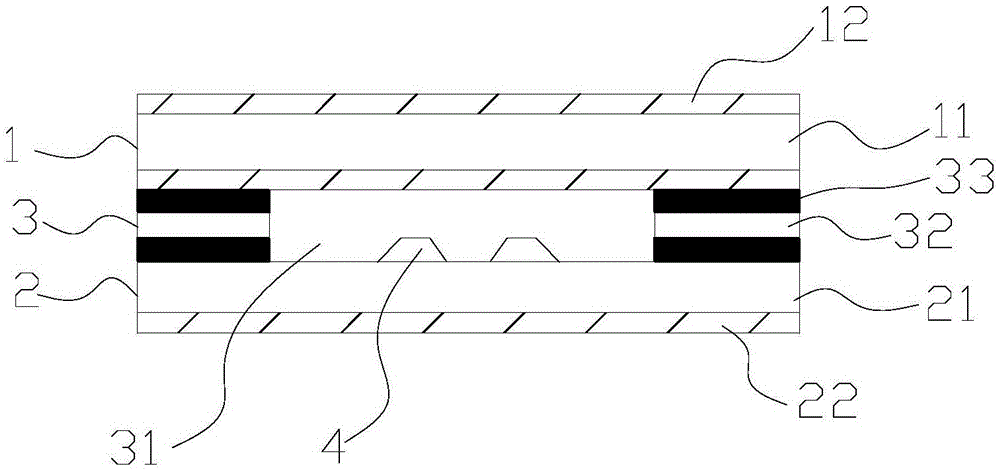

Thin film balun

ActiveUS8203396B2Avoid resonant frequencyHigh frequencyMultiple-port networksOne-port networksEngineeringCapacitor

The present invention provides a thin film balun capable of preventing a resonant frequency from being increased to a high frequency, and thus realizing a preferable passage characteristic. A thin film balun 1 includes: an unbalanced transmission line 2 having a first coil portion C1 and a second coil portion C2; and a balanced transmission line 3 having a third coil portion C3 and a fourth coil portion C4 which are magnetically coupled with the first coil portion C1 and the second coil portion C2, respectively. The first coil portion C1 is connected to an unbalanced terminal T0, and the second coil portion C2 is connected to a ground terminal G (ground potential) via a capacitor D (C component). The third coil portion C3 is connected to a balanced terminal T1 and the fourth coil portion C4 is connected to a second balanced terminal T2. The capacitor D is provided, in a plan view, in an area S1 between the outer end of the unbalanced terminal T0 and the outer end of the ground terminal G.

Owner:TDK CORPARATION

Filter arrangement having first and second duplex filters

ActiveUS8723619B2Enhanced transmission signalSave spaceMultiple-port networksRadio transmissionRadio receptionTransmitter

Owner:KATHREIN SE

Thin film balun

ActiveUS20100164643A1Avoid resonant frequencyPreferable characteristicMultiple-port networksOne-port networksEngineeringCapacitor

The present invention provides a thin film balun capable of preventing a resonant frequency from being increased to a high frequency, and thus realizing a preferable passage characteristic. A thin film balun 1 includes: an unbalanced transmission line 2 having a first coil portion C1 and a second coil portion C2; and a balanced transmission line 3 having a third coil portion C3 and a fourth coil portion C4 which are magnetically coupled with the first coil portion C1 and the second coil portion C2, respectively. The first coil portion C1 is connected to an unbalanced terminal T0, and the second coil portion C2 is connected to a ground terminal G (ground potential) via a capacitor D (C component). The third coil portion C3 is connected to a balanced terminal T1 and the fourth coil portion C4 is connected to a second balanced terminal T2. The capacitor D is provided, in a plan view, in an area S1 between the outer end of the unbalanced terminal T0 and the outer end of the ground terminal G.

