Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Timing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

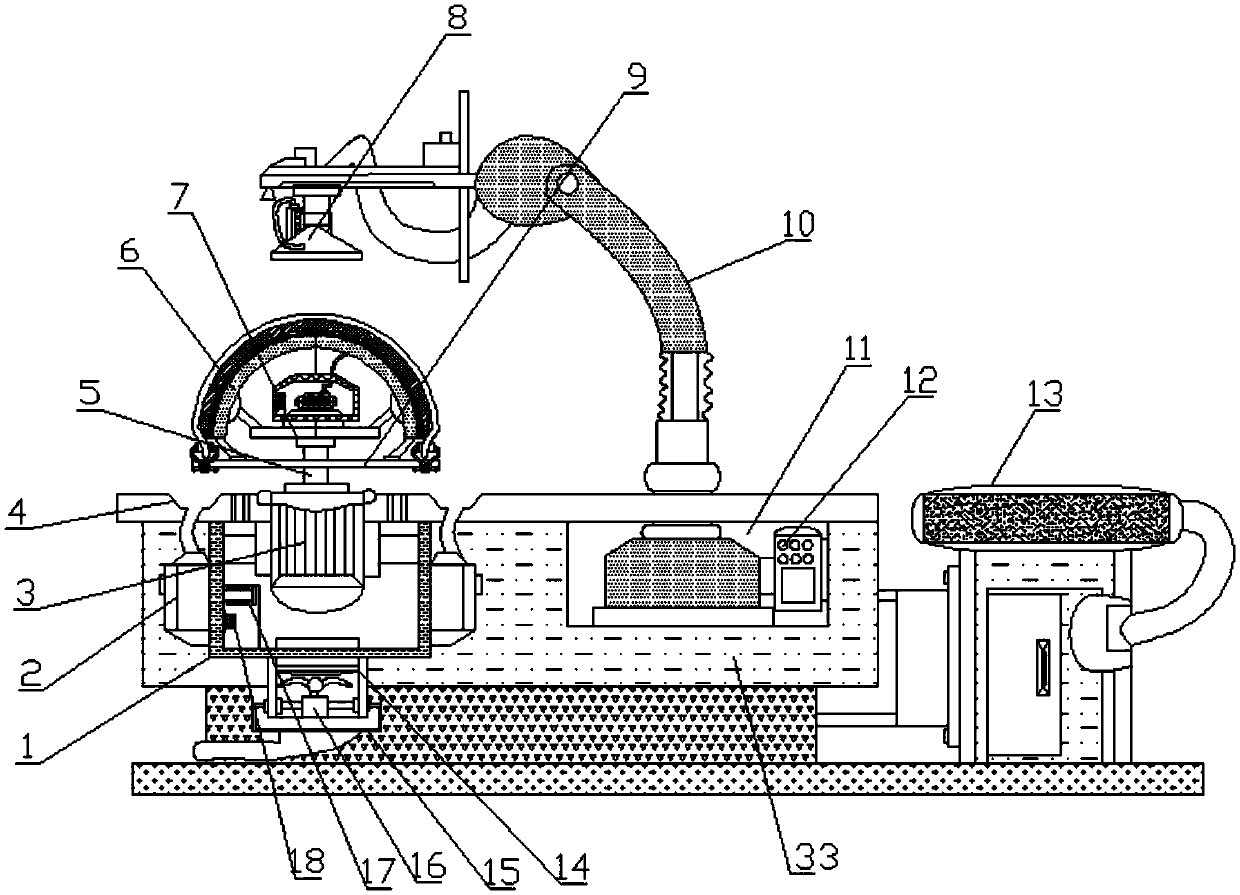

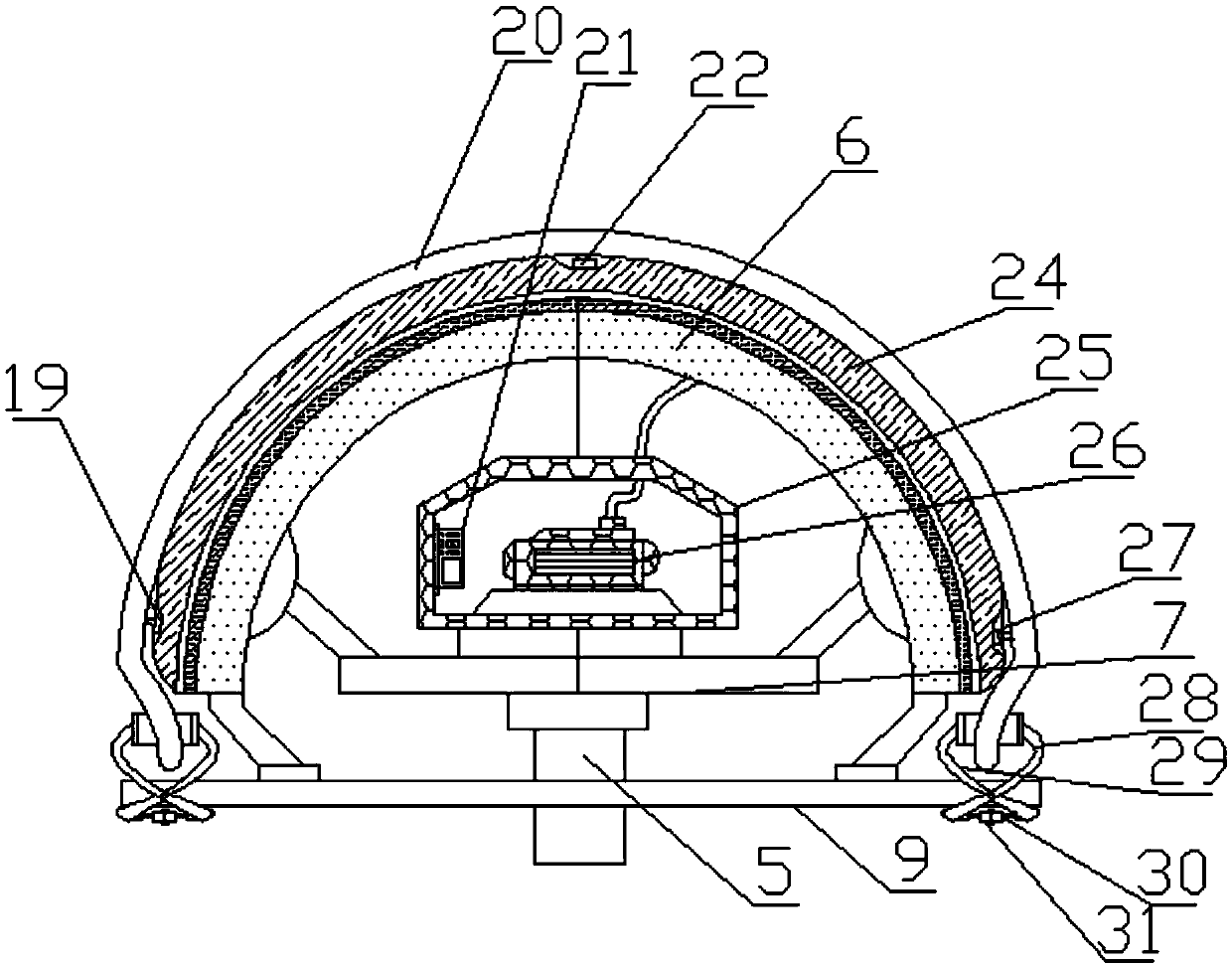

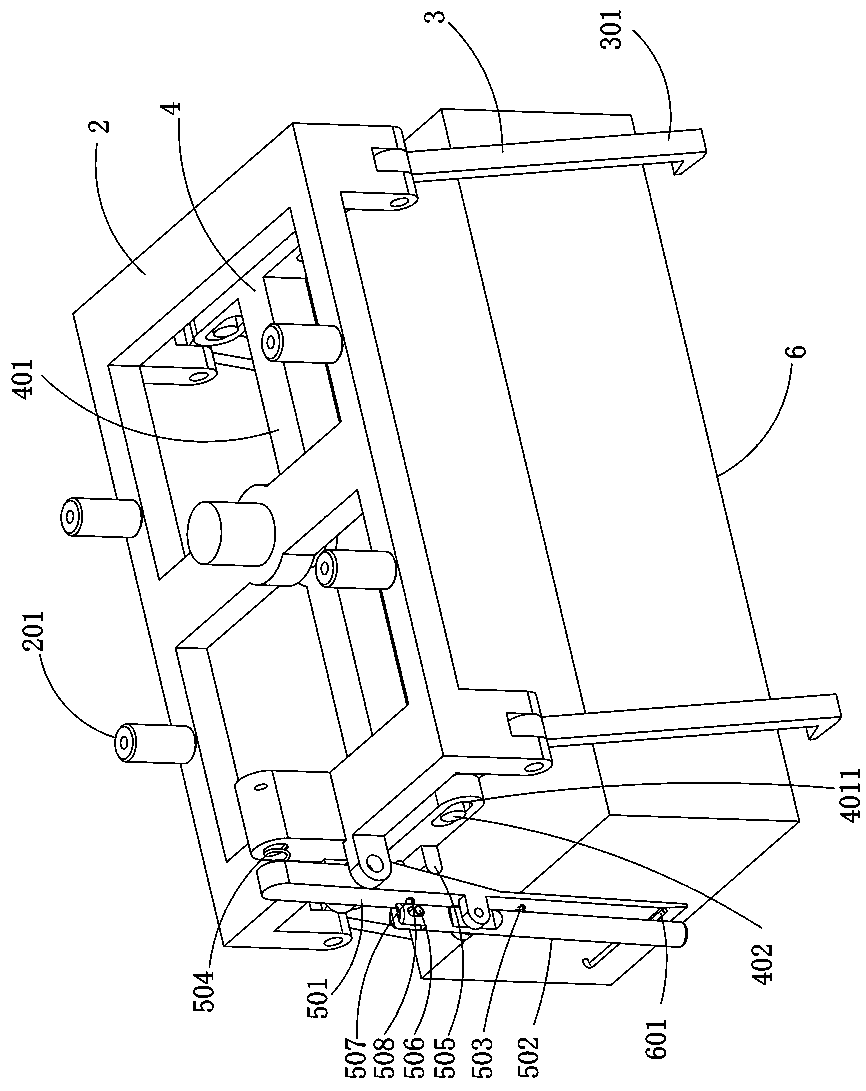

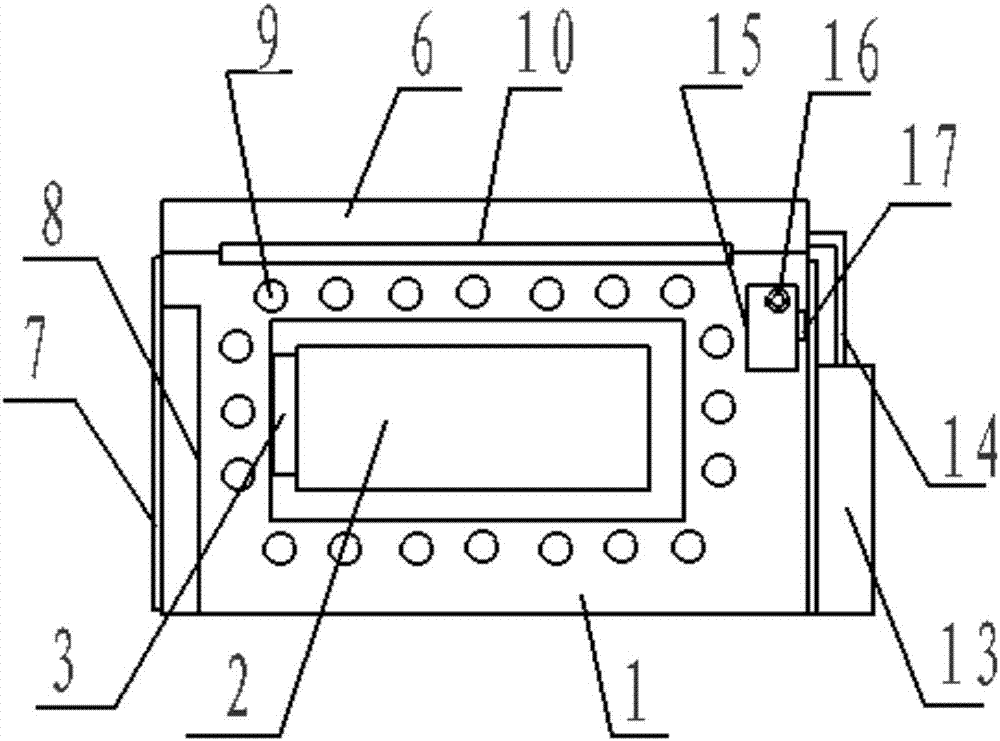

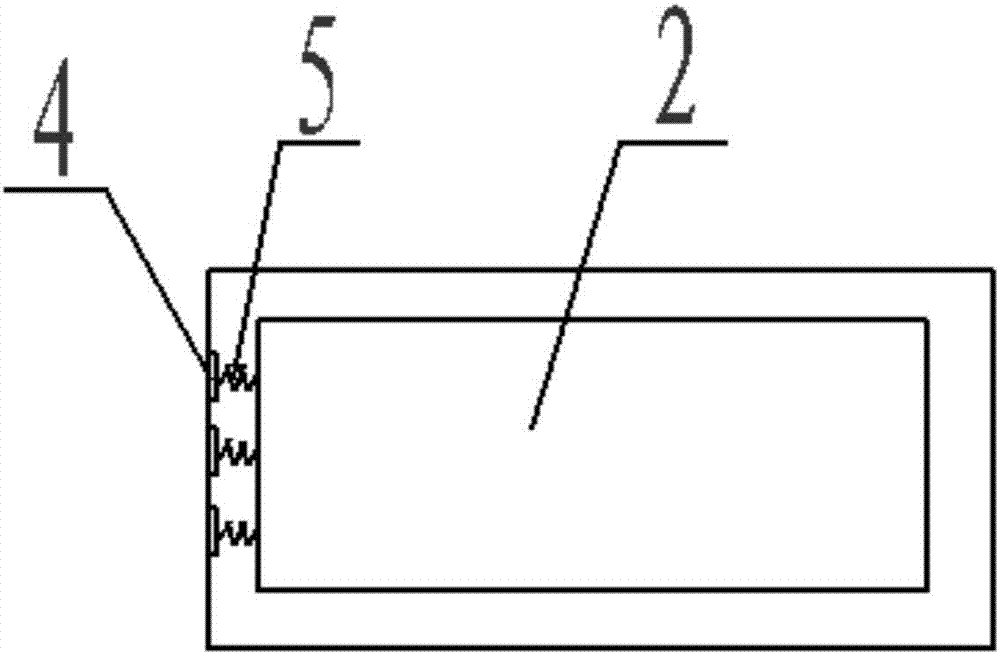

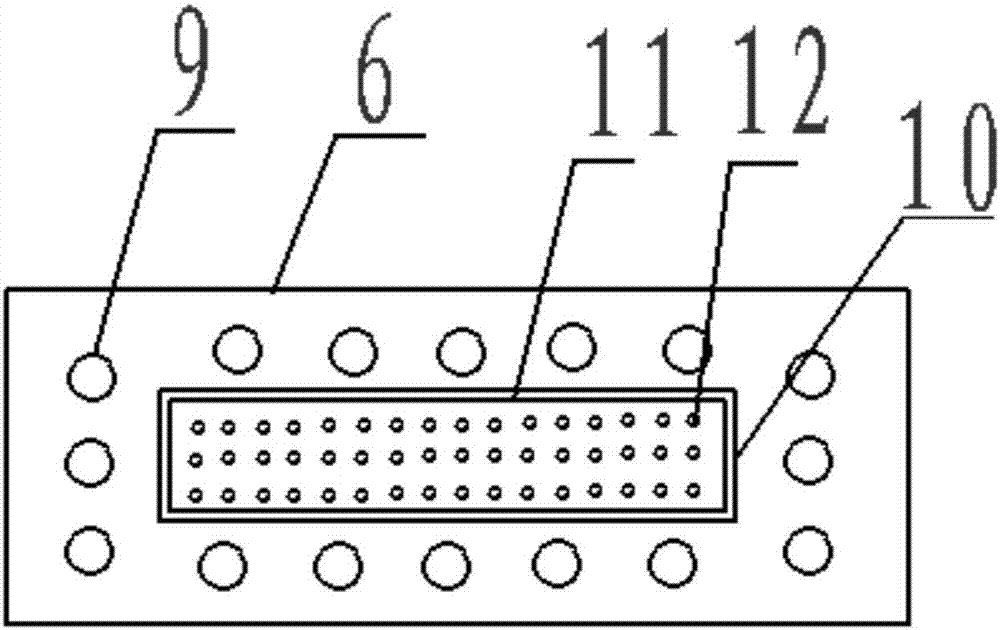

Automatic bottom grinding and opening turning device for pot

InactiveCN109676480AQuick squeezeGrinding pressure is uniformGrinding wheel securing apparatusGrinding feed controlEngineeringConveyor belt

The invention discloses an automatic bottom grinding and opening turning device for a pot. The device comprises a working platform and a conveyor belt, wherein a machine chamber is formed in one innerend of the working platform; a single-chip controller and a time controller are mounted at one side of the inner wall of the machine chamber through mounting grooves; a rotating motor is arranged atthe inner upper end of the machine chamber through a fixing part; a heat radiating bottom chamber is mounted at the bottom part of the machine chamber through a screw; a cooling fan is arranged in theheat radiating bottom chamber through a mounting part; a pot body fixing die is arranged at one end of the top part of the working platform, and a mounting support is mounted in the pot body fixing die through a bolt; a box body is arranged on the top part of the mounting support through a bolt; and an electric air charging pump is mounted in the box body through a mounting plate. The device is multifunctional, simple to operate, low in mechanical cost, and convenient to produce, and meets various demands in the pot producing and grinding processes, and can be widely popularized and used.

Owner:宁波华数机器人有限公司

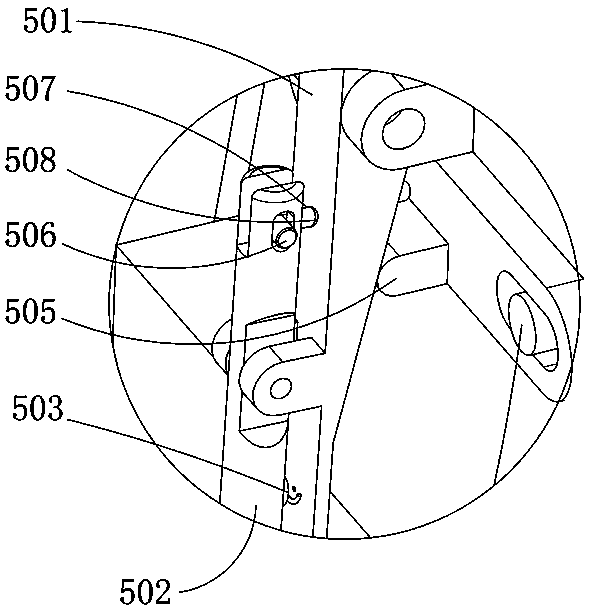

Valve mechanism

ActiveCN103061845ARealize stepless adjustmentTimingValve arrangementsMachines/enginesHydraulic pumpEngineering

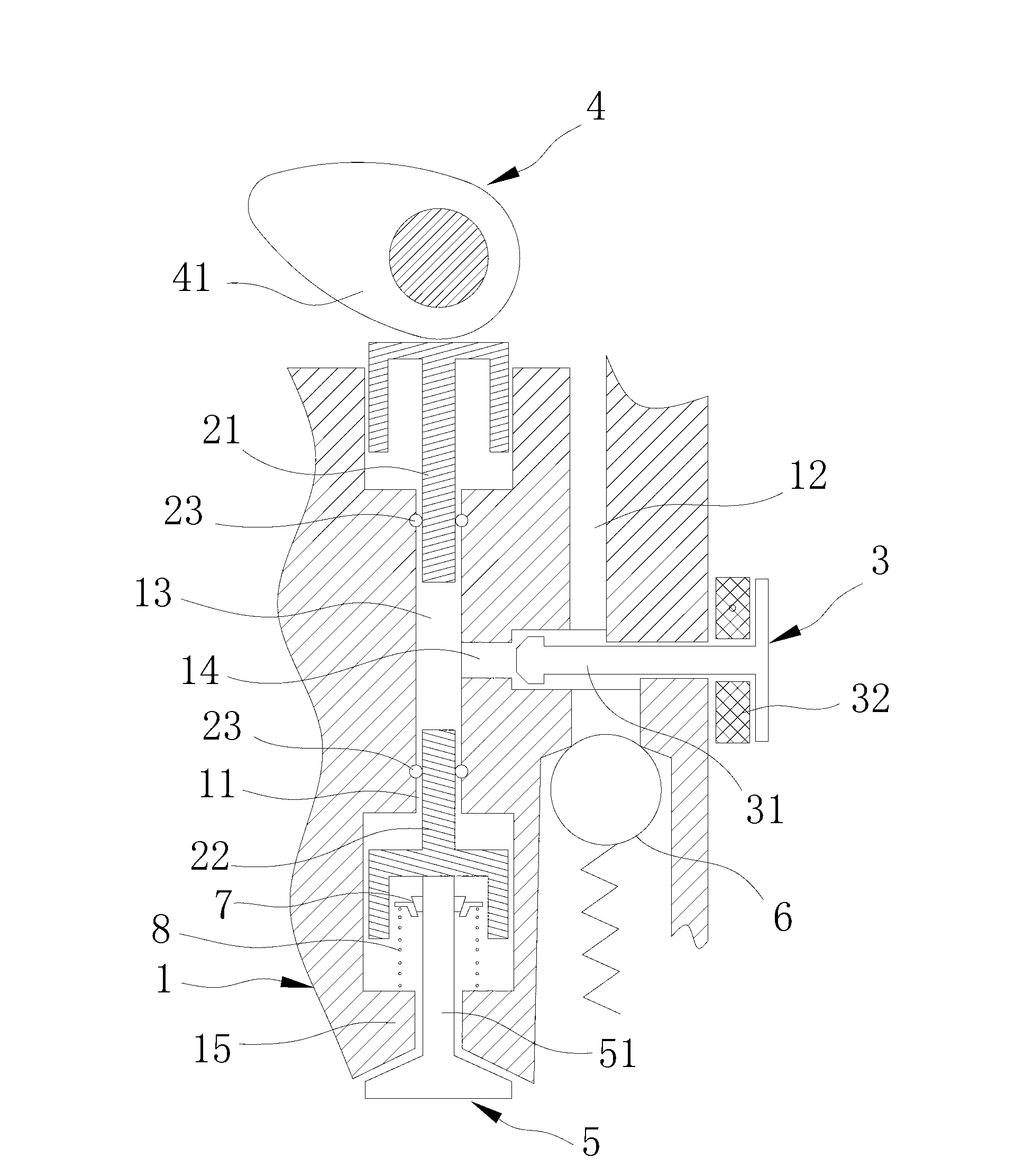

The invention discloses a valve mechanism which comprises a cylinder cover, a first hydraulic tappet, a second hydraulic tappet, a switch valve, a drive part, and a valve. The cylinder cover is provided with a passage and a high-pressure oil duct, the first hydraulic tappet and the second hydraulic tappet are respectively and slidingly arranged at two ends of the passage, the first hydraulic tappet, the second hydraulic tappet and the inner wall of the passage enclose to form a hydraulic cavity, the hydraulic cavity is communicated with the high-pressure oil duct through a connecting oil duct, the switch valve is arranged on the connecting oil duct and controls the on-off of the connecting oil duct, the drive part is connected with the first hydraulic tappet and drives the first hydraulic tappet to slide in the passage, and the valve is connected onto the second hydraulic tappet. By the aid of the valve mechanism, stepless regulation of valve lift and valve control can be achieved, and the valve mechanism is simple in structure and low in cost.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

