Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

99results about How to "Stable production and operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

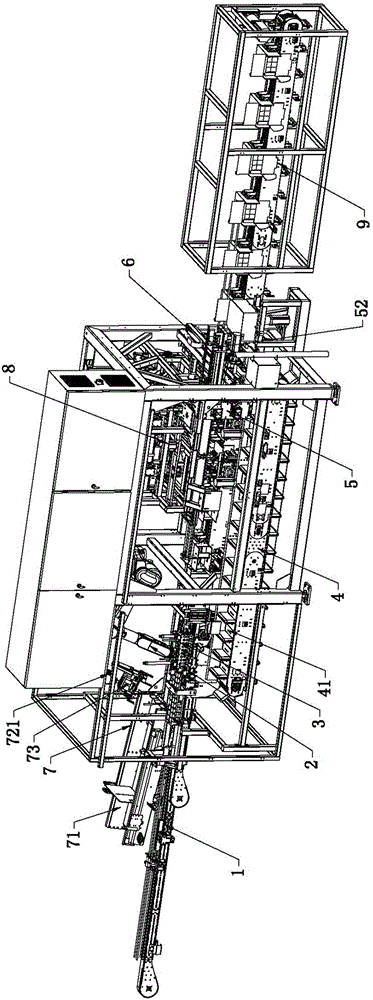

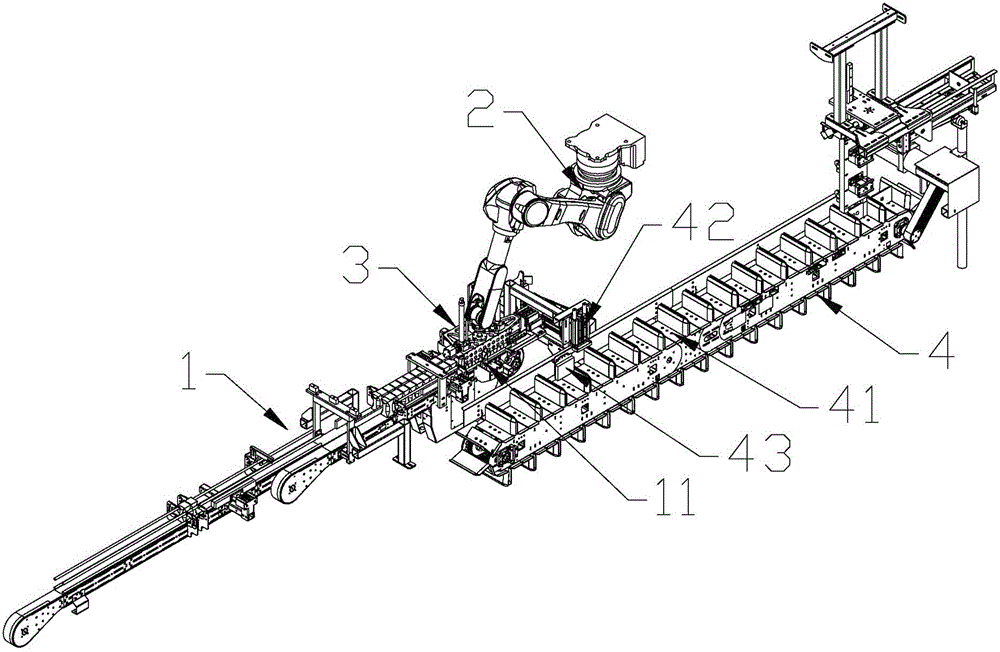

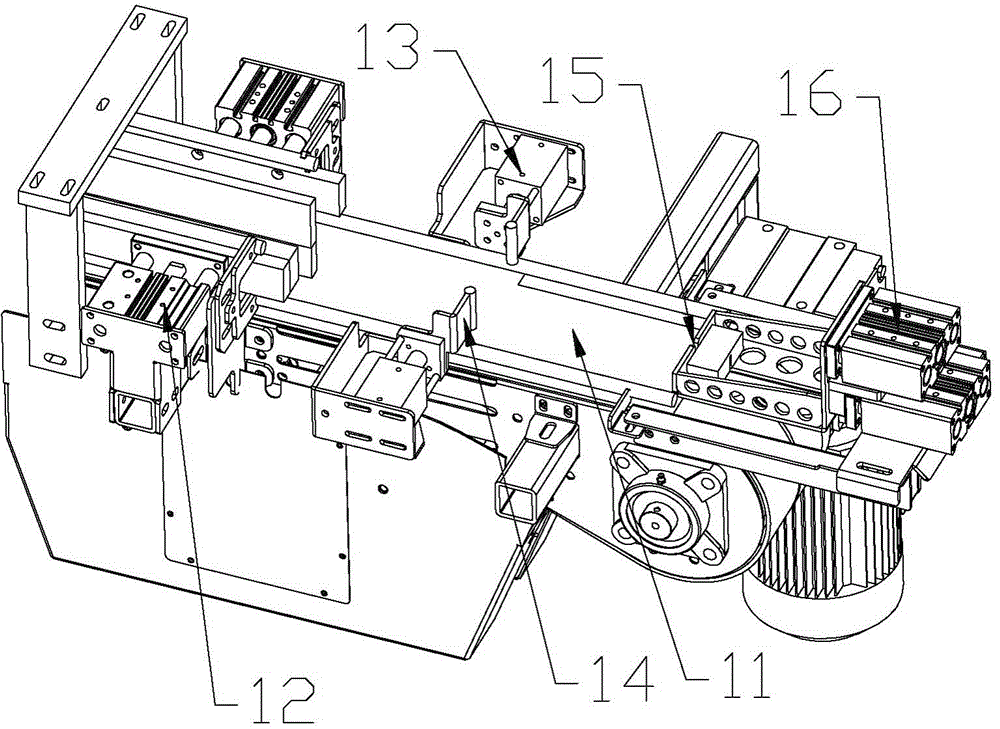

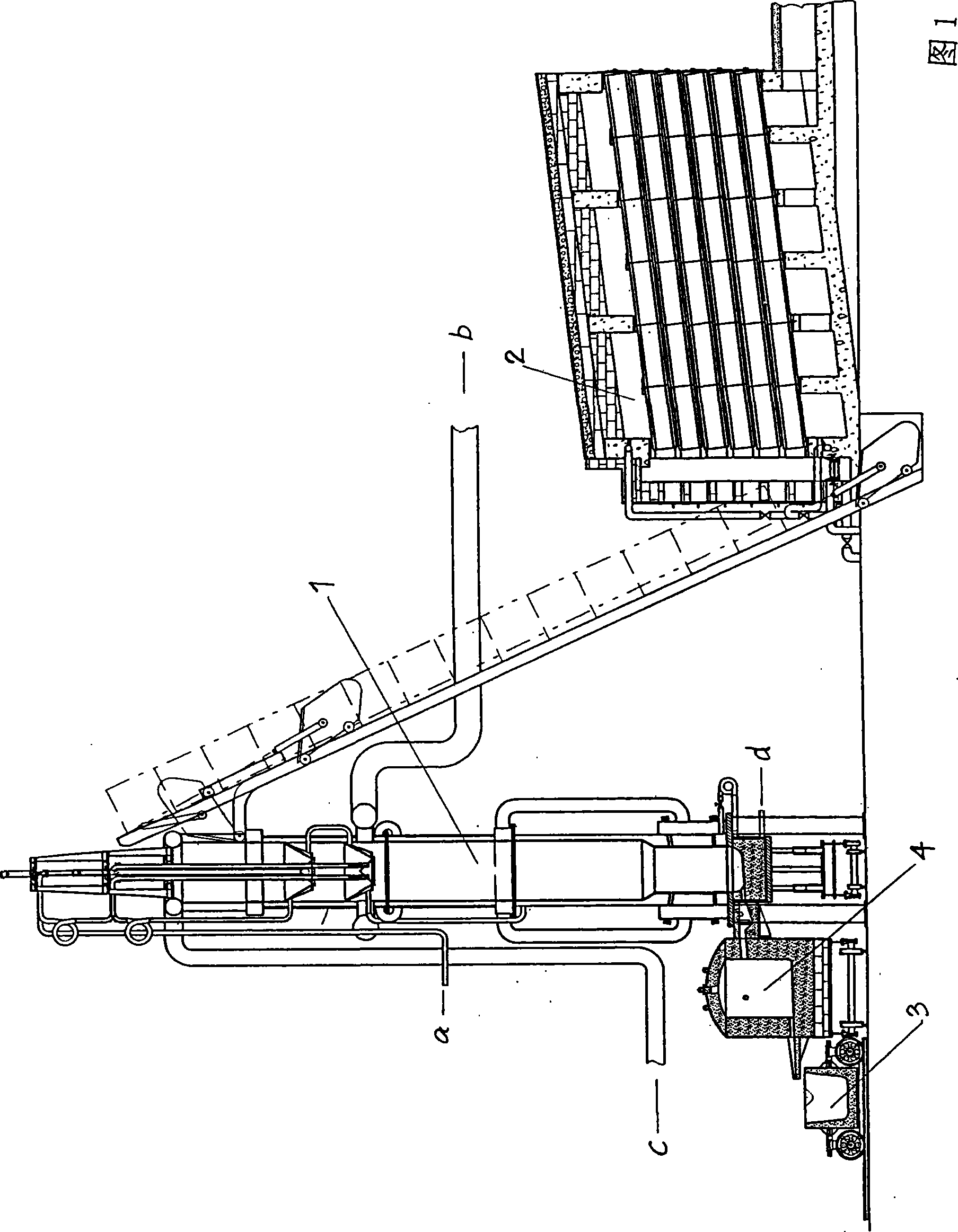

Automatic encasement system for Lilezuan milk bag gift boxes

ActiveCN104828288ASolve the problem that it is difficult to vertically transport automatic packingPrecise movement controlIndividual articlesEngineeringWorkload

