Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

143results about How to "Strong puncture resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

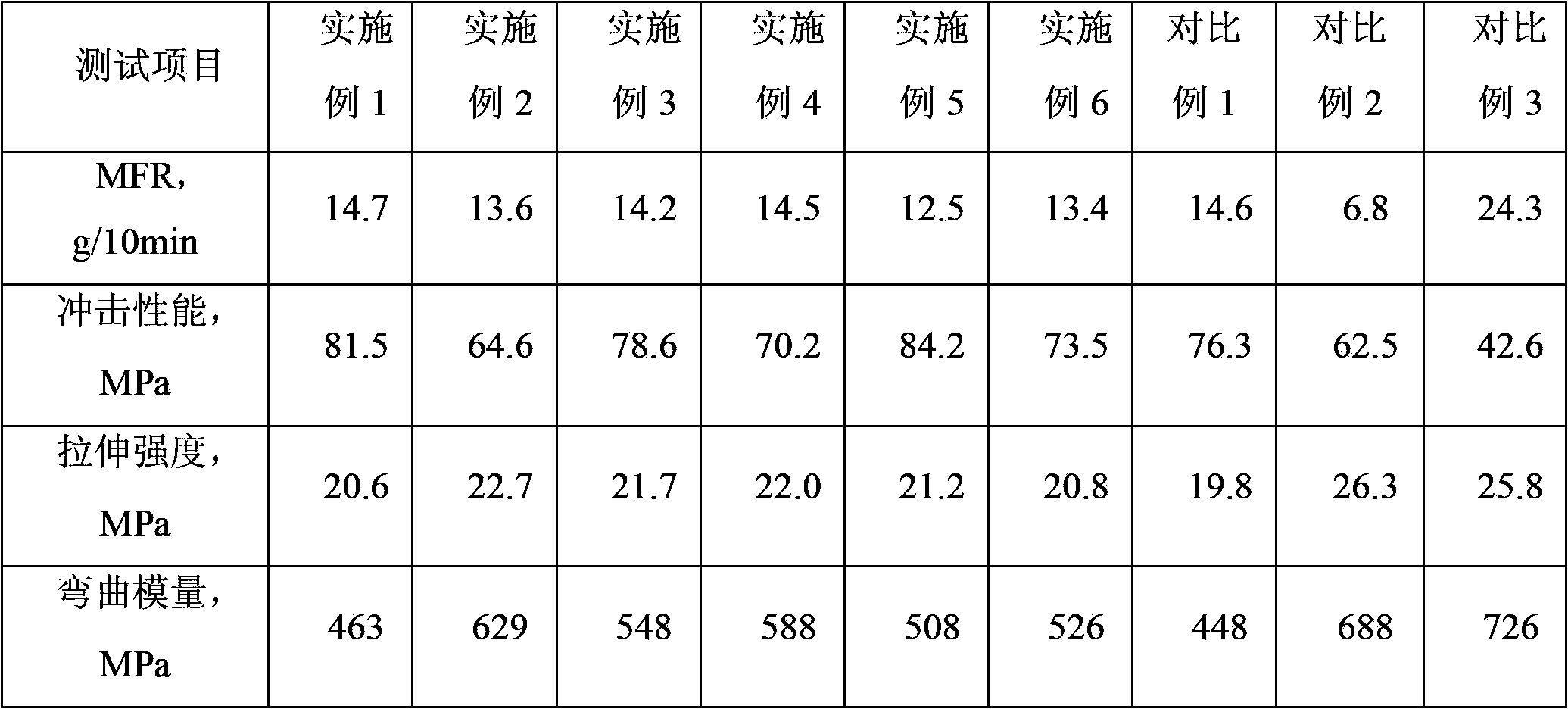

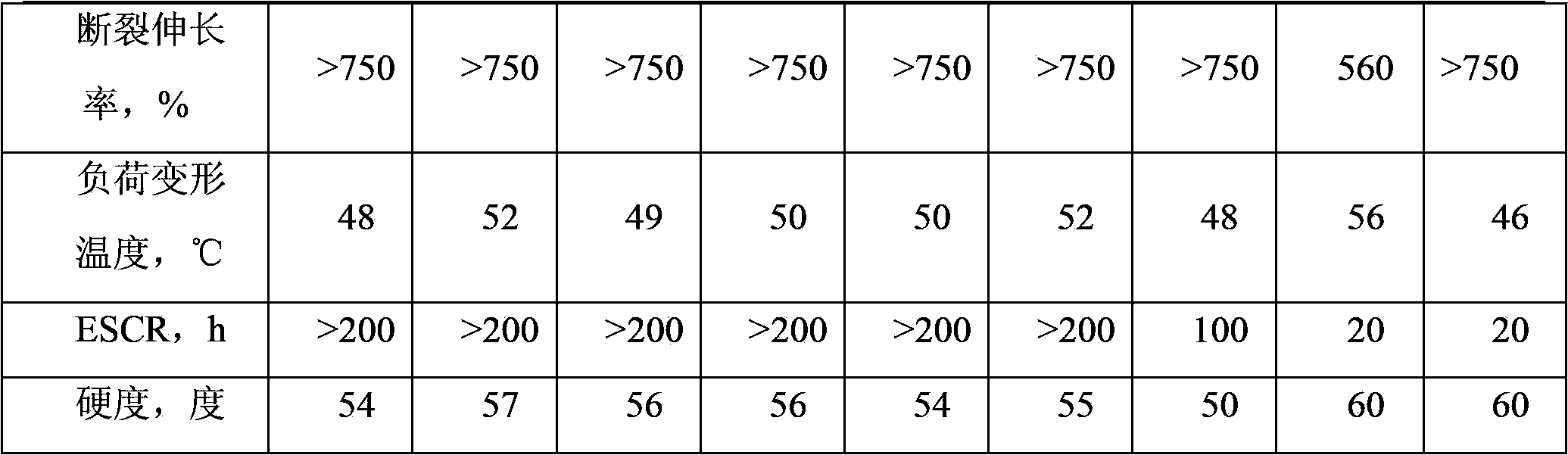

Polyethylene composite for drip irrigation pipes

ActiveCN103665508AHigh strengthGood flexibilityClimate change adaptationWatering devicesLow-density polyethyleneAntioxidant

The invention discloses a polyethylene composite for drip irrigation pipes, belongs to the technical field of high polymer materials, and particularly relates to a polyethylene composite. The polyethylene composite is characterized by comprising the following components in parts by weight: 40-60 parts of high-density polyethylene resin, 20-30 parts of high-pressure polyethylene resin, 10-30 parts of metallocene polyethylene resin, 0.15-1.2 parts of antioxidant, and 1.2-3 parts of carbon black. The composite, besides having good strength, flexibility, processability and aging resistance, has excellent abrasion resistance, ESCR (environmental stress cracking resistance) and puncture resistance and good high-temperature hydrostatic performance.

Owner:CHINA PETROLEUM & CHEM CORP

Water-based non-curable rubber asphalt coating and preparation method thereof

ActiveCN105038593ASolve the problem of heating to constructionSimple construction processConjugated diene hydrocarbon coatingsBituminous coatingsWater basedBituminous waterproofing

The invention discloses a water-based non-curable rubber asphalt coating and a preparation method thereof and belongs to the field of coatings. Modified rubber asphalt and mixed tackifying resin are emulsified, and a self-adhesive additive, an interface additive, an anti-freezing agent and an anti-ageing agent are compounded. The problem that the non-curable rubber asphalt waterproof coating cannot be applied until the coating is heated is solved, a process is simplified, and the application range of a product is widened. The initial adhesivity and persistent adhesivity of the coating are improved by using a tackifying resin emulsion. The problem that the non-curable rubber asphalt waterproof coating cannot be fully spread on a damp interface due to poor adhesivity is solved by using a silane interface agent, full-spreading seamless construction can be achieved, the hidden danger of water leakage or seepage is completely eradicated, and the permeation resisting performance meets the industrial standard. The water-based non-curable rubber asphalt coating is cured no longer by innovatively using the self-adhesive additive after coating construction is completed, and is good in puncture resistance and self-curing performance. Quick demulsification of the water-based non-curable rubber asphalt coating is achieved by adopting a double-component spraying technology.

Owner:SHANDONG DASHAN ROAD & BRIDGE ENG

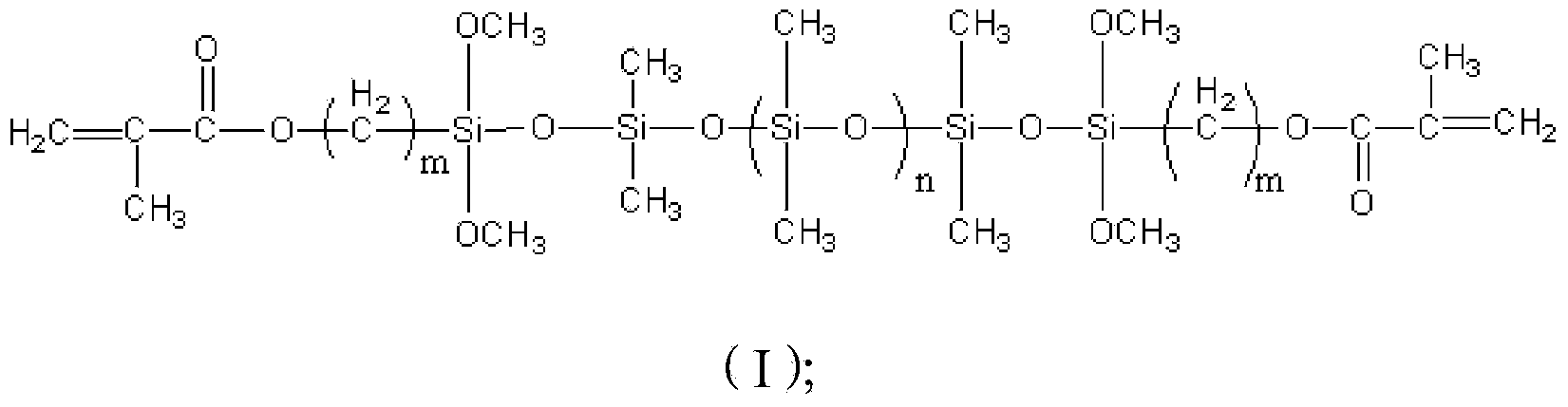

Frame sealant composition and display device

InactiveCN103965821ASolve the lack of adhesionStrong puncture resistanceLayered productsEster polymer adhesivesAdhesion forceSolvent molecule

The invention discloses a frame sealant composition capable of improving a residual image. Novel dual-cured resin materials are introduced into a conventional frame sealant system and serve as components of an auxiliary frame sealant to form a frame sealant system in a multi-cured mode. The frame sealant system has thermo-curing and / or UV curing properties of a main adhesive to endow the main adhesive with sufficient strength, the auxiliary frame sealant can be UV-cured and moisture-cured through corresponding curing groups, and a glass substrate can be combined with the main adhesive and a frame sealant together, so that the phenomenon of insufficient adhesion force caused by solvent molecules such as water vapor when the glass substrate is packaged by a conventional frame sealant is avoided, and the frame sealant is high in adhesion strength and excellent in puncture resistance.

Owner:BOE TECH GRP CO LTD +1

Thin layer application type water-proof and thermal insulation coating

A water-proof and insulating thin-layer paint is proportionally prepared from elastic emulsion of acrylic acid, asbestos wool, talc powder, defoaming agent, anticorrosion agent, thickening agent, water, hollow glass micro-beads, disperser and opaque polymer. Its advantages are high water-proof and insulating effect, and thin coated layer (2mm).

