Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

100results about How to "The composition ratio is scientific and reasonable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Uvioresistant, antibacterial and moisture conductive terylene fiber, preparation method and application thereof

ActiveCN101629334AImproves UV resistanceLong-lasting antibacterialFilament/thread formingMonocomponent polyesters artificial filamentYarnFiber

The invention discloses an uvioresistant, antibacterial and moisture conductive terylene fiber, a preparation method and an application thereof. The terylene fiber comprises the following raw materials in percentage by weight: 1-5 percent of uvioresistant parent granule, 1-10 percent of silver series antibacterial parent granule and 85-98 percent of terylene fiber forming resin, wherein the cross section of the fiber is a profile cross section. The uvioresistant, antibacterial and moisture conductive terylene fiber, the component proportions of which are scientific and reasonable, is prepared by the following steps: scientifically and organically combining the antibacterial silver series parent granules, the uvioresistant parent granules and the terylene fiber forming resin; preparing a pre-oriented yarn by using a profile hole spinning plate; and then elasticizing and deforming the pre-oriented yarn; thus the terylene fiber has wide range of application. The preparation method of the uvioresistant, antibacterial and moisture conductive terylene fiber has strong operability, reasonable process and high production efficiency and can realize industrial mass production.

Owner:微笑纺织科技(太仓)有限公司

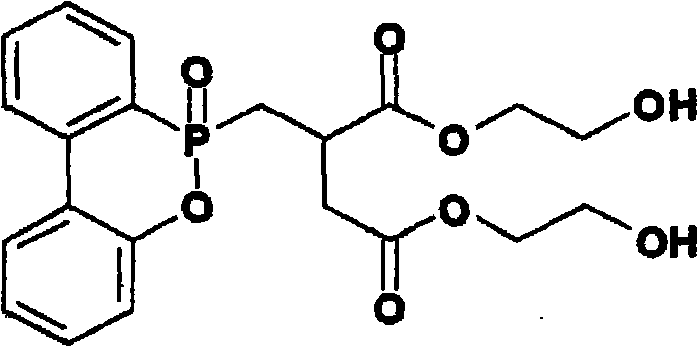

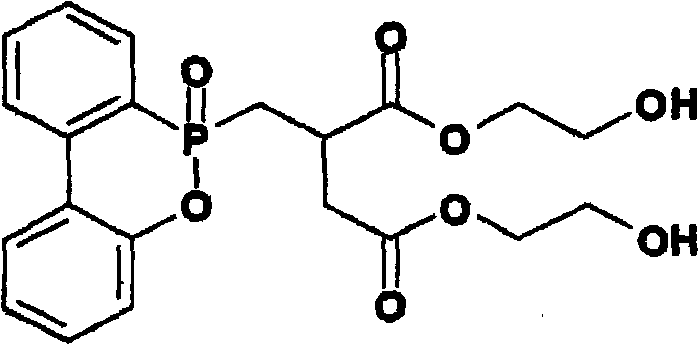

Uvioresistant, antibacterial and flame retardant terylene fiber, preparation method and application thereof

ActiveCN101629335AHas antibacterial propertiesThe composition ratio is scientific and reasonableMonocomponent polyesters artificial filamentProtective garmentFiberYarn

The invention discloses an uvioresistant, antibacterial and flame retardant terylene fiber, a preparation method and an application thereof. The terylene fiber comprises the following raw materials in percentage by weight: 1-10 percent of silver series antibacterial parent granule, 1-5 percent of uvioresistant parent granule and 85-98 percent of copolymerized type phosphorus flame retardant terylene fiber forming resin. The uvioresistant, antibacterial and flame retardant terylene fiber , the component proportions of which are scientific and reasonable, is prepared by the following steps: scientifically and organically combining the antibacterial silver series parent granules, the uvioresistant parent granules and the copolymerized type phosphorus flame retardant terylene fiber forming resin; preparing a pre-oriented yarn; and then elasticizing and deforming the pre-oriented yarn to produce low-elasticity deformed yarn; thus the terylene fiber has wide range of application. The preparation method of the uvioresistant, antibacterial and flame retardant terylene fiber has strong operability, reasonable process and high production efficiency and can realize industrial mass production.

Owner:微笑纺织科技(太仓)有限公司

Aqueous PU fog face rubbing surface treatment agent for synthetic leather and preparation method thereof

The invention discloses an aqueous PU fog face rubbing surface treatment agent for synthetic leather, comprising the following components by weight percentage: 40-50% of aqueous polyurethane resin, 30-40% of water, 3-6% of matting agent, 1-5% of organic silicon antifoaming agent, 0.5-5% of organic silicon flatting agent and 0.5-5% of aqueous polyurethane thickener. The surface treatment agent provided by the invention takes water as solvent which replaces poisonous solvents such as dimethylformamide and butanone and has the performances of non-combustion, safety, environmental protection and less cost; after being treated by the surface treatment agent provided by the invention in a wiping manner, the prepared leather has good fog face rubbing effect, sharp contrast between colours of a surface layer and a rubbing layer, good visual effect and excellent general effect.