The invention discloses an automatic encasement system for Lilezuan milk bag gift boxes. The automatic encasement system comprises a milk bag integration conveying line (1), a milk bag robot (2) and a milk bag unit conveying line (4), wherein a milk bag clamp (3) at the lower end of a manipulator of the milk bag robot (2) catches a milk bag unit on the milk bag integration conveying line (1) and pushes the milk bag unit into a corresponding milk bag unit separation slot (41) under the condition that the milk bag unit is in a horizontal state; then a small baffle plate insertion machine (5) inserts a small baffle plate into a middle clearance of the milk bag unit, and a horizontal pushing mechanism (6) is used for horizontally pushing the milk bag unit with the inserted small baffle plate into a packaging case already provided with a large lining plate on a packaging case conveying line (9); finally the packaging case already provided with the large lining plate, the small baffle plate and the milk bag unit is covered and encased to finish the whole automatic encasement process. According to the automatic encasement system for the Lilezuan milk bag gift boxes, the milk bag encasement operation is creatively changed from vertical encasement into horizontal encasement, so that the production operation is more stable, the maintenance is easy and convenient, and the workload can be reduced to the maximum extent.

Owner:苏州澳昆智能机器人技术有限公司

Method for controlling stability and uniformity of aluminum oxide concentration in aluminum electrolysis cell

The invention discloses a method for controlling stability and uniformity of aluminum oxide concentration in an aluminum electrolysis cell. The method comprises the following steps of: firstly, setting the aluminum oxide concentration control target at a low resistance concentration area, and performing two main control processes, namely long-term 'blanking as required' and short-term 'concentration check', to realize feeding as required in time in the aluminum electrolysis cell and stable operation in the low resistance concentration area; secondly, performing online measurement of current distribution on each anode of the electrolysis cell, and adjusting the blanking proportion of each blanking point according to the consumption rate of aluminum oxide of the anode around each blanking point to realize uniform distribution of the aluminum oxide concentration in the space; and thirdly, improving a blanking device and a blanking manner to reduce aluminum oxide sediment generated by accumulation at the blanking port. The method is favorable for stable, efficient, low-voltage, low-power consumption and low-discharge production operation of the aluminum electrolysis cell.

Owner:包头铝业有限公司 +1

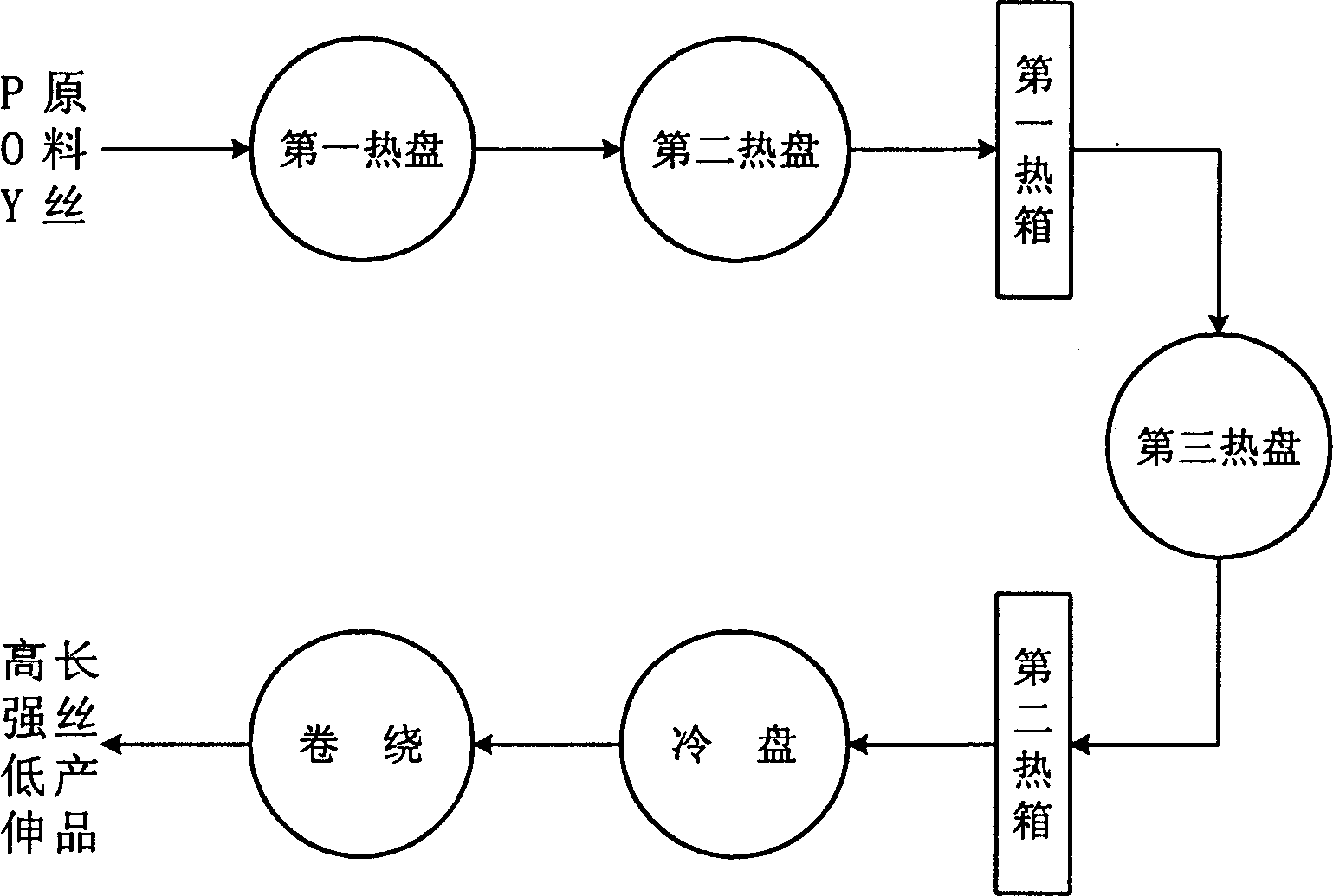

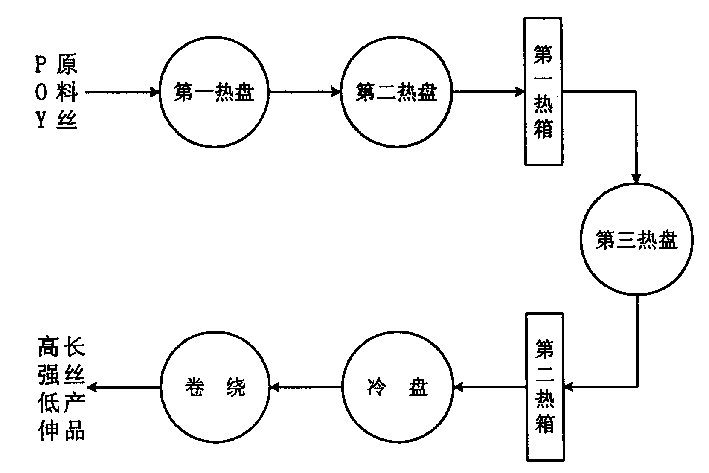

Manufacture of high tenacity low-stretch polyester filaments

InactiveCN1448547AWide variety of sourcesIncrease production capacityMelt spinning methodsYarnHigh intensityUltimate tensile strength

The present invention relates to Dacron producing process, and is especially preparation process of high-strength and low-elongation Dacron filament for sewing thread. The preparation process with routine pre-oriented POY filament includes successive first high-power drafting in the first and the second heating discs, high temperature tensed heat setting in the first heating box and the third heating box, the second drafting and the high temperature relax heat setting in the second heating box. In the process, POY filament has good drafting performance, no teasing and breaking, and the final product has high strength, low elongation and less heat shrinkage.

Owner:SINOPEC YIZHENG CHEM FIBER

Through hole conductive film, preparation method thereof and application

InactiveCN101567231AGood vertical conductionImprove shielding effectConductive layers on insulating-supportsMagnetic/electric field screeningAdhesiveDyne

The invention provides a through hole conductive film, a preparation method thereof and application. The preparation method of the through hole conductive film comprises the following steps: a, taking a single-layer or multi-layer film of which the thickness is between 3 and 1,000 microns to perform plasma, ion beam or corona treatment so that the surface dyne value is between 39 and 75; b, perforating the film after the treatment; c, performing ion plating, magnetron sputtering plating, vapor deposition and chemical sensitization on the hole wall and at least one surface of the perforated film until a conductive layer of which the thickness is between 0.005 and 0.5 microns is generated; and d, electroplating or chemically plating metal outside the conductive layer until the thickness of the plating layer is between 0.01 and 5 microns, the resistance value is between 0.003 and 10 omega / sq, and the pore diameter of a product is between 1 and 5,000 microns. The surface resistance and the vertical resistance of the through hole conductive film are between 0.005 and 10 omegas, the adhesive force is good, and the screening effectiveness is more than 70 dB; besides, the through hole conductive film is applied to the field of software electromagnetic screen and omnibearing conductive adhesives, and can obtain various functional materials which are heat resistant, inflaming retarding and the like.