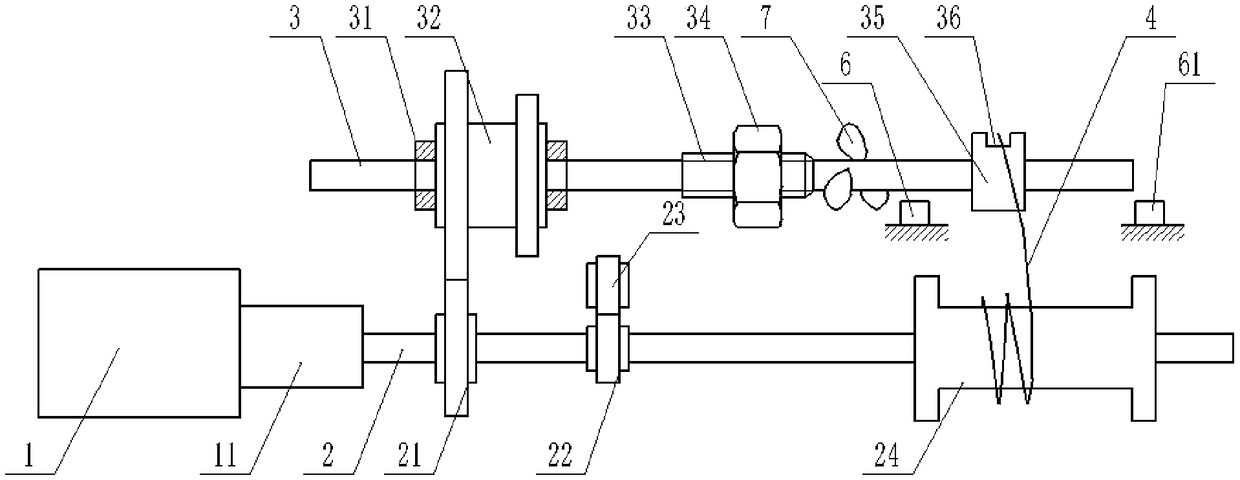

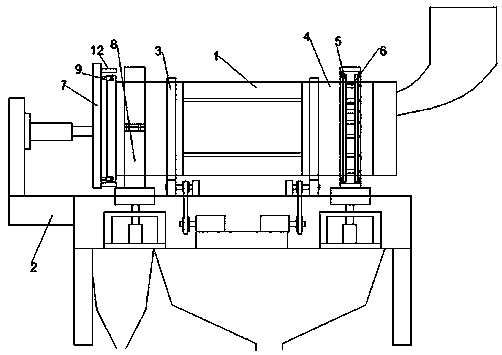

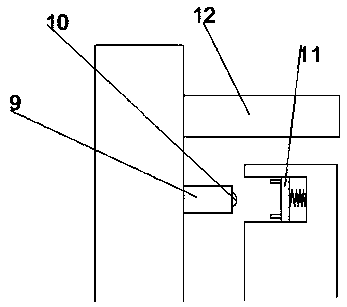

Woven bag flat silk winding machine

The invention belongs to the technical field of woven bag processing and particularly discloses a woven bag flat silk winding machine comprising a rack. A motor and an air cylinder are fixed to the rack, a shifting fork, a joint sleeve and a first rotary shaft are sequentially connected to the air cylinder, and the joint sleeve is in spline connection with the first rotary shaft. The joint sleeveis fixedly sleeved with a duplex gear, a threaded section is arranged in the middle of the first rotary shaft, and a nut is connected to the threaded section. A second rotary shaft is connected to themotor and sequentially and fixedly sleeved with a large gear and a pinion, the upper portion of the pinion is engaged with an idle gear, and a winding cylinder is connected to the end of the second rotary shaft. A first limiting switch and a second limiting switch are fixed to the position, above the winding cylinder, of the rack, a guiding block is rotatably connected to the end of the first rotary shaft, and a groove for guiding flat silks to the winding cylinder is further formed in the guiding block. By adopting the scheme, the requirement that the flat silks are wound into even column bodies is met, and the woven bag flat silk winding machine is mostly applied to a woven bag producing and processing assembly line.

Owner:重庆市中塑新材料有限公司

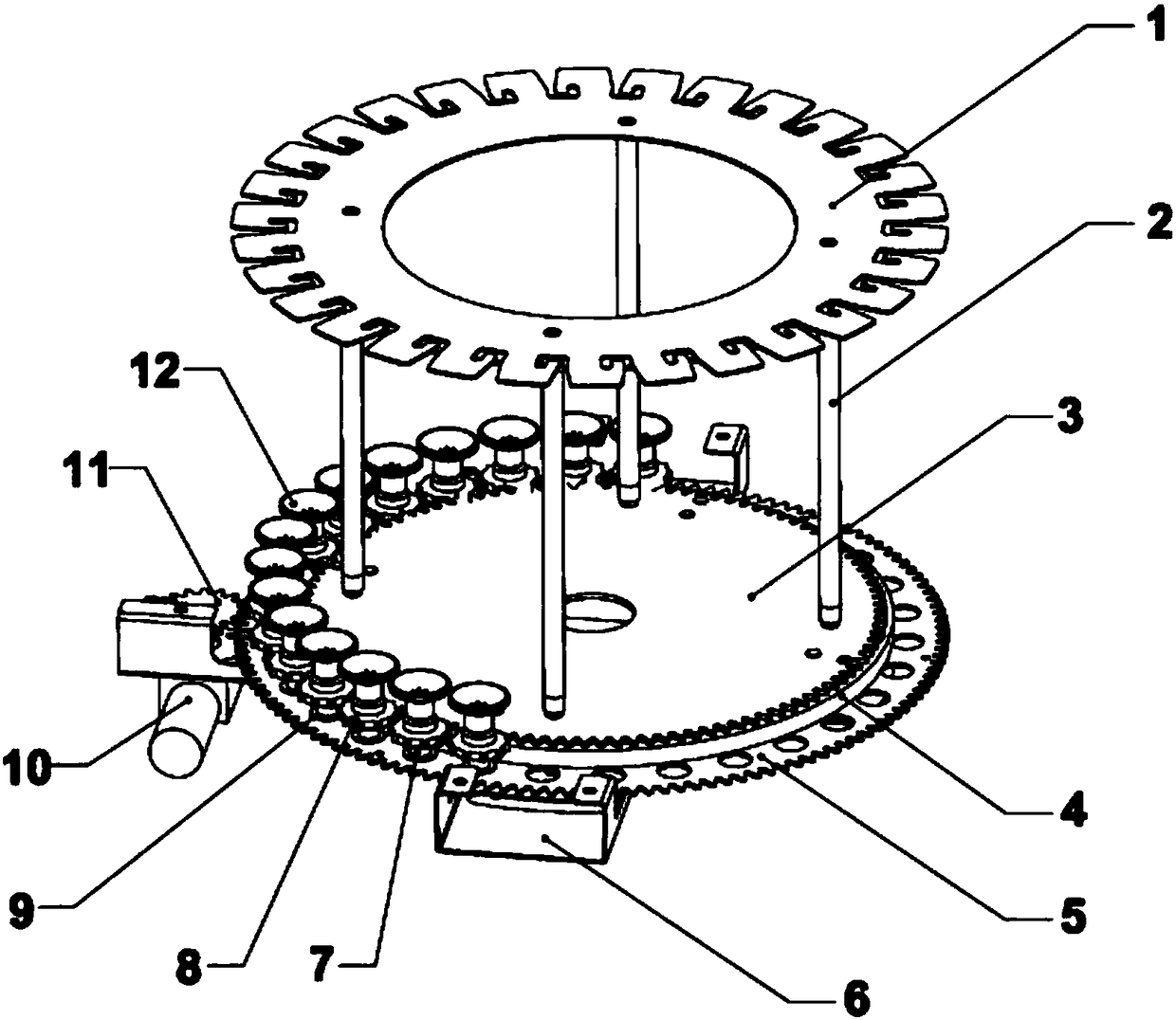

Using method of barbecuing equipment

InactiveCN108433561AEvenly heatedImprove grilling effectRoasting apparatusRoasters/grillsManufacturing technologyEngineering

The invention belongs to the technical field of barbecuing equipment manufacturing, and relates to a using method of barbecuing equipment. The method comprises the steps that skewers are well fixed and placed through a clamping groove formed in a top fixing plate after a heating source is selected, an outer gear plate is driven to rotate by starting a motor, the outer gear plate is driven to rotate by a driving gear, and a miniature range hood is driven to rotate by starting the motor to absorb lampblack in a carrying box; during the barbecuing process, dropping oil drops move downwards to reach an oil guiding plate along the skewers under the action of gravity, penetrate through the bottom of the oil guiding plate and drop into an oil receiving plate directly, during the barbecuing process, a lower turning door of the carrying box is directly closed to achieve the purpose of heat insulation of a preservation box, after the barbecuing of the skewers is completed, the lower turning doorof the carrying box is opened, and the skewers can be taken out when the motor is stopped or operated. The method has the advantages that the operation is simple and convenient, heat can be distributed uniformly, the barbecuing effect is good, using is safe and convenient, the method is good in environment protection performance and environmentally friendly, and the market prospect is wide.

Owner:王晓珮

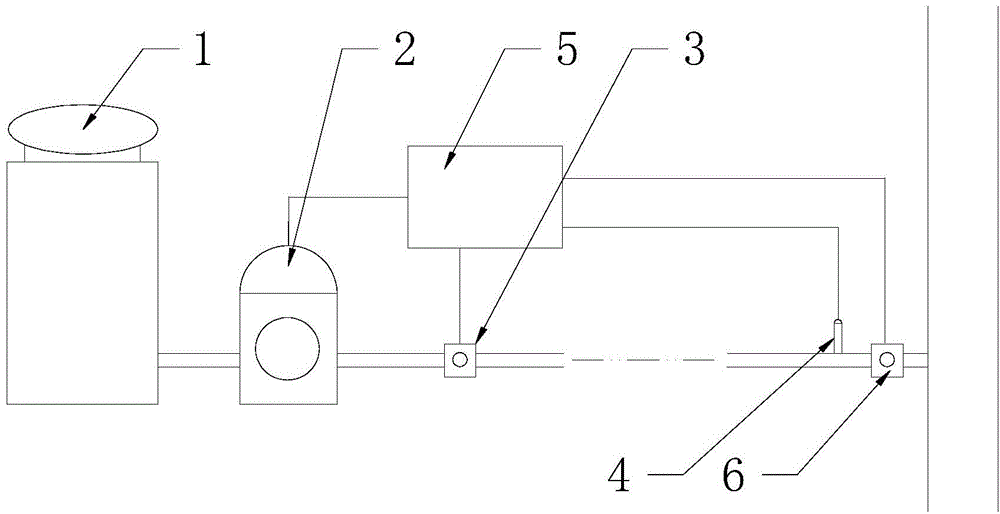

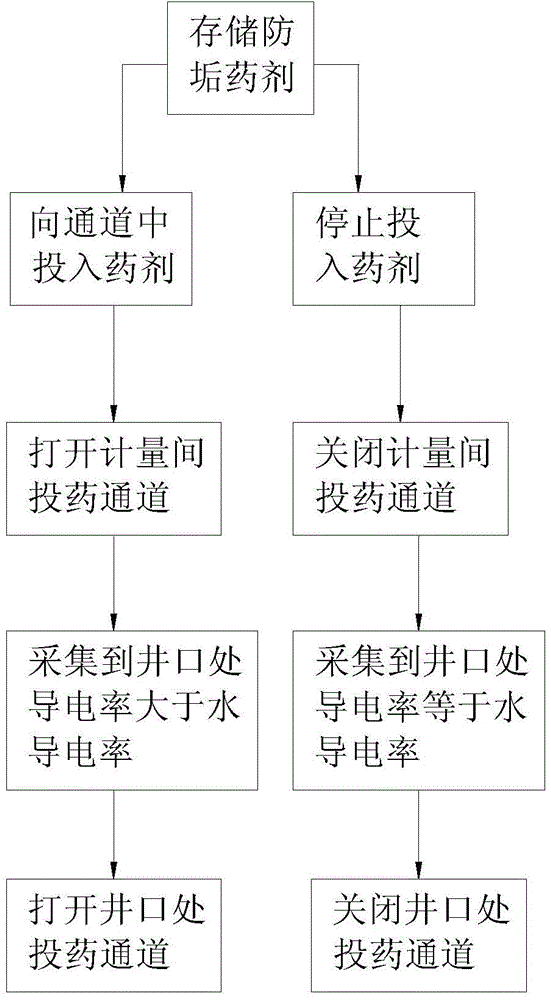

Automatic reagent feeding method and device for oil well scale prevention

The invention discloses an automatic reagent feeding method and system for oil well scale prevention. The problems that a traditional reagent feeding device is large in single-well reagent feeding workload, is greatly influenced by weather and well site conditions, cannot guarantee time rate easily, has multiple corollary devices, and is large in maintenance workload, high in cost and large in worker labor intensity can be solved. The system comprises a reagent storage tank with a metering room storing an antiscale agent, and further comprises a plunger pump, a metering room electric valve, a reagent detection device, a controller and a well mouth electric valve, wherein the plunger pump feeds the antiscale agent stored in the metering room into a reagent feeding channel, the metering room electric valve opens or closes the reagent feeding channel, the reagent detection device collects electric conductivity information of a well mouth, the controller compares the collected electric conductivity with electric conductivity of water and then judges whether the antiscale agent is fed into the reagent feeding channel at the well mouth or not, and the well mouth electric valve opens or closes the reagent feeding channel at the position of the well mouth according to the result judged by the controller. The system is high in efficiency, small in labor input, automatic and intelligent.

