Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

307results about How to "Stir thoroughly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

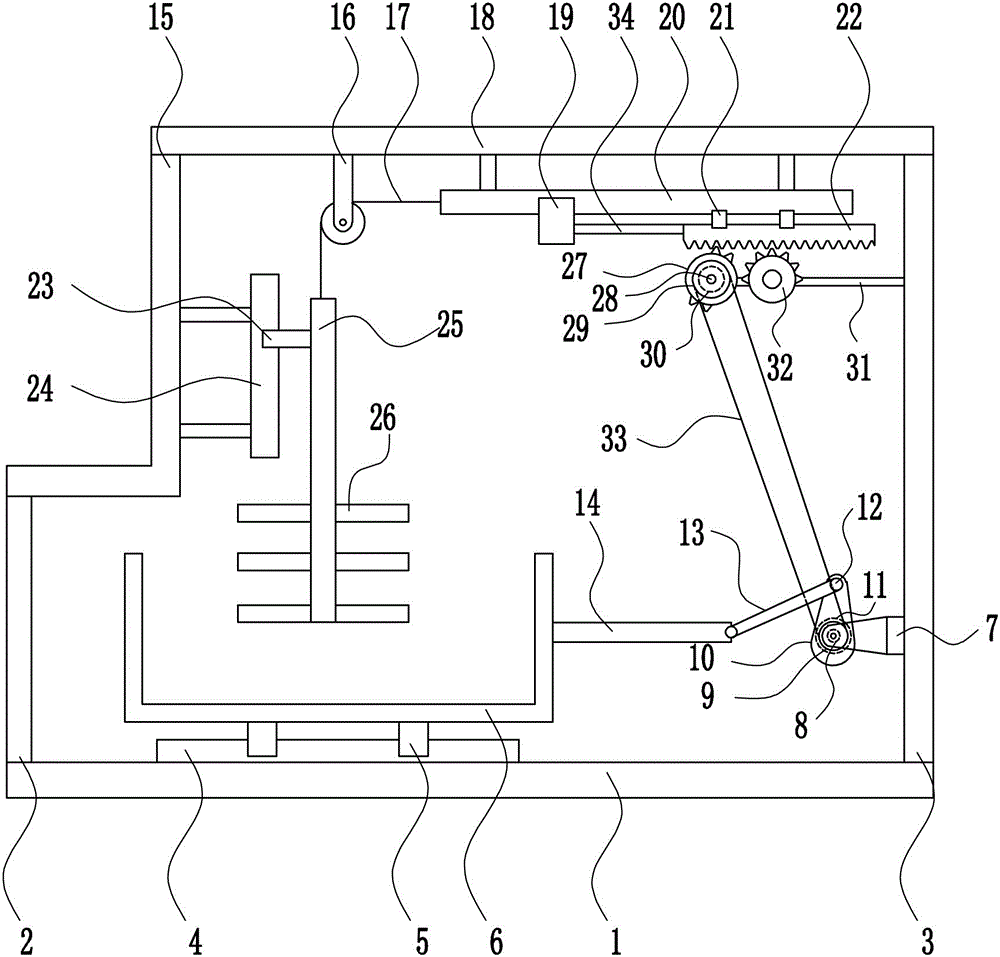

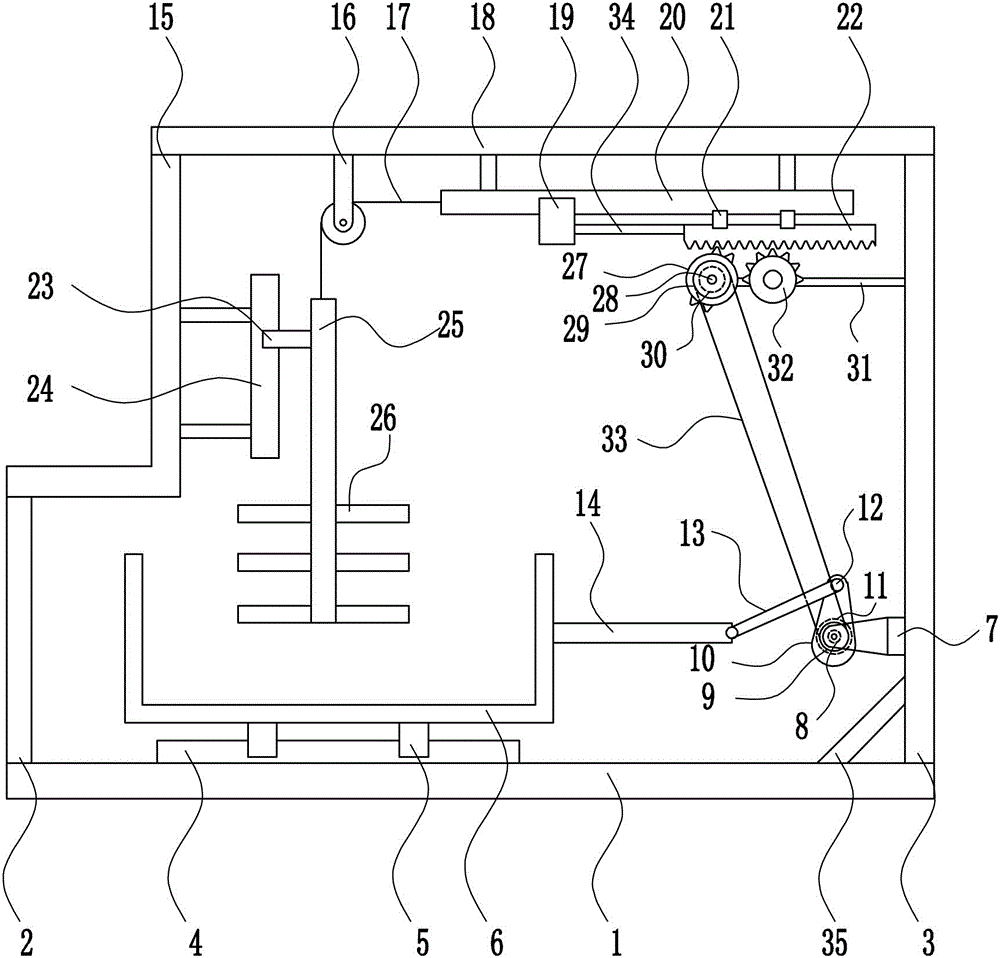

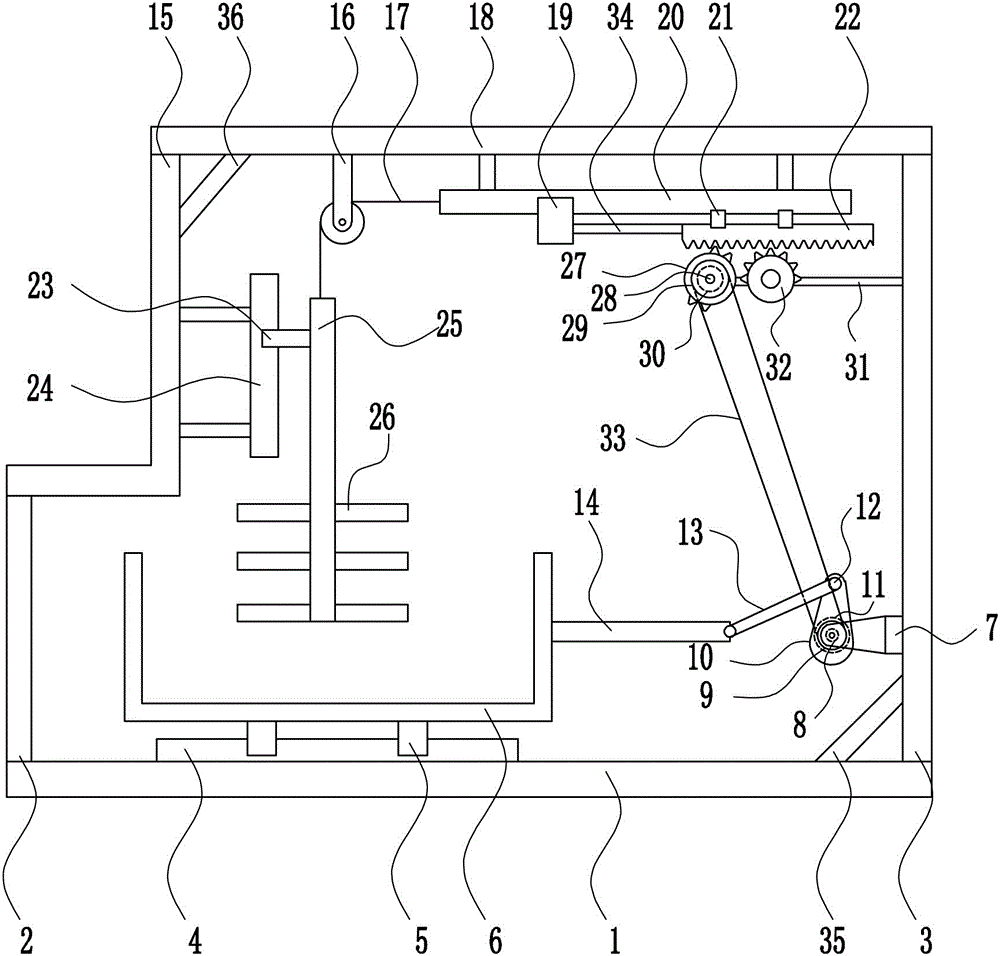

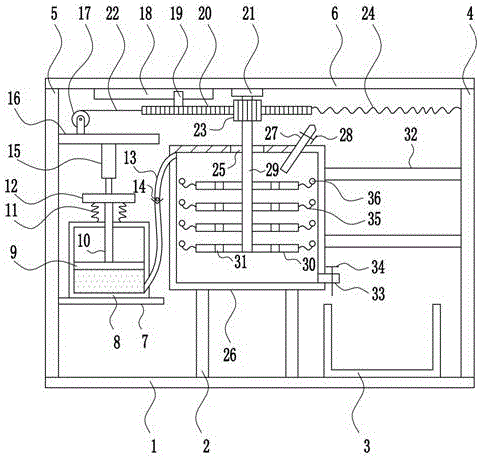

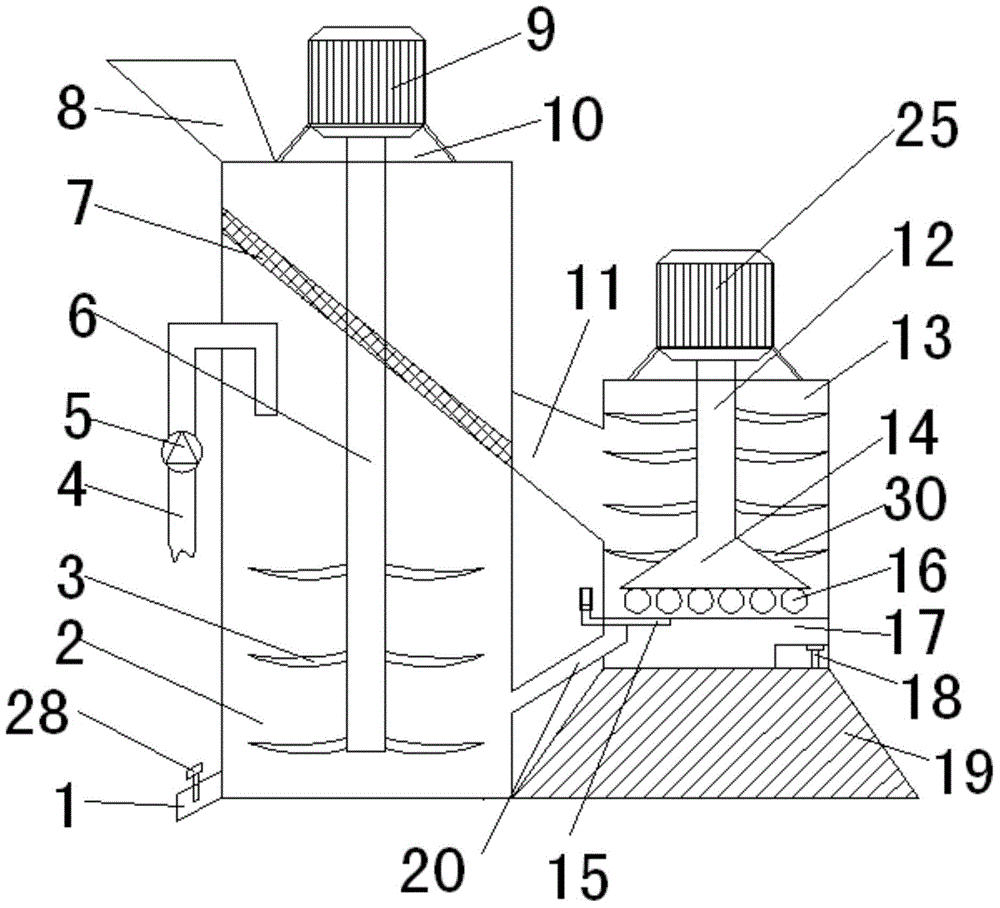

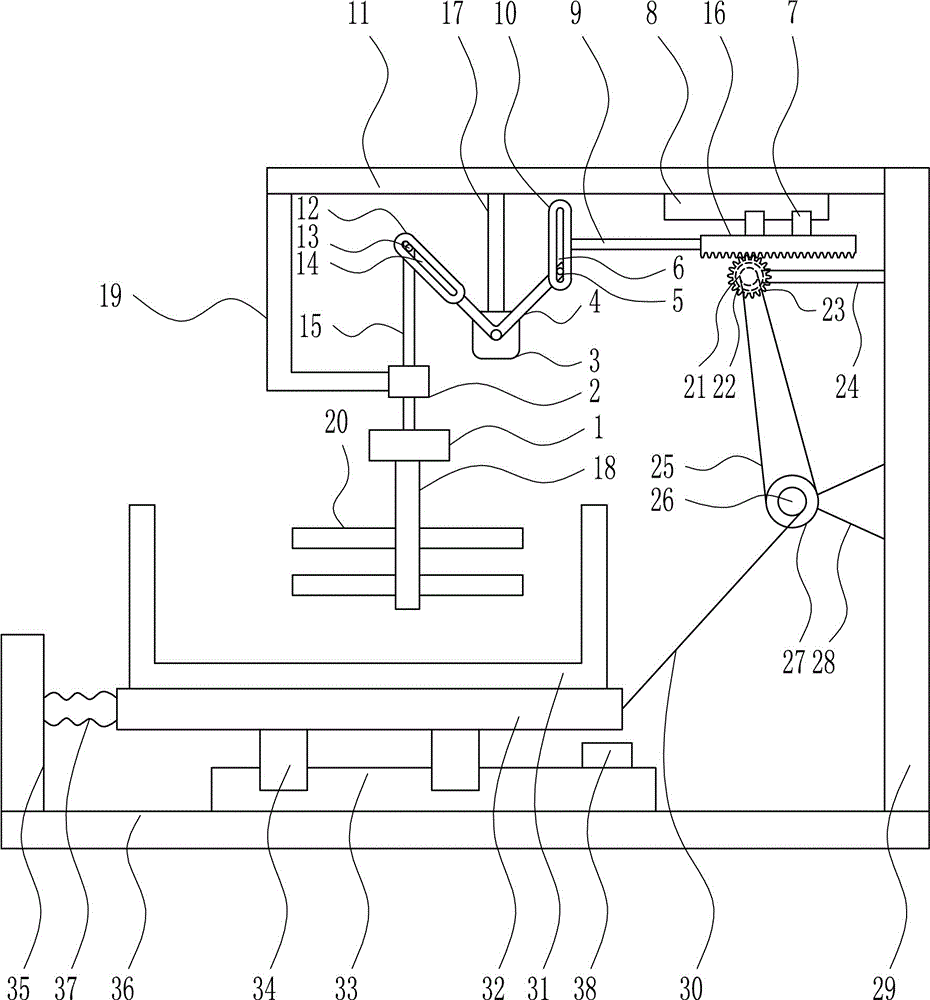

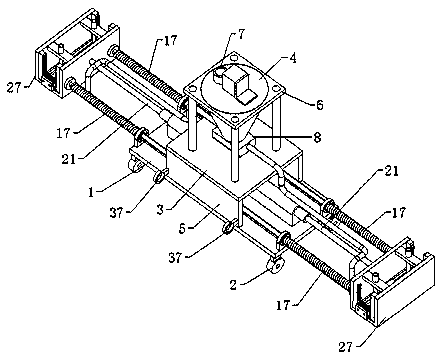

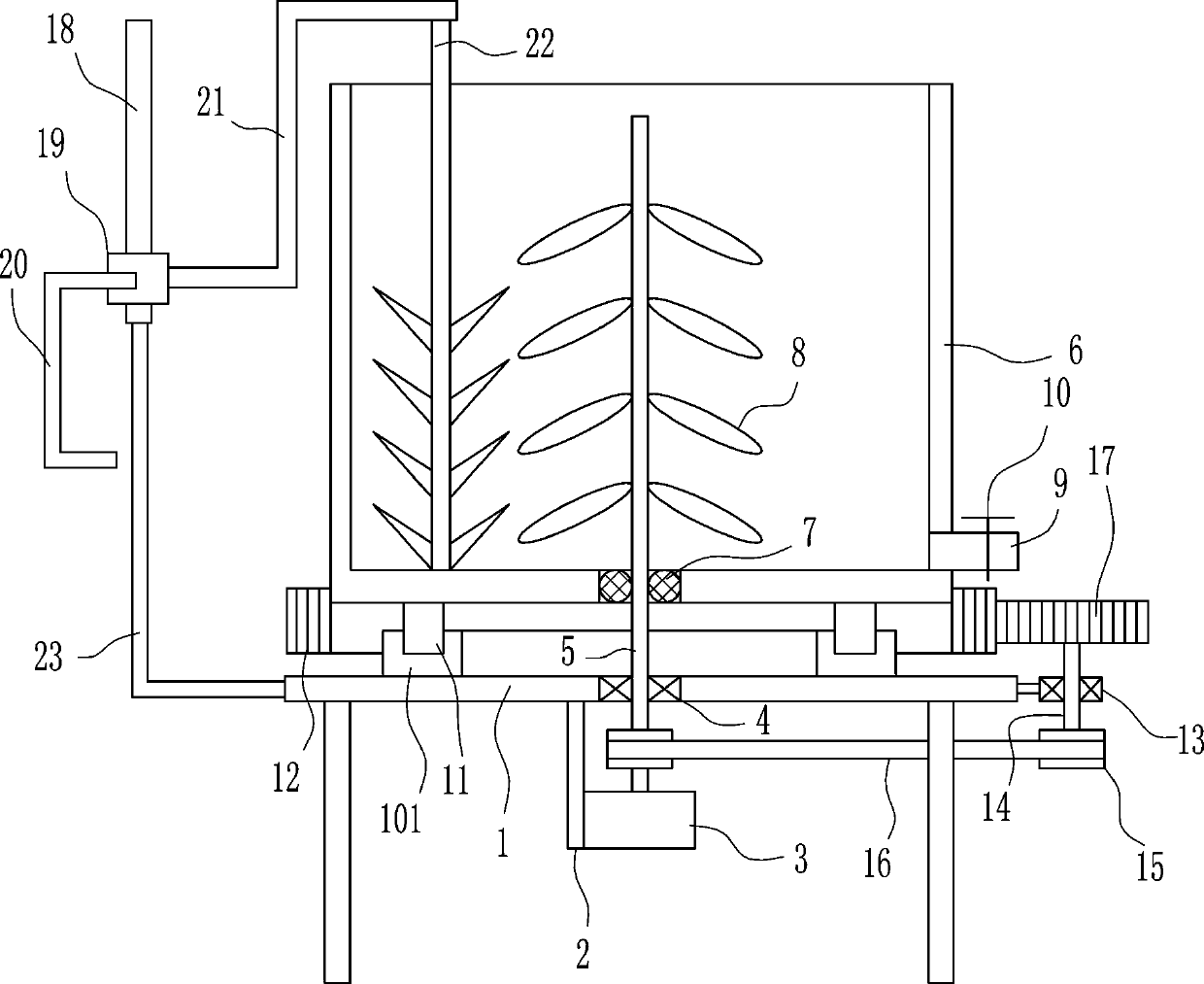

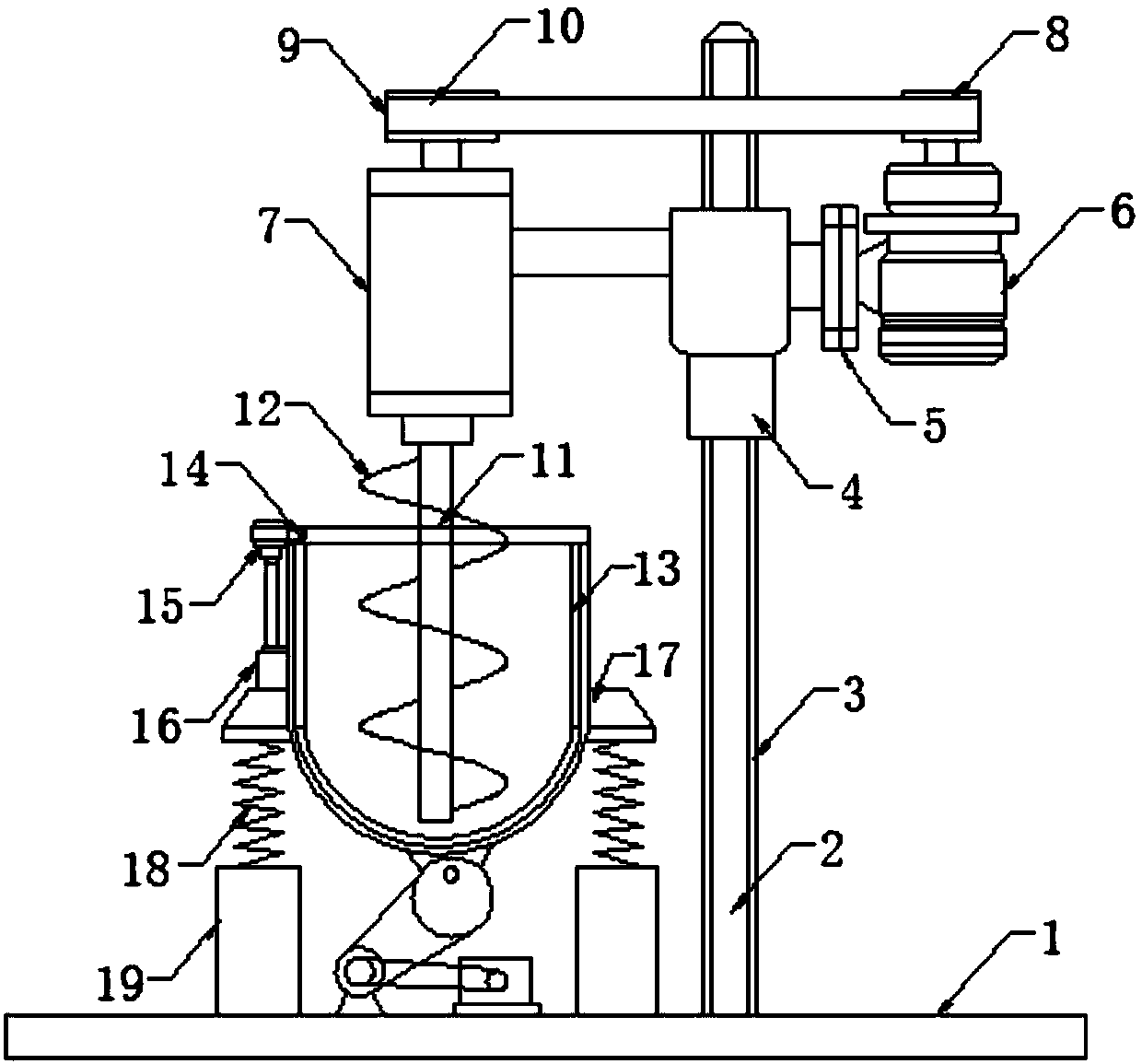

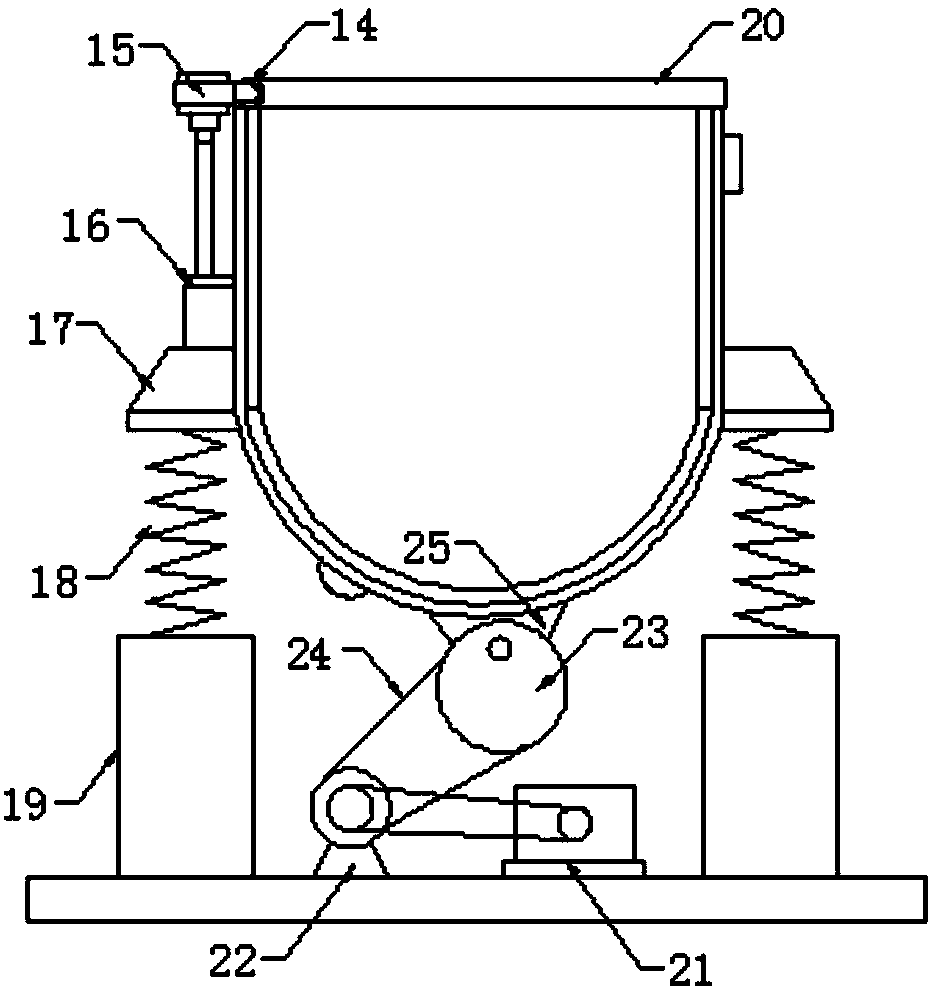

Efficient preparation device of grinding fluid for maintenance of electrical mechanical equipment

InactiveCN106563379AGuaranteed stabilityExtend your lifeShaking/oscillating/vibrating mixersTransportation and packagingEngineeringMechanical equipment

The invention relates to a grinding fluid preparation device, in particular to an efficient preparation device of grinding fluid for maintenance of electrical mechanical equipment, and aims to provide an efficient preparation device, which is uniform in stirring, thorough in stirring and high preparation speed, of the grinding fluid for maintenance of the electrical mechanical equipment. In order to solve the technical problem, the invention provides the efficient preparation device of the grinding fluid for maintenance of the electrical mechanical equipment. The efficient preparation device comprises a bottom plate, a left frame, a right frame, a first sliding rail, a first sliding block, a stirring tank, a mounting seat, a first rotating shaft, a small belt wheel, a crank, a first bearing pedestal, a hinge component and the like, wherein the left frame is welded at the left end of the top of the bottom plate; and the top of the left frame is connected with an L-shaped fixed plate in a bolt connection manner. The efficient preparation device achieves the effects of uniform and thorough stirring and high preparation speed; and furthermore, under the action of a first reinforcing bar and a second reinforcing bar, the efficient preparation device is reasonable in structure, low in manufacturing cost and easy to maintain.

