Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64results about How to "To achieve the purpose of defoaming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Printing ink

The invention discloses printing ink which comprises the following materials in parts by weight, 20-40 parts of pigments, 20-40 parts of binders, 25-45 parts of solvents, 1-2 parts of calcium carbonate, 1-3 parts of defoaming agents, 1-3 parts of flatting agents, 2-6 parts of 5A molecular sieves, 1-2 parts of fumed silica, 2-6 parts of dispersing agents, 0.5-1.5 parts of adhesion promoters, 2-5 parts of gummy oil, 1-3 parts of slipping agents, 1-4 parts of adhesives and 1-3 parts of hydrotalcite. The adhesion force of the ink can be enhanced, ink penetration and ink permeability of the ink are prevented, and the ink is high in chemical stability, long in storage time and stable in printing performance.

Owner:SUZHOU ANJIE TECH

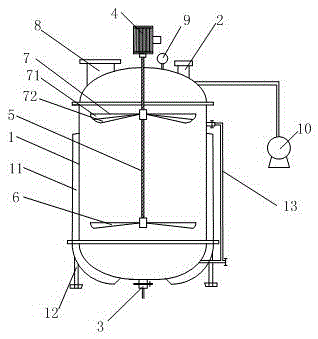

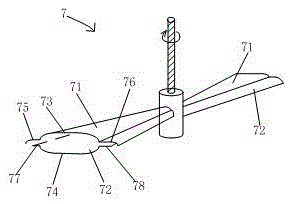

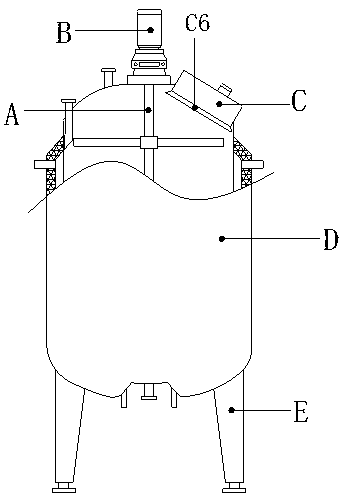

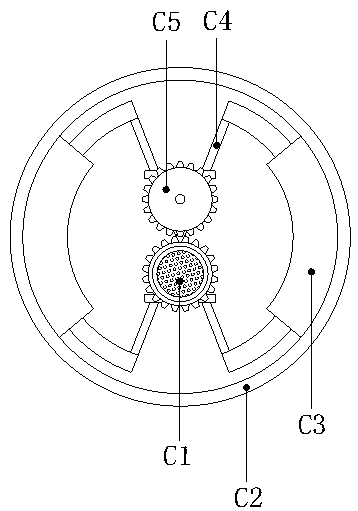

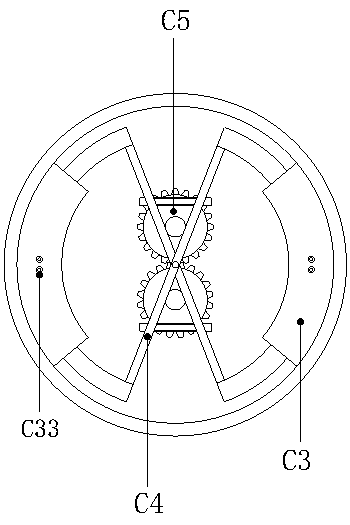

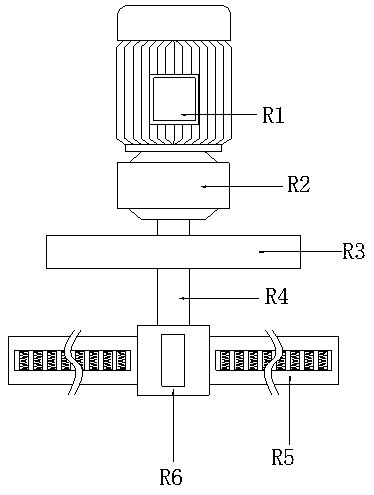

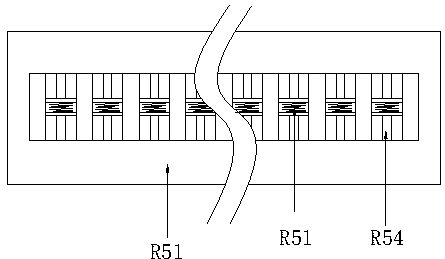

Novel defoaming and stirring device

InactiveCN106823477ATo achieve the purpose of defoamingEasy to observeRotary stirring mixersTransportation and packagingBiochemical engineeringVacuum pump

The invention belongs to the technical field of chemical equipment, and in particular relates to a novel defoaming and stirring device. The device comprises a tank body; a feeding port is formed in the top end of the tank body; a discharging port is formed in the bottom end of the tank body; a stirring shaft is arranged in the tank body along the vertical direction; the upper end of the stirring shaft is fixedly connected with a rotating shaft of a motor; the lower end of the stirring shaft is fixedly connected with a stirring paddle through a bearing; a defoaming blade is fixed on the stirring shaft; the defoaming blade consists of a defoaming plate and a collecting plate; the defoaming plate is positioned on the collecting plate; a clamping sleeve is arranged on the outer side of the tank body; a heating pipe is arranged at the bottom end of the clamping sleeve; and a vacuum pump is connected outside the tank body. The device has the advantages of various defoaming modes and high defoaming efficiency.