Owner:PETROCHINA CO LTD +1

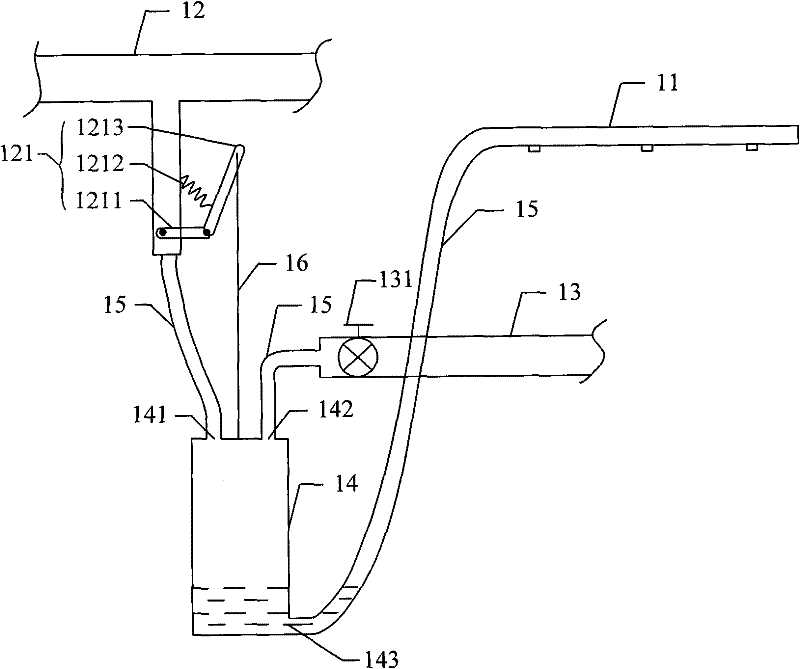

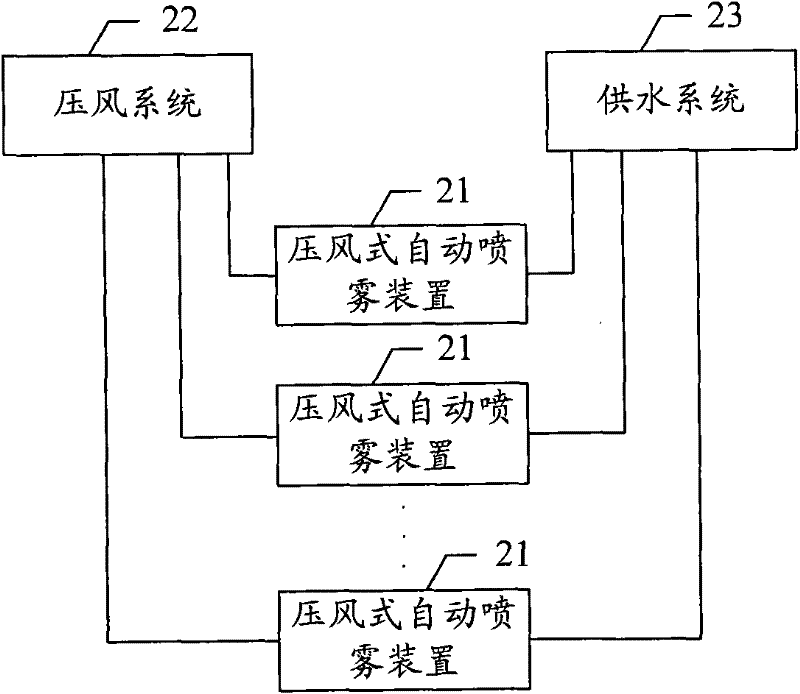

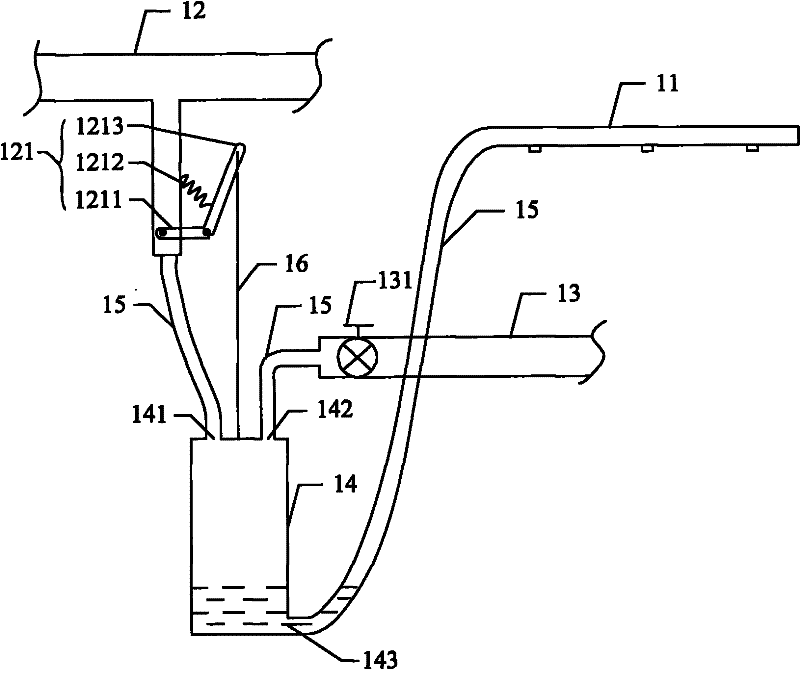

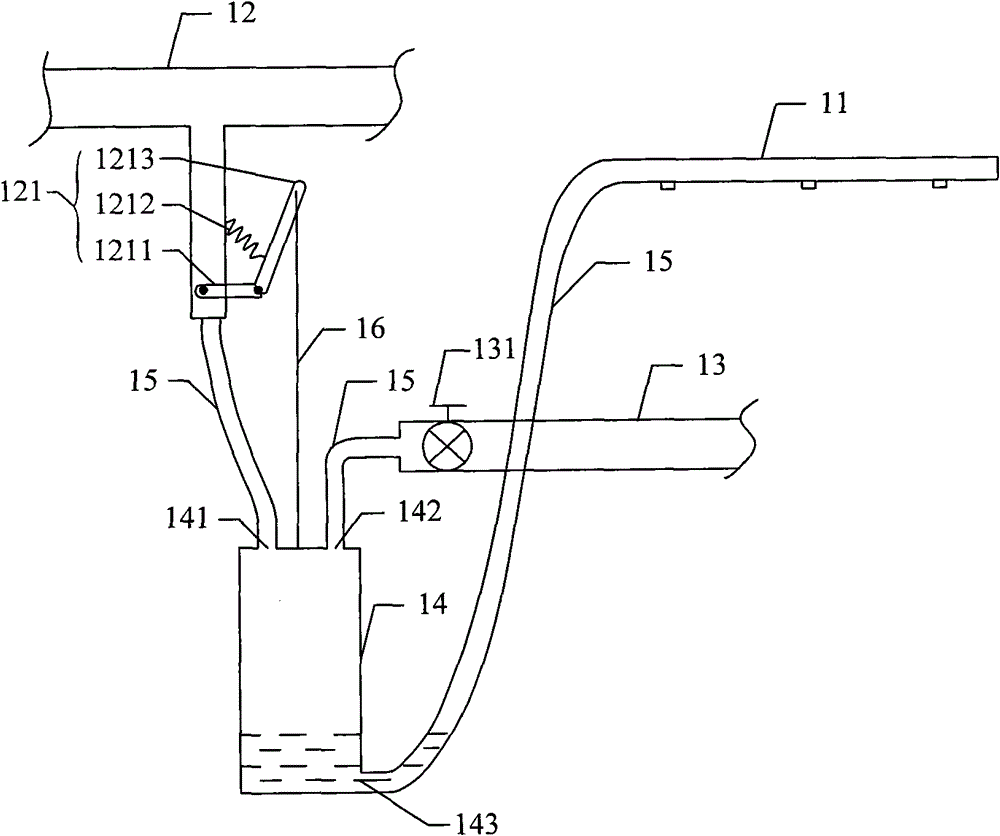

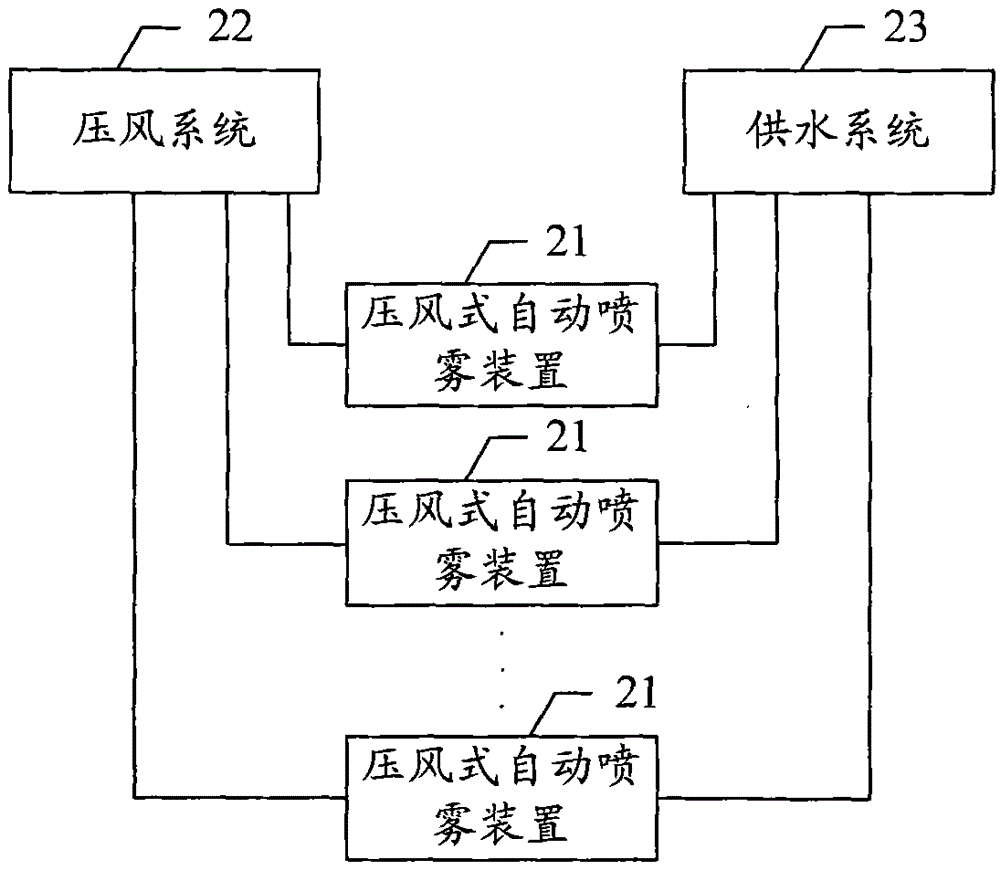

Compressed-air automatic spraying device and system

ActiveCN102125901AWeight increaseSolve the defect of explosionDust removalFire preventionWorking environmentControl engineering

The invention provides a compressed-air automatic spraying device and system. The automatic spraying device comprises a spray head, an air pipe, a water pipe and a water storage device, wherein, the water storage device is respectively connected with the air pipe, the water pipe and the spray head; the water pipe is equipped with a water valve; the air pipe is equipped with an air pipe spring switch; and the air pipe spring switch is connected to the outer wall of the water storage device through a rope. The compressed-air automatic spraying device and system provided by the invention have the advantages of overcoming the defect of the prior art that gas explosion is easily caused when an electric control automatic spraying device or an acoustic control automatic spraying device is applied to a working environment of a coal mine with higher gas content, and achieving the purpose of regularly and safely performing automatic spray by virtue of compressed air.

Owner:HUAINAN MINING IND GRP

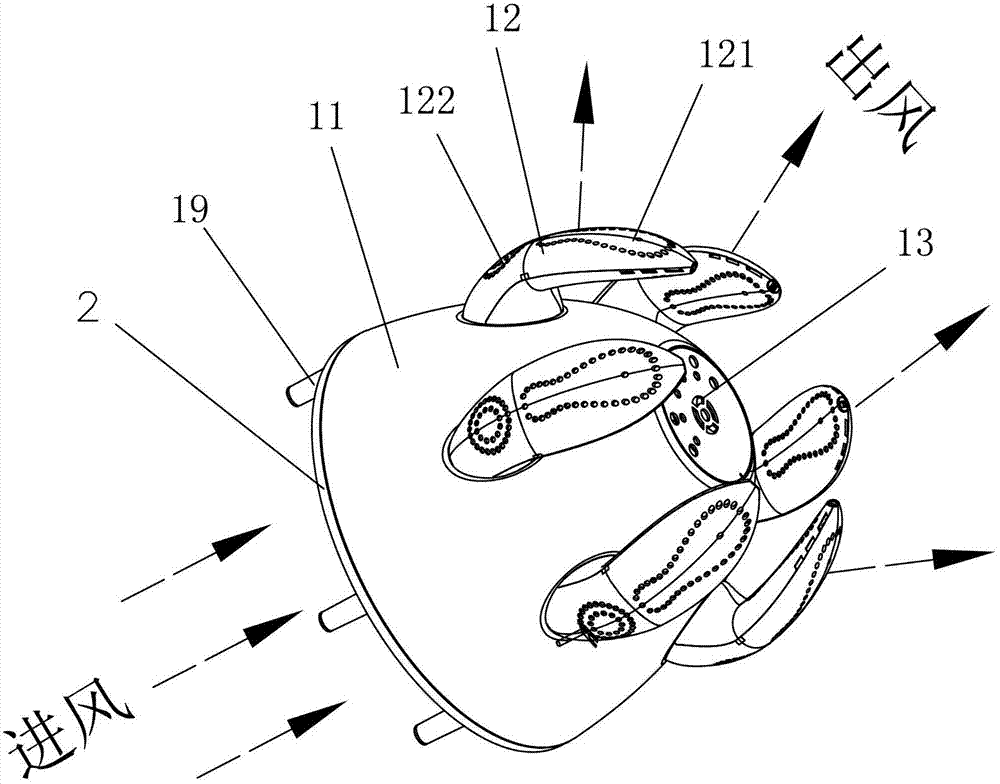

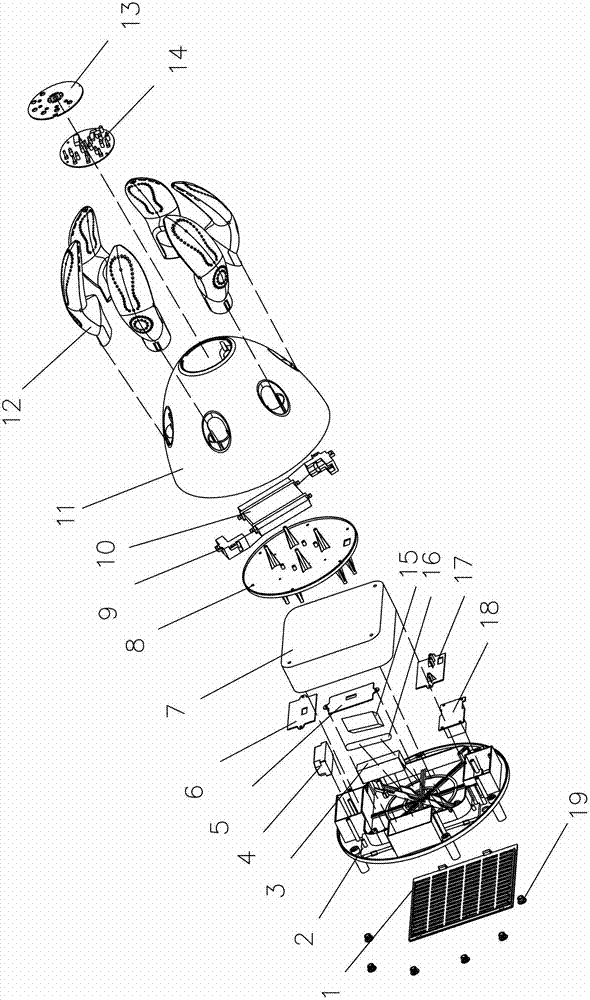

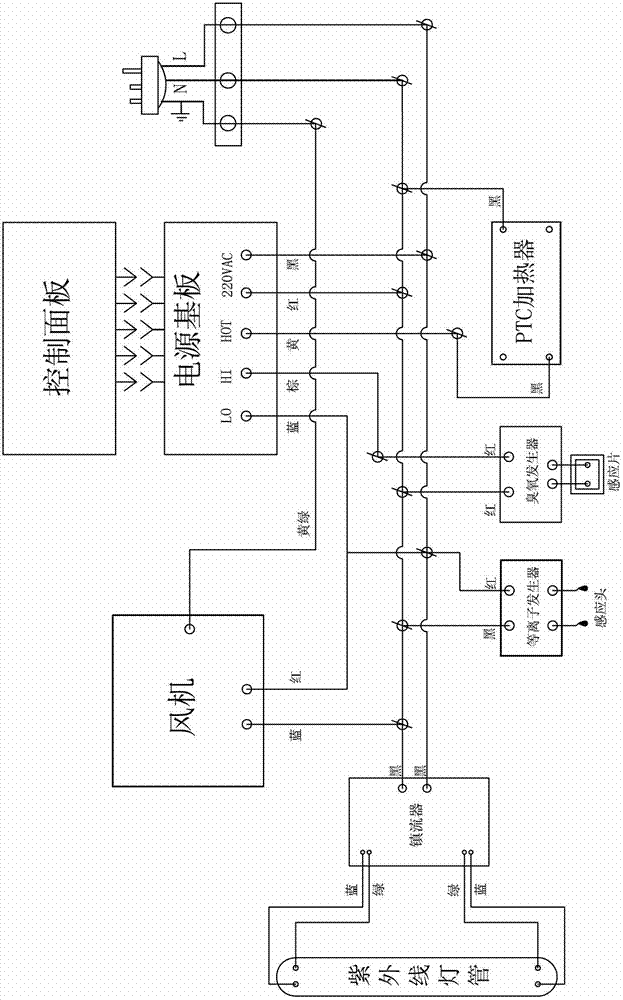

Novel multifunctional shoe drying machine

InactiveCN102824151ANovel structureIngenious ideaDeodrantsFootwear cleanersKey pressingOzone generator

The invention discloses a novel multifunctional shoe drying machine, belongs to the field of a drying device, and particularly relates to a shoe drying machine which can be used for drying six shoes at the same time and also can be used for deodorizing, sterilizing, purifying and drying the shoes. The shoe drying machine structurally comprises a body, a base, a filtering net, an air blower, an ultraviolet lamp tube, an ozone generator, a plasma generator, a PTC (Positive Temperature Coefficient) heating device, a panel, a control substrate, a substrate supporting frame and a shoe type supporting frame capable of discharging air in a plurality of directions; and the heating device is arranged inside the body and above the substrate supporting frame. According to the novel multifunctional shoe drying machine disclosed by the invention, press keys arranged on a body panel to select functions of deodorizing, drying the shoes, purifying the air, selecting needed time at regular time and the like; the heating device and the ozone device can be independently controlled so that the unnecessary energy resource waste is avoided and the novel multifunctional shoe drying machine is energy-saving and environment-friendly; and the novel multifunctional shoe drying machine has the functions of purifying the air and deodorizing.

Owner:GUANGZHOU THEODOOR +1

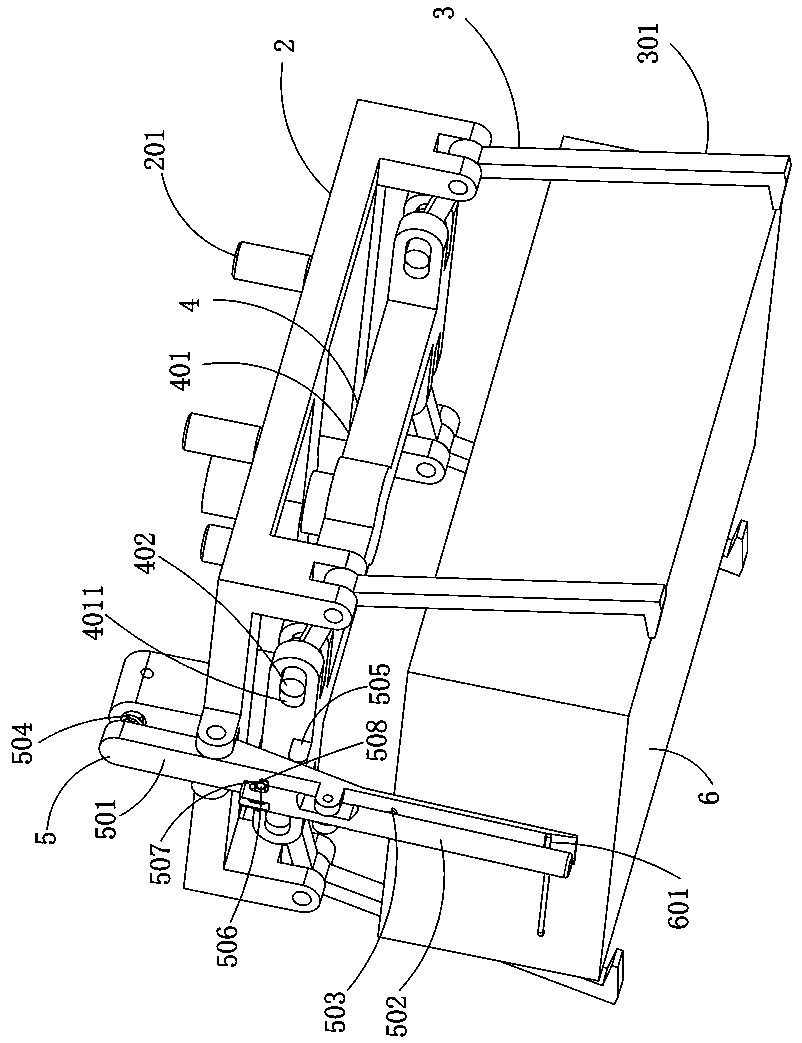

Firework loading and unloading mechanism for firework unmanned aerial vehicle and firework unmanned aerial vehicle

PendingCN110015422ARealize automatic loading and unloadingEasy to transportFreight handlingLaunching weaponsFireworksEngineering

The invention discloses a firework loading and unloading mechanism for a firework unmanned aerial vehicle. The firework loading and unloading mechanism for the firework unmanned aerial vehicle comprises a fixing seat, a hook component, a driving component and an ignition component, wherein the fixing seat is fastened on an unmanned aerial vehicle main body; the hook component is rotationally mounted on the peripheral side of the fixing seat; the driving component is mounted on the fixing seat and used for driving each hook component to rotate to be enclosed or scattered to realize loading andunloading of fireworks; and the ignition component is mounted on the fixing seat and used for automatically igniting leads of the fireworks. The invention further discloses the firework unmanned aerial vehicle; the firework unmanned aerial vehicle comprises the unmanned aerial vehicle main body; and the firework loading and unloading mechanism is mounted at the belly part of the unmanned aerial vehicle main body. The firework loading and unloading mechanism for the firework unmanned aerial vehicle and the firework unmanned aerial vehicle both have the advantages of simple structure, automatic,simple and convenient firework loading and unloading, synchronous loading and unloading of the leads and the fireworks and the like.

Owner:长沙市云智航科技有限公司

a valve train

ActiveCN103061845BRealize stepless adjustmentTimingValve arrangementsMachines/enginesHydraulic pumpHigh pressure

The invention discloses a valve mechanism which comprises a cylinder cover, a first hydraulic tappet, a second hydraulic tappet, a switch valve, a drive part, and a valve. The cylinder cover is provided with a passage and a high-pressure oil duct, the first hydraulic tappet and the second hydraulic tappet are respectively and slidingly arranged at two ends of the passage, the first hydraulic tappet, the second hydraulic tappet and the inner wall of the passage enclose to form a hydraulic cavity, the hydraulic cavity is communicated with the high-pressure oil duct through a connecting oil duct, the switch valve is arranged on the connecting oil duct and controls the on-off of the connecting oil duct, the drive part is connected with the first hydraulic tappet and drives the first hydraulic tappet to slide in the passage, and the valve is connected onto the second hydraulic tappet. By the aid of the valve mechanism, stepless regulation of valve lift and valve control can be achieved, and the valve mechanism is simple in structure and low in cost.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

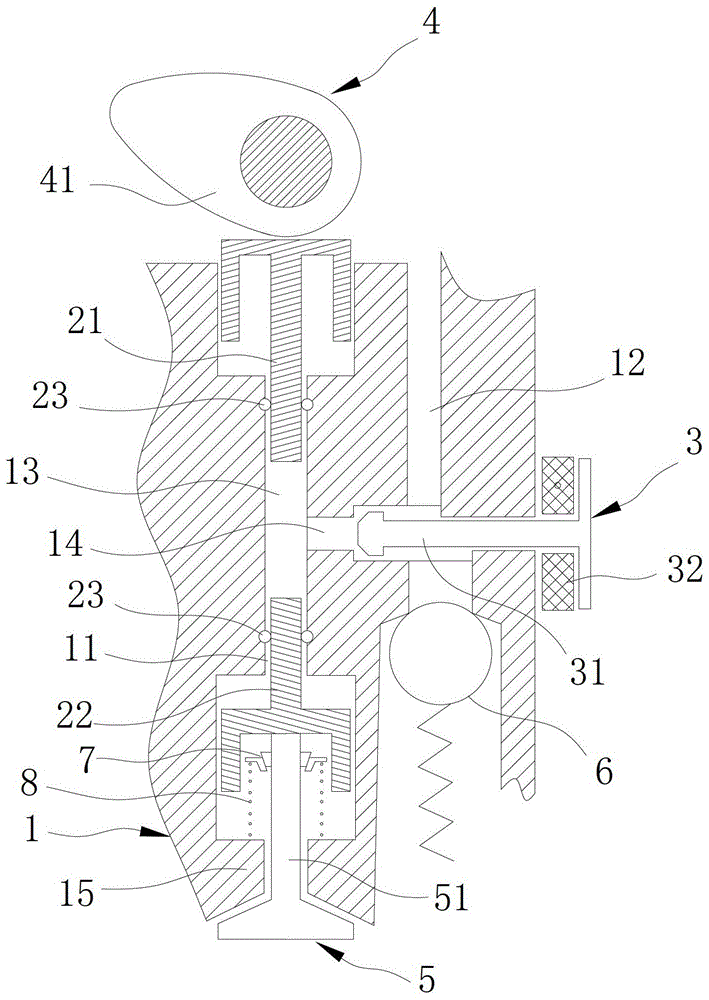

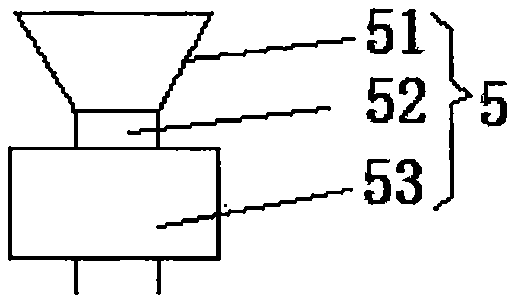

Stirring device for biological pharmacy

InactiveCN107790021ASimple structureImprove stirring efficiencyRotary stirring mixersTransportation and packagingPharmacyEngineering

The invention discloses a stirring device for biological pharmacy. The device comprises a machine frame; the top end of the machine frame is fixedly provided with a first motor, a first rotation shaftis rotatably connected with the first motor, and first fan blades are fixedly arranged on the first rotation shaft in the radial direction of the first rotation shaft; the bottom end of the machine frame is fixedly provided with a second motor, one end of the second motor is movably connected with a second rotation shaft, and second fan blades are fixedly arranged on the second rotation shaft inthe radial direction of the second rotation shaft; one side of the machine frame is fixedly provided with a viewing opening, and the other side of the machine frame is fixedly provided with a timer, acontroller, and a switch, wherein the timer is located directly on the controller, and the controller is located directly on the switch; the top end of the machine frame is fixedly provided with material inlet devices, each material inlet device includes a material inlet, the lower end of each material inlet is fixedly provided with a material inlet pipe, and one side of each material inlet pipeis fixedly provided with a metering device; and the bottom end of the machine frame is fixedly provided with a material outlet, and the bottom end of the machine frame is fixedly provided with supports. The novel double-paddle stirring machine provided by the invention is simple in structure and convenient and practical, and enables materials to be stirred more fully.