Owner:南京长高电气科技有限公司

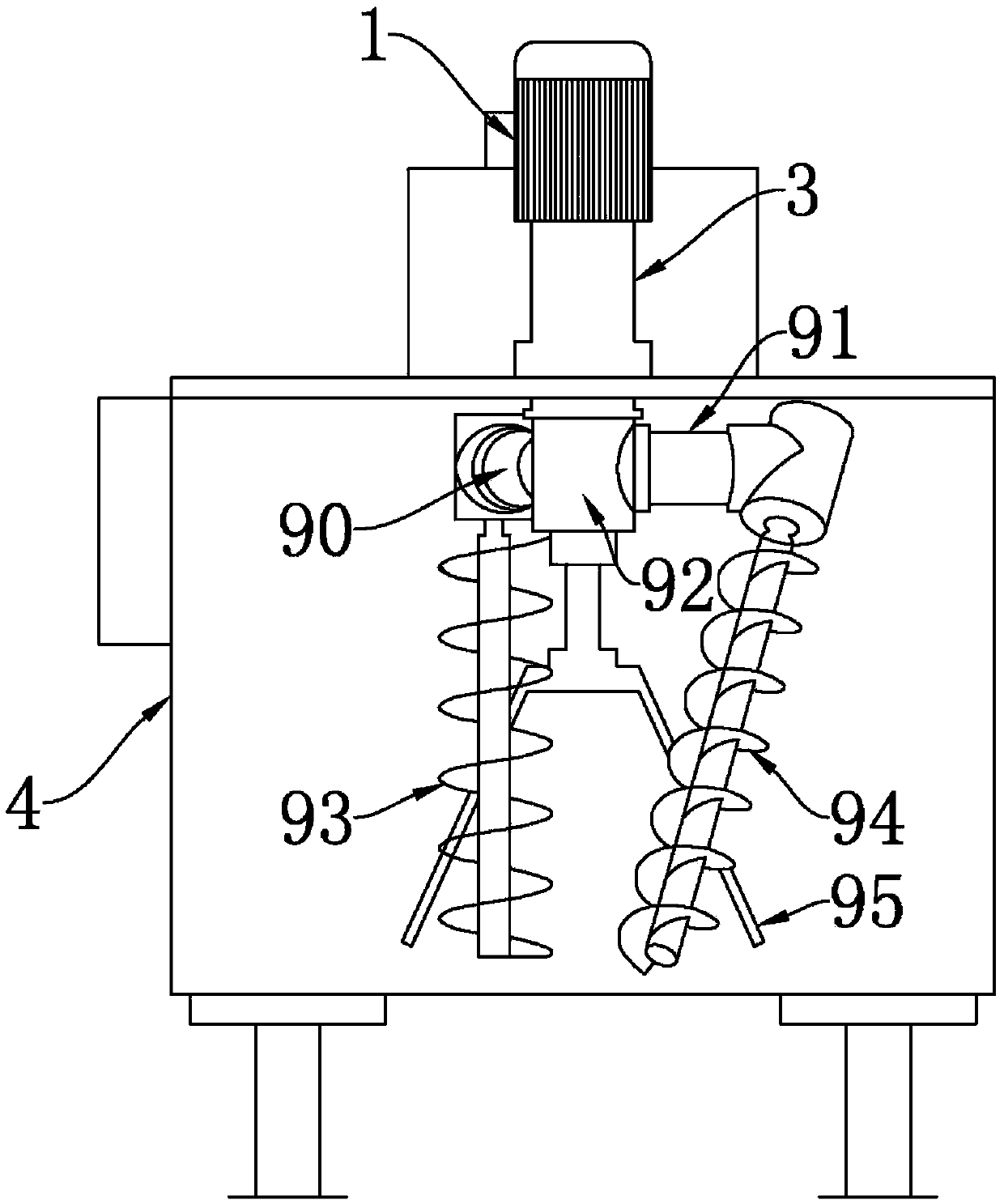

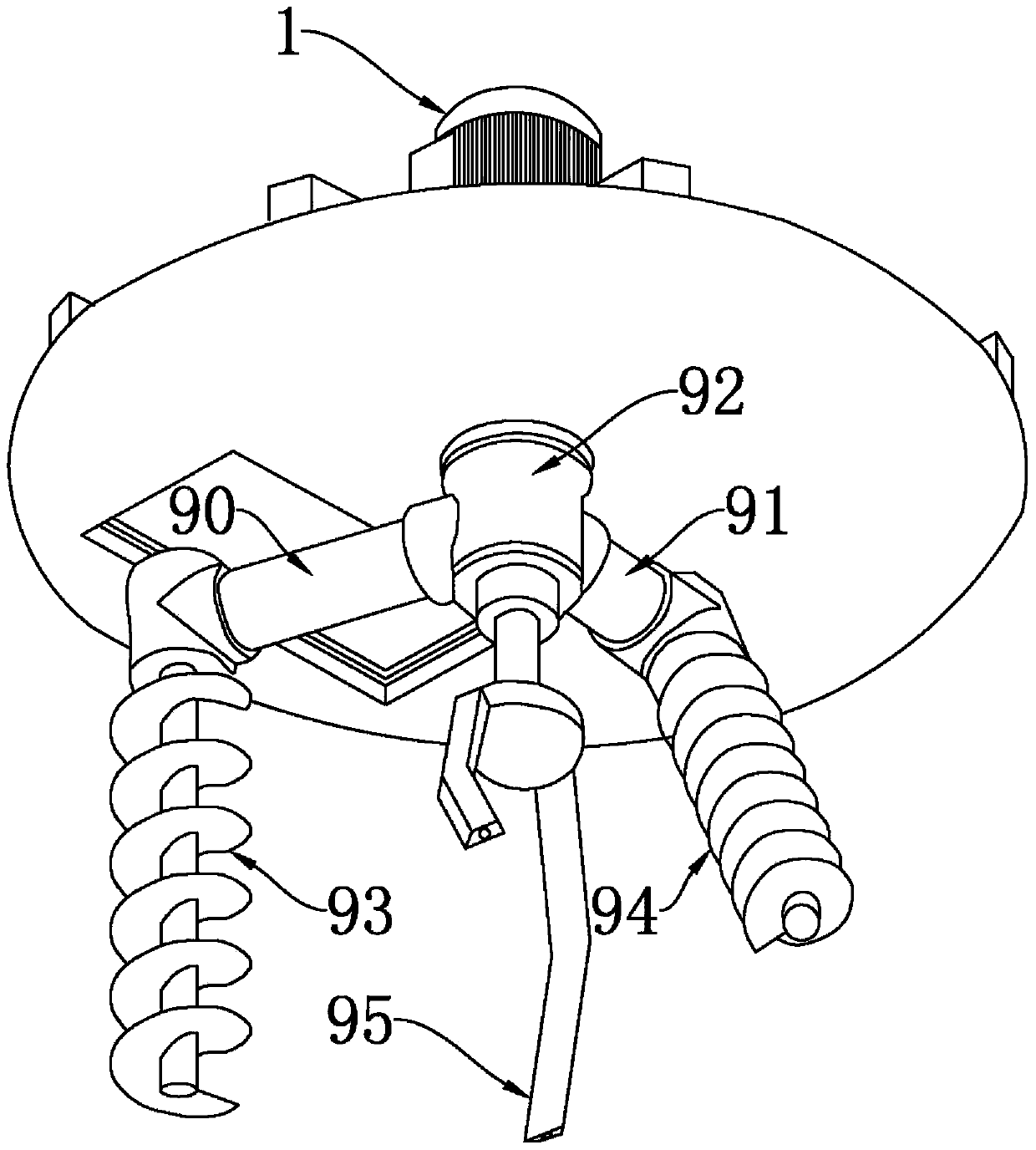

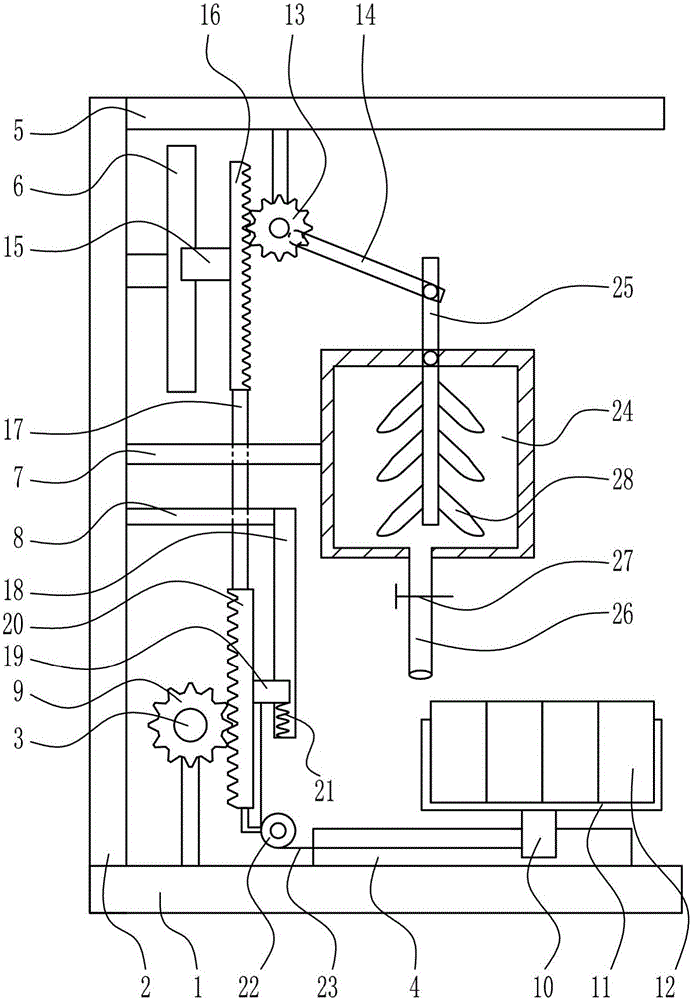

Raw material preparing and mixing machine for processing technology of polyurethane foaming plastic

InactiveCN106478908AWell mixedStir thoroughlyRotary stirring mixersTransportation and packagingPistonEngineering

The invention belongs to the technical field of polyurethane foaming plastic processing, and particularly relates to a raw material preparing and mixing machine for a processing technology of polyurethane foaming plastic. The raw material preparing and mixing machine for the processing technology of the polyurethane foaming plastic achieves the technical purposes of being uniform and thorough in stirring and mixing and high in stirring and mixing efficiency. In order to achieve the technical purposes, the raw material preparing and mixing machine for the processing technology of the polyurethane foaming plastic comprises a bottom plate, a first support rod, a collection box, a right frame, a left frame, a top plate, an installation plate, a cylinder body, a piston, a first push rod, a first spring, a pressing plate, a flexible pipe and the like. The left end of the top of the bottom plate is welded with the left frame, and a fixed plate is connected with the upper portion on the right side of the left frame through bolts. According to the machine, an electric reel is controlled to rotate clockwise or anticlockwise, a rack is pulled by a guy wire, the rack is matched with a gear, and mixing blades are driven to rotate clockwise or anticlockwise.