Owner:陕西庆鸿置业有限公司

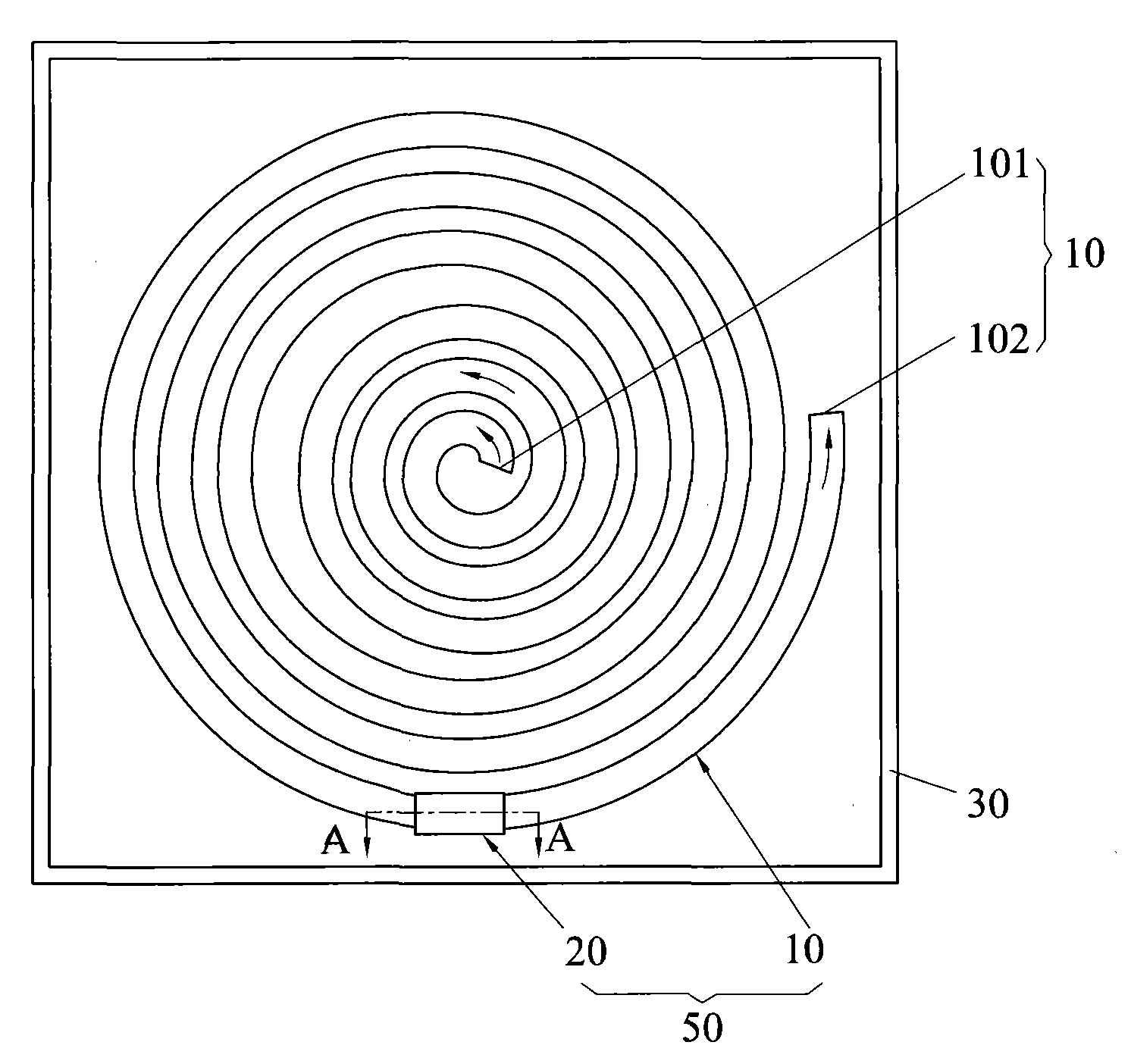

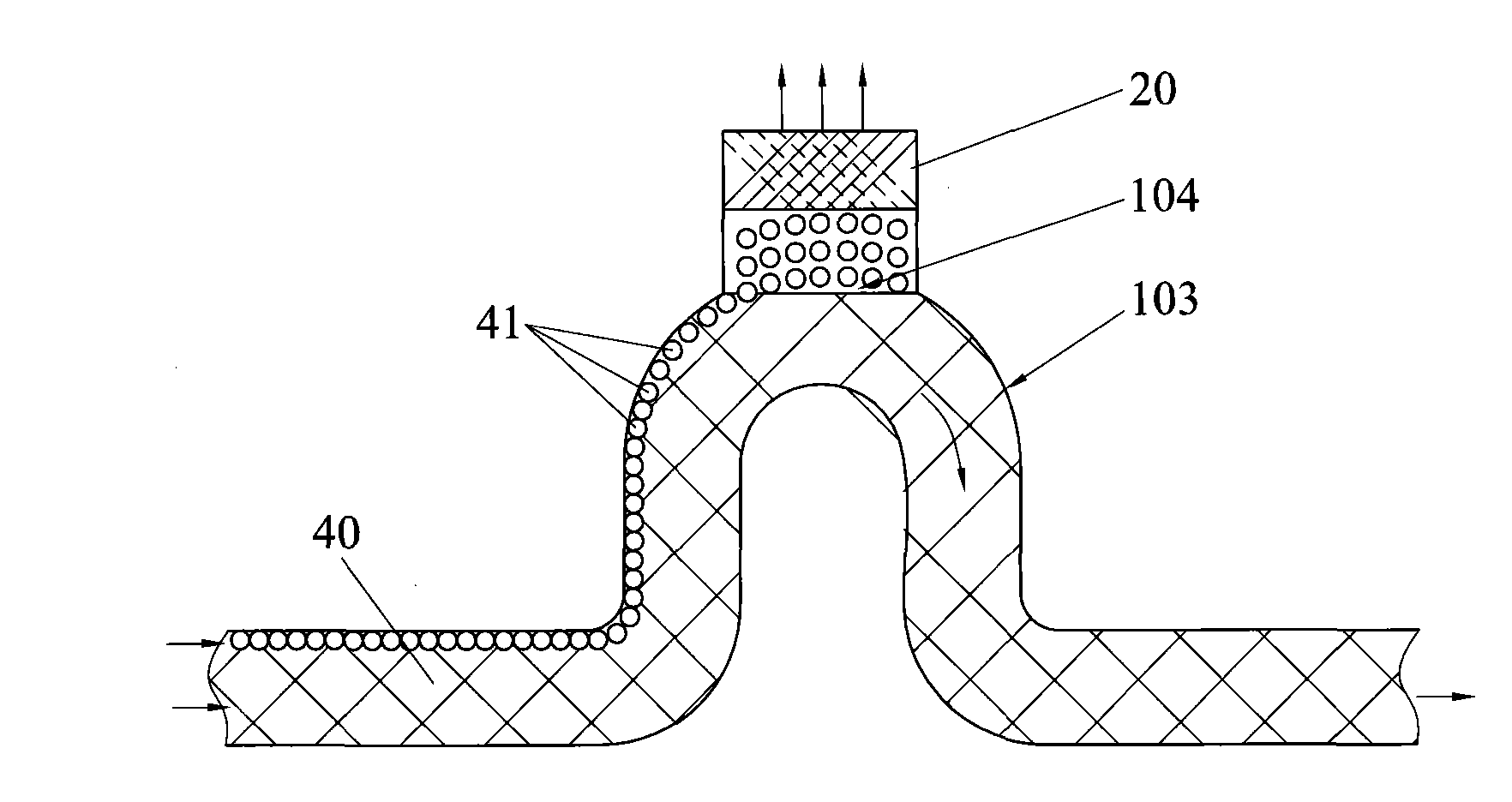

Gluewater-defoaming device and defoaming method

InactiveCN101537269ATo achieve the purpose of defoamingGood defoaming effectFoam dispersion/preventionEngineeringMechanical engineering

The invention discloses a gluewater-defoaming device which comprises a heating device, a container and a defoaming mechanism, wherein the defoaming mechanism comprises a gluewater-guiding pipeline and a filter device, and the gluewater-guiding pipeline is provided with a gluewater-pressing inlet and a gluewater-pressing outlet which is provided with a bending protruding arc loop with a defoaming opening; the filter device is arranged at the defoaming opening of the protruding arc loop, and the gluewater-guiding pipeline is contained in the container; and gluewater is pressed in the gluewater-guiding pipeline to heat the whole gluewater-guiding pipeline so that foam contained in the gluewater gradually floats up above the inner wall of the gluewater-guiding pipeline and is discharged from the filter device at the defoaming opening while the gluewater flows by the defoaming opening arranged on the arc loop, therefore, the defoaming effect is favorable and the requirement for mass production is satisfied. The device has simple structure and is convenient to transplant to the prior various technological equipment. In addition, the invention also discloses a gluewater-defoaming method using the gluewater-defoaming device.

Owner:HENAN KAIRUI DIGITAL

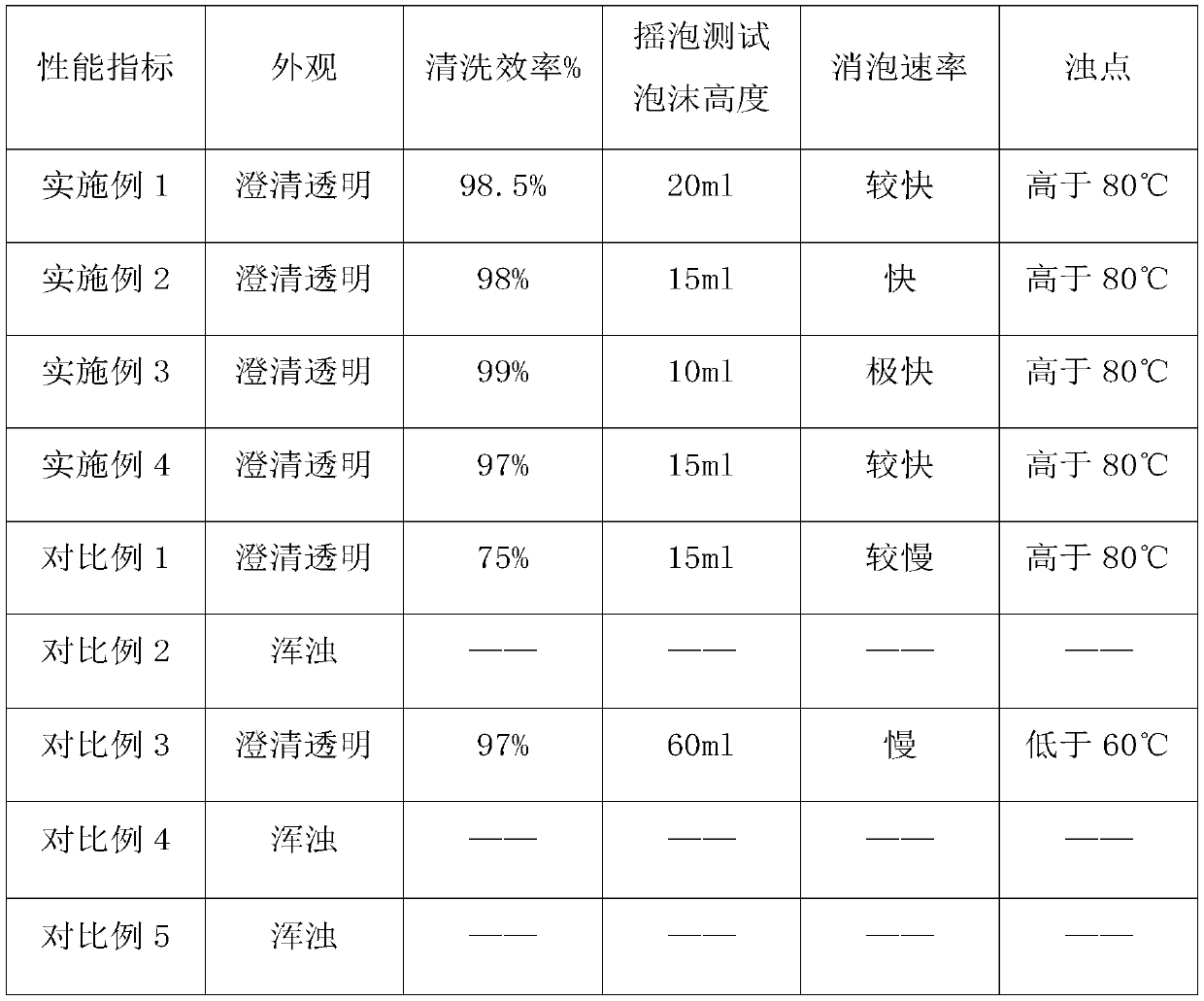

Cleanser and preparation method thereof

InactiveCN109705996AGood synergyEasy to cleanInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsCleansers skinSulfate

The invention provides a cleanser; according to 100 parts, the cleanser is prepared from: 10 to 20 parts of inorganic alkali, 5 to 15 parts of a chelating agent, 5 to 15 parts of a composite surfactant, 0.5 to 2 parts of a dispersant, 0.5 to 3 parts of a solubilizer, 3 to 10 parts of a solvent, and the balance being pure water. The composite surfactant includes one or more of propylene glycol block polyether, TMN-10, isooctyl sulfate, RhodaNop-880 and pine oil, and alkyldiphenyloxide disulfonate. The cleanser has excellent cleaning effect, and has strong removal effect on abrasive powder, oildirt and composite-type dirt, is non-foam or low-foam and satisfies the cleaning requirement of a plate-type cleaning machine. The cleanser can reach more than 80 DEG C in cloud point and can work athigh temperature. The invention also provides a preparation method of the cleanser, which is simple and has great economic benefit.

Owner:LENS TECH CHANGSHA

High shearing rate method for spinning poly-terephthaloyl p-phenylenediamine fibre

ActiveCN1752300AWell mixedStable mixFilament/thread formingMonocomponent polyamides artificial filamentFiberSlurry

The invented method includes the following steps: uniformly mixing PPTA and concentrated sulfuric acid whose concentration is greater than 99% in mixing cylinder, preparing mixed solution in which PPTA content is 14%-24%; making the prepared PPTA mixed solution pass through twin screw extruder, further dissolving to form liquid crystal spinning solution, defoaming, fully mixing and regulating temperature, applying high shear stress to the defoamed PPTA spinning slurry in extruder machine head, filtering and metering, adopting dry-jet wet-spinning process to obtain the invented PPTA fibre.