Owner:JIANGSU BAOZE POLYMER MATERIAL

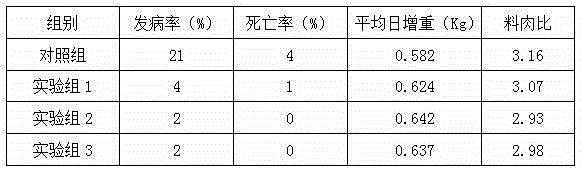

Bee cultivation method

InactiveCN106614401AImprove spawning effectProlong the harvesting cycleAnimal feeding stuffAccessory food factorsSpecies selectionCultural methods

The invention discloses a bee cultivation method. The bee cultivation method comprises the steps of bee species selection and queen bee cultivation, place selection, beehive arrangement, honey collecting management, and feeding management. By the reasonable cultivation method, the egg laying effect of the queen bee is improved, the honey gathering circle is prolonged, the honey variety is enriched, the honey quality is improved, and bee-keeping economic benefits are increased; the honey is gathered in the forest rich in traditional Chinese medicine honey source, in the honey gathering flower changing stage, the bees are fed on the nectar with the coming flowering phase, the warm-property sweet water is blended to neutralize medicine properties of the traditional Chinese medicine, the honey gathering circle is prolonged, the honey variety is enriched, the honey quality is improved, and bee-keeping economic benefits are increased; the honey output rate in the bee cultivation process can be effectively increased, the death rate of the swarm is reduced and the market prospect is good; and the feed nutrition is comprehensive and balanced, the functional additive can improve the disease resistance of the bees and enhance the physique, and quick and healthy growth and reproduction of the bees are promoted.

Owner:周渊泉

Aqueous PU velvet resin used for synthetic leather

InactiveCN101634109ALow costThe ratio is scientific and reasonableFibre treatmentDimethyl formamideChemistry

The invention discloses an aqueous PU velvet resin used for synthetic leather, which comprises the following raw materials by weight percent: 40-50% of aqueous polyurethane resin, 40-50% of water, 2-5% of low-temperature sheep bar powder, 2-4% of silicon dioxide velvet powder, 1-3% of organic silicone oil smoothing agent, 1-4% of extinction powder, 0.5-1% of organic silicon flatting agent, 2-5% of organic silicon antifoaming agent and 0.5-2% of aqueous polyurethane thickening agent. The aqueous PU velvet resin used for synthetic leather of the invention takes water as solvent to replace toxic solvent, such as dimethyl fomamide, butanone and the like and has the advantages of being non-combustible, safe and environment-friendly, saving cost and the like. The aqueous PU velvet resin also has the advantages of good film-forming resistance, firm bonding, coating solvent resistance, cold resistance, hydrolysis resistance and heat-proof aging. Products fabricated by using the resin have the characteristics of plump feel, unique velvet effect, strong real leather quality, fine and smooth texture, good air permeability and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Waterborne PU high smooth wax resin for synthetic leather

The invention discloses a waterborne PU high smooth wax resin for synthetic leather and the resin comprises the following raw materials by weight percent: 30-40% of waterborne silicon-fluorine resin,20-30% of waterborne polyurethane, 10-30% of water, 0.2-0.8% of waterborne wax emulsion, 1-3% of organic silicone oil smoothing agent, 0.5-1% of organic silicone flatting agent, 2-5% of organic silicone defoamer and 0.5-2% of waterborne polyurethane thickener. The waterborne PU high smooth wax resin for synthetic leather provided by the invention uses water as solvent instead of toxic solvents such as dimethyl formamide, butanone and the like and has the advantage of noninflammability, safety, environmental protection, cost-saving and the like. The finished product prepared from the waterbornePU high smooth wax resin for synthetic leather provided by the invention has full hand feeling, high luster and high luminance, extremely smooth waxy feeling, delicate texture and good air permeability; and the prepared synthetic leather has good comprehensive effect in hand feeling, smoothness, water resistance, waxy feeling and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Bamboo charcoal, flame retardant and moisture conductive terylene fiber, preparation method and application thereof

InactiveCN101629333AImprove adsorption capacityImprove deodorizationFilament/thread formingMonocomponent copolyesters artificial filamentFire retardantMoisture

The invention discloses a bamboo charcoal, flame retardant and moisture conductive terylene fiber, a preparation method and an application thereof. The terylene fiber comprises the following raw materials in percentage by weight: 5-10 percent of active carbon parent granule and 90-95 percent of copolymerized type phosphorus flame retardant terylene fiber forming resin, wherein the cross section of the fiber is a profile cross section. The terylene fiber has good functions of adsorption, deodorization, bactriostasis and rot resistance and flame retardance, and because the cross section of the fiber is the profile cross section, the moisture conductive function of the fiber is also excellent, thus the terylene fiber has wide range of application. The preparation method of the bamboo charcoal, flame retardant and moisture conductive terylene fiber has strong operability, reasonable process and high production efficiency and can realize industrial mass production.

Owner:苏州金辉纤维新材料有限公司

Water-based PU brush surface conditioning agent for synthetic leather

InactiveCN101705623AExcellent crosslink hardnessGood recoatabilityFibre treatmentWater basedSilicon dioxide

The invention discloses a water-based PU brush surface conditioning agent for synthetic leather, which comprises the following materials by weight percent: 10 to 20 percent of water-based stoving varnish resin, 1 to 6 percent of water-based polyurethane, 60 to 70 percent of water, 5 to 13 percent of silicon dioxide matting agent, 0.5 to 2 percent of organic silicon flatting agent, 1 to 5 percent of organic silicon foam killer and 2 to 6 percent of water-based modified polyethylene wax emulsion. In the water-based PU brush surface conditioning agent for synthetic leather, water is taken as solvent to replace noxious solvents, such as dimethyl formamide and butanone, so that the water-based PU brush surface conditioning agent has the performances of non-inflammation, safety, environmental protection and cost saving, and resin has the advantages of good film reforming property, firm bonding, solvent resistance, cold resistance, hydrolysis resistance and thermosenescence resistance of coating, and the finished product made of the surface conditioning agent has unique brush effect, strong dermis effect, water resistance and good air permeability.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Water-based PU matte surface finishing agent for synthetic leather