Owner:TIANNUO PHOTOELECTRIC MATERIAL

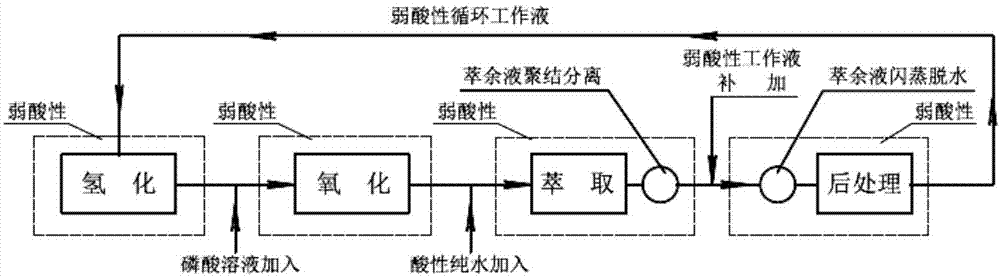

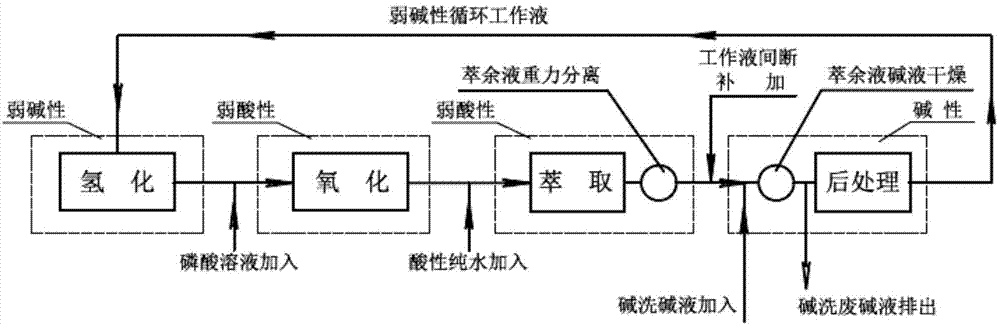

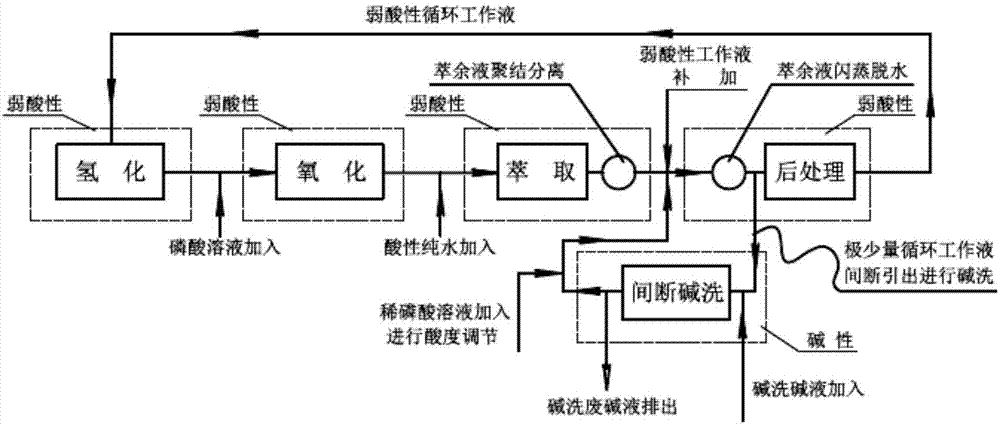

Method of preparing hydrogen peroxide from all-acid working solution system by anthraquinone process

ActiveCN103496674AGuaranteed outputQuality assurancePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesOperational costsPurified water

The invention discloses a method of preparing hydrogen peroxide from an all-acid working solution system by the anthraquinone process. The method includes hydrogenation, oxidization, extraction and post-treatment of working solution. During the method, the whole working solution system is faintly acid constantly. The method includes: hydrogenating prepared faintly acidic working solution to obtain hydrogenated solution; mixing the hydrogenated solution with acid, and performing air oxygenation to obtain oxidized liquid; extracting the oxidized liquid with purified water; purifying extract to obtain finished hydrogen peroxide; removing free water and free hydrogen peroxide from the extract, performing vacuum flashing to remove dissolved water and dissolved hydrogen peroxide, and using vacuum-flashed residual extract as circulating working solution. Very little circulating working solution can further be intermittently guided out of a main process for alkali washing by the method. The method has the advantages that safety and reliability of the production process of hydrogen peroxide can be improved effectively and fixed capital input and production operational cost can be reduced.

Owner:北京凯迪森科技有限公司

Tube furnace-shaft furnace twin coal-base fusing reduction iron-smelting method

The invention relates to a coal-based smelting reduction iron making process, specifically to a duplex coal-based smelting reduction iron making method of tubular furnace and shaft furnace, which solves the problems existing in the coal-based smelting reduction iron making methods of the prior art. Technological procedures include: preparation: iron ore powder, coal powder and lime powder; adding water to mix; shaping by high-pressure briquette; enhancing preheating and drying; pre-reducing the tubular furnace; carrying out final reduction of shaft furnace smelting reduction and practicing forehearth separation of iron and slag. The invention has advantages of small overall investment, low overall energy consumption, little pollution, low failure rate of equipments and stable production operation; flexible production scale, easiness in unified production for casting; low cost and high investment return; short process, easiness in operation, few equipments needed and easiness in maintenance.