Owner:王立华

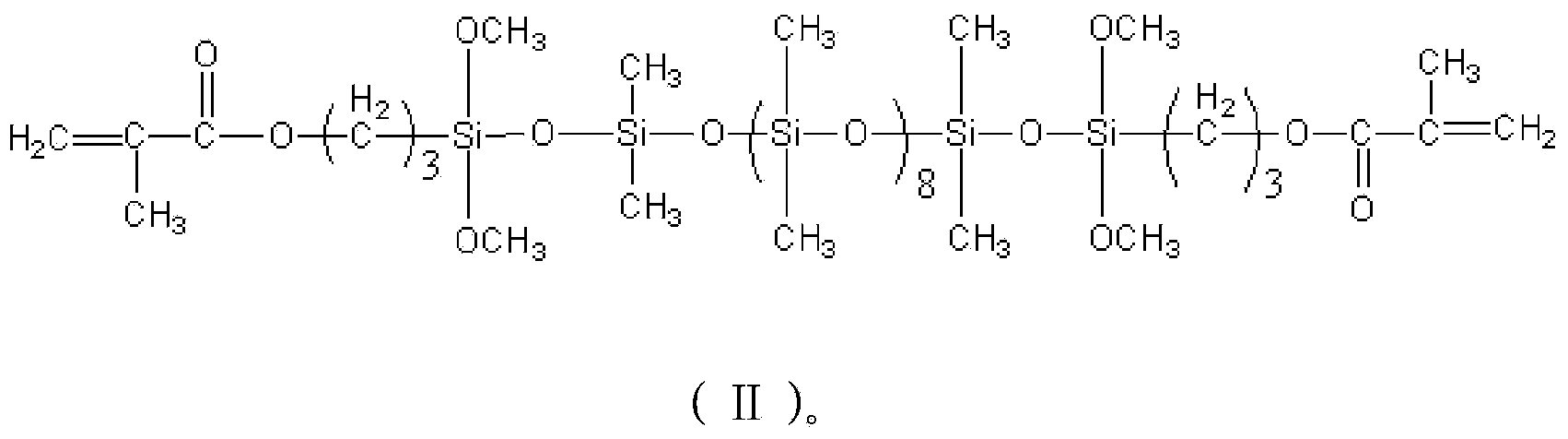

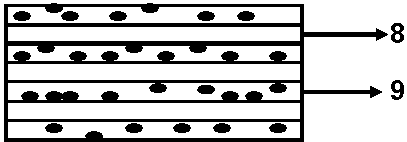

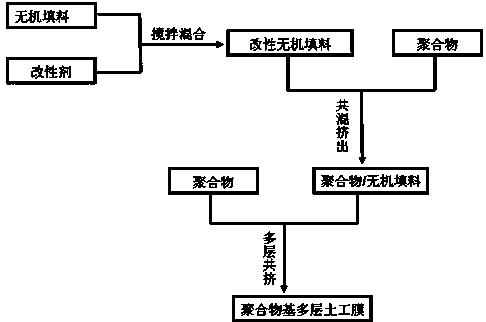

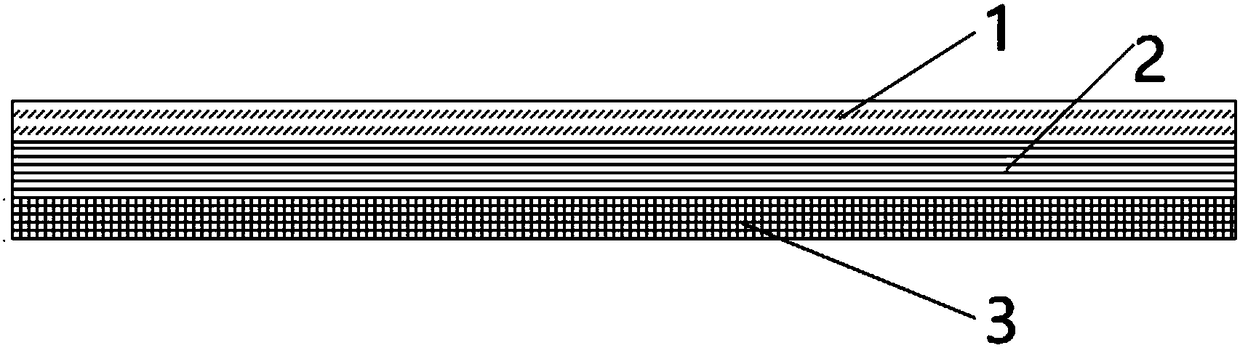

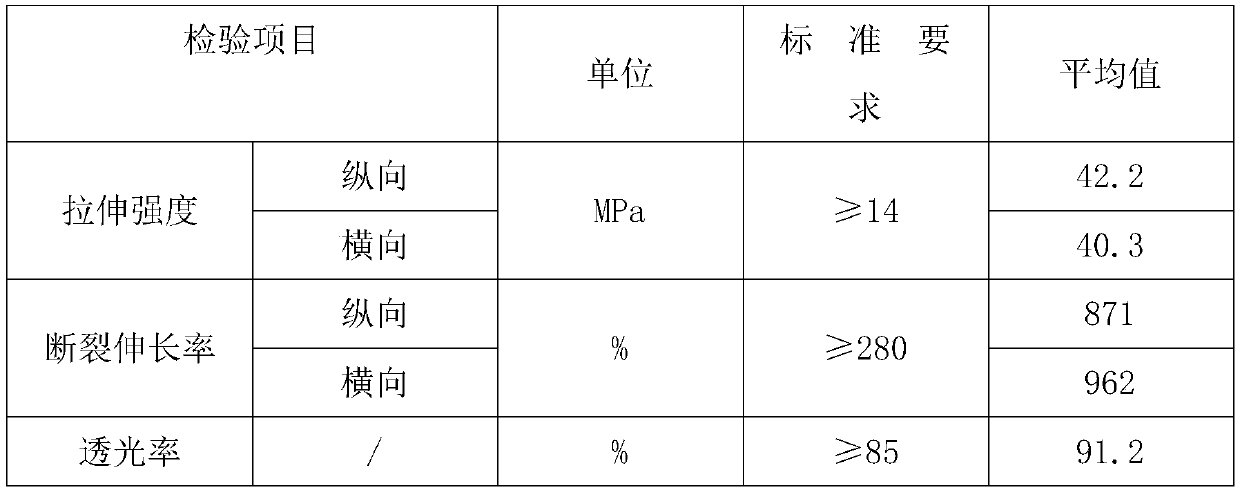

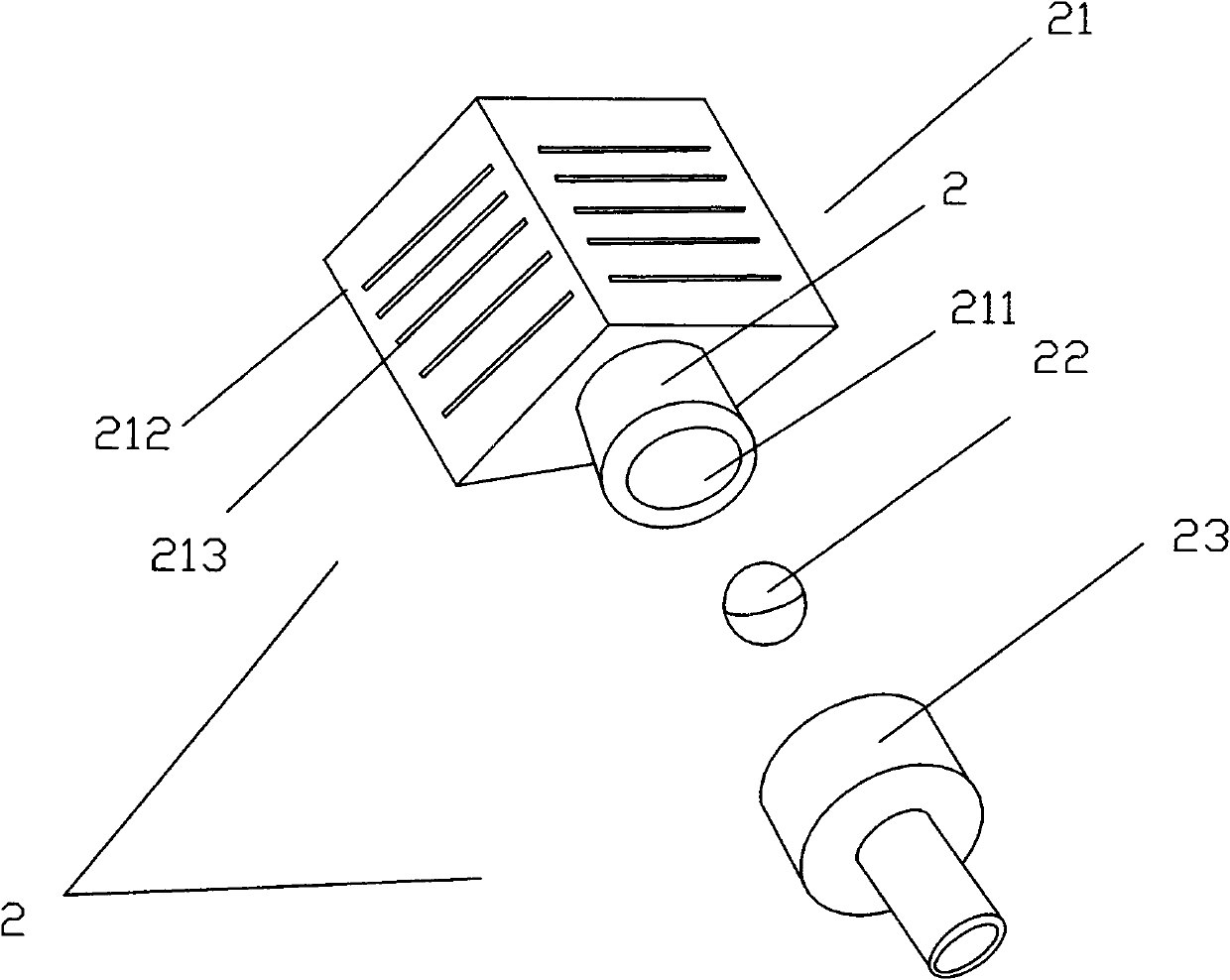

Micro-nano multilayer polymer geomembrane as well as preparation method and device thereof

The invention discloses a micro-nano multilayer polymer geomembrane as well as a preparation method and device thereof. The micro-nano multilayer polymer geomembrane, in parts by weight, comprises 60-95 parts of polymers, 4-40 parts of inorganic filler and 1-10 parts of a modifier. According to the invention, the formula and preparation process of products are preferred, and a prepared multilayer polymer geomembrane is high in tensile strength, high in elongation at break, excellent in penetration resistance, and excellent in barrier property, and compared with existing products, the micro-nano multilayer polymer geomembrane is lower in cost, and green and environment-friendly in the production process, and can achieve continuous production. The preparation method disclosed by the invention is simple in process and easy to operate, therefore, the preparation method is extremely suitable for industrial production.

Owner:GUIZHOU MATERIAL IND TECH INSTITUE

Cardboard starch gum activating agent and cardboard starch gum

InactiveCN101054501AImprove stress resistanceStrong puncture resistanceStarch adhesivesCardboardPlasticizer

The invention relates to a cardboard starch glue activating agent and cardboard starch glue. Said activating agent includes following matters by weight (wt.%): 65-75% of sepiolite powder, 10-20% of light calcium powder, 1-5% of sand pulp plasticizer, 3-6% of sodium carboxymethylcellulose, 1-5% of custer sugar. Said starch glue has 1-6% of activating agent. The starch glue produced by inventive activating agent is non-poisonous and harmless and is not tending to the phenomenon of water gel separation, and has a good bonding capacity, a simple producing craft, a stable product quality, a small pollution. The cardboard has a big pressure resistance, a fast car speed, a powerful puncturing resistance.

Owner:邹栋华 +3

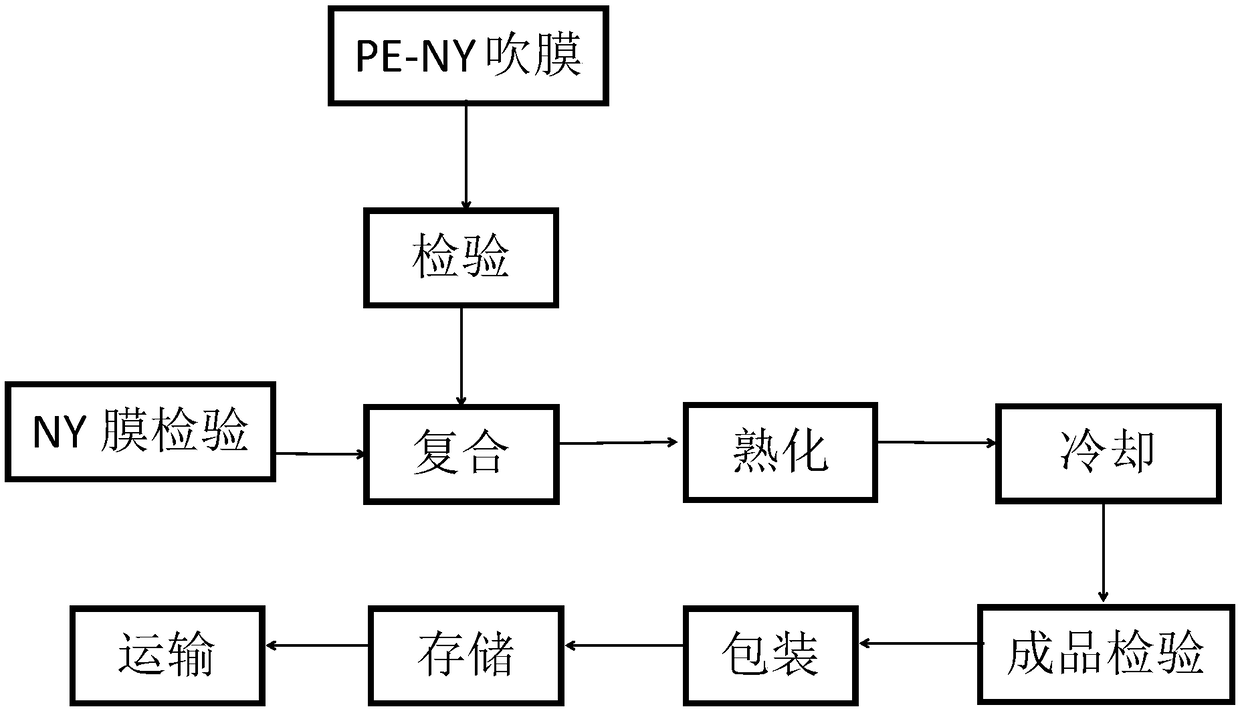

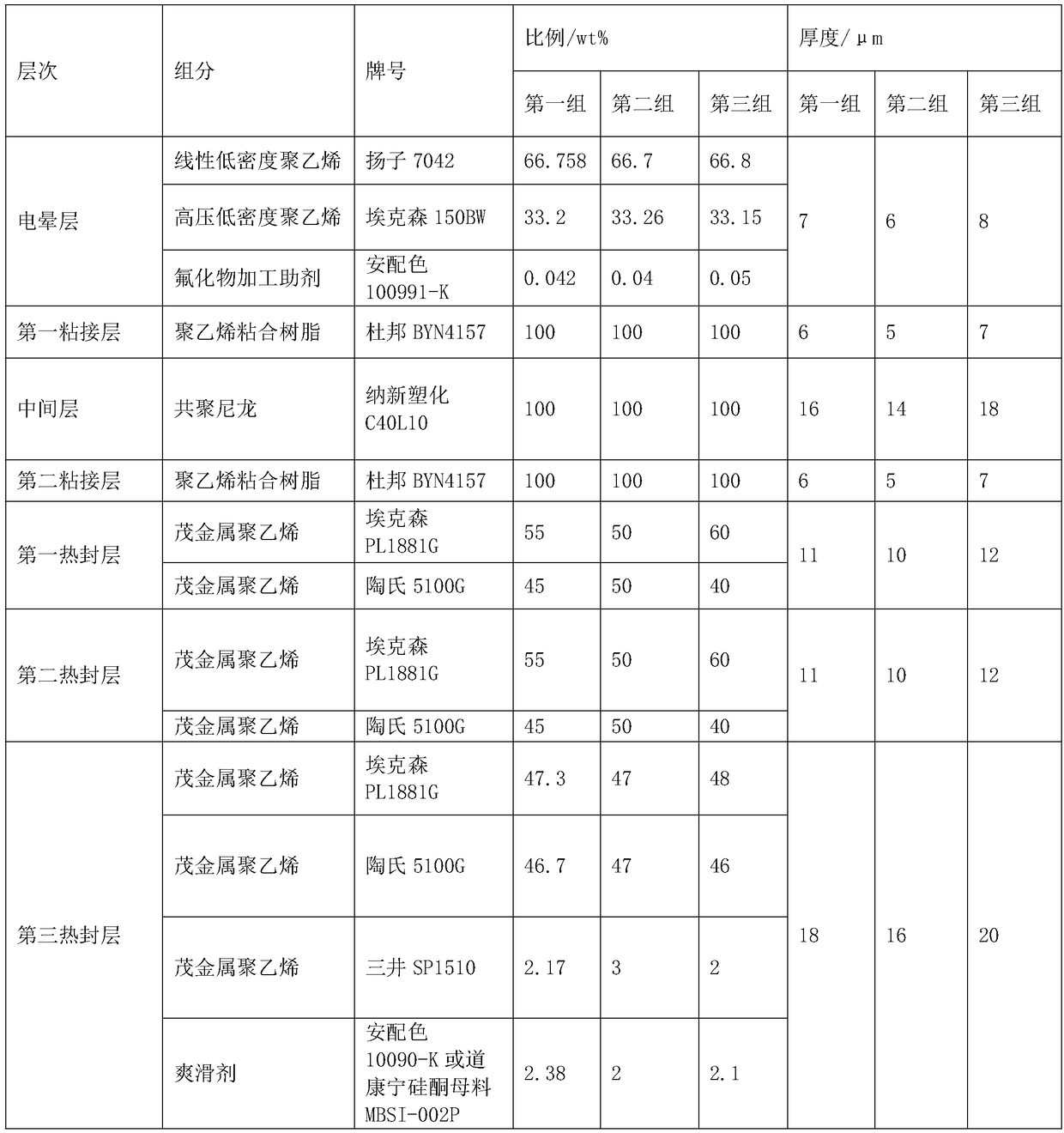

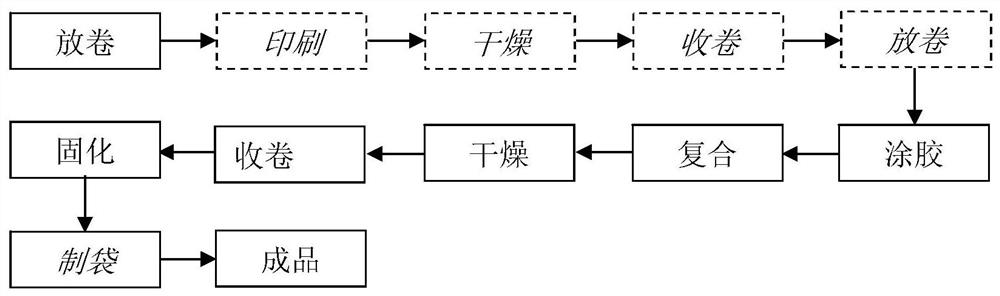

Transparent packaging film and preparation method thereof

PendingCN108790352AHigh solid contentLow viscosityFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

The invention relates to a transparent packaging film and a preparation method thereof. The transparent packaging film comprises an NY (nylon) film layer, an adhesive layer and a PE-NY (polyethylene-nylon) co-extrusion film which are tightly bonded, wherein the PE-NY co-extrusion film layer consists of a corona layer, a first adhesive layer, a middle layer, a second adhesive layer, a first heat sealing layer, a second heat sealing layer and a third heat sealing layer which are sequentially adhered together; the corona layer comprises 66.7 to 66.8wt% of linear low density polyethylene, 33.1 to33.3wt% of high-pressure low density polyethylene and 0.04 to 0.05wt% of fluoride processing additive; the first adhesive layer and the second adhesive layer comprise polyethylene bonding resin; the middle layer comprises copolymerizing nylon; the first heat sealing layer and the second heat sealing layer comprise metallocene polyethylene; the third heat sealing layer comprises 95 to 97wt% of metallocene polyethylene, 2 to 3wt% of smoothing agent and 1 to 2wt% of opening agent. The transparent packaging film is a composite film with good heat sealing and packaging adaptability.