Owner:WUXI TONGXIN PLASTIC PROD

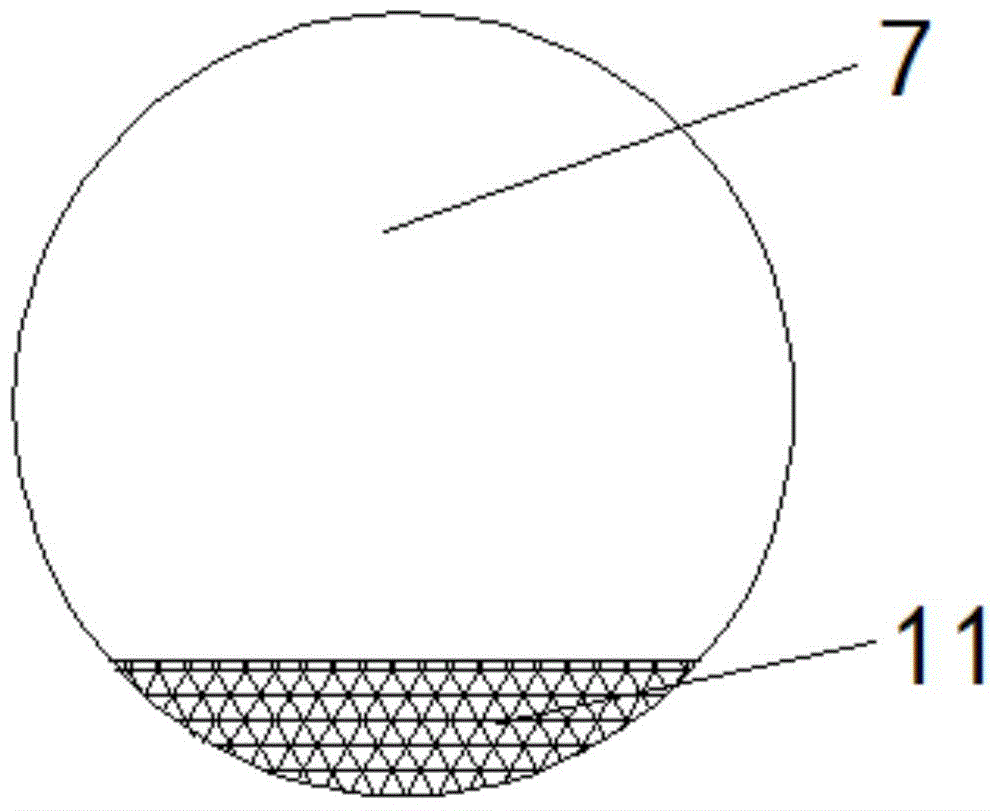

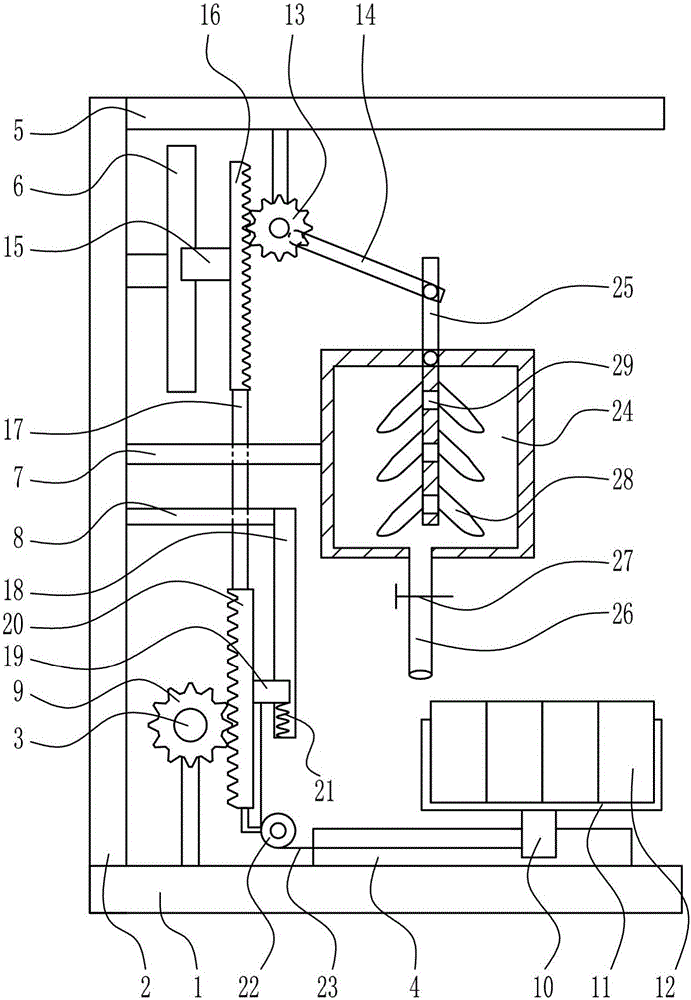

Medical and chemical crushing and stirring machine applicable to processing of paste

InactiveCN104785140AImprove the effectStir thoroughlyRotary stirring mixersGrain treatmentsEngineeringLarge particle

The invention discloses a medical and chemical crushing and stirring machine applicable to processing of paste. The crushing and stirring machine comprises a liquid outlet, a stirring box, stirring blades, a liquid inlet pipe, a gauge, a first center shaft, a filter net, a feeding port, a stirring motor, a residue discharging pipe, a second center shaft, a crushing box, a base plate, grinding balls, a lifting device and a base, wherein the stirring box and the crushing box are connected through the residue discharging pipe in the middle, the first center shaft connected with the stirring motor in a support at the top of the stirring box is arranged in the stirring box, the stirring blades are arranged at the bottom of the first center shaft, the feeding port, the liquid inlet pipe and the liquid outlet are also arranged on the stirring box, the second center shaft connected with a crushing motor in a support at the top of the crushing box is arranged in the crushing box, and the bottom of the second center shaft is connected with the base plate. The crushing and stirring machine is reasonable in design, convenient to use, capable of filtering, grinding and crushing larger particles of medicines and chemical raw materials and particularly applicable to production of pasty medicines and chemical raw materials.

Owner:CHENGDU GUANYU TECH

Stirring device for building materials

The invention relates to the technical field of processing of building materials and particularly relates to a stirring device for the building materials. The stirring device comprises a stirring shaft and a rotary blade arranged on the stirring shaft, wherein a plurality of limiting seats sleeve and are fixed on the stirring shaft; the rotary blade is fixedly connected with the stirring shaft by the limiting seats and extends outwards to form a sector shape; the side surface of the rotary blade is a plane and is parallel to the axis of the stirring shaft; a flexible rubber piece is fixed on the outer edge of the rotary blade, and is fixed with the rotary blade by a rivet; and a plurality of through holes are uniformly distributed on the rotary blade at intervals. The stirring device adopting the technical scheme has the advantages of convenience in installation and disassembly, good stirring effect and long service life.

Owner:CHONGQING JUKANG BUILDING MATERIAL

Mixing mechanism

InactiveCN103285761AStir wellStir thoroughlyMixing methodsRotary stirring mixersEconomic benefitsEngineering

The invention relates to a mixing mechanism which comprises a shell with an opening in the upper end, a mixing shaft arranged in the shell, and a motor connected with the mixing shaft, wherein a plurality of rows of bulge groups are arranged on the mixing shaft, each row of bulge group comprises at least two bulges, and a mixing blade group is detachably connected to the mixing shaft between every two adjacent bulge groups and comprises two reversely-arranged mixing blades. The mixing mechanism is simple in structure and convenient to use; through arranging the plurality of rows of bulges groups and the mixing blade groups, materials in the shell are uniformly and thoroughly mixed; the mixing blade groups can be dismantled from the mixing shaft so as to be conveniently replaced, thus the cost is saved, and good social and economic benefits are obtained.

Owner:广州金霖塑胶制品有限公司

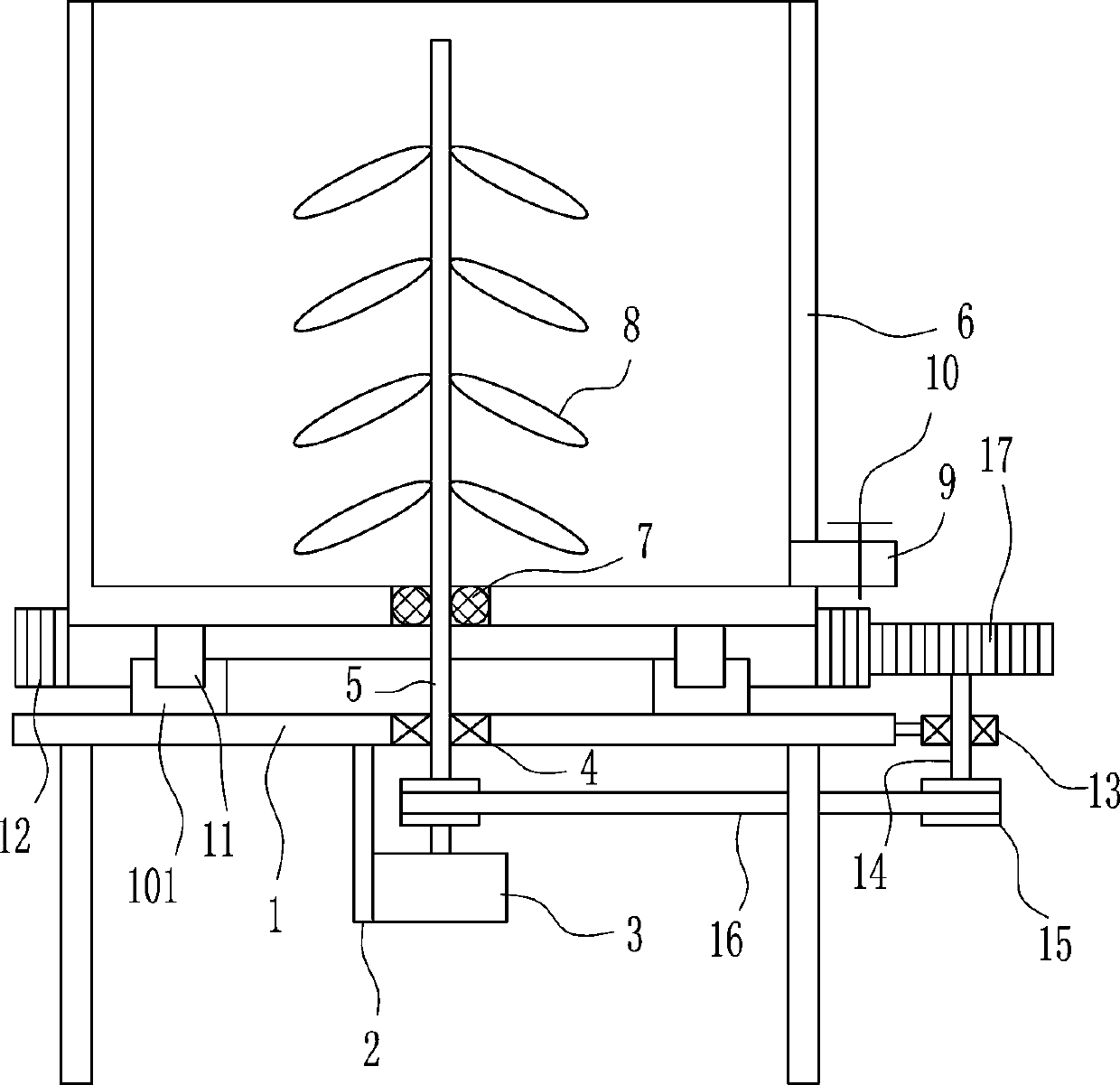

Stirring equipment of plant protecting unmanned aerial vehicle for spraying pesticide

InactiveCN107469681AImprove distributionReduce wasteAircraft componentsRotary stirring mixersToxic gasPulp and paper industry

The invention relates to pesticide stirring equipment and particularly relates to stirring equipment of a plant protecting unmanned aerial vehicle for spraying a pesticide, which has time- and labor-saving effects, stirs the pesticide sufficiently and thoroughly, and prevents people from inhaling toxic gas in the stirring process. In order to solve the technical problems, the stirring equipment comprises a bottom plate, a bracket, a connecting plate, a stirring box and the like; the left side of the top of the bottom plate is connected to the bracket by way of bolt connection, and the right side of the upper portion of the bracket is connected to the connecting plate by way of bolt connection. A first stirring device is driven by the driving device to stir the pesticide and clean water. The stirring equipment is also provided with an air stirring device, so that the pesticide and clean water stirring effect is further improved, and the effects that the stirring equipment has time- and labor-saving effects and stirs the pesticide sufficiently and thoroughly, and people are unlikely to inhale toxic gas in the stirring process are achieved.

Owner:陈建福

High-performance uniform-mixing equipment for anti-corrosive materials

PendingCN106362635AExtended service lifeStir wellShaking/oscillating/vibrating mixersRotary stirring mixersEngineeringCam

The invention relates to uniform-mixing equipment for anti-corrosive materials, in particular to high-performance uniform-mixing equipment for the anti-corrosive materials. The high-performance uniform-mixing equipment for the anti-corrosive materials is uniform and thorough in stirring and high in uniform-mixing efficiency. The high-performance uniform-mixing equipment for the anti-corrosive materials comprises a bottom plate, a left frame, a right frame, a first spring, a first supporting rod, a first sliding rail, first sliding blocks, a mixing frame, a discharging pipe, a valve, a cam, a first bearing pedestal and others; the left frame is welded to the left end of the top of the bottom plate, the first spring is symmetrically connected to the lower portion of the right side of the left frame through a hook, and the first support rod is symmetrically welded to the center of the top of the bottom plate. The uniform-mixing equipment for the anti-corrosive materials achieves the effects of uniform and thorough stirring and high uniform-mixing efficiency, and is reasonable in structure, low in manufacturing cost and easy to maintain, and the stability of the equipment can be kept due to reinforcing ribs.

Owner:麻城小龟龟机械科技有限公司

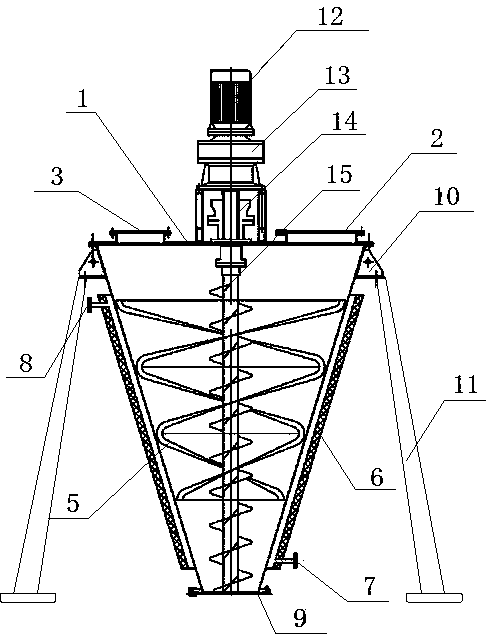

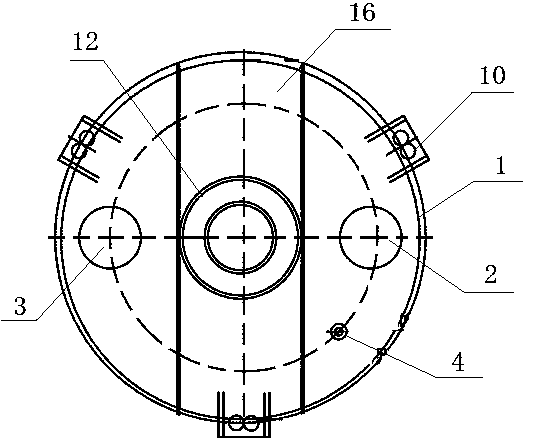

Vacuum drying mixer used for soft magnetic raw materials

InactiveCN104359291AStir thoroughlyHigh speedRotary stirring mixersMixer accessoriesEngineeringThermal water

The invention discloses a vacuum drying mixer used for soft magnetic raw materials. The vacuum drying mixer comprises a drying mixer body, a powder inlet, a powder outlet, an air inlet, a transmission component, a vacuum orifice and mixing blades, wherein the drying mixer body is an inverted cone platform body, a double-layer hollow jacket body is wrapped outside the inverted cone platform body, and a hot and cold water inlet and a hot and cold water outlet are formed in the double-layer hollow jacket body; the powder inlet, the air inlet, the transmission component and the vacuum orifice are respectively mounted on the upper end face of the drying mixer body; the powder outlet is formed in the lower end face of the drying stirrer body; the mixing blades are mounted on the transmission component. Through the double-layer jacket body and the arranged hot and cold water inlet and hot and cold water outlet, hot water can enter for heating, and cold water can also enter for cooling; two layers of coaxial screw blades in sleeve joint are more thorough in mixing during drying and cooling, the speed is higher, time and energy sources are saved while the quality is improved, and the vacuum drying mixer is suitable for rapid mass production.

Owner:ANHUI SHOUWEN HIGH TECH MATERIALS

Efficient stirring device for aerated concrete

The invention relates to a stirring device for aerated concrete, in particular to an efficient stirring device for aerated concrete. The efficient stirring device for the aerated concrete is convenient to operate and quick and thorough in stirring. The efficient stirring device for the aerated concrete comprises a first motor, a guide sleeve, a swing base, an arc-shaped connection rod, a first sliding shaft, first sliding blocks, a first sliding rail, a first connection rod, a first moving frame, a top plate, a second moving frame, a second sliding shaft, a lifting rod, a rack and the like; and the top of a bottom plate is provided with a fixed plate, a second sliding rail and a right frame from left to right in sequence, and second sliding blocks are slidably connected to the top of the second sliding rail. The efficient stirring device for the aerated concrete achieves the effects of being convenient to operate and quick and thorough in stirring and is low in manufacturing cost, reasonable in structure, easy to maintain and repair and convenient to use, so that the investment of manpower and material resources is decreased, and the cost is reduced.