Owner:DONGHUA UNIV

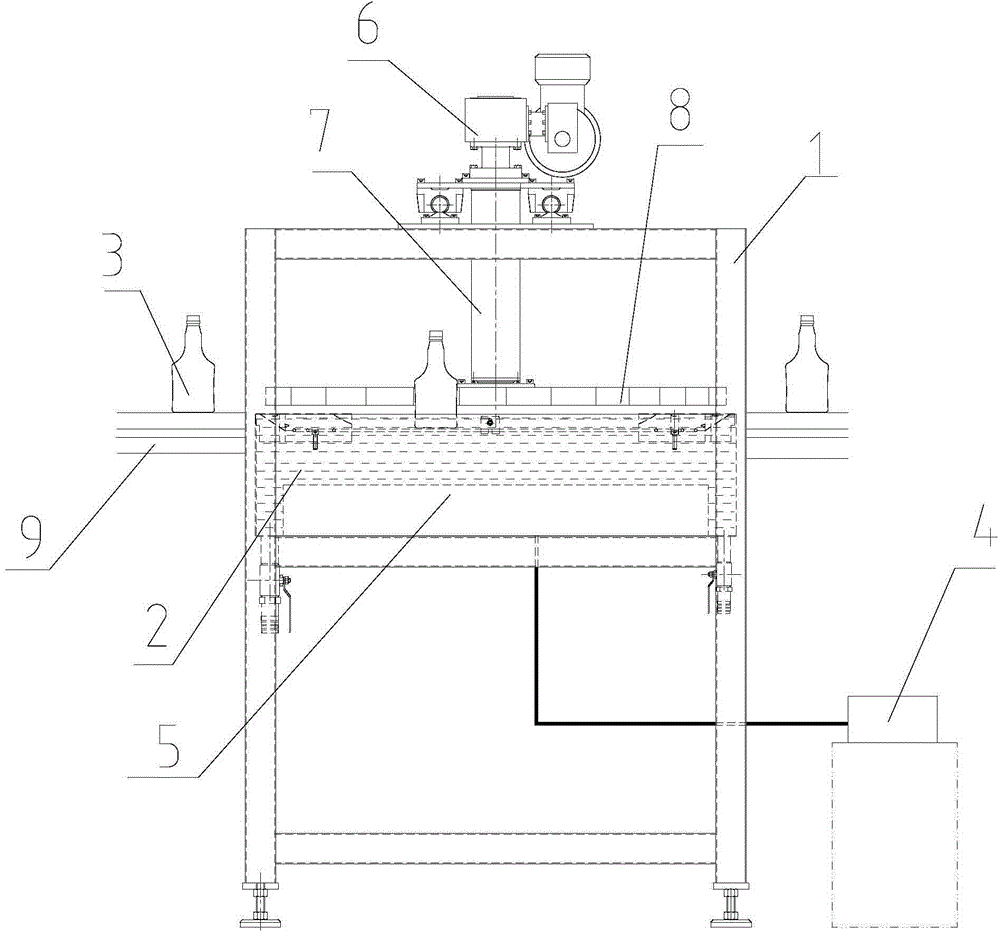

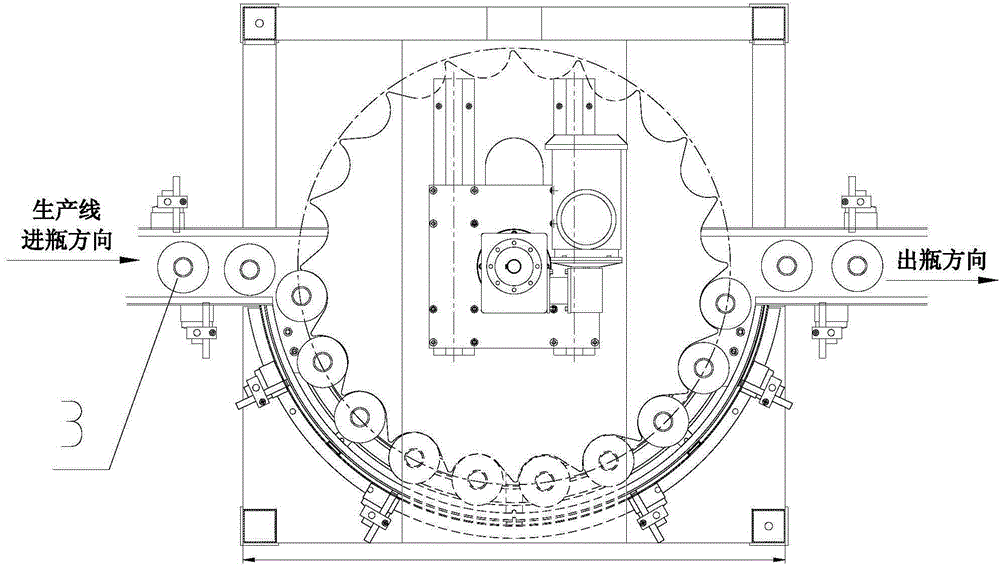

Defoaming device before bottled liquid light inspection and defoaming method of defoaming device

InactiveCN105983381AEliminate Bubble ProblemsSmall footprintEnergy based chemical/physical/physico-chemical processesFoam dispersion/preventionLiquid mediumEngineering

The invention provides a defoaming device before bottle liquid light inspection and a defoaming method of the defoaming device. The defoaming device comprises a rack, a liquid containing container, a conveying device and an ultrasonic device, the liquid containing container is located on the upper portion of the rack and filled with a liquid medium, the conveying device and the ultrasonic device are both partially arranged in the liquid containing container, and the conveying device does not make contact with the ultrasonic device; the conveying device can convey bottles and enable the bottles to be immersed in the liquid medium. The defoaming method comprises the steps that the ultrasonic device is started, and meanwhile the conveying device is started; filled bottles enter the conveying device, the conveying device lowers the bottles to below the liquid level of the liquid medium, the ultrasonic device sends out an ultrasonic oscillation signal to remove liquid bubbles in the bottles, and the conveying device conveys the bottles to the light inspection process. The defoaming device can thoroughly remove the bubbles in the bottle liquid and can be arranged on a production line without separately occupying a production space.

Owner:CHENGDU HONGRUI TECH

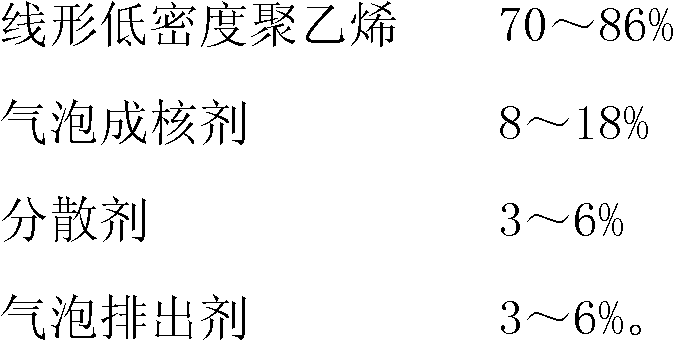

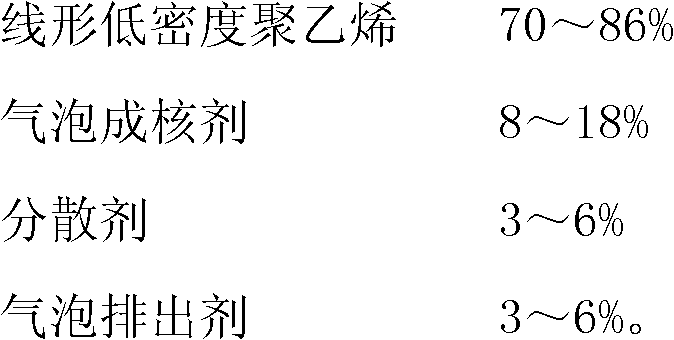

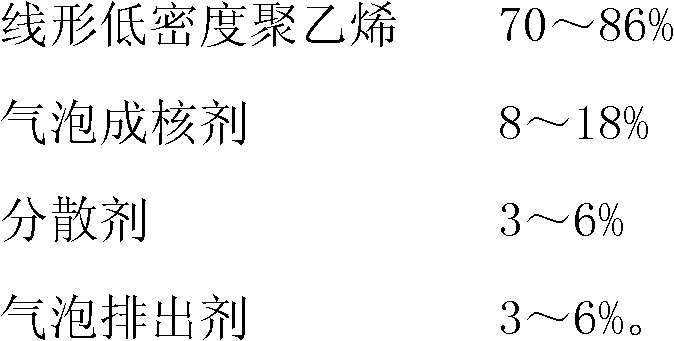

Defoaming master batch for rotational molding and preparation method thereof

ActiveCN102952322AIncrease surface tensionEnhanced interactionLinear low-density polyethyleneExtrusion Granulation

The invention relates to a defoaming master batch for rotational molding and a preparation method thereof, belonging to the technical field of plastic processing. The defoaming master batch is prepared by mixing and stirring raw materials in a certain ratio and then extruding and granulating. The defoaming master batch is characterized by containing the following raw materials in percentage by mass: 70-86% of linear low-density polyethylene, 8-18% of bubble nucleating agent, 3-6% of dispersing agent and 3-6% of bubble eliminant. The invention aims to provide a defoaming master batch for rotational molding and a preparation method thereof. The defoaming master batch is low in cost and can solve the problem on bubbles of a rotational molding product; the rotational molding product prepared from the defoaming master batch is free of bubbles and has favorable processability, good plasticization performance, high production efficiency and high product performance; and the preparation method is scientific and reasonable, and is simple and easy to implement.