Owner:HUANGSHAN NOVEL

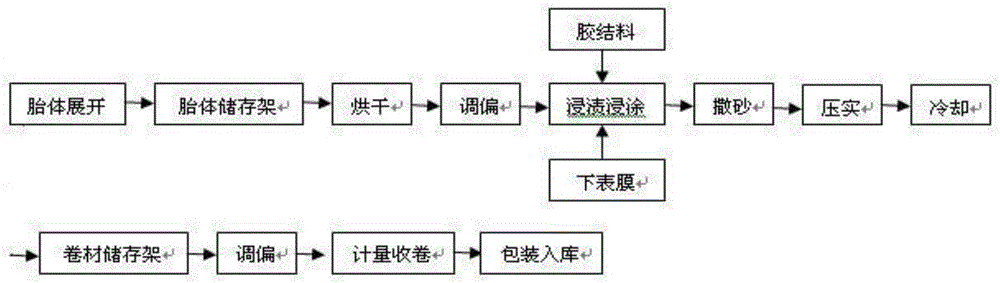

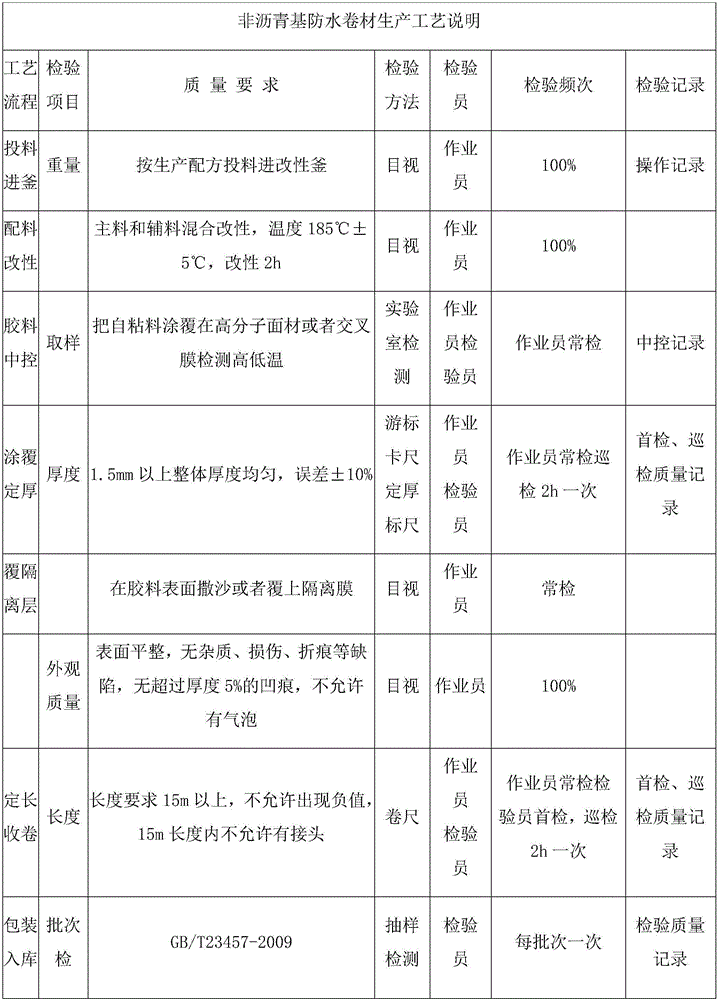

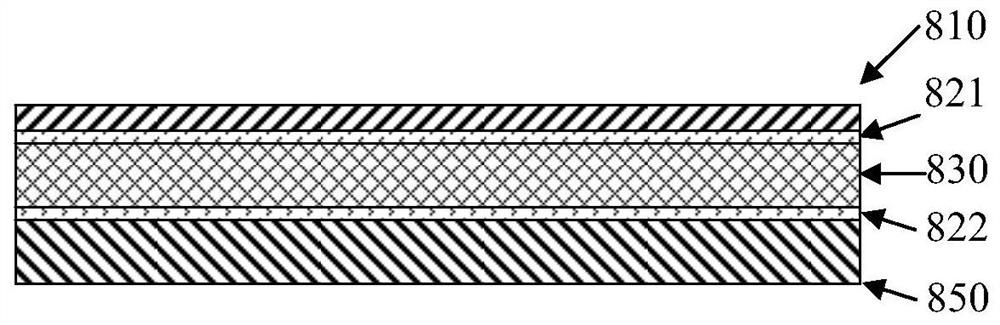

Super weather-proof composite waterproof roll material

InactiveCN104553185AWith super weather resistanceResistant to UV radiationLamination ancillary operationsSynthetic resin layered productsHigh resistanceEnvironmental resistance

The invention relates to the field of waterproof roll materials, and particularly relates to a super weather-proof composite waterproof roll material. The super weather-proof composite waterproof roll material comprises a bonding and sealing adhesive layer and an isolating film protection layer, and also comprises a super weather-proof polymeric film layer, wherein the super weather-proof polymeric film layer, the bonding and sealing adhesive layer and the isolating film protection layer are sequentially arranged from top to bottom and are adhered into a whole in a hot pressing way. The hot pressing temperature is 30 to 220 DEG C, includes but is not limited to 30 to 220 DEG C, and can be adjusted according to factors such as specific production equipment and a hot pressing technology. The bonding and sealing adhesive layer is compounded with the a super weather-proof polymeric film structure, so that the structure has high environmental resistance, corrosion resistance, high strength and high toughness, good dimensional stability, and high impact resistance and puncture resistance, does not need to be protected by cement and mortar, and can be constructed in various environments.

Owner:HANGZHOU FUMO NEW MATERIAL TECH

Lead-acid storage battery separator and preparation method thereof

InactiveCN104852002AReasonable structureTightly bondedFinal product manufactureCell component detailsGlass fiberPolyester

The invention discloses a lead-acid storage battery separator which comprises 85-95 percent by weight of superfine glass fibers, 4-10 percent by weight of polyester fibers and 1-5 percent of cellulose acetate fibers. A preparation method comprises the following steps: pulping the superfine glass fibers for 5-10min and then adding the polyester fibers and the cellulose acetate fibers, pulping for 8-12min, forming and beating to enter a drying system at a constant speed, drying at a temperature of 160-2500 DEG C, winding and cutting to obtain the lead-acid storage battery separator. The lead-acid storage battery separator prepared by adopting the preparation method is reasonable in structure; the polyester fibers and the cellulose acetate fibers are added, so that the advantages of insulation, isolation and storage of an acid liquor of an existing AGM separator can be kept, the relatively high mechanical strength, excellent puncture resistance and excellent compression rebound property are obtained, the performance of a storage battery is improved, the service life of the storage battery is prolonged, and the application is relatively wide.

Owner:QIDONG HENGRUI POWER SUPPLY TECH CO LTD

Multilayered functional prepreg fabric as well as preparation method and application thereof

PendingCN108274858AImprove toughnessHigh strengthProtective equipmentSynthetic resin layered productsFiberChemistry

The invention discloses a multilayered functional prepreg fabric as well as a preparation method and application thereof. The prepreg fabric is formed by superposing three structure layers, namely anupper surface short-fiber non-woven fabric layer, an intermediate unidirectional fiber layer and a lower surface two-dimensional fabric layer, wherein the thicknesses of the upper surface short-fibernon-woven fabric layer, the intermediate unidirectional fiber layer and the lower surface two-dimensional fabric layer are controlled in a range of 0.01-0.05mm. According to the three-layer structure,the short-fiber non-woven fabric layer provides overall penetration resistance of the prepreg, the intermediate unidirectional fiber layer provides the overall high-speed impact energy absorption characteristics of the prepreg, and the lower surface two-dimensional fabric layer provides rigid deformation resistance of the overall prepreg. The synergistic effect of functional characteristics of the three-layer structure provides a guarantee for improving the overall integrated bulletproof protection characteristics.

