Automatic copper removal system

A copper-removing and automatic technology, applied in photographic crafts, instruments, photographic auxiliary crafts, etc., can solve the problems of extensive working methods, vibrating and falling off of sponge copper, low working efficiency, etc. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

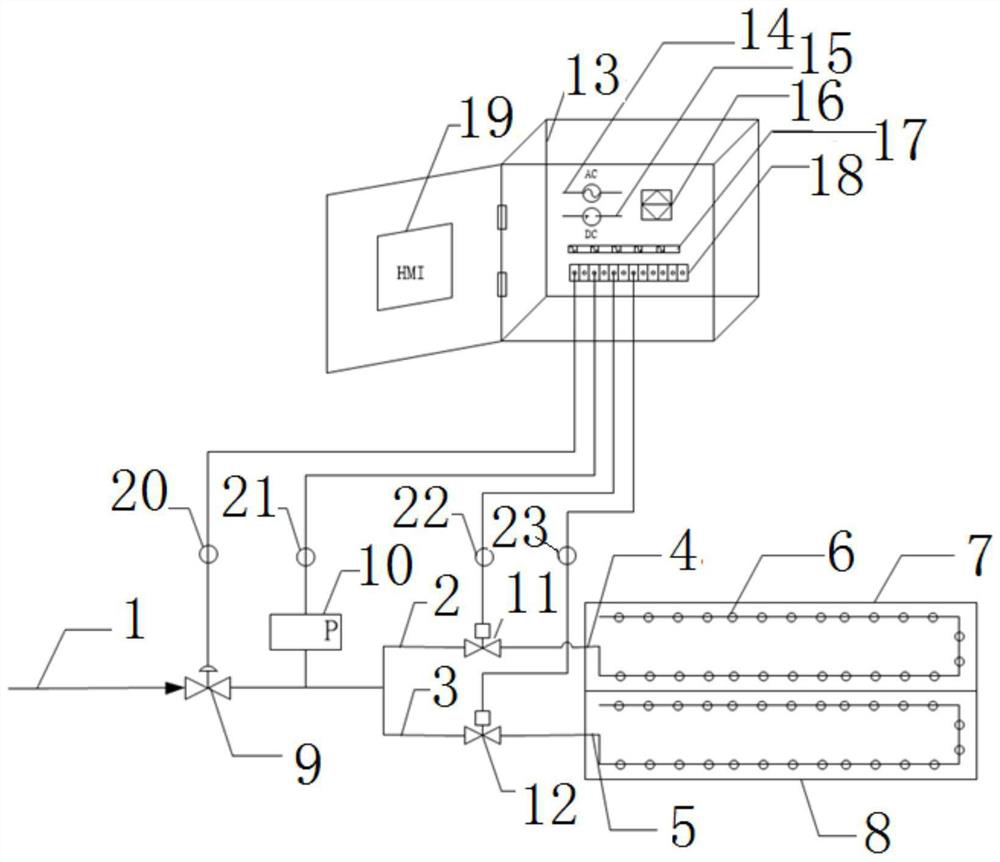

[0017] Such as figure 1 As shown, an automatic decopper system includes: a gas delivery device, an air flow stirring device, and a controller;

[0018] The gas transmission device comprises a gas transmission main pipe 1, and one end of the gas transmission main pipe 1 is connected to one end of the first gas transmission branch pipe 2 and the second gas transmission branch pipe 3; the other end of the gas transmission main pipe 1 is connected to the compressed air supply device (gas source )connect;

[0019] The air flow stirring device includes a first ventilation pipe 4 and a second ventilation pipe 5, both of which are annular coils, and the upper pipe wall of the annular coil is provided with a plurality of evenly distributed air outlets 6 , to achieve the purpose of airflow stirring, the opening angle of the air outlet and the horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com