Owner:CHINA PETROLEUM & CHEM CORP

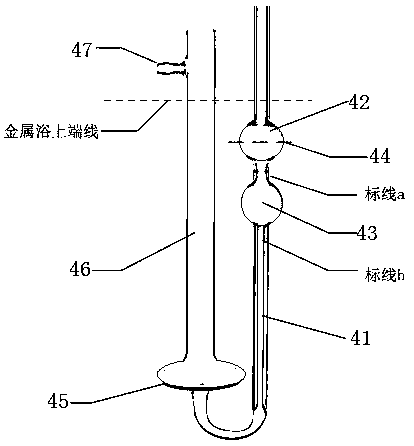

Device for full-automatically measuring kinematic viscosity and viscosity index of electrical equipment oil and measuring method

PendingCN108645753AGuaranteed accuracyAccurate measurementDirect flow property measurementPropellerTransmittance

The invention relates to a device for full-automatically measuring the kinematic viscosity and the viscosity index of electrical equipment oil and a measuring method. A current kinematic viscosity measuring product commonly adopts water bathing to control temperature, meanwhile, a viscometer is a fixed coefficient, and cannot meet the requirement for measuring in a larger range, the error is large, and most of products cannot measure the viscosity index of an oil product. The device adopts the Lambert-Beer's law to judge the moment of an oil sample passing the marked line through the transmittance of the viscometers filled with the oil product and empty viscometers after being washed, and by comparing the transmittance before measuring and in the measuring process, high precision and fullautomatic measuring of the kinematic viscosity and the viscosity index of the electrical equipment oil are achieved. Meanwhile, a metal constant temperature bathing is adopted to replace a traditionalwater bathing and oil bathing constant temperature pool, operation and maintenance is more convenient, and temperature control is more precise. Quantitative pipes and automatic propellers are arranged so as to achieve automatic sample feeding; a compressor is arranged to pressurize and boost to fill the oil sample, and generation of bubbles can be effectively reduced; and by designing a vacuum bottle, oil is drained, and by designing an anti-suck-back stopping plate, oil can be drained more thoroughly.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Silk-screen printing ink

The invention discloses silk-screen printing ink. The silk-screen printing ink is prepared from, by weight, 15-25 parts of pigments, 25-40 parts of a binder, 45-70 parts of solvent, 1-3 parts of calcium carbonate, 1-3 parts of a defoaming agent, 1-3 parts of a leveling agent, 2-7 parts of a 5A molecular sieve, 1-3 parts of fumed silica, 2-7 parts of a dispersing agent, 0.5-1.5 parts of an adhesion promoter, 2-5 parts of gummy oil, 1-3 parts of a slipping agent, 1-4 parts of barium sulfate, 1-3 parts of hydrotalcite and 1-3 parts of a light stabilizer. According to the silk-screen printing ink, adhesion of ink can be enhanced, the ink penetration and ink fusion phenomena of the ink are prevented, the chemical stability is high, the storage time is long, the printing property is stable, the uvioresistant capacity and the antioxidant capacity are high, and wear resistance is achieved.

Owner:SUZHOU ANJIE TECH

Defoaming master batch for rotational molding and preparation method thereof

ActiveCN102952322BIncrease surface tensionEnhanced interactionLinear low-density polyethyleneRotational molding

The invention relates to a defoaming master batch for rotational molding and a preparation method thereof, belonging to the technical field of plastic processing. The defoaming master batch is prepared by mixing and stirring raw materials in a certain ratio and then extruding and granulating. The defoaming master batch is characterized by containing the following raw materials in percentage by mass: 70-86% of linear low-density polyethylene, 8-18% of bubble nucleating agent, 3-6% of dispersing agent and 3-6% of bubble eliminant. The invention aims to provide a defoaming master batch for rotational molding and a preparation method thereof. The defoaming master batch is low in cost and can solve the problem on bubbles of a rotational molding product; the rotational molding product prepared from the defoaming master batch is free of bubbles and has favorable processability, good plasticization performance, high production efficiency and high product performance; and the preparation method is scientific and reasonable, and is simple and easy to implement.

Owner:CHINA PETROLEUM & CHEM CORP

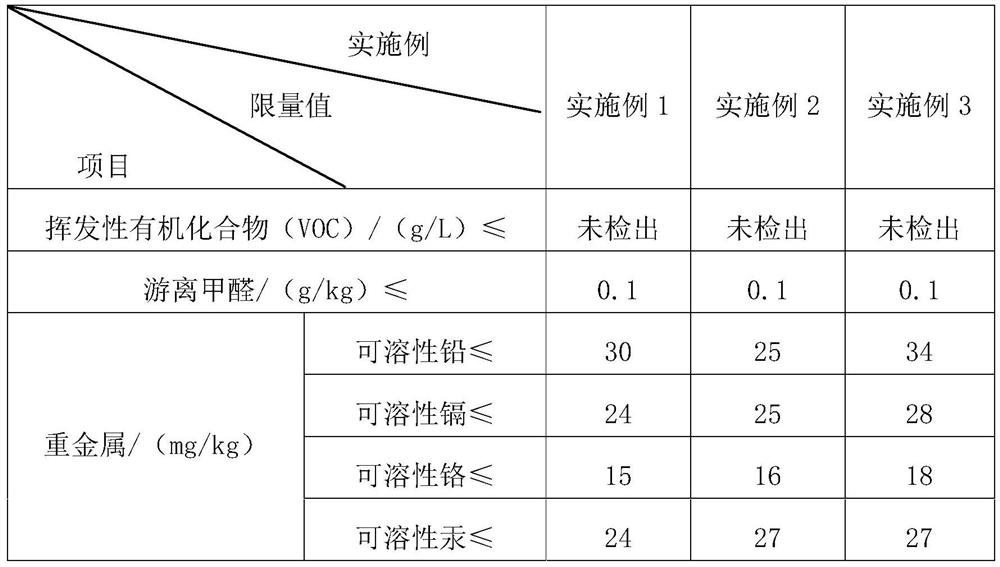

Water-resistant moisture-proof putty powder capable of defoaming and leveling as well as preparation method and use method thereof

The invention relates to the technical field of building materials, in particular to waterproof and moistureproof putty powder capable of defoaming and leveling, which is prepared by mixing the following materials: Portland cement, calcium hydroxide, quartz sand, ground calcium carbonate, active vitrified micro bubbles, hydroethyl cellulose, lignin, amylase and anti-cracking fibers. The use methodof the water-resistant moisture-proof putty capable of defoaming and leveling comprises the step of uniformly mixing the materials with water, wherein the solid-liquid mass ratio is 5-10:3. Comparedwith the prior art, the invention has the following beneficial effects: the physical properties of the material are changed, wood fibers and cellulose ether are added on the basis of the prior art toplay roles in retaining water, ventilating and condensing, light vitrified micro bubbles and machine-made sand are added to fill pores on the surface, and the combination of the light vitrified microbubbles and the machine-made sand achieves the effects of ventilation and foam inhibition; therefore, the purpose of defoaming is achieved; the product meets the standards of GB 18582-2001 and JG / T 298-2020 (water-resistant type N), and the surface of the product is flat and smooth, free of bubbles and free of needle holes.

Owner:谭华勇

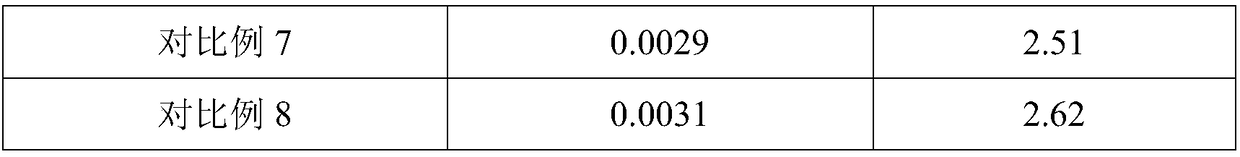

Method for measuring emission blast furnace slag and defoaming blast furnace slag

ActiveCN109439812AAccurate calculationReduce processing timeVolume measurement apparatus/methodsRecycling and recovery technologiesLiquid heightSlag

The invention relates to a method for measuring emission blast furnace slag and defoaming blast furnace slag, belonging to the technical field of calculating the emission of blast furnace slag and thedefoaming method. When the method provided by the invention is carried out, the blast furnace slag is subjected to weighing calibration at different temperatures in advance so as to obtain a graph ofrelation or a relation between the density and the temperature of the blast furnace slag; the blast furnace slag enters a deslagging tank; after defoaming treatment, the liquid height of the deslagging tank is measured; meanwhile, the slag temperature is tested; the volume number of the loaded slag is calculated according to the liquid height; the density of the loaded slag is obtained accordingto the graph of relation or the relation between the density and the temperature of the blast furnace slag; and finally, the slag quantity loaded in the deslagging tank is obtained by calculating thevolume number and the density of the loaded slag. Under the condition of not increasing a weighing device, the method provided by the invention can measure the emission of the blast furnace slag accurately; therefore, the influence of the residual slag iron quantity of the hearth on the stability of the blast can be analyzed. A defoaming agent comprises extracted vanadium tailings, which can realize the defoaming purpose of blast furnace slag and harmless treatment of the extracted vanadium tailings.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