Owner:郭瑛

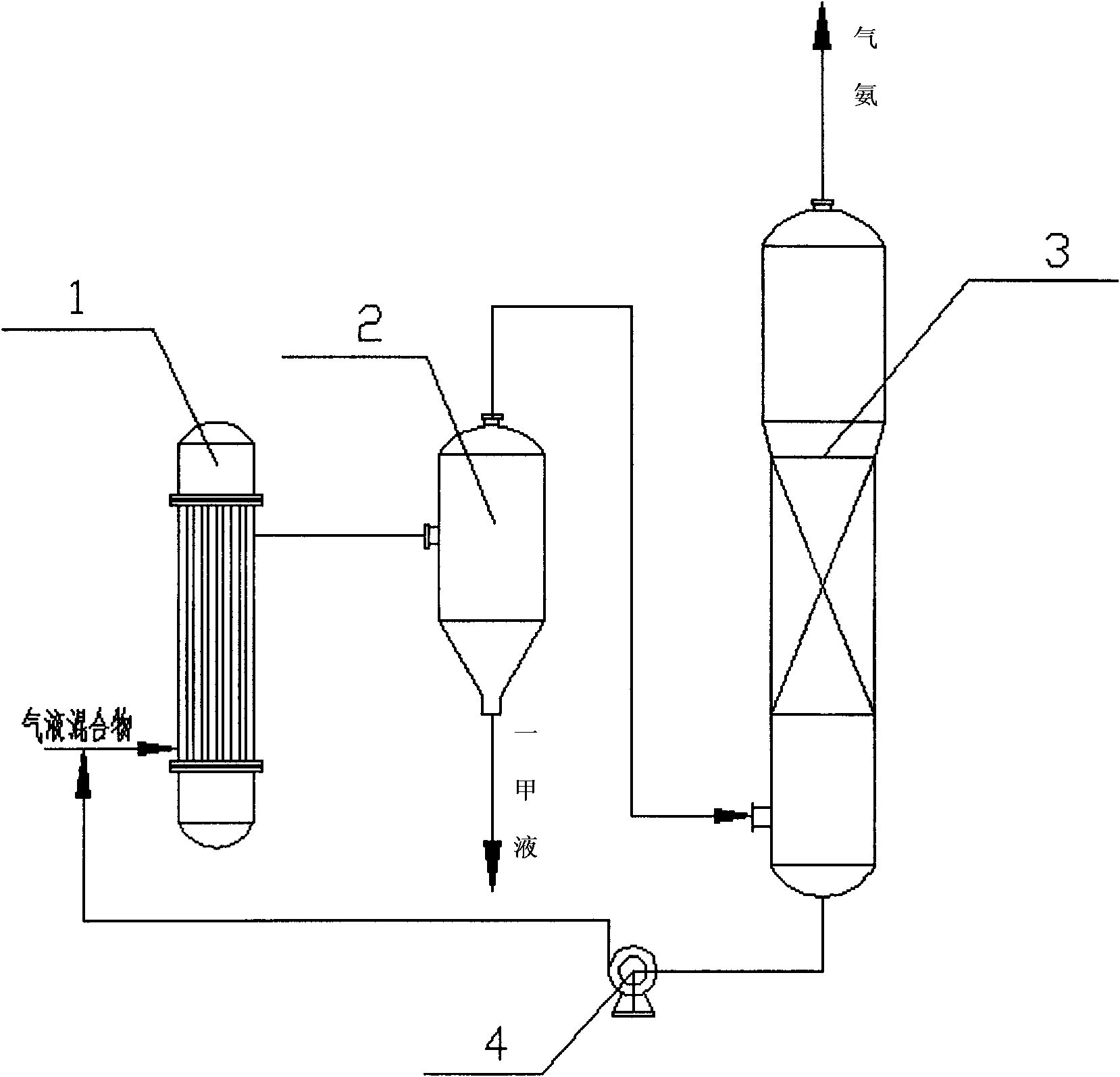

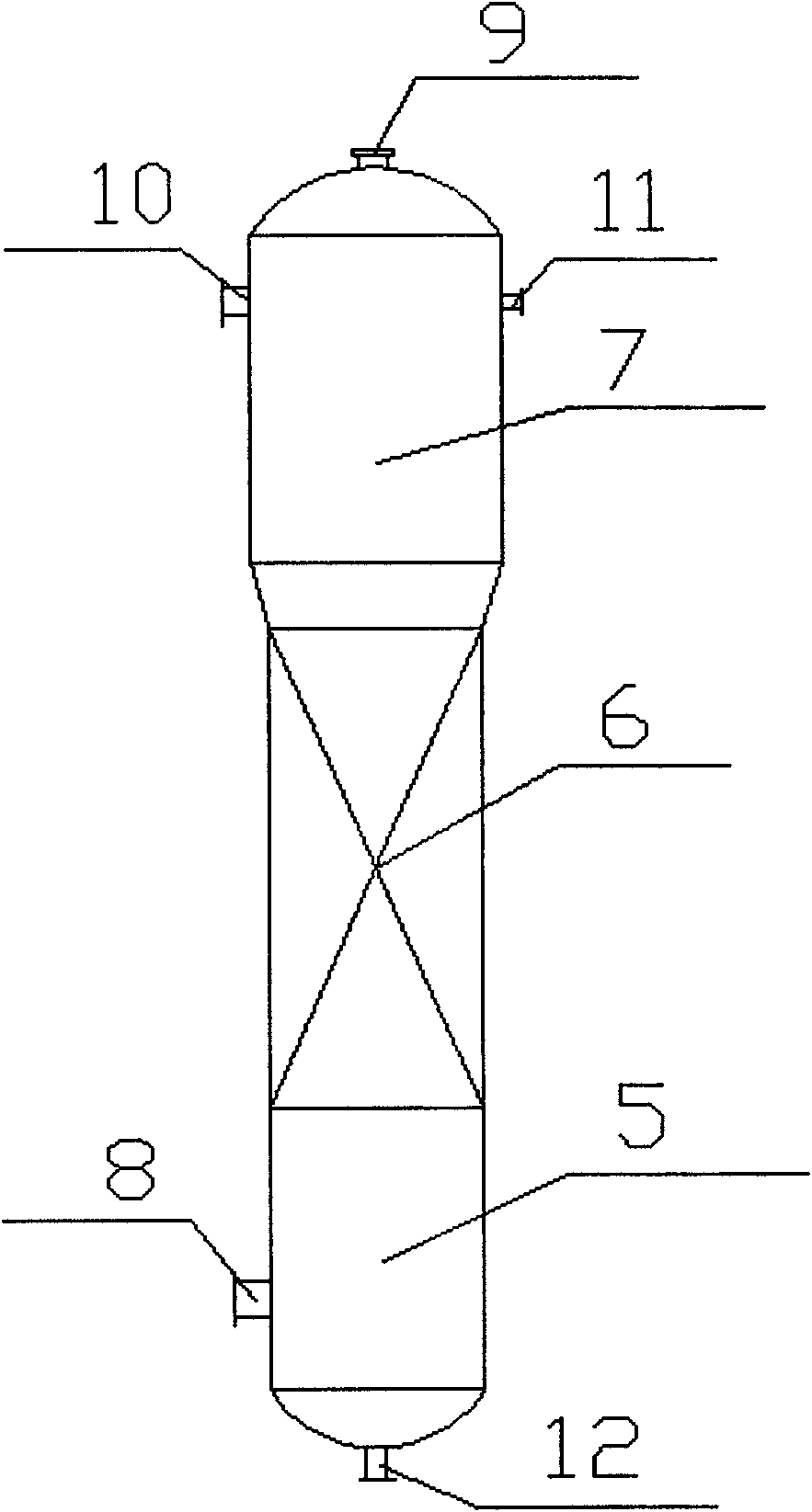

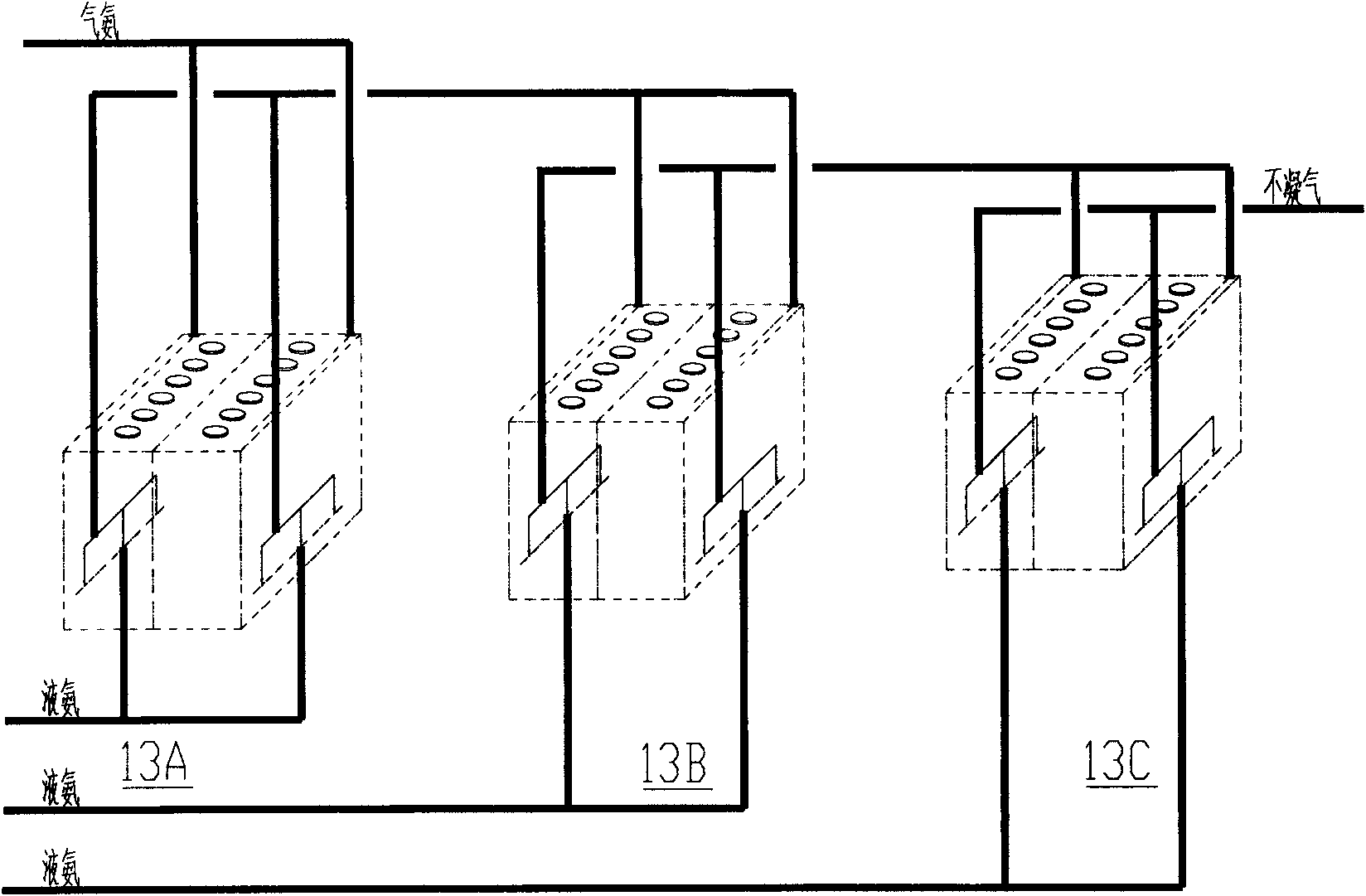

Medium-pressure recovery process of low steam/carbon ratio-three-section adsorption-evaporative ammonia-cooling carbamide production

ActiveCN101624355AHigh synthesis rateReduce energy consumptionUrea derivatives preparationOrganic compound preparationGas phaseTower

The invention discloses a medium-pressure recovery process of carbamide production, comprising four process steps: condensation adsorption, separation, medium-pressure adsorption and ammonia condensation recovery; wherein the temperature of the condensation adsorption is improved to 105 DEG C from 90 DEG C to 95 DEG C of traditional process, the medium-pressure adsorption is improved into three-section adsorption from two-section adsorption, and an ammonia condenser of the ammonia condensation recovery is changed into an evaporative ammonia condenser from a tubular heat exchanger, so as to lead steam / carbon mole ratio in ammonium carbamate solution recycled and returned to a carbamide synthesis tower in a system to be reduced to 1.5 from 2.0, the carbon dioxide content in gas phase exhausted from a medium-pressure adsorption tower is greatly reduced, and is decreased within 5ppm from 100ppm, thereby being beneficial to improving the carbamide synthetic ratio and reducing the investment and consumption; in addition, the operation is convenient and safe.

