High-barrier high-temperature-resistant sterilization digestion membrane and preparation method thereof

A high-temperature-resistant, high-barrier technology, applied in the field of high-barrier high-temperature-resistant sterilization cooking film and its preparation, can solve the problems of high-temperature resistance to be improved, and achieve good impact resistance, high heat-sealing strength, and strong puncture resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

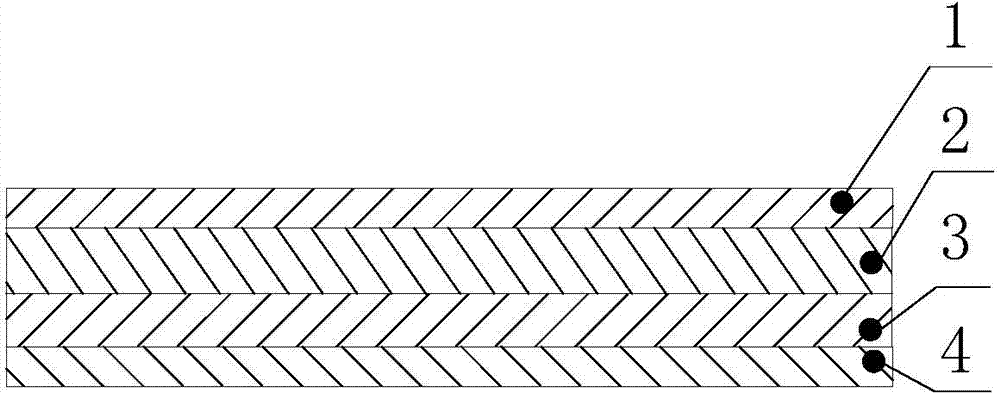

[0019] like figure 1 As shown, a high-barrier high-temperature resistant sterilization retort film is composed of a heat-sealing layer 1, a first core layer 2, a second core layer 3, and a corona layer 4. The mass percentages of the heat-sealing layer 1, the first core layer 2, the second core layer 3, and the corona layer 4 are: 20%, 30%, 30%, and 20%, respectively;

[0020] The heat-sealing layer is made of polypropylene resin (F800E) [binary copolymer resin F800E], an anti-adhesive agent and a smooth agent, and the amount of the anti-adhesive agent is 2% of the mass of the polypropylene resin. The adding amount of slipping agent is 2.5% of the quality of polypropylene resin. The anti-adhesive agent is the anti-adhesive agent AB6018PP, SiO 2 A kind of in; Described slippery agent is a kind of in the slippery agent GL5068PP of Constamp, oleamide (or oleic acid amide), erucamide, ethylene bisstearamide. Provides better coefficient of friction and heat sealing properties.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com