The invention discloses a water-based PU matte surface finishing agent for synthetic leather, which comprises the following materials in parts by weight: 30 to 40 parts of water-based polyurethane resin, 45 to 55 parts of water, 4 to 10 parts of modified organic silicon polymer, 0.5 to 1.5 parts of organic silicon flatting agent, 1 to 2 parts of organic silicon foam killer, 1 to 2 parts of water-based polyurethane thickening agent, and 3 to 5 parts of modified organic silicon matting agent. For the water-based PU matte surface finishing agent, the mixture ratio of the components is scientific and reasonable, and the components are coordinated with each other and act together. The matte surface finishing agent has the advantages of good film reforming property, firm bonding, solvent resistance, hydrolysis resistance and thermosenescence resistance of coating. The finished product made of the synthetic leather, the surface of which is treated by the matte surface finishing agent, has the advantages that the original effect of the leather surface is not affected, particularly the combined application of the modified organic silicon matting agent and the polyurethane resin ensures that the treated leather surface has unique matte surface effect, and the synthetic leather has good comprehensive effects of good air permeability, good hand feel, water resistance, cohesiveness and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Hydraulic PU crazy horse resin for synthetic leather

The invention discloses a hydraulic PU crazy horse resin for synthetic leather; the hydraulic PU crazy horse resin is constituted by the following raw materials by weight percentage: 35-45 percent of waterborne polyurethane, 30-40 percent of water, 5-8 percent of silicon dioxide color changing powder, 1-3 percent of silicone oil slip agents, 1-4 percent of extinction powder, 0.5-1 percent of organic silicon flatting agent, 2-5 percent of silicone defoaming agents, 0.5-2 percent of waterborne polyurethane thickeners and 2-5 percent of villus. The hydraulic PU crazy horse resin for synthetic leather takes water as solvent, toxic solvents such as dimethyl fomamide and butanone are replaced, therefore, the hydraulic PU crazy horse resin has non-inflammable, safe, environmental-protection, cost-saving performances, and the crazy horse resin has the advantages of good film forming property, firm adhesion, solvent-proof, cold-resistance, hydrolyzation-resistance and heat-proof ageing coating. The finished products manufactured by the crazy horse resin has the advantages of full handle, good crazy horse color-changing effect, fine and smooth texture, good air permeability and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Piglet fattening feed and preparation method thereof

The invention discloses a piglet fattening feed, characterized by being prepared from the following raw materials in parts by weight: 130-150 parts of corn, 40-50 parts of extruded soybean, 20-30 parts of cassava starch, 20-26 parts of beet leaves, 16-20 parts of fermented soybean meal, 8-10 parts of emilia sonchifolia, 6-8 parts of loofah stems, 10-12 parts of shrimp meal, 4-6 parts of hawthorn, 6-7 parts of pink, 7-8 parts of eucommia bark, 6-8 parts of mulberry leaves, 8-10 parts of mangnolia officinalis, 2-3 parts of salt, 5-6 parts of zeolite powder, 6-8 parts of trace element preparation and 7-9 parts of nutrition additive. The feed is prepared from easily available raw material, is low in price, is scientific and reasonable in component proportion and is balanced in nutrition arrangement, has an effect of significantly promoting growth, ensuring balanced daily gain of piglets, realizing health growth of piglets in the fattening period, reducing the fattening cost, and ensuring healthy growth of piglets and strong, green and harmless pork.

Owner:枞阳县兴龙综合养殖有限公司

Synthetic leather water-based mist-surface skin-feeling high-temperature-resistant pretreatment agent and preparation process thereof

A synthetic leather water-based mist-surface skin-feeling high-temperature-resistant pretreatment agent and a preparation process thereof are disclosed. The synthetic leather water-based mist-surface skin-feeling high-temperature-resistant pretreatment agent comprises the following raw materials by weight: 30-40% of waterborne polyurethane, 10-15% of an emulsifier, 1-3% of polyether modified amino silicone oil, 0.5-1% of a polyether polyester modified organo-siloxane leveling agent, 2-5% of a silicon ether copolymer defoaming agent, 5-10% of light extinction powder, 0.5-2% of a waterborne polyurethane associative thickener and 40-60% of water. The waterborne polyurethane is prepared from diisocyanate, a polyol, an extender, a catalyst and a neutralizer by an acetone method. The synthetic leather water-based mist-surface skin-feeling high-temperature-resistant pretreatment agent uses the water as a solvent for replacement of a poisonous solvent, has the propertied of being non-burning, safe, environmentally-friendly and cost-saving, and has the advantages of good film forming property, solvent resistance, cold resistance, hydrolysis resistance, high temperature resistance and embossing. The synthetic leather prepared by the synthetic leather water-based mist-surface skin-feeling high-temperature-resistant pretreatment agent has the advantages of no change in hand feeling before and after the embossing, fullness, fineness and good permeability, and the like.

Owner:嘉兴禾大科技有限公司

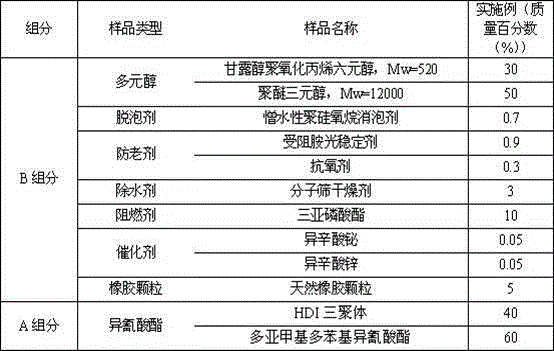

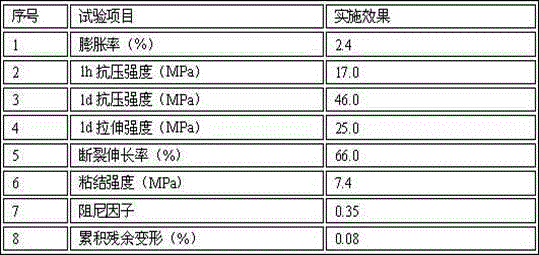

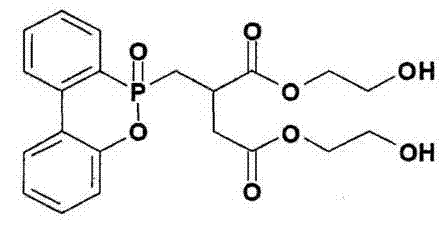

Cured track bed sinking repairing high-viscosity vibration attenuation polyurethane repairing material

