Automatic reagent feeding method and device for oil well scale prevention

An automatic chemical dosing and oil well technology, which is applied in earthwork drilling, wellbore/well components, production fluids, etc., can solve problems such as many supporting equipment, heavy maintenance workload, and difficulty in ensuring time rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

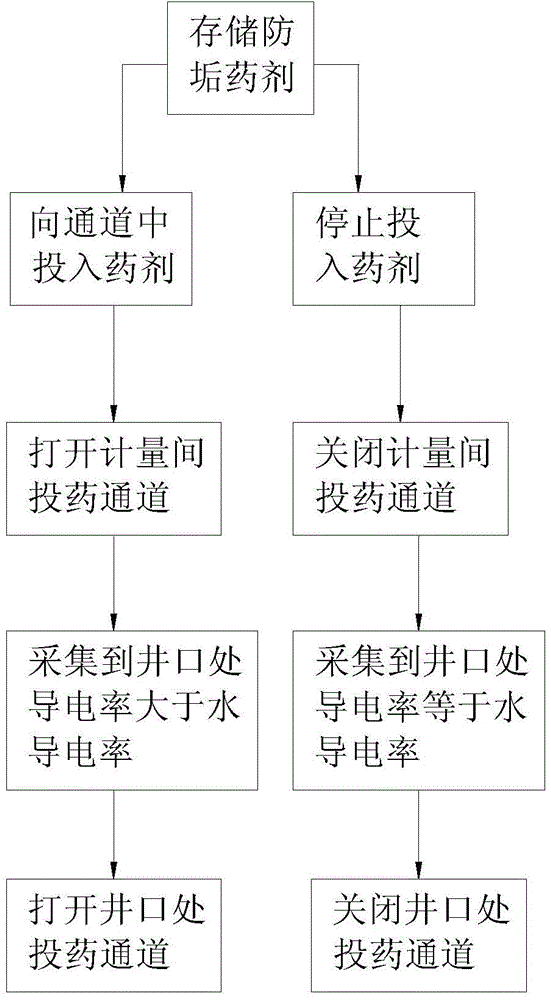

[0027] Embodiment 1: an automatic dosing method for oil well scale prevention, the method specifically comprises the following steps:

[0028] Step 1: Store the anti-scaling agent in the metering room so that it can be used at any time;

[0029] Step 2: throwing the anti-scale agent stored in the metering room into the dosing channel, so as to flow to the wellhead through the dosing channel, and then enter the oil pipe;

[0030] Step 3: Open or close the dosing channel, after opening the dosing channel, the anti-scaling agent enters the dosing channel and flows to the wellhead, and closes the dosing channel so that the drug will not flow to the wellhead to avoid waste;

[0031] Step 4: Collect the conductivity information of the wellhead, and collect the information of the conductivity of the liquid in the dosing channel at the wellhead;

[0032] Step 5: Compare the conductivity collected in step 4 with the conductivity of water, so as to determine whether an anti-scaling age...

Embodiment 2

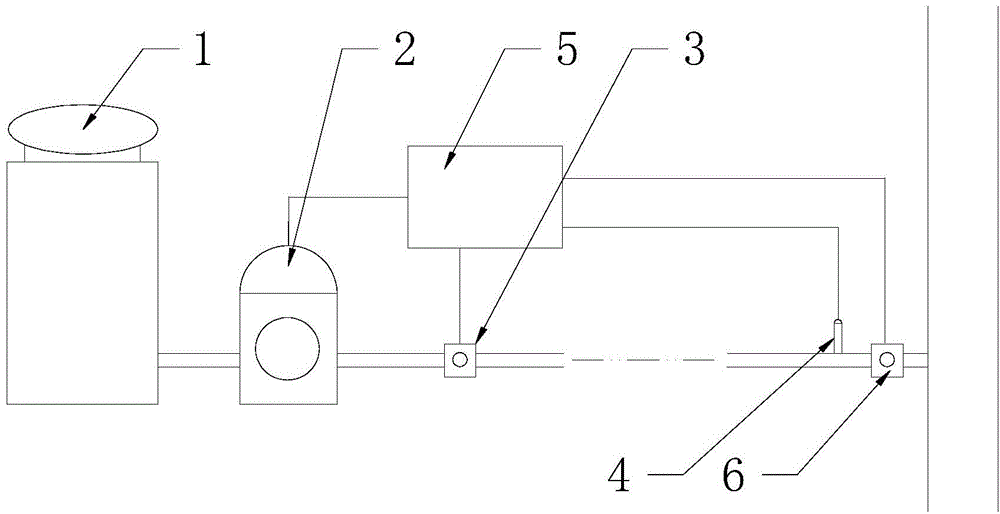

[0036] Embodiment 2: an automatic dosing system for oil well scale prevention corresponding to the above method, the system includes a medicine storage tank 1 storing an anti-scale agent in a metering room;

[0037] It also includes a plunger pump 2 for throwing the anti-scaling agent stored in the metering room into the dosing channel to provide power for the anti-scaling agent;

[0038] Open or close the electric valve 3 of the metering room for the drug delivery channel;

[0039] The drug detection device 4 that collects the conductivity information of the wellhead, judges whether to administer the drug through the conductivity;

[0040] Compare the collected conductivity with the conductivity of water, and then judge whether the controller 5 of the anti-scaling agent is put into the dosing channel at the wellhead;

[0041] Open or close the wellhead electric valve 6 of the dosing channel at the wellhead according to the result judged by the controller 5;

[0042] Wherein...

Embodiment 3

[0043] Embodiment 3: Further, in order to better reduce labor and improve automatic control, the plunger pump 2 and the electric valve 3 between metering are respectively connected with the controller 5, which enables the staff to control the opening or closing through the controller 5. Plunger pump 2 and control to open or close the electric valve 3 between metering.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com