Owner:TDK CORPARATION

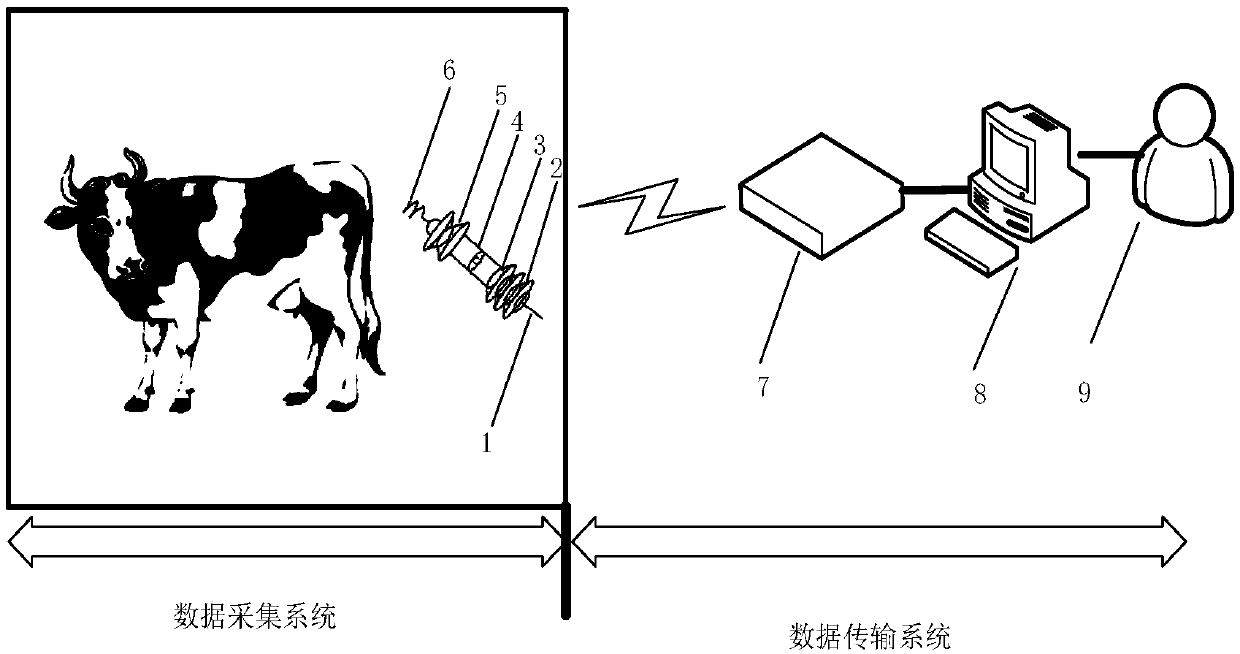

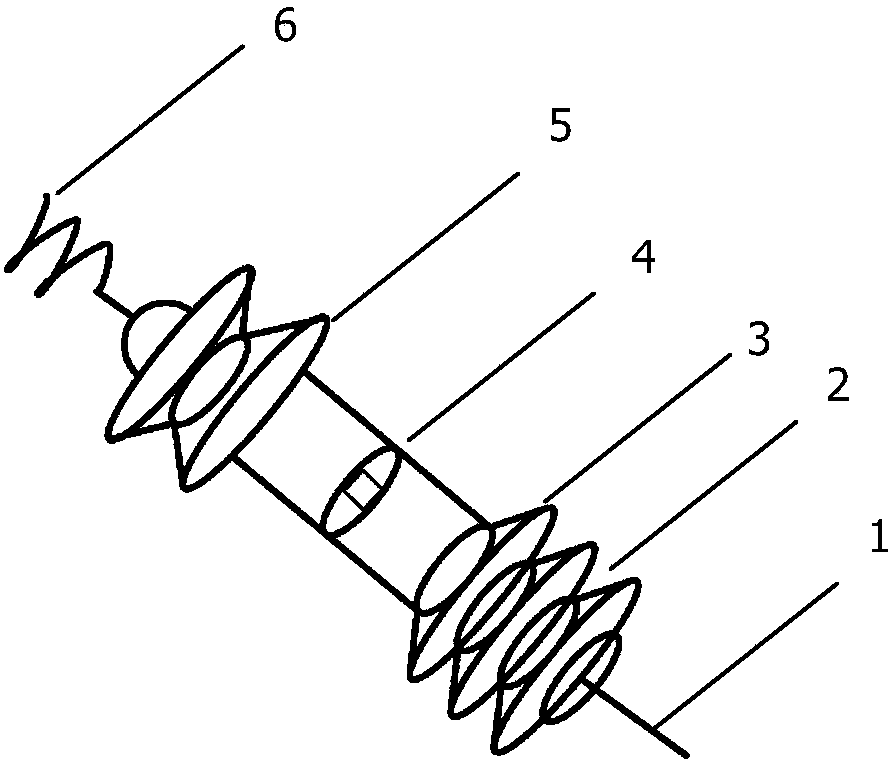

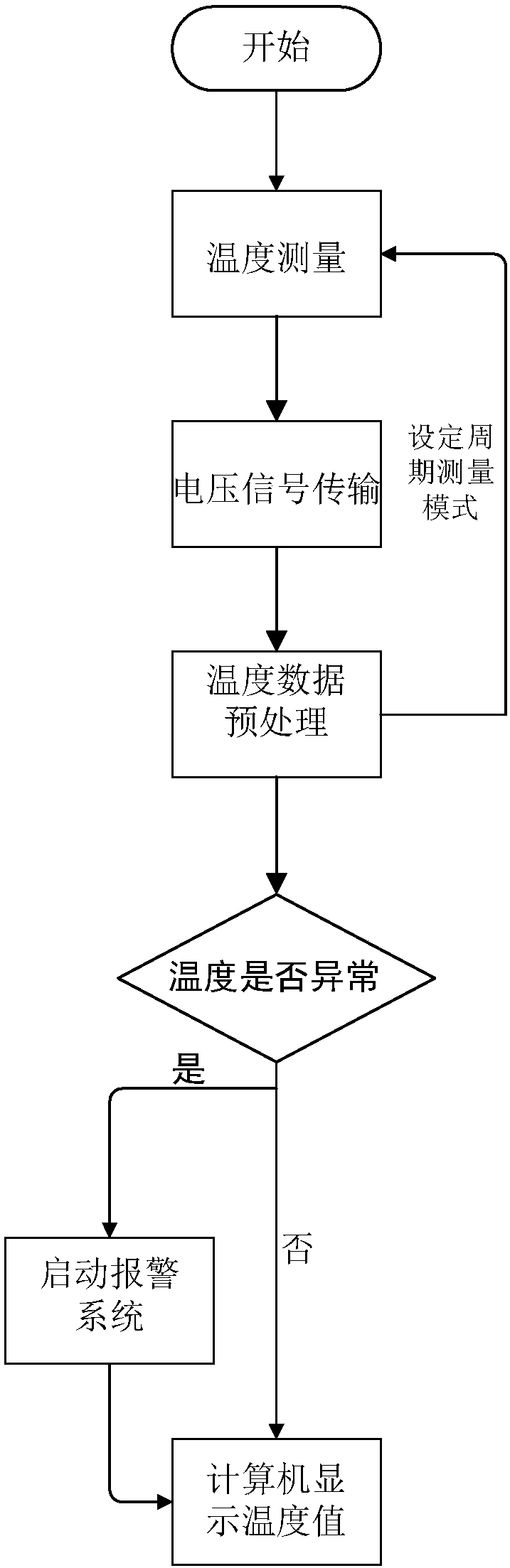

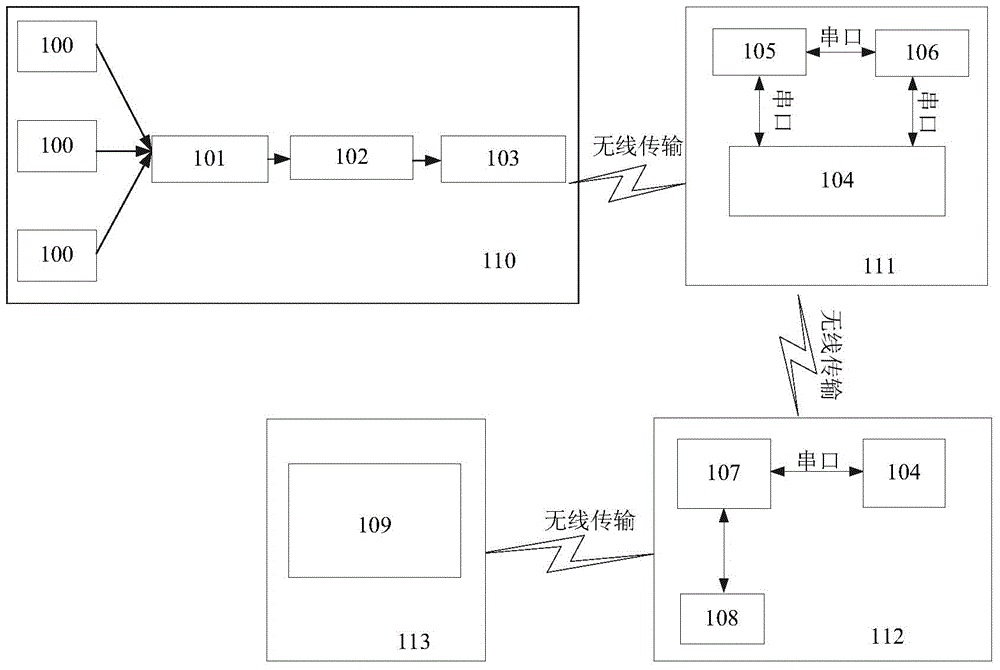

System and method for monitoring body temperature of dairy cow in real time

InactiveCN107593498AOvercome errorHigh precisionThermometers using electric/magnetic elementsUsing electrical meansConstant current sourceTemperature measurement

The invention provides a system and a method for monitoring the body temperature of a dairy cow in real time. According to the invention, a PT 1000 platinum resistance is used as a temperature measuring probe for acquiring the body temperature data of the dairy cow, and electric pressure generated by two ends of the PT 1000 platinum resistance are transmitted to a temperature treatment platform through an analog-digital converter, wherein the process of temperature acquisition is as follows: implanting a temperature sensor into the vagina of the dairy cow, and allowing the temperature measuring probe to contact with the vagina of the dairy cow, wherein the whole circuit module connected with the probe comprises a constant current source, the analog-digital converter, MCU and a wireless communication module; and the temperature information measured by the temperature sensor realizes wireless communication with a computer of a user through an STM32 microcontroller, so the temperature ofthe interior of the vagina of the dairy cow is finally displayed on the computer. The invention has the following advantages: the true body temperature of the dairy cow can be measured; meanwhile, themonitoring of the temperature information is realized; the body temperature information of the dairy cow is accurately monitored in real time; and simple structure, convenient operation and low priceare achieved.

