Multilayered functional prepreg fabric as well as preparation method and application thereof

A fabric and pre-impregnation technology, applied in applications, other household appliances, chemical instruments and methods, etc., can solve the problems of cumbersome preparation process, unfavorable large-scale production, impact resistance, poor puncture performance, etc., and achieve simple preparation process, The effect of broad practical application value and broad industrial application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

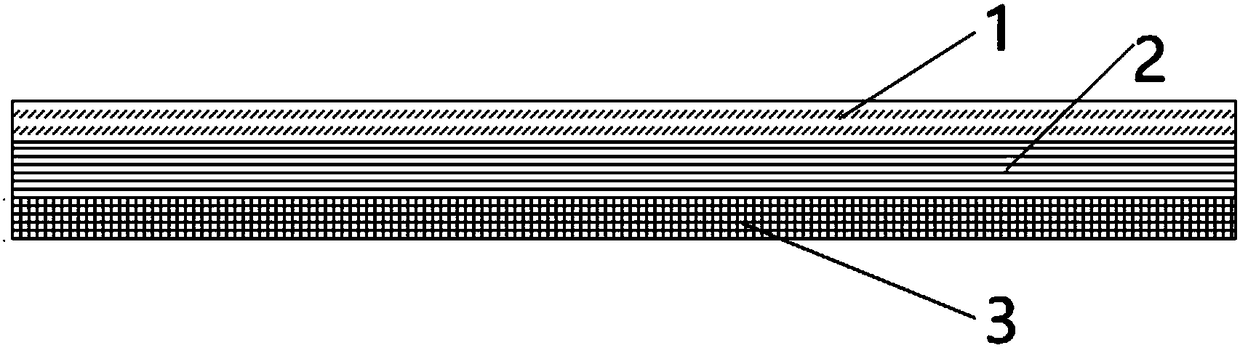

[0035] A multi-layer functional prepreg fabric structure is composed of a puncture-resistant layer of short-fiber non-woven fabric, an impact-resistant layer of unidirectional fiber, and a high-rigidity layer of two-dimensional fabric. Among them, the puncture-resistant layer of the short-fiber non-woven fabric is composed of a 4cm-long Kevlar 49 aramid fiber carding mesh to form a non-woven fabric structure, and the above-mentioned non-woven fabric is impregnated with a polyurethane resin glue solution, and the resin content in the fabric is 20%. The thickness is 0.04mm; the unidirectional fiber impact-resistant layer is composed of UHMWPE fiber and T300 carbon fiber in a mixed unidirectional arrangement, where the ratio of UHMWPE fiber to T300 carbon fiber is 4:1, and the above-mentioned unidirectional fiber fabric layer is impregnated with polyethylene resin emulsion. The resin content in the unidirectional fiber layer is 26%, and the thickness of the layer is 0.05 mm; the t...

Embodiment 2

[0038] A multi-layer functional prepreg fabric structure is composed of a puncture-resistant layer of short-fiber non-woven fabric, an impact-resistant layer of unidirectional fiber, and a high-rigidity layer of two-dimensional fabric. Among them, the puncture-resistant layer of the short fiber non-woven fabric is composed of a 5cm-long Kevlar 29 aramid fiber card to form a non-woven fabric structure, and the above-mentioned non-woven fabric is impregnated with polyethylene emulsion glue, and the resin content in the fabric is 18%. The thickness of the layer is 0.01mm; the unidirectional fiber impact-resistant layer is composed of UHMWPE fiber and E glass fiber mixed in one direction, and the ratio of UHMWPE fiber to E glass fiber is 2:1, and the above unidirectional fiber is impregnated with polypropylene resin emulsion For the fabric layer, the resin content in the unidirectional fiber layer is 21%, and the thickness of the layer is 0.02mm; the two-dimensional fabric layer is...

Embodiment 3

[0041] A multi-layer functional prepreg fabric structure is composed of a puncture-resistant layer of short-fiber non-woven fabric, an impact-resistant layer of unidirectional fiber, and a high-rigidity layer of two-dimensional fabric. Among them, the puncture-resistant layer of short-fiber non-woven fabric is composed of UHMWPE fiber carding with a length of 6cm to form a non-woven fabric structure, and the above-mentioned non-woven fabric is impregnated with polymethyl methacrylate resin glue, and the resin content in the fabric is 15%. The thickness is 0.02mm; the unidirectional fiber impact-resistant layer is composed of UHMWPE fiber and T800 carbon fiber hybrid unidirectional arrangement, in which the ratio of UHMWPE fiber to T800 carbon fiber is 3:1, and the polyurethane resin emulsion is used to impregnate the above unidirectional fiber fabric layer. The resin content in the fiber layer is 20%, and the thickness of the layer is 0.03mm; the two-dimensional fabric layer is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com