The invention relates to a high-viscosity vibration attenuation polyurethane repairing material for sinking repairing of a polyurethane cured track bed of a high speed railway or a heavy haul railway. The high-viscosity vibration attenuation polyurethane repairing material consists of a component A and a component B which are mixed and stirred together mechanically, wherein the mass ratio of the component A to the component B is (1:0.9)-(1:1.5); the component A is a mixture of an HDI tripolymer and polymethylene polyphenyl isocyanate ester; the mass ratio of the HDI tripolymer to polymethylene polyphenyl isocyanate ester is (3:7)-(6:4); the content of -NCO is 27-29%; and the component B consists of polyhydric alcohol, a catalyst, a defoaming agent, a moisture scavenger, an anti-aging agent, a flame retardant and rubber granules. The high-viscosity vibration attenuation polyurethane repairing material is characterized in that the polyhydric alcohol is a mixture which consists of 6-functionality-degree mannitol poly(propylene oxide polyol) and 3-functionality-degree high molecular weight polyether polyol with the molecular weight of 12000. According to the polyurethane repairing material provided by the invention, the volume expansion ratio is 1-3%, the compressive strength of 1 hour is greater than or equal to 12MPa, the adhesion strength is greater than or equal to 6MPa, the damping factor is 0.25-0.40, the accumulated residual deformation is less than or equal to 0.5% after 5 million times of fatigue loading, and the polyurethane repairing material can be applied to polyurethane cured track bed sinking repairing and railway ballast cured track bed sinking repairing as well.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +2

Organic fertilizer

InactiveCN105565955AThe composition ratio is scientific and reasonableNo chemical pollutionFertilizer mixturesPhosphatePoultry manure

Owner:崔子扬

Aqueous PU color changing treating agent used for synthetic leather

InactiveCN101634110ALow costThe ratio is scientific and reasonableFibre treatmentEnvironmental chemistryColor changes

The invention discloses an aqueous PU color changing treating agent used for synthetic leather, which comprises the following raw materials by weight percent: 30-40% of aqueous polyurethane resin, 10-15% of emulsifying agent, 1-3% of amino silicone oil, 0.5-1% of organic silicon flatting agent, 2-5% of organic silicon antifoaming agent, 0.5-2% of aqueous polyurethane thickening agent and 40-60% of water. The aqueous PU color treating agent used for synthetic leather of the invention takes water as solvent to replace toxic solvent, such as dimethyl fomamide, butanone and the like and has the performance of being non-combustible, safe, environment-friendly and saving cost. The aqueous PU color treating agent also has the advantages of no influence on the original effect of leather surfaces, good hand feel, fine and smooth texture, good air permeability and the like, especially when being used in treating sheep bar leather. The synthetic leather manufactured by the color changing treating agent in the invention has fine comprehensive effects, such as hand feel, smoothness, water proof, waxy feel and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Anti-ultraviolet, flame-retardant and moisture-transfer bamboo-charcoal polyester fiber and preparation method and application thereof

InactiveCN102534854AThe composition ratio is scientific and reasonableMoisture wickingFilament/thread formingMonocomponent polyesters artificial filamentActivated carbonPolyester

The invention discloses an anti-ultraviolet, flame-retardant and moisture-transfer bamboo-charcoal polyester fiber, which is formed by the following raw materials: by weight, 5-10 parts of anti-ultraviolet master batches, 10-20 parts of activated carbon master batches and 70-85 parts of copolymerized phosphorus flame-retardant polyester fiber-forming resin. The section of the fiber is special-shaped. The polyester fiber has good adsorption, deodorizing, anti-bacterium mold-proof functions, good flame retardance and anti-ultraviolet effects. Besides, due to the fact that the section of the fiber is special-shaped, the moisture-transfer function of the polyester fiber is good, and the polyester fiber is multifunctional and wide in applied range.

Owner:WUJIANG SANHUI TEXTILE

Uvioresistant and flame retardant polyester fiber and preparing process and application thereof

InactiveCN102560728APermanently UV resistantPermanently flame retardantMelt spinning methodsFilament-forming treatmentFiberPolyester

The invention discloses an uvioresistant and flame retardant polyester fiber and a preparing process and an application thereof. The uvioresistant and flame retardant polyester fiber is made of, by weight, 8-15 parts of uvioresistant master batch and 85-92 parts of copolymerization phosphorus flame retardant polyester fiber-forming resins. According to the polyester fiber, the ratio between components is scientific and reasonable, the uvioresistant master batch and the copolymerization phosphorus flame retardant polyester fiber-forming resins are scientifically bonded organically so as to prepare pre-oriented yarns, the pre-oriented yarns are subjected to elasticizing texturing to produce low stretch yarns, and then multifunctional polyester fibers which are resistant to ultraviolet permanently and flame retardant can be obtained, and the polyester fibers are wide in application. The preparing process for the uvioresistant and flame retardant polyester fiber is high in operability, reasonable in technology, high in production efficiency and capable of achieving industrial production.

