Filtration and backwashing device, coal coke recovery device and filtration and backwashing method, gasification composite power generation equipment

A filter device and backwashing device technology, applied in separation methods, filter separation, mechanical equipment, etc., can solve the problems of filter device pressure loss increase, performance degradation, etc., and achieve the effect of inhibiting increase and inhibiting deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In addition, this invention is not limited to this embodiment. In addition, the components in the following embodiments include those that can be easily replaced by those skilled in the art or those that are substantially the same. In addition, the components described below can be appropriately combined, and when there are a plurality of embodiments, the respective embodiments can also be combined.

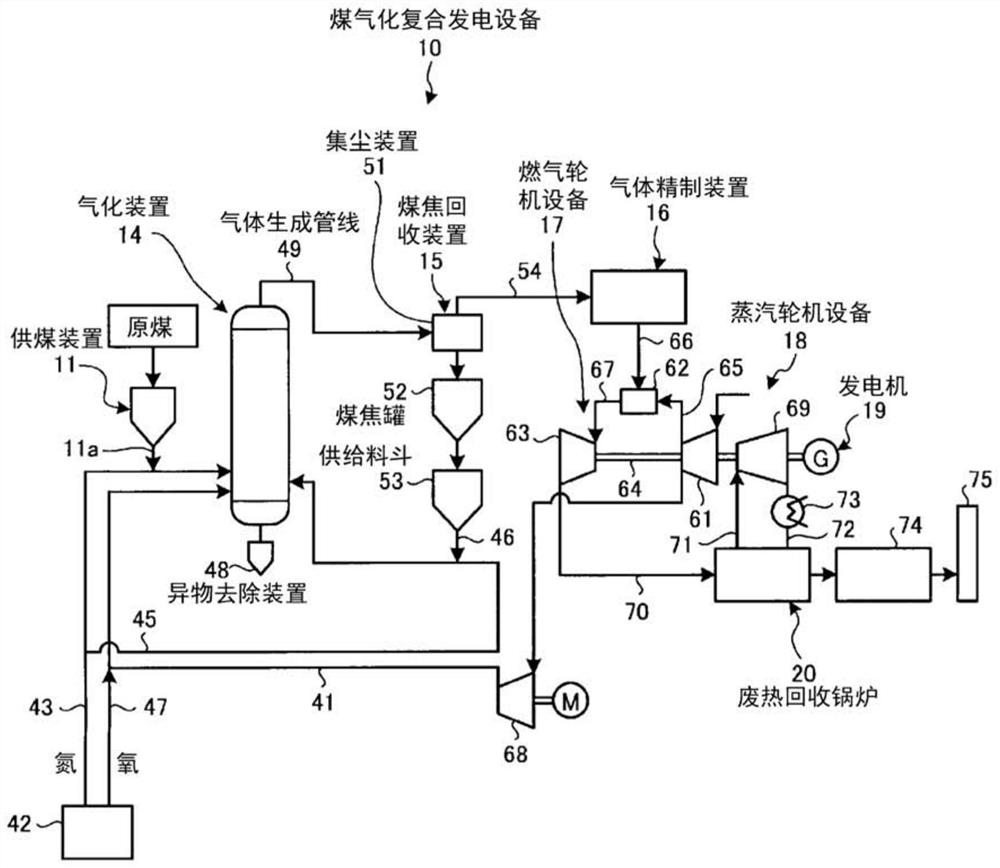

[0036] figure 1 It is a schematic configuration diagram of a combined coal gasification power generation facility (combined gasification power generation facility) to which a coal char recovery device is applied according to the present embodiment. The integrated coal gasification combined cycle (IGCC: Integrated Coal Gasification Combined Cycle) 10 using the gasification device 14 of this embodiment employs an air system in which air is used as an oxidant and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com