Owner:SHANDONG ZHONGHENG CARBON FIBER TECH DEV CO LTD +1

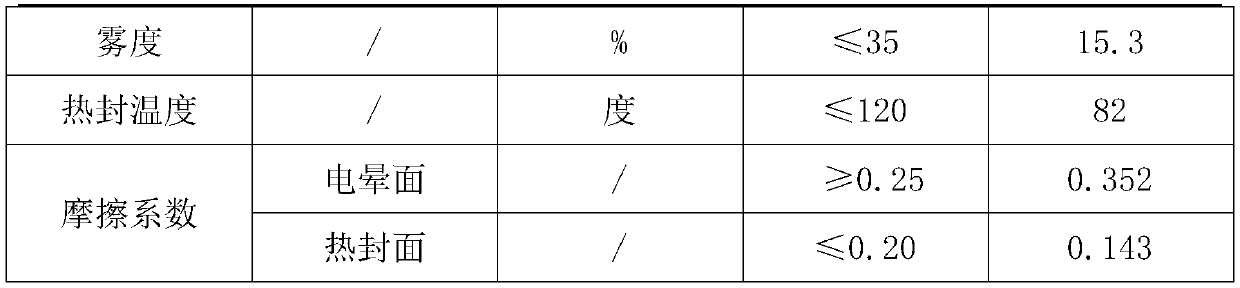

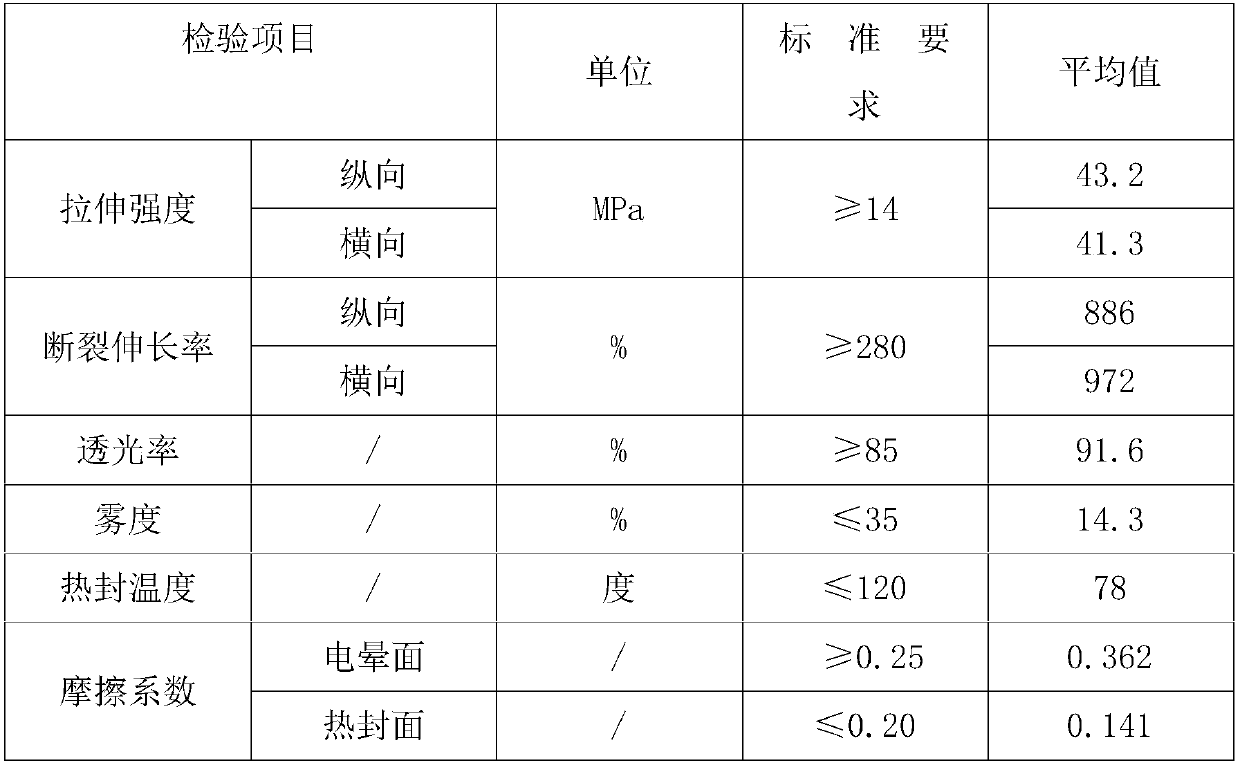

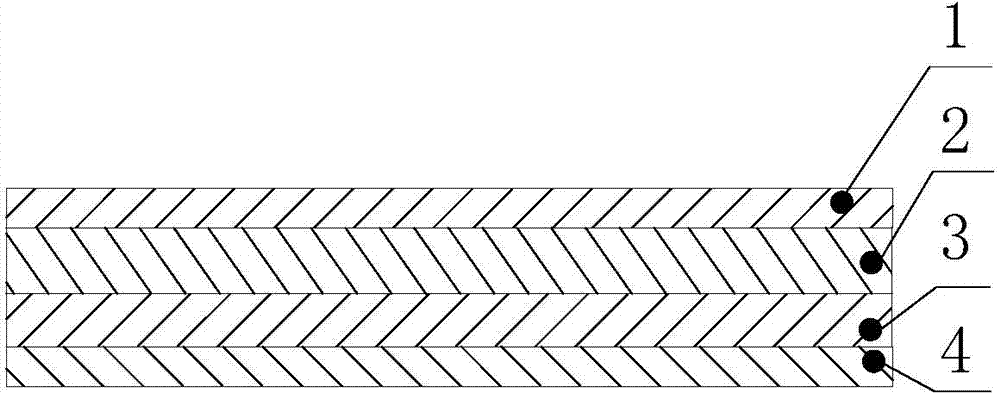

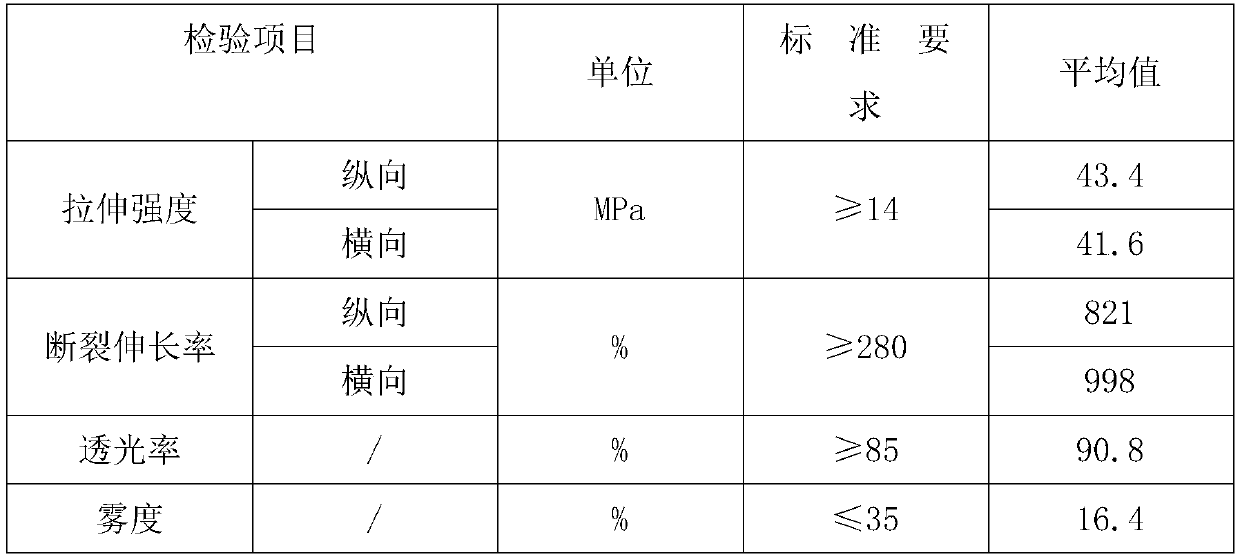

Three-layer co-extrusion ultra-low temperature heat-sealing package thin film

ActiveCN109605890AGood light transmissionReduce heat sealing temperatureFlexible coversWrappersEngineeringCo extrusion

The invention discloses a three-layer co-extrusion ultra-low temperature heat-sealing package thin film, and belongs to the field of package films. America imported metallocene is added into an outerlayer, Japanese imported metallocene is added into a middle layer and an inner layer, the outer layer, the middle layer and the inner layer are different in formula and uniformly mixed according to formulas, three-layer thin film extrusion is formed through a co-extrusion die head, and finally the three-layer co-extrusion ultra-low temperature heat-sealing package thin film is prepared. Compared with a common package thin film, the three-layer co-extrusion ultra-low temperature heat-sealing package thin film has improved transparency and strength, and is quite low in heat sealing temperature and quite suitable for high-speed low-temperature package, wherein the heat sealing temperature can reach 80 DEG C or below to the minimum degree.

Owner:HENAN YINFENG PLASTIC

High-barrier high-temperature-resistant sterilization digestion membrane and preparation method thereof

InactiveCN104742463AAvoid deformationHigh heat sealing strengthSynthetic resin layered productsLaminationElastomerPolymer science

The invention belongs to the technical field of digestion membranes. A high-barrier high-temperature-resistant sterilization digestion membrane is characterized by being formed by performing curtain coating and co-extrusion on four layers, including a heat seal layer, a fire core layer, a second core layer and a corona layer which are arranged sequentially, have the mass percentage of 20%, 30%, 30% and 20%; the heat seal layer is formed by mixing polypropylene resin, an abherent and a slipping agent. The addition amount of the abherent is 2% of the mass of the polypropylene resin; the addition amount of the slipping agent is 2.5% of the mass of the polypropylene resin; the first core layer is prepared by mixing drawing-level polypropylene resin, an elastomer, nylon and a slipping agent; the material of the second core layer is the same as the material of the first core layer. The digestion membrane prepared by the method provided by the invention has the characteristics of high temperature resistance, as well as difficulty in deformation, high heat seal intensity, strong penetration resistance, good toughness and good impact resistance under high temperature.

Owner:HUBEI DEWEI PACKAGING TECH

Run-flat tire side support rubber, preparation method and tire structure thereof

InactiveCN109438787AGood physical and mechanical propertiesImprove heat generationTyre partsSteering wheelTear resistance

The invention relates to the technical field of tires and in particular to run-flat tire side support rubber, a preparation method and a tire structure thereof. Neodymium series butadiene rubber usedby a sizing material is polybutadiene with high cis-form-1,4-structure content obtained by using a neodymium compound as a main catalyst, so the support rubber has higher tensile property and resilience property, good carbon black dispersing performance, and more excellent aging-resistant performance. White carbon black adopts a 1115MP type with high dispersion and a low superficial area. The high-dispersion-type low-superficial-area white carbon black is capable of effectively improving tear resistance and thermal aging resistance of a support rubber part, and effectively reducing 15% of thermogenesis performance. Through a formula of the relayed sizing material, the prepared support rubber has stronger physical characteristics of tear resistance, high stretching, high strength, high temperature resistance and the like. Through a special design and a matching ratio in structure and formula aspects, the tires can be guaranteed to be continuously driven still in a speed of 80 km / h in azero air pressure state, and a steering wheel cannot be easily deviated from a driving direction in a driving process, until a next maintenance point is found out.

Owner:万达集团股份有限公司 +1

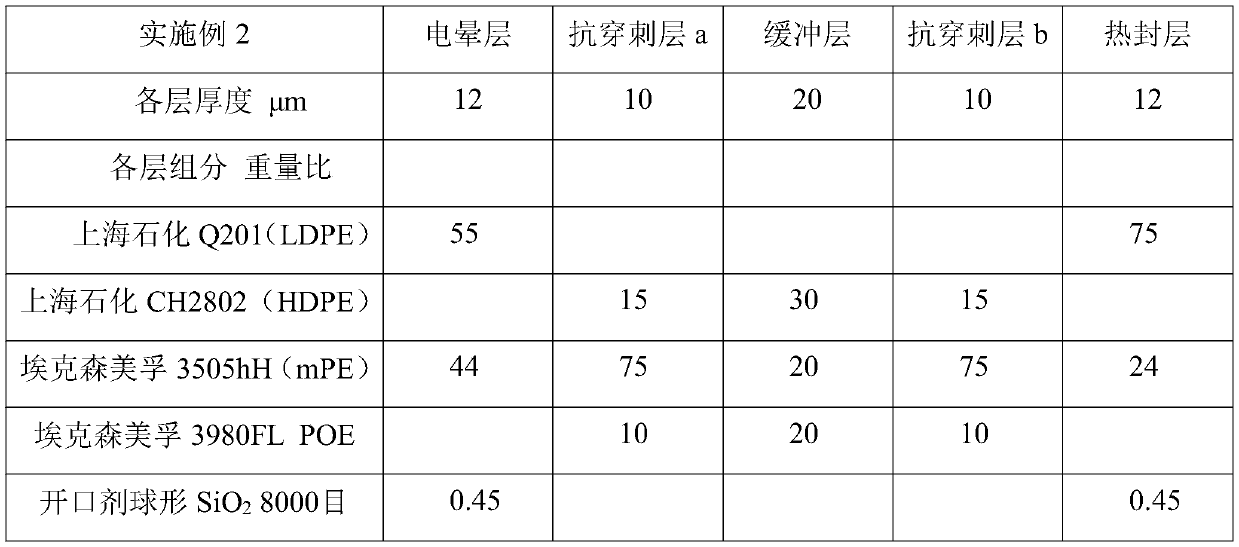

High puncture resistant cast polyethylene film and preparation method thereof

ActiveCN110509646AImprove toughnessImprove impact resistanceFlexible coversWrappersPuncture resistanceUltimate tensile strength

The invention provides a high puncture resistant cast polyethylene film and a preparation method thereof. The polyethylene film has a five-layer structure, which is composed of a corona layer, a puncture resistant layer a, a buffer layer, a puncture resistant layer b and a heat-seal layer from the outside in respectively. The puncture resistant layer a and puncture resistant layer b have a high metallocene polyethylene content, and can provide good puncture resistance; the buffer layer high density polyethylene can provide good basic strength, POE can improve the toughness and impact resistance of the buffer layer, mica powder is sheet filler, and can form a "multilayer scale" structure parallel to the film in the buffer layer because of melt flow in the extrusion process, and interface constraint can be generated together with polyethylene, and a synergistic effect can be formed together with a sandwich structure formed by the puncture resistant layer a, the buffer layer and the puncture resistant layer b, thus improving the overall puncture resistance of the film.

Owner:四川厚诚新材料有限公司

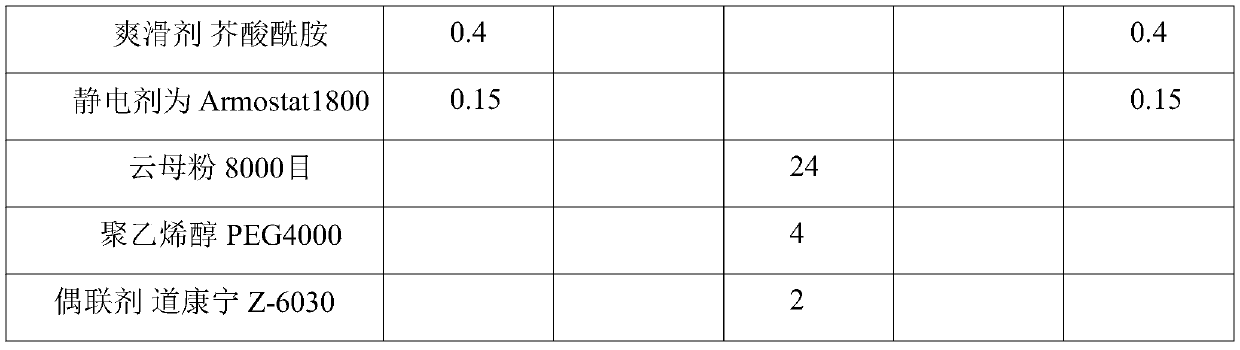

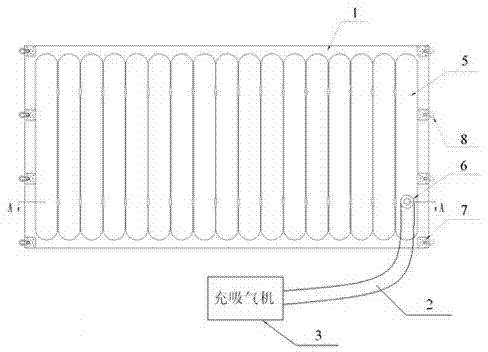

Inflating device for operation in shoal environment

ActiveCN102806983ASolve the problem of not being able to disembark and operateStrong pressure capacityLife-savingEngineeringGas-filled tube

The invention provides an inflating device for operation in a shoal environment. The inflating device comprises an air cushion body, an inflating pipe, an inflating and deflating machine and an inflating valve cap. The air cushion body consists of an upper rectangular air cushion outer layer, a lower rectangular air cushion outer layer and reinforcing sheets adhered between the upper and lower rectangular air cushion outer layers which are identical in shape. The air cushion body is adhered and partitioned into a plurality of air chambers which are identical in shape and arrayed closely by the reinforcing sheets, and each two adjacent air chambers are communicated. An inflating valve is optionally arranged on one of the two outmost air chambers in the array direction of the multiple air chambers. The inflating and deflating machine is connected with the inflating valve through the inflating pipe and used for inflating the air chambers or pumping air from the air chamber through the connected inflating pipe. After inflating / deflating of the air cushion body is completed, the inflating valve cap is mounted on the inflating valve to seal the air chamber. The inflating device is capable of floating on a shoal, changeable in length according to practical needs, high in air tightness and pressure bearing capacity and convenient to maintain.