Owner:TIANJIN ZHONGRUI PHARMA

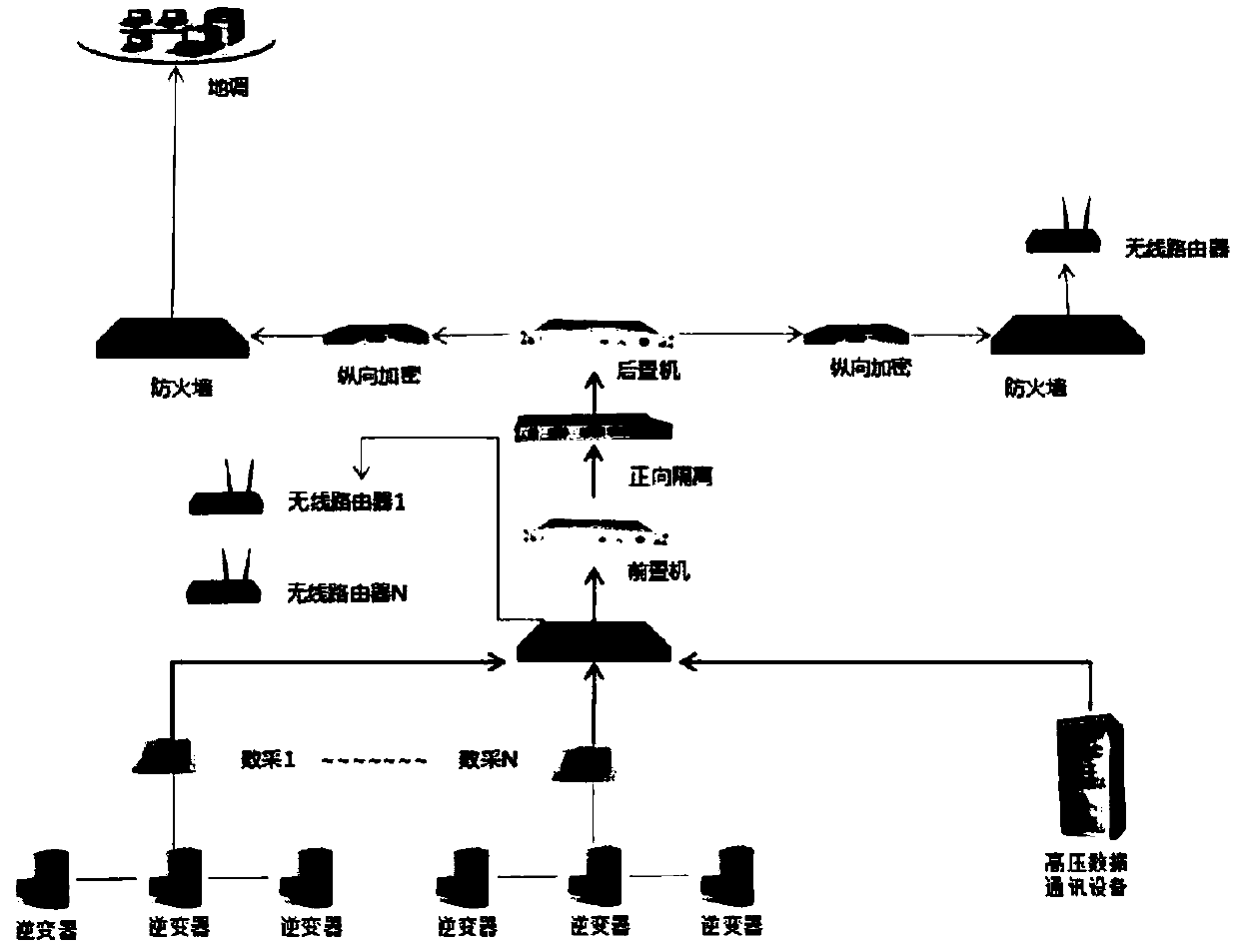

Time checking method for forward isolating external network side and internal network side

InactiveCN109525348AEnsure safetyTimingTime-division multiplexTransmissionData transmissionSpecific time

The invention relates to the technical field of information communication technology of a power secondary system, in particular to a time checking method for forward isolating external network side and internal network side, comprising the following steps of: S1, setting a front-end machine for collecting data of a production control area; S2, setting a rear-end machine for transmitting data to the management information area; S3, setting a power-specific horizontal one-way safety isolating device tested and certified by a national designated department between the front-end machine and the rear-end machine for realizing one-way data transmission from the large area of the production control area to the management information area; S4, the post-machine obtaining the accurate time through the external network, and encoding the time according to the combination of FF and 00, wherein the number of FFs represents a specific time, and 00 represents an interval; S5, the front-end machine firstly dividing the area by 00 after receiving the code, then finding the FF of the corresponding year, month and day, and counting the number of FF to restore the specific time. The time checking method for forward isolating external network side and internal network side realizes the time checking for external network side and internal network side, and the method is simple and easy to implement.

Owner:南京天谷电气科技有限公司

Impregnated diamond bit matrix material with high wear resistance and method for manufacturing diamond bit by using same

ActiveCN111822715ATimely edgeRight amount of edgeDrill bitsHigh wear resistanceHot isostatic pressing

The invention provides an impregnated diamond bit matrix material with high wear resistance and a method for manufacturing a diamond bit by using the same. The matrix material comprises the followingcomponents of, by weight, 42%-56% of FAM-1020(Fe80Ni18Co2), 16%-22% of FAM-3010(Fe81Ni7Mn12), 28%-36% of FAM-2120(Fe85Ni6Cu6Sn3) and inevitable impurities. The manufacturing method comprises the following steps of heating the matrix material; carrying out low-pressure sintering treatment on the matrix material; cooling the matrix material to room temperature; carrying out hot isostatic pressing treatment on an impregnated diamond bit blank; and cooling to room temperature. By reasonably designing the components of the impregnated diamond bit matrix material and adopting the special low-pressure sintering heating isostatic pressing manufacturing method matched with the components, the wear resistance and the comprehensive mechanical property of the impregnated diamond bit matrix are effectively improved, and the drilling target with high efficiency and long service life can be achieved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

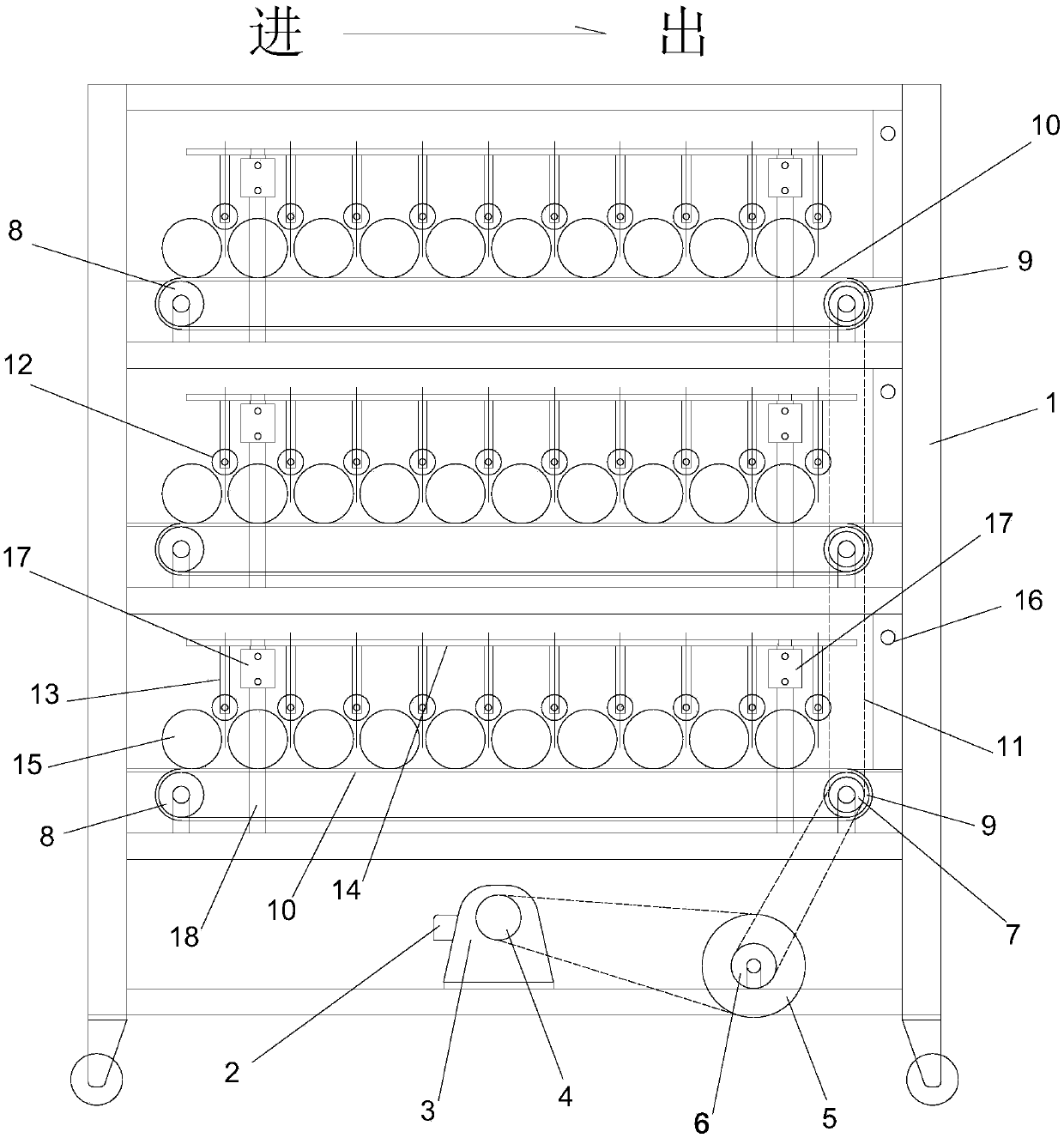

Printing ink stirring device for coloring cable

PendingCN107930482AStable and orderly stirringTimingRotating receptacle mixersTransportation and packagingPrinting inkEngineering

The invention discloses a printing ink stirring device for coloring a cable. The printing ink stirring device comprises a rack, a motor fixed on the rack, a speed reduction and transmission mechanismand a plurality of printing ink bottle conveying and stirring mechanisms, wherein each printing ink bottle conveying and stirring mechanism comprises a printing ink bottle conveying device and a pressing-down and isolating device; each printing ink bottle conveying device comprises a driven conveying wheel, a driving conveying wheel and a printing ink bottle conveyor belt; an output end of the speed reduction and transmission mechanism is in transmission connection with one driving conveying wheel; all the driving conveying wheels are in synchronous transmission connection; each pressing-downand isolating device horizontally comprises a plurality of pressing wheels, a pressing wheel bracket, a pressing plate and a pressing-down driving mechanism; the pressing plates are mounted on the rack through the pressing driving mechanisms in an up-down driving manner; when the pressing plates are pressed down, printing ink bottles at the lower side can be isolated and in-situ rolling movement of the printing ink bottles is kept. According to the printing ink stirring device disclosed by the invention, sequential operation can be carried out in a first-in first-out manner of printing ink bottles in a utilization process; working hours and the complexity degree in a manual operation process are greatly reduced; the automation degree and the working efficiency are extremely improved.

Owner:YANGTZE OPTICAL FIBRE & CABLE (SHANGHAI) CO LTD

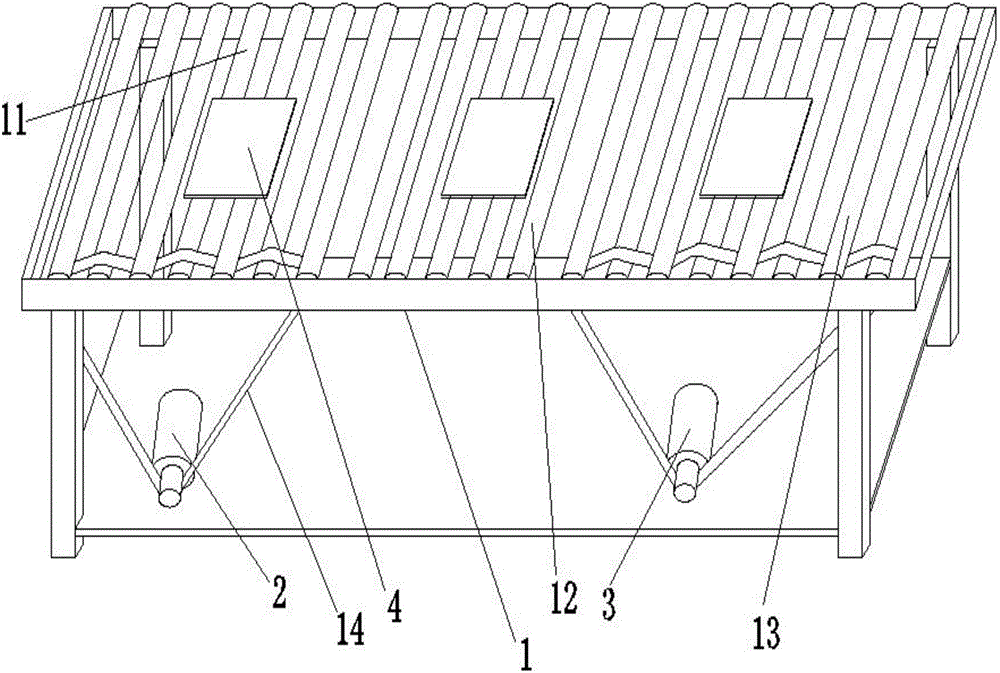

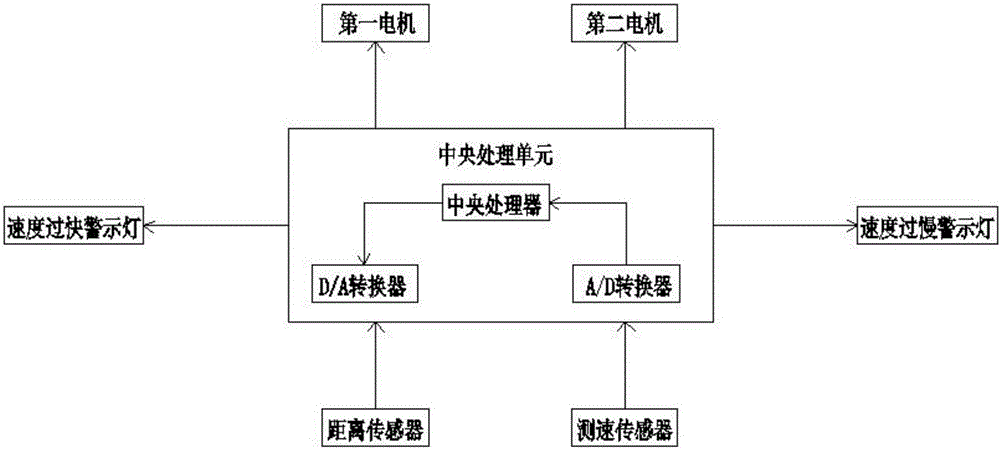

Feeding device specially used for colour burning furnace

PendingCN106839781AIncrease speedRPM increase or decreaseCharge manipulationElectricityControl system

The invention discloses a special feeding device for a color-burning furnace, which includes a feeding frame, a first motor, a second motor, a feeding tray and a control system; In the direction of the entrance, there are several first power rollers, non-power rollers and second power rollers in sequence. The first motor and several first power rollers are respectively connected in rotation through the transmission unit, and the second motor and several second power rollers are respectively connected through the transmission unit. The unit is rotationally connected; the control system includes a central processing unit, a speed sensor and a distance sensor respectively arranged on the feeding tray, the central processing unit and the distance sensor are respectively wirelessly connected, and the central processing unit is connected to the speed sensor, the first motor and the second motor respectively electrical connection. Compared with the prior art, the present invention can effectively control the timing when the feeding tray enters the color-burning furnace, so that the space in the color-burning furnace can be maximized and waste of resources can be avoided.