Owner:SICHUAN GOLDEN ELEPHANT SINCERITY CHEM CO LTD

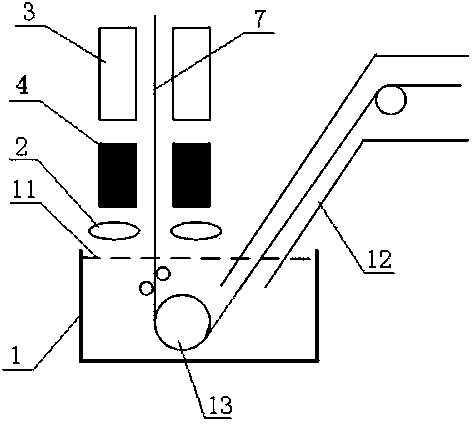

Low boiling water contraction rate polyester fiber drafting textured filament yarn and its producing method and use

ActiveCN1554816ALow boiling water shrinkageAchieve the purpose of the inventionYarnPolymer sciencePolymer chemistry

The present invention relates to drafting deformed dacron filament with low boiling water shrinkage and its production process and application. The POY material filament is processed successively through the first drafting roller, the first heating box, cooling plate, false twisting unit, the second drafting roller, network forming unit, 2bis roller, the second heating box, filament guide unit and filament breaking detector; adding weak network in the resilience increasing process; oiling and winding steps to obtain DTY filament. The present invention has lower deformation temperature, higher settling temperature, short process, reasonable technological control and stable production operation; and the product has boiling water shrinkage not higher than 1.0%, excellent built-in curling elasticity and wrapping. The product may be used in making embroidery string and trademark string.

Owner:SINOPEC OILFIELD SERVICE CORPORATION

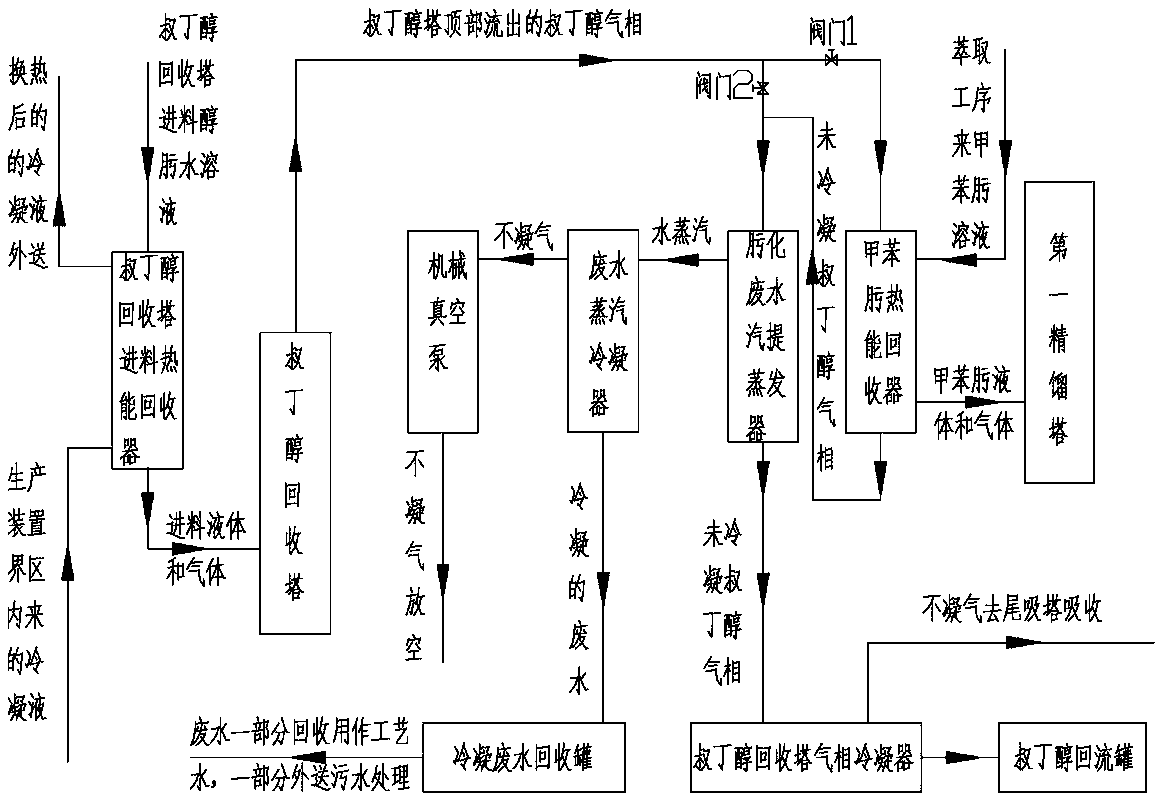

System and method for utilizing heat energy of oximation device

PendingCN108530317ALow costReduce usageLactams preparationOrganic compound preparationGas phaseEngineering

The invention discloses a system and a method for utilizing heat energy of an oximation device. The system comprises a TBA (Tert Butyl Alcohol) recovery tower feeding heat energy recoverer, a TBA recovery tower, a valve 1, a valve 2, an oximation wastewater steam stripping evaporator, a methylbenzene oximate heat energy recoverer, a first rectification tower, a TBA recovery tower gas-phase condenser, a TBA reflux tank, a wastewater steam condenser, a mechanical vacuum pump and a condensed wastewater recovery tank, wherein the oximation wastewater steam stripping evaporator and the methylbenzene oximate heat energy recoverer are in parallel and serial arrangement. According to the system and the method for utilizing the heat energy of the oximation device, disclosed by the invention, heat of high-temperature condensate during a production process of caprolactam can be recovered through the TBA recovery tower feeding heat energy recoverer, and heat of gas-phase steam flowing out of the TBA recovery tower can be recovered through the oximation wastewater gas stripping evaporator and the methylbenzene oximate heat energy recoverer which are in parallel and serial arrangement, so that the using amount of boiler steam is reduced; through the whole system and the method, the boiler steam can be saved by about 1.5 to 1.6 tons through the production of caprolactam per ton, the cost of steam is reduced from original 560 yuan to about 310 yuan, and huge economic benefit is gained.

Owner:宋心红

Method for treating phosphate-containing wastewater

InactiveCN108675529AStable production and operationAchieving zero emissionsWater treatment parameter controlSpecific water treatment objectivesPhosphateFresh water organism

A method for treating phosphate-containing wastewater comprises the following steps: the wastewater is lifted to a mixed reaction tank by a pump, and the pH value of the wastewater is adjusted to a first range by using an inorganic alkali in order to precipitate first-type metal cations from a formed primary reaction liquid in order to obtain a primary precipitate and a primary filtrate, wherein the first precipitate includes phosphorus and nitrogen salts; the pH value of the primary filtrate is adjusted to a second range by using the inorganic alkali to precipitate second-type metal cations from a formed secondary reaction liquid in order to obtain a secondary precipitate and a secondary filtrate, wherein the second precipitate includes phosphorus and nitrogen salts; a secondary reactionliquid is filtered by a tubular microfiltration membrane to obtain micro-filtered water; and the micro-filtered water goes through a concentrating reverse osmosis device to obtain concentrated water and freshwater, and the concentrated water is mechanically evaporated by an evaporator to obtain industrial grade ammonium sulfate and ammonium dihydrogen phosphate. The method for treating phosphate-containing wastewater has the advantages of stability in production running, environmental protection, high efficiency, and realization of zero discharge of sewage.

Owner:深圳市华虹清源环保科技有限公司

Production method of low boiling water contraction rate polyester fiber drafting textured filament yarn

ActiveCN100489168CLow boiling water shrinkageAchieve the purpose of the inventionYarnContraction rateEngineering

The present invention relates to drafting deformed dacron filament with low boiling water shrinkage and its production process and application. The POY material filament is processed successively through the first drafting roller, the first heating box, cooling plate, false twisting unit, the second drafting roller, network forming unit, 2bis roller, the second heating box, filament guide unit and filament breaking detector; adding weak network in the resilience increasing process; oiling and winding steps to obtain DTY filament. The present invention has lower deformation temperature, higher settling temperature, short process, reasonable technological control and stable production operation; and the product has boiling water shrinkage not higher than 1.0%, excellent built-in curling elasticity and wrapping. The product may be used in making embroidery string and trademark string.

