High-toughness resin-based aramid fiber composite material and production method thereof

A composite material and production method technology, applied in the textile field, can solve the problems of uneven stab-proof performance of resin-based aramid fiber composite materials, being susceptible to knife cutting, penetration of knife stabs, weak stab-proof performance of raised parts, and the like, Achieve the effect of uniform distribution of stab resistance, high stab resistance and uniform stab resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

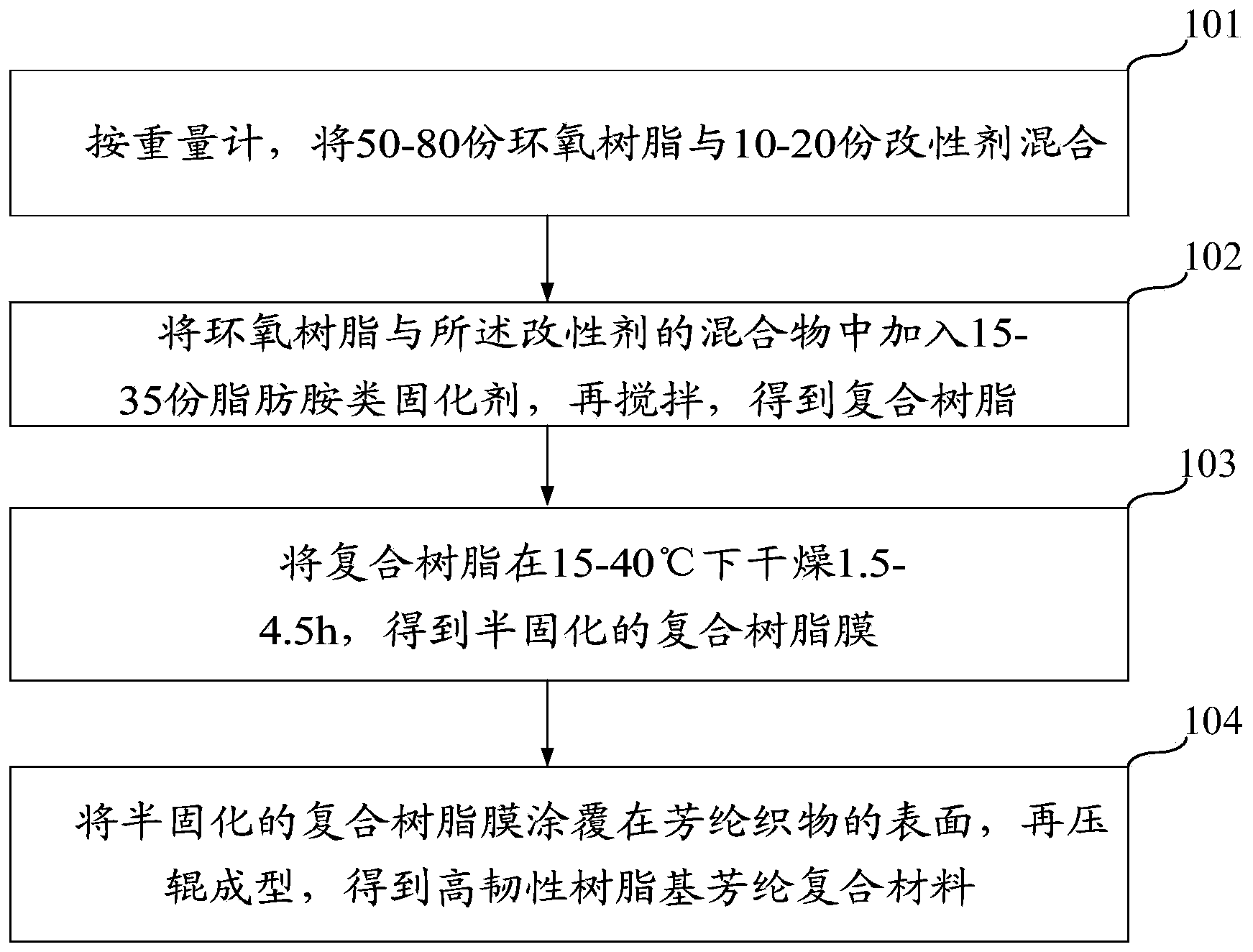

[0022] A kind of production method of high-toughness resin-based aramid fiber composite material, such as figure 1 shown, including the following steps:

[0023] Step 101: Mix 50-80 parts of epoxy resin with 10-20 parts of modifier by weight.

[0024] Step 102: Add 15-35 parts of aliphatic amine curing agent to the mixture of epoxy resin and modifier, and then stir to obtain a composite resin.

[0025] Step 103: drying the composite resin at 15-40° C. for 1.5-4.5 hours to obtain a semi-cured composite resin film.

[0026] Step 104: Coating the semi-cured composite resin film on the surface of the aramid fiber fabric, forming by pressing rollers to obtain a high-toughness resin-based aramid fiber composite material.

[0027] Wherein, the modifying agent is one or more of liquid polysulfide rubber, liquid silicone rubber, and polyethylene glycol ether.

[0028] The production method of the above high-toughness resin-based aramid fiber composite material is to prepare the comp...

