High-frequency valveless pump on the basis of intelligent material

A technology of intelligent materials and valve pumps, applied in the field of hydraulic pump manufacturing, can solve the problems of only a few tens of Hz, some with superior performance can only reach 100 Hz, can only be within 100 Hz, and cannot exert energy density. Achieve the effect of fast working frequency, simple structure and convenient flow control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below.

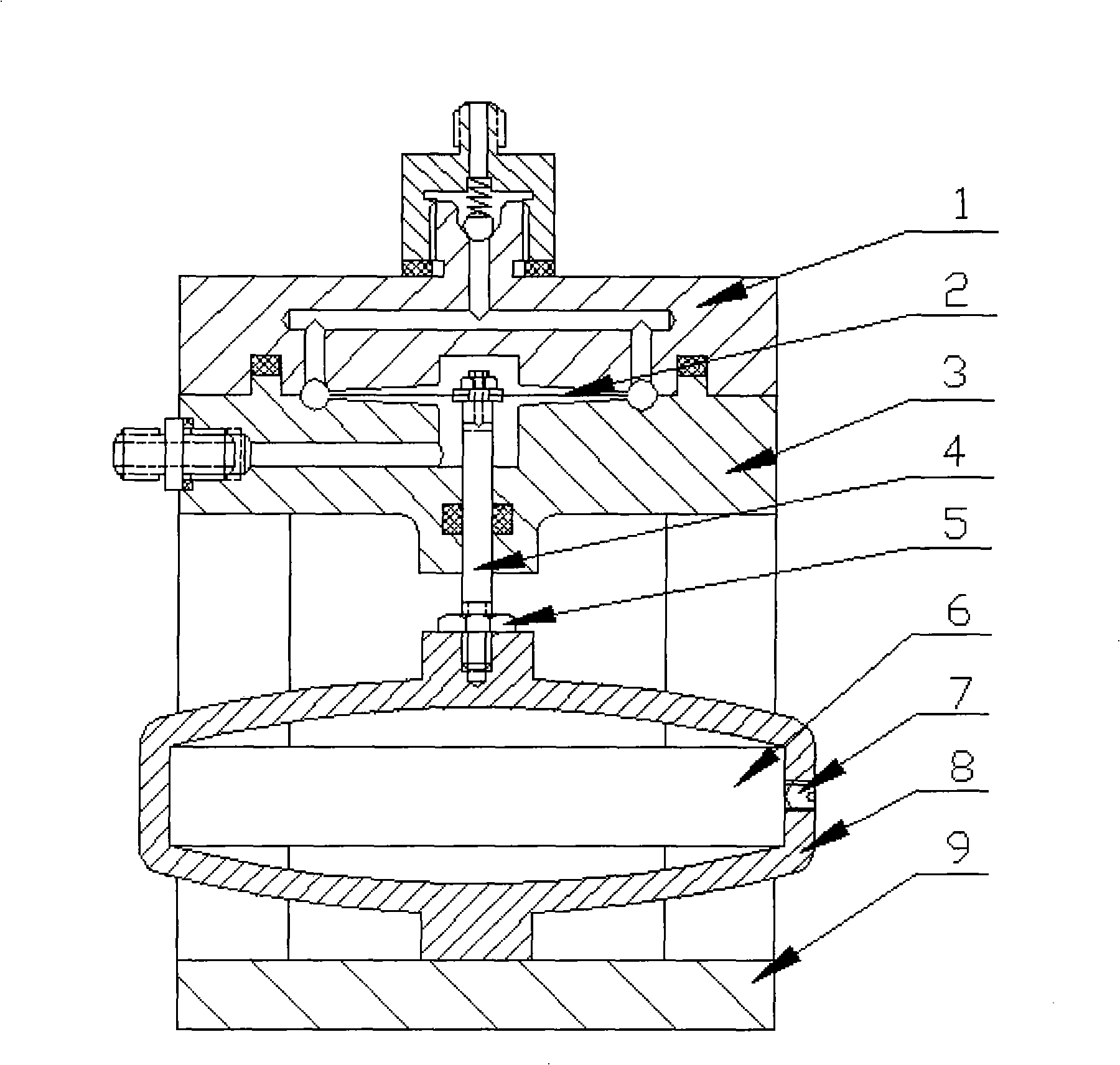