Owner:SINOPEC OILFIELD SERVICE CORPORATION

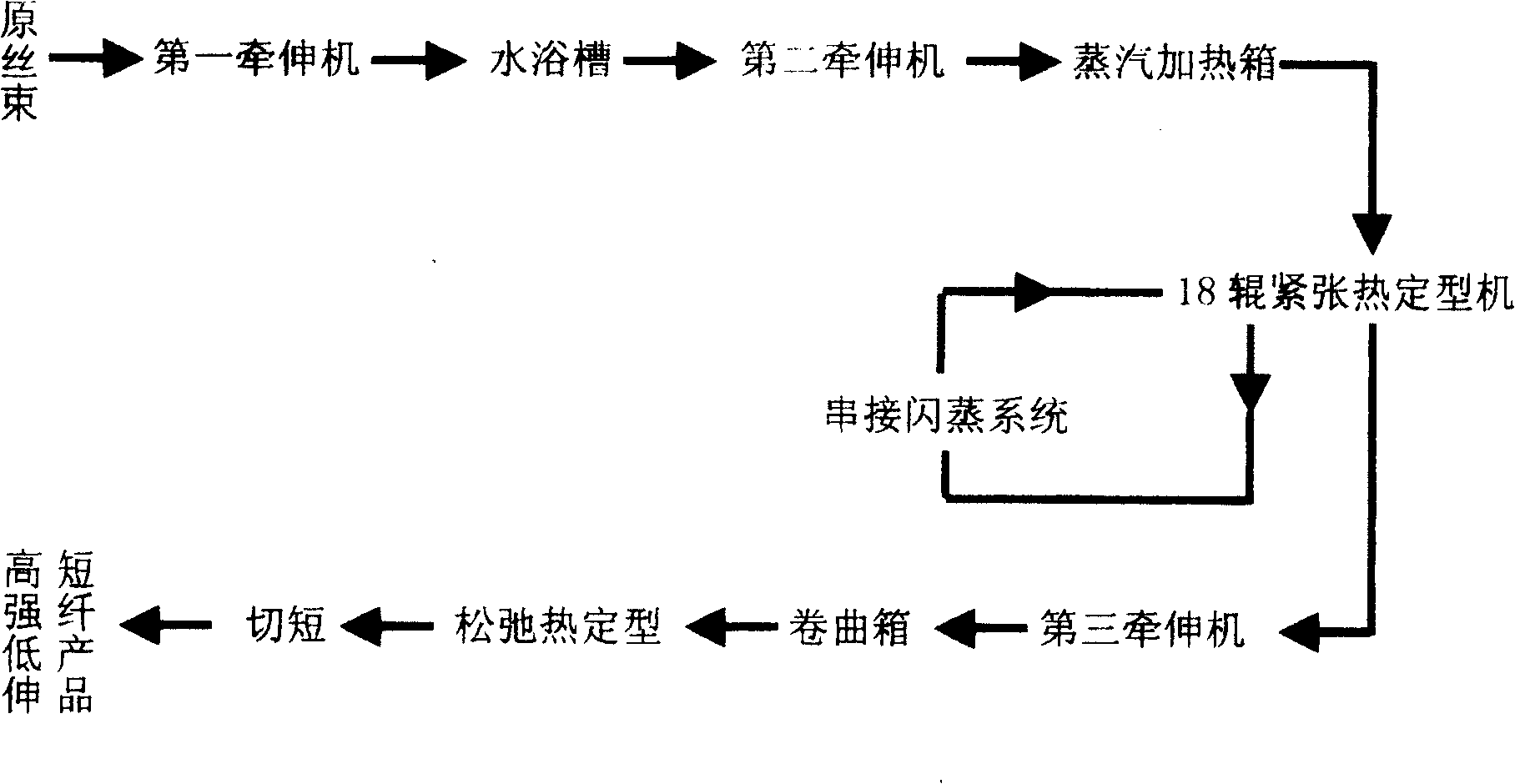

High-strength low-extension polyester staple fiber preparation method

ActiveCN100422400CGuarantee and meet the requirements of temperature uniformity and stabilityReduce consumptionArtificial filament heat treatmentMelt spinning methodsPolyesterWater baths

This invention relates to a terylene product technology, especially to a preparing method for short fabric with high strength and low elongation. This method uses the tow without drawing-off (short for original tow) for raw material, the working procedure for the production as follows: the first drawing-off, the second drawing-off, 18 roll tense thermoforming, the third drawing-off, curling, loose thermoforming, cutting off. Namely carrying out the first drawing-off through the water bath which between the thirst drafting machine and the second drafting machine; carrying out the second drawing-off through the steam heater which between the second drafting machine and the 18 roll tensely thermoforming machine; and then carrying out the thermoforming through the 18 roll tense thermoforming machine; carrying out the surplus drawing-off through the third drafting machine; curling through the curling machine; then drying through the loose thermoforming machine and cutting off after the thermoforming treatment. The original tow in this technology has a better drawing off, basically it hasn't the none-drawing off product, double long product and exceed long product, and the final product has the high strength, low elongation, and low thermal contraction and so on. The rupture strength >= 6.0CN / dtex, the rupture elongate rate 11-25%, the dry thermal contraction rate<8%.

Owner:上海太平洋二纺机化纤成套设备有限公司

A Generalized Boiler Combustion Overall Optimization and Energy Saving Composite Control System

InactiveCN102297452ASolve the problem of maximum combustion efficiencyReduce carbon contentIndirect carbon-dioxide mitigationCombustion regulationAir preheaterCombustion

The present invention relates to a generalized boiler combustion overall optimization and energy-saving composite control system, including a combustion optimization control system, a boiler and a fuel improvement and addition system, the combustion optimization control system and the boiler are connected through a boiler interface module, and the fuel improvement and addition system It is connected with a combustion optimization control system through a signal line, and the fuel improvement adding system is connected with a boiler through a transmission line, and a control system, a data acquisition system and an air preheating device are arranged in the boiler. The invention solves the problem of how to maximize the combustion efficiency of the boiler under the existing conditions - the fully automatic combustion optimization technology can increase the thermal efficiency of the boiler by 2-5%, and significantly reduce the amount of fly ash and the carbon content of the fly ash, and the thermal efficiency of the limited site Can be higher than 5%.

Owner:宋群

Production device for minimized spangle on surface of cold-rolled steel sheet

InactiveCN104099552AEvenly distributedStable production and operationHot-dipping/immersion processesSheet steelEngineering

The invention discloses a production device for minimized spangles on a surface of a cold-rolled steel sheet. The device comprises an air knife above a zinc pot and air spray tanks positioned between the air knife and a cooling-after-plating bellows, and a fan; the fan is connected with the air spray tanks through pipelines; the air spray tanks are arranged between the air knife and the cooling-after-plating bellows and are symmetrically distributed at two sides of the cold-rolled steel sheet. The device overcomes the defect of the traditional production of minimized spangles on the surface of the cold-rolled steel sheet, so that the minimized spangles on the surface of the cold-rolled steel sheet are uniformly distributed; and the production is stable, has reduced production cost, and improves the quality of minimized spangle cold-rolled steel sheet products.

Owner:BAOSTEEL IND FURNACE ENG TECH

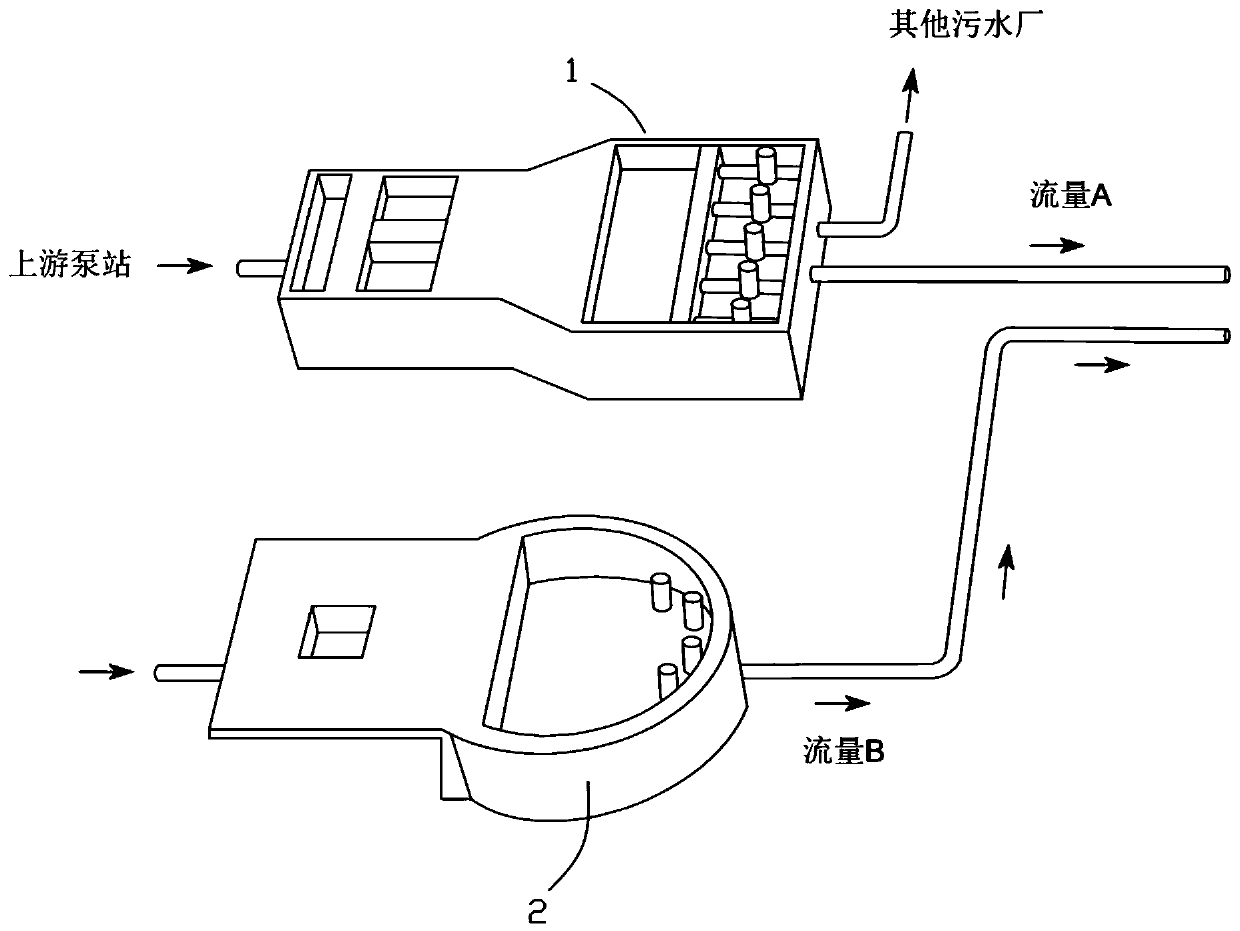

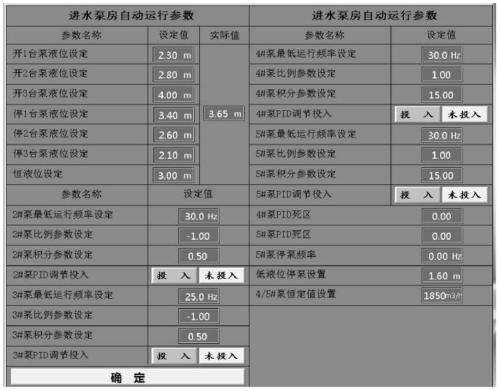

Automatic control method combining constant water level and constant water quantity of sewage plant