Owner:儒拉玛特自动化技术(合肥)有限公司

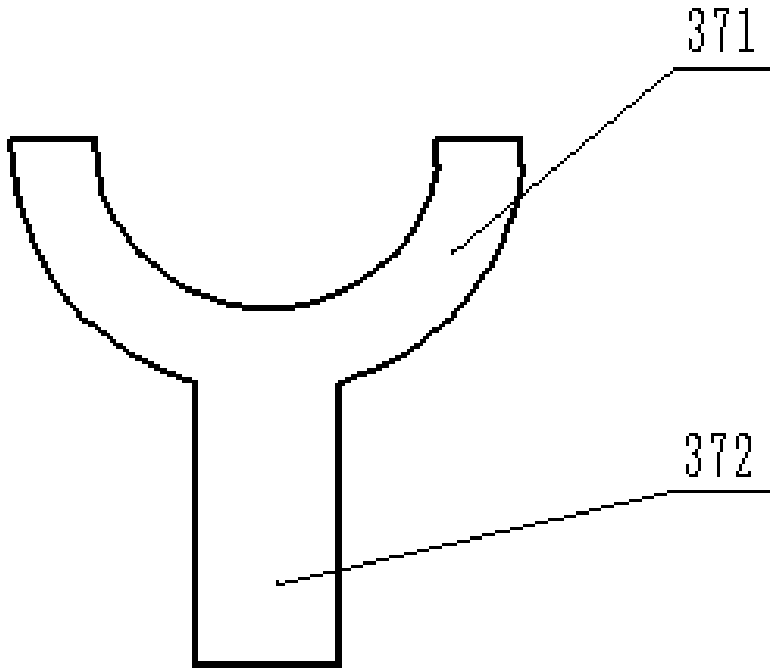

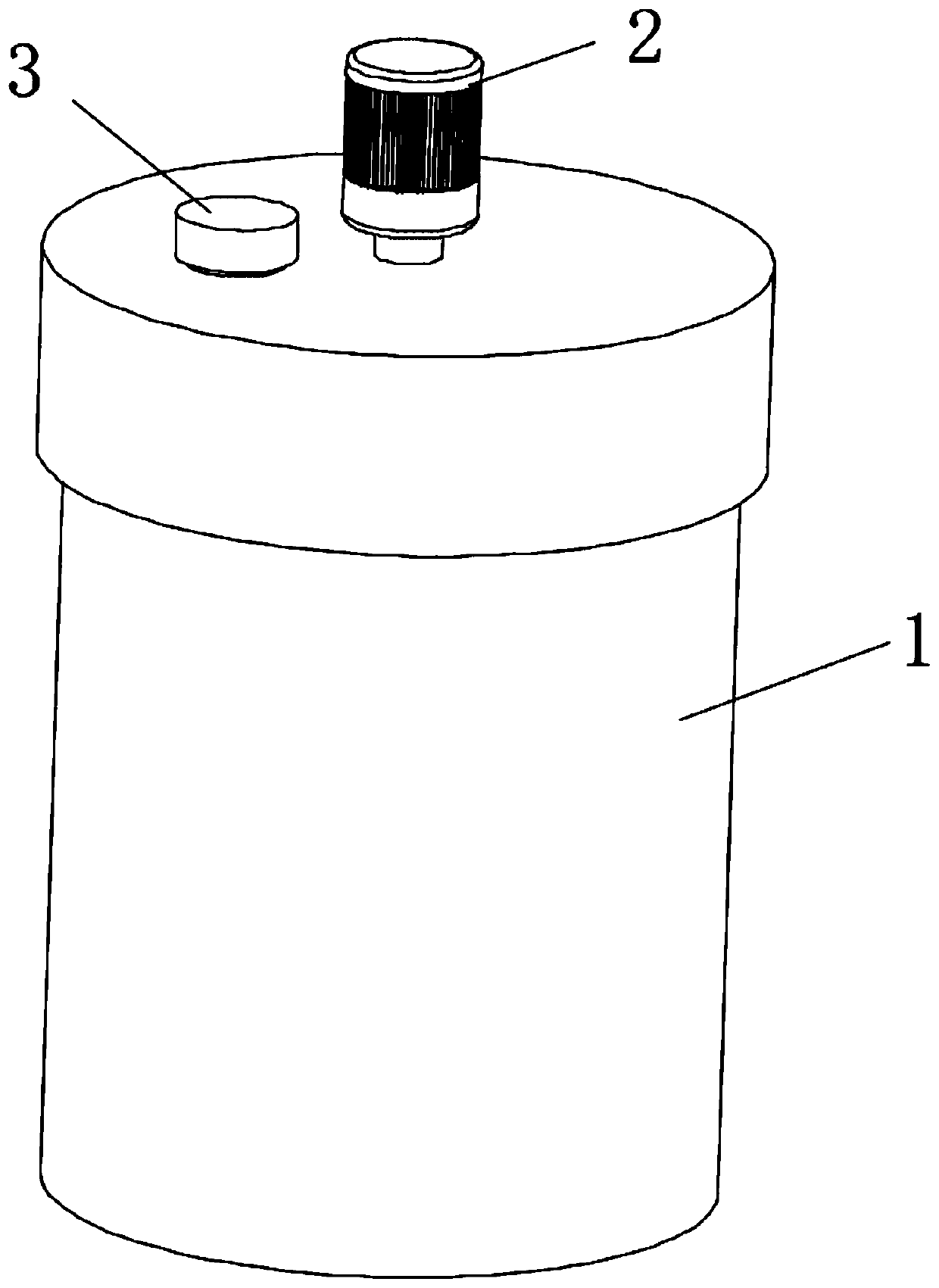

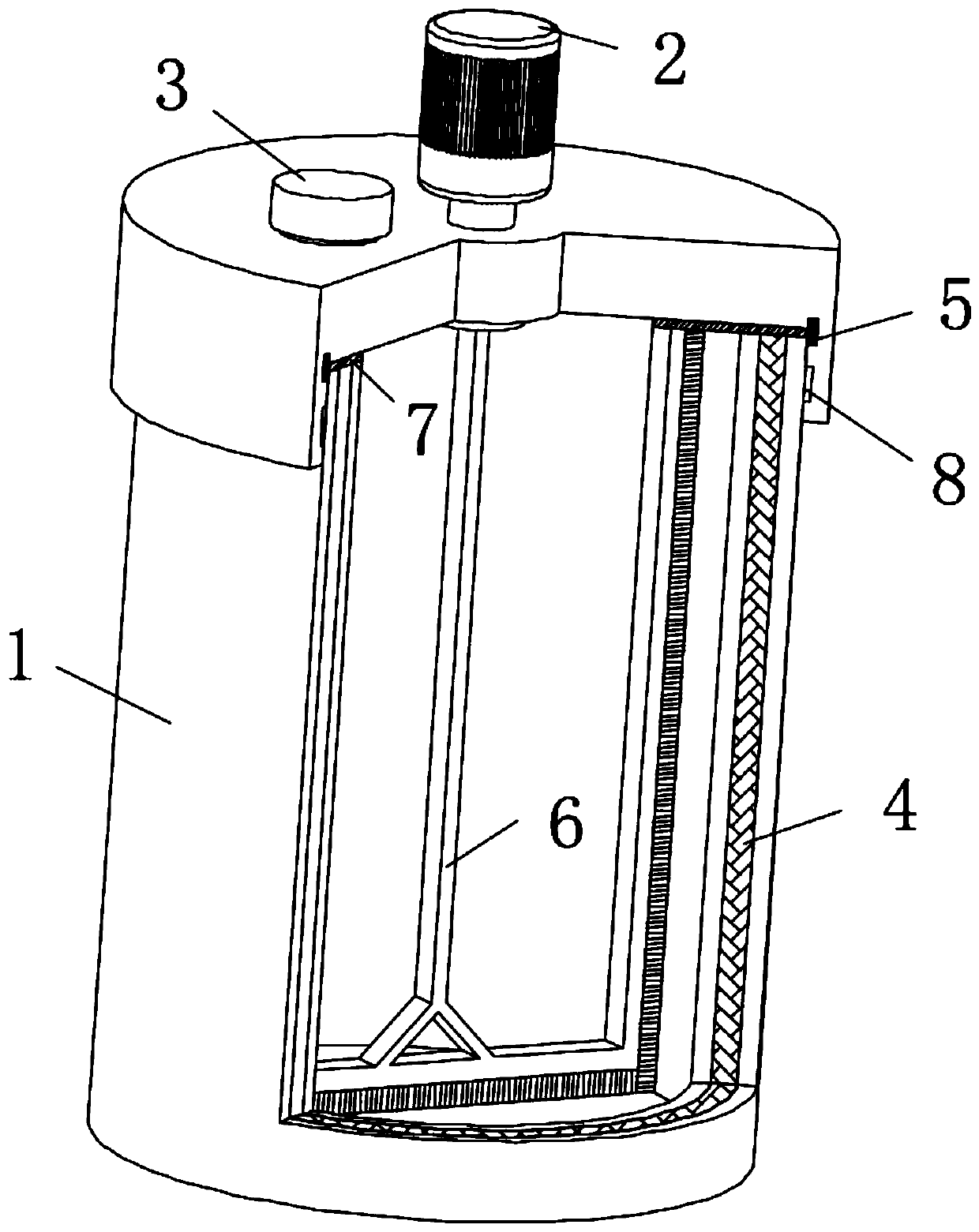

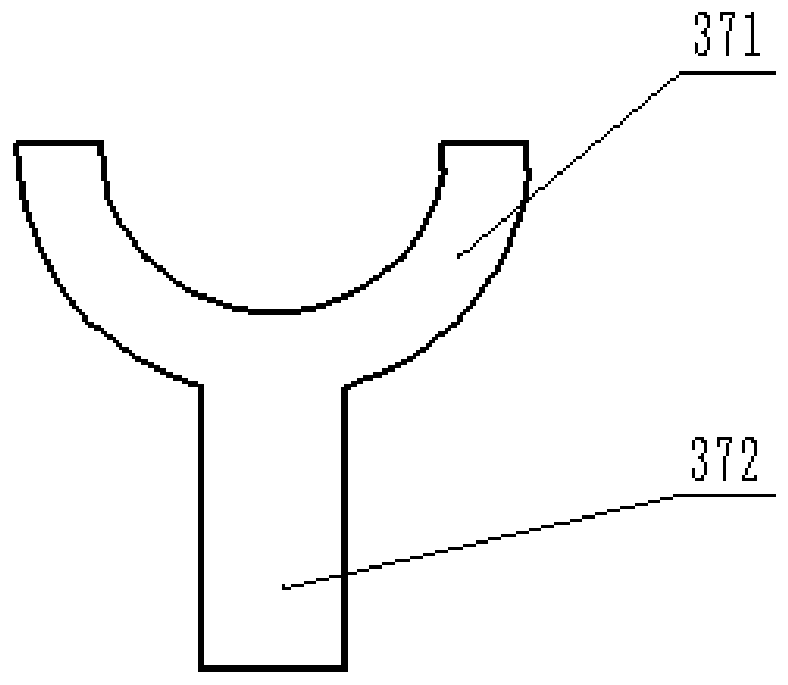

Storage equipment for uniformly stirred waterproof coating

InactiveCN110711514AAvoid failureTimingRotary stirring mixersTransportation and packagingInsulation layerElectric machine

The invention relates to the technical field of coating equipment. The invention further discloses storage equipment for uniformly stirred waterproof coating. The equipment comprises a tank body, wherein a feeding port is formed in one side of the top end of the tank body, a sealing ring is arranged at a tank cover of the tank body, a motor is fixedly installed in the middle of the top end of thetank body, a heat insulation layer is arranged in the tank wall of the tank body, the motor is fixedly connected with a U-shaped stirring device, and a filter screen is installed in the tank cover part of the tank body. The stirring device driven by the motor is arranged, so that the waterproof coating in the tank body can be prevented from being precipitated and accumulated to deteriorate, the sealing performance and the heat insulation performance are good, and the uniformly stirred waterproof coating can be stored for a long time.

Owner:湖南古圣砖瓦科技有限公司

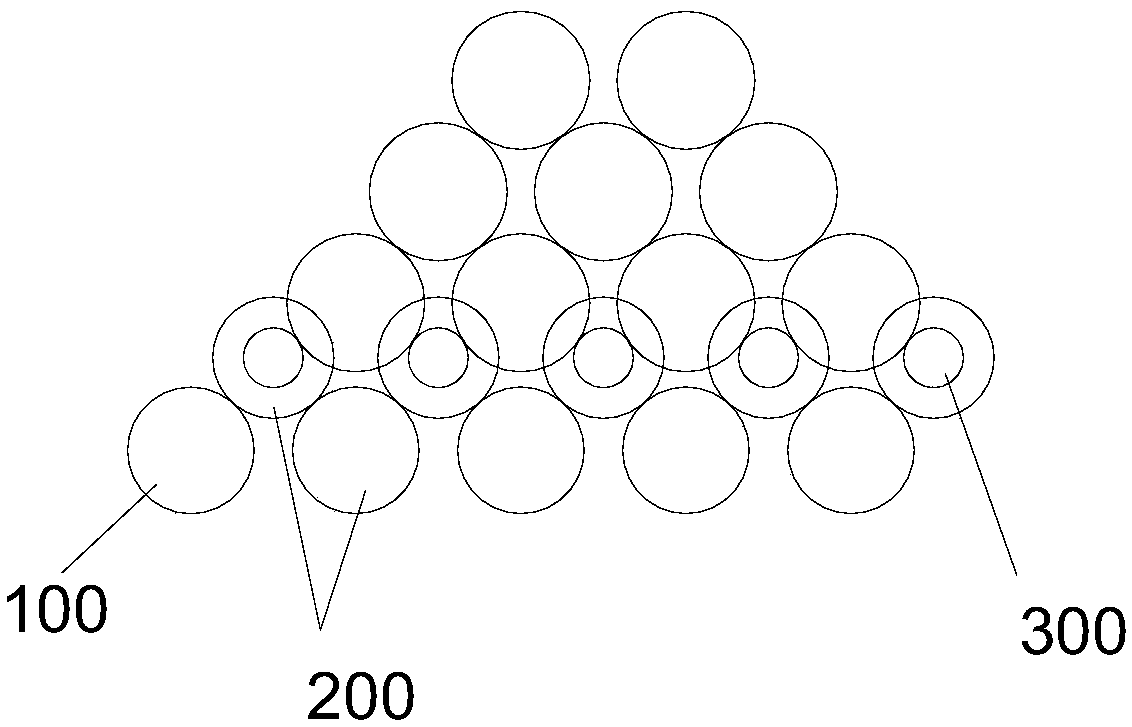

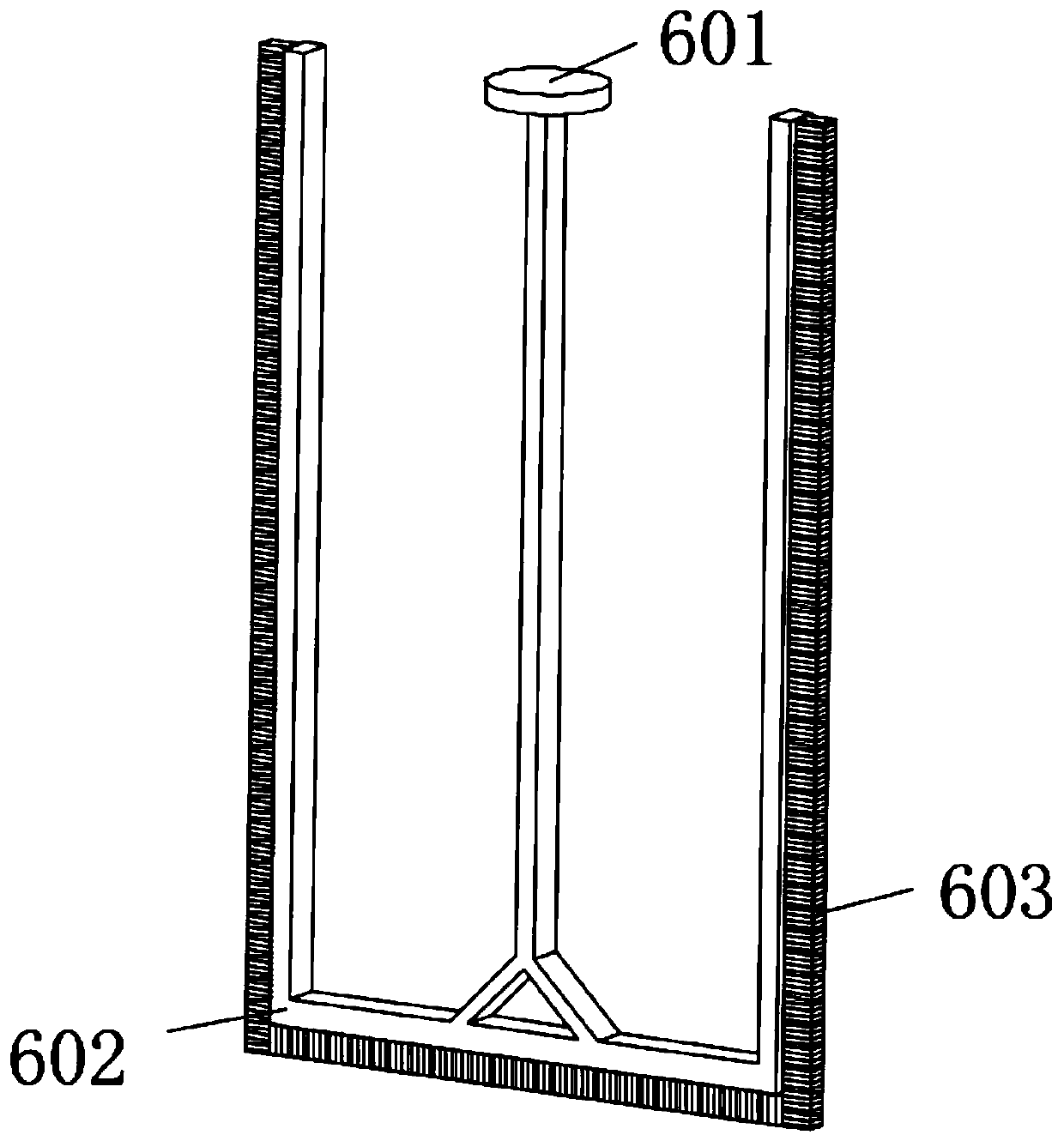

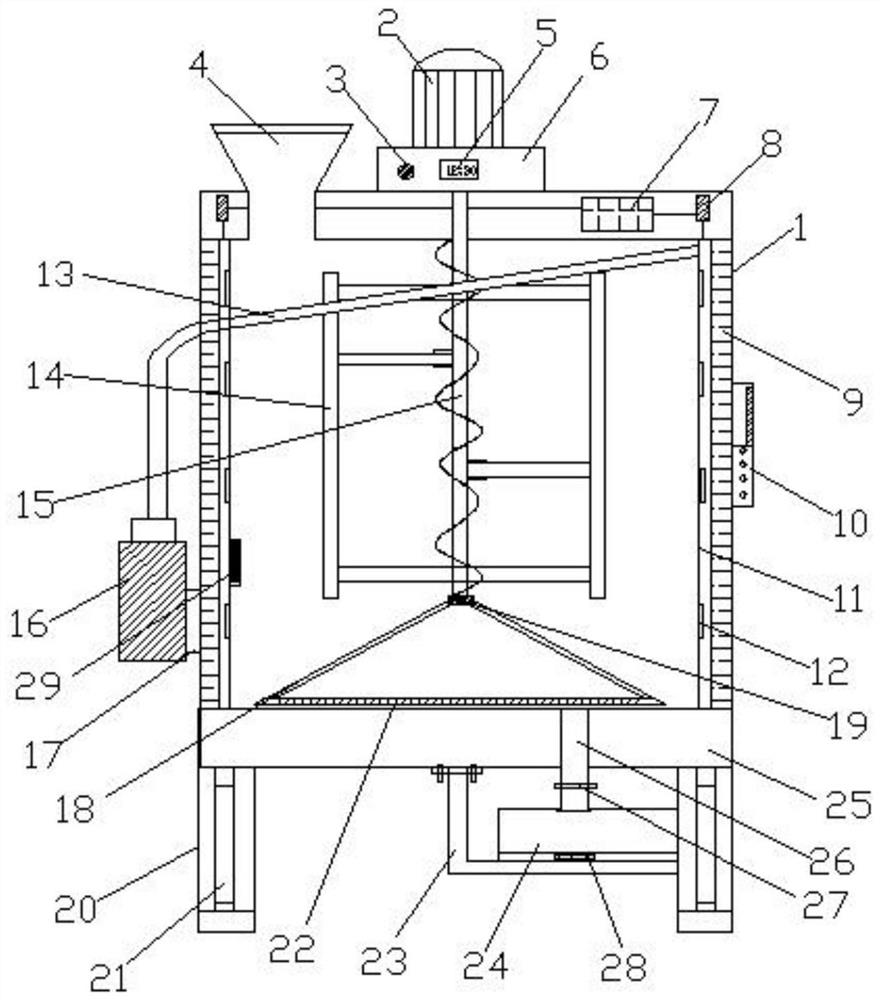

Barrel screen facilitating regular discharging

The invention relates to a discharging structure of a barrel screen. The discharging structure comprises a barrel body and a barrel body support for supporting the barrel body. The barrel body comprises a barrel body supporting framework and a screen wrapping the barrel body supporting framework. Gear rings are arranged on end plates at the front end and the rear end of the barrel body. Supportingstructures are arranged on the two end plates. Each supporting structure comprises two supporting plates fixed to the corresponding end plate. Rolling wheels are fixed between the two supporting plates of each supporting structure. Supporting seats are arranged on the barrel body support and comprise the fixed supporting seat and the moving supporting seat. A feeding hopper is arranged at the front end of the barrel body. An air cylinder arranged at the rear end of the barrel body support drives a discharging baffle to move. Multiple balls are embedded in protruding portions arranged on the discharging baffle. The protruding portions are fixed in grooves in locating plates on the end plates. Contact plates in contact with the balls are fixed in the grooves through springs. Multiple detection columns are arranged on the outer sides of the protruding portions. Multiple pressure sensors are arranged on the supporting seats. The discharging structure is simple in structure and reasonablein design, materials can be completely screened, regular discharging is achieved, and collection is facilitated.

Owner:南通飞跃重型工程设备制造有限公司

Compressed-air automatic spraying device and system

ActiveCN102125901BWeight increaseAutomatic spray timingDust removalFire preventionWater storageWorking environment

The invention provides a compressed-air automatic spraying device and system. The automatic spraying device comprises a spray head, an air pipe, a water pipe and a water storage device, wherein, the water storage device is respectively connected with the air pipe, the water pipe and the spray head; the water pipe is equipped with a water valve; the air pipe is equipped with an air pipe spring switch; and the air pipe spring switch is connected to the outer wall of the water storage device through a rope. The compressed-air automatic spraying device and system provided by the invention have the advantages of overcoming the defect of the prior art that gas explosion is easily caused when an electric control automatic spraying device or an acoustic control automatic spraying device is applied to a working environment of a coal mine with higher gas content, and achieving the purpose of regularly and safely performing automatic spray by virtue of compressed air.

Owner:HUAINAN MINING IND GRP

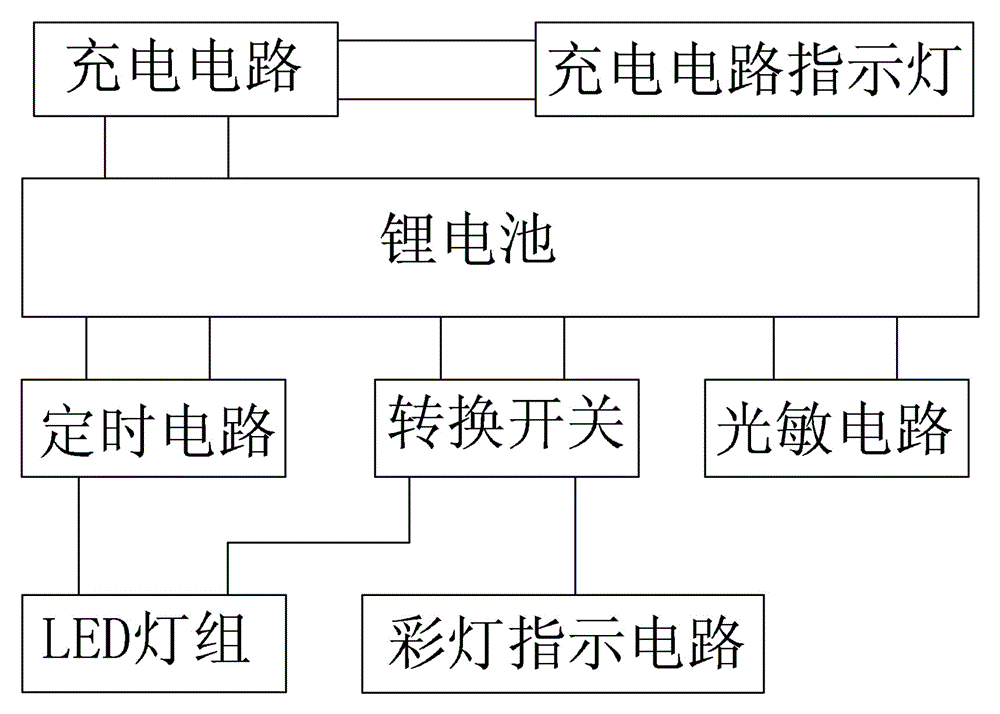

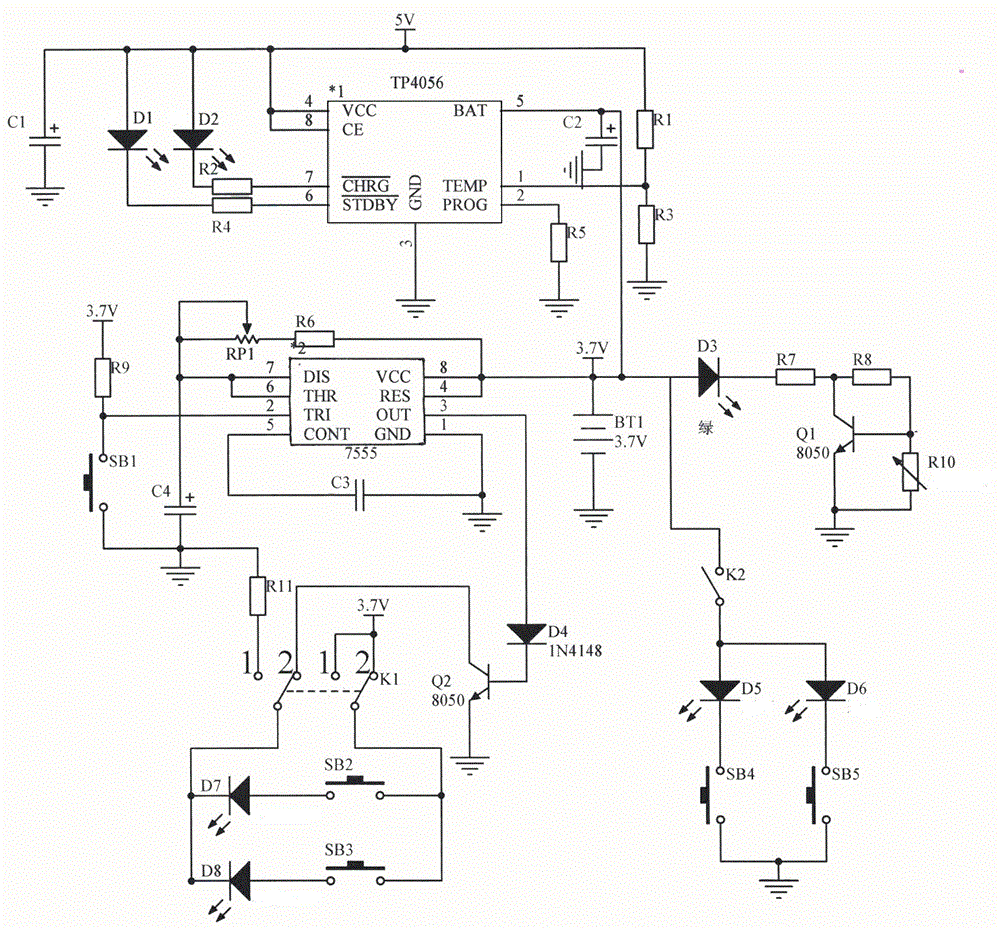

Lithium battery based illuminating apparatus

InactiveCN105163446AReduce volumeReduce weightElectric light circuit arrangementEnergy saving control techniquesLED lampComputer science

The invention discloses a lithium battery based illuminating apparatus. The lithium battery based illuminating apparatus comprises a lithium battery; the charging input end of the lithium battery is connected with an external power supply through a TP 4056 chip based charging circuit; the power supply output end of the lithium battery is connected with an LED lamp set used for illuminating after passing through a change-over switch; the change-over switch is further connected with the LED lamp set through a timing circuit; and the power supply input end of the timing circuit is also connected with the power supply output end of the lithium battery. According to the lithium battery based illuminating apparatus, the lithium battery is small in volume, light in weight and long in service life, and the illuminating apparatus is multifunctional and more user-friendly in design. The lithium battery based illuminating apparatus is suitable for illuminating in various work and life environments.