Owner:NORTHWEST A & F UNIV

Transmission circuit, and communication apparatus using the same

InactiveUS7742541B2Enhanced transmission signalImprove efficiencyTelephonic communicationModulation with suppressed carrierTime segmentAngle modulation

A compact transmission circuit for outputting a highly linear transmission signal regardless of the output power level and operating at a high efficiency is provided. A signal generation section 11 generates an amplitude signal and quadrature data based on input data. A calculation section 21 calculates using the amplitude signal and the quadrature data to output a discrete value having a level discrete at every predetermine time period, and first and second phase signals. An amplitude amplification section 17 outputs a voltage controlled in accordance with the discrete value. Angular modulation sections 13 and 14 angular-modulate the phase signals and output first and second angle-modulated signals. Amplitude modulation sections 15 and 16 amplitude-modulate the angle-modulated signals with the voltage from the amplitude amplification section 17 and output first and second modulated signals. A combining section 18 combines the first and second modulated signals and outputs a transmission signal.

Owner:PANASONIC CORP

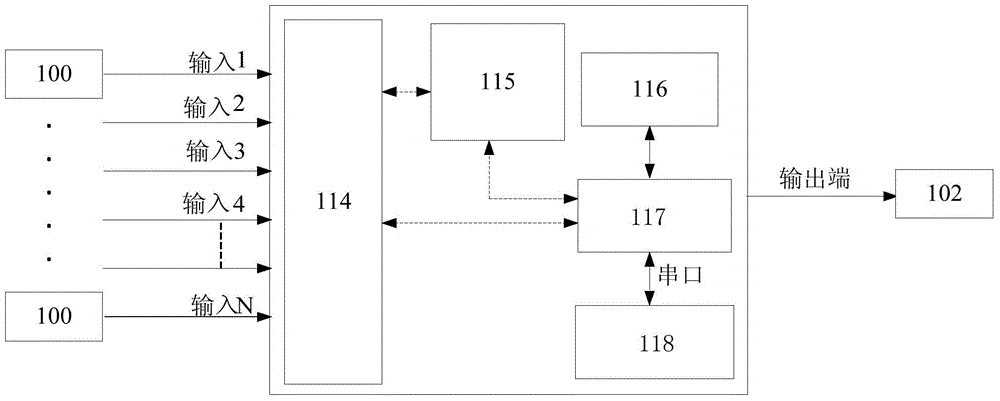

Lithium battery remote intelligent monitoring system based on Internet of Things

ActiveCN104932374AReduce processingLow efficiencyProgramme controlTransmission systemsInformation processingWireless transmission

The invention discloses a lithium battery remote intelligent monitoring system based on Internet of Things and a monitoring method. The lithium battery remote intelligent monitoring system based on the Internet of Things comprises an information collection module, an information processing and transferring module, a monitoring and data center module, an information publication module and wireless transmission between all modules. The information collection module comprises a programmable data chooser, a voltage sensor and an Internet of Things relay node. The fact that a programmable data chooser, a voltage sensor and an Internet of Things relay node can perform joint monitoring on voltage signals of N lithium batteries can be realized through connecting the input terminal of the programmable data chooser. The lithium battery remote intelligent monitoring system based on Internet of Things disclosed by the invention is simple in the structure, can remotely monitor the working state of the lithium battery on real time, improves the working efficiency, greatly reduces the human resources, prolongs the service life of the lithium battery, and further reduces the cost.

Owner:SHANGHAI MARITIME UNIVERSITY

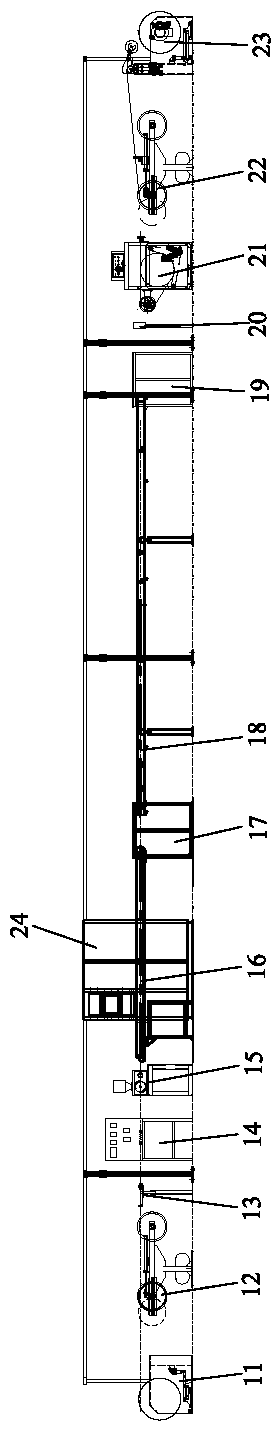

Production line for steel wire coating

PendingCN108387985AImprove production efficiencyHigh tensile strengthFibre mechanical structuresUltrasound attenuationProduction line

The invention discloses a production line for steel wire coating. The production line comprises a paying out machine, a first tension dance device, a dust removal device, a steel wire heating device,a skin-foam-skin main machine, a movable warm water tank, a warm water tank, a fixed water tank, a cold water tank, an outer diameter measuring instrument, a leading machine, a second tension dance device and a take-up machine. The paying out machine, the first tension dance device, the dust removal device, the steel wire heating device, the skin-foam-skin main machine, the movable warm water tank, the warm water tank, the fixed water tank, the cold water tank, the outer diameter measuring instrument, the leading machine, the second tension dance device and the take-up machine are sequentiallyand transversely arranged side by side and are controlled by a main control electric box to work. Based on the cooperation of all the above mechanisms, the automatic production of coated steel wireson the whole production line is realized. The production benefit of enterprises is greatly improved. Particularly, by means of the dust removal device and the steel wire heating device, steel wires are subjected to dust removing, cleaning and heating respectively. By using an optical cable with a coated steel wire, the tensile strength of an optical fiber can be effectively enhanced, and the shrinkage of the optical cable is reduced. The optical fiber attenuation performance is stable, and the signal transmission performance is enhanced. The performance of an optical device is more stable, andthe overhead performance of the optical cable is effectively improved.