Embodiment 2

[0041] This embodiment provides a high-toughness resin-based aramid fiber composite material, which is prepared by using Embodiment 1 or its preferred method. It can be seen that the high-toughness resin-based aramid fiber composite material of this embodiment can also achieve the above-mentioned technical effects.

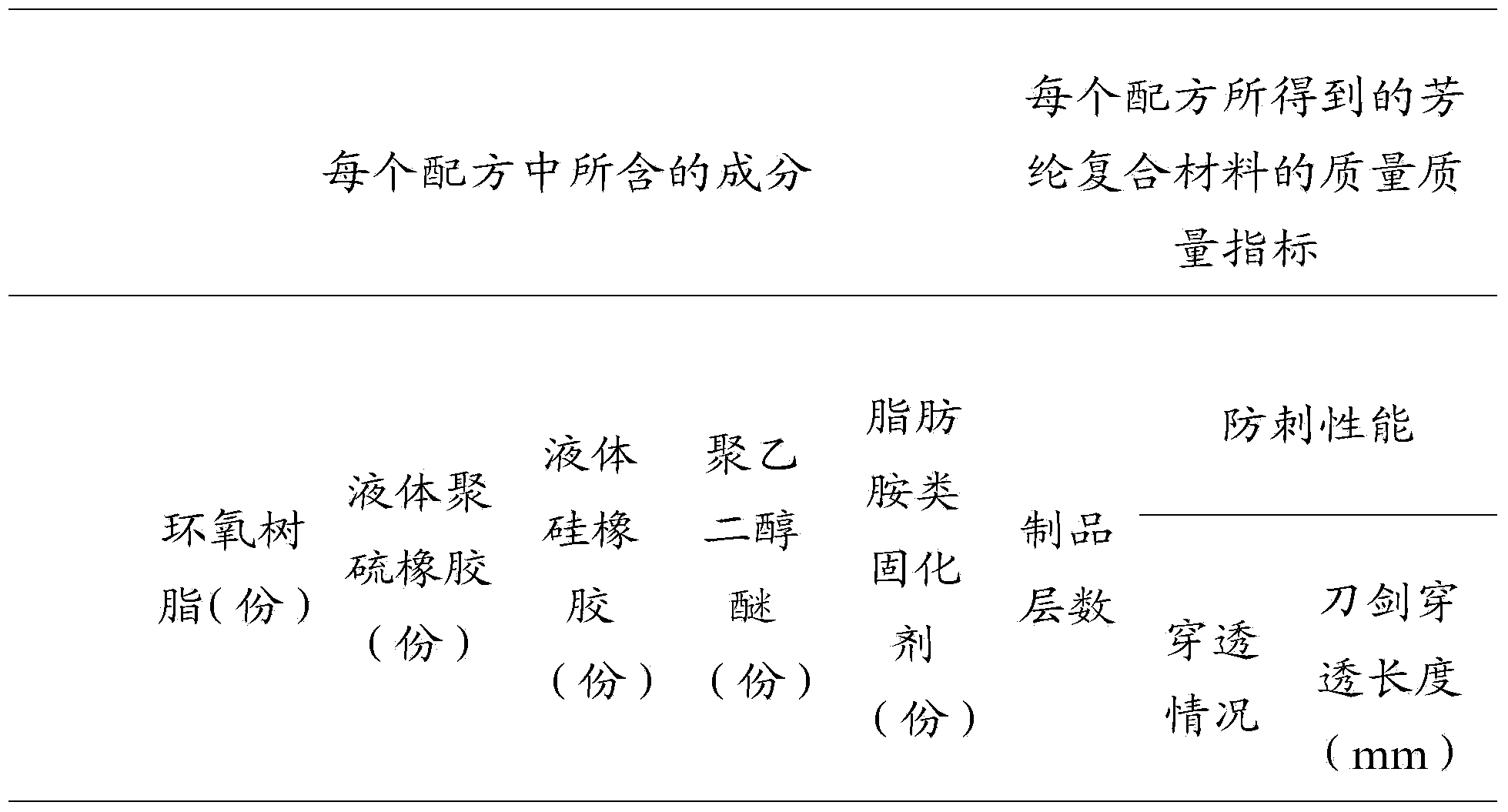

[0042] Wherein, each component in the composite resin used can adopt any part within its part number range, such as the formula shown in Table 1 (this table only lists some formulas, and the scope of protection of the present invention is not limited to the following formulas).

[0043] The formula of table 1 composite resin

[0044]

[0045]

[0046]

Embodiment 3

[0048] Mix the epoxy resin with the modifier, stir evenly for 25 minutes to fully mix the two components, continue to add aliphatic amine curing agent to catalyze, stir fully for 25 minutes, and transfer the modified composite resin to the release paper (PET, PE, PC or paper release paper) to ensure that the resin adheres evenly and smoothly to the release paper, and put it in a drying oven to dry in a vacuum at room temperature to form a film for storage, then make a film with a flexible resin with good thickness and uniform thickness, and transfer it to a flat surface for the second time On aramid cloth. The rolling speed and pressure of the pressing roller are properly regulated, the speed is guaranteed to be 8m / s, the pressure is kept at 5MPa, and the constant speed and constant pressure are uniformly pressed, so that the modified epoxy resin film and the aramid fiber cloth can be tightly compounded without bubbles, and it is made of Aramid stab-resistant material with exc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com