Owner:WUJIANG SANHUI TEXTILE

Cashew amine epoxy curing agent for marine heavy anti-corrosion coating and preparation method for curing agent

ActiveCN102898623AThe composition ratio is scientific and reasonableHigh viscosityAnti-corrosive paintsEpoxy resin coatingsSolubilityAlcohol

The invention discloses a cashew amine epoxy curing agent for a marine heavy anti-corrosion coating. The curing agent is sequentially prepared from the following raw materials in parts by weight: 20 to 23 parts of cardanol, 1 to 1.2 parts of diethylenetriamine, 12 to 15 parts of 37 percent formaldehyde aqueous solution, 9 to 10 parts of diethylenetriamine, and 7 to 8 parts of 37 percent formaldehyde aqueous solution. According to the cashew amine epoxy curing agent for the marine heavy anti-corrosion coating, the raw material composition and the optimal proportion and the adding sequence of the raw materials are selected through a large quantity of experiments, and the proportion of each component is scientific and reasonable; acetal is catalyzed by adopting diethylenetriamine to control the viscosity parameter, and then Mannich addition is carried out on the periphery of molecules to improve the alcohol solubility; and the cashew amine curing agent prepared by the method is high in activity, viscosity and solid content and good in compatibility, does not release oil, and can overcome many defects of the cashew amine epoxy curing agent prepared by the method in the prior art.

Owner:JIANGSU SANMU GROUP CORPORATION

Water-based PU bright surface brush clear varnish for synthetic leather

The invention discloses a water-based PU bright surface brush clear varnish for synthetic leather, which comprises the following materials in parts by weight: 35 to 45 parts of water-based polyurethane resin, 50 to 65 parts of water, 0.5 to 1 part of organic silicon flatting agent, and 2 to 5 parts of organic silicon foam killer. The water-based PU bright surface brush clear varnish has the advantages that the mixture ratio of the component is scientific and reasonable, and the components are coordinated with each other and act together; the bright surface brush clear varnish has the advantages of good film reforming property, firm bonding, solvent resistance, hydrolysis resistance and thermosenescence resistance of coating; the finished product made of the synthetic leather, the surface of which is treated by the bright surface brush clear varnish, has the advantages that the original effect of the leather surface is not affected, the treated leather surface has unique slippery effect, and the synthetic leather has good comprehensive effects of good air permeability, good hand feel, water resistance, cohesiveness and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Bamboo-charcoal wet guide type polyester fiber and preparation method and application thereof

InactiveCN102560727ADeodorizingHeat storageMelt spinning methodsFilament-forming treatmentPolyresinBamboo charcoal

The invention discloses a bamboo-charcoal wet guide type polyester fiber and a preparation method and application thereof. The bamboo-charcoal wet guide type polyester fiber is prepared by the following raw materials in part by weight: 10 to 20 parts of active carbon masterbatch and 80 to 90 parts of polyester fiber forming resin, wherein the section of the fiber is abnormally shaped. The polyester fiber has high adsorption, deodorization, bacteriostatic and mildewproof functions; a pre-oriented yarn is prepared by an abnormally-shaped spinning plate; a low-elasticity textured filament yarn is prepared by elastic deformation; and the multifunctional polyester fiber with a wet guide function is obtained, and has a wide application range. The method for preparing the bamboo-charcoal wet guide type polyester fiber is high in operability, rational in process and high in production efficiency, and industrial production can be realized.

Owner:WUJIANG SANHUI TEXTILE

Hydraulic PU pressing color-changing resin for synthetic leather

The invention discloses a hydraulic PU pressing color-changing resin for synthetic leather; the hydraulic PU pressing color-changing resin is constituted by the following raw materials by weight percentage: 35-45 percent of waterborne polyurethane, 25-35 percent of water, 5-15 percent of silicon dioxide color changing powder, 5-10 percent of extinction powder, 0.3-1 percent of organic silicon flatting agents, 1-3 percent of silicone defoaming agents, and 0.5-2 percent of waterborne polyurethane thickeners. The hydraulic PU pressing color-changing resin for synthetic leather takes water as solvent, toxic solvents such as dimethyl fomamide and butanone are replaced, therefore, the hydraulic PU pressing color-changing resin has non-inflammable, safe, environmental-protection, cost-saving performances, and the pressing color-changingresin has the advantages of good film forming property, firm adhesion, solvent-proof, cold-resistance, hydrolyzation-resistance and heat-proof ageing coating. The finished products manufactured by the pressing color-changing resin has the advantages of full handle, good pressing double-color effect, fine and smooth texture, good air permeability and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

A multi-nutrient major-element water-soluble fertilizer powder product and a preparing method thereof

InactiveCN107892636AIncrease concentrationBalanced nutritionMagnesium fertilisersAlkali orthophosphate fertiliserEthylenediamineSolubility

A multi-nutrient major-element water-soluble fertilizer powder product is provided. The product includes urea, urea phosphate, ammonium polyphosphate, potassium nitrate, potassium dihydrogen phosphate, calcium nitrate, magnesium sulfate, water-soluble trace elements, wormcast, a composite chelating agent, a growth regulator, Solifix and a carboxymethyl cellulose-grafted N-isopropylacrylamide copolymer. The water-soluble trace elements include two or more of iron, copper, zinc, boron, manganese and molybdenum compounds. The composite chelating agent is a composition of disodium ethylenediamintetraacetate and biodegradable ethylenediamine-N,N'-disuccinic acid. The growth regulator is one of diethylaminoethyl hexanoate, alpha-naphthaleneacetic acid or indoleacetic acid or a composition thereof in any ratio. A preparing method of the product is simple and the product is cheap. The product has a high fertilizer efficiency, balanced nutrients, good water solubility, capability of being environment-friendly and pollution-free, and scientific and reasonable component proportions, and can be stored for long time without caking.