InactiveCN111362397AGuaranteed Processing LoadLower the water levelWater treatment parameter controlSewerage structuresAutomatic controlStream flow

The invention provides an automatic control method combining a constant water level and constant water quantity of a sewage plant. The sewage plant is provided with a water inlet pump room and at least one pump station. A water inlet pump and a transfer pump are arranged in the water inlet pump room, the water inlet pump is used for conveying water into a biological pool in a sewage plant, the flow of the water inlet pump is A, the transfer pump is used for transferring water to other sewage plants, the pump stations independently convey water to the biological pool in the plant, the flow of the pump stations is B, the total flow in the plant is A+B, the transfer pump executes a constant liquid level control mode, so that the liquid level of the water inlet pump room is kept unchanged, thewater inlet pump executes a constant-flow control mode, so that the total flow in the plant is kept constant. According to the automatic control method, a constant water level-constant water quantitycontrol mode of the sewage plant can be realized, the production operation is stabilized under the condition of ensuring the treatment load of the sewage plant, and the water level of an outer pipe network is reduced.

Owner:苏州市排水有限公司

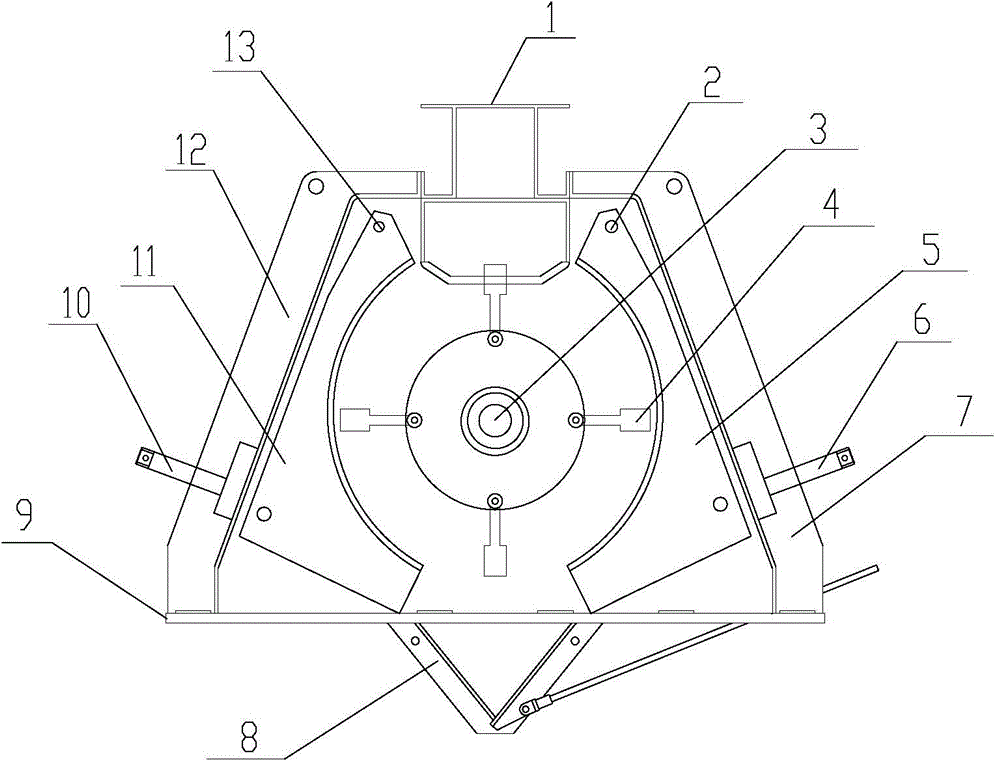

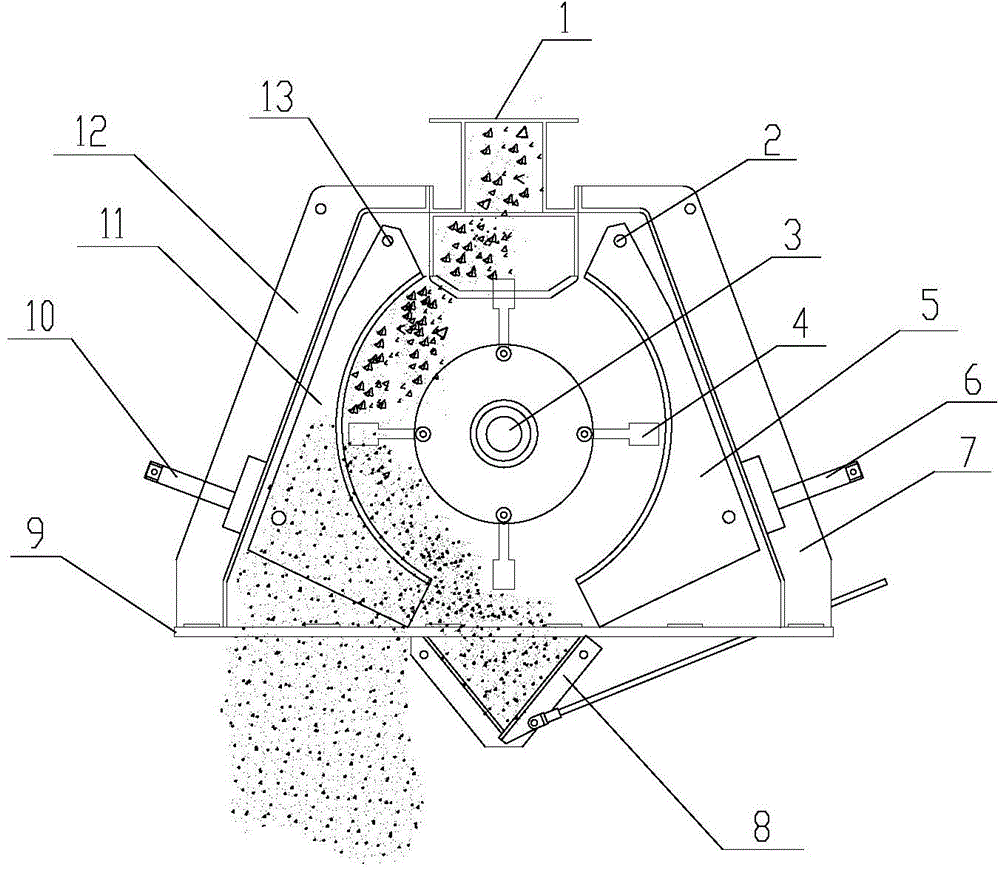

Reversible hammer crusher

InactiveCN104668033ASimple structureStable production and operationGrain treatmentsMechanical crushingEngineering

The invention discloses a reversible hammer crusher, and relates to the technical field of mechanical crushing equipment, which is used for solving the problem that an existing hammer crusher and reversible hammer crusher can only produce particles with one particle diameter specification and thus cannot meet the use requirement. The reversible hammer crusher comprises a shell, wherein the shell is internally provided with a crushing plate; the crushing plate is internally provided with a rotor assembly; the center of the rotor assembly is provided with a main shaft and the rotor assembly rotates around the main shaft; the main shaft is connected with a reversible motor; a crushing cavity is formed between the crushing plate and the rotor assembly; the rotor assembly comprises a rotation disc and hammer bodies uniformly suspended on the rotation disc; the crushing plate comprises a first crushing plate and a second crushing plate; the first crushing plate is connected with a first adjusting mechanism; the second crushing plate is connected with a second adjusting mechanism; the crushing plate respectively comprises a crushing part and screen plate parts; the size of the first screen plate part is smaller than that of the second screen plate part. The reversible hammer crusher is simple in structure, is convenient to install and replace, is stable in production and running, and is uniform in particle discharge granularity, thus meeting the requirement of customers for particles with different particle sizes.

Owner:沈阳科翔电力环保设备有限公司

Method for processing polyester staple fibers special for vortex spinning

ActiveCN103572400AStable production and operationFiber modulus reductionMonocomponent copolyesters artificial filamentCopolyesterYarn

The invention discloses a method for processing polyester staple fibers special for vortex spinning. According to the method, co-polyester is prepared by adopting a direct esterification method in the preparation process of the co-polyester, and the adopted raw materials include binary acid and diatomic alcohol. The method specifically comprises a step of esterification reaction and a step of condensation and polymerization reaction. Compared with the existing polyester staple fibers special for vortex spinning, the polyester staple fibers special for vortex spinning, used in the method disclosed by the invention, have reduced degree of crystallinity and fiber modulus; due to the reduction of the modulus and rigidity and the increase of softness of the fibers, when the polyester staple fibers are used as raw materials to perform production of pure-polyester vortex spinning or polyester-viscose blended vortex spinning, the hand feeling of yarns is effectively improved; meanwhile, the air pressure of a spinning nozzle can be reduced to ensure that the energy consumption is effectively reduced; moreover, the quality of untwisting and knotting after cutting by an electronic yarn clearer on vortex spinning equipment is improved, the quality of vortex spinning yarns and the quality of a fabric of the yarns are further improved, and requirements of users are met.

