Efficient aeration sewage treatment pool with bubble eliminating function

A sewage treatment tank and defoaming technology, which is applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, water aeration, etc., can solve problems such as troublesome, excessive foam defoaming, etc., to improve dissolved oxygen rate, Improve efficiency, good aeration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

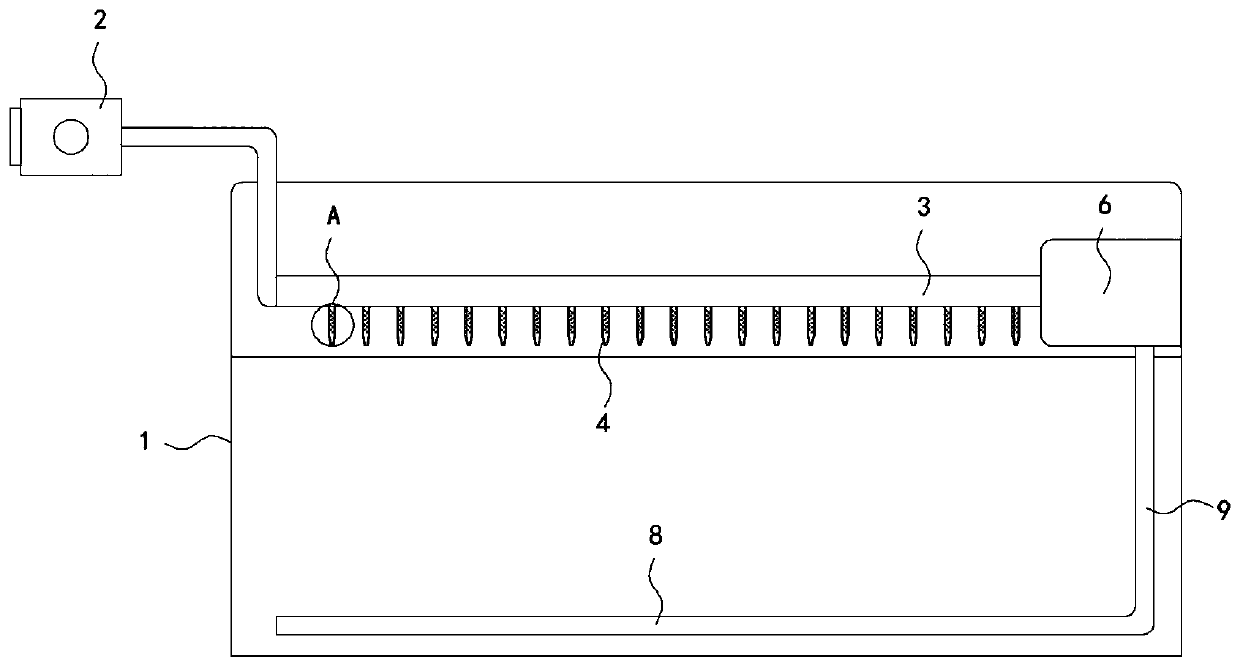

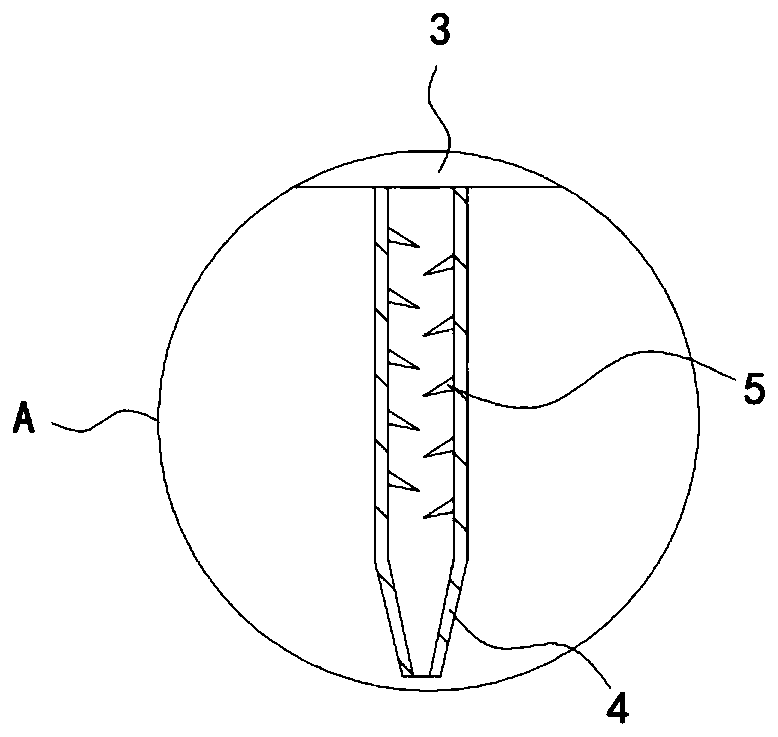

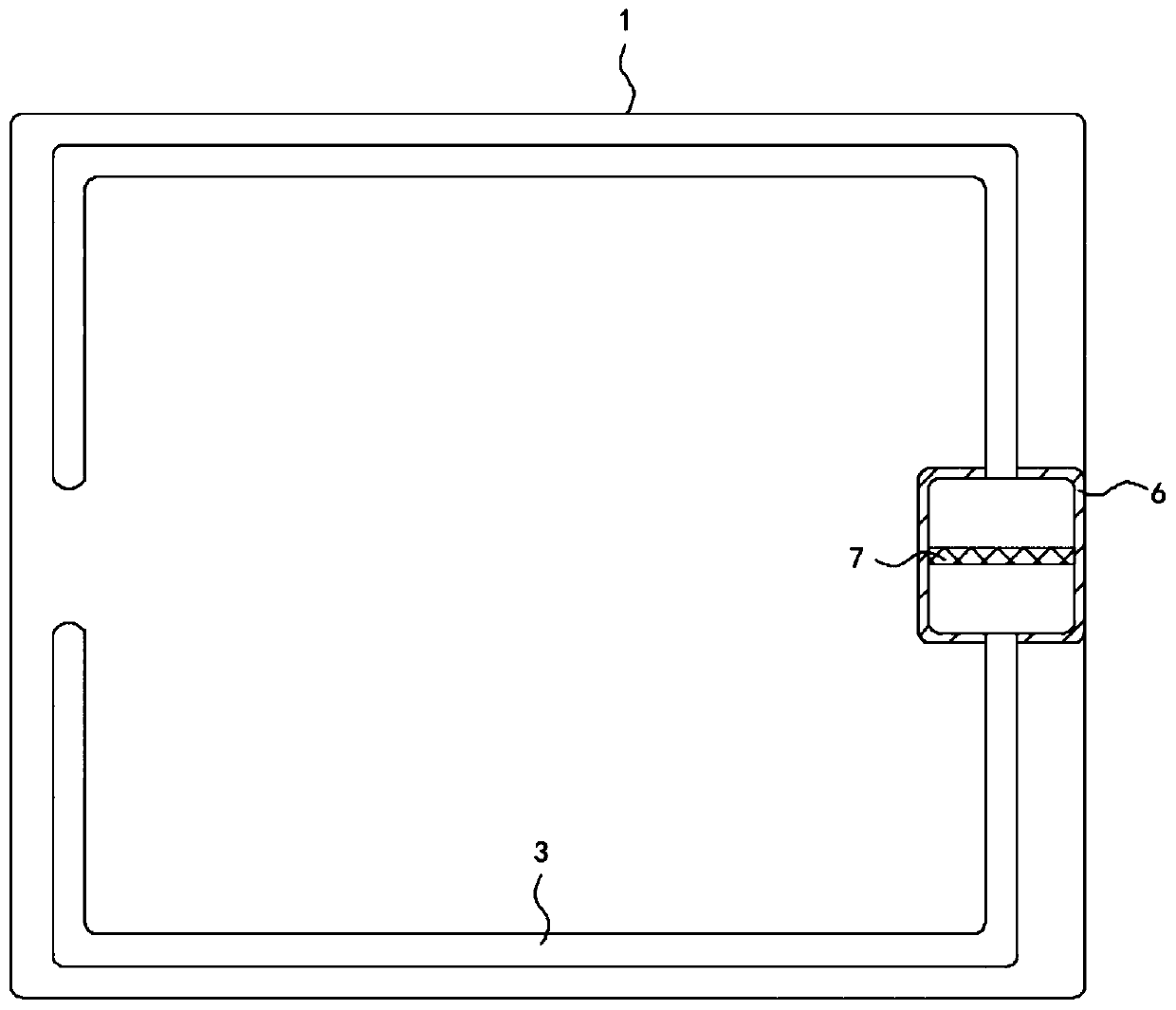

[0022] Such as Figure 1-5 As shown, a high-efficiency aerated sewage treatment tank with defoaming function includes a tank body 1 and an air supply pump 2. Two horizontally arranged semi-circular shunt pipes 3 are fixedly connected to the side wall of the tank body 1, which is worth It should be mentioned that a spoiler 11 is provided in the semi-annular shunt pipe 3, and the spoiler 11 is arranged in a spiral shape. The spoiler 11 can make part of the oxygen in the air dissolve into the small air when flowing in the semi-annular shunt pipe 3. In the liquid droplets, the dissolved oxygen rate is increased, and one end of the two semi-annular shunt pipes 3 is connected to the air supply pump 2, and the lower side wall of the semi-annular shunt pipe 3 is fixedly connected to a plurality of equidistantly arranged defoaming pipes 4 The lower end of the defoaming pipe 4 is tapered and extends to the water surface in the pool body 1, and the inner wall of the defoaming pipe 4 is f...

Embodiment 2

[0026] Such as Image 6 As shown, the difference between this embodiment and Embodiment 1 is that a strip baffle 12 is provided above the aeration tube 8, and the strip baffle 12 is fixedly connected with the aeration tube 8 through a support rod. The width of 12 is equal to the diameter of aeration pipe 8.

[0027] In this embodiment, the air flows out from the aeration hole 10 into the pool body 1, and floats upward under the action of buoyancy. According to the phenomenon of Karman vortex street, when the steady incoming flow bypasses some objects under certain conditions, the two sides of the object will The side will periodically fall out of the opposite direction of rotation and arranged in a regular double-row linear vortex, then in the process of floating upward, the air needs to bypass the bar-shaped baffle 12 to form a double-row vortex in the opposite direction of rotation and arranged in a regular pattern. Alignment vortex, during the floating process, the air has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com