Owner:GUANGDONG HONGKAI OPTICAL FIBER EQUIP TECH CO LTD

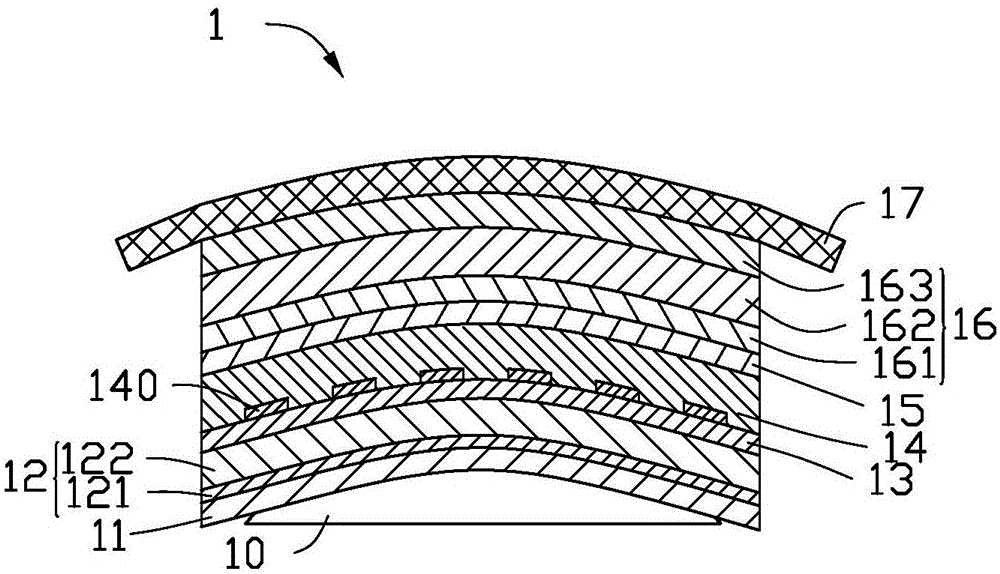

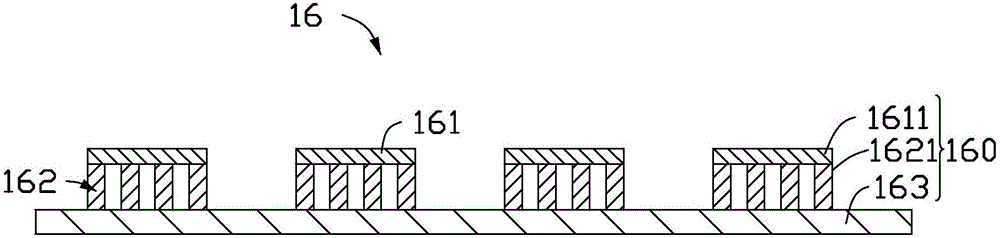

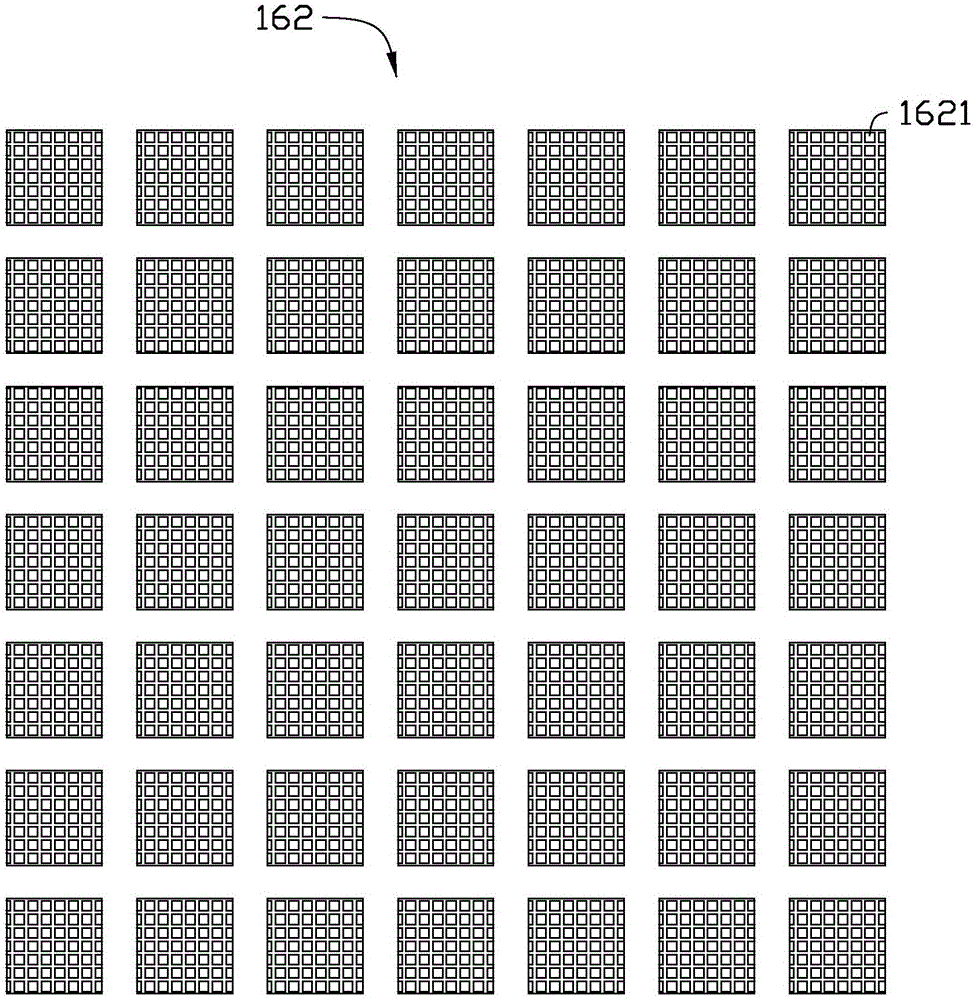

Wearable ultrasonic sensing device

InactiveCN106618637AHigh monitoring sensitivityEnhanced transmission signalBlood flow measurement devicesHeart/pulse rate measurement devicesElectricityProtection layer

A wearable ultrasonic sensing device comprises a first protection layer, an ultrasonic receiving unit, a circuit board, an ultrasonic emitting unit and a second protection layer which are stacked sequentially. The ultrasonic emitting unit comprises a first electrode layer, a first piezoelectric layer and a second electrode layer which are stacked sequentially. The first electrode layer comprises a plurality of electrode units which are arrayed at intervals. The first piezoelectric layer comprises a plurality of piezoelectric units which are arranged between the electrode units and the second electrode layer respectively. One electrode unit, the second electrode layer and the piezoelectric units arranged between the electrode unit and the the second electrode layer form a piezoelectric sensing and detecting unit.