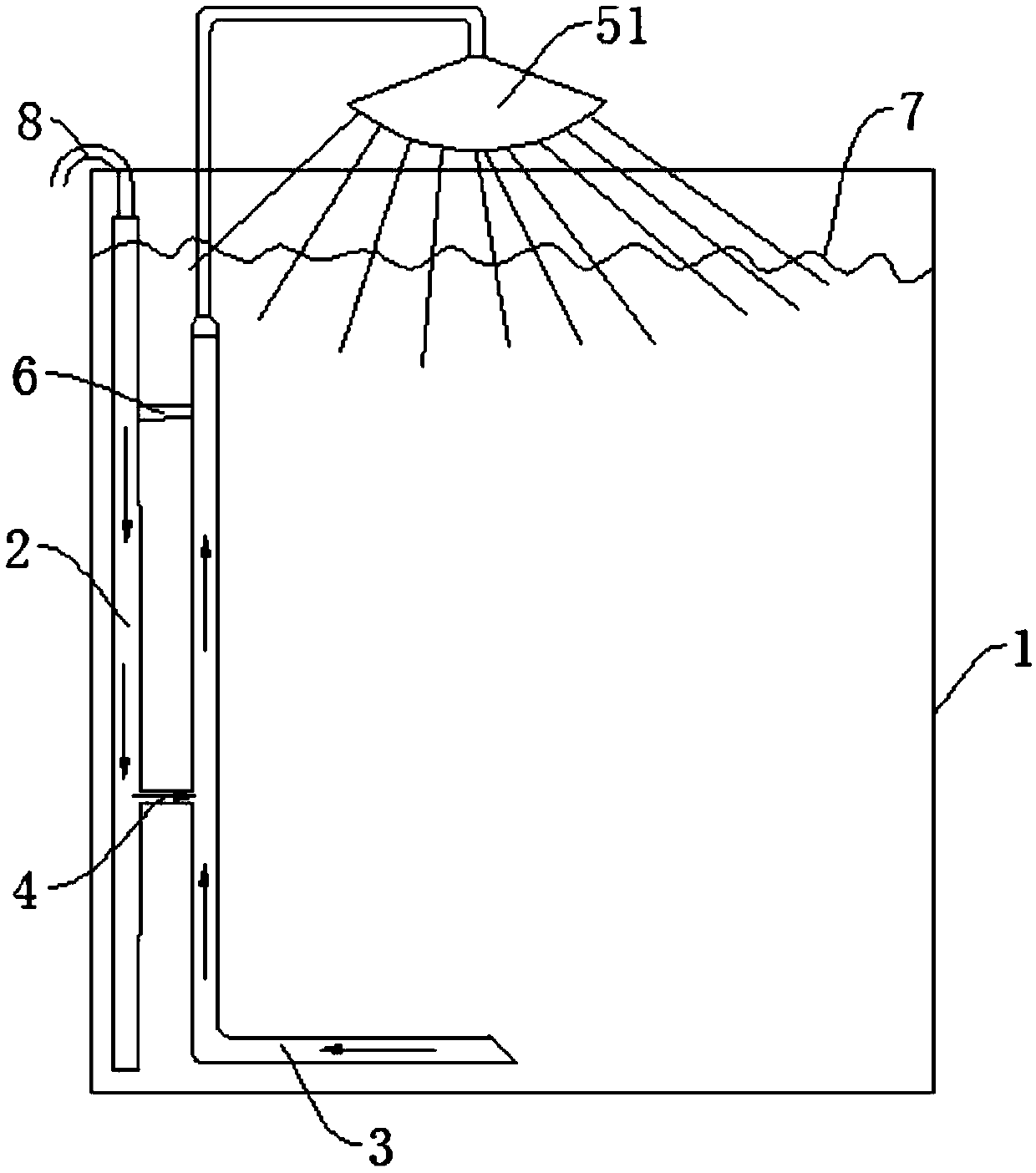

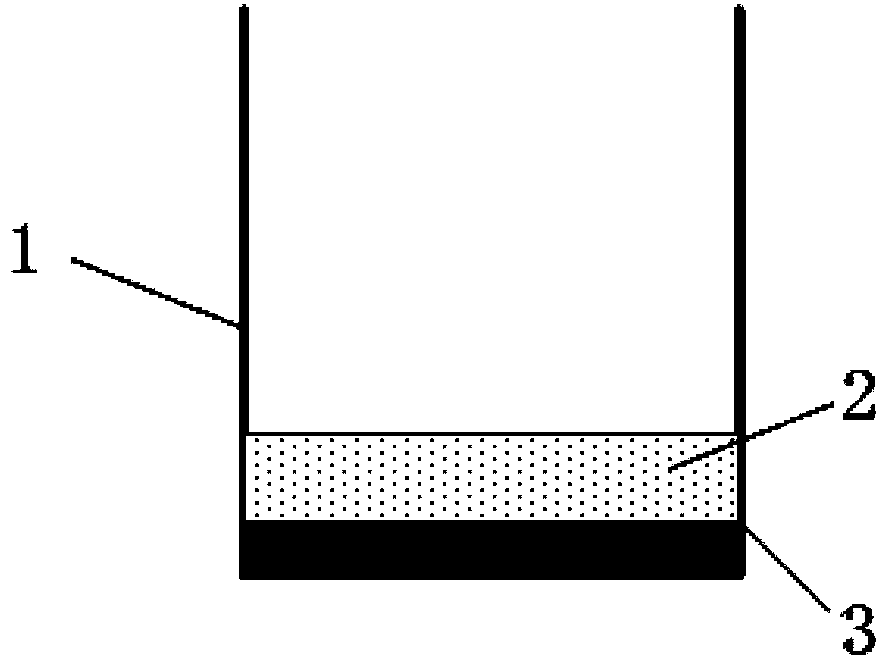

Defoaming device

PendingCN107557268ATo achieve the purpose of defoamingEliminate defoaming dead angleBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismEnvironmental engineering

The invention discloses a defoaming device. The defoaming device comprises a reactor body, an air inlet pipe, a sprinkling pipe and a ventilating pipe, wherein the air inlet pipe is connected to the inner wall of the reactor body; one end of the air inlet pipe is connected with an air compressor through a hose; one end of the sprinkling pipe is arranged on the liquid level in the reactor body, andthe other end of the sprinkling pipe is arranged under the liquid level in the reactor body; a sprinkling device is arranged on one end of the sprinkling pipe arranged on the liquid level in the reactor body; the sprinkling device is arranged on the liquid level in the reactor body; the sprinkling pipe is communicated with the air inlet pipe through the ventilating pipe; through holes are formedin a position, which is connected with the air inlet pipe, of the sprinkling pipe; the ventilating pipe is arranged under the liquid level in the reactor body. Through the way, defoaming is carried out by adopting an air-water combination sprinkling mode, the purpose of defoaming is achieved by utilizing an impact force to break foams, defoaming dead angles can be removed, and a defoaming effect is increased; liquid in a reactor can be repeatedly utilized, no pollutant is introduced in, fermented microorganisms can be protected, and the application range is wider.

Owner:苏州富园生物科技有限公司

Water-based ink

The invention discloses a water-based ink which comprises the following materials in parts by weight: 10-25 parts of a pigment, 25-40 parts of a binding material, 35-70 parts of a solvent, 1-3 parts of a defoaming agent, 1-3 parts of a leveling agent, 2-5 parts of a 5A molecular sieve, 1-2 parts of fumed silica, 2-5 parts of a dispersant, 0.5-1.5 parts of an adhesion promoter, 1-3 parts of ethanolamine, 3-5 parts of triethylamine, 1-3 parts of 2-amino-2-methyl-1-propanol, 2-3 parts of a drying retarder and 1-2 parts of gummy oil. The water-based ink provided by the invention can enhance the adhesion force of the ink, prevents the ink from ink penetration, ink melting and other phenomena, and has high stability, long storage time, a certain anti-drying capacity and low pollution.

Owner:SUZHOU ANJIE TECH

Method for sample defoaming in thermal analysis test

InactiveCN103386217AReduce the impactTo achieve the purpose of defoamingMaterial thermal analysisFoam dispersion/preventionMass ratioCrucible

The invention discloses a method for sample defoaming in a thermal analysis test. The method comprises the following steps of 1, filling a sample to be analyzed into a crucible, 2, selecting a corresponding mass ratio of defoaming powder to the sample to be analyzed, and size distribution of the defoaming powder according to the distribution of foam of the sample to be analyzed in the crucible used for thermal analysis in a reaction, and the sizes of the foam, and 3, uniformly paving the defoaming powder on an oil sample surface of the sample to be analyzed to cover the whole oil sample surface so that in analysis, the produced foam layer is torn, deforms and is broken in flowing in and passing through defoaming powder gaps. The method for sample defoaming can realize deformation and breaking of foam in flowing in and passing through the defoaming powder gaps so that defoaming is realized. Alumina and quartz powder subjected to high-temperature treatment have no pollution and can produce very small influence on an experiment result.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