Owner:QINGDAO GUANGMING ENVIRONMENTAL TECH

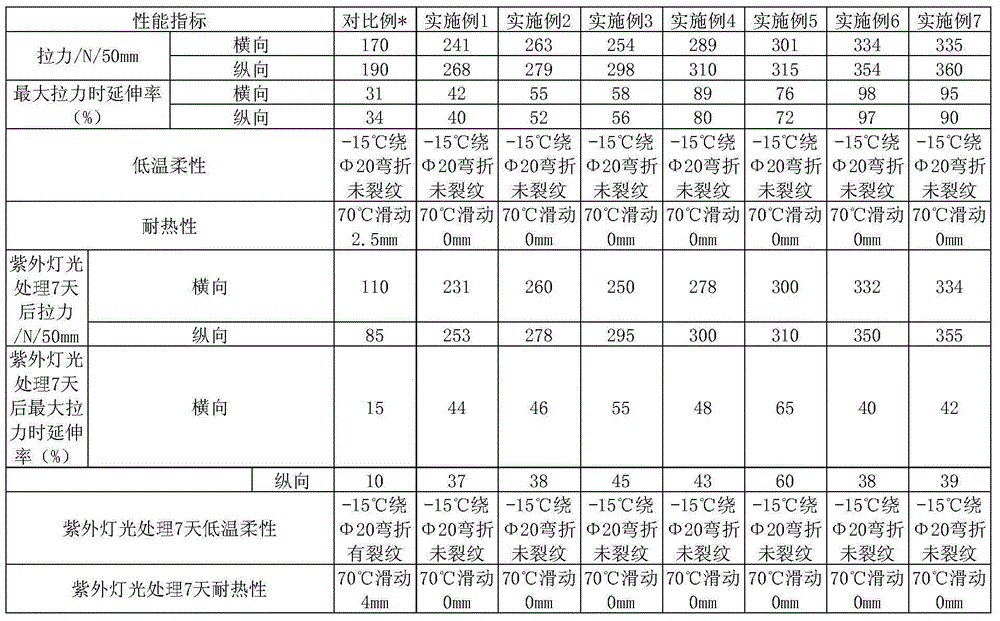

Polyethylene composite with excellent puncture resistance and weather resistance

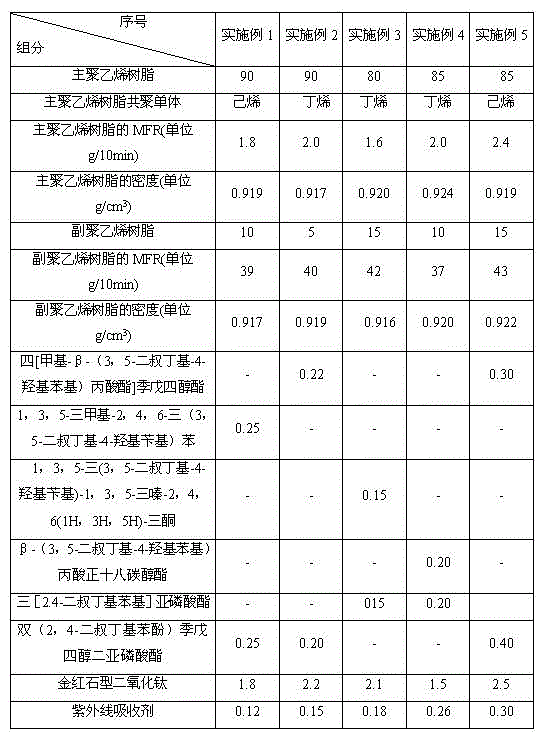

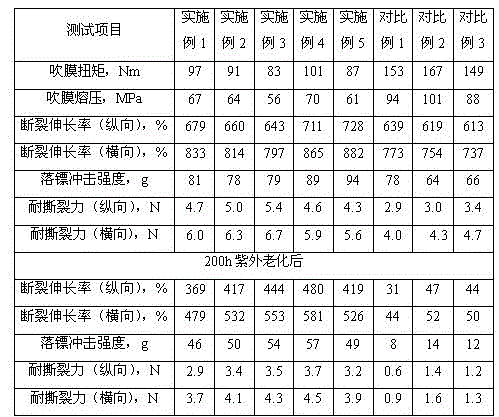

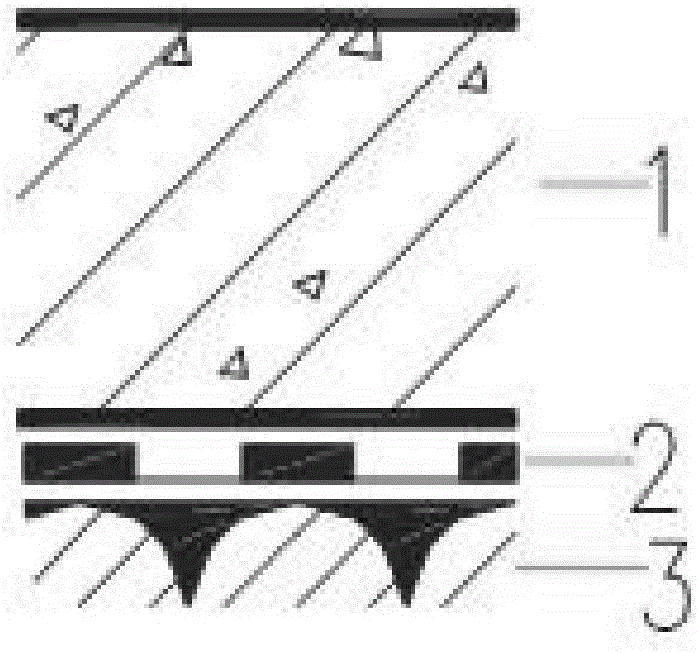

ActiveCN104558788AStrong puncture resistanceStrong anti-ultraviolet aging abilityAntioxidantUltraviolet

The invention discloses a polyethylene composite with excellent puncture resistance and weather resistance, and belongs to the field of high polymer materials. The composite is characterized by being prepared from the following components in parts by weight: 80-90 parts of polyethylene resin A, 5-15 parts of polyethylene resin B, 0.3-0.7 parts of antioxidant, 1.5-2.5 parts of nano titanium oxide and 0.1-0.3 parts of ultraviolet absorber, wherein the polyethylene resin A is a copolymer of ethylene and 1-butylene or / and 1-hexylene; the density is 0.917-0.924g / cm<3>; a melt flow rate (MFR) is 1.6-2.4g / 10min; the polyethylene resin B is metallocene polyethylene; the density is 0.916-0.922g / cm<3>; and an MFR is 37-43g / 10min. The composite has good ultraviolet ageing resistance, good puncture resistance and higher physical and mechanical strength; and the strength of a film material after long-term use under an ultraviolet condition can be improved.

Owner:CHINA PETROLEUM & CHEM CORP

Waterproof coiled material pre-paving and inverted sticking process

InactiveCN105908787AResist radiationGuaranteed bonding performanceProtective foundationGasketsBasementEngineering

The invention provides a waterproof coiled material pre-paving and inverted sticking process. A waterproof coiled material is paved under a basement bottom plate and on a cushion layer and comprises an HDPE bottom film, a self-adhesive glue film and a reaction sand anti-sticking layer. The reaction sand anti-sticking layer is arranged on the self-adhesive glue film. The HDPE bottom film is arranged under the self-adhesive glue film. The waterproof pre-paving construction technology comprises the following processes of a, basic layer examination and acceptance, b, working surface transfer, c, basic layer cleaning, d, joint enhancement treatment, e, snapline positioning; f, coiled material paving, g, coiled material lapping treatment, h, coiled material head unwinding and fixing, i, self-checking and acceptance and j, working surface transfer. According to the waterproof coiled material pre-paving and inverted sticking process, compared with a traditional waterproof method, the construction time and the maintenance time of a leveling layer and a protective layer are omitted, the structure level is optimized, so that the construction period is greatly shortened, and the construction cost is greatly reduced; and the effects of environmental protection and safety are achieved, solvent and fuel are not needed in the construction process, environmental pollution and firefighting hidden dangers are avoided, and energy sources are saved.

Owner:SHENZHEN LANDUN WATERPROOF ENG

Modified polyolefin composite membrane composition, modified polyolefin composite membrane and preparation method and application thereof

ActiveCN112721372AImprove barrier propertiesStrong puncture resistancePackage recyclingFlexible coversPolymer sciencePolyolefin

The invention relates to the technical field of composite packaging and processing, and discloses a modified polyolefin composite film composition, a modified polyolefin composite film and a preparation method and application of the modified polyolefin composite film. The composition comprises a first layer of film material, a middle layer of film material and a third layer of film material, wherein the third layer of film material comprises a PE corona layer material, a barrier layer film material and a PE heat-seal layer material; wherein the first layer of film material and the middle layer of film material respectively contain one or more selected from C4-C8 polyethylene, unitary homo-polypropylene, binary co-polypropylene and ternary co-polypropylene; and the barrier layer film material contains an ethylene-vinyl alcohol copolymer and / or thermoplastic polyvinyl alcohol. The composite film has high barrier property, puncture resistance, pressure resistance and falling property.

Owner:SHANGHAI ROYAL NEW MATERIALS TECH CO LTD

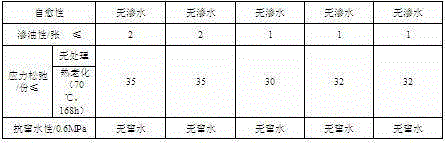

Flexible thermoplastic polyolefin anti-seepage material and preparation method thereof

The invention provides a flexible thermoplastic polyolefin seepage-resistant material and a preparation method thereof, belongs to the technical field of anti-seepage materials, and can solve the anti-seepage problem that an existing impervious material cannot be used in a harsh environment for a long term. The flexible thermoplastic polyolefin seepage-resistant material provided by the invention comprises raw material thermoplastic polyolefin resin, a processing aid and a light stabilizer, wherein the bending modulus of the thermoplastic polyolefin resin is 2-300 MPa, and the Shore hardness is 10-50 shores D. The flexible thermoplastic polyolefin seepage-resistant material provided by the invention has excellent puncture resistance, hydraulic pressure resistance and multi-directional bursting resistance, and can be used for seepage prevention of dams, reservoirs, embankments, cofferdams, canals, tunnels, artificial lakes, refuse landfills, railway and road soft foundation reinforcement, nuclear power plants and other newly-built and maintenance works. The preparation method of the flexible thermoplastic polyolefin seepage-resistant material is simple and quick to process, and capable of continuous production.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

