Cleanser and preparation method thereof

A cleaning agent and solvent technology, applied in the field of cleaning agents, can solve the problems of surfactants not resistant to acid and alkali, foam accumulation, and poor cleaning effect of compound dirt, so as to reduce the surface tension of the system and increase the interaction , Excellent cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

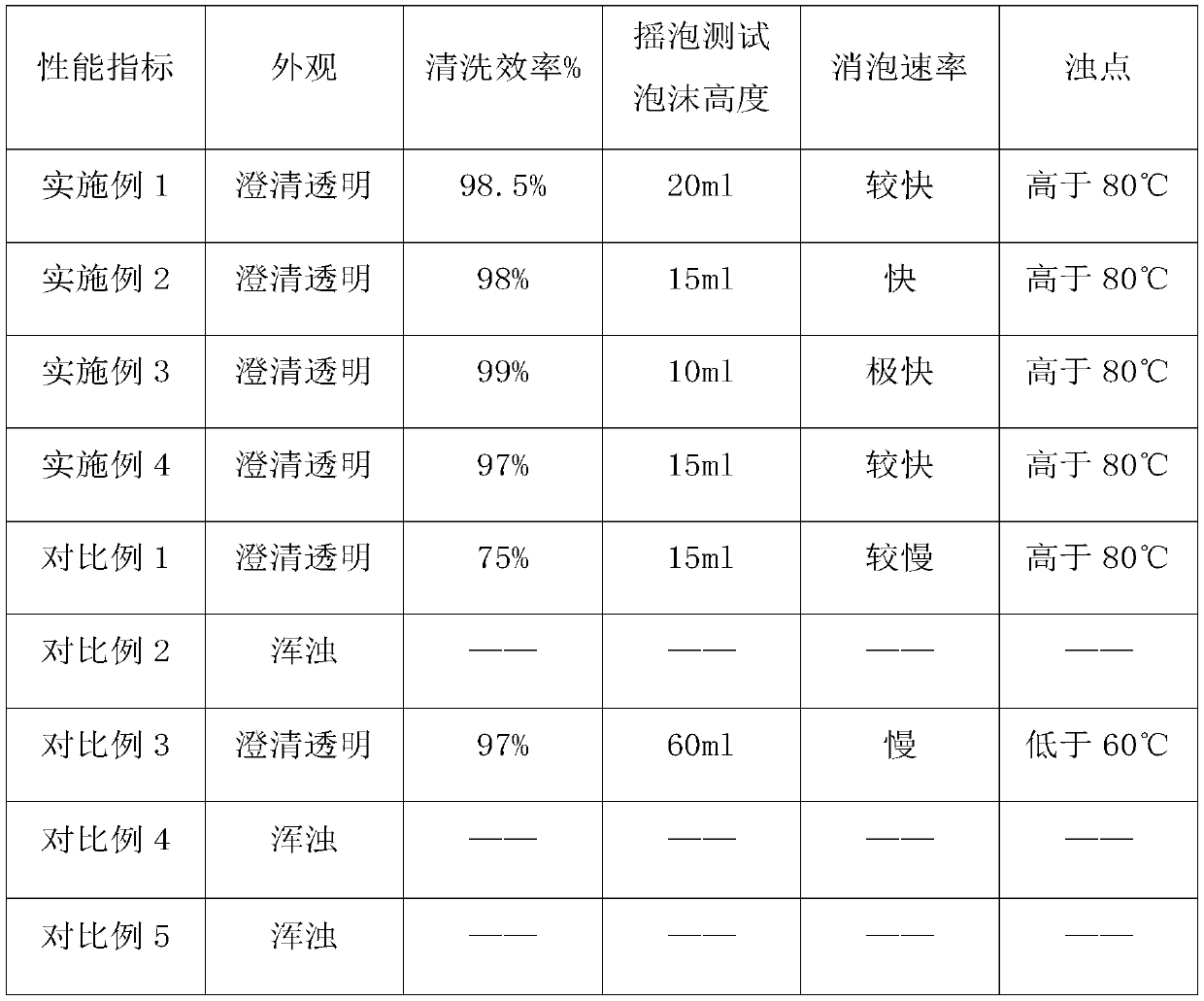

Examples

Embodiment 1

[0025] A cleaning agent formulated from the following components by weight percentage:

[0026] Sodium hydroxide 3.3%, potassium hydroxide 6.7%, tetrasodium edetate 4%, sodium citrate 3%, propylene glycol block polyether 3%, 83903%, sodium polyacrylate 1%, octenyl succinic anhydride 1%, 3% diethylene glycol butyl ether, and the rest is pure water.

[0027] The preparation method of this cleaning agent is prepared according to the following steps:

[0028] 1) Prepare and weigh the above raw materials;

[0029] 2) Add sodium hydroxide and potassium hydroxide into pure water, fully stir to dissolve them, and after they are completely dissolved, let them stand for cooling to obtain solution I;

[0030] 3) Add tetrasodium ethylenediaminetetraacetic acid, sodium citrate and sodium polyacrylate into solution I, stir well until they are completely dissolved, and obtain solution II;

[0031] 4) Add propylene glycol block polyether, 8390 and diethylene glycol methyl ether into soluti...

Embodiment 2

[0035] A cleaning agent formulated from the following components by weight percentage:

[0036] Sodium hydroxide 5%, potassium hydroxide 10%, edetate disodium 4%, sodium citrate 3%, hydroxyethylidene diphosphonic acid 1%, propylene glycol block polyether 8%, 83902%, polyacrylic acid Sodium 1%, isocapric acid 1.5%, N-methylpyrrolidone 3%, and the rest is pure water.

[0037] Concrete preparation method is with embodiment 1.

Embodiment 3

[0039] A cleaning agent formulated from the following components by weight percentage:

[0040] Sodium hydroxide 3.3%, potassium hydroxide 6.7%, sodium gluconate 4%, edetate tetrasodium 1%, hydroxyethylidene diphosphonic acid 1%, propylene glycol block polyether 3%, isooctyl sulfate 3%, 83900.5%, RhodaNop-8804%, acrylic acid-maleic acid copolymer 0.5%, octenyl succinic anhydride 2%, diethylene glycol butyl ether 5%, and the rest is pure water.

[0041] Concrete preparation method is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com