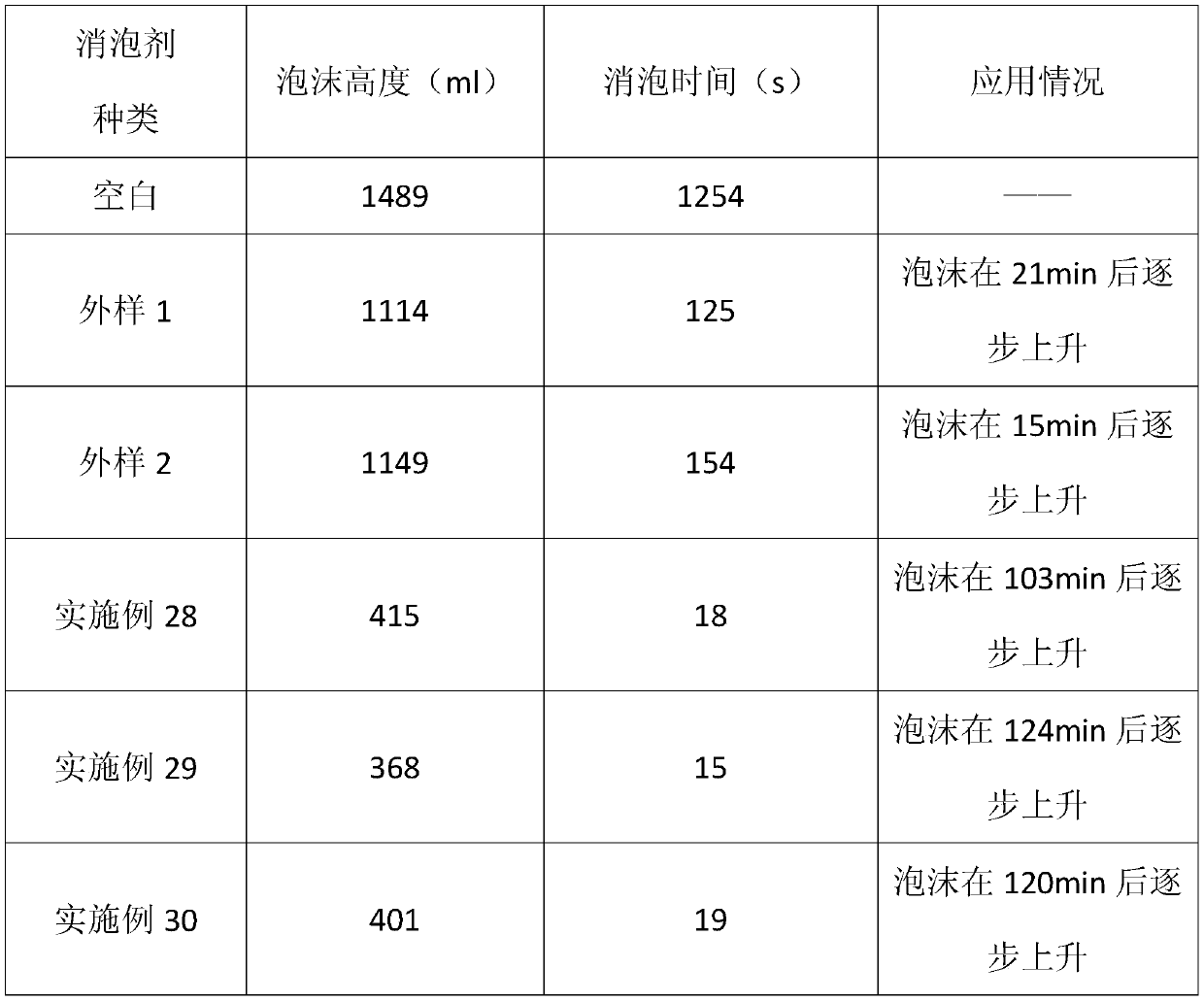

Antifoaming agent for phosphoric acid extracting production, and preparation method thereof

InactiveCN110152357AQuality is not affectedWide variety of sourcesFoam dispersion/preventionWater bathsRoom temperature

The invention discloses an antifoaming agent for phosphoric acid extracting production. The antifoaming agent comprises, by weight, 20-40 parts of an antifoaming dispersant, 20-50 parts of a foaming inhibitor, 5-30 parts of an emulsifier and 20-60 parts of water. The antifoaming agent of the invention solves the defoaming problem of wet process phosphoric acid by combining the antifoaming and foam-inhibiting components; and the antifoaming agent of the invention does not affect the quality of the phosphoric acid, and has good antifoaming and foam-inhibiting effect in phosphoric acid extraction. The invention also discloses a preparation method of the antifoaming agent for phosphoric acid extracting production. The preparation method comprises the following steps: adding water into a reaction kettle, simultaneously slowly adding the foam inhibitor and the emulsifier to the obtained water bath pot, performing stirring at room temperature for 10-20 min, then slowly adding the antifoamingdispersant, and performing stirring for 2-4 min. The preparation method of the invention has the advantages of simple process, easiness in preparation, and short reaction time.

Owner:云南祺华科技有限公司

Organosilicon-free easy-to-defoam guitar musical instrument nitro paint formula and preparation method thereof

InactiveCN106811024AEliminate bad effectsTo achieve the purpose of defoamingPolyester coatingsSlurryPolymer solution

An organosilicon-free easy-to-defoam guitar musical instrument nitro paint formula is prepared from 15kg of ethyl acetate, 15kg of n-butyl acetate, 5kg of isopropanol, 5kg of propylene glycol methyl ether acetate, 20kg of 1 / 16-second nitrocotton, 2kg of high-efficiency matting powder, 30kg of 70 pecent of an alkyd resin polymer, 5kg of non-matting wax slurry and 0.1kg of a bubble-breaking polymer solution (containing no organosilicon). A preparation method comprises the following steps: sequentially adding the ethyl acetate, the n-butyl acetate, the isopropanol, the propylene glycol methyl ether acetate and the 1 / 16-second nitrocotton, and continuously stirring for 30 minutes; then adding the 70 percent of alkyd resin polymer after completely dissolving the 1 / 16-second nitrocotton, and continuously stirring for 30 minutes; finally adding the high-efficiency matting powder, the non-matting wax slurry and the bubble-breaking polymer solution (containing no organosilicon), and stirring for 5 minutes.

Owner:闫斐斐

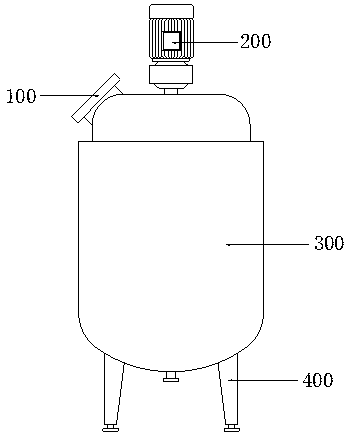

Environment-friendly energy-saving straw anaerobic fermentation efficient treatment equipment

InactiveCN110551619AAvoid wastingIncrease production capacityBioreactor/fermenter combinationsBiological substance pretreatmentsDecompositionFermentation

The invention discloses environment-friendly energy-saving straw anaerobic fermentation efficient treatment equipment. The equipment structurally comprises a stirring device, an efficient energy-saving motor, a pressurizing and bubble removing device, a fermentation tank machine body, and supporting legs; the supporting legs are welded at the bottom of the fermentation tank machine body. Comparedwith the prior art, the equipment has the beneficial effects that the pressurizing and bubble removing device consisting of the energy-saving motor, a disc, a pressurizing and bubble removing group, ahinge fork, a reciprocating type movable group and a gas exhaust cover is additionally arranged in an existing anaerobic fermentation tank, and bubbles are broken by increasing the internal pressureintensity of the fermentation tank to achieve the purpose of removing the bubbles, so that straws can be prevented from overflowing due to relatively numerous bubbles generated by stirring, the wasteof the straws is avoided, the production capacity is improved, bacteria can normally breathe, the lignocellulose of the straws can be decomposed, the decomposition efficiency is improved, and the fermentation time is shortened.

Owner:黄晓琴

Ultrasonic-assisted rapid straw anaerobic fermentation equipment

InactiveCN110591892APrevent crustingReduce the degree of polymerizationBioreactor/fermenter combinationsBiological substance pretreatmentsUltrasonic assistedPulp and paper industry

The invention discloses ultrasonic-assisted rapid straw anaerobic fermentation equipment. The equipment structurally comprises a sight glass device, an anti-dross crusting device, an anaerobic fermentation tank and support legs, wherein the bottom of the anaerobic fermentation tank is connected with three support legs arranged at equal intervals, the sight glass device is mounted on one side of the top of the anaerobic fermentation tank, and the anti-dross crusting device is further arranged on the anaerobic fermentation tank. Compared with the prior art, the equipment has the beneficial effects as follows: a dross layer is stirred by an anti-dross crusting plate to prevent lignocelluloses from crusting, cellulose, hemicelluloses and lignin intertwined structures can be dissolved by a dispersion and dissolution promoting assembly, the crusting phenomenon can be effectively prevented, fermentation of straw is facilitated while manual clearing is not required, continuous pumping can be realized by boosting and bubble removal to boost to make bubbles burst so as to remove bubbles, a pumping ring is arranged to increase the pumping travel and increase the pumping volume, and the bubbleremoval efficiency is improved.