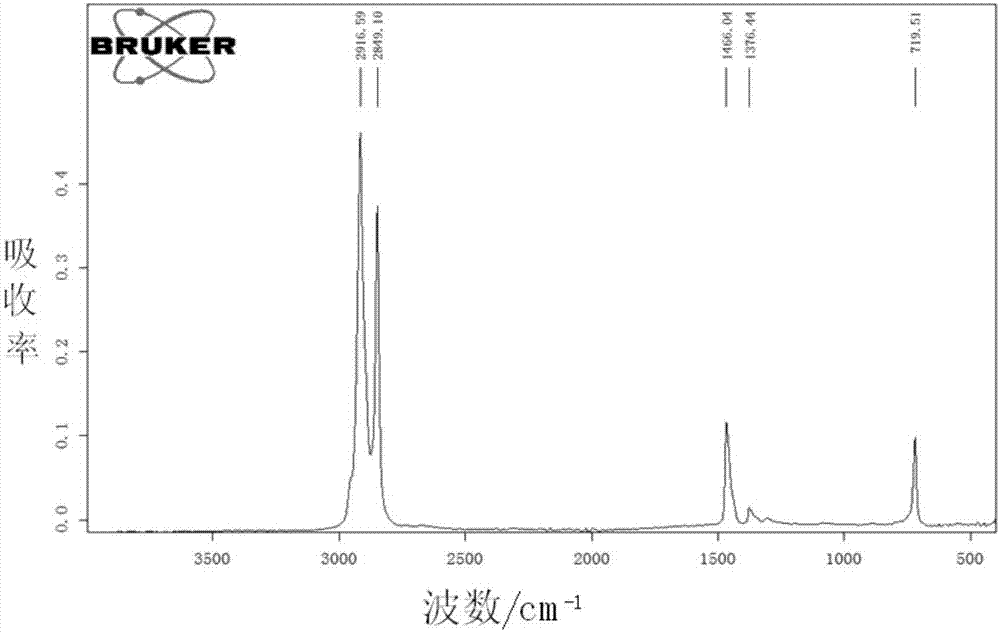

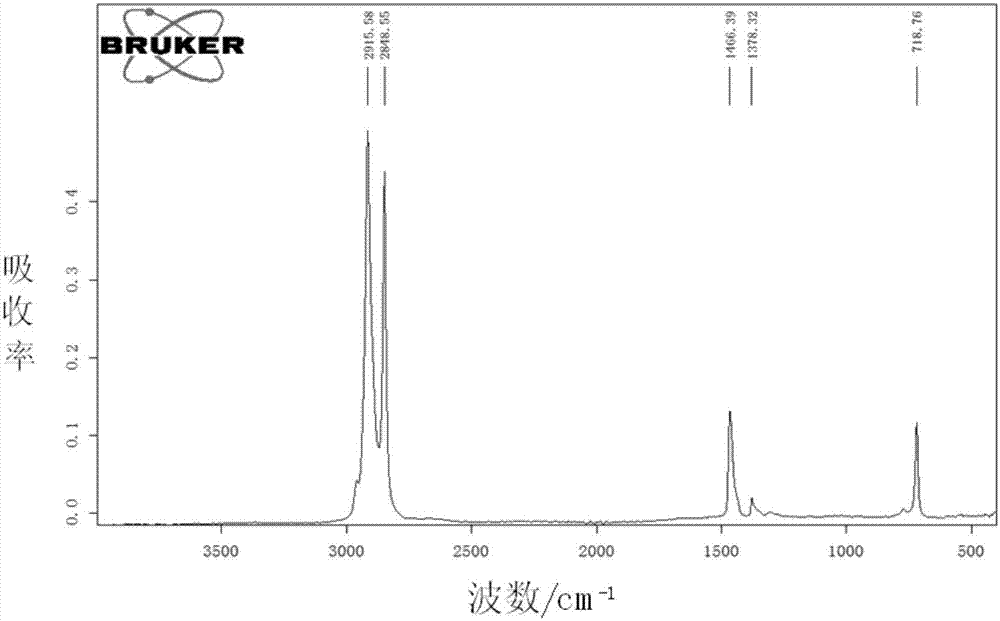

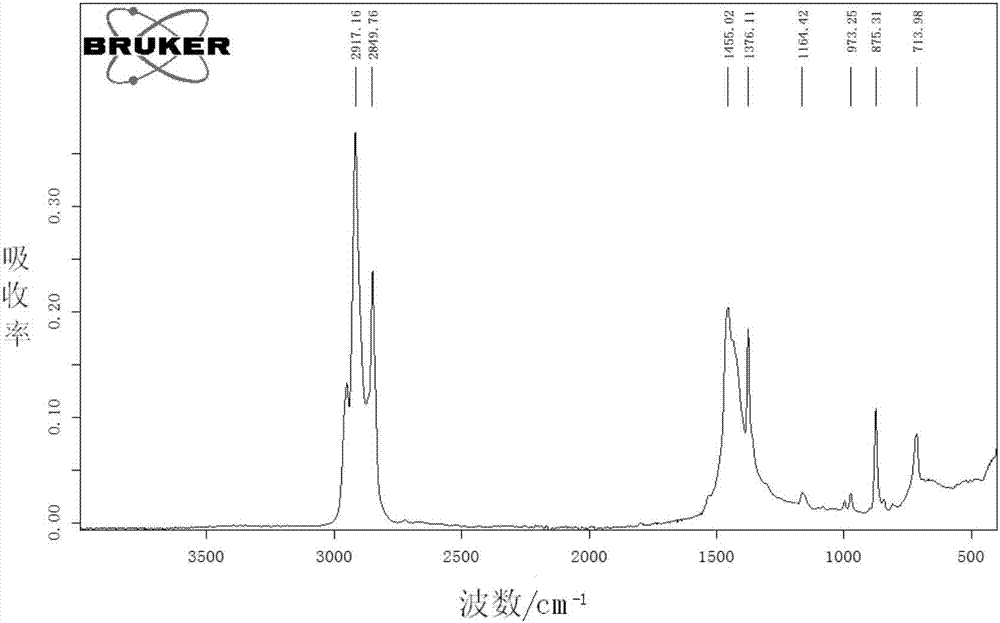

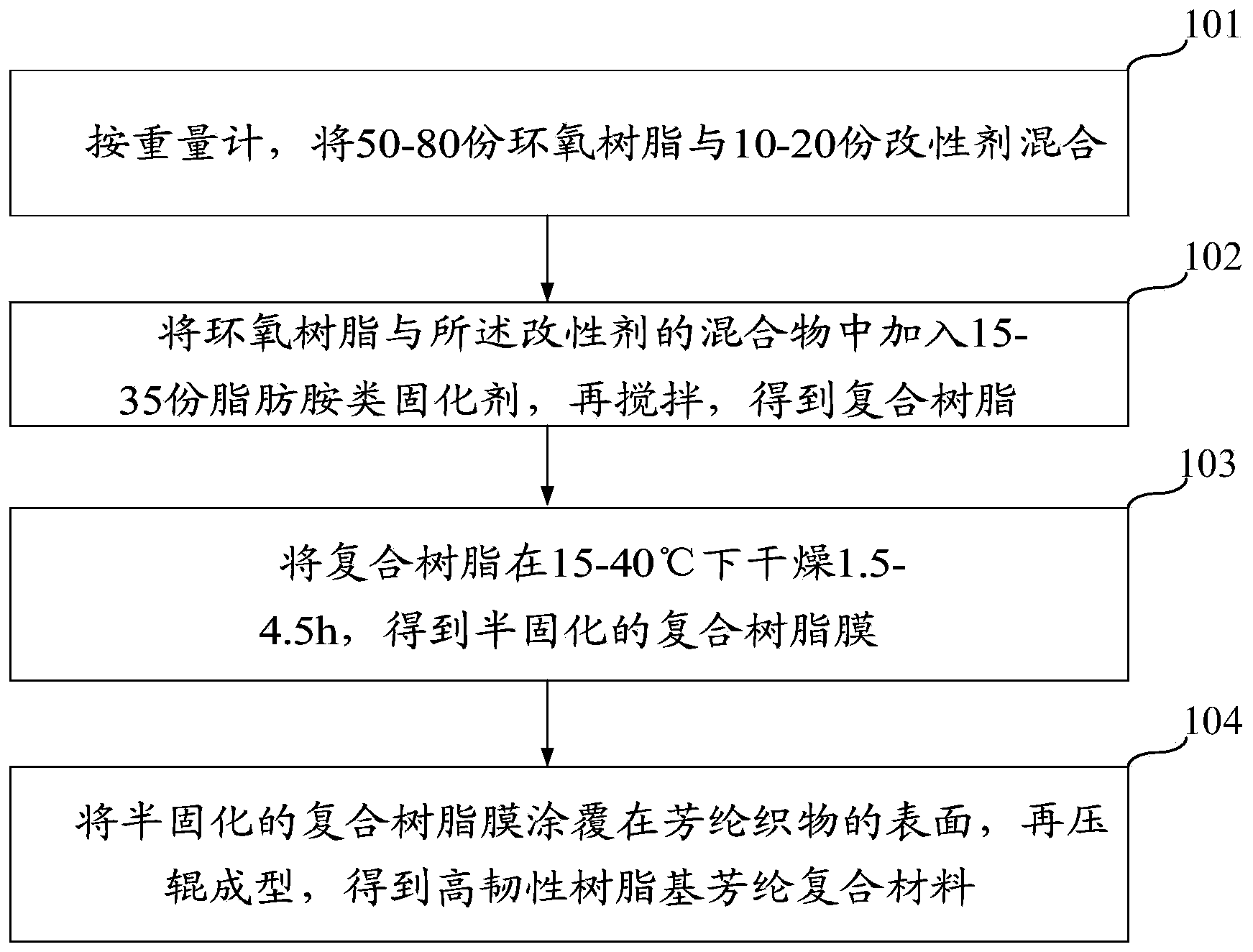

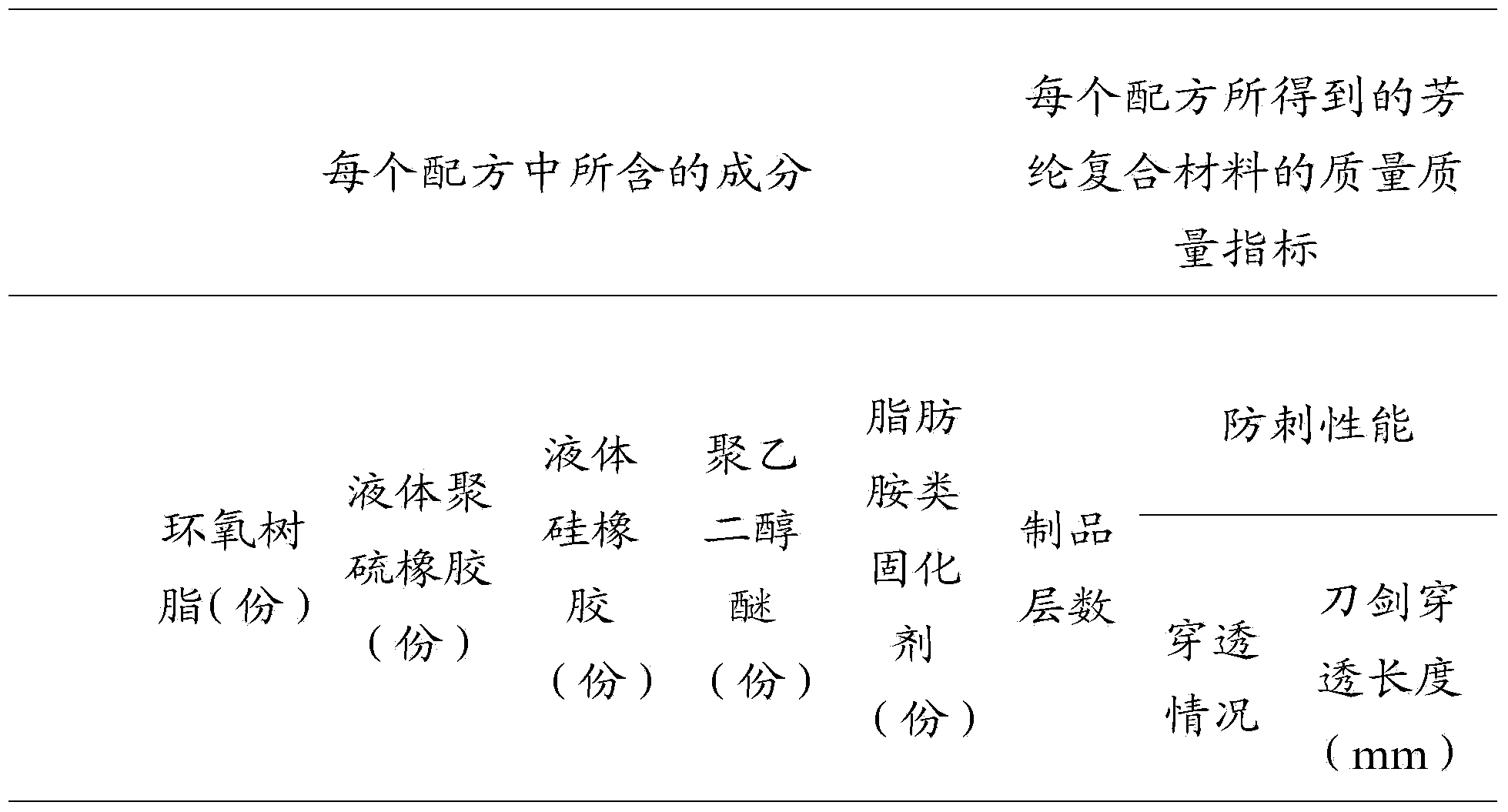

High-toughness resin-based aramid fiber composite material and production method thereof

ActiveCN103753904AUniform stab resistanceImprove stab resistanceSynthetic resin layered productsPolysulfide rubberFatty amine

The invention relates to the technical field of textiles and in particular relates to a high-toughness resin-based aramid fiber composite material and a production method thereof. The production method of the high-toughness resin-based aramid fiber composite material comprises the following steps: mixing 50-80 parts by weight of epoxy resin and 10-20 parts by weight of a modifier, wherein the modifier is one or more of liquid polysulfide rubber, liquid silicone rubber and polyglycol ether; adding 15-35 parts by weight of a fatty amine curing agent into the epoxy and modifier mixture, and stirring again to obtain composite resin; drying the composite resin at 15-40 DEG C for 1.5-4.5 hours to obtain a half-cured composite resin film; coating the surface of an aramid fiber fabric with the half-cured composite resin film, and molding through a pressing roller to obtain the high-toughness resin-based aramid fiber composite material. Compared with a conventional presoaking technology in the prior art, the production method disclosed by the invention has the advantages that the obtained high-toughness resin-based aramid fiber composite material is high in puncture prevention performance, and the puncture prevention performance is uniformly distributed.

Owner:SHANGHAI LIANBO SECURITY EQUIP

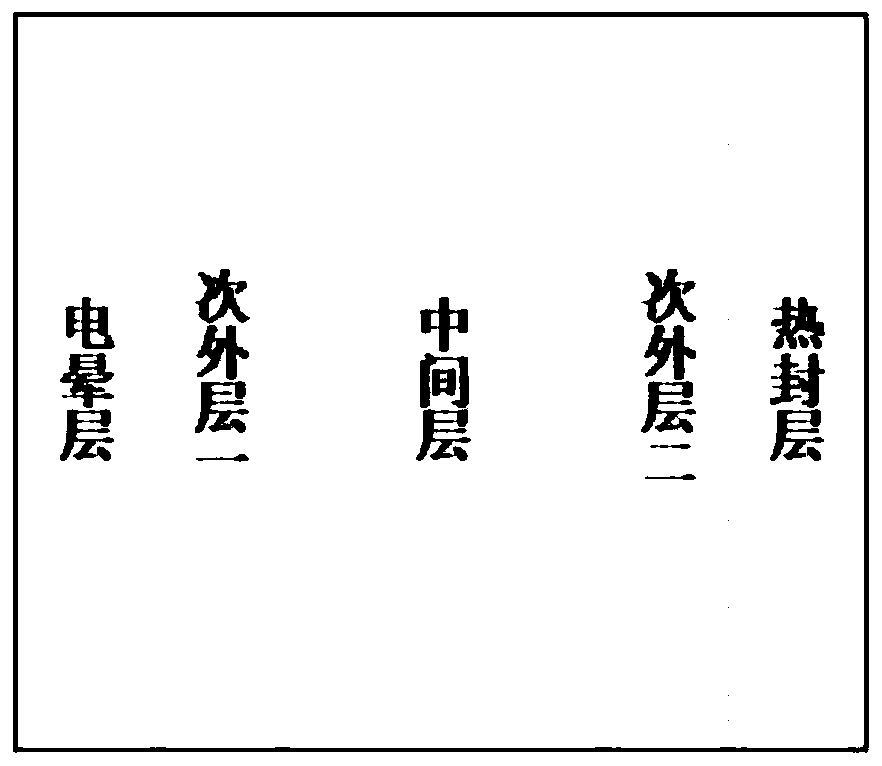

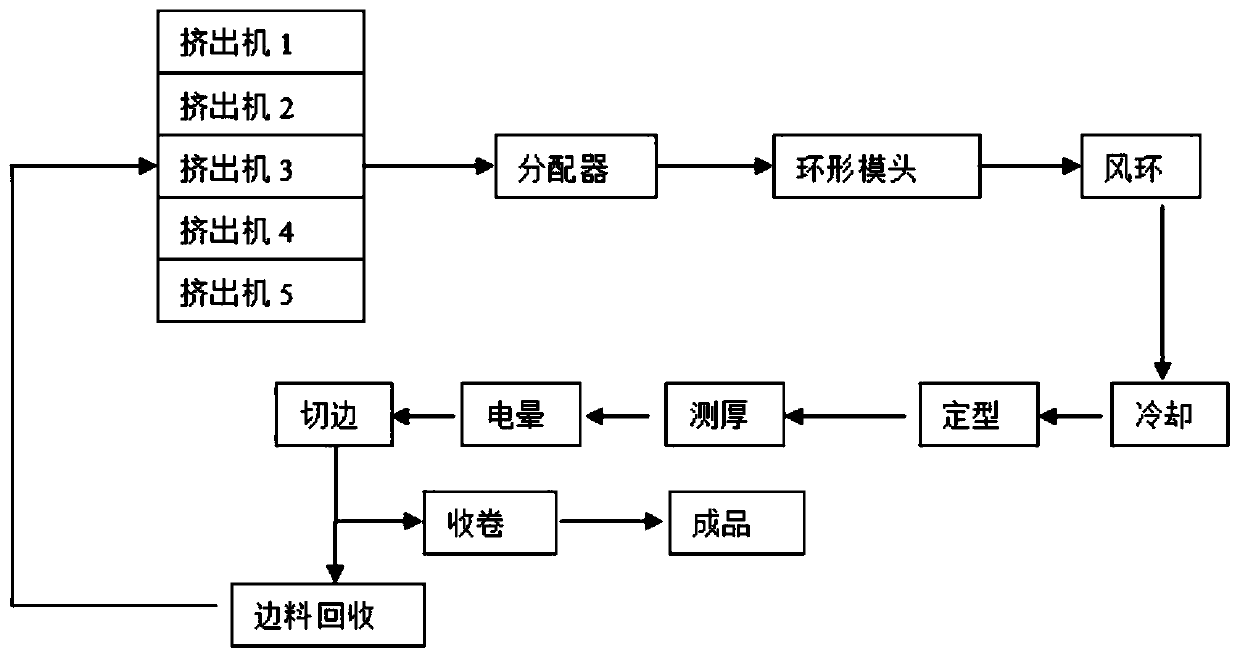

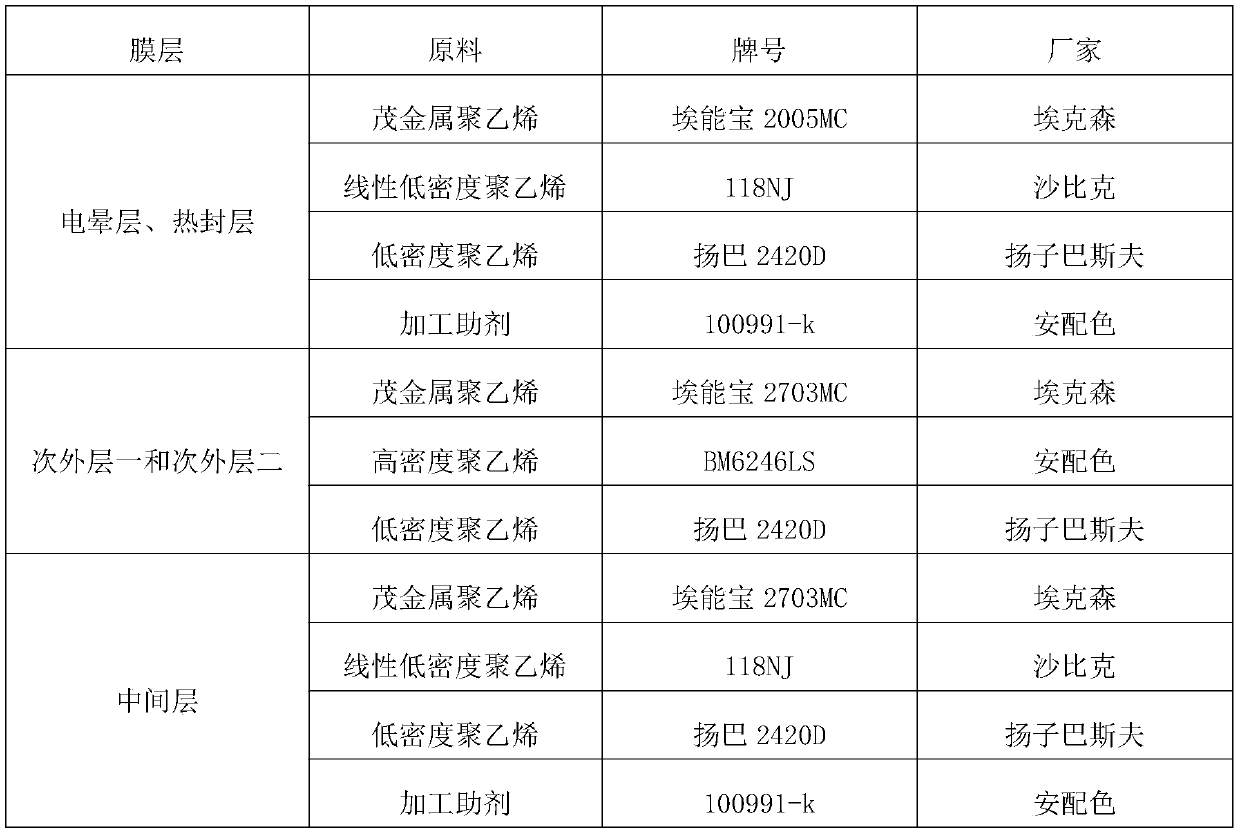

High-light low-haze PE heat shrinkable film and preparation method thereof

ActiveCN110216960AFlat forceIncrease productivitySynthetic resin layered productsLaminationLow-density polyethyleneLinear low-density polyethylene

The invention relates to a high-light low-haze PE heat shrinkable film and a preparation method thereof. A film layer structure of the PE heat shrinkable film successively comprises a corona layer, afirst sub-outer layer, an intermediate layer, a second sub-outer layer and a heat sealing layer; the corona layer, the intermediate layer and the heat sealing layer separately comprise metallocene polyethylene, linear low-density polyethylene, low-density polyethylene and a processing aid in a mass ratio of (28-32):(8-12):(58-62):(0.1-0.3); and the first sub-outer layer and the second sub-outer layer separately comprise metallocene polyethylene, high-density polyethylene and low-density polyethylene in a mass ratio of (28-32):(28-32):(38-42). The PE heat shrinkable film has high shrinkage rate, powerful shrinkage memory function, large tensile strength, powerful puncture resistance and anisotropic tearing resistance, and has the characteristics of low haze, high transparency and high gloss, the friction coefficient is moderate and stable, thickness uniformity and flatness are good, and printing adaptability is good.