Owner:麻城小龟龟机械科技有限公司

Stirring device for glue used for electronic processing

InactiveCN110935369AStir wellStir thoroughlyShaking/oscillating/vibrating mixersTransportation and packagingReciprocating motionAdhesive glue

The invention discloses a stirring device for a glue used for electronic processing, and relates to the technical field of electric power processing. The stirring device comprises a fixed frame, wherein a stirring groove is arranged in the fixed frame; a stirring mechanism driven by a transverse translation mechanism to stir the glue in the stirring groove is arranged in the fixed frame; and a pushing mechanism used for driving the stirring groove to vertically reciprocate is arranged on the fixed frame. According to the invention, through arrangement of the stirring mechanism, the glue in thestirring groove is rotationally stirred; through arrangement of a transmission shaft, stirring blades can be driven to rotate around the rotation center of a connecting plate; meanwhile, the stirringblades can be driven to rotate around the transmission shaft; through arrangement of the transverse translation mechanism, the stirring mechanism can be driven to move back and forth at a horizontalposition, so the glue at different positions in the stirring groove can be fully stirred, and the glue is stirred more fully; and through arrangement of the pushing mechanism, the stirring groove canbe driven to reciprocate up and down relative to the stirring mechanism, so the glue is stirred fully, thoroughly and efficiently.

Owner:江西诺驰科技咨询有限公司

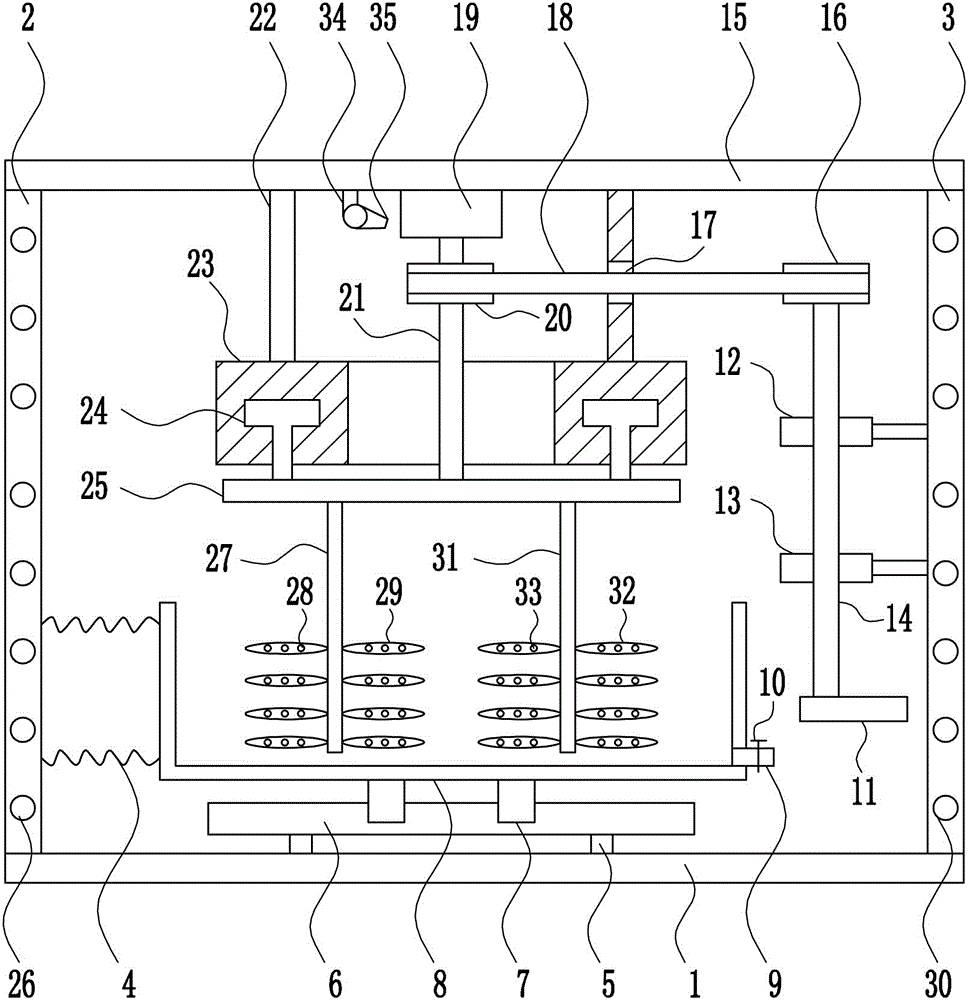

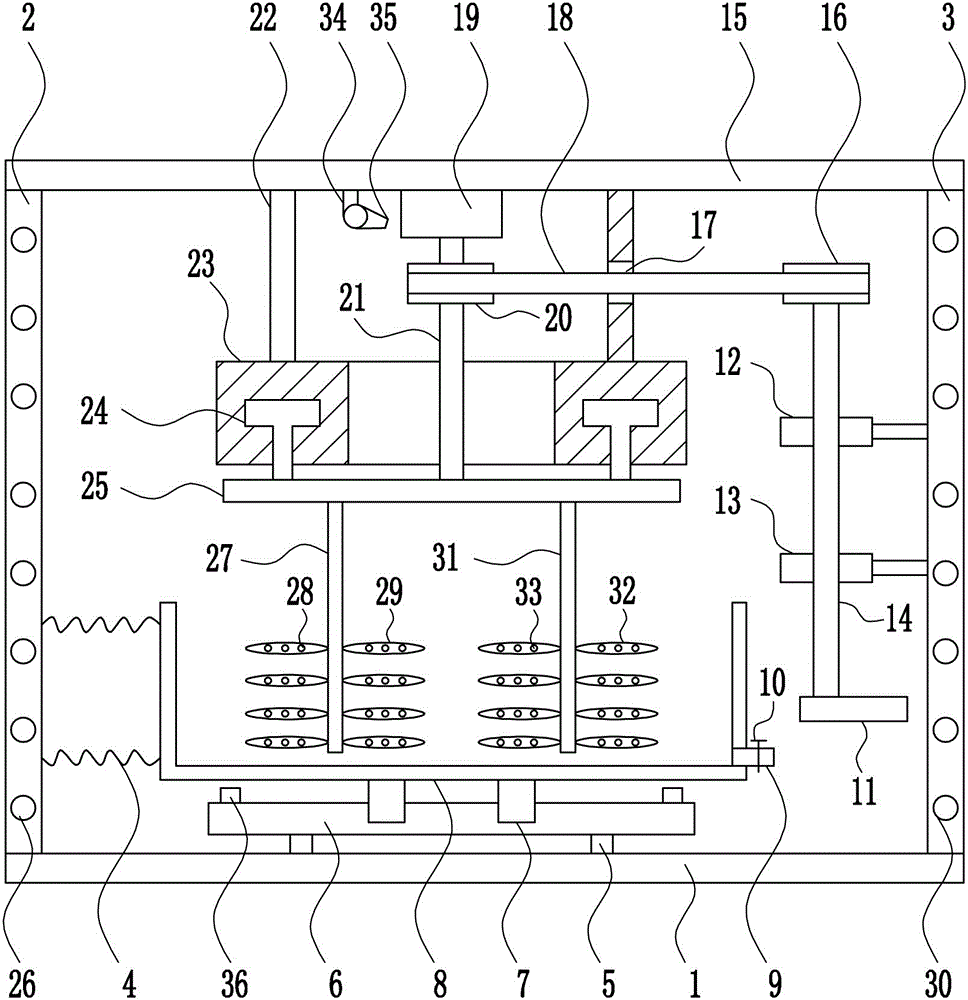

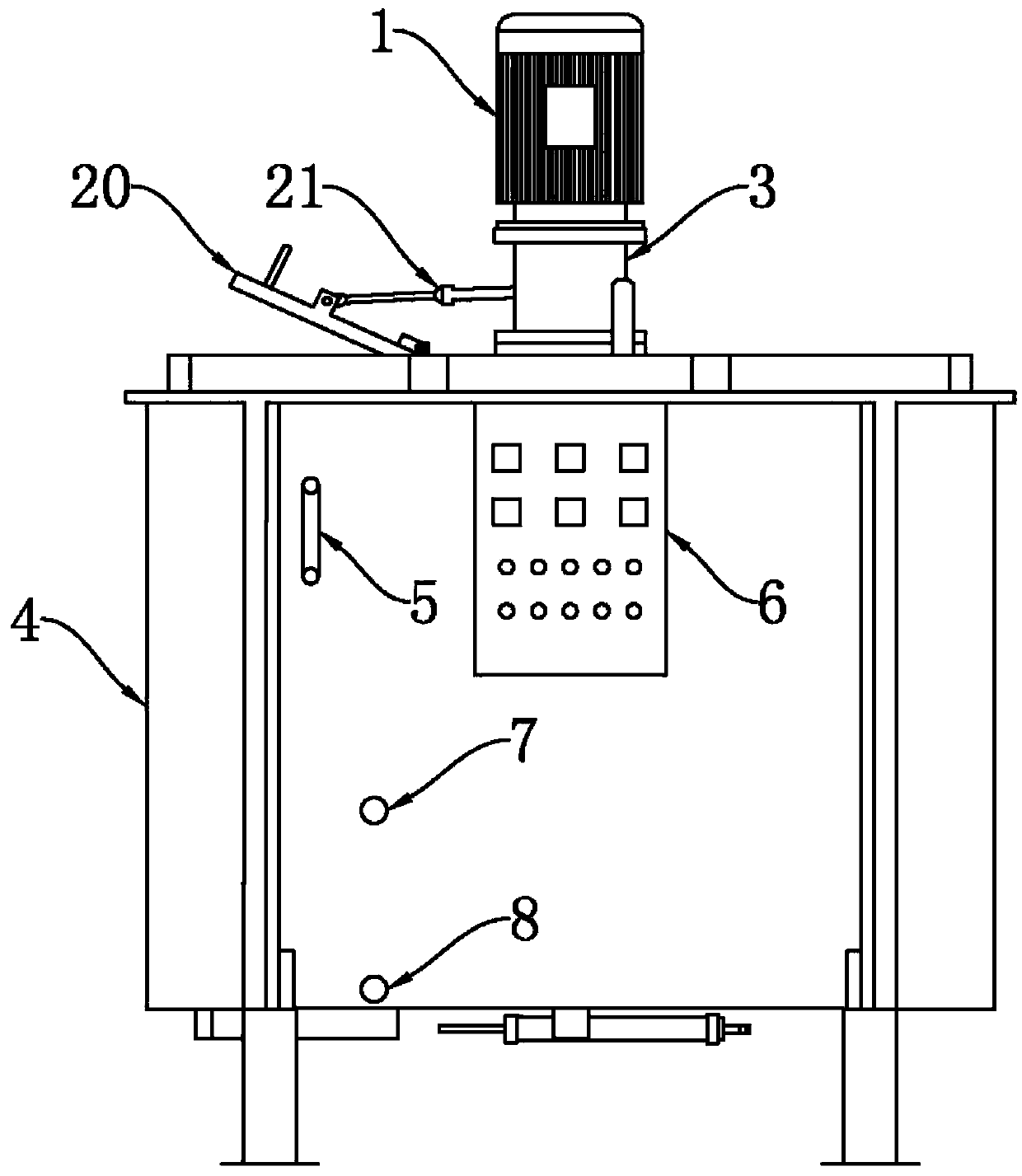

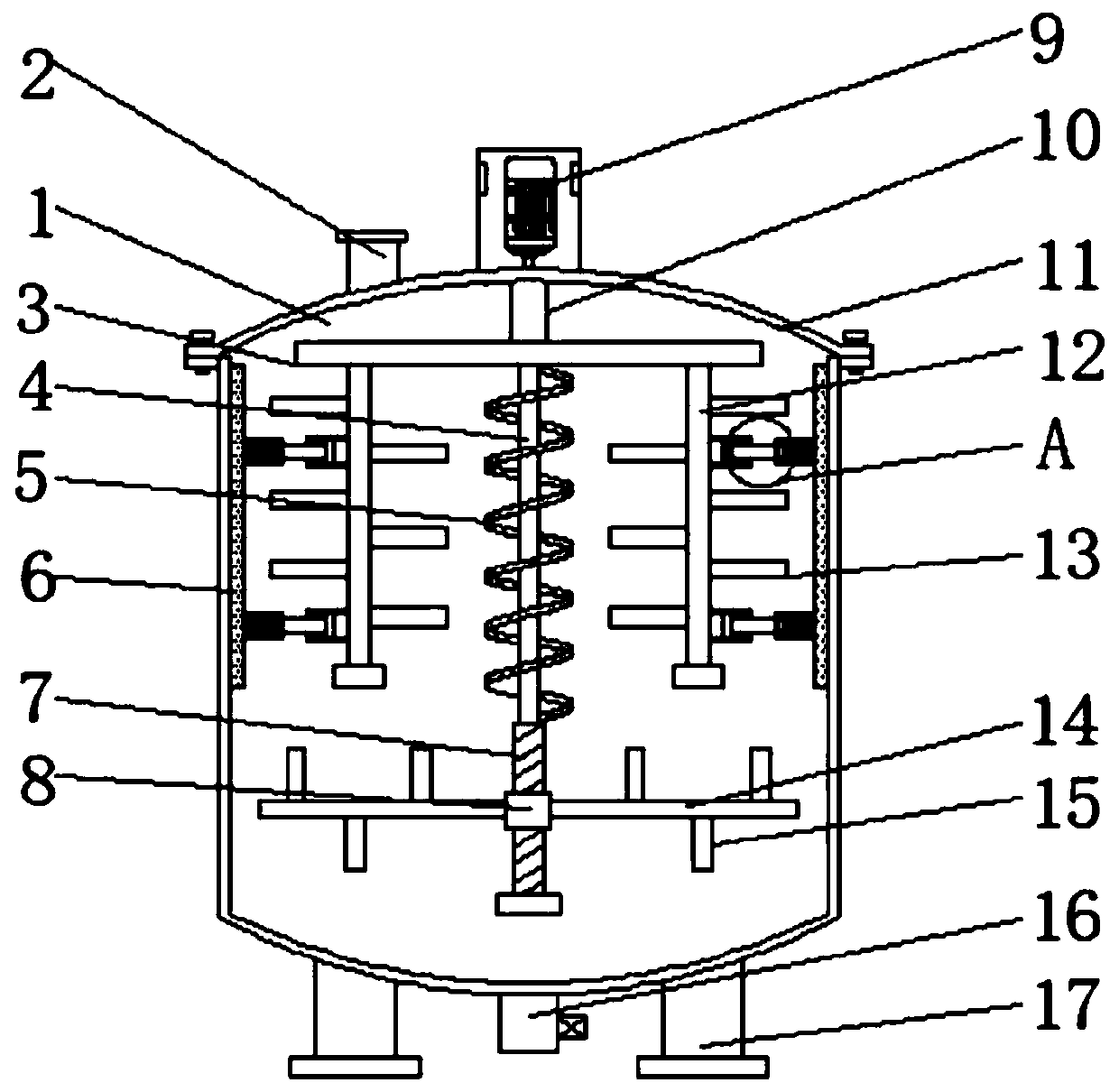

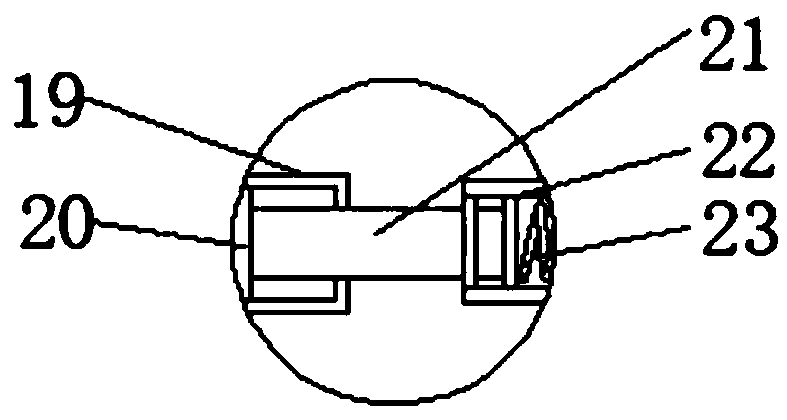

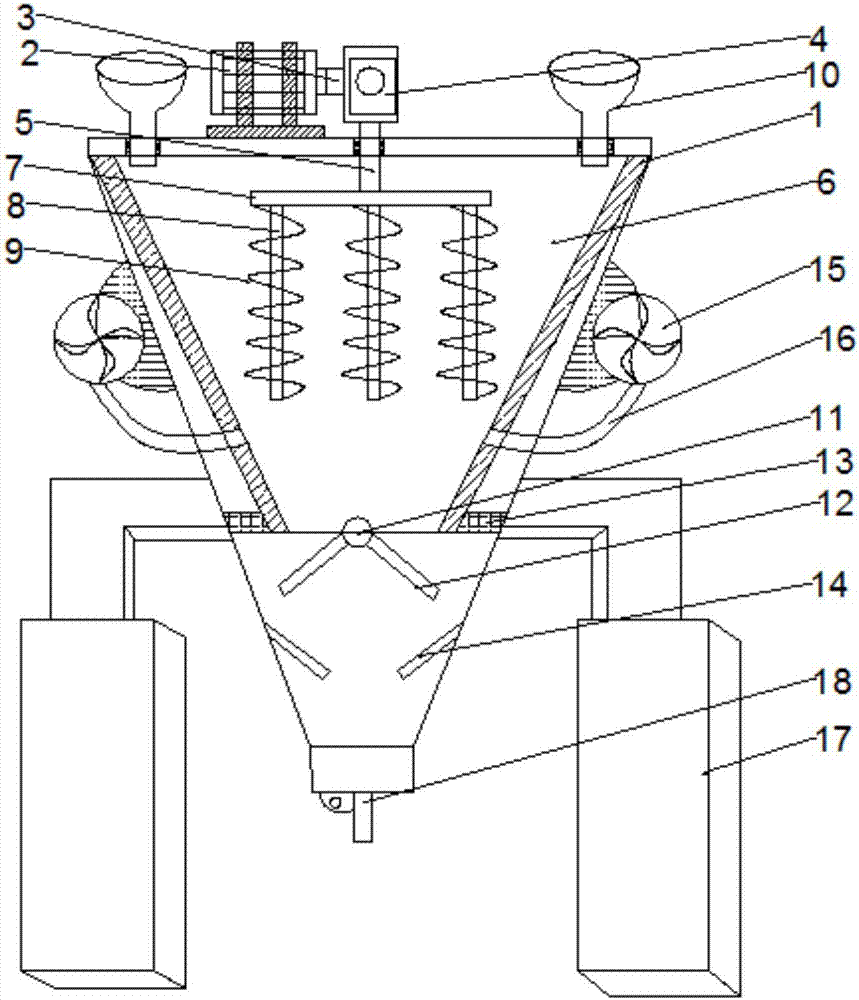

Multifunctional solid-phase saccharification and fermentation equipment

InactiveCN105505771ATake advantage ofSave resourcesBioreactor/fermenter combinationsBiological substance pretreatmentsMotor driveAgricultural engineering

The invention discloses multifunctional solid-phase saccharification and fermentation equipment. The multifunctional solid-phase saccharification and fermentation equipment comprises a housing, wherein a motor and a speed reducer are arranged on the upper side of the housing, stirring arms are arranged in the housing, the motor drives the speed reducer and the speed reducer drives the stirring arms; a feed opening is formed in the upper wall of the housing, and a discharge opening is formed in the lower wall of the housing; the motor is connected with a controller, and a liquid level instrument, a temperature sensor and a humidity sensor are mounted on the housing. The multifunctional solid-phase saccharification and fermentation equipment is improved on the basis of conventional equipment, is greatly increased in material processing quantity, has a favorable crushing and mixing function of various dry powder materials, half-wet materials and clumpy materials, is radical and non-dead-angle in stirring, can realize material sterilizing and aging according to production requirements, is wide in application range, and can meet various different fermentation conditions, such as single-strain anerobic fermentation, single-strain aerobic fermentation, multi-strain solid-phase dual-dynamic recycling fermentation, according to the fermentation conditions of various strains.