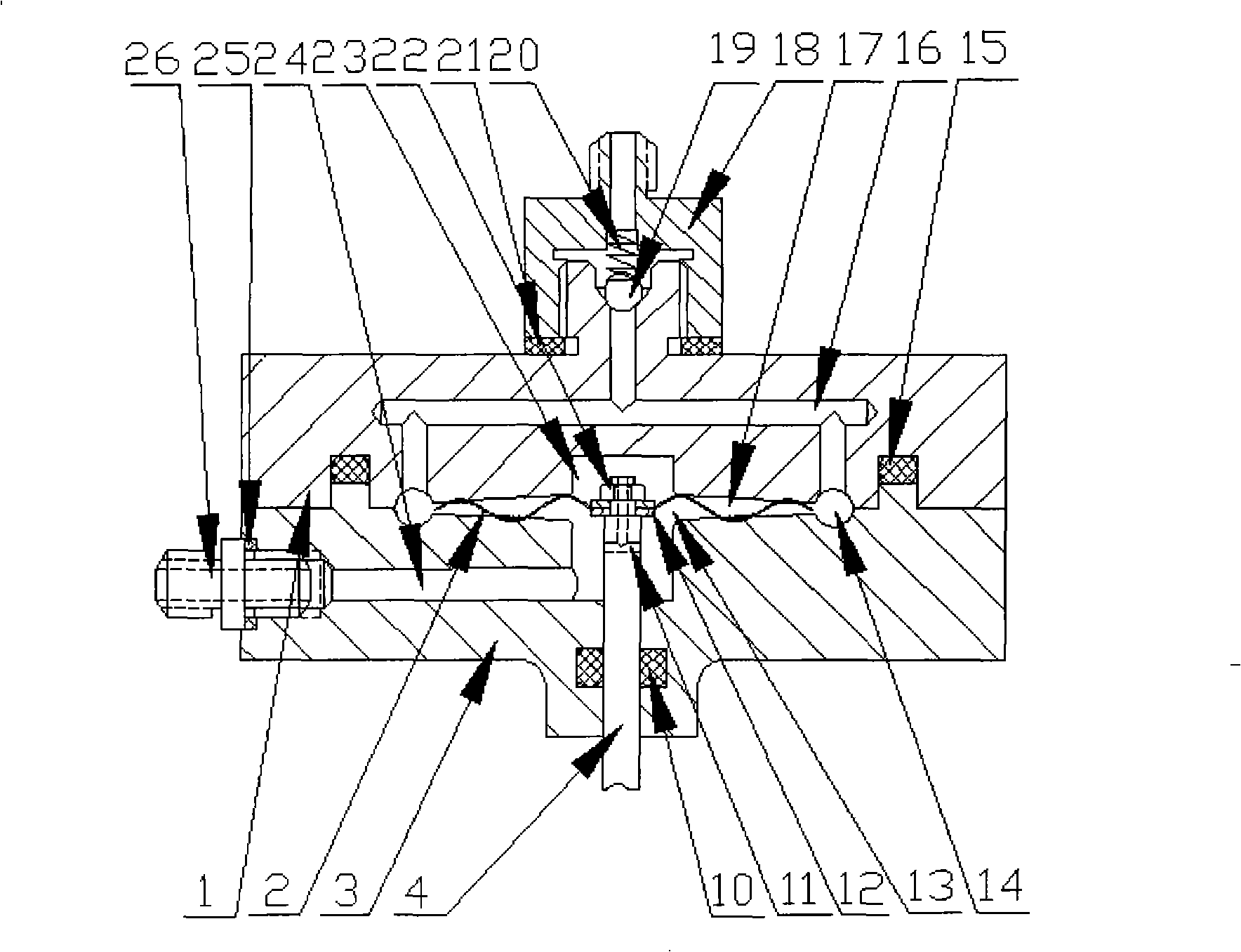

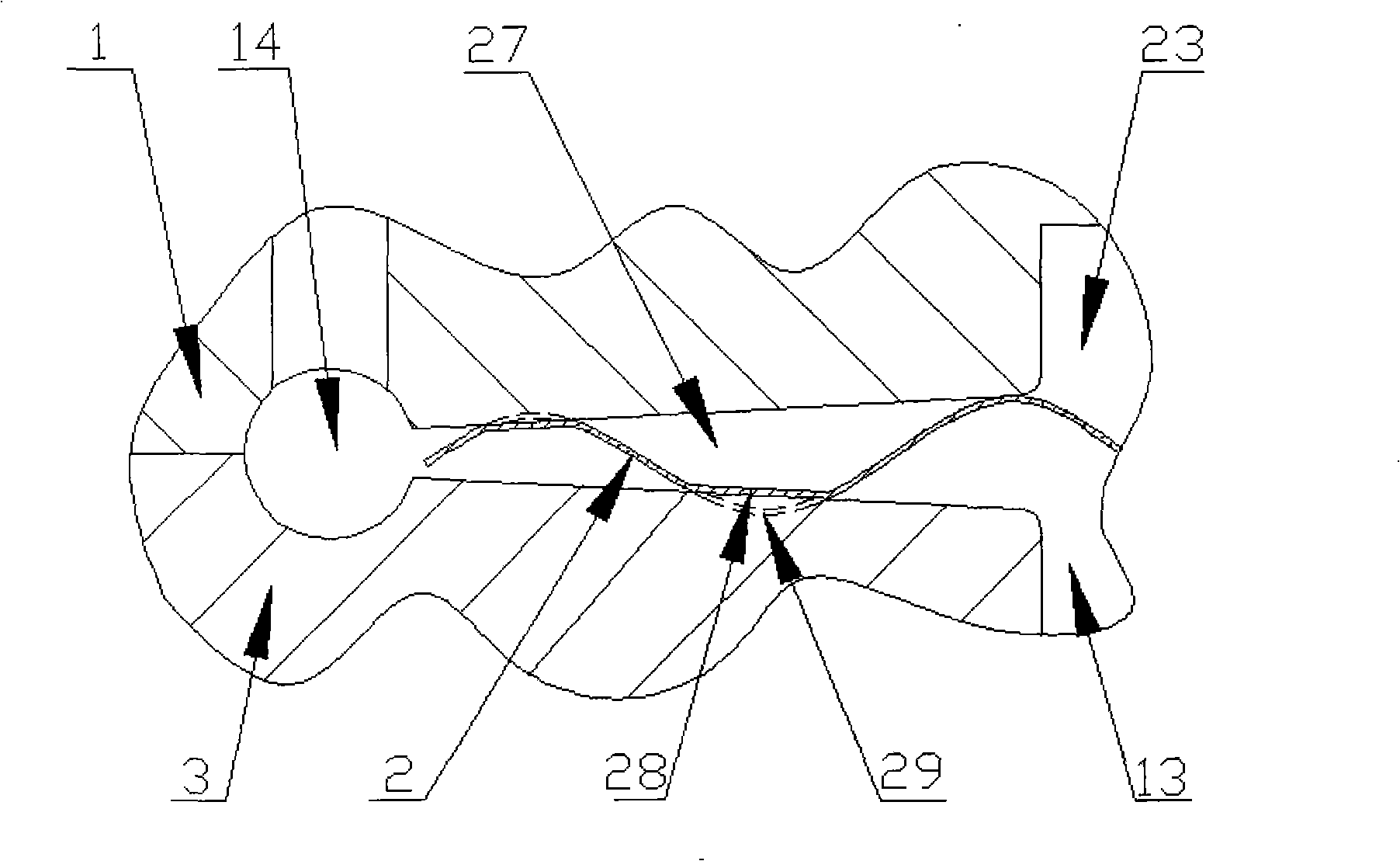

[0010] The hardware of the hydraulic pump mainly includes: an intelligent material drive amplification mechanism, a metal diaphragm vibration booster mechanism, an oil suction circuit, and an oil discharge non-return oil circuit.

[0011] The intelligent material drives the amplifying mechanism, which uses intelligent materials to convert electrical energy into mechanical vibration energy, and amplifies and outputs the mechanical displacement; the metal diaphragm vibration booster mechanism uses the vibration of the metal diaphragm to generate annular shear waves, realizing the transformation from the low pressure cavity to the The function mechanism of pumping oil in the high-pressure chamber; the oil suction circuit, which connects the oil suction port and the low-pressure chamber, and ensures the equal pressure of the upper and lower low-pressure chambers; the oil discharge non-return oil circuit, conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com