Owner:黄相兰

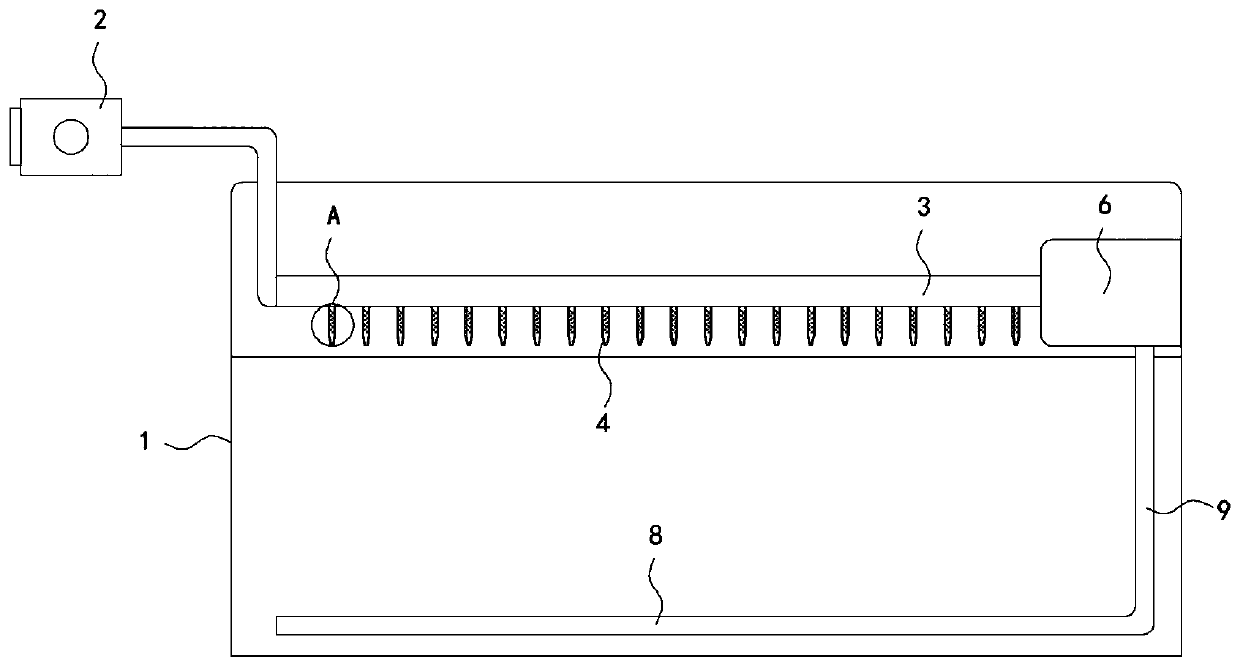

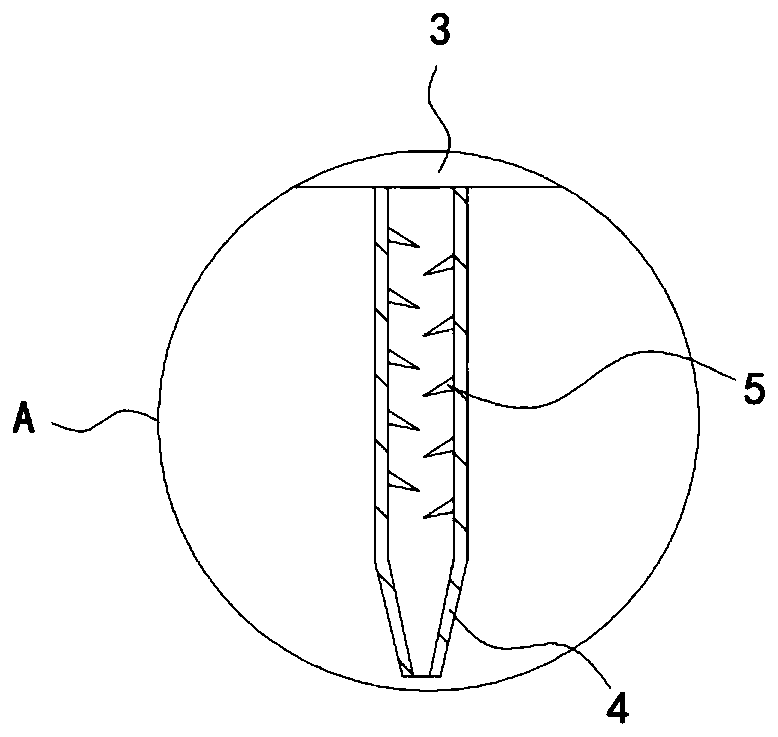

Efficient aeration sewage treatment pool with bubble eliminating function

ActiveCN110818106AAffect growthTo achieve the purpose of defoamingTreatment using aerobic processesWater contaminantsSewage treatmentWater treatment

The invention belongs to the field of sewage treatment facilities, and particularly relates to an efficient aeration sewage treatment pool with bubble eliminating function. The efficient aeration sewage treatment pool comprises a pool body and a gas supply pump, wherein the peripheral side wall of the pool body is fixedly connected with two semi-annular flow splitting pipes horizontally arranged,one ends of the two semi-annular flow splitting pipes are communicated with the gas supply pump, a plurality of bubble eliminating pipes distributed at equal intervals are fixedly communicated with the lower side walls of the semi-annular flow splitting pipes, the lower ends of the bubble eliminating pipes are conical and extend to the water surface in the pool body, the inner side wall of the bubble eliminating pipe is fixedly connected with a plurality of obliquely downward bubble poking needles, the two semi-annular flow splitting pipes are fixed and communicated through a mixing box, the outflow ends of the two semi-annular flow splitting pipes are right opposite to each other, and the inner side wall of the mixing box is fixedly connected with a condensate net plate. According to theinvention, large gas bubbles can be punctured by the bubble eliminating pipes, and small gas bubbles are sucked into the bubble eliminating pipes and are subjected to contact fusion with air, so thatthe oxygen dissolving efficiency is improved, and the activity of aerobic bacteria is effectively improved.

Owner:广州中晟水务环保科技有限公司

Automobile spray paint formula easy to defoam and manufacturing method of automobile spray paint formula

InactiveCN106554720ATo achieve the purpose of defoamingGuaranteed speedRosin coatingsWaxPolyethylene glycol

The invention relates to an automobile spray paint formula easy to defoam and a manufacturing method of the automobile spray paint formula. The manufacturing method comprises the steps that sec-butyl acetate, methyl ethyl ketone, isopropanol, oxidation castor oil and 1 / 16 second nitro-cotton are added, stirring is continuously conducted for 30 min, and after the nitro-cotton is completely dissolved, modified rosin resin is added, and stirring is continuously conducted for 30 min; and finally, an efficient matting agent, non-matting wax pulp and a defoaming polysiloxane and polyethylene glycol hydrophobicity solid mixture are added, and stirring is conducted for 5 min. An application method comprises the steps that a nitro coating and banana oil are mixed according to the proportion of 7:3 and evenly stirred and then can be used for spraying. The 1 / 16 second nitro-cotton and modified rosin resin polymer is the main film forming substance of the coating, the sec-butyl acetate, the methyl ethyl ketone, the isopropanol and the oxidation castor oil are primary solvents for dissolving the nitro-cotton, the defoaming polysiloxane and polyethylene glycol hydrophobicity solid mixture is a main additive for eliminating coating bubbles, the surface tension of the bubbles can be changed, and the bubbles are rapidly broken.

Owner:孙正国

Formula and preparation method of organosilicone-free easy defoaming nitrolacquer for clarinets

InactiveCN108373798AEliminate bad effectsTo achieve the purpose of defoamingPolyester coatingsPolymer scienceEthyl ester

The invention discloses a formula and preparation method of organosilicone-free easy defoaming nitrolacquer for clarinets. 1 / 16s nitrocellulose and an alkyd resin polymer are used as main film-formingsubstances. Ethyl acetate, n-butyl acetate, isopropanol and propylene glycol methyl ether acetate are used as main solvents for dissolving nitrocotton. A defoaming polymer solution (without organosilicone) is the main additive to eliminate the bubbles of the paint and can change the surface tension of the bubbles to fast break the bubbles.

Owner:黄克格

Dyeing agent for fabric dyeing

InactiveCN106498779AImproves UV resistanceImprove antioxidant capacityDyeing processStainingEthyl acetate

The invention discloses a dyeing agent for fabric dyeing. The dyeing agent is prepared from, by weight, 3-4 parts of yellow dyestuff, 3-4 parts of tea polyphenol, 10-13 parts of water, 1-3 parts of copper sulfate pentahydrate, 0.4-0.6 part of boric acid, 1-2 parts of propylene glycol, 1-3 parts of jack fruit shell powder, 0.5-1 part of ethyl acetate, 2-3 parts of assistant, 1-2 parts of defoamer, 3-6 parts of initiator, 1-3 parts of polyethyleneimine and 1-3 parts of light stabilizer. Dyed fabric has good color fastness, washing resistance, friction resistance and light fastness resistance all reach the level IV or above, the staining fastness can reach the level VI, The K / S value reaches 8.81 or above, environmental friendliness is achieved, and a certain healthcare function is achieved; the jack fruit shell powder is natural yellow and has the complementary effect with a tea polyphenol-copper yellowish-brown complex and the yellow dyestuff, the dyeing fastness can be greatly improved, and the color is fuller, more natural and softer.

