High-polymer self-compacting concrete for filling layer of ballastless track of steel truss girder

A technology of ballastless track and high polymer, which is applied in the field of building materials, can solve problems such as difficulty in ensuring project quality, achieve the effects of alleviating flow performance and stability performance, reducing porosity, and improving firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

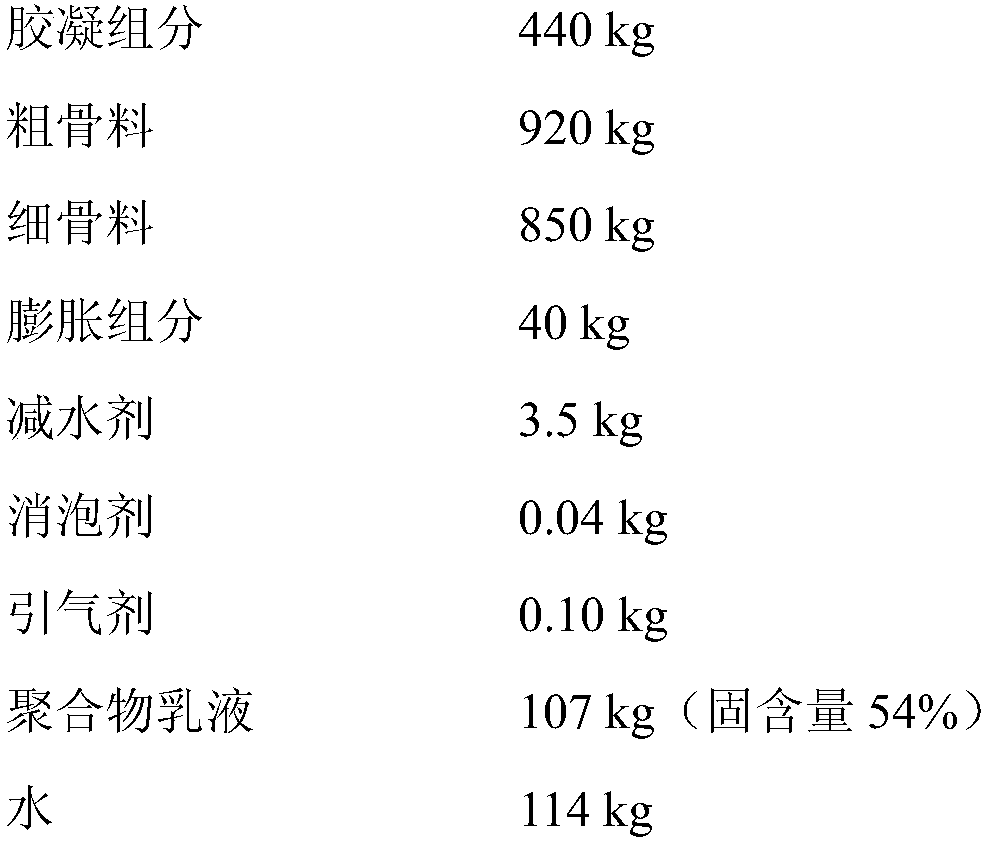

[0040] Embodiment 1: The weight ratio of each component of high polymer self-filling concrete is:

[0041]

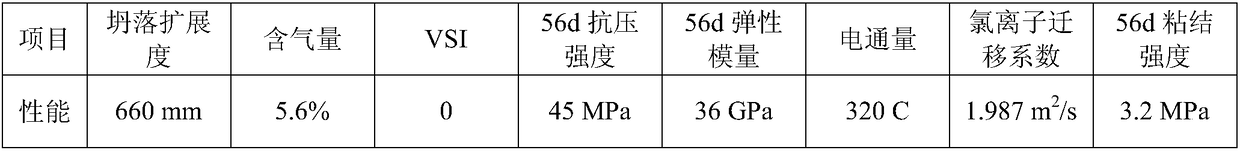

[0042] The main properties of the polymer self-filling concrete are shown in Table 1.

[0043] Table 1 Main properties of polymer self-filling concrete

[0044]

[0045] It can be seen from Table 1 that the polymer self-filling concrete proposed by the present invention has high fluidity, good stability, high bonding strength, and excellent durability, and can be used for the filling layer structure of steel truss girder slab ballastless track.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| slump spread | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com