Owner:葛轩铭 +1

Spinning size stirring device for spinning

InactiveCN112957997AStir wellStir thoroughlyRotary stirring mixersTransportation and packagingInsulation layerElectric machine

The invention discloses a spinning size stirring device for spinning. The device comprises a main body and a motor, a speed reducer is arranged at the upper end of the main body, the motor is arranged at the upper end of the speed reducer, a warning lamp is arranged at the front end of the speed reducer, a timer is arranged on the right side of the warning lamp, a feeding port is formed in the left side of the speed reducer, a rotating shaft is connected to the lower end of the speed reducer, stirring paddles are arranged on the outer side of the rotating shaft, a storage battery is arranged in the top end of the body, a heater is arranged on the right side of the storage battery, a heating pipe is arranged at the lower end of the heater, a heating block is arranged in the heating pipe, a heat insulation layer is arranged on the outer side of the heating pipe, a control panel is arranged on the right side of the body, a temperature detector is arranged on the inner wall of the left side of the body, a flow guide plate is arranged on the right side of the temperature detector, a water collecting tank is connected to the left side of the flow guide plate, and a fixing seat is arranged on the right side of the water collecting tank. The device can fully stir the slurry, stir thoroughly, can stir regularly, and is safe and reliable.

Owner:NINGBO UNIV

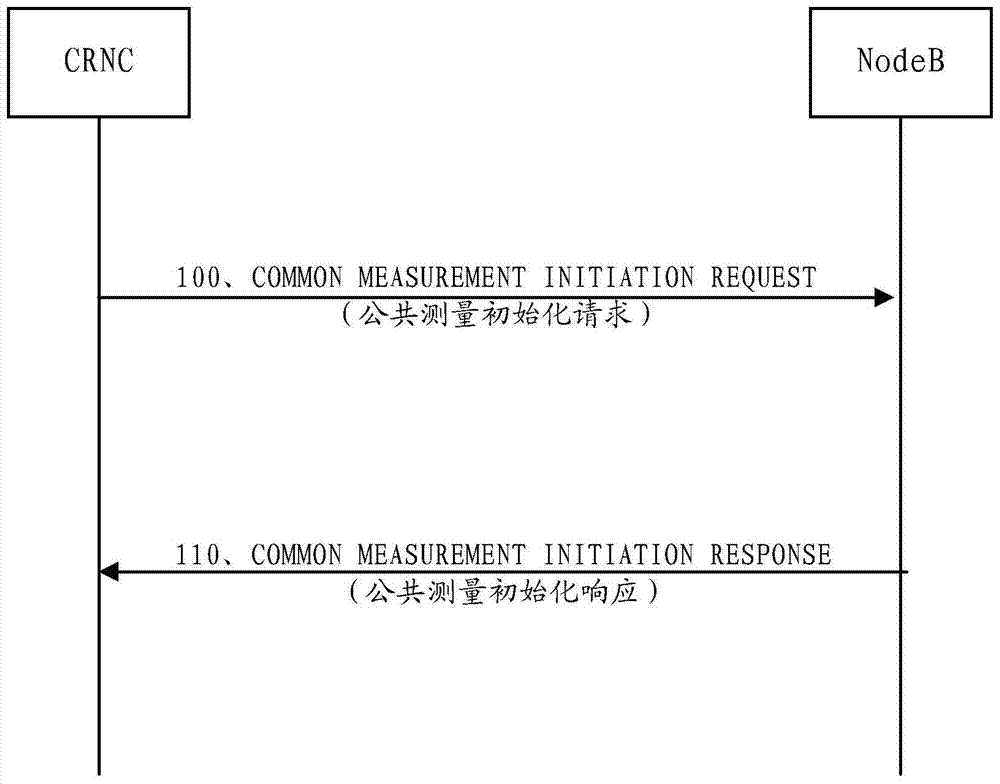

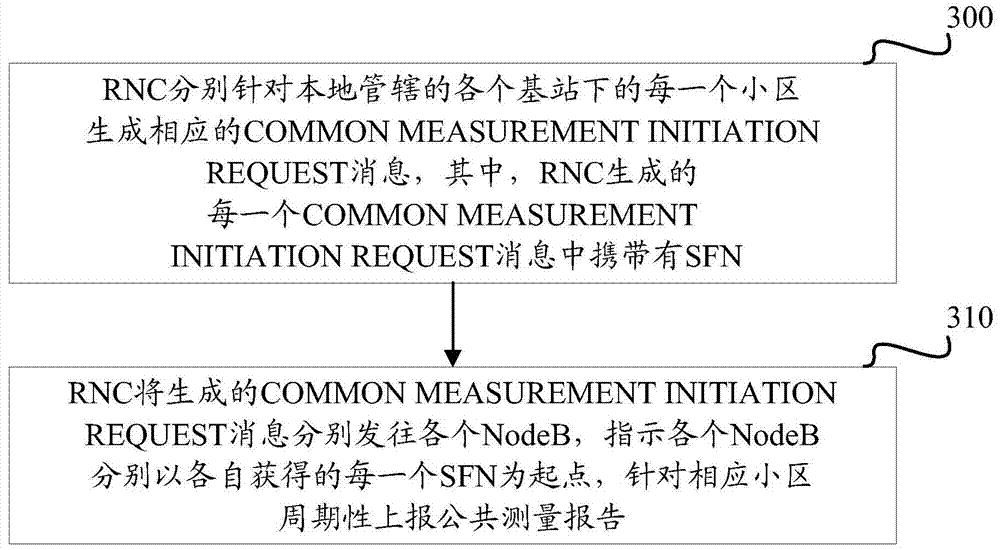

A method and device for reporting a public measurement report

ActiveCN104053181BReduce the probability of signaling stormsEasy to handleWireless communicationComputer scienceBase station

The invention relates to communication technology, and discloses a method and device for reporting public measurement reports, which are used to prevent public measurement reports from being reported to RNC in a short period of time, thereby causing a processing bottleneck of the RNC. The method is as follows: the RNC associates the value of the SFN with the identification information of the cell, so that after the RNC sends the public measurement initialization request message carrying the SFN to each base station, it can instruct each base station to acquire each SFN as The starting point periodically reports public measurement reports for corresponding cells. Since the identification information of the cell under one RNC is not repeated, generating SFN based on the identification information of the cell is equivalent to smoothing the value of SFN, so that the value of SFN can be dispersed as much as possible, so that the periodicity can be effectively controlled The reporting timing of the public measurement report reduces the probability of a signaling storm occurring in the RNC, thereby improving the overall processing capability of the RNC system.

Owner:DATANG MOBILE COMM EQUIP CO LTD

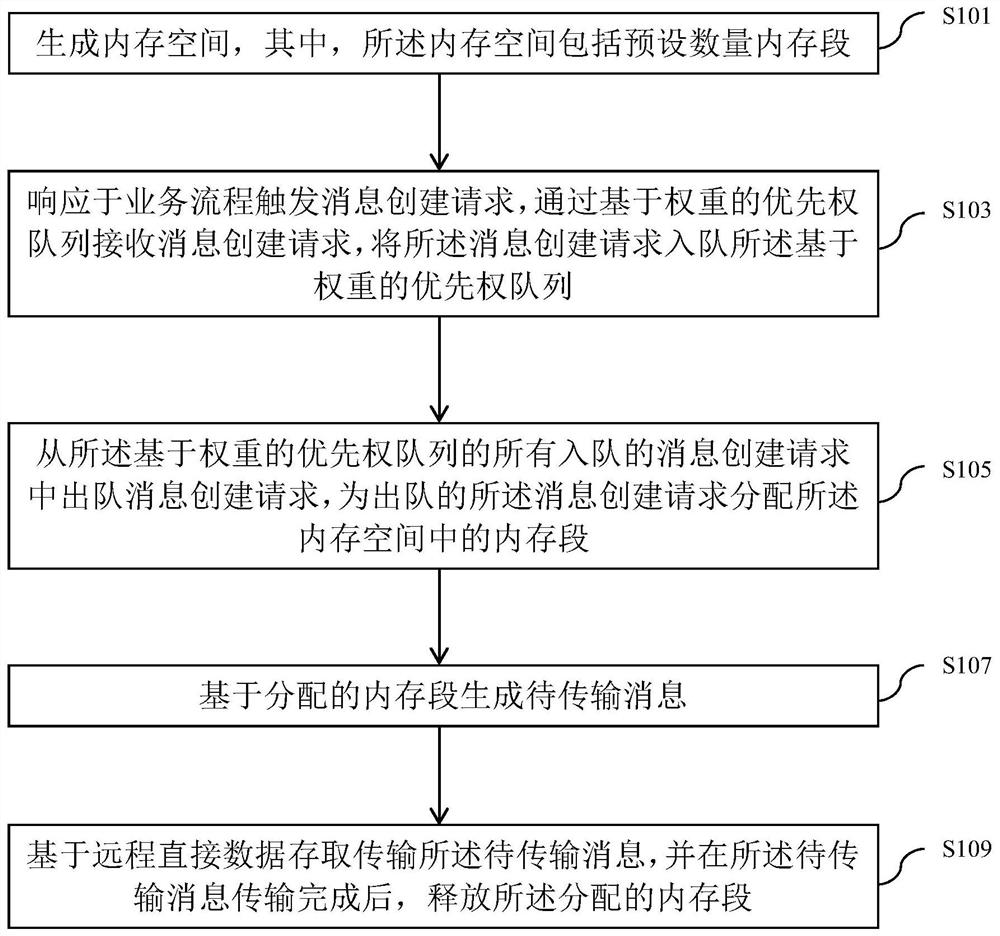

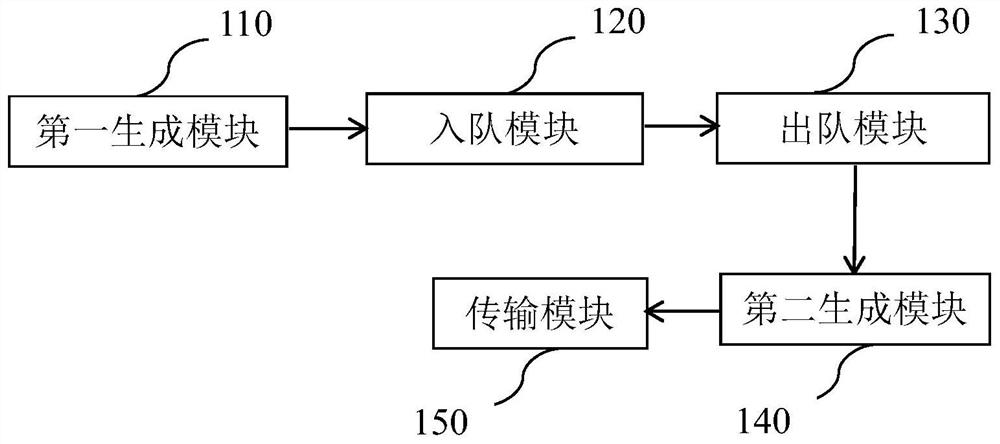

Method and system for optimizing network application performance based on remote direct data access

The invention discloses a method and system for optimizing network application performance based on remote direct data access, and the method comprises the steps: generating a memory space which comprises a preset number of memory segments; triggering a message creation request in response to the business process, receiving the message creation request through the weight-based priority queue, and enqueueing the message creation request into the weight-based priority queue; dequeueing the message creating requests from all the enqueued message creating requests of the weight-based priority queue, and allocating memory segments in the memory space for the dequeued message creating requests; generating a to-be-transmitted message based on the allocated memory segment; and transmitting the to-be-transmitted message based on the remote direct data access, and releasing the allocated memory segment after the transmission of the to-be-transmitted message is completed. Through the scheme of the invention, the opportunity and the response time of obtaining the memory by different types of messages are effectively controlled, the memory copy overhead and the demand of the system for the total memory amount are reduced, and the system performance and the message transmission efficiency are improved.

Owner:济南浪潮数据技术有限公司

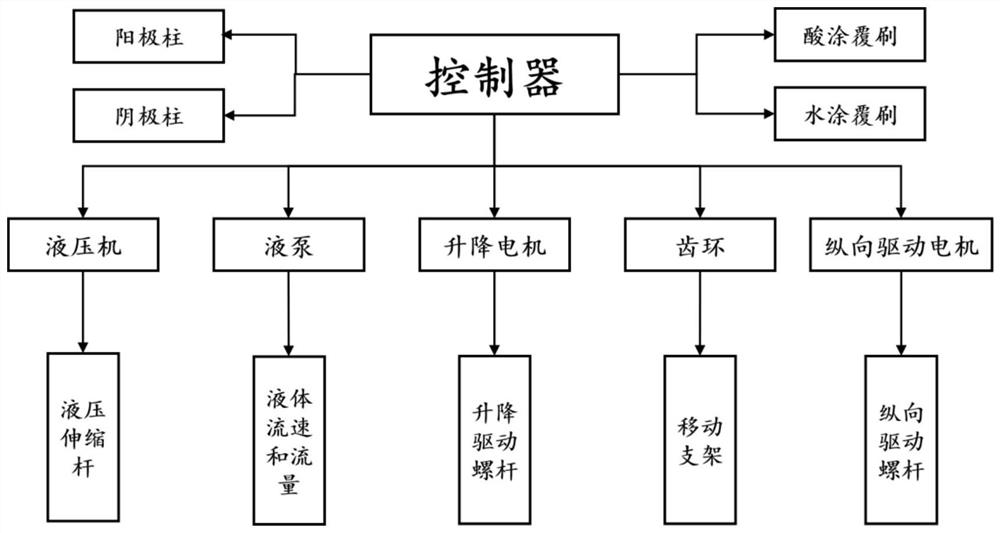

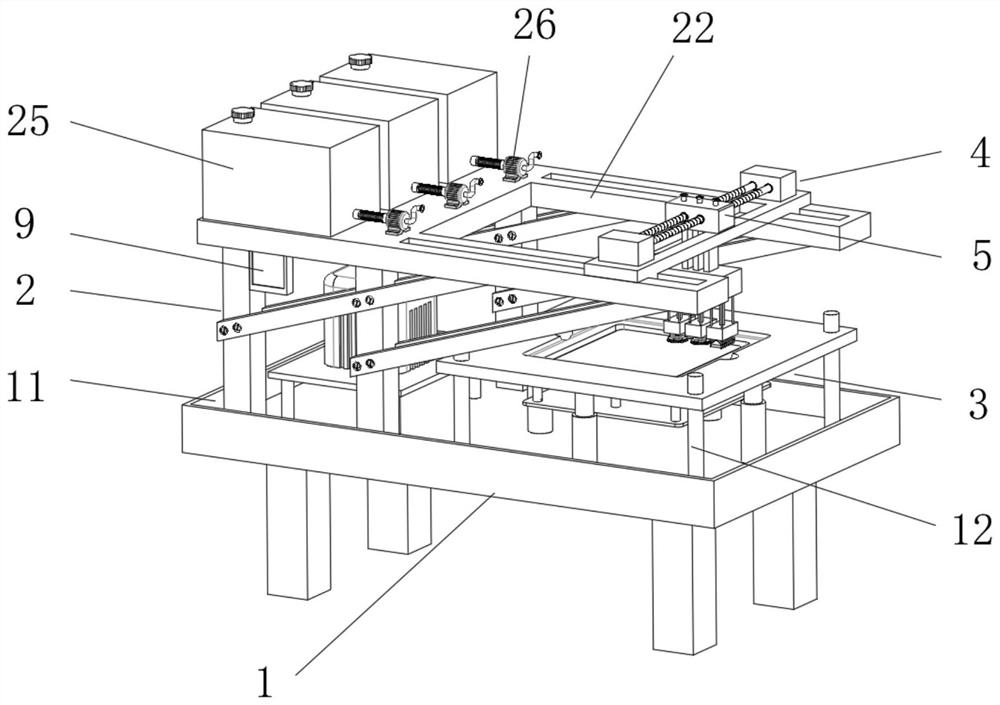

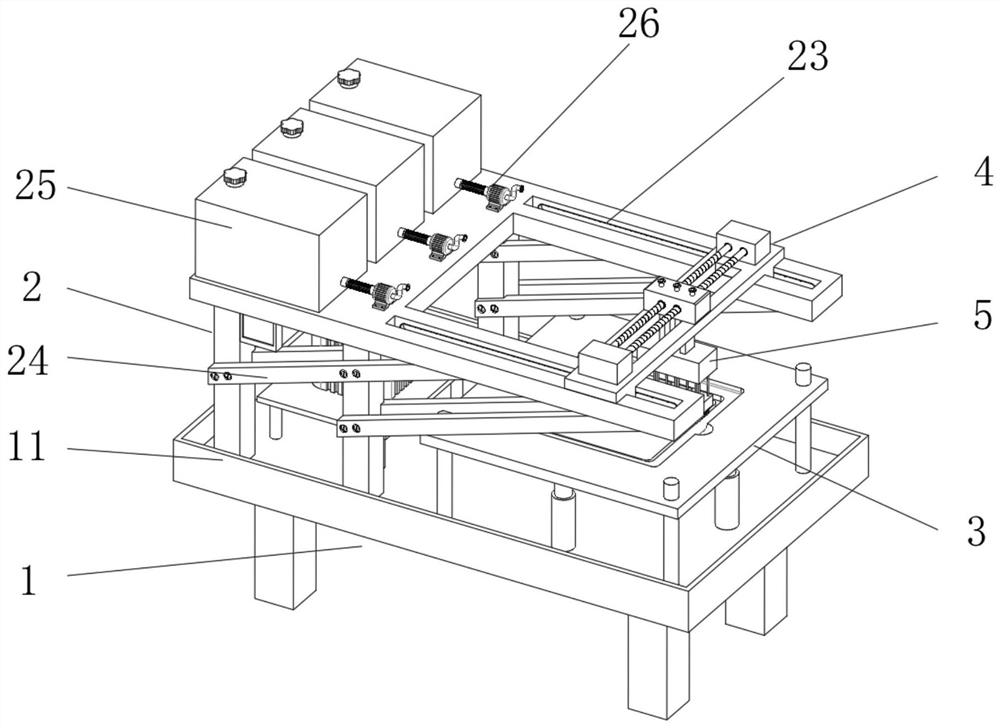

Printed circuit board (PCB) printing and copper plating equipment and technology

ActiveCN113293427AAffect removal effectGuarantee the effect of printing copper platingElectrolysis componentsCleaning using toolsEngineeringPrinted circuit board

The invention relates to the technical field of printed circuit board processing, and discloses PCB printing and copper plating equipment and a technology. The PCB printing and copper plating equipment comprises a supporting table, a supporting frame is arranged on one side of the top end of the supporting table, a supporting platform and two supporting cross beams are erected at the top end of the supporting frame, and a transverse moving mechanism is erected on the two supporting cross beams; and an operating mechanism is erected in the transverse moving mechanism and comprises a positioner at the top end, a connecting flow divider, a pickling device, a water scrubber and an electroplating device, wherein the pickling device, the water scrubber and the electroplating device are arranged on the lower surface of the connecting flow divider in a hanging manner. Under the control of a controller, the whole process can be orderly and rapidly carried out in a mode similar to printing, the electroplating effect is guaranteed, meanwhile, pickling, water washing and electroplating steps can be synchronously carried out, the time of full-plate pickling and water washing in the conventional steps is shortened, it is ensured that stain removal and electroplating processes of all point positions are effectively carried out, meanwhile, the time required by all procedures is effectively shortened, accordingly, the overall production efficiency is improved, and the copper plating capacity is increased.