Owner:INTERFACE TECH CHENGDU CO LTD +1

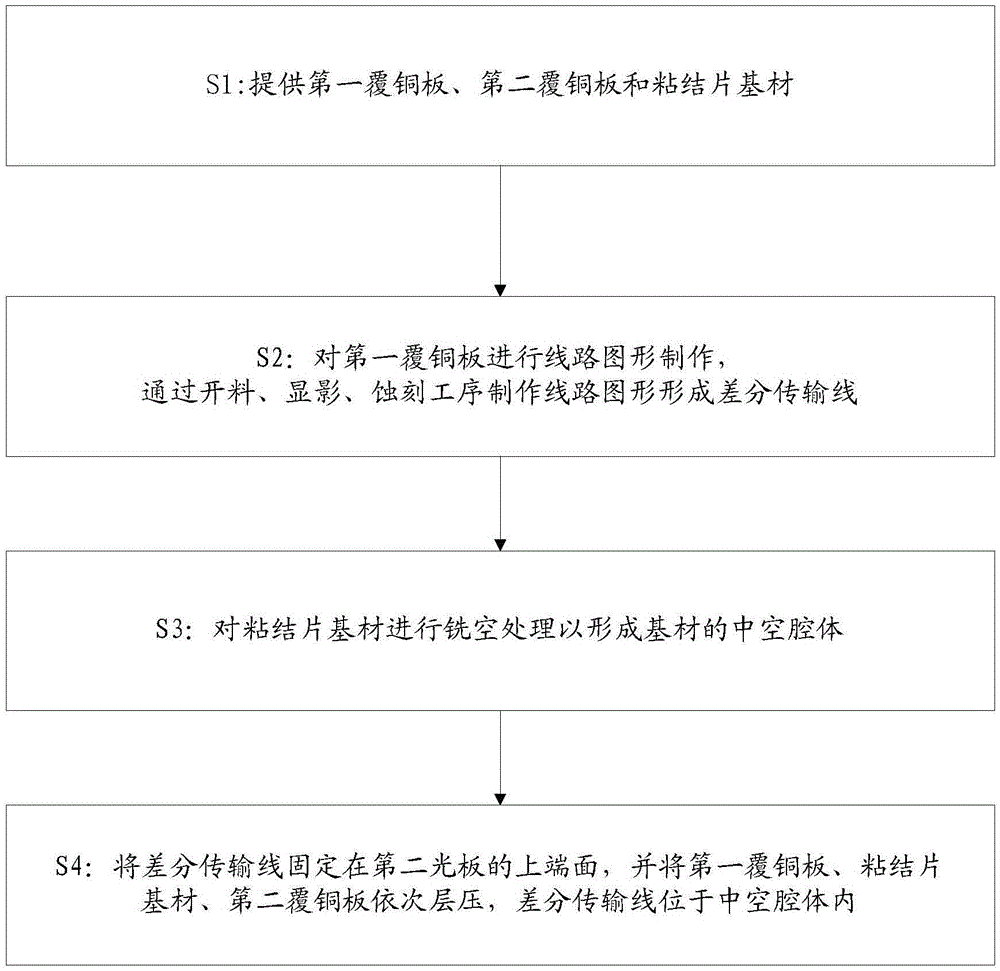

PCB with hollow cavity structure and manufacturing method therefor

InactiveCN105636341AImprove PCB signal transmission signalReduce lossPrinted circuit aspectsMultilayer circuit manufactureTransmission propertiesTransmission line

The invention relates to a PCB with a hollow cavity structure and a manufacturing method therefor. The PCB comprises a first copper-coated plate, a second copper-coated plate, a bonding sheet substrate and a differential transmission line, wherein the first copper-coated plate comprises a first optical plate; first copper-coated layers are arranged on the upper end plane and the lower end plane of the first optical plate respectively; the second copper-coated plate comprises a second optical plate; a second copper-coated layer is arranged on the lower end plane of the second optical plate; the upper end plane of the bonding sheet substrate is adhered to the first copper-coated layer on the lower end plane of the first optical plate; the lower end plane of the bonding sheet substrate is adhered to the upper end plane of the second optical plate; a hollow cavity is formed in the bonding sheet substrate; the differential transmission line and the lower end plane of the second optical plate are fixed; and the differential transmission line is positioned in the hollow cavity. According to the PCB and the manufacturing method therefor, the PCB signal transmission property can be effectively realized, and the loss of the transmission line can be greatly lowered; and in addition, the PCB has a simple manufacturing process and low cost.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