Owner:HUANGSHAN NOVEL

A composite geomembrane

InactiveCN104476883AStrong chemical resistanceImprove stabilitySynthetic resin layered productsConstructions elementsLow-density polyethyleneLinear low-density polyethylene

A composite geomembrane is provided. The composite geomembrane comprises a non-woven fabric layer, a geotechnical cloth layer and an impermeable membrane layer. The impermeable membrane layer comprises a first impermeable layer, a second impermeable layer and a third impermeable layer. The first impermeable layer, the second impermeable layer and the third impermeable layer are combined in order. The impermeable membrane layer is prepared from 30-80 parts by weight of high density polyethylene and 40-60 parts by weight of linear high density polyethylene. The impermeable membrane layer also comprises following auxiliary materials by weight: 0.05-0.4 part of an antioxidant, 0.1-0.6 part of an ultraviolet-light-resistant absorbent, 0.1-0.3 part of an anti-ageing agent, 0.05-0.5 part of carbon black, 0.1-0.5 part by weight of a fire retardant, and the like. The composite geomembrane has high impermeability, chemical stability and penetration resistance, effectively prevents permeation of harmful chemical compounds, and has good stretching flexibility and resistance to stress cracking. In addition, addition of the auxiliary materials improves safety performance of the composite geomembrane and largely prolongs the service lifetime of the composite geomembrane.

Owner:NANYANG FENGHUI PLASTIC

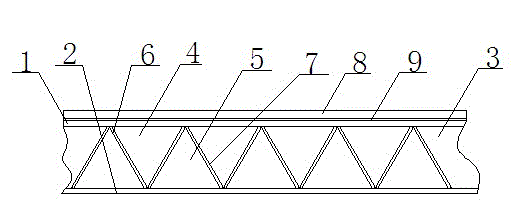

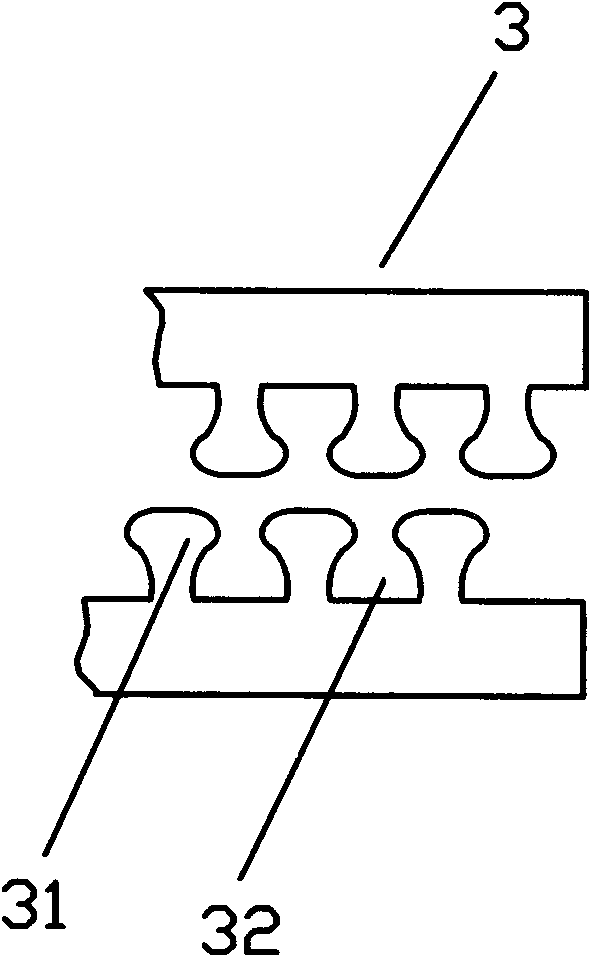

Conveyor belt

The invention relates to the technical field of a slide device, especially to a conveyor belt. The conveyor belt comprises an upper wrapping layer, a lower wrapping layer, a frame layer, fasteners 1, fasteners 2, projections and grooves. The frame layer is equipped between the upper wrapping layer and the lower wrapping layer. The frame layer is composed of fasteners 1 and fasteners 2. The two sides of each fastener 1 are provided with projections. The two sides of each fastener 2 are provided with grooves. A stop block is equipped on the upper wrapping layer. The upper wrapping layer and the stop block are connected through a channel section. The fasteners 1 and the fasteners 2 are fixedly connected through the projections and the grooves. The conveyor belt has the advantages of simple structure, convenient use, strong practicality, relatively strong anti-puncture capability, prolonged service lifetime, using cost decrease, easy application, and easy popularization.

Owner:CHANGZHOU DONGWU CHAIN TRANSMISSION MFGCO

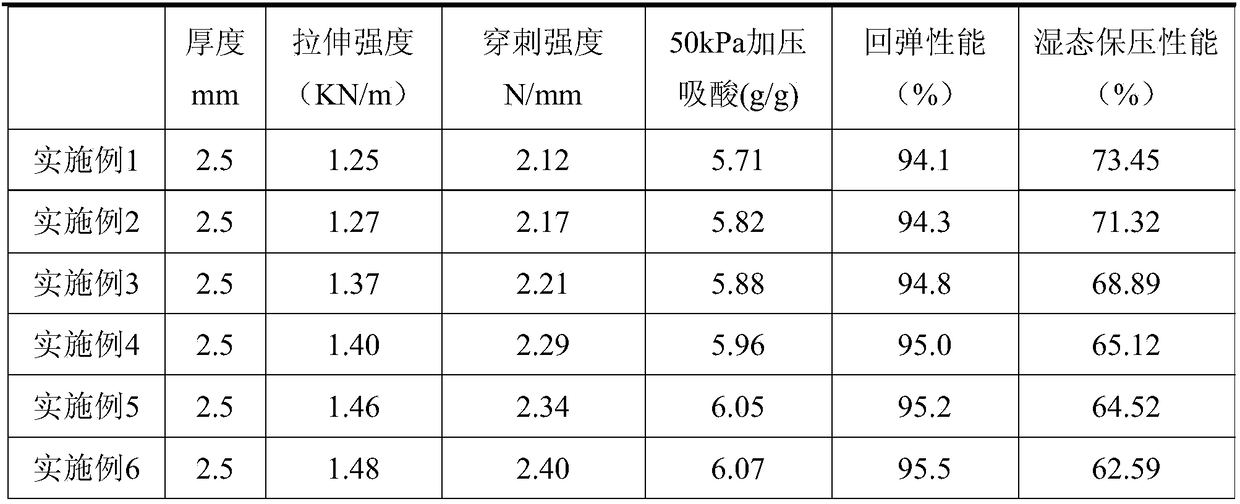

AGM membrane for lead-carbon battery and preparation method of AGM membrane

ActiveCN108448029AHigh tensile strengthStrong puncture resistanceLead-acid accumulatorsCell component detailsChemistryMembrane configuration

The invention discloses an AGM membrane for a lead-carbon battery and a preparation method of the AGM membrane. According to the AGM membrane for the lead-carbon battery, the membrane is prepared by compounding coarse and thin high-alkali glass fibers through a wet process. The obtained membrane is good in strength property, assembly mechanization production can be met and a short circuit of the battery due to the fact the membrane is punctured by lead dendrites in the using process can be prevented; the pressurized acid absorption property is good and enough electrolyte can be absorbed to ensure high-capacity discharging of the battery; the AGM membrane is good in resilience, the membrane and a polar plate are kept in close contact and peeling of active substances is reduced; the wet pressure maintaining property is good, the capacity of the battery is improved and the cycle life of the battery is prolonged; and the preparation technology is simple and the lead-carbon battery producedby using the AGM membrane has excellent high-current charge-discharge performance and cycle life.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

Water resistant carton adhesive

InactiveCN104293238ASimple structureImprove liquidityNon-macromolecular adhesive additivesStarch adhesivesAdhesiveWater quality

The invention discloses a water resistant carton adhesive which is prepared from the following raw materials in parts by weight: 65-75 parts of water, 28-34 parts of sweet potato powder, 12-16 parts of calcium carbonate, 1-2 parts of sodium hydroxide, 2-3 parts of keto-aldehyde polyvinyl alcohol compound, 3-4 parts of sepiolite powder, 1.2-1.6 parts of bridging agent, 0.15-0.18 part of sodium carboxymethyl cellulose, 0.10-0.12 part of water quality stabilizer and 0.26-0.36 parts of borax; the water resistant carton adhesive is prepared according to the following steps: pouring water into a container, regulating the temperature of the water to 33-45 DEG C, adding sodium hydroxide and uniformly stirring; then adding the sweet potato powder, and continuously stirring to be sticky; adding calcium carbonate and borax and stirring for 13-20 min; adding the water quality stabilizer and stirring for 5-10min; adding the sepiolite powder, the keto-aldehyde polyvinyl alcohol compound, the bridging agent and sodium carboxymethyl cellulose, uniformly stirring, standing and cooling. The water resistant carton adhesive disclosed by the invention has strong adhesive ability and good waterproof performance.