Owner:中山家普乐电子科技有限公司

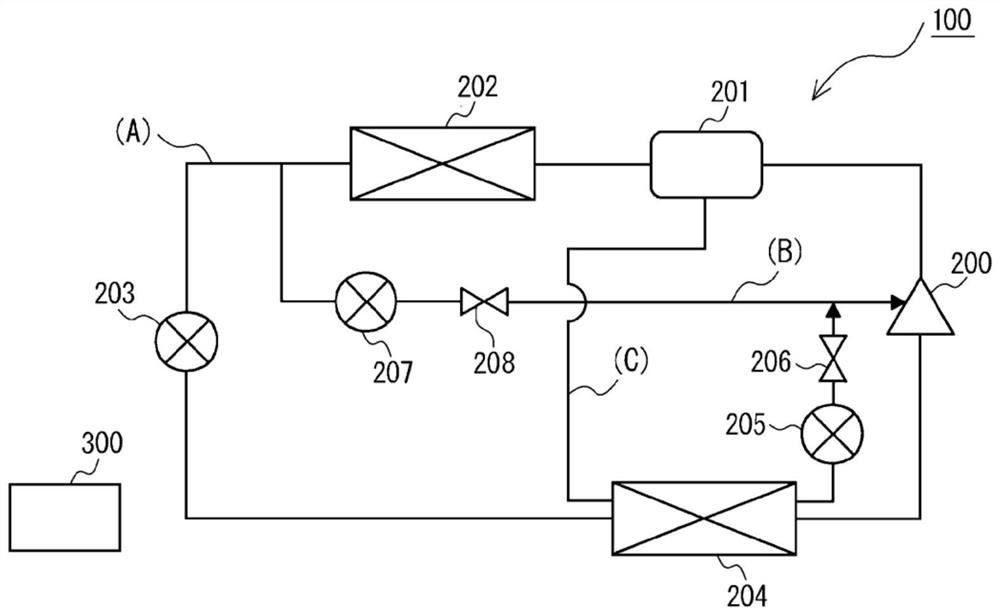

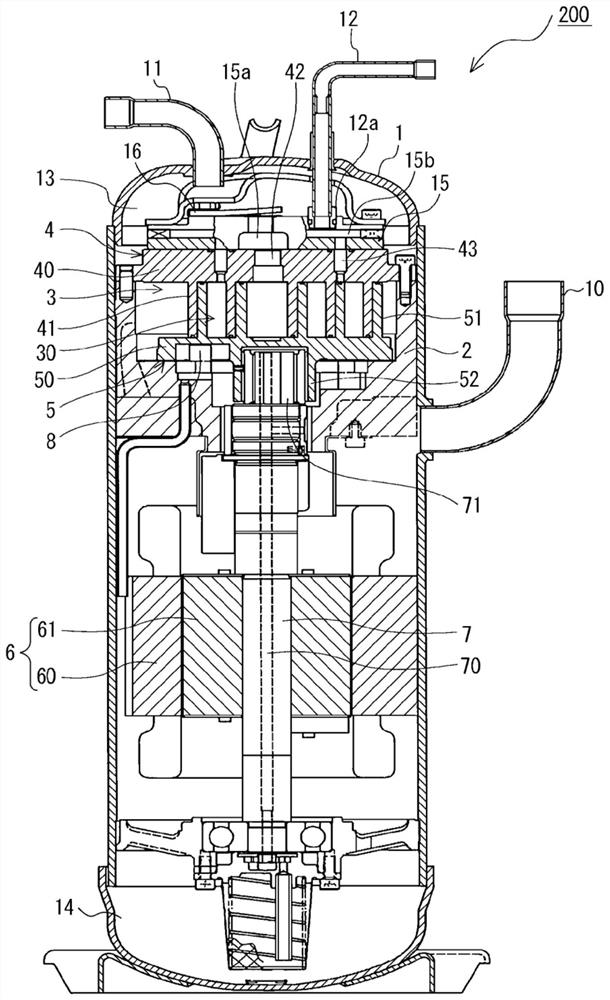

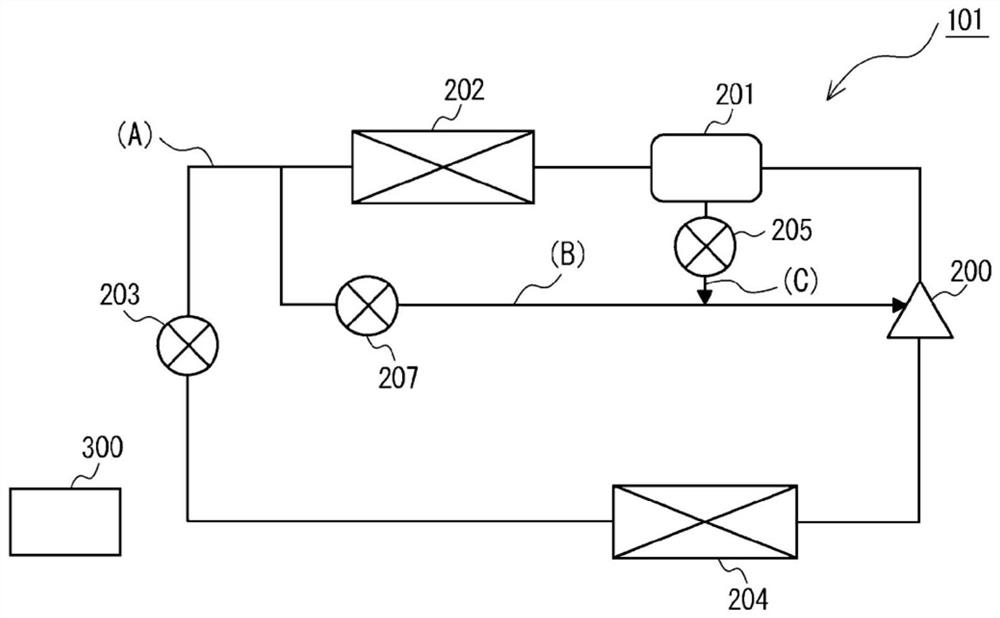

Refrigeration cycle device

PendingCN114846283AControl flowTimingCompression machines with non-reversible cycleOil separationControl valves

The purpose of the present disclosure is to provide a refrigeration cycle device capable of controlling the amount of oil injected into a compression chamber. This refrigeration cycle device is provided with: a main circuit in which a scroll compressor, an oil separator, a first heat exchanger, a pressure reduction device, and a second heat exchanger are connected in this order by piping, and in which a refrigerant circulates; an oil injection circuit branched from the oil separator and connected to an injection pipe of the scroll compressor; and a control device that controls the operation of the refrigeration cycle device. The oil injection circuit is provided with a first control valve which is controlled by a control device to adjust the flow rate of oil flowing in the oil injection circuit.

Owner:MITSUBISHI ELECTRIC CORP

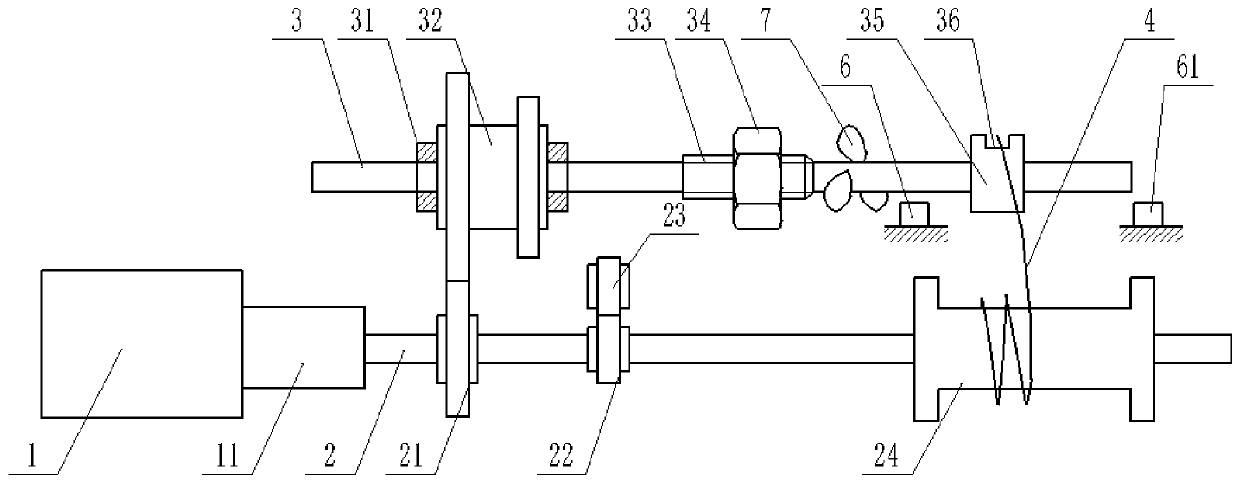

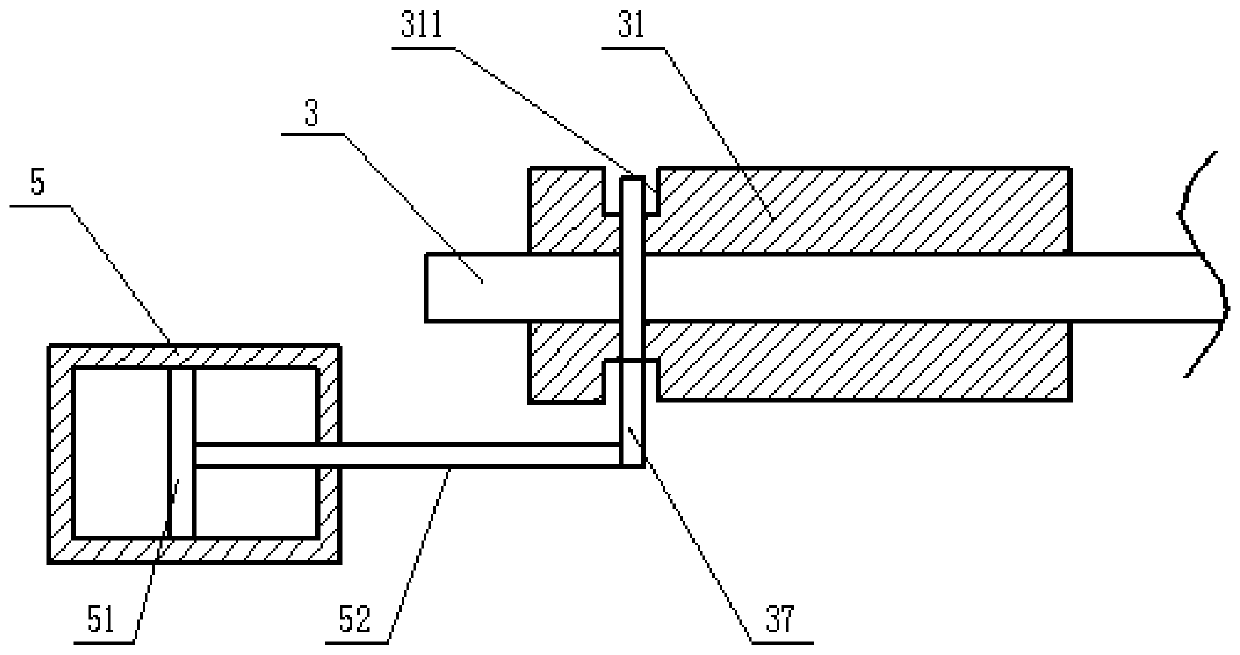

Woven bag tape winding machine

The invention belongs to the technical field of woven bag processing and particularly discloses a woven bag flat silk winding machine comprising a rack. A motor and an air cylinder are fixed to the rack, a shifting fork, a joint sleeve and a first rotary shaft are sequentially connected to the air cylinder, and the joint sleeve is in spline connection with the first rotary shaft. The joint sleeveis fixedly sleeved with a duplex gear, a threaded section is arranged in the middle of the first rotary shaft, and a nut is connected to the threaded section. A second rotary shaft is connected to themotor and sequentially and fixedly sleeved with a large gear and a pinion, the upper portion of the pinion is engaged with an idle gear, and a winding cylinder is connected to the end of the second rotary shaft. A first limiting switch and a second limiting switch are fixed to the position, above the winding cylinder, of the rack, a guiding block is rotatably connected to the end of the first rotary shaft, and a groove for guiding flat silks to the winding cylinder is further formed in the guiding block. By adopting the scheme, the requirement that the flat silks are wound into even column bodies is met, and the woven bag flat silk winding machine is mostly applied to a woven bag producing and processing assembly line.

Owner:重庆市中塑新材料有限公司

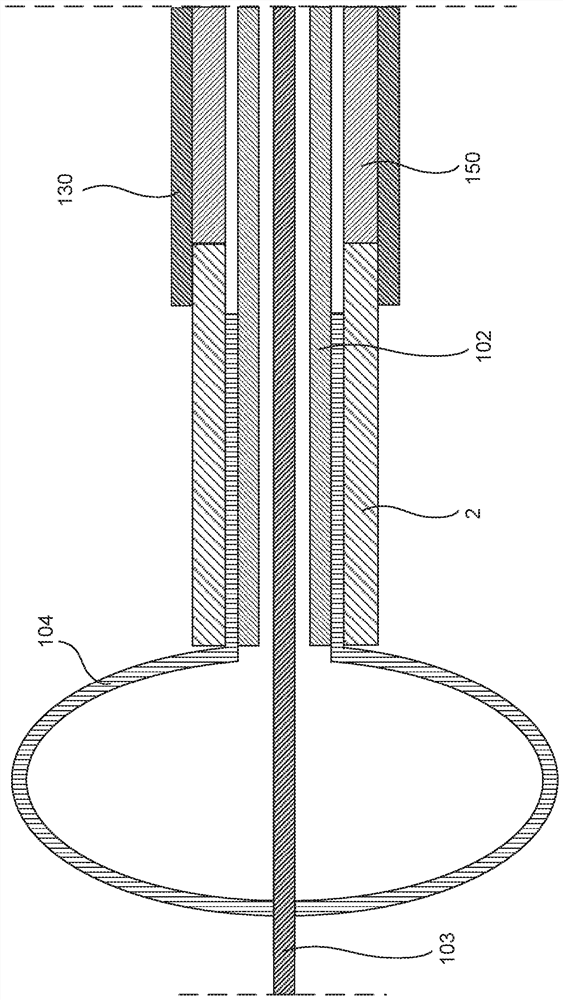

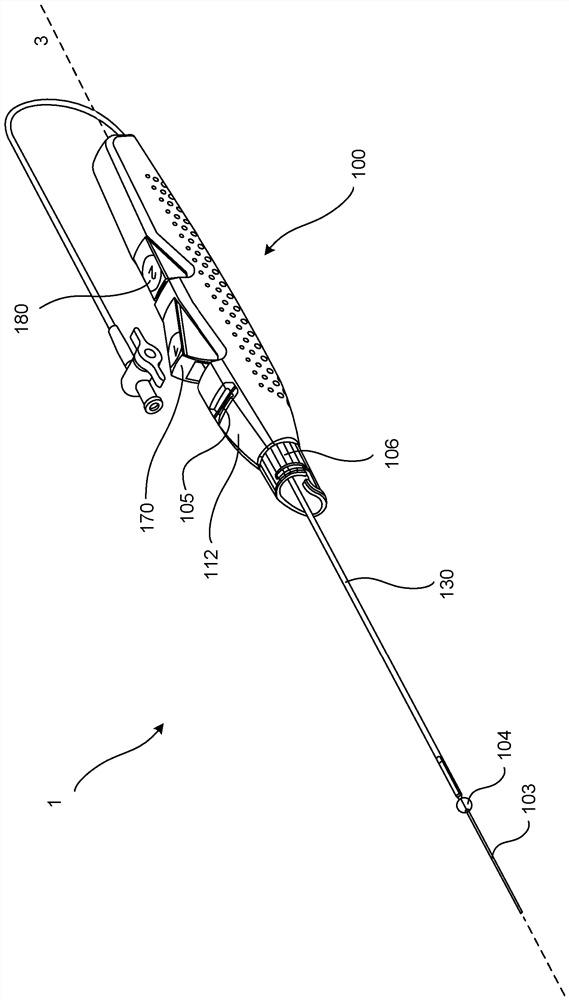

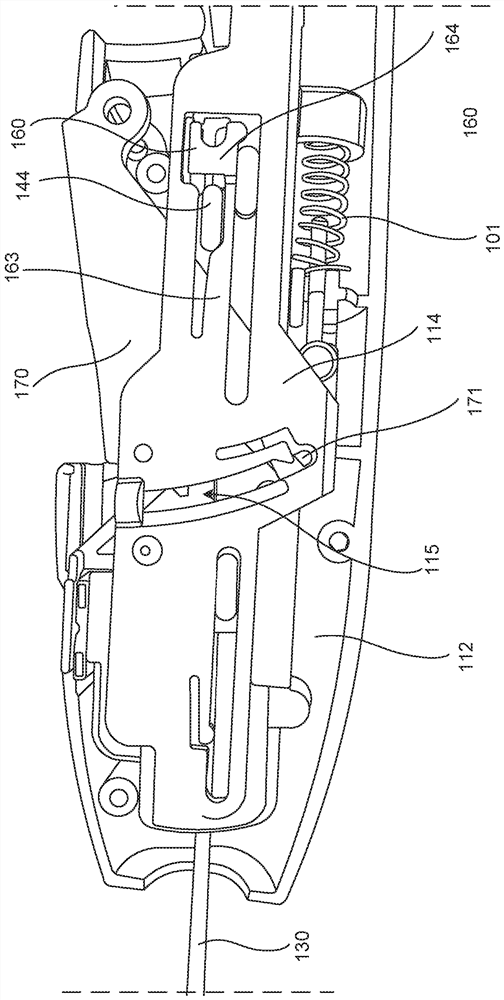

Apparatus and method for sealing vascular puncture

Closure devices for sealing a puncture and methods of sealing a puncture are described herein. A closure device may be used to position a sealant in a puncture. The sealant may be provided in a sheathwhich is retracted to expose the sealant in the puncture. A support member may be advanced to compress the sealant. The device may have a lock that prevents the support member from advancing prematurely. The lock may be unlocked when the sheath is at least partially retracted. The device may have an actuator that controls movement of the sheath and the support member. The lock may remain in a locked position until the sheath is at least partially retracted.

Owner:通合公司

Multifunctional bus station advertising board

The invention discloses a multifunctional bus station advertising board comprising an advertising board body made from wood material, wherein an advertising board mounting groove is embedded into the center of the advertising board body; a spring mechanism is in threaded connection with one side of the advertising board mounting groove; the spring mechanism comprises a spring cushion and spring strips; an awning is in threaded connection with the upper side of the advertising board body; sun shields are in threaded connection with two sides of the advertising board body; a power supply column is arranged on one side of the advertising board body; LED energy-saving lamps are uniformly arranged under the awning and around the advertising board mounting groove; and an air humidifier is in threaded connection with the upper side of the awning. The multifunctional bus station advertising board is simple in structure, convenient to operate, elegant, convenient to mount, saving in time, manpower and material resources due to spring type installation, and meanwhile has the function of voice broadcasting and air humidifying, good sunshade and rain shade effects, and an illumination function.