Owner:张家港市双盈印染有限公司

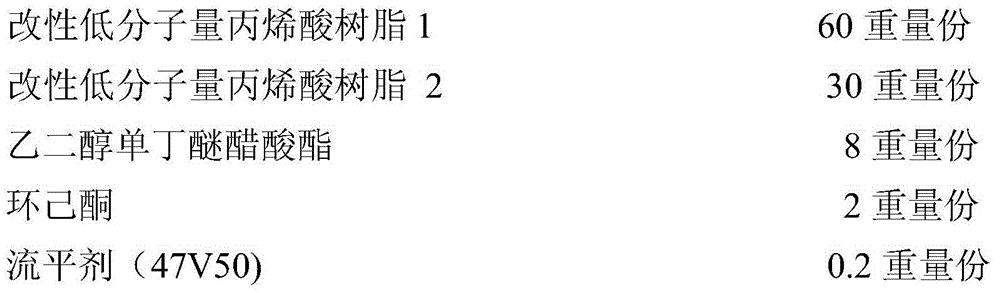

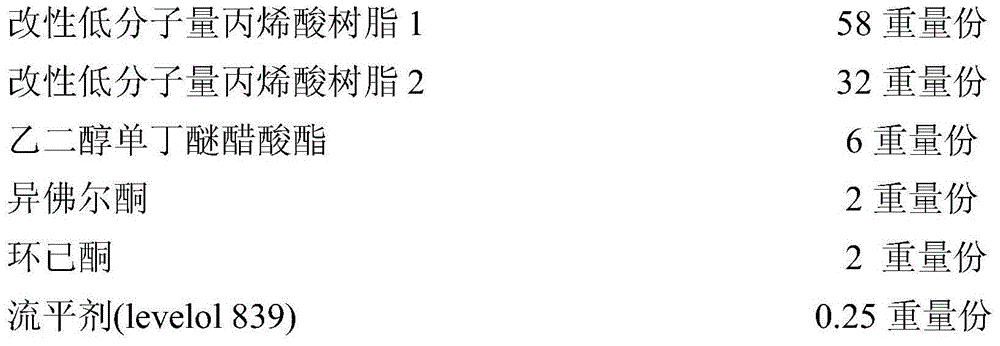

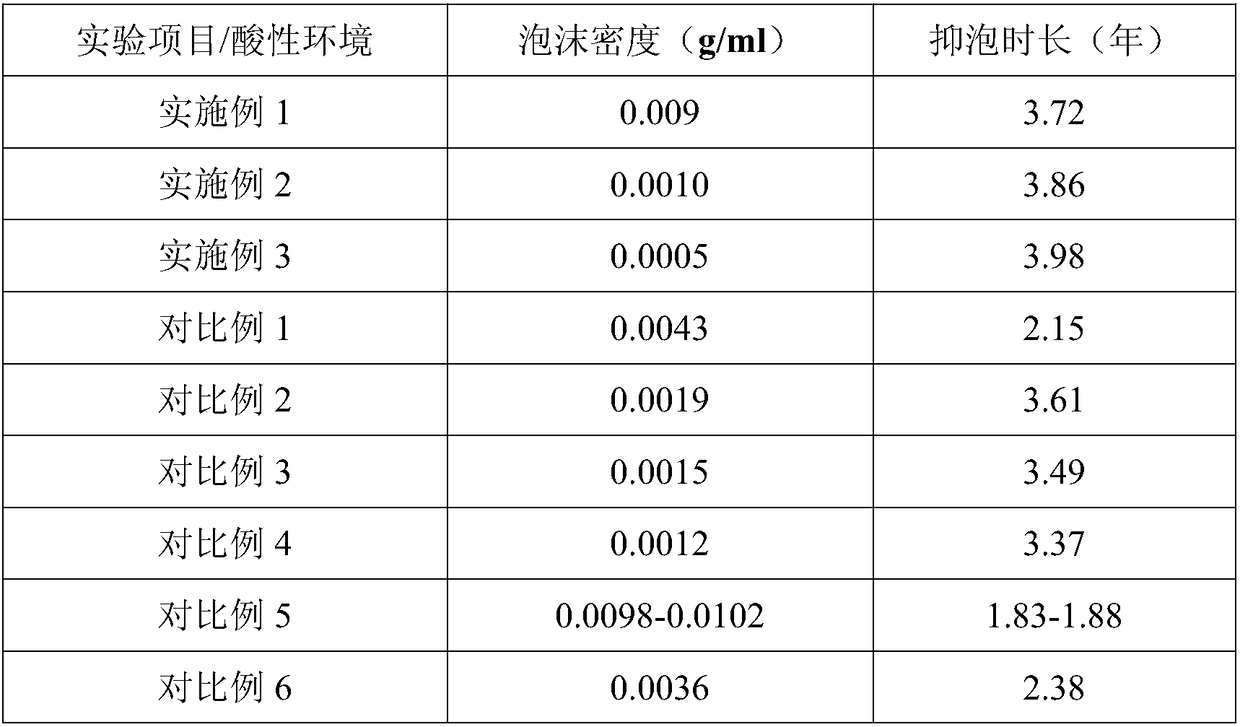

A kind of screen printing waterproof adhesive for thin film circuit and preparation method thereof

ActiveCN103773286BImprove adhesionOvercome the disadvantages of waterproof performance declineNon-macromolecular adhesive additivesMacromolecular adhesive additivesAcrylic resinAdhesive

The invention discloses a silk-screen printing waterproof adhesive for thin-film circuit and a preparation method thereof. The waterproof adhesive is prepared by mixing modified acrylate resin polymers (1 and 2) of low molecular weight and different degrees of functionality obtained by performing organic peroxide cracking on commercially available acrylic resins of different degrees of functionality with a leveling agent and a solvent at a specific ratio; during use, the waterproof adhesive can be coated to thin-film circuits made of PET, PE and PP through silk-screen printing by matching with corresponding curing agents, and the aims of resisting water, insulating moisture and protecting the circuit are achieved. According to the waterproof adhesive, a defoaming agent is not needed, the waterproof adhesive has the advantages of excellent printing performance, long construction time, high adhesive force, high-temperature and humidity resistance, creep resistance, simplicity in repeated attachment and excellent waterproof performance and has wide market application prospects, and the service life of the thin-film circuit is greatly prolonged.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD

Formula and production method of organosilicon-free easy-defoaming ceramic nitro paint

InactiveCN108300205AEliminate bad effectsTo achieve the purpose of defoamingPolyester coatingsMetallurgyPolymer solution

The technical scheme provides a formula and a production method capable of solving the problem of the presence of organosilicon in the easy-defoaming ceramic nitro coating material. The ceramic nitrocoating material of the present invention comprises, by weight, 10-15% of ethyl acetate, 10-15% of n-butyl acetate, 5-10% of isopropanol, 3-5% of propylene glycol methyl ether acetate, 20-25% of 1 / 16second nitrocellulose, 1-5% of efficient matting powder, 20-30% of a 70% alkyd resin polymer, 1-5% of non-matting wax slurry, and 0.1-1.1% of a (organosilicon-free) defoaming polymer solution.

Owner:黄克格

Method for measuring blast furnace slag discharge and blast furnace slag defoaming

ActiveCN109439812BAccurate calculationReduce processing timeVolume measurement apparatus/methodsRecycling and recovery technologiesMolten slagBlast furnace

The invention relates to a method for measuring blast furnace slag discharge and blast furnace slag defoaming, and belongs to the technical field of blast furnace slag discharge measurement and defoaming methods. When the present invention is implemented, the blast furnace slag is weighed and calibrated at different temperatures in advance to obtain the relationship curve or relational expression between the blast furnace slag density and temperature; The liquid level height of the tank and the temperature of the slag are tested at the same time; the volume of the slag loaded is calculated according to the liquid level, and the density of the slag loaded is obtained according to the relationship curve or relational formula between the density of the blast furnace slag and the temperature. The volume number and the density are calculated to obtain the amount of slag loaded in the slag tank. The invention can accurately measure and calculate the discharge amount of blast furnace slag under the condition of not adding a weighing device, and thereby analyze the influence of the amount of slag and iron remaining in the furnace hearth on the stability of the blast furnace. The defoaming agent includes vanadium extraction tailings, which can achieve the purpose of blast furnace slag defoaming and harmless treatment of vanadium extraction tailings.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Piano lacquer formula with easy defoaming and production method thereof

InactiveCN106467703AGuaranteed speedPromote rupturePolyester coatingsPolymer sciencePolyvinyl alcohol

The invention relates to a piano lacquer formula with easy defoaming and a production method thereof. The piano lacquer formula comprises the following components: 30 kg of glyceride maleic anhydride resin, 15 kg of styrene, 0.01 kg of polyethylene glycol (600), 1 kg of dibutyltin dilaurate, 2 kg of polyamide wax (a mixture of n-butyl alcohol and naphtha), 50 kg of orthophthalic unsaturated polyester resin, 10.1 kg of polyvinyl butyral, and 0.1 kg of a defoaming hydrophobic solid mixture of polysiloxanes and polyethylene glycol. The production method comprises the following steps: mixing glyceride maleic anhydride resin, styrene, polyethylene glycol (600), dibutyltin dilaurate, and polyamide wax (the mixture of n-butyl alcohol and naphtha), continuously stirring the materials for 30 min, adding orthophthalic unsaturated polyester resin, polyvinyl butyral, polyvinyl butyral, and the defoaming hydrophobic solid mixture of polysiloxanes and polyethylene glycol, and continuously stirring the materials for 30 min.

Owner:孙正国

De-foaming agent and preparation method

InactiveCN109499106AImprove acid resistanceGood dispersion utilityFoam dispersion/preventionFatty alcoholPolylactic acid

The invention discloses a de-foaming agent and a preparation method. The de-foaming agent is prepared from the following raw materials: polysiloxane silicone grease, 2-methyl-3-butyn-2-ol, a dispersant, a thickening agent, water, polylactic acid, corn starch, polynaphthalene formaldehyde sulfonate, ammonium fatty alcohol polyoxyethylene ether sulfate and acrylate. The de-foaming agent is preparedthrough the steps of modifying the polysiloxane silicone grease, modifying the 2-methyl-3-butyn-2-ol, mixing residual raw material components with the modified polysiloxane silicone grease and the modified 2-methyl-3-butyn-2-ol and emulsifying and the like. According to the de-foaming agent, a reinforcing system composed of the polynaphthalene formaldehyde sulfonate, the ammonium fatty alcohol polyoxyethylene ether sulfate and the acrylate is adopted, so that the acid resisting performance and high temperature resisting performance of the de-foaming agent are improved.

Owner:CHANGSHA XIAORU INFORMATION TECH CO LTD

Easy-defoaming guitar musical instrument nitrocellulose paint and manufacturing method thereof

InactiveCN106811032ATo achieve the purpose of defoamingGuaranteed speedPolyester coatingsNitrocellulosePolyethylene glycol

The technical scheme of the invention relates to an easy-defoaming guitar musical instrument nitrocellulose paint and a manufacturing method thereof, and aims to solve the problem of poor defoaming property in the guitar musical instrument nitrocellulose paint. The nitrocellulose paint comprises the following ingredients in percentage by weight: 10-15% of ethyl acetate, 10-15% of n-butyl acetate, 5-10% of isopropanol, 3-5% of propylene glycol methyl ether acetate, 20-25% of 1 / 16-second nitrocellulose, 1-5% of high-efficiency matting powder, 20-30% of 70% alkyd resin polymer, 1-5% of non-matting wax slurry and 0.2-1.2% of defoaming polysiloxane / polyethyleneglycol hydrophobic solid mixture.

Owner:黄克格

Formula and production method of organosilicon-free easy-defoaming clarinet polyurethane paint

InactiveCN108300227AEliminate bad effectsTo achieve the purpose of defoamingPolyurea/polyurethane coatingsWaxOrganosilicon

A purpose of the present invention is to solve the problem of the presence of organosilicon in the easy-defoaming clarinet polyurethane coating material in the prior art. According to the present invention, an improved formula and a production of a silicon-free defoaming agent are utilized; and the technical scheme provides a formula and a production method capable of solving the problem of the presence of organosilicon in the easy-defoaming clarinet polyurethane coating material, wherein the clarinet polyurethane coating material of the present invention contains a component A and a componentB, the component A comprises ethyl acetate, n-butyl acetate, cyclohexanone, a polyketone resin, 1 / 16 second nitrocellulose, efficient matting powder, hydroxyl polyacrylic resin, non-matting wax slurry and a (organosilicon-free) defoaming polymer solution, and the component B comprises ethyl acetate, n-butyl acetate, 1,6-hexamethylene diisocyanate, an isocyanate adduct and a matt trimer curing agent.

Owner:闫斐斐

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com