Owner:HEFEI DONGCAI PRINTING TECH

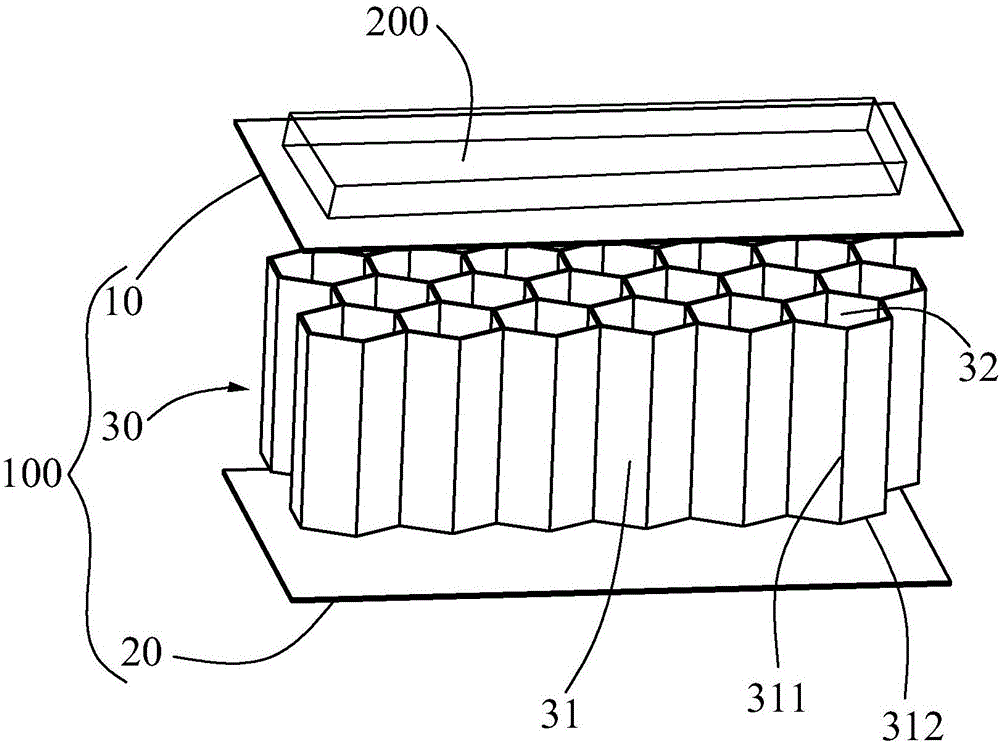

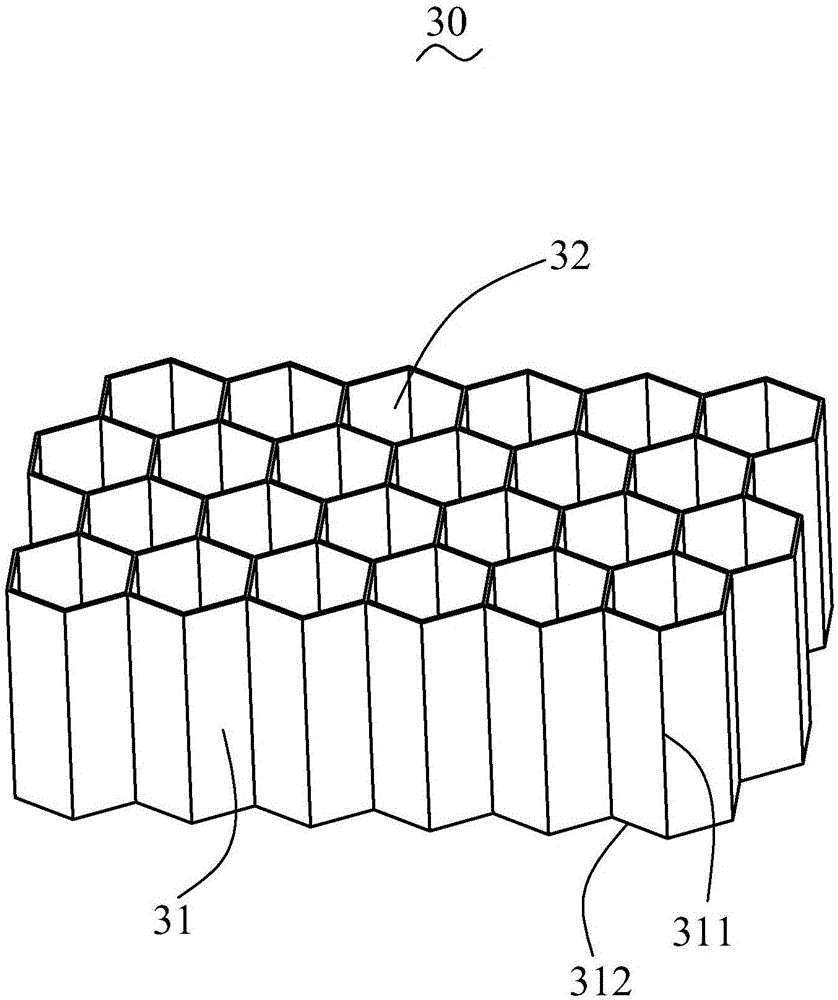

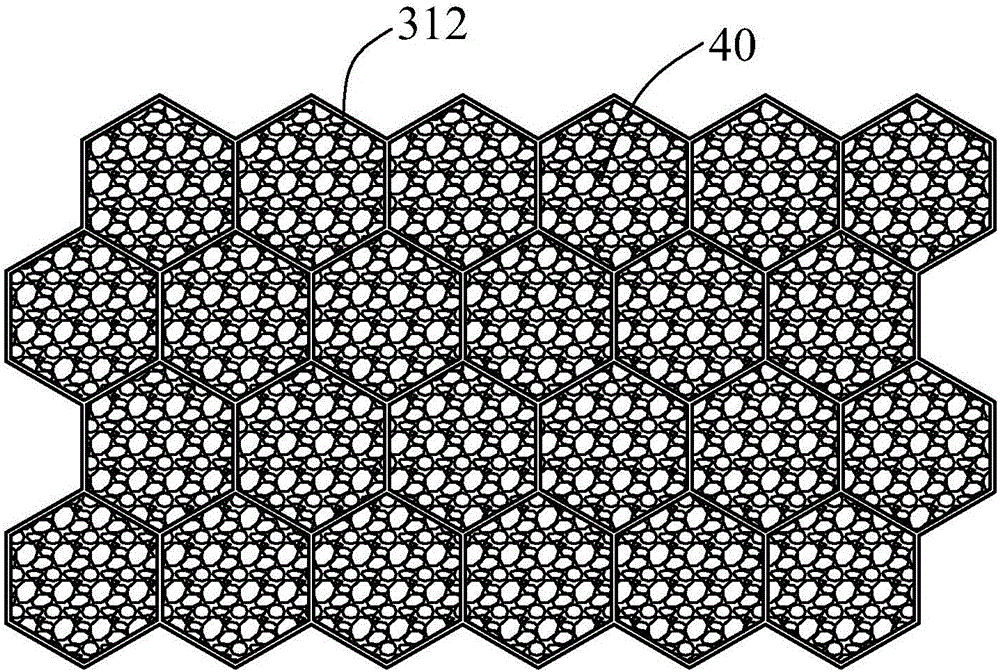

Electric vehicle chassis protection plate

PendingCN106585522AImprove anti-corrosion performanceImprove shock absorptionVehicle componentsHeat conductingHoneycomb

The invention provides an electric vehicle chassis protection plate, which is applied to an electric automobile. The electric automobile comprises a battery box, wherein a battery is mounted in the battery box to provide power to the electric automobile. The electric vehicle chassis protection plate comprises a first panel, a second panel and a honeycomb, wherein the first panel and the second panel are oppositely arranged, and the honeycomb is arranged between the first panel and the second panel; the first panel is close to the battery box; the first panel and the second panel are aluminum alloy plates; the honeycomb core is an aluminum alloy honeycomb core; and the honeycomb core is filled with a solid organic phase-change material. The electric vehicle chassis protection plate provided by the invention has the advantages of excellent corrosion resistance, excellent vibration reduction performance, excellent puncture performance and good heat conducting and soaking effect.

Owner:OPTIMUM BATTERY CO LTD

Puncture resistant high-barrier plastic composite film and packaging bag

ActiveCN108608696AStrong impact resistanceStrong barrier performanceSynthetic resin layered productsBagsHigh-density polyethylenePuncture resistance

The invention discloses a puncture resistant high-barrier plastic composite film and a packaging bag manufactured through the film. The film is a polyethylene film with excellent performance, which ismainly composed of linear low density polyethylene, low density polyethylene, metallocene polyethylene and an elastomer to a certain degree, takes the polyethylene film as a puncture resistant layer,and moreover separately takes a biaxially oriented nylon film, aluminum foils and biaxially oriented phthalic glycolate as a stretching layer, a barrier layer and a printing layer. A multilayer composite film structure comprising the puncture resistant layer, the stretching layer, the barrier layer and the printing layer achieves the effects of sealing, puncture resistance and high resistance.

Owner:青岛方大包装股份有限公司

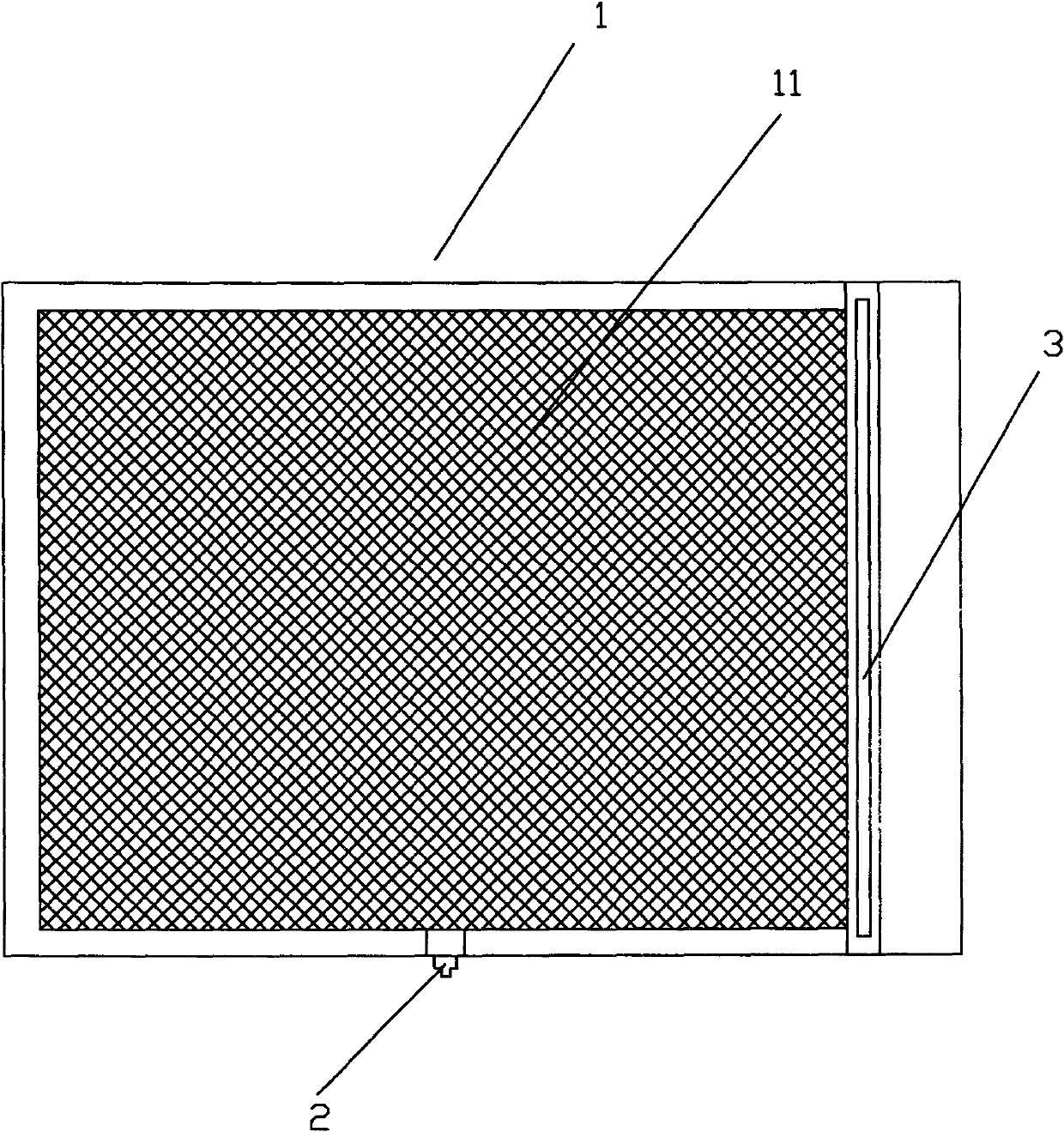

Vacuum bag convenient for exhausting and manufacturing process

The invention relates to a vacuum bag and a manufacturing process. The vacuum bag comprises a bag body, an air valve and a placing seal, wherein the air valve is sealed on the side part of the bag body, the inner side of the bag body is provided with an air guide groove, and the air guide groove is provided with pressing die groove grains of the bag body. The pressing die groove grains are netlike, and the pressing die groove grains are at least distributed on one bag surface of the vacuum bag. The air valve comprises an air valve seat, a sealing ball and an exhaust nozzle; a cylindrical hole is formed in the air valve seat, the diameter of an inner end hole is smaller than that of an outer hole, and the outer end of the air valve seat is provided with an exhaust nozzle mounting seat; the exhaust nozzle is sleeved on the air valve seat; and the sealing ball is placed in an air valve cavity formed by the cylindrical hole and the exhaust nozzle. The vacuum bag is made of 25 percent of polyamide (PA) material and 75 percent of polyethylene (PE) material. The production process comprises the following steps of: mixing PA and PE to manufacture a bag body film; and manufacturing the bag body, and pressing the air valve and the bag body. The air in the bag body is easily exhausted out of the bag body through the air guide groove on the inner side of the bag body so as to greatly improve the vacuum degree in the bag body.

Owner:DONGGUAN HAIYI INDAL

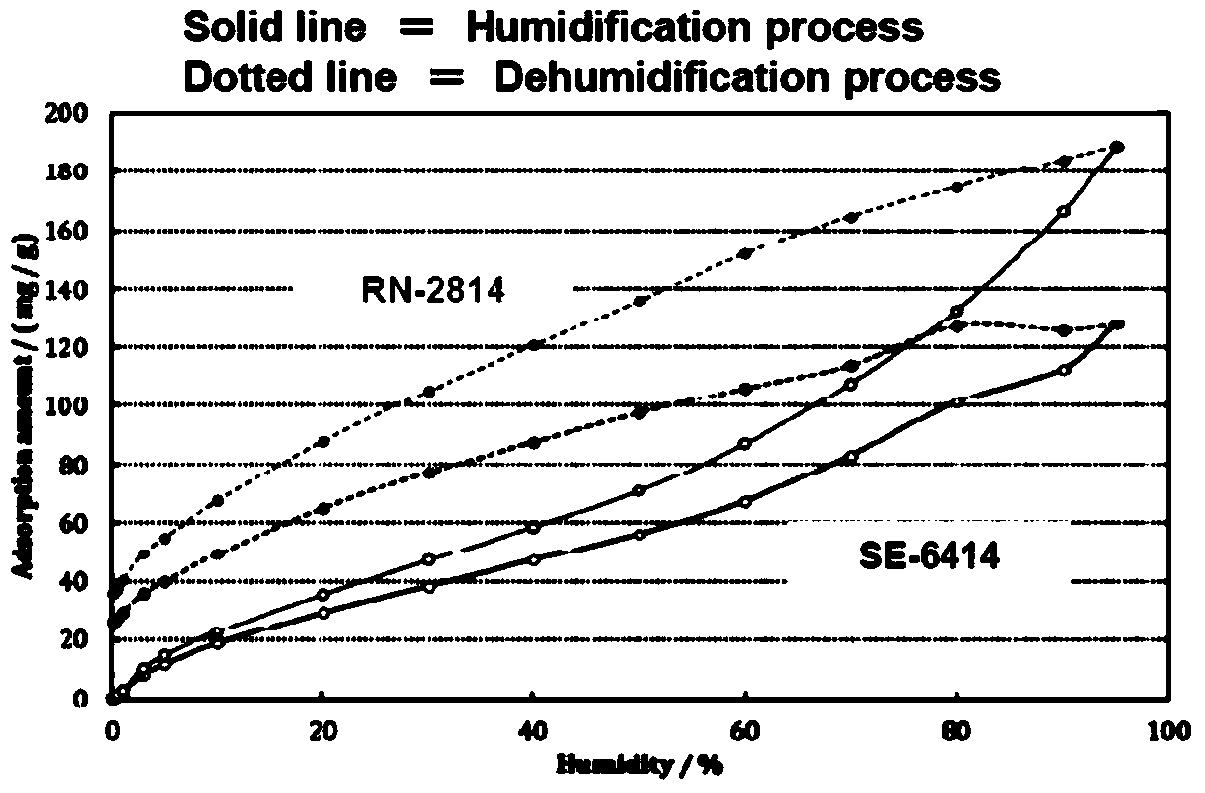

TPU film with good moisture permeation rate as well as manufacturing method and application of TPU film

The invention discloses a TPU film with a good moisture permeation rate as well as a manufacturing method and application of the TPU film. The TPU film contains the following materials: perfluoropolyether diol, a chain extender, aliphatic diisocyanate, TPO resin, master batches, an antioxidant, a light stabilizer, an anti-yellowing agent, erucamide, oleamide and stearic acid. The preparation method of the TPU film comprises the following steps: (1) preparing fluorine-containing TPU; (2) uniformly stirring fluorine-containing TPU with the TPO resin, the master batches, the antioxidant, the light stabilizer, the anti-yellowing agent, erucamide, oleamide and stearic acid; and (3) adding the material obtained in the step (2) into an internal mixer, carrying out internal mixing for 5-10 minutes, and extruding by virtue of an extruder. The TPU film is used as a fabric of garments and shoes. The TPU film utilizing the technical scheme has a good moisture permeation rate and excellent water tolerance, and a product is safe, environment-friendly and comfortable.

Owner:ZHEJIANG HUANLONG NEW MATERIAL SCI & TECH

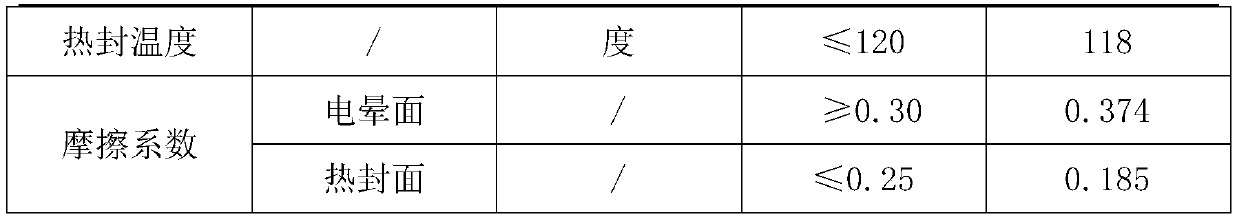

Special polyethylene flour bag packaging film

ActiveCN109648899AGood puncture resistanceHeat-sealed firmlyFlexible coversWrappersEngineeringCo extrusion

The invention discloses a special polyethylene flour bag packaging film, and belongs to the field of packaging films. Metallocene imported from America is added in the outer layer, metallocene B and Aimported from Japan are added into the middle layer and the inner layer, the formulas of the outer layer, the middle layer and the inner layer are different and are mixed evenly, a three-layer film is formed by a co-extrusion mold head to be extruded, and the special polyethylene flour bag packaging film is obtained. The sealing performance is better, the cost is better, the preparation process is concise, the heat-seal temperature is low, firmness is better, and the special polyethylene flour bag packaging film is very suitable for small-batch packages.

Owner:HENAN YINFENG PLASTIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com