Valve mechanism

A valve mechanism and hydraulic tappet technology, which is applied in mechanical equipment, engine components, machines/engines, etc., can solve the problem that the valve phase cannot be adjusted and precisely controlled, and the valve mechanism structure cannot be realized. Bloated and complex problems, to achieve the effect of being conducive to rapid implementation, flexible and variable design, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, specific embodiments will be described in detail below with reference to the accompanying drawings.

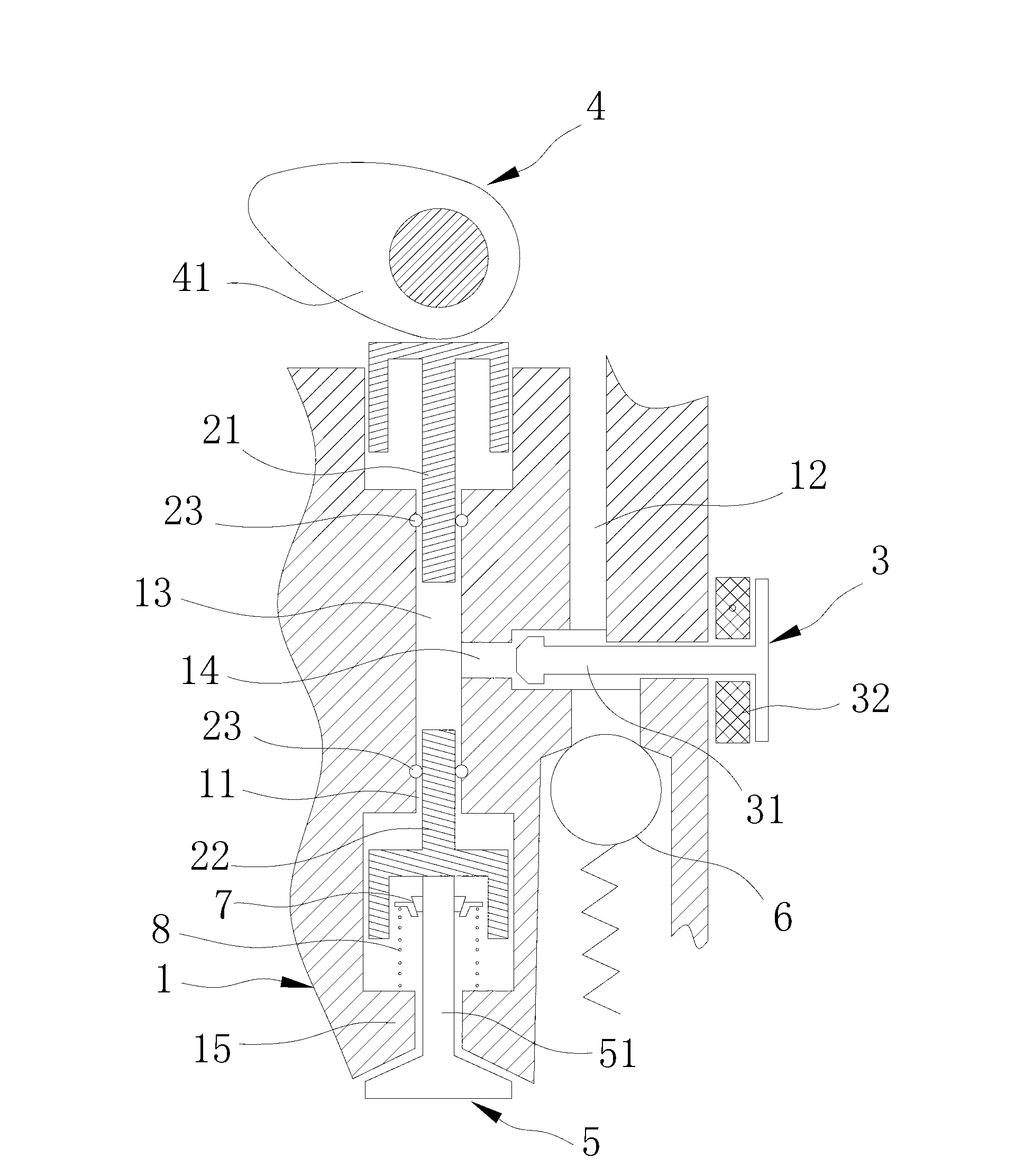

[0044] Please refer to figure 1 , is a structural schematic diagram of the valve mechanism of the present invention, as shown in the figure, the valve mechanism of the present invention mainly includes: a cylinder head 1, which is provided with a passage 11 and a high-pressure oil passage 12; a first hydraulic tappet 21 and a second hydraulic tappet 22. It can be slidably arranged at both ends of the passage 11. The first hydraulic tappet 21, the second hydraulic tappet 22 and the inner wall of the passage 11 enclose a hydraulic chamber 13, and the hydraulic chamber 13 communicates with the high-pressure oil passage 12 through the connecting oil passage 14 The switch valve 3 is located in the connecting oil passage 14 and controls the on-off of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com