De-foaming agent and preparation method

A technology of defoamer and dispersant, which is applied in the field of defoamer preparation, can solve the problem of defoamer limiting defoaming ability, and achieve the effect of improving acid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

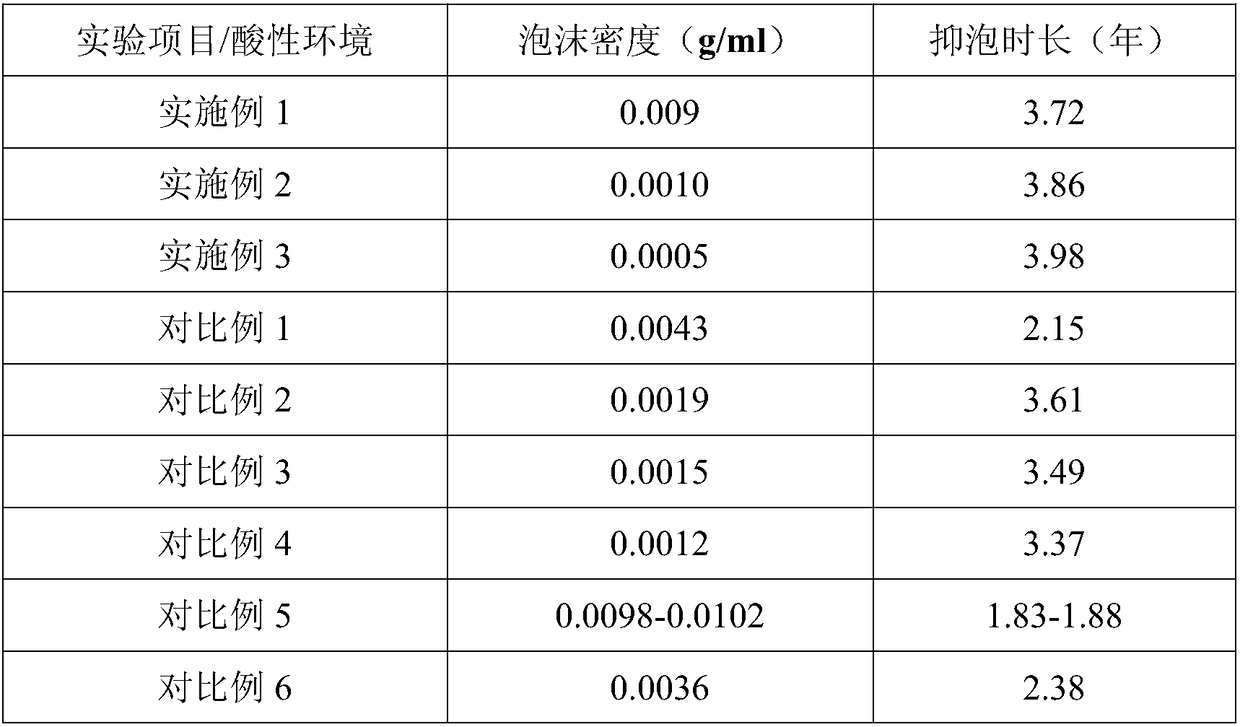

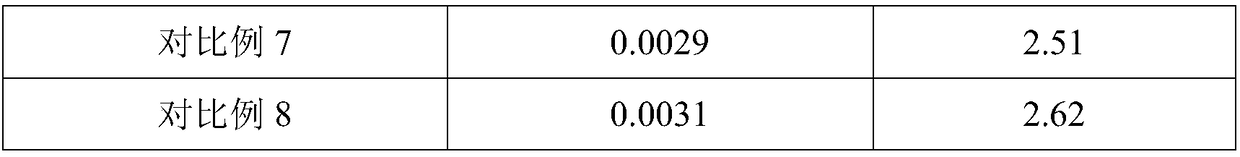

Examples

preparation example Construction

[0028] In an embodiment of the present invention, the preparation method of the defoamer comprises the following steps:

[0029] S1. Weigh raw materials according to the following parts by weight: polysiloxane silicone grease 8-45 parts, 2-methyl-3-butyn-2-ol 5-20 parts, dispersant 0.2-5 parts, thickener 1 -6 parts, 20-30 parts of water, 3-10 parts of polylactic acid, 3-6 parts of corn starch, 4-10 parts of polynaphthalene sulfonate, 9-15 parts of fatty alcohol polyoxyethylene ether ammonium sulfate, acrylate 4-9 copies;

[0030] The polynaphthalene sulfonate includes one or more of polynaphthalene sulfonate sodium salt, polynaphthalene sulfonate potassium salt, and polynaphthalene sulfonate ammonium salt;

[0031] S2. Modified polysiloxane silicone grease: Mix and stir siloxane silicone grease, fatty alcohol polyoxyethylene ether ammonium sulfate, and water evenly, and react for 30-50 minutes at a temperature of 500-900°C and in a closed space. A modified substance A is obt...

Embodiment 1

[0036] A kind of antifoaming agent and preparation method, comprise the following steps:

[0037]S1. Weigh raw materials according to the following parts by weight: 45 parts of polysiloxane silicone grease, 19 parts of 2-methyl-3-butyn-2-ol, 4.5 parts of dispersant, 5 parts of thickener, 28 parts of water, 6 parts of polylactic acid, 5 parts of corn starch, 7 parts of polynaphthalene sulfonate, 14 parts of fatty alcohol polyoxyethylene ether ammonium sulfate, 8 parts of acrylate;

[0038] Described polynaphthalene sulfonate is sodium polynaphthalene sulfonate;

[0039] S2. Modified polysiloxane grease: Mix silicone grease, fatty alcohol polyoxyethylene ether ammonium sulfate, and water and stir evenly, and react for 46 minutes at a temperature of 870°C in a closed space to obtain a modified substance A, the modified substance A is the addition of fatty alcohol polyoxyethylene ether ammonium sulfate to the end group of polysiloxane silicone grease to form a new ether group;

...

Embodiment 2

[0043] A kind of antifoaming agent and preparation method, comprise the following steps:

[0044] S1. Weigh raw materials according to the following parts by weight: 11 parts of polysiloxane silicone grease, 7 parts of 2-methyl-3-butyn-2-ol, 1 part of dispersant, 2 parts of thickener, 22 parts of water, 4 parts of polylactic acid, 3 parts of corn starch, 5 parts of polynaphthalene sulfonate, 10 parts of fatty alcohol polyoxyethylene ether ammonium sulfate, 8 parts of acrylate;

[0045] Described polynaphthaldehyde sulfonate is polynaphthaldehyde ammonium sulfonate;

[0046] S2. Modified polysiloxane silicone grease: Mix silicone grease, fatty alcohol polyoxyethylene ether ammonium sulfate, and water and stir evenly, and react for 38 minutes at a temperature of 600°C in a closed space to obtain a modified substance A, the modified substance A is the addition of fatty alcohol polyoxyethylene ether ammonium sulfate to the end group of polysiloxane silicone grease to form a new e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com