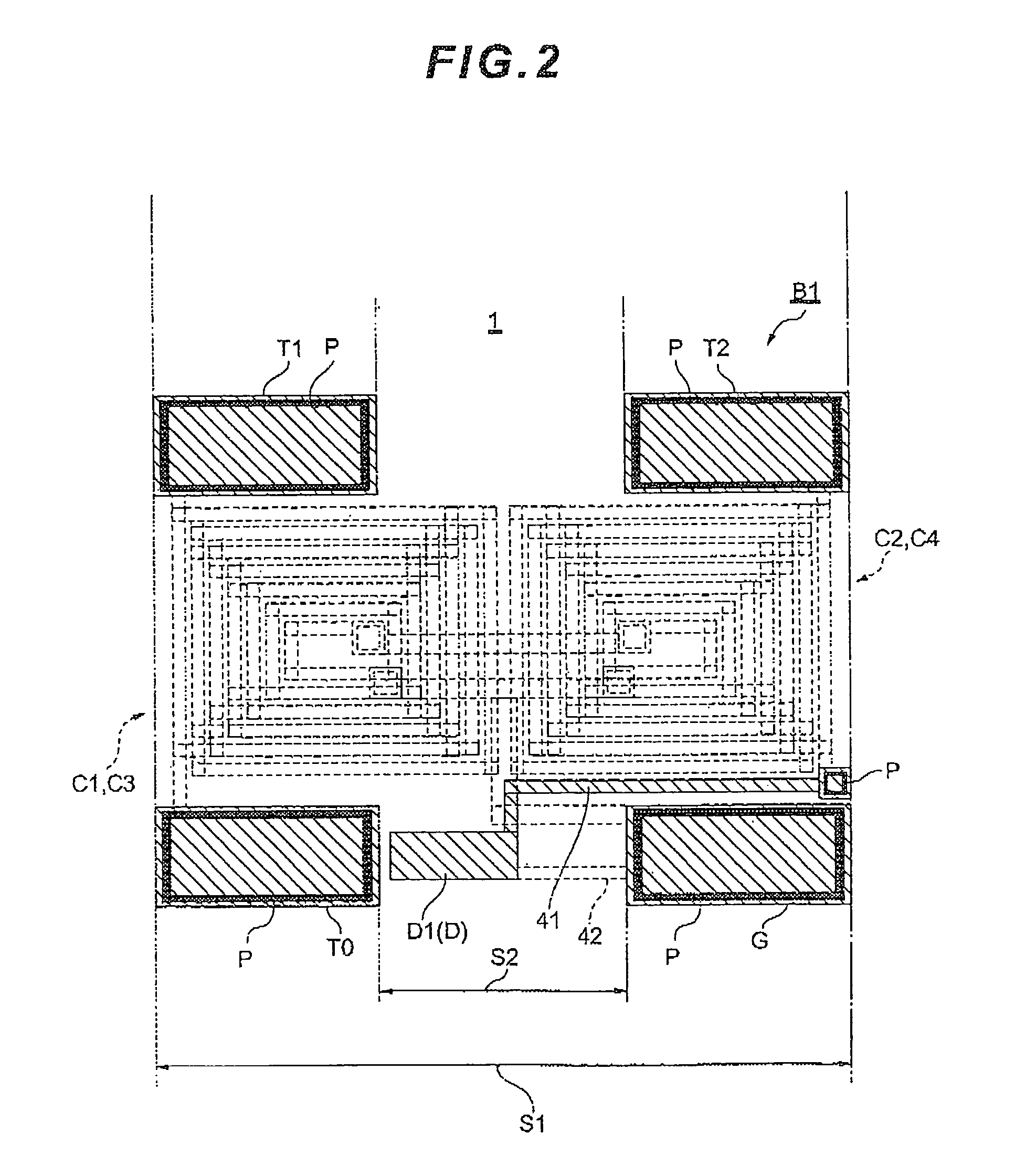

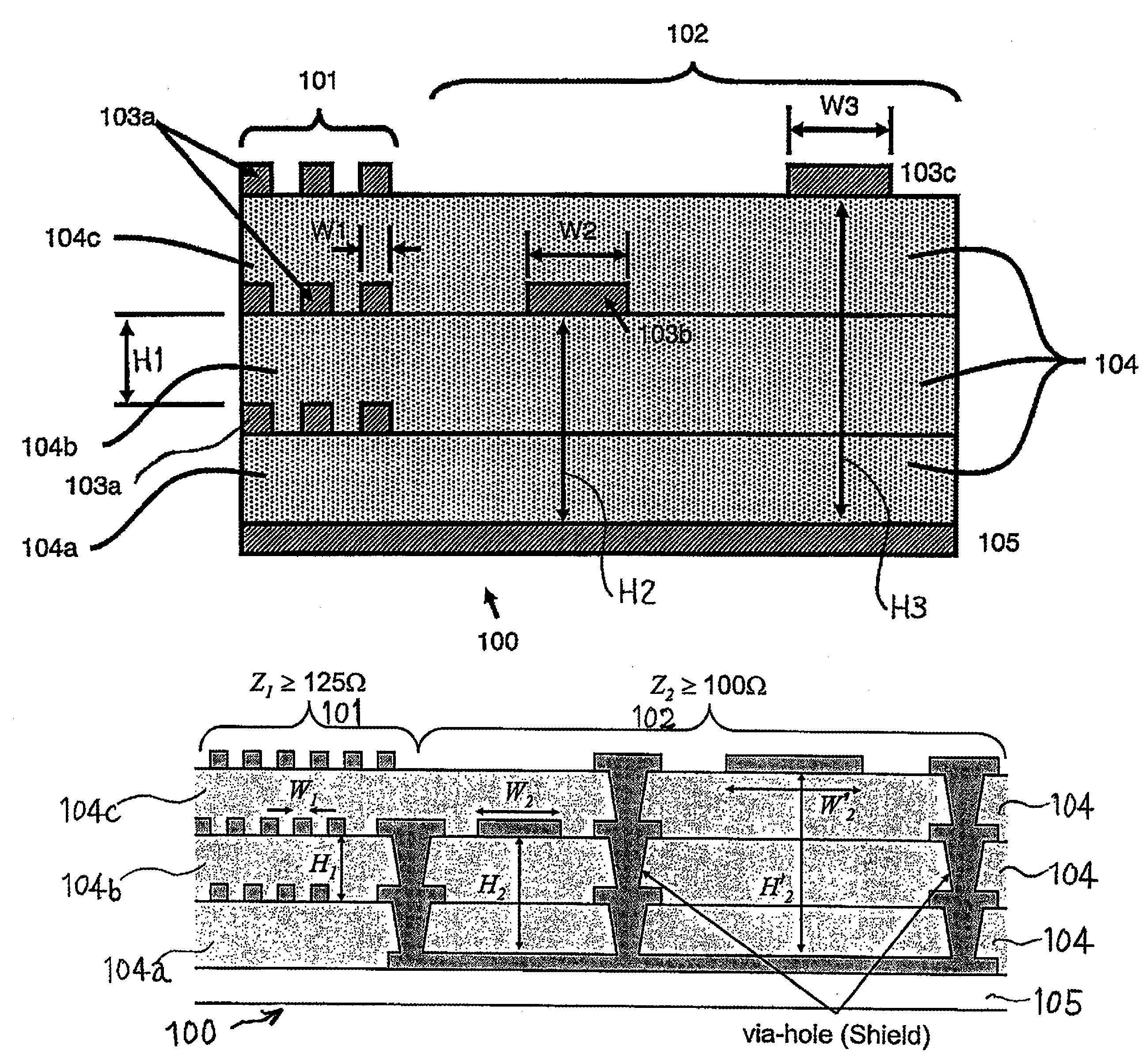

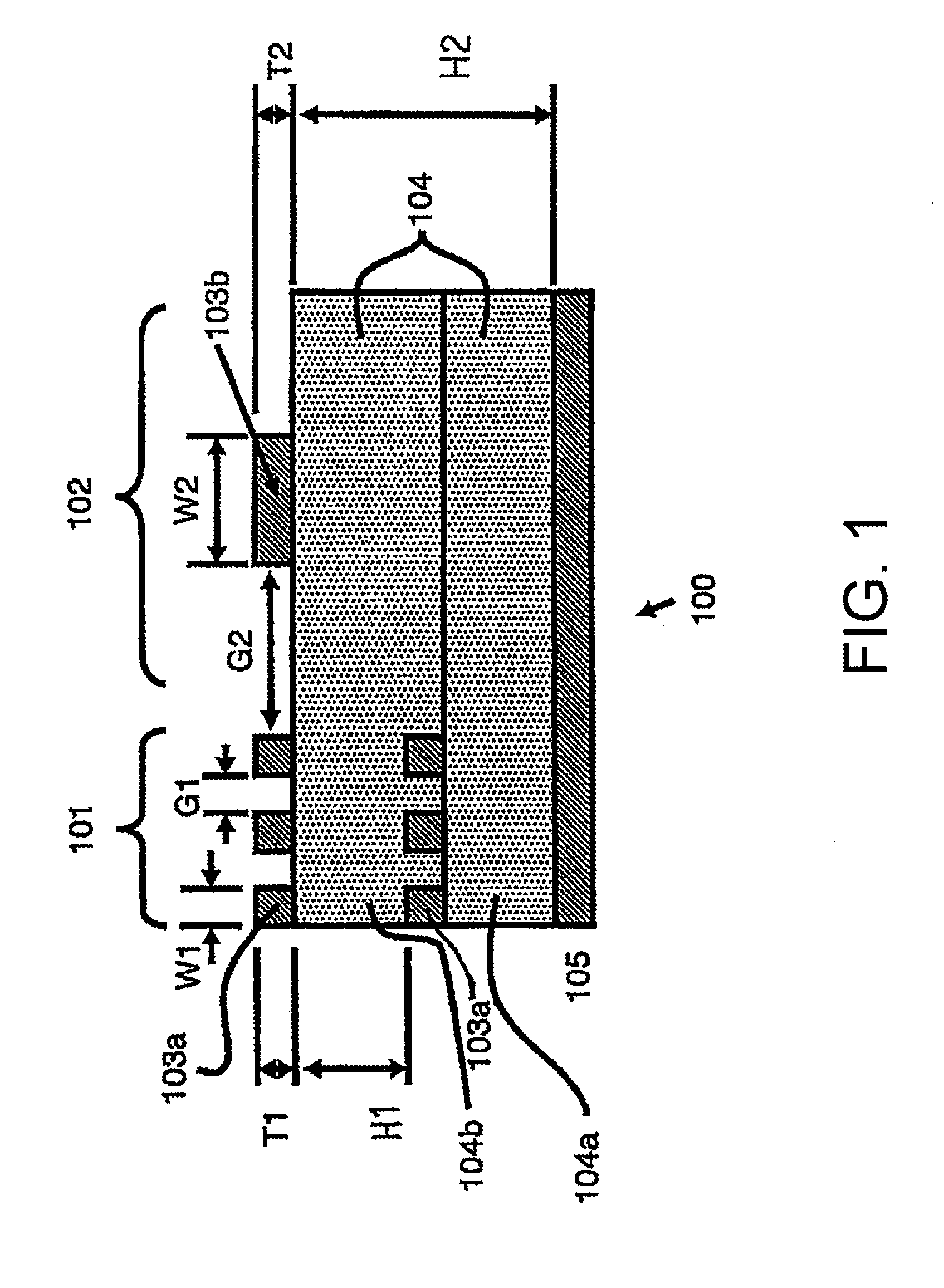

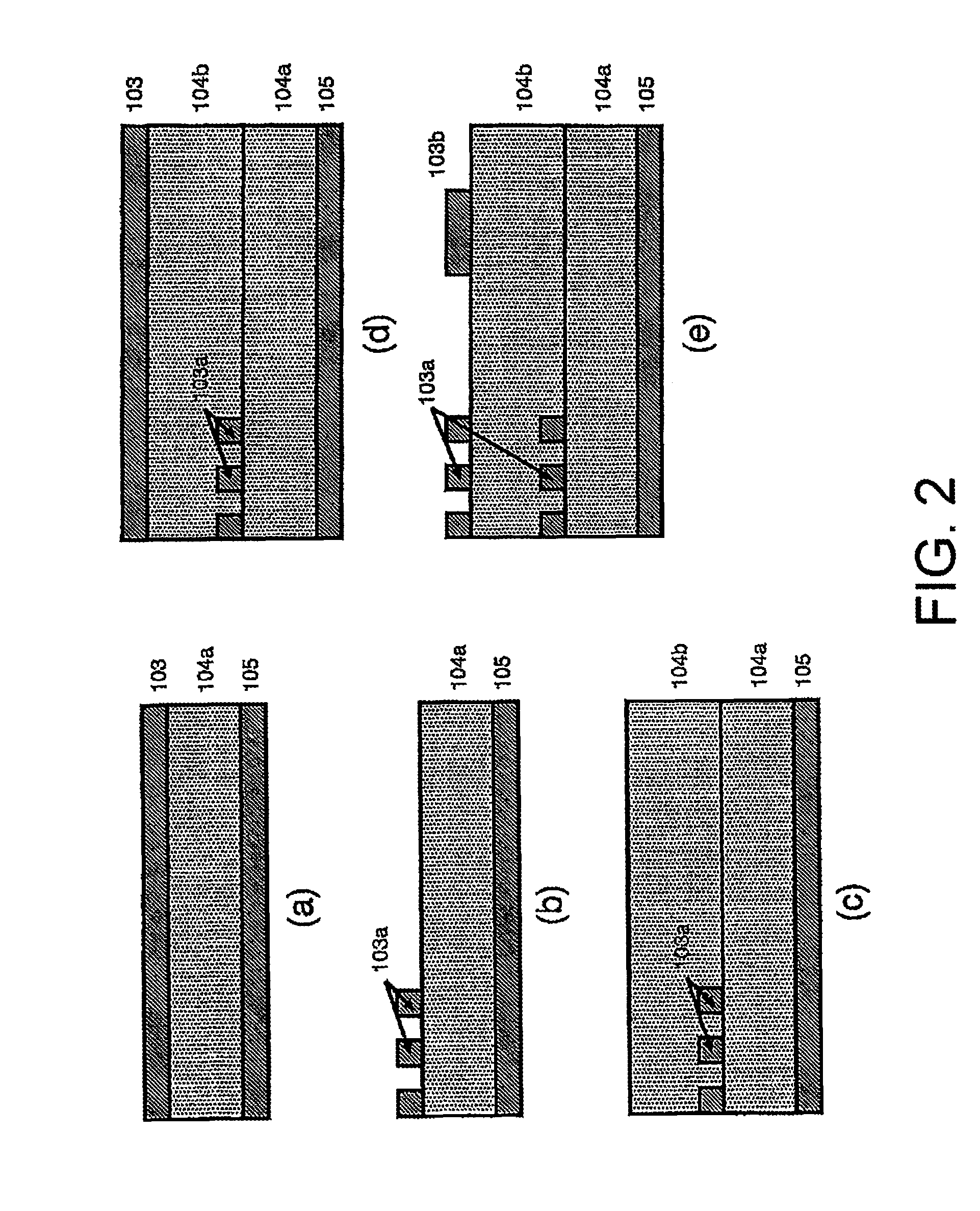

Multilayer wiring board

ActiveUS8633395B2Improve installation densitySuppress signal degradationSemiconductor/solid-state device detailsCross-talk/noise/interference reductionElectrical and Electronics engineeringEngineering

A multilayer wiring board 100 comprises a first wiring region 101 where wirings 103a and insulating layers 104a and 104b are alternately laminated, and a second wiring region 102 where a thickness H2 of an insulating layer 104 is twice or more a thickness H1 of the insulating layer in the first wiring region 101 and a width W2 of a wiring 103b is twice or more a width W1 of the wiring in the first wiring region 101. The first wiring region 101 and the second wiring region 102 are integrally formed on the same board.

Owner:TOHOKU UNIV +1

Radio apparatus

InactiveUS20070014258A1Enhanced transmission signalKeep for a long timeModulated-carrier systemsFrequency-division multiplexRadio equipmentTerminal equipment

A control unit estimates the time required from when signals are transmitted respectively to a plurality of terminal apparatuses to when responses from them are received. In a plurality of partial periods, partial periods for receiving signals continue after partial periods for transmitting the signals continue, and the order of terminal apparatuses assigned in the partial periods for receiving signals are defined in the order of terminal apparatuses assigned in the partial periods for transmitting signals, and the control