Method for sample defoaming in thermal analysis test

A technology of test process and thermal analysis, applied in the direction of material thermal analysis, material analysis, foam dispersion/prevention, etc., can solve problems such as affecting the experimental results, and achieve the effect of convenient and simple operation, low cost and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

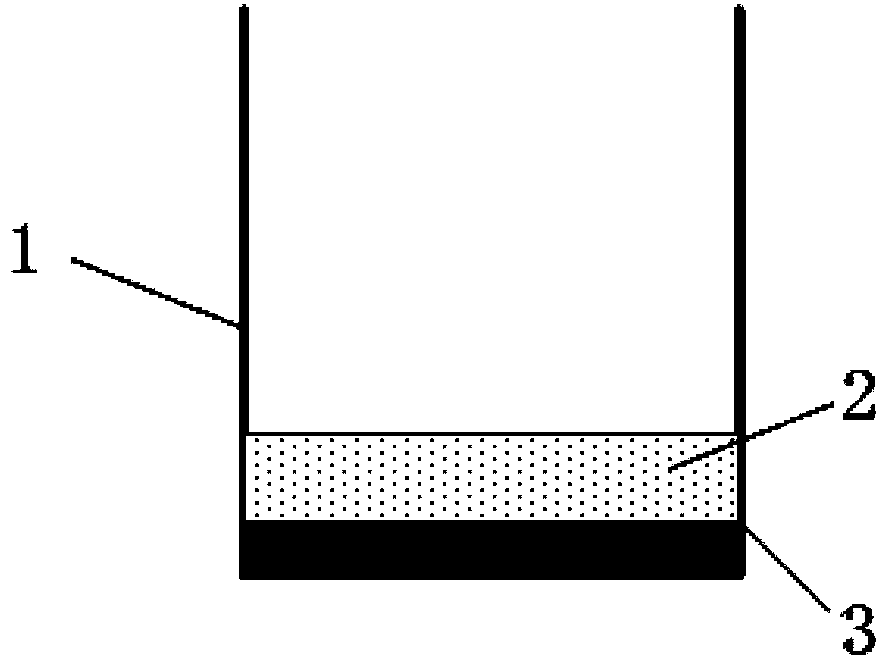

Image

Examples

Embodiment 1

[0025] Put an oil sample 1 with a mass of 15 mg into a thermal analysis crucible 1 . After the thermal analysis of the oil sample, the reactants bubbled a lot and overflowed out of the crucible 1, which affected the experimental results and seriously polluted the experimental instruments.

Embodiment 3

[0029] Put oil sample 2 with a mass of 15 mg into thermal analysis crucible 1 . After the thermal analysis of the oil sample, the reactant foamed slowly during the pyrolysis process, the inner wall was completely blackened, and the outside of the top was also dipped. The experimental results were affected, and the pollution to the testing equipment was relatively light, but the scope of the pollution wider.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com