Bamboo charcoal, flame retardant and moisture conductive terylene fiber, preparation method and application thereof

A technology for moisture-conducting polyester and bamboo charcoal is applied in the field of polyester fibers to achieve the effects of strong operability, improved working surface, and enhanced water absorption and moisture-conducting capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

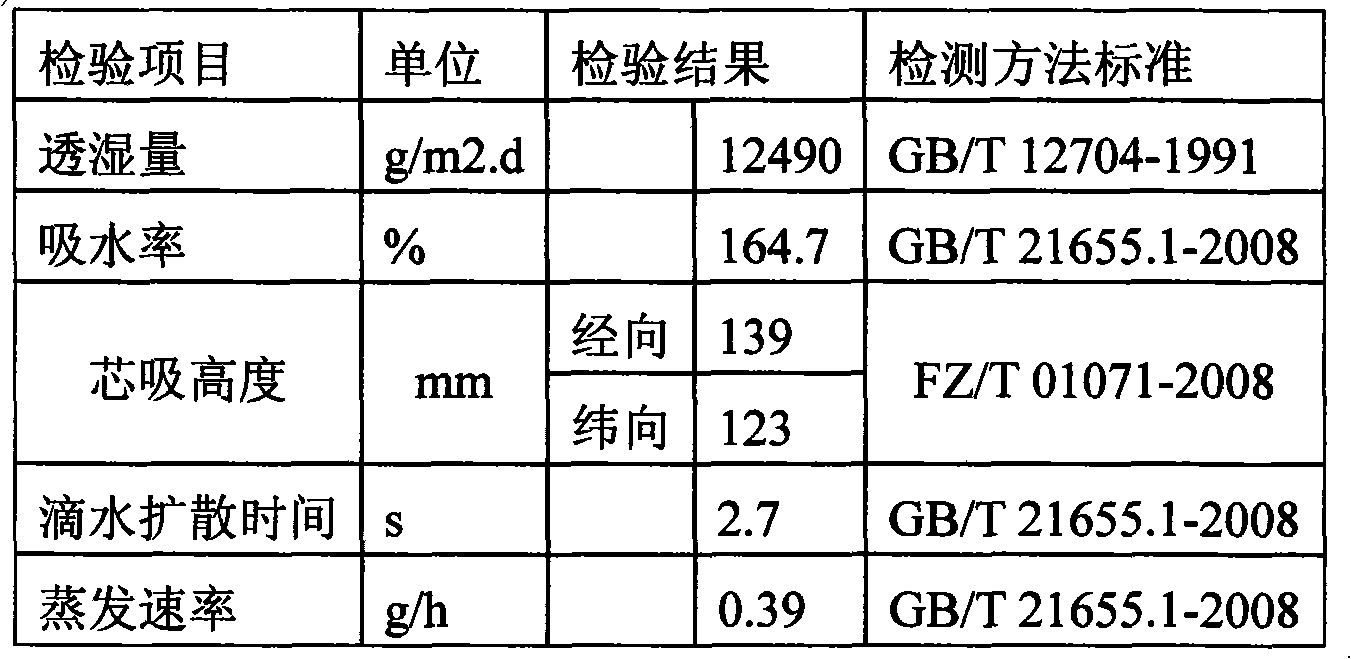

Image

Examples

Embodiment 1

[0022] 1, a kind of bamboo charcoal, flame-retardant, moisture-conducting polyester fiber, it is made up of the raw material of following weight: 50 kilograms of activated carbon master batches, 950 kilograms of copolymerization type phosphorus flame-retardant polyester fiber-forming resins.

[0023] 2. Preparation of bamboo charcoal, flame retardant and moisture-conducting polyester fibers:

[0024] (1) First, the bamboo charcoal is ground into fine powder, then the bamboo charcoal fine powder is blown with compressed air, enriched to obtain activated carbon particles of 300nm to 500nm, and then 20% by weight of activated carbon with a particle size of 300 to 500nm and 80% poly Ethylene terephthalate is blended, extruded with a screw extruder, pelletized, and activated carbon masterbatches are prepared, and the blending temperature is 250 ° C, and the screw speed is 100 rpm;

[0025] (2) get 50 kilograms of activated carbon masterbatches that step (1) obtains by weight and 95...

Embodiment 2

[0042] 1, a kind of bamboo charcoal, flame-retardant, moisture-conducting polyester fiber, it is made up of the raw material of following weight: 100 kilograms of active carbon master batches, 900 kilograms of copolymerization type phosphorus flame-retardant polyester fiber-forming resins.

[0043] 2. Preparation of bamboo charcoal, flame retardant and moisture-conducting polyester fibers:

[0044] (1) First, the bamboo charcoal is ground into fine powder, then the bamboo charcoal fine powder is blown with compressed air, enriched to obtain activated carbon particles of 300nm to 500nm, and then 30% by weight of activated carbon with a particle size of 300 to 500nm and 70% poly Ethylene terephthalate is blended, extruded with a screw extruder, pelletized, and activated carbon masterbatches are prepared, and the blending temperature is 270 ° C, and the screw speed is 200 rpm;

[0045] (2) get 100 kilograms of activated carbon masterbatches obtained by step (1) and 900 kilograms ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com