Owner:苗强

Aqueous PU (Polyurethane) dry slippery feel treated agent for synthetic leather

InactiveCN101929075ALow costThe ratio is scientific and reasonableFibre treatmentDefoaming AgentsOrganosilicon

The invention discloses an aqueous PU (Polyurethane) dry slippery feel treated agent for synthetic leather, which comprises the following raw materials in percentage by weight: 30-40 percent of aqueous PU resin, 50-60 percent of water, 1-3 percent of modified organosilicon polymer, 5-7 percent of modified amino silicone oil, 0.5-1 percent of organosilicon flatting agent, 2-5 percent of organosilicon defoaming agent and 0.5-2 percent of aqueous PU thickening agent. The aqueous PU (Polyurethane) dry slippery feel treated agent for the synthetic leather has the advantages of scientific and reasonable proportion of all the components, coordination and combined action of the components, good film forming, firm bonding, solvent resistance of a coating, cold resistance, hydrolysis resistance, heat resistance and anti-aging; and particularly, the combined action of the modified organosilicon polymer and the modified amino silicone oil ensures that the dry slippery feel of treated leather is unique, and the synthetic leather has good combined effect in the aspects of feeling, waterproofing, bonding, and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

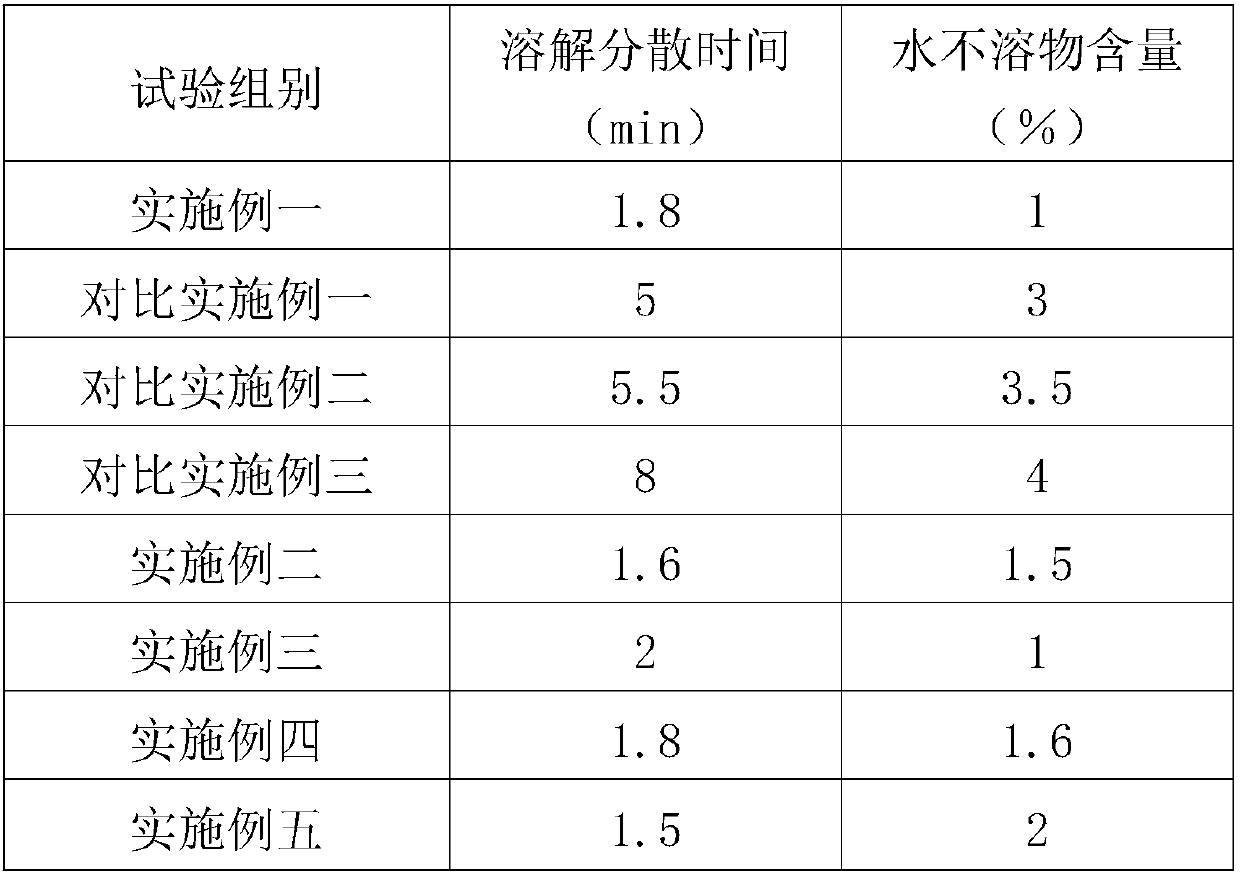

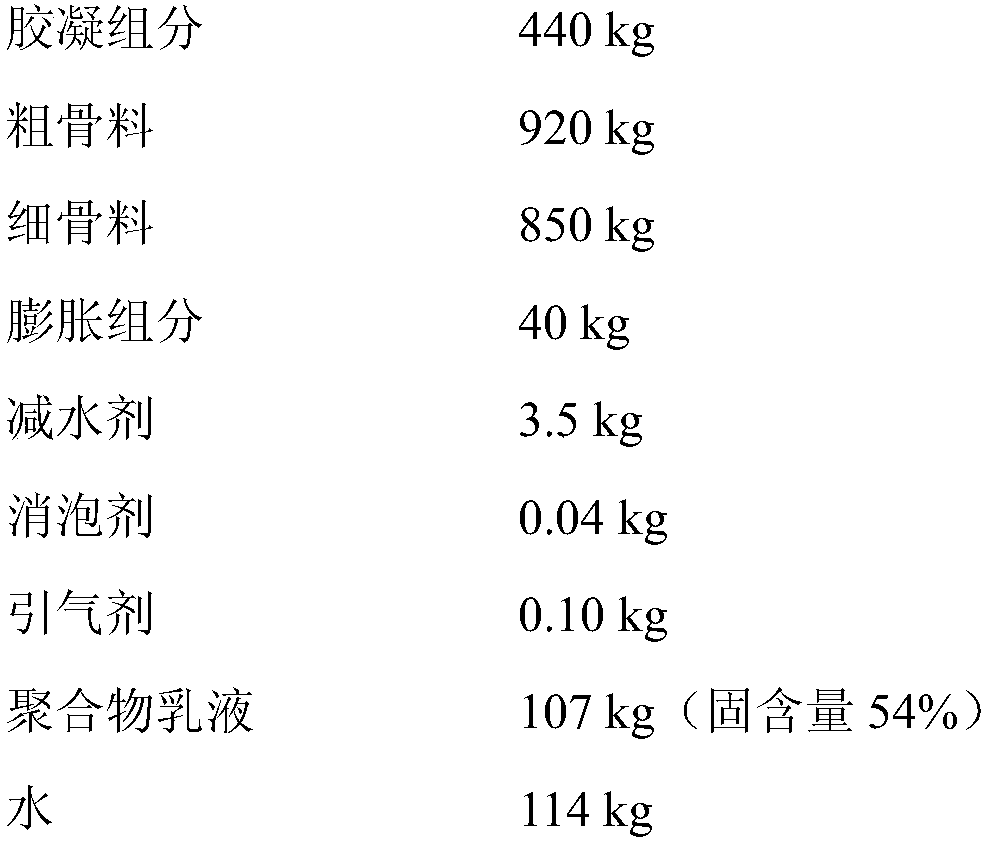

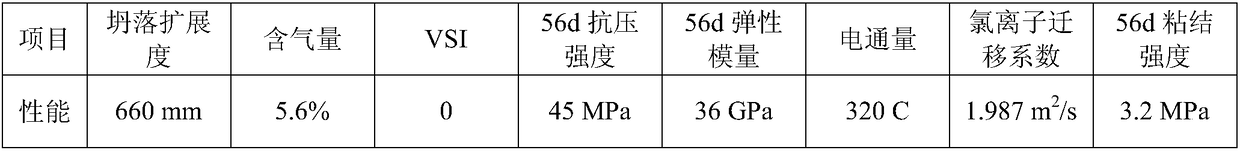

High-polymer self-compacting concrete for filling layer of ballastless track of steel truss girder

The invention belongs to the technical field of materials and in particular relates to high-polymer self-compacting concrete for a ballastless track of a steel truss girder. The high-polymer self-compacting concrete is characterized by being prepared by mixing a dry material and a liquid material in a forced mixer according to a certain ratio, wherein the ratio of the dry material to the liquid material is 1:(0.08-0.25). The dry material is prepared from a cementitious component, an inert mineral admixture, an expansive component, coarse aggregates and fine aggregates; and the liquid materialis prepared from a polymer emulsion, a water reducer, a defoaming agent, an air entraining agent and water. The high-polymer self-compacting concrete has the characteristics of high flowability (slumpflow is 560-700mm), good stability, high cementing strength and excellent durability, is suitable for the ballastless track of the steel truss girder and is also suitable for bridges, civil buildingsas well as repairing and strengthening fields.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