Owner:CHINA PETROLEUM & CHEM CORP +1

Coastal power plant ship traffic dispatching management system

ActiveCN109817024AImprove traffic management capabilitiesImprove controlMarine craft traffic controlInformation technologyElectronic information

The invention relates to a coastal power plant ship traffic dispatching management system, and belongs to the technical field of electronic information. The system is used for solving the problems that it is difficult for a power plant to timely grasp the specific position, navigation state and other real-time information of coal ships and carry out emergency control, so that the regulation and control over coal for the power plant are unreasonable, and therefore insufficient coal supply to units and shutdown are caused. The system has the advantage that a system establishment scheme is completed based on mature VTS and AIS technologies widely applied to ships, starting from defining an idea and target of constructing the ship traffic information management system, under an overall framework of the system and through a specific implementation plan.

Owner:DALIAN UNIVERSITY

Online problem capturing method, system and device, electronic equipment and storage medium

PendingCN110471787AImprove troubleshooting efficiencySolve the pain points of inefficiencyFault responseSoftware simulation/interpretation/emulationInformation findingByte

The embodiment of the invention provides an online problem capturing method, system and device, electronic equipment and a storage medium. The method comprises: receiving input information of a user,and searching for a target process according to the input information; injecting a preset byte code into a target JAVA virtual machine corresponding to the target process; receiving a capture request,and executing the preset byte code to capture target data according to the capture request; and returning the captured target data. According to the method, online problem diagnosis can be achieved under the condition that the system is not shut down, problems are rapidly and efficiently positioned, and stable production and operation are guaranteed.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

Novel temperature-reducing device of temperature-reducing and pressure-reducing valve

InactiveCN109139138ASolve crackingStable production and operationMachines/enginesSafety/regulatory devicesEngineeringSpray cooling

The invention discloses a novel temperature-reducing device of a temperature-reducing and pressure-reducing valve. A tubular spray device is embedded into a downstream steam pipeline of the pressure-reducing valve; and the opening and closing of a temperature-reducing water self-adjusting valve and spray cooling of the tubular spray device are controlled through outlet steam temperature. With theadoption of the structure, the purpose of spraying steam to cool is achieved.

Owner:HUBEI SANNING CHEM

Technique for preparing bright polyester filament yarn with high extension

InactiveCN101270509ALow boiling water shrinkageNormal intensityMonocomponent polyesters artificial filamentArtifical filament manufactureManufacturing technologyEconomic benefits

The invention relates to a manufacture technology of a high stretching bright polyester filament which is a bright polyester filament product manufactured by adopting a common chip spinning manufacture flow with a micro-injection method to add a special aether additive in a melt through a special technique. The high stretching bright polyester filament manufactured by the method has the qualities of normal intensity, more than 40 percent of crack stretching rate, low boiling water shrinkage factor and few broken filament end cracking; besides, the manufacture operation is more stable. As a common terylene high speed spinning technique line is adopted, the invention has low requirements on the device; the output is high, the additive value of the product is high, the investment cost can be reduced and the economic benefit can be improved.

Owner:JIANGSU HUAYA FIBER

Anti-blocking rotary screen

The invention provides an anti-blocking rotary screen, and relates to the technical field of screening equipment, so as to solve the problem that the comb-type cleaning device of the existing anti-blocking rotary screen is bad in cleaning effect and easy to be damaged. The anti-blocking rotary screen comprises a rotationally installed cylindrical screen drum. A main shaft in parallel with the central axis of the screen drum is arranged inside the screen drum. The main shaft rotates in synchronization with the screen drum. A plurality of smooth shafts for connecting the main shaft with the screen drum is further arranged inside the screen drum. All the smooth shafts are sleeved with vibrating hammers which are able to slide freely. The anti-blocking rotary screen is simple in structure, reasonable in arrangement, convenient in installation, good in blockage cleaning effect, saves the time for cleaning the screen drum manually, avoids the occurrence of unnecessary human body and mechanical damages, and reduces labor intensity. The anti-blocking rotary screen can also screen materials whose water content is more than 15%. The anti-blocking rotary screen shortens the screening time, increases the production efficiency, and the anti-blocking rotary screen is stable in production operations, and can be used for years without maintenance.

Owner:沈阳科翔电力环保设备有限公司

Method for accurate positioning and control of coal stacking and reclaiming

InactiveCN107364729AAvoid mixing accidentsStable production and operationLoading/unloadingEngineeringYard

The invention relates to a method for precise positioning and control of stacking and taking coal. The coal stacking operation is based on incoming coal information and the cargo location of the raw material yard, and a stacking operation plan is compiled. When the plan is executed, the planned cargo location is compared with the actual operation cargo location. When the two do not match, an alarm will be given to the stacking operation to avoid the mixed quality of coal washing caused by misoperation. Coal fetching operation is based on the material information of the bucket chute and the location of the raw material yard, and the material picking operation plan is compiled. When the plan is executed, the actual operation location is compared with the planned location and the location of the hopper for the coal in the bucket chute. The three do not match. When the reclaiming operation is carried out, the alarm will be given, and the reclaiming operation will be stopped to avoid the mixed quality of coal washing caused by misoperation.

Owner:ANGANG STEEL CO LTD

Impedance matching transformer for high-frequency transmission line

InactiveUS20170149407A1Stable production and operationImprove product quality stabilityMultiple-port networksFixed transformers or mutual inductancesElectricityTransformer

An impedance matching transformer for high-frequency transmission line includes a carrier plate, a plurality of conductive posts, a magnetic core and a microstrip inductor. During high frequency transmission, the impedance matching transformer is used as a balanced-to-unbalanced transformation between high-frequency transmission lines. The microstrip inductor includes a plurality of laminated non-conductive substrates, a plurality of conductive tracks laid on the laminated non-conductive substrates respectively. Each of the conductive tracks is electrically connected through vias. Finally, several outlet paths are led out, and then connected to conductively accessing holes.

Owner:PROSPERITY DIELECTRICS

Industrial producing method and device for diluting concentrated nitric acid

This invention relates to a commercial method and equipment for diluting concentrated nitric acid. First, the desalinized water is injected into dilution tank, the concentrated nitric acid pump is started, the acid flows passing through stepwise unit of the tank and enters the tank uniformly. At the same time an external circulation pump and an external cooling apparatus start to work for removing heat released during the mixing. When the temperature of the tank reaches 40deg.C, the controller connected with the thermometer cuts off the acid injection pump, the external circulation pump works continuously. Till the temperature lowers to 30deg.C, the concentrated nitric acid is injected into said tank. When acid in the tank is of the preset volume, the injection pump is cut-off, but external system ifs continued. The nitrogen dioxide produced during dilution is pumped into water absorption tank, then discharged off. This invention has advantages of: stable production, safety, convenient operation and various indexes meet the desigh requirements.

Owner:CHINA GASOLINEEUM ENG

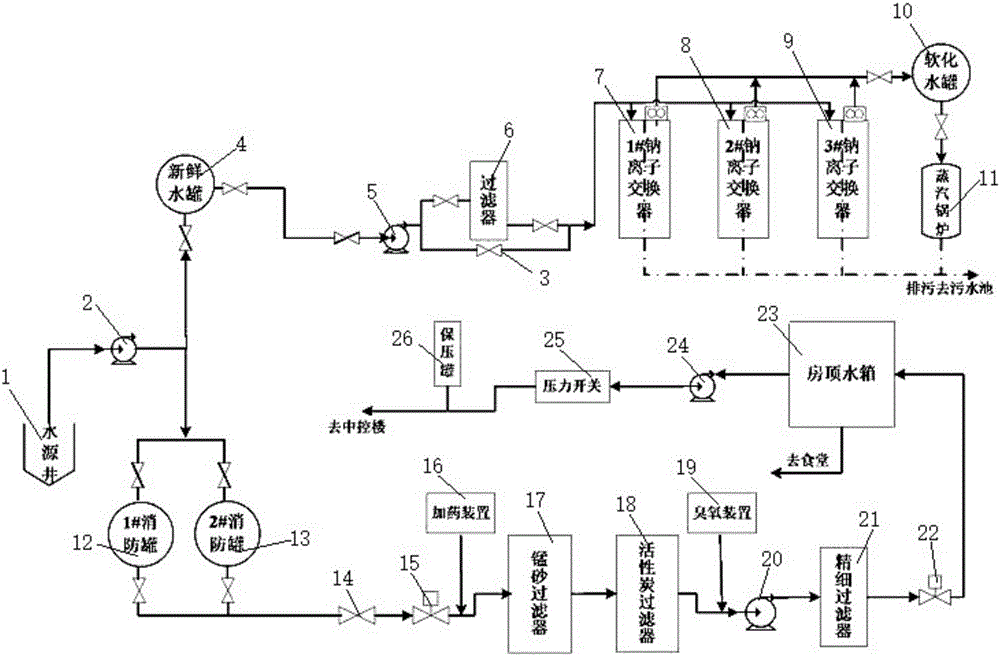