Owner:SHANDONG BAIDE BIOLOGICAL TECH

Chemical efficient stirring fermentation device

InactiveCN111378554AEfficient mixingWell mixedBioreactor/fermenter combinationsBiological substance pretreatmentsElectric machineryEngineering

The invention discloses a chemical efficient stirring fermentation device, and relates to the technical field of chemical engineering. The chemical efficient stirring fermentation device comprises a fermentation tank, wherein the top edge of the fermentation tank is in threaded connection with a cover body through a fastening bolt; one side of the top surface of the cover body communicates with afeeding pipe. The chemical efficient stirring fermentation device has the advantages that through the matching effect of a motor, a rotating rod, a rotating plate, a stirring shaft, spiral stirring blades, a first connecting rod, first stirring blades, a threaded rod, a threaded sleeve, a second connecting rod and second stirring blades, chemical raw materials can be simultaneously stirred in thevertical direction and the horizontal direction; through the mutually staggered first stirring blades and second stirring blades, the stirring of mixed materials is more sufficient and thorough; the stirring efficiency is improved; the efficient stirring is realized; through the matching effect of a fixing block, a position limiting plate, a slide rod, a connecting frame, a spring and a scraping plate, the mixed materials on the inner wall of the fermentation tank can be scraped; the utilization rate of the chemical raw materials is improved; and the purity of chemical products and the production efficiency are improved.

Owner:LIANYUNGANG JINKANG PHARMA TECH

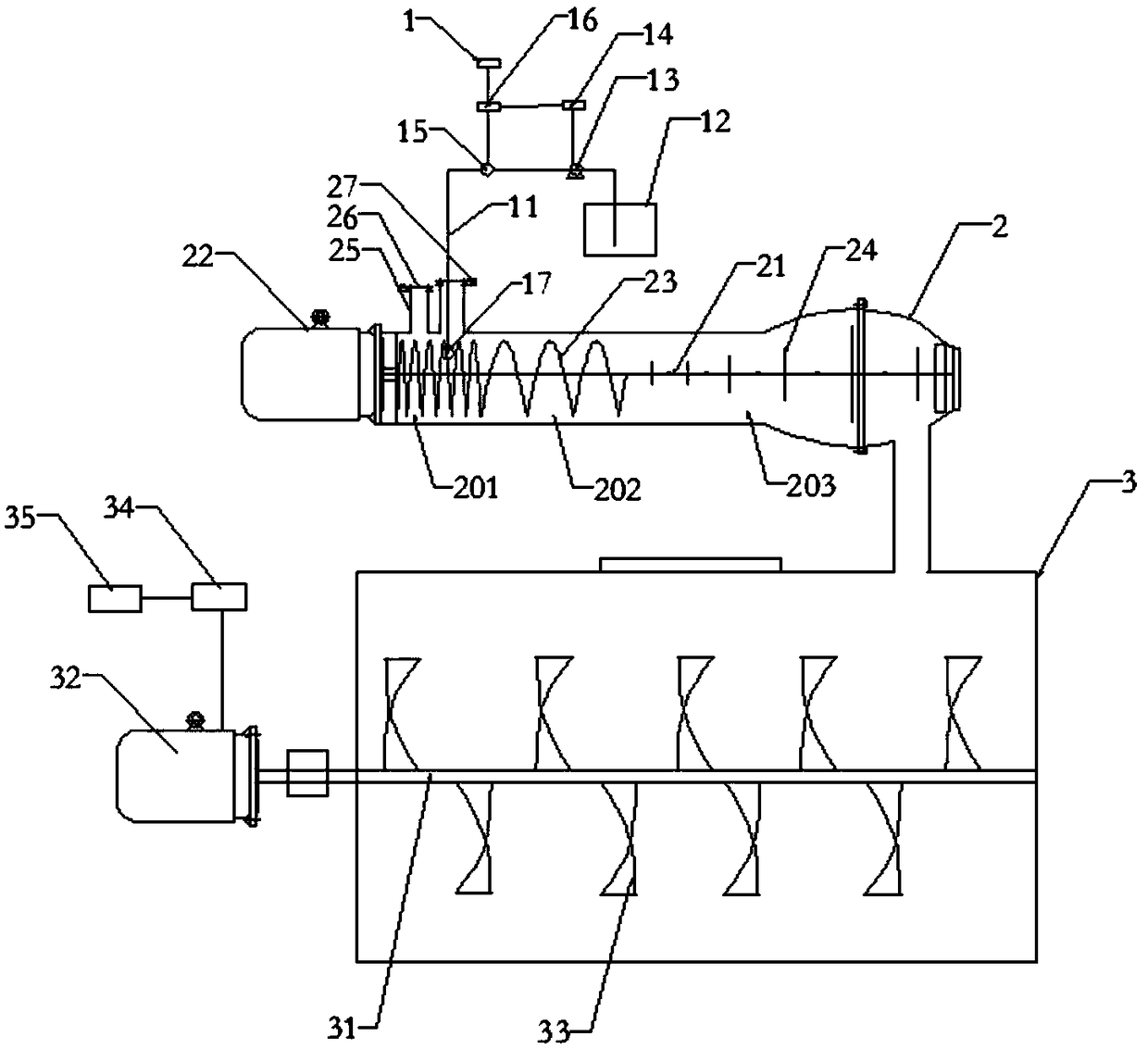

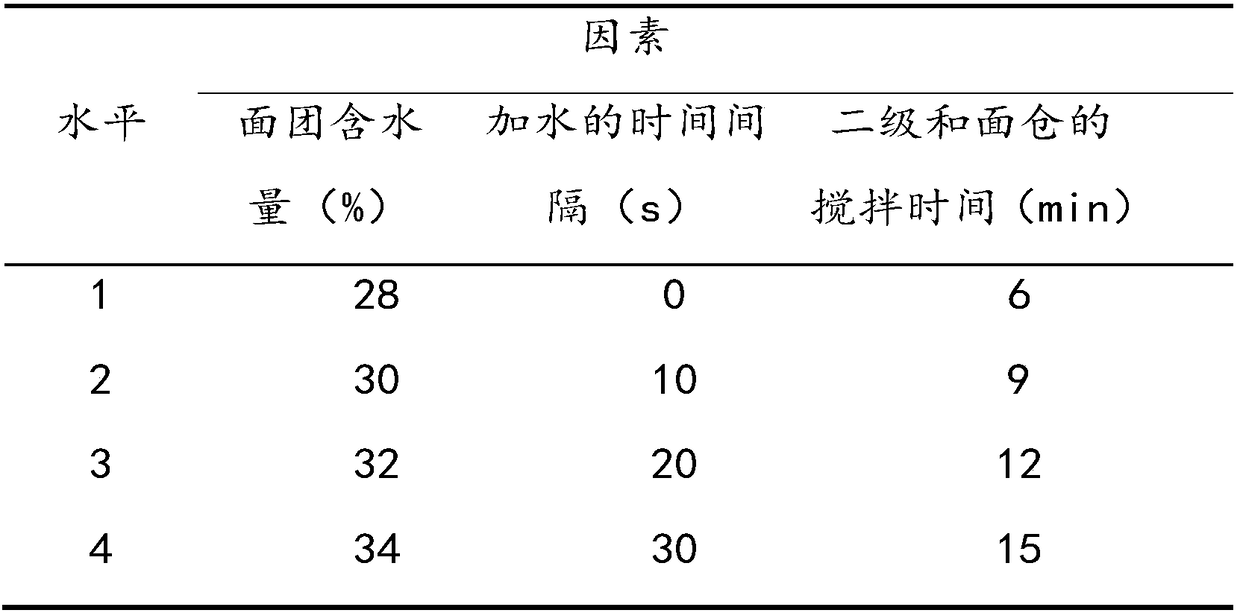

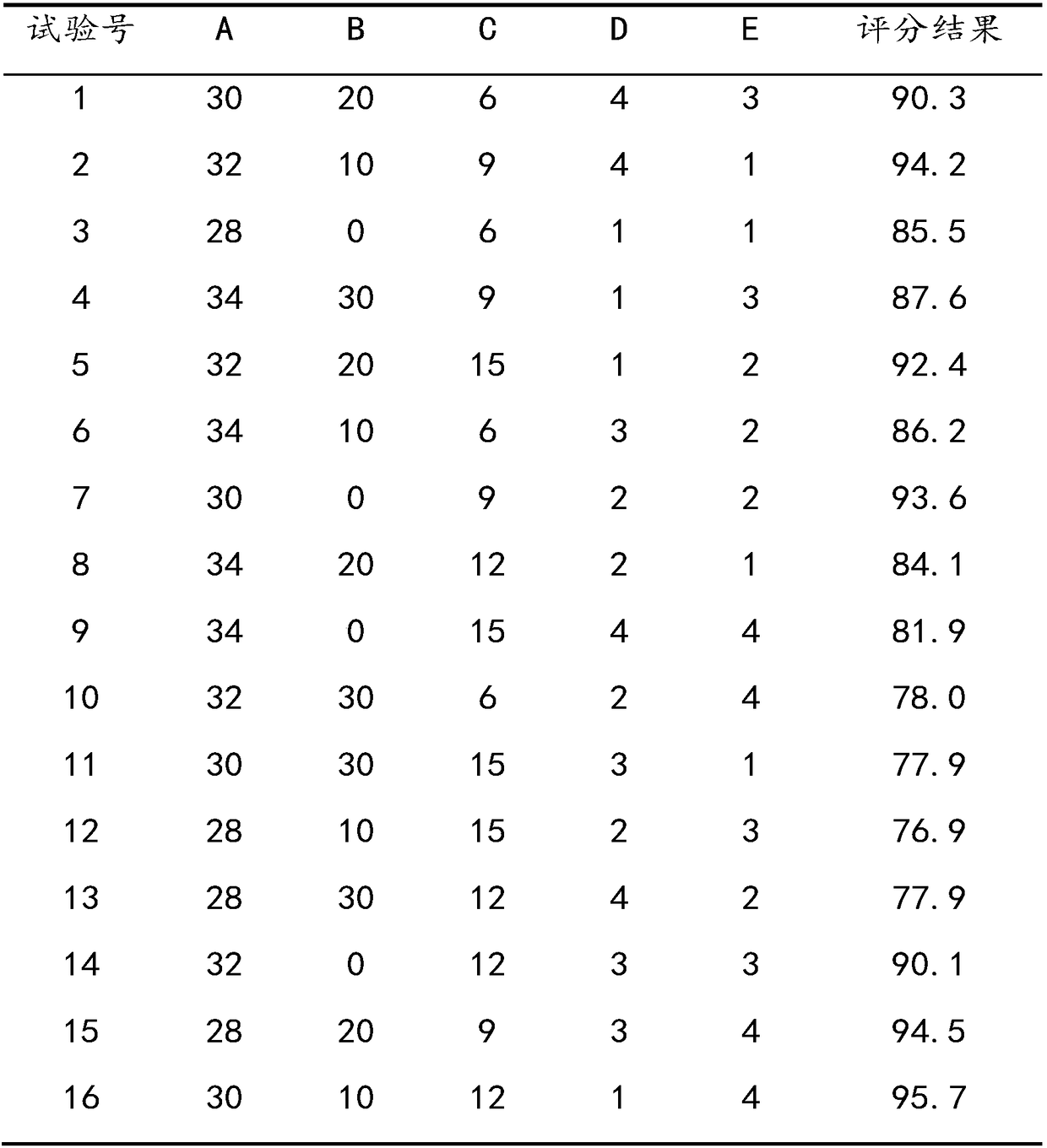

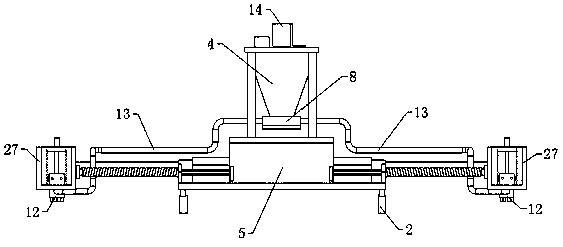

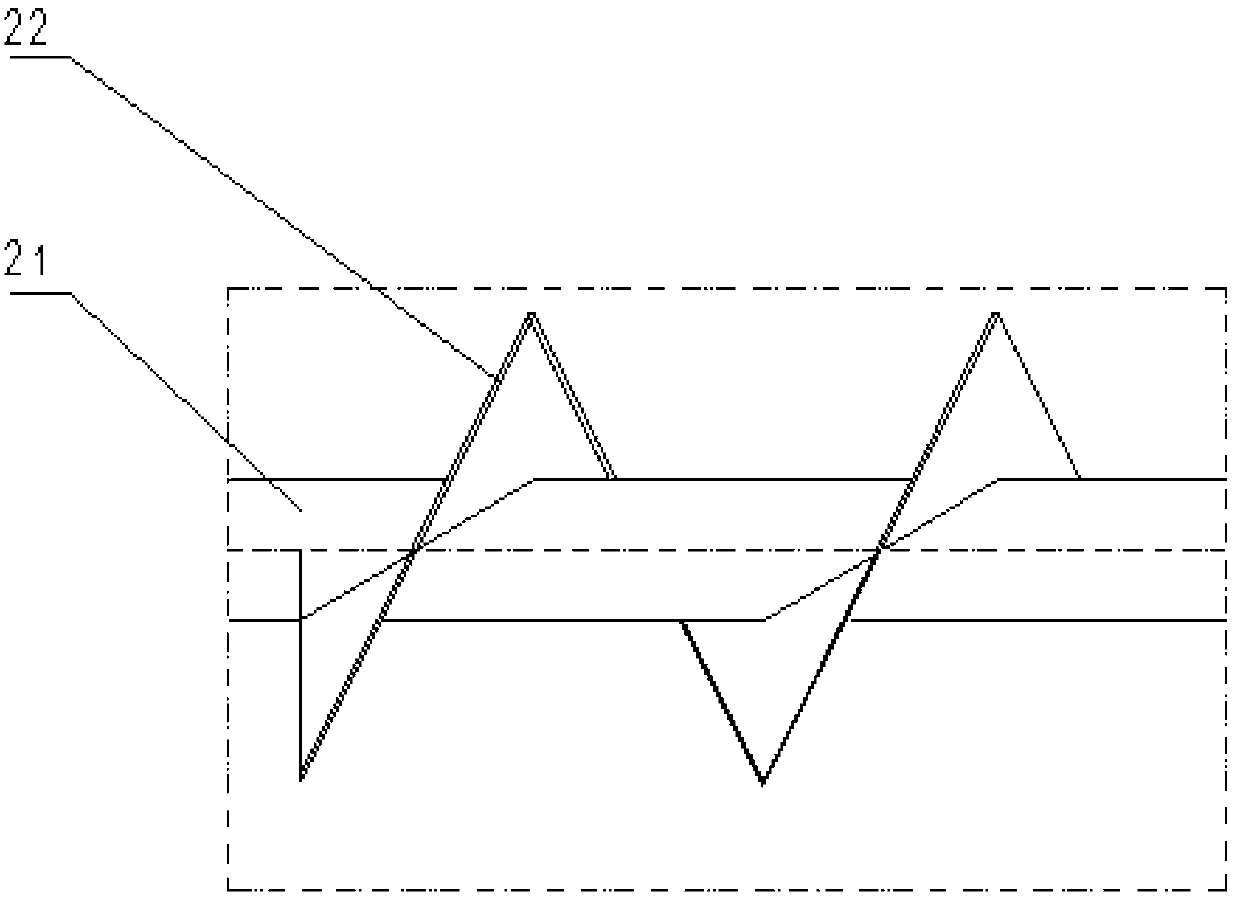

Dough kneading device, dough kneading method and noodle making machine

ActiveCN108260615AIncrease contact areaStir wellMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsGlutenPulp and paper industry

The invention belongs to the technical field of mechanical dough kneading and relates to a dough kneading device, a dough kneading method and a noodle making machine. The dough kneading device provided by the invention comprises a water supply mechanism, a primary dough kneading chamber and a secondary dough kneading chamber, wherein a first stirring shaft is arranged in the primary dough kneadingchamber, and one end of the first stirring shaft is connected with a first power mechanism; the interior of the primary dough kneading chamber is divided into three mutually communicating stirring areas, namely a first stirring area, a second stirring area and a third stirring area sequentially, paddles are arranged in the first stirring area and the second stirring area, and a stirring rod is arranged in the third stirring area; at least one material inlet is formed in the primary dough kneading chamber and the material inlet communicates with the first stirring area; and the water supply mechanism comprises a water pipe, one end of the water pipe extends into the first stirring area by virtue of the material inlet, and the water pipe at the end is connected with a water atomization device. The dough kneading device can enable wheat flour to quickly absorb water and be thoroughly mixed with water and is helpful to form dough with proper expansion of gluten, loos particles and uniformcolor for high quality fine dried noodles.

Owner:想念食品股份有限公司

Marking device for road paving

The invention relates to the field of road engineering, in particular to a marking device for road paving. The marking device comprises a mobile bottom plate and also comprises a stirring mechanism and a double-side marking mechanism. The bottom of the mobile bottom plate is provided with four swivel wheels; the stirring mechanism comprises a supporting platform and a stirring tank; the stirring tank is fixedly connected to the top of the supporting platform through a second support frame; the top of the stirring tank is provided with a feeding pipe; the bottom of the stirring tank is providedwith a material guiding pipe; the double-side marking mechanism comprises a synchronous driving assembly, two telescopic assemblies and two lifting and marking assemblies; each of the lifting assemblies comprises a spraying pipe capable of lifting and lowering; working ends of the spraying pipes are arranged downwards; and the inner ends of the spraying pipes are separately and fixedly connectedto the material guiding pipe through guiding hoses. The marking device for road paving can simultaneously perform marking on two sides of a road, and perform adjustment according to the width of the road. Through the cooperation with stirring, the marking device can prevent powder from knotting and improve the clarity of markings.