Young chicken fattening fodder and processing method thereof

InactiveCN105475673AWide variety of sourcesLow priceFood processingAnimal feeding stuffBiotechnologyGrowth promoting

The invention discloses young chicken fattening fodder and a processing method thereof, which is prepared from following raw materials in parts by weight: 200-250 parts of corn flour, 100-150 parts of sorghum rice, 80-100 parts of brown rice, 100-120 parts of wheat bran, 2-4 parts of sweet potato, 2-5 parts of pumpkin, 5-7 parts of rice husk, 7-9 parts of sweet potato seedling powder, 20-30 parts of cassava starch, 20-26 parts of beet leaves, 16-20 parts of fermented soybean meal, 8-10 parts of Sowthistle tasselflower, 6-8 parts of towel gourd stem, 5-8 parts of peanut seedling powder, 3-5 parts of cavings, 7-11 parts of mountain flour, 3-5 parts of Schisandra chinensis, 2-3 parts of radix pseudostellariae, 5-6 parts of Rhizoma Polygonati Odorati, 2-3 parts of fructus rosae laevigatae, 5-6 parts of Poria cocos powder, 2-7 parts of ampullaria gigas, 2-5 parts of jujube powder, 2-6 parts of sodium chloride, 1-3 parts of lysine, 5-9 parts of methionine, 2-4 parts of glycine, 3-6 parts of cordyceps militaris, 1-4 parts of wormwood and 10-12 parts of citric acid. Compared with the prior art, the fodder is wide in source, low in cost, scientific and reasonable in component match and balanced in nutrition match, has obvious growth promoting action, realizes healthy growth of young chicken in a fattening period and reduces fattening cost at the same time.

Owner:铜陵润生生态养殖有限公司

Bee breeding feed

InactiveCN106036260AImprove disease resistanceEnhance physical fitnessAnimal feeding stuffAccessory food factorsDiseaseAnimal science

The invention belongs to the technical field of insect breeding feeds, and particularly relates to a bee breeding feed. The breeding feed is prepared from, by weight, 70-120 parts of soybean cake powder, 10-25 parts of egg powder, 0.5-2.5 parts of vitamins, 15-45 parts of pollen, 15-30 parts of sugar and 0.6-2.5 parts of functional additive. The bee breeding feed is scientific is formula, balanced in nutrition and good in palatability, the feed intake and the immunity of bees can be improved, body quality is fundamentally enhanced, the risk of diseases is reduced, rapid and healthy growth and reproduction of bees are promoted, the preparing technology is simple, batch production can be achieved, and the bee breeding feed is suitable for industrial popularization.

Owner:广西驰胜农业科技有限公司

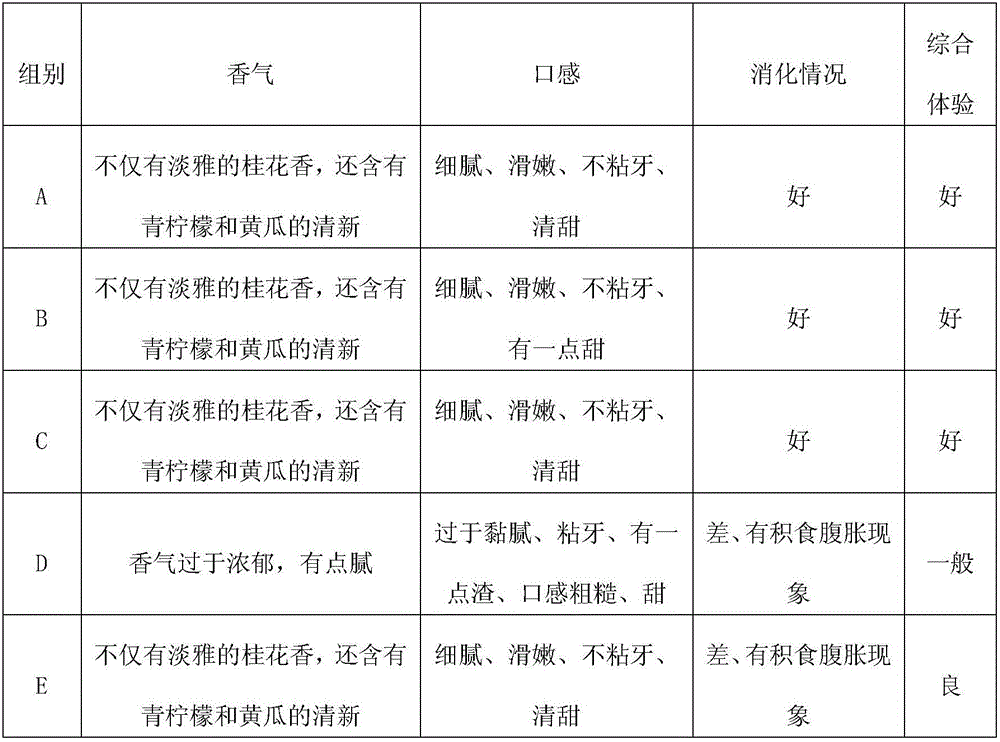

Osmanthus cake and making method thereof

InactiveCN106173981APleasant aromaFresh tasteFood ingredient functionsGrape seedExtracted grape seeds

The invention belongs to the technical field of food processing, and particularly relates to an osmanthus cake and a making method thereof. The osmanthus cake is made from, by weight, 40-55 parts of glutinous rice, 0.1-0.3 part of sweetening agent, 15-22 parts of osmanthus flowers, 8-15 parts of rice, 0.2-0.6 part of grape seed extracts, 1-3 parts of green lemons, 3-5 parts of cucumbers, 0.7-1.2 parts of pumpkin juice and 0.3-0.7 part of Chinese herbal medicine preparation. In addition, the invention discloses the making method of the osmanthus cake. The osmanthus cake is pleasant in fragrance, fresh in taste, delicate in mouthfeel, not sticky, rich in nutrition, capable of strengthening the spleen and stomach and aiding digestion, nutritional and healthy, and the making method is simple and suitable for industrial popularization.

Owner:覃政强

High-manganese low-carbon composite alloy and method for preparing same

The invention discloses a kind of high manganese and low carbon composition alloy and the preparation method of it, the composition alloy contain the percentage by weight component as follow: Mn 70~75, Si 11~17, Al 7~14, P<0.2, C<0.3, S<0.03,surplus is Fe. The invention of composition alloy component proportioning science and rational, specific weight controlling strict, the method can deoxidize efficient for liquid steel, remove the foreign substance in liquid steel and deoxidize rapidly, make the steel slag easily floated upward and removed to obtain high degree of purity liquid steel, the composition alloy can be used as deoxidant in smelting kinds of steel, especially suitable for smelting conduit wiring steel, bridge and canal steel and high-strength ship plate steel that need strength deoxidation capacity, the composition alloy can reach high deoxidation effect.

Owner:危松林

Fire-resistant, oil-resistant and high-and low-temperature resistant industrial rubber

InactiveCN106750596AHigh temperature resistantImprove high temperature resistanceOther chemical processesAdhesiveTemperature resistance

The invention discloses fire-resistant, oil-resistant and high-and low-temperature resistant industrial rubber which is prepared from the following raw materials: natural rubber, neoprene, nitrile rubber, ceramic ultrafine powder, palm oil, an adhesive, dimethicone, polyurethane, oleic acid, a softener, zinc oxide, PEG4000 and an anti-aging agent. The industrial rubber has great advantages in the aspects of fire resistance, oil resistance and high temperature resistance, cannot be worn or broken in use and is long in service life, the components are scientific and reasonable in proportion, safe and effective, the preparation method is easy to operate and the fire-resistant, oil-resistant and high-and low-temperature resistant industrial rubber is suitable for massive promotion in industry.

Owner:吴中区穹窿山天仲高分子材料技术研究所

Composite heat conductive material for LEDs

InactiveCN105086461AReduce surface tensionSmall viscosity-temperature coefficientTemperature coefficientSilicone resin

The invention provides a composite heat conductive material for LEDs. The heat conductive material comprises components in parts by weight as follows: 10-20 parts of organic silicone resin, 10-20 parts of branched silicone oil, 15-25 parts of linear silicone oil, 1-10 parts of an antioxidant, 10-20 parts of graphene, 5-15 parts of nanoscale heat conductive metal fibers, 15-25 parts of an inorganic filling material and 15-25 parts of 95% aluminum oxide ceramic fibers. Filling materials such as the graphene with excellent heat conductivity, mechanical and chemical stability and the like, the nanoscale heat conductive metal fibers and the like are introduced into organic silicone resin which is low in surface tension, low in viscosity-temperature coefficient, high in compressibility and high in gas permeability and the branched silicone oil which is long in service life, free of sun crack and hardening and good in heat conduction effect, all the components are matched scientifically and reasonably, and the prepared composite heat conductive material is excellent in aging performance, stable in property, good in heat resistance, good in heat conductivity and particularly applicable to LED lamps.

Owner:桂林健评环保节能产品开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com