Owner:HUZHOU HUIXIN CULTURE COMM CO LTD

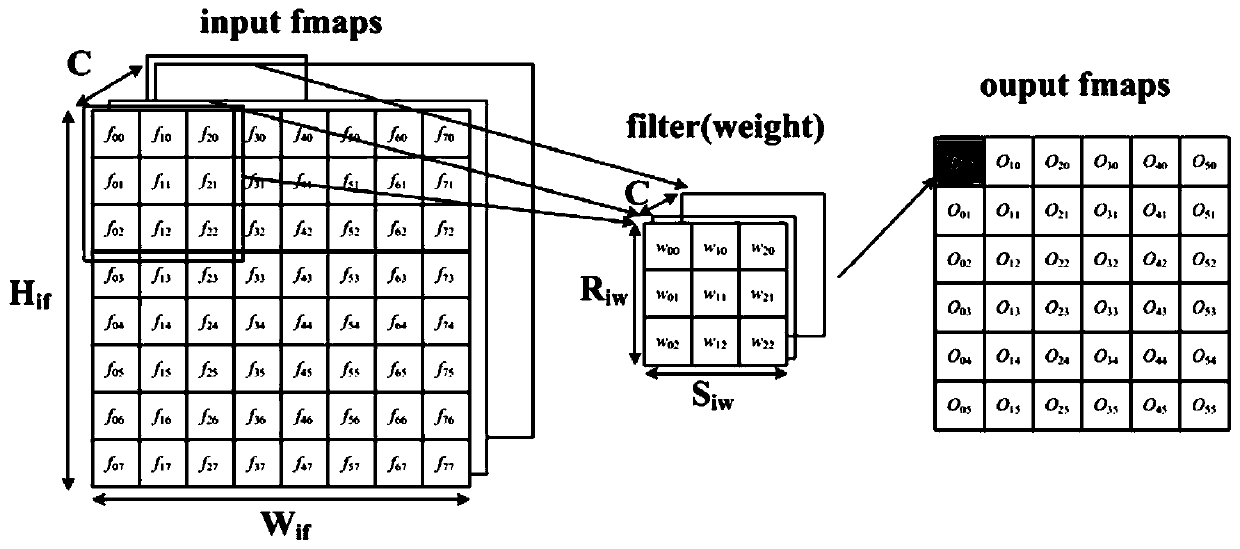

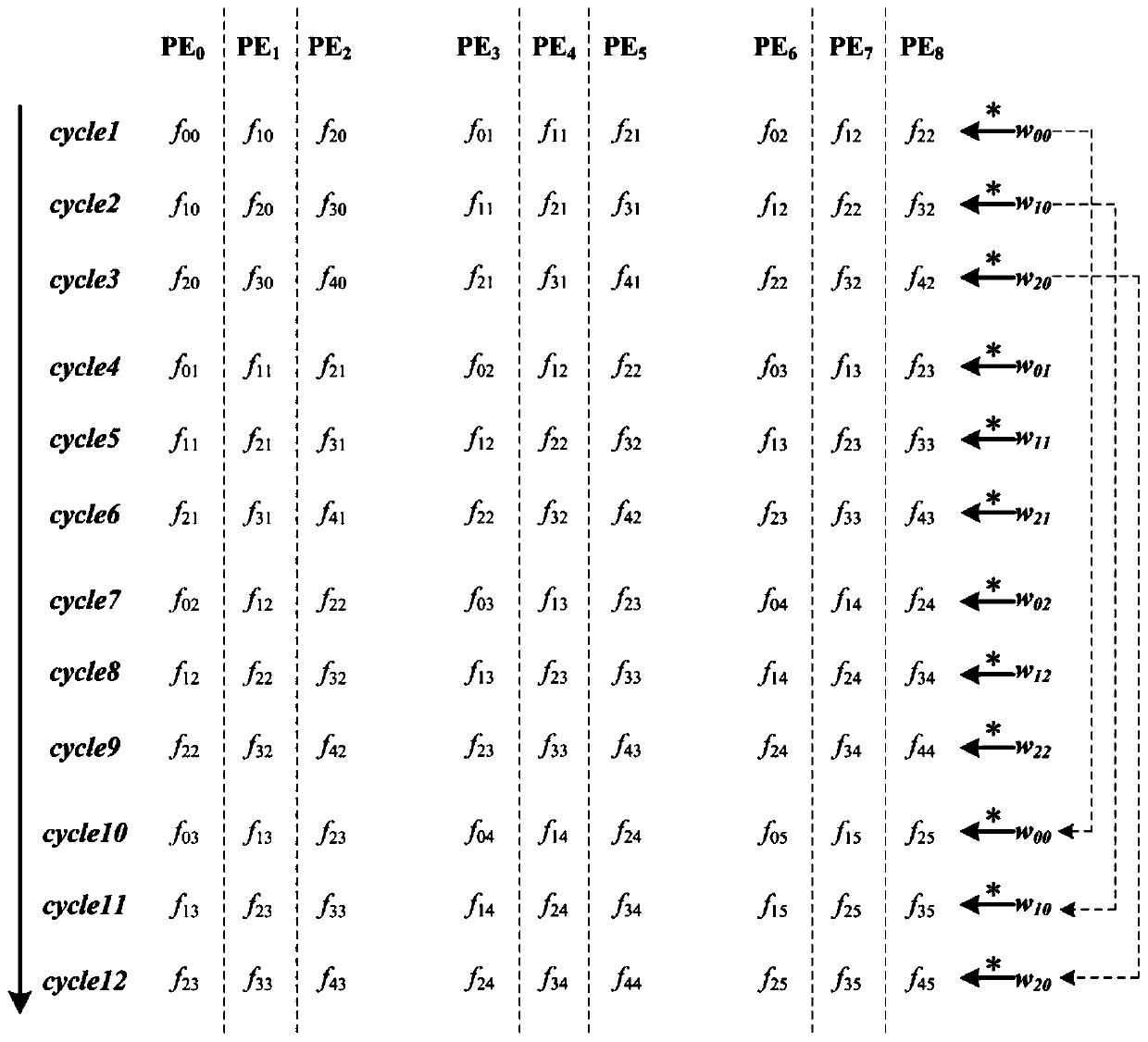

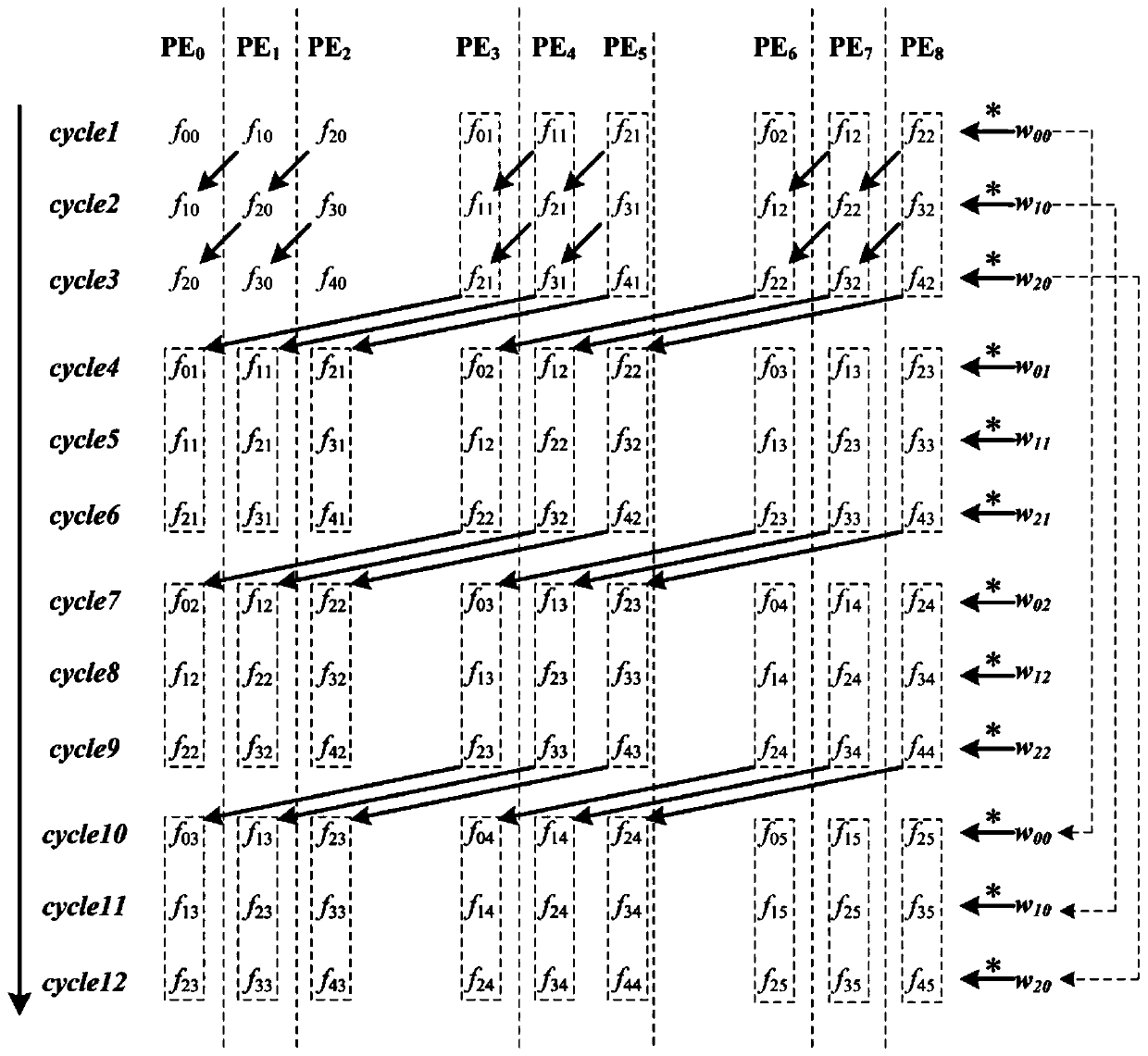

Convolution operation structure for reducing data migration and power consumption of deep neural network

ActiveCN111275180AReduce dynamic power consumptionSimple control structureNeural architecturesPhysical realisationBinary multiplierMultiplexer

The invention discloses a convolution operation structure for reducing data migration and power consumption of a deep neural network. The convolution operation structure comprises a multiplier and anadder. The input end of the multiplying unit is connected with the multiplexer MUX1 and the multiplexer MUX2 respectively; the output end of the multiplier and the output end of the multiplexer MUX1 are connected with the input end of the adder through the multiplexer MUX3; the input end of the adder is also connected with the input end of a multiplexer MUX4; wherein the output ends of the multiplexer MUX1, the multiplexer MUX2, the multiplier, the multiplexer MUX3, the multiplexer MUX4 and the adder are respectively connected with the register reg1, the register reg2, the adder and the register reg3; the output end of the adder is connected with the register reg2, and the output end of the register reg2 is connected with the input end of the multiplexer MUX4 and used for achieving multiply-accumulate operation of convolution operation. The convolution operation structure is suitable for all current convolutional neural network models, effectively reduces the dynamic power consumptionof global calculation on the premise of meeting the data parallelism degree to the maximum extent, is simple in control structure, and is very high in universality.

Owner:XIAN MICROELECTRONICS TECH INST

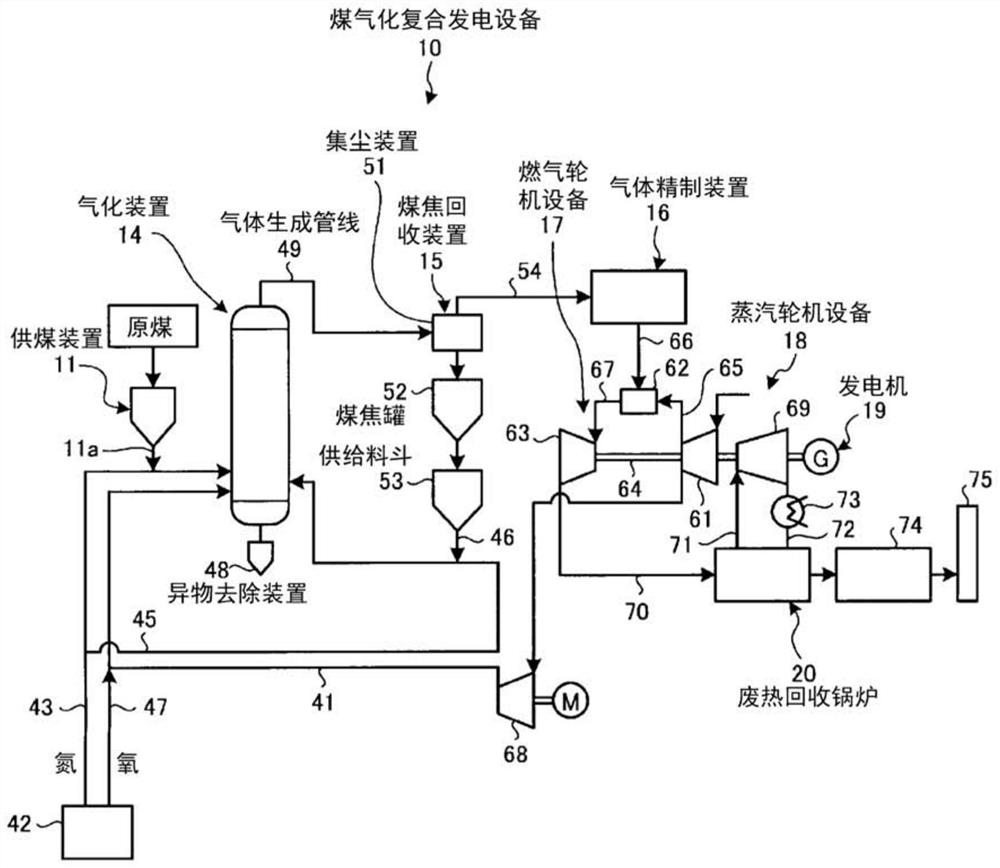

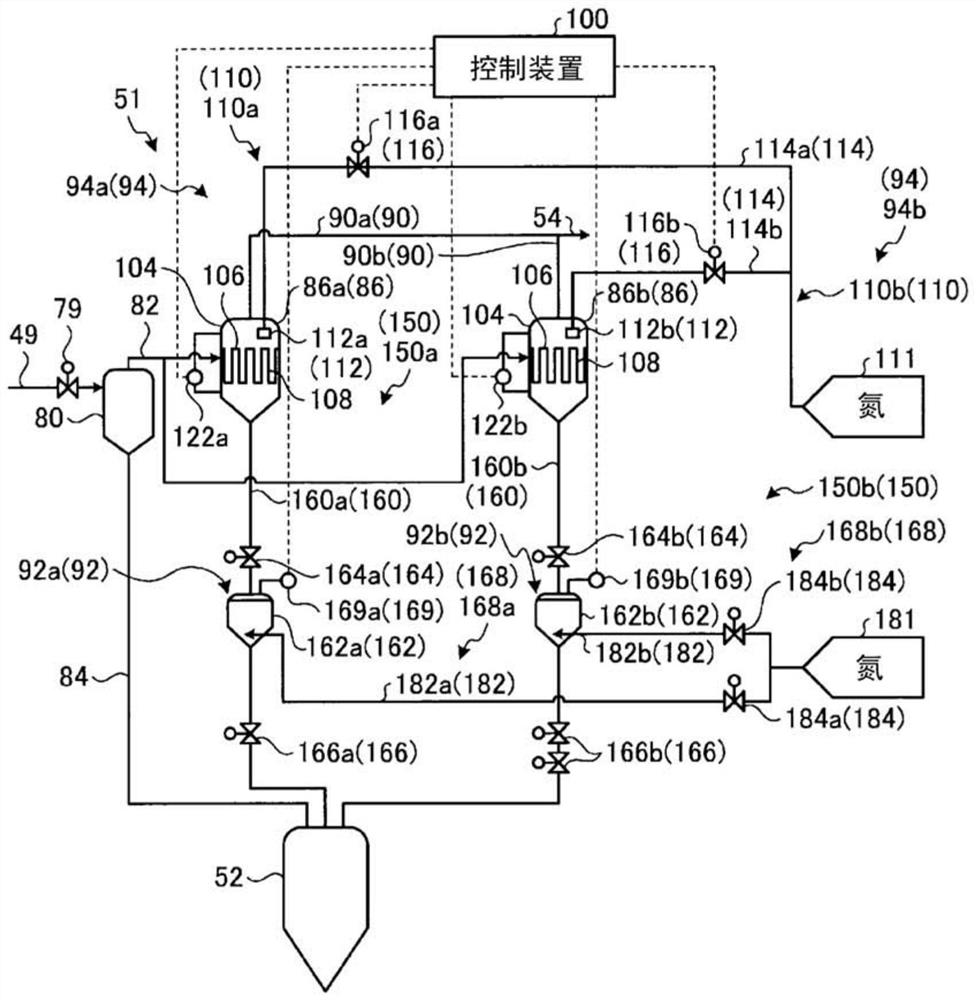

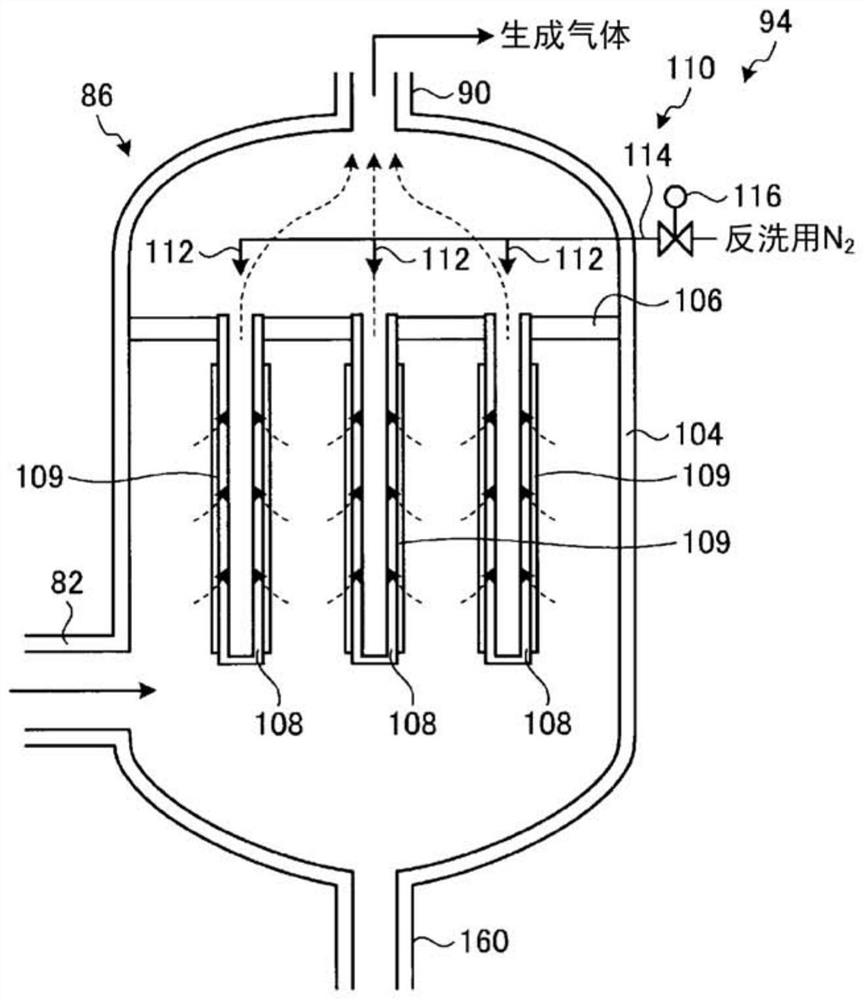

Filtration and backwashing device, coal coke recovery device and filtration and backwashing method, gasification composite power generation equipment

ActiveCN108367226BInhibit deteriorationIncrease consumptionCombination devicesDispersed particle filtrationThermodynamicsDifferential pressure

The present invention provides a filter backwashing device capable of recovering the dust-collecting performance of a filter and suppressing an increase in the number of times of backwashing, a coal char recovery device having the filter backwashing device, and a filter backwashing method. The filter backwashing device (94) has: a gas injection device (110), which is arranged on the downstream side of the element (108) in the flow direction of the circulating gas, and sprays backwashing gas from the downstream side towards the element (108); the parameter detection device (accumulation detection device (169) or differential pressure gauge (122 a , 122b)), which detects the parameters for judging the state of the dust attached to the element (108); and the control device (100), which estimates the thickness of the dust based on the detection results of the parameter detection device, and The interval of spraying backwash gas from the gas injection device (110) to backwash the element (108) is determined according to the thickness of the discharged dust.

Owner:MITSUBISHI POWER LTD

High wear resistance impregnated diamond bit matrix material and method for manufacturing diamond bit using it

ActiveCN111822715BTimely edgeRight amount of edgeDrill bitsHigh wear resistanceHot isostatic pressing

The invention provides a kind of high wear resistance impregnated diamond bit matrix material and the method for using it to manufacture diamond bit, the content of each component of the matrix material is calculated as: FAM‑1020 (Fe 80 Ni 18 co 2 ) accounted for 42 to 56%, FAM‑3010 (Fe 81 Ni 7 mn 12 ) accounted for 16 to 22%, FAM‑2120 (Fe 85 Ni 6 Cu 6 sn 3 ) accounted for 28 to 36% and unavoidable impurities. The manufacturing method includes: raising the temperature of the matrix material; performing low-pressure sintering treatment on the matrix material; cooling the matrix material to room temperature; performing hot isostatic pressing treatment on the impregnated diamond drill body; cooling to room temperature. The present invention effectively improves the wear resistance and comprehensive performance of the impregnated diamond bit matrix by rationally designing the matrix material components of the impregnated diamond bit and adopting a special low-pressure sintering heating isostatic pressing manufacturing method matching the components. Mechanical properties, can achieve high-efficiency, long-life drilling goals.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

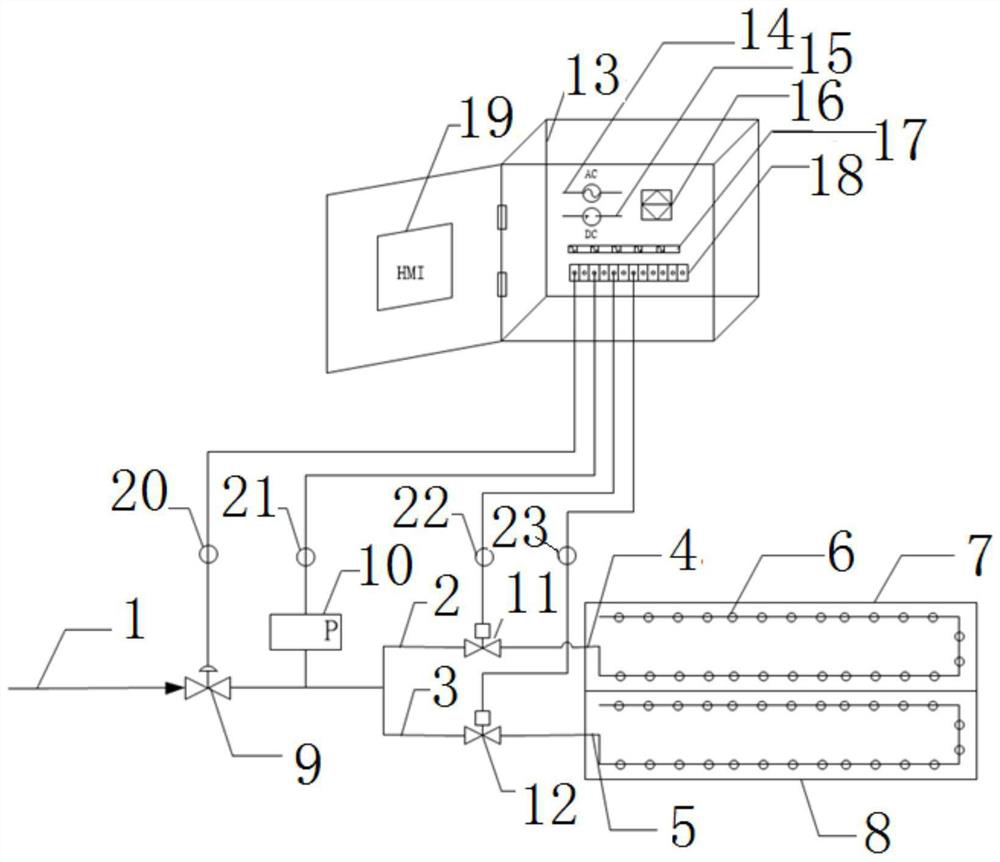

Automatic copper removal system

PendingCN112095126ARealize automatic decopper functionSolve the problem of unsatisfactory mass transfer effectElectrolysis componentsPhotography auxillary processesElectrolysisEngineering

The invention discloses an automatic copper removal system. The automatic copper removal system comprises an air conveying device, an air flow stirring device and a controller. The air conveying device comprises an air conveying main pipe, and one end of the air conveying main pipe is connected with one end of a first air conveying branch pipe and one end of a second air conveying branch pipe; theair flow stirring device comprises a first breather pipe and a second breather pipe, the first breather pipe is arranged in a first liquid making tank, the second breather pipe is arranged in a second liquid making tank, the air inlet end of the first breather pipe is connected with the other end of the first air conveying branch pipe, and the air inlet end of the second breather pipe is connected with the other end of the second air conveying branch pipe; a pressure regulating valve and a pressure sensor are arranged on the air conveying main pipe; control valves are arranged on the first air conveying branch pipe and the second air conveying branch pipe; and the pressure regulating valve, the pressure sensor and the control valves are connected with the controller. According to the automatic copper removal system provided by the invention, a mass transfer effect of a solution in a nickel electrolysis liquid making tank can be automatically improved, and meanwhile, an automatic copper removal function is realized.

Owner:金川集团信息与自动化工程有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com