Owner:倪晋挺

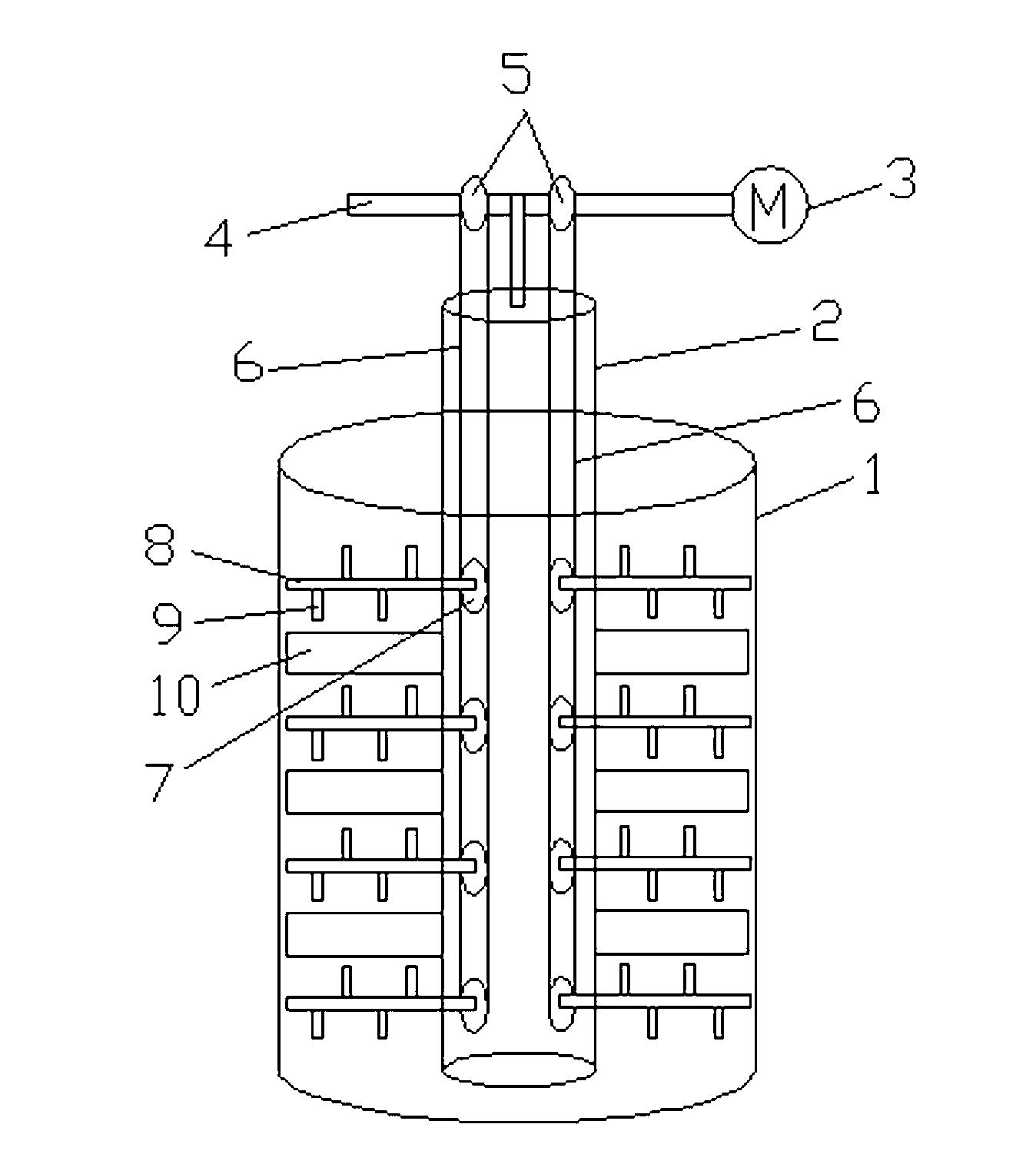

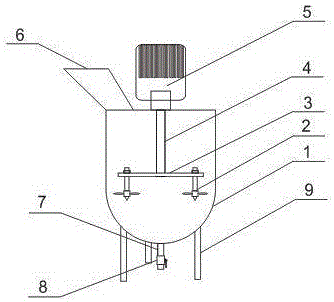

Mixing and stirring tank

InactiveCN103100333AStir thoroughlyImprove the mixing effectRotary stirring mixersBiochemical engineeringMixing effect

The invention discloses a mixing and stirring tank which comprises a tank body, a main vertical stirring device and a stirring motor, wherein a stirring blade at the lower end of the main stirring device is positioned in the tank body; the other end of the main stirring device is connected with the stirring motor outside the tank body; one or more transverse auxiliary stirrers are arranged in the tank body; and one ends of the auxiliary stirrers are connected with a spindle of the main stirring device trough a gear, and the other ends of the auxiliary stirrers are connected to the tank body through a bearing. According to the device, materials can be rotated and mixed in the tank body in the horizontal direction and can be further turned and mixed up and down, so that the materials are stirred more fully and completely, and the mixing effect is obviously improved.

Owner:YIXING JUNDA SLURRY TECH

Novel building material processing powder mixer

InactiveCN107138091AStirring speed is fastIncrease productivityTransportation and packagingMixer accessoriesEngineeringAir blower

The invention discloses a novel building material processing powder mixer comprising a mixer body which takes the shape of a cone, wherein a motor is arranged at the top of the mixer body, and connected with a differential mechanism via a power rod; the differential mechanism is connected with an inner mixing cavity of the mixer body via a rotation shaft; the rotation shaft is connected with three stirring rods via sub-rotation rods; a spiral plate is arranged around each of the three stirring rods; feeding funnels are arranged at twp ends of the top of the inner mixing cavity in a penetrating manner; a hinge rotation shaft is arranged at the middle of the bottom of the inner mixing cavity, closing plates are arranged on two sides of the hinge rotation shaft; electromagnets are arranged on the upper sides of the closing plates; baffle plates are arranged on the lower sides of the closing plates; air blowers are symmetrically arranged on two sides of the outside of the mixer body, and connected with the inner mixing cavity of the mixer body via air pipes; a telescopic support pillar is arranged on the lower side of the air blowers. Therefore, powder can be uniformly mixed, and the outflow speed of the powder can be reduced.

Owner:安徽新兴翼凌机电发展有限公司

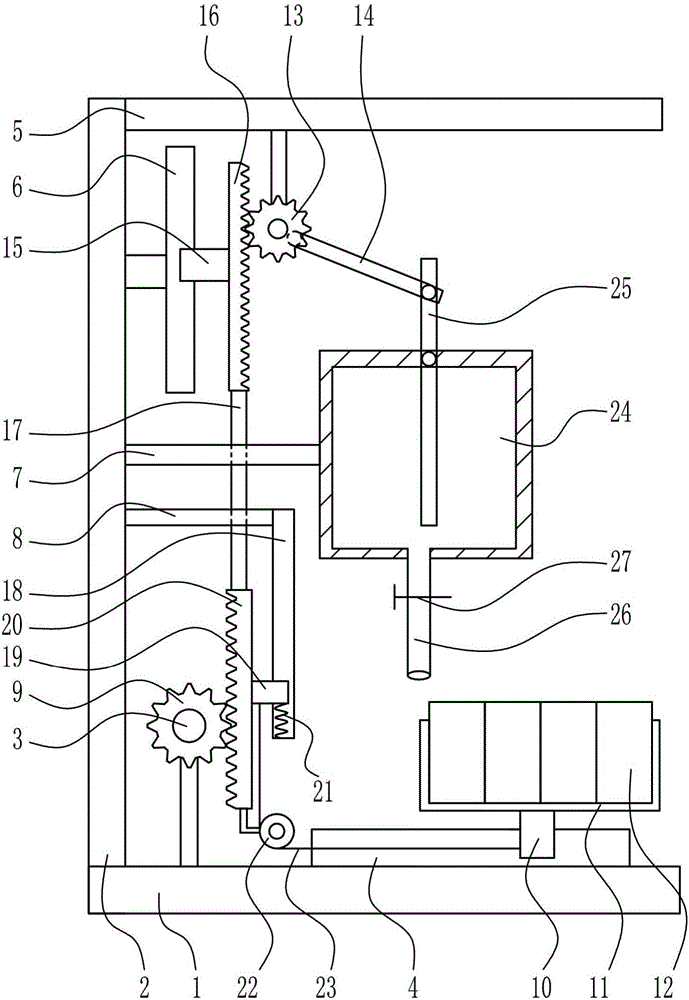

Environment-friendly movable sampling device for industrial wastewater

ActiveCN106644581AReduce resistanceStir thoroughlyWithdrawing sample devicesIndustrial effluentEngineering

The invention relates to a sampling device and particularly relates to an environment-friendly movable sampling device for industrial wastewater. The environment-friendly movable sampling device for the industrial wastewater has the beneficial effects that the sampling effect is good, the sampling speed is high, and the sampling is accurate. The environment-friendly movable sampling device for the industrial wastewater comprises a base, a left side plate, a speed reduction motor, a first slide rail, a top plate, a third slide rail, a first transverse plate, a second transverse plate, a first gear, a first side block, a placement frame and the like, wherein the top plate, the third slide rail, the first transverse plate and the second transverse plate are sequentially arranged on the right side of the left side plate from top to bottom, the first gear is connected to the rear side of the speed reduction motor, and the first slide block is connected to the first slide rail in a sliding manner. According to the environment-friendly movable sampling device, fan-shaped stirring blades are adopted, multiple first holes are formed in a stirring rod, and an electromagnet, an iron block, a second spring and a rubber pad are arranged in a placement platform.

Owner:常州润成环境科技有限公司

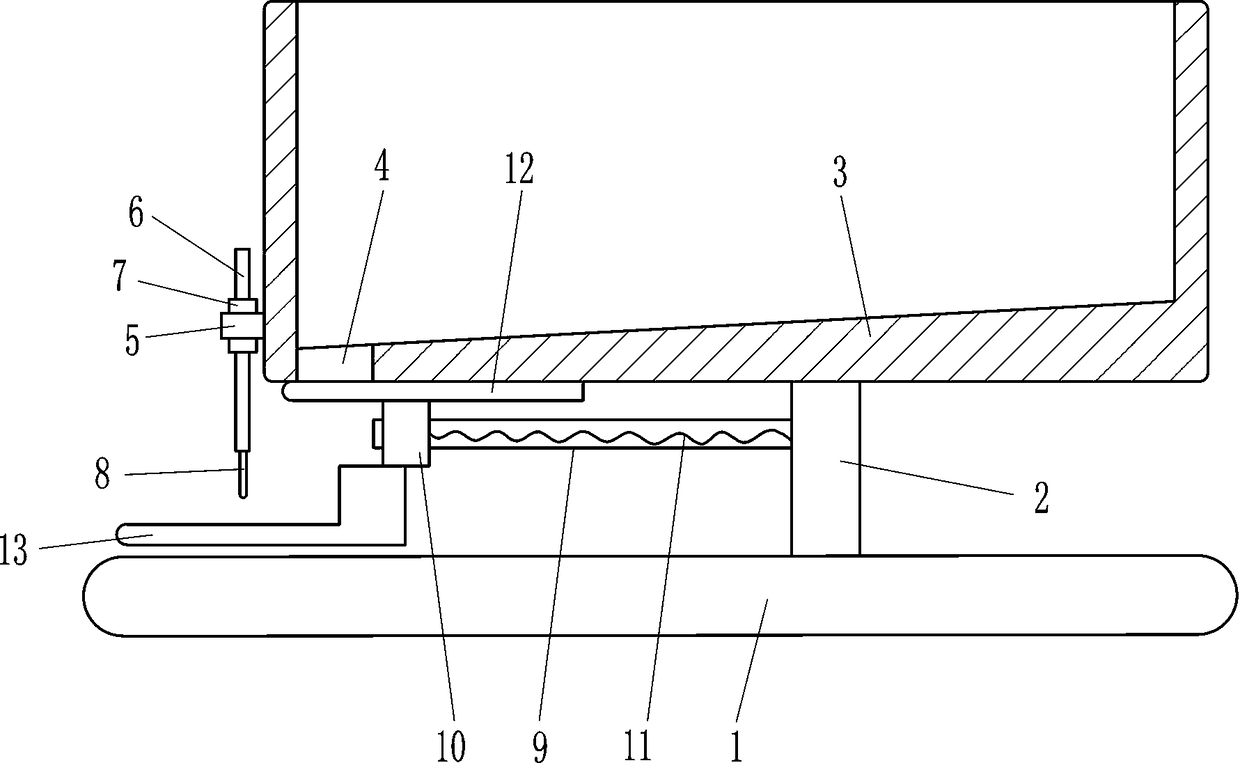

Equipment for applying cement on back face of ceramic tile for building construction

ActiveCN108868072AStir thoroughlyPrevent solidificationBuilding constructionsMaterials scienceCement

The invention relates to cement applying equipment, in particular to equipment for applying cement on the back face of a ceramic tile for building construction. The to-be-solved technical problem is to provide equipment for applying cement on the back face of a ceramic tile for building construction capable of being operated simply and easily, saving manpower, applying the cement more uniformly. According to the technical scheme, the equipment for applying the cement on the back face of the ceramic tile for the building construction comprises a base, a supporting rod, a frame body, a circularring, a first bolt, a nut, a push plate, a sliding rail and the like; the right portion of the upper side of the base is provided with the supporting rod, the top of the supporting rod is provided with the frame body, the left side of the bottom of the frame body is provided with a through hole, the lower portion of the outer wall of the left side of the frame body is provided with the circular ring, the circular ring is internally provided with the nut, the nut is internally in threaded connection with the first bolt, and the lower end of the first bolt is provided with the push plate. The equipment for applying the cement on the back face of the ceramic tile for the building construction has the advantages that the push plate is arranged, so that when a baffle plate and an L-shaped placement plate move leftward, the push plate can apply the cement on the back face of the ceramic tile more uniformly, thereby achieving the effects that the operation is simple and easy and saves labor and the cement can be applied uniformly.

Owner:徐州凯全特建筑新材料有限公司

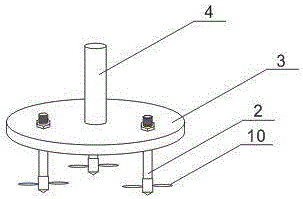

Stirring device

Owner:SUZHOU JINXIANG TITANIUM EQUIP

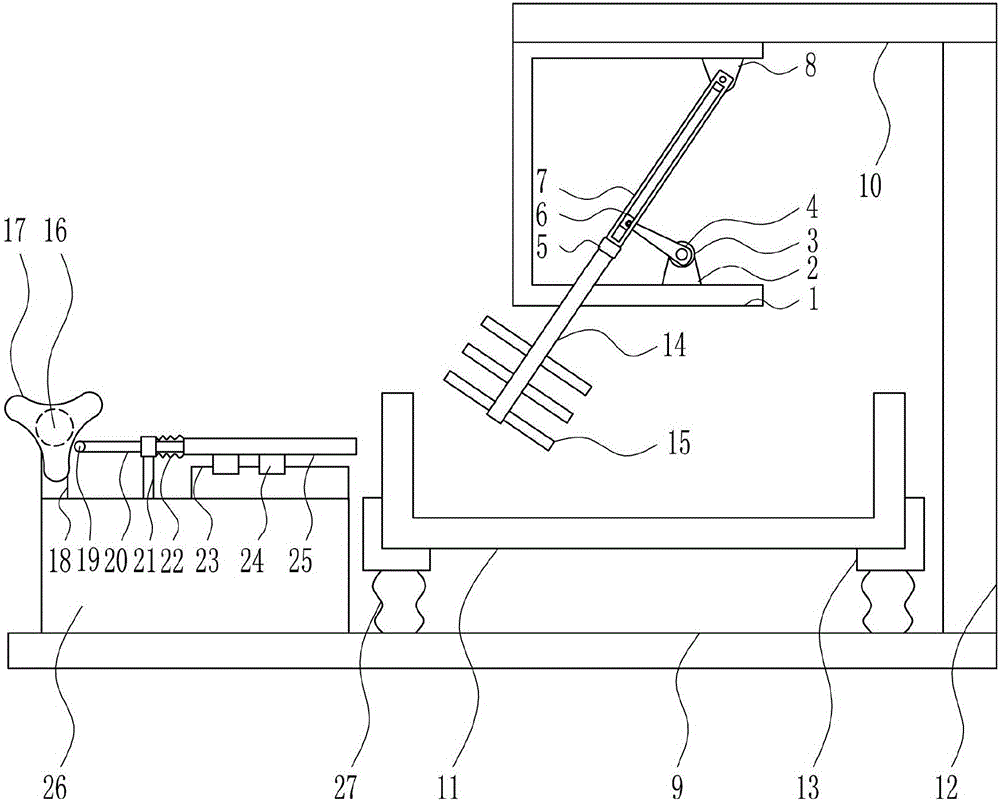

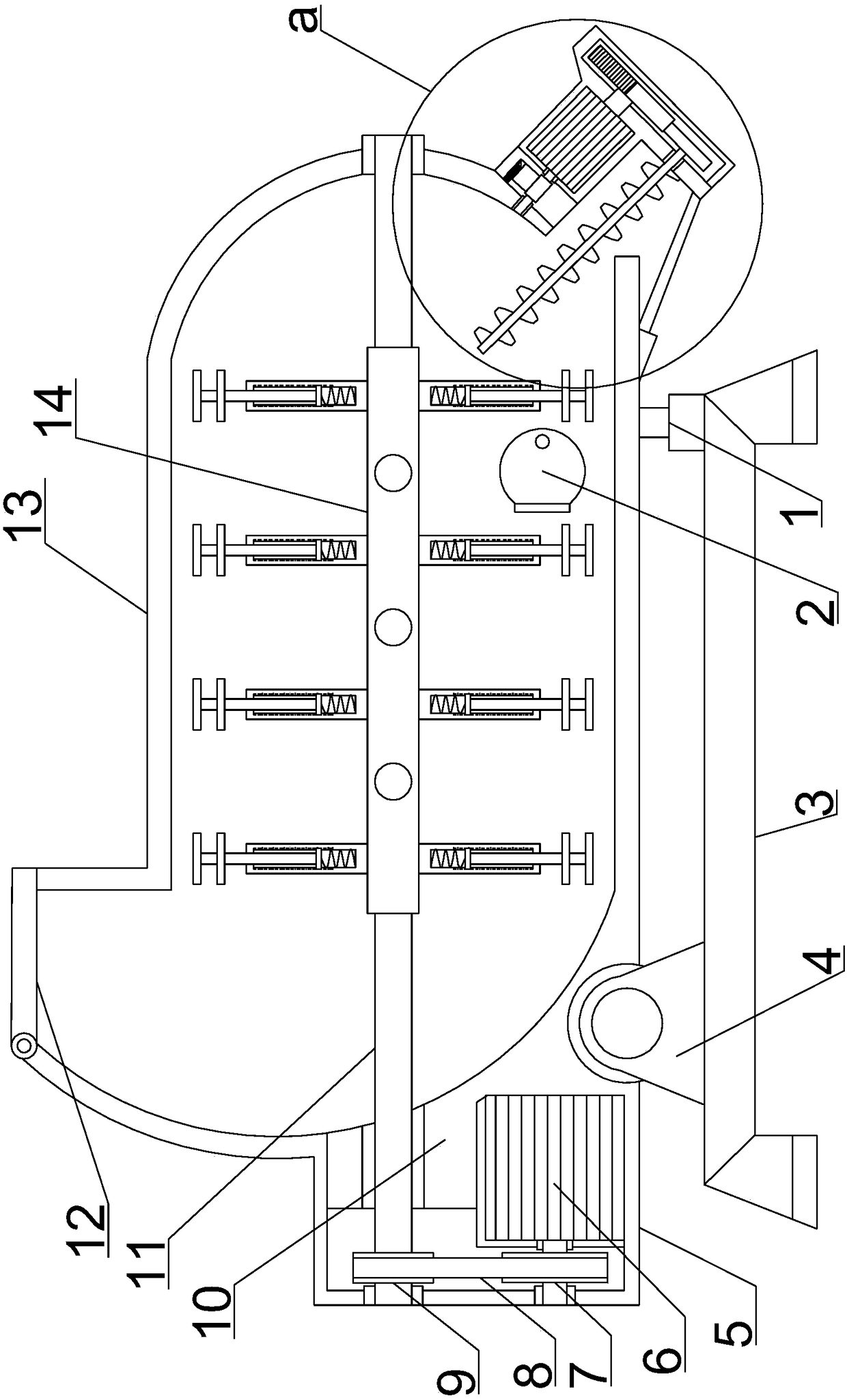

Vibrating feed efficient stirring device for animal husbandry

InactiveCN106311052AEasy to operateEasy to useShaking/oscillating/vibrating mixersTransportation and packagingEngineeringCam