unit assigns a terminal apparatus, whose estimated required time is longer, to an early partial period in a series of partial periods for transmitting signals. A radio unit and the like perform communication with the plurality of terminal apparatuses to which the respective plurality of partial periods have been assigned.

Owner:HERA WIRELESS

Preparation method of twill aluminum foil composite strip

InactiveCN109979683AIncrease the level of automationReduce manual workApparatus for feeding conductors/cablesApparatus for manufacturing conducting/semi-conducting layersSolventTransmission rate

The invention discloses a preparation method of a twill aluminum foil composite strip, which comprises the steps of 1) unwinding an aluminum foil roll and a PET mylar roll; 2) coating the unwound PETmylar roll with a color paste solvent, and drying to obtain coated PET mylar; 3) hollowing the unwound aluminum foil by hollowing equipment of a laminating machine to obtain a hollowed-out aluminum foil, and setting a meter counting wheel to adjust the opening size; 4) laminating and adhering the coated PET mylar and the hollowed-out aluminum foil by a laminating device of the laminating machine to obtain a composite strip; 5) winding the composite strip by winding equipment of the laminating machine to obtain a composite strip roll; and 6) cutting the composite strip roll. The preparation method is high in production efficiency, can customize the opening size, reduces the production cost and improves the signal transmission rate, and is applicable to processing network cables used in thehigh-end network transmission process.

Owner:中山市华子电缆有限公司

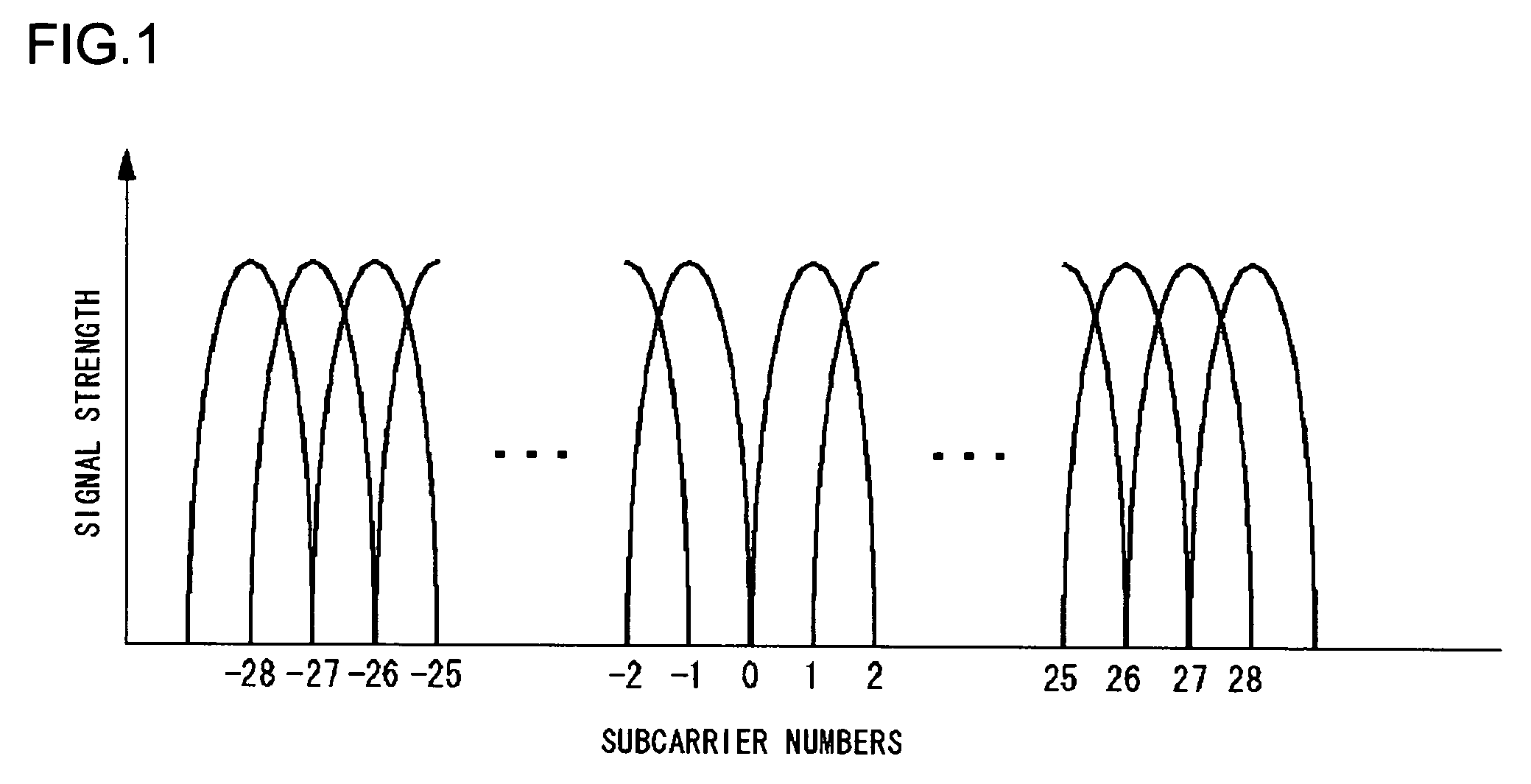

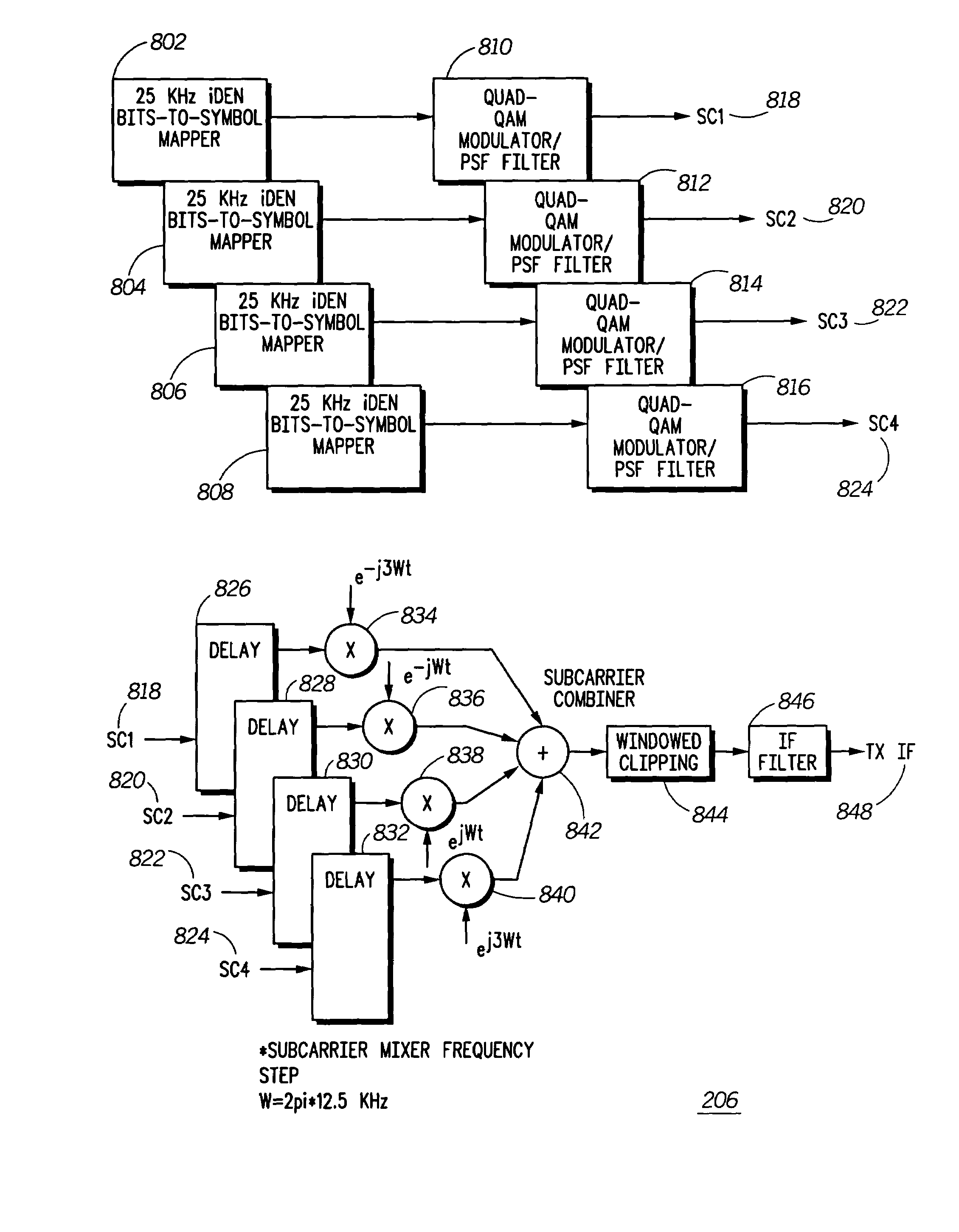

Subcarrier time offsets for improved peak-to-average power of a transmitter

ActiveUS7313188B2Reduce peak-to-average power of transmitterIncrease power ratioSecret communicationMulti-frequency code systemsData streamCarrier signal

A system, wireless device (102) and method reduce the peak-to-average power of a transmitter by creating at least two sampled carrier data streams, running each carrier through a separate delay block, mixing each carrier over in frequency an appropriate amount, resulting in at least two frequency division multiplexed signals, and combining the at least two frequency division multiplexed signals together. The four sampled carrier data streams may each have a bandwidth of 25 kHz. Each separate delay block is less than 20% of its corresponding symbol time. The transmitter may be used to transmit wideband integrated digitally enhanced network (WiDEN) signals.

Owner:GOOGLE TECH HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com