The invention relates to a feed stirring device, in particular to a vibrating feed efficient stirring device for animal husbandry. The vibrating feed efficient stirring device is convenient to operate and quick and thorough in stirring and comprises a mounting frame, a mounting seat, a first motor, a crank, a second motor, a first slider, a hollow-square sliding rail, a swing seat, a baseplate, a top plate, a stirring frame, a right frame, a fixed block, a rotating rod, a third motor, a disc-shaped cam, a supporting rod, a roller, a moving rod, a guide sleeve, a first spring and a second sliding rail, and a placement block is arranged on the left side of the top of the baseplate. The vibrating feed efficient stirring device has the advantages of convenience in operation and quickness and thoroughness in stirring and is low in manufacturing cost, reasonable in structure, easy to maintain and repair, convenient to use, time-saving, labor-saving and capable of effectively improving working efficiency.

Owner:潘李秀

Stirring device

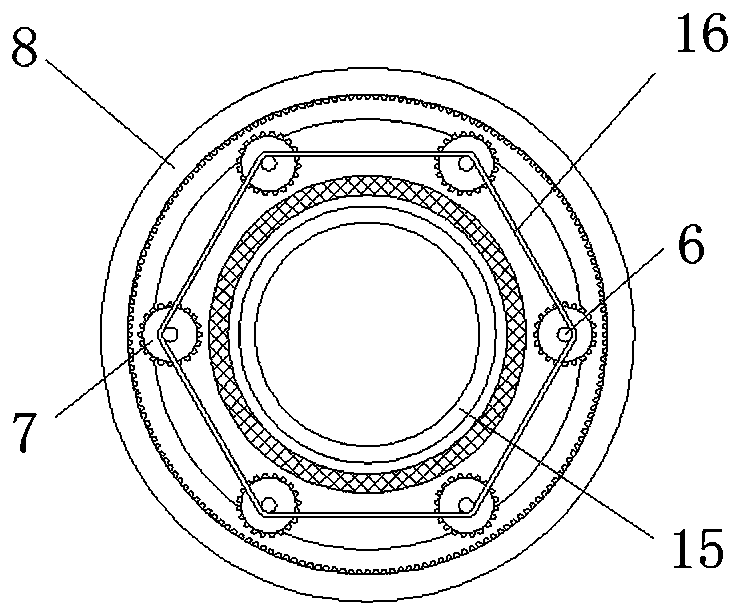

InactiveCN108295737ASimple structureStir thoroughlyShaking/oscillating/vibrating mixersTransportation and packagingSpur gearPlinth

The invention discloses a stirring device which comprises a circular base, wherein a stirring bucket is connected with the top of the circular base; a first annular groove is formed in the top of thecircular base around the stirring bucket; a sliding ring is arranged inside the first annular groove; a second annular groove is arranged at the outer ring of the sliding ring; a plurality of second rotating shafts are rotationally connected with the inner wall of the second annular groove; a spur gear is connected onto the second rotating shaft in a sleeving manner; a spur gear ring meshed with the spur gear is fixedly connected with the inner wall of the first annular groove. The stirring device is simple in structure; with the combination of a motor, the second rotating shaft, the spur gear, a sliding ring, a chain, a P-shaped rod, a sliding sleeve, a connecting rod, a fixing sleeve rod, a stirring rod, a conical gear and an arc-shaped conical gear ring, the stirring rod can be swung upand down and rotated at the same time, so that materials inside the stirring bucket can be relatively and thoroughly stirred, the whole rotation movement and up and down movement can be carried out through only one power output device, and the stirring device is relatively energy saving and environmental-friendly.

Owner:黄赐东

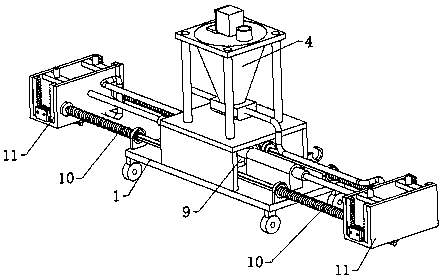

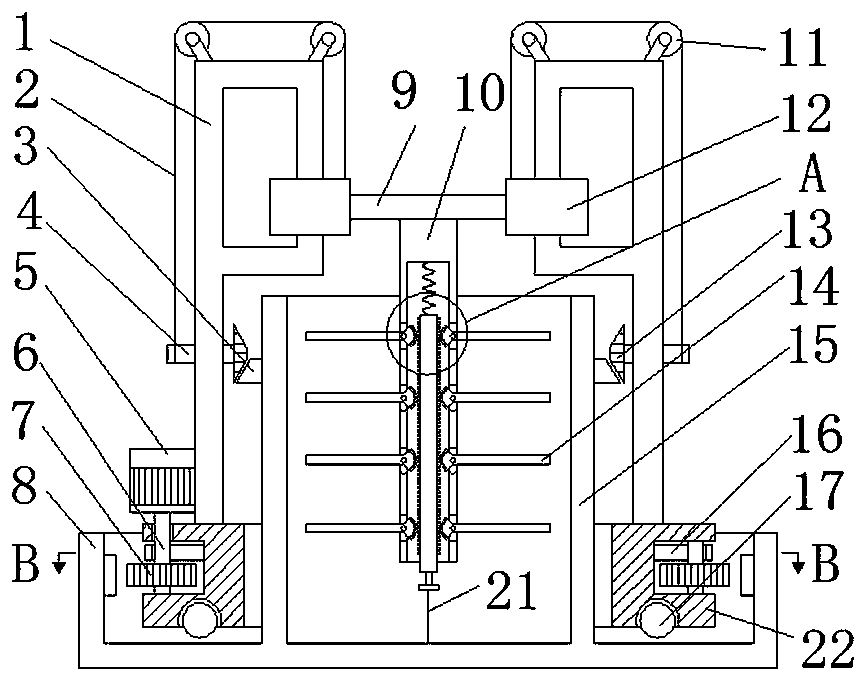

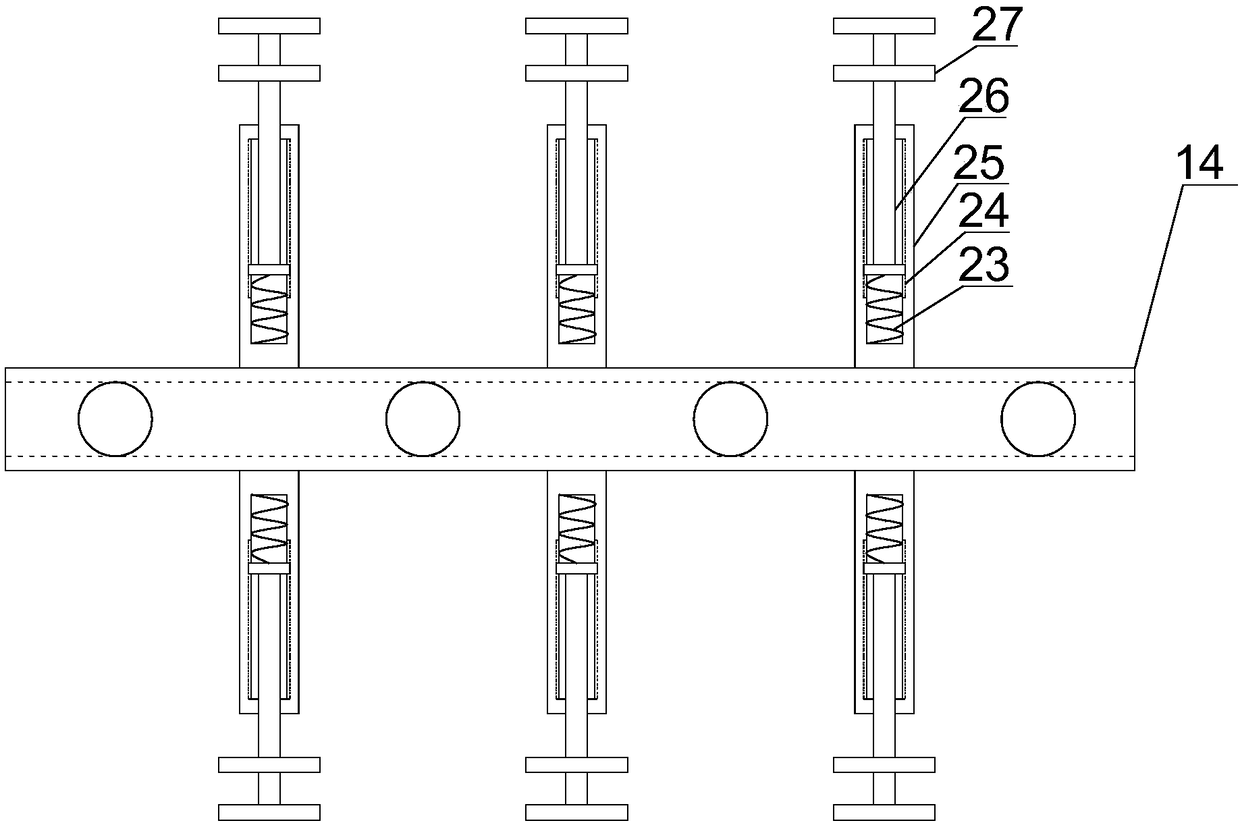

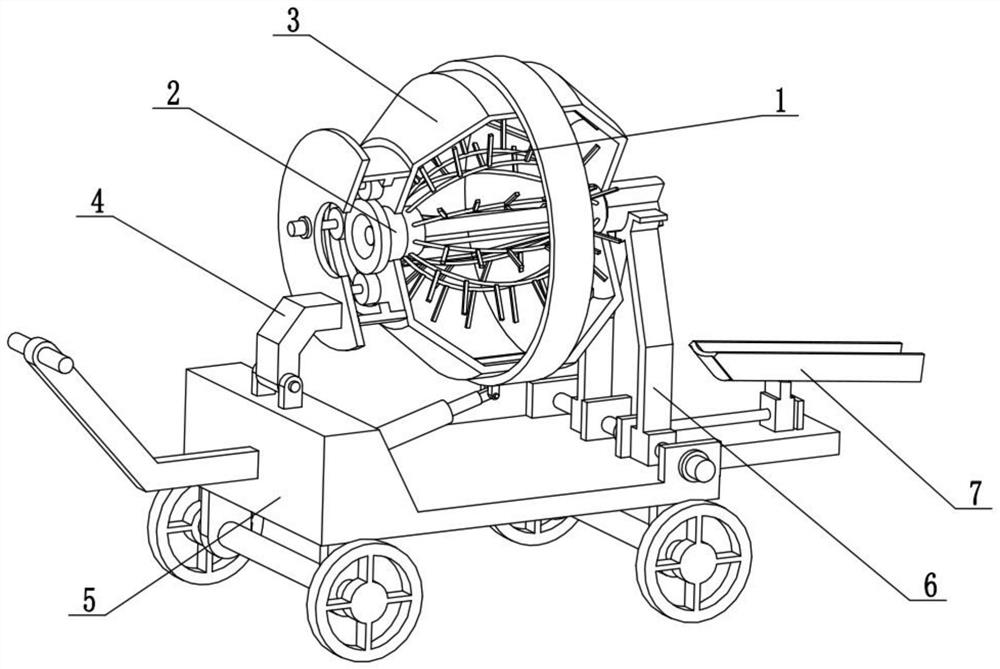

High-speed stirring and periodic discharging device for mortar

ActiveCN108437202AQuality improvementStir thoroughlyDischarging apparatusCement mixing apparatusEngineeringMechanical engineering

The invention discloses a high-speed stirring and periodic discharging device for mortar. The high-speed stirring and periodic discharging device for the mortar comprises a high-speed stirring supporting module and a periodic rotary discharging module, wherein the high-speed stirring supporting module comprises a supporting mounting plate, the left upper end of the supporting mounting plate is provided with a feeding transmission plate through triangular supporting plates which are arranged in a front-back symmetry mode and a supporting rotating shaft which penetrates through the upper ends ofthe triangular supporting plates, a stirring discharging cylinder is horizontally arranged on the right side of the feeding transmission plate, a stirring transmission cover is arranged at the left end of the feeding transmission plate, and a driving stirring motor is inlaid in the left lower corner of the feeding transmission plate in a horizontal and leftward mode; and the left end of the driving stirring motor is matched with the stirring transmission cover and is coaxially provided with a driving belt wheel through a horizontally-arranged motor rotating shaft, and the upper half section of the stirring transmission cover horizontally penetrates through the feeding transmission plate and is horizontally provided with a stirring operation shaft. The high-speed stirring and periodic discharging device for the mortar has the advantages that the structure design is compact and complete, the stirring speed is high, stirring is thorough, the mortar quality is good, transmission is stable, and the discharging quality is high.

Owner:浙江恒尊新材料科技有限公司

Paper production method capable of recycling water

InactiveCN107513876ASave waterEasy to crushPulp beating/refining methodsRaw material divisionWater storageFiber

The invention discloses a paper production method capable of water recycling. The paper production equipment capable of water recycling includes a crushing box, the crushing box is fixedly connected with a stirring box through a material guide pipe fixedly connected at the bottom, and the bottom of the side of the stirring box is fixedly connected There is a discharge pipe, and the mixing tank is fixedly connected to the water storage tank through the catheter tube fixedly connected at the bottom. One end of the tube is fixedly connected to the top of the stirring tank. The invention crushes the trees through the crushing box, stirs the crushed trees through the stirring box to separate the plant fibers, collects the used water in the stirring box through the water storage tank, and then imports the water collected in the water storage tank into the stirring box through the water suction pump , to achieve the advantages of recycling water resources to stir the crushed trees, and has the advantage of saving water resources.

Owner:傅恺

Straight through cement mixer

ActiveCN101497217AReduce manufacturing costSimple designFlow mixersTransportation and packagingEngineeringOil well

A cement mixing method for mixing cement used in cementing oil wells casing and the mixer used in that method. The mixer employs a straight bulk cement inlet, five annular recirculation jet and five annular water jet orifices located downstream of the recirculation jets so that all of the jets discharge at an angle towards the mixing chamber. The five annular recirculation jets are located in alternating longitudinal alignment within the mixing chamber relative to the five annular water jets. This five jet, intersecting flow design allows for more thorough wetting of the cement powder with a smaller, lighter, less expensive and more durable mixer that is less inclined to foul and easier to clean.

Owner:赛瓦集团有限责任公司

Efficient stirring device for paint production

InactiveCN107551872AStir thoroughlyAvoid working dead endsRotary stirring mixersMixer accessoriesDrive motorThree level

The invention discloses an efficient stirring device for paint production. The device comprises a base, a stirring barrel is arranged on the upper side of the base, a bracket is arranged on the outerside, of the stirring barrel, on the upper side of the base; the bracket is higher than the stirring barrel; a supporting plate is horizontally arranged at the top end o the bracket; a through slot isformed in the middle of the supporting plate; a driving motor is arranged in the through slot; a rotary shaft is arranged at the output end of the driving motor; the bottom end of the rotary shaft isconnected to a stirring device; a hydraulic cylinder is arranged at the left end of the upper side of the supporting plate. The efficient stirring device for paint production disclosed by the invention is simple in structure and convenient to use and has a relatively good stirring effect; in the stirring process, the hydraulic cylinder drives the stirring device to move left and right to avoid the stirring dead angles, so that precise quantative feeding can be achieved without manual operations, and the time is shortened and the labor is saved; in addition, by adopting a three-level damping system, vibration of the device during work can be reduced to a great extent, so that the working stability of the device is improved and the service life is prolonged.

Owner:TIANJIN KECHUANG FUXIN TECH CONSULTING CO LTD

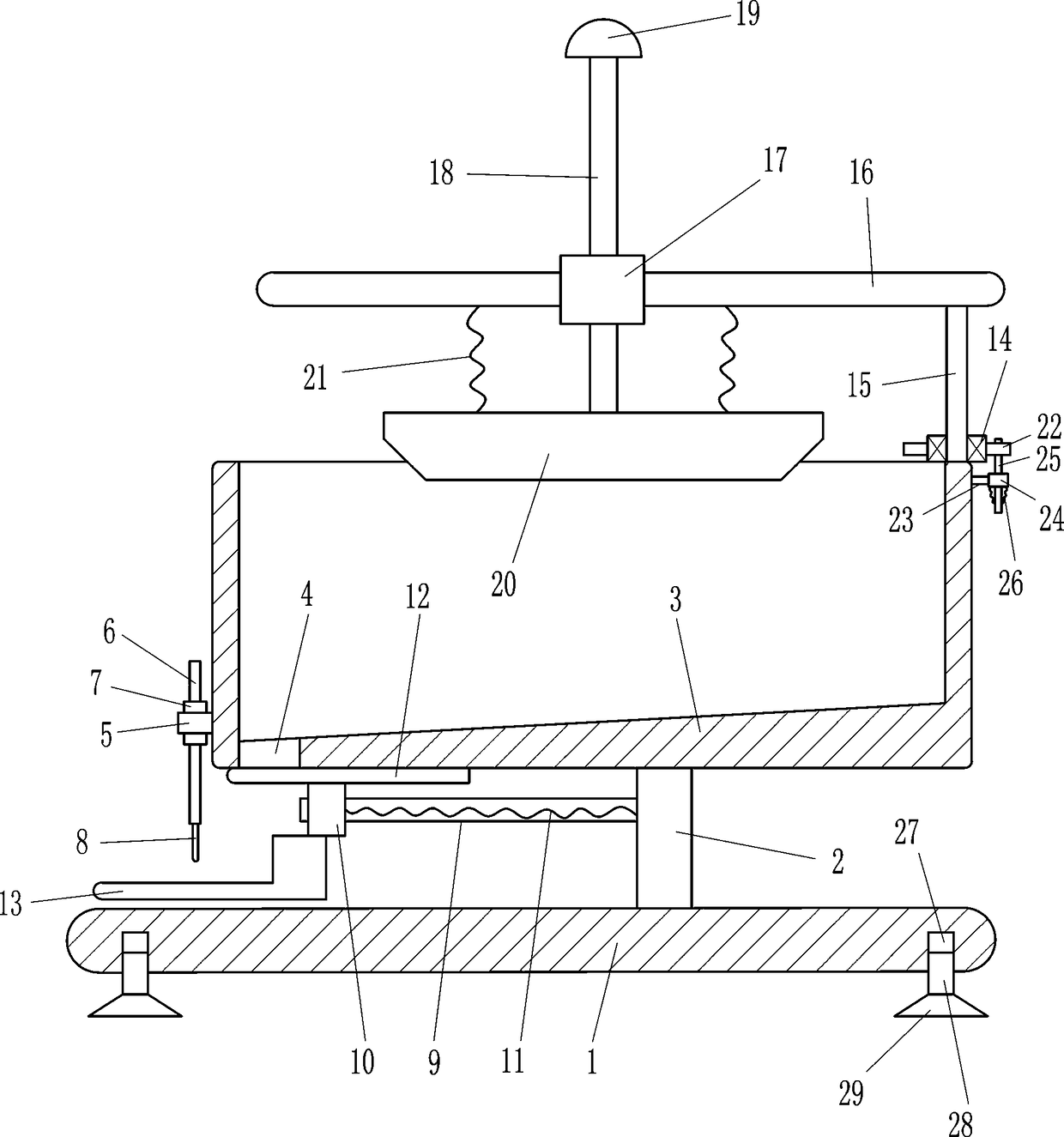

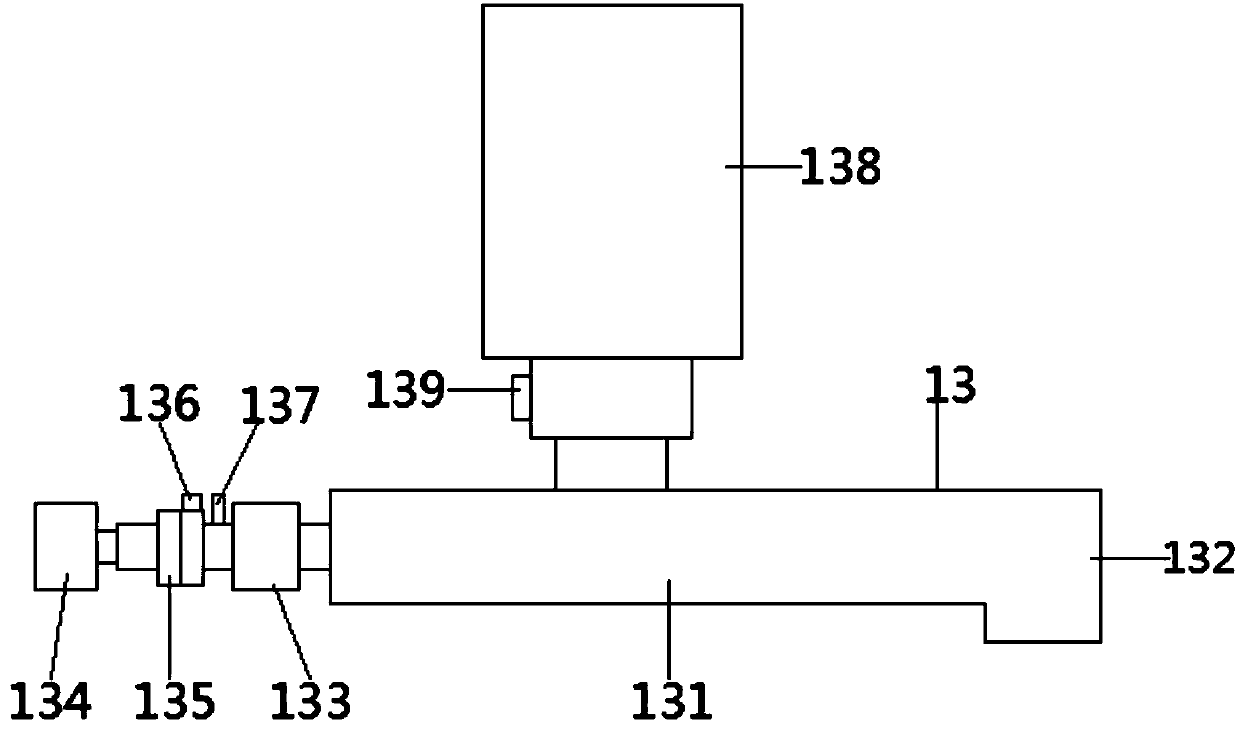

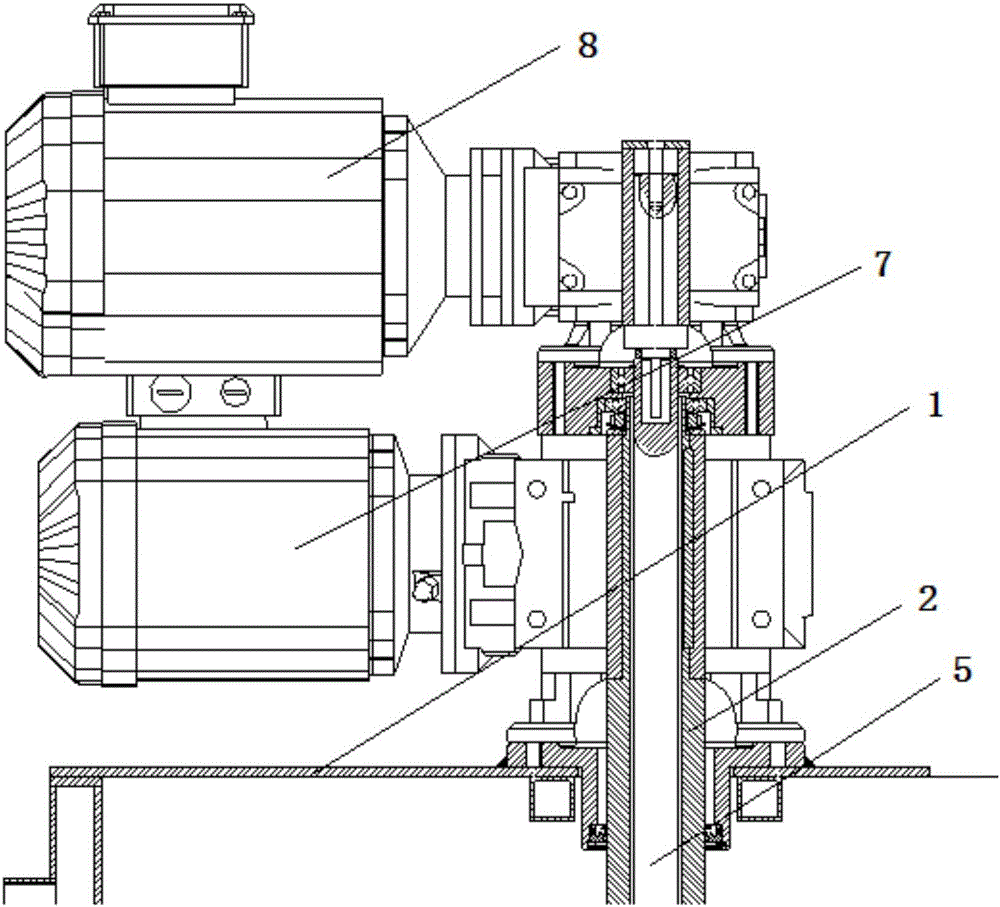

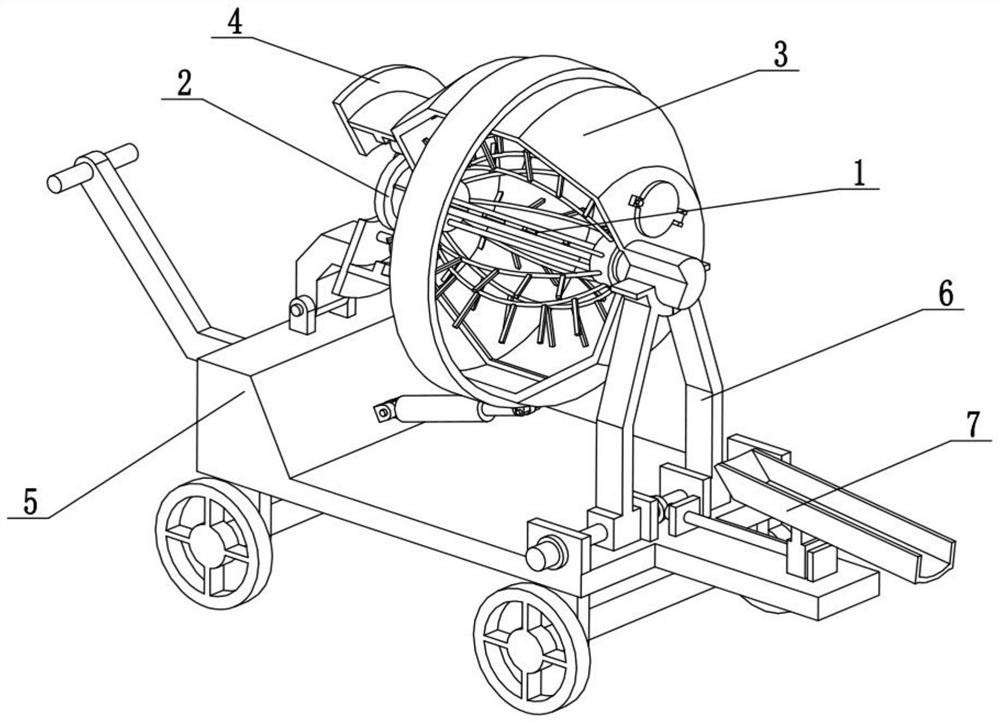

Rotary lift type mixing equipment for lithium battery cell paste

InactiveCN109569380ATo achieve the effect of mixing cell pasteWell mixedRotating receptacle mixersShaking/oscillating/vibrating mixersEngineeringLithium battery

The invention relates to mixing equipment, in particular to rotary lift type mixing equipment for lithium battery cell paste, which can stir paste horizontally or vertically thoroughly. The technicalscheme includes that the rotary lift type mixing equipment for lithium battery cell paste comprises a workbench, a mounting board, a motor, a first bearing block, a first rotating rod, a mixing box, aseal ring and the like; the first bearing block is arranged in the middle of the top of the workbench, and the first rotating rod is mounted in the first bearing block. The rotary lift type mixing equipment can not only stir paste horizontally but vertically with thorough effect; with the arrangement of the first rotating rod, stirring blades and a stirring rod, users cannot only stir cell pastehorizontally by the equipment, but stir the cell paste vertically, thereby achieving a thorough stirring effect.

Owner:魏冬

Premixing stirring system for cake stirring machine

InactiveCN106212583AStir thoroughlyStir wellMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsPulp and paper industry

The invention discloses a premixing stirring system for a cake stirring machine. The premixing stirring system comprises a stirring tank, wherein a longitudinal hollow external rotating shaft is arranged at the top of the stirring tank in a rotatable form; a stirring frame type blade matched with the inner wall of the stirring tank in shape is fixedly arranged at the lower part of the external rotating shaft; a plurality of external horizontal blades are fixedly distributed on the inner side of the stirring frame type blade; an inner rotating shaft is arranged in the external rotating shaft in the rotatable form; the lower end of the inner rotating shaft extends out of the external rotating shaft and penetrates through the stirring frame type blade and then is arranged in a mounting hole at the lower part of the stirring frame type blade in the rotatable form; a plurality of inner horizontal blades which alternate with the external horizontal blades are arranged on the inner rotating shaft; the external rotating shaft and the inner rotating shaft are respectively controlled to reversely rotate by two motors. The premixing stirring system has the advantages that the structure design is reasonable, the premixing is more uniform, the residues on the inner wall of the stirring tank can be timely removed and the cleaning is easy and simple.

Owner:安徽政乐机械有限公司

Eccentric stirring device

The invention discloses an eccentric stirring device. The eccentric stirring device comprises a stirring barrel, a stirring shaft, and a motor. The upper opening of the stirring barrel is provided with a barrel cover. The barrel cover is provided with a material inlet. The motor is fixedly arranged on the barrel cover. The output shaft of the motor is rotatingly connected to the upper end of the stirring shaft through a coupler. The stirring shaft has an eccentric shaft structure. The lower end of the stirring shaft is fixedly provided with a rotation disc. The lower end surface of the rotation disc is connected to a plurality of rotation shafts, each rotation shaft is provided with a shaft sleeve, and a blade is fixedly arranged on each shaft sleeve. During the stirring process, the eccentric stirring shaft rotates and then drives the rotation disc and rotation shafts on the rotation disc to rotate; thus the materials in the stirring barrel can be fully mixed, and the stirring efficiency and quality are prominently improved.

Owner:洛阳市西工区华科精密机械厂

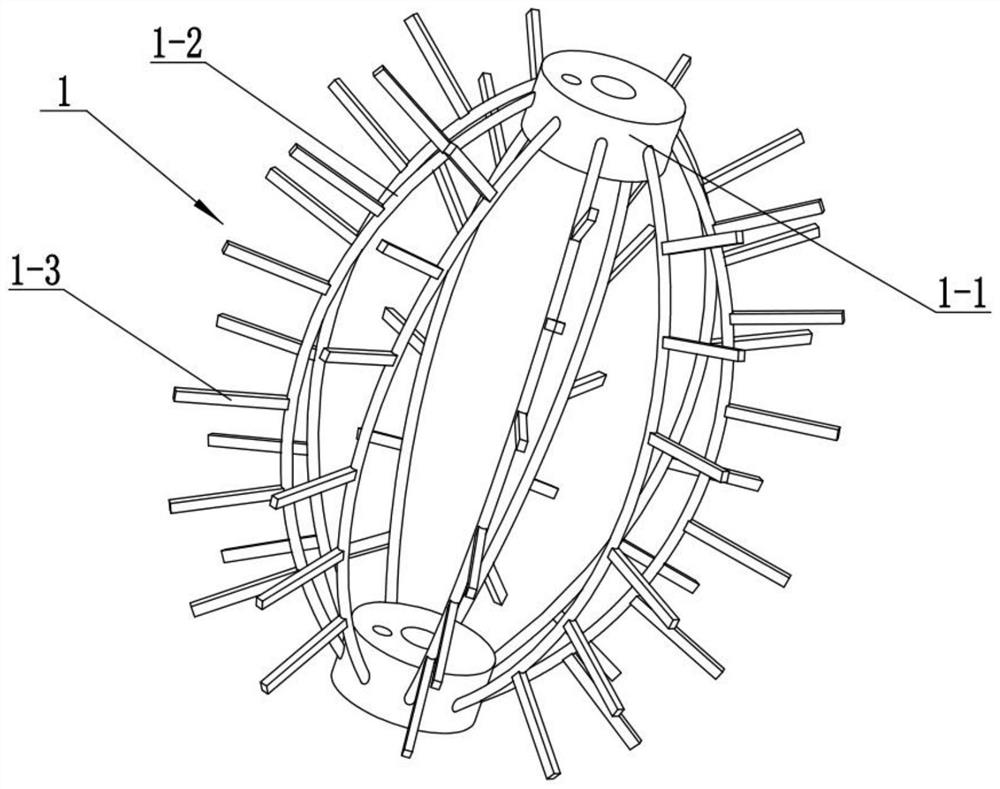

Foaming machine

InactiveCN112044326AStir ingredients well and thoroughlyAvoid swirling and stratificationRotating receptacle mixersTransportation and packagingPhysicsEngineering

The invention relates to the technical field of foaming machines, in particular to a foaming machine which can change the stirring form to avoid rotational flow layering of raw materials. The foamingmachine comprises an elastic adjustment foaming mechanism, an adjustment driving mechanism, a foaming rotating tank mechanism, a rotating power mechanism, a feeding and discharging rotating mechanism,a tank supporting mechanism and a discharging flow guide mechanism; and an adjusting motor independently drives a rotating lead screw to rotate, so that the rotating lead screw drives two opening andclosing adjusting shaft sleeves on the rotating lead screw to move and get close to or away from each other; the two opening and closing adjusting shaft sleeves extrude and stretch the multiple arc-shaped elastic connecting rods, and in the extruding and stretching process, the multiple arc-shaped elastic connecting rods are bent, so that the angles, perpendicular to the horizontal plane, of themultiple foaming stirring rods on the multiple arc-shaped elastic connecting rods are changed, and raw materials are stirred in different forms; raw materials are stirred more fully and thoroughly, and rotational flow layering is avoided.

Owner:高梦竹

High-efficiency cement stirring device

ActiveCN107718278AWon't leaveIncrease reaction rateShaking/oscillating/vibrating mixersTransportation and packagingHydraulic cylinderDrive wheel

The invention discloses a high-efficiency cement stirring device. The high-efficiency cement stirring device comprises a base, a stand column, longitudinal slide rails, a lifting sliding sleeve, connection pieces, a stirring motor, a main shaft box, a drive wheel, a driving belt, a driven wheel, a main shaft, a stirring blade, a cylinder, a movable shaft, a lifting connector, a hydraulic cylinder,positioning sleeves, limiting springs, supporting bases, a cylinder cover, a drive motor, a transmission wheel, an eccentric wheel, a belt and a positioning piece. When the high-efficiency cement stirring device is used for conducting stirring processing on cement, the cylinder is vibrated and shaken, the reaction rate of materials in the cylinder is accelerated, stirring processing is more thorough, while the reaction rate is accelerated, the phenomenon that the materials adhere to the inner wall of the inner wall of the stirring cylinder is effectively avoided, and therefore the internal capacity of the cylinder is kept, the unnecessary waste of the raw materials is avoided, the working time is effectively shortened, the working efficiency is improved, relatively-high practicality is improved, the operation effect is guaranteed, the high-efficiency cement stirring device adapts to multiple different working modes, and the labor using is effectively reduced.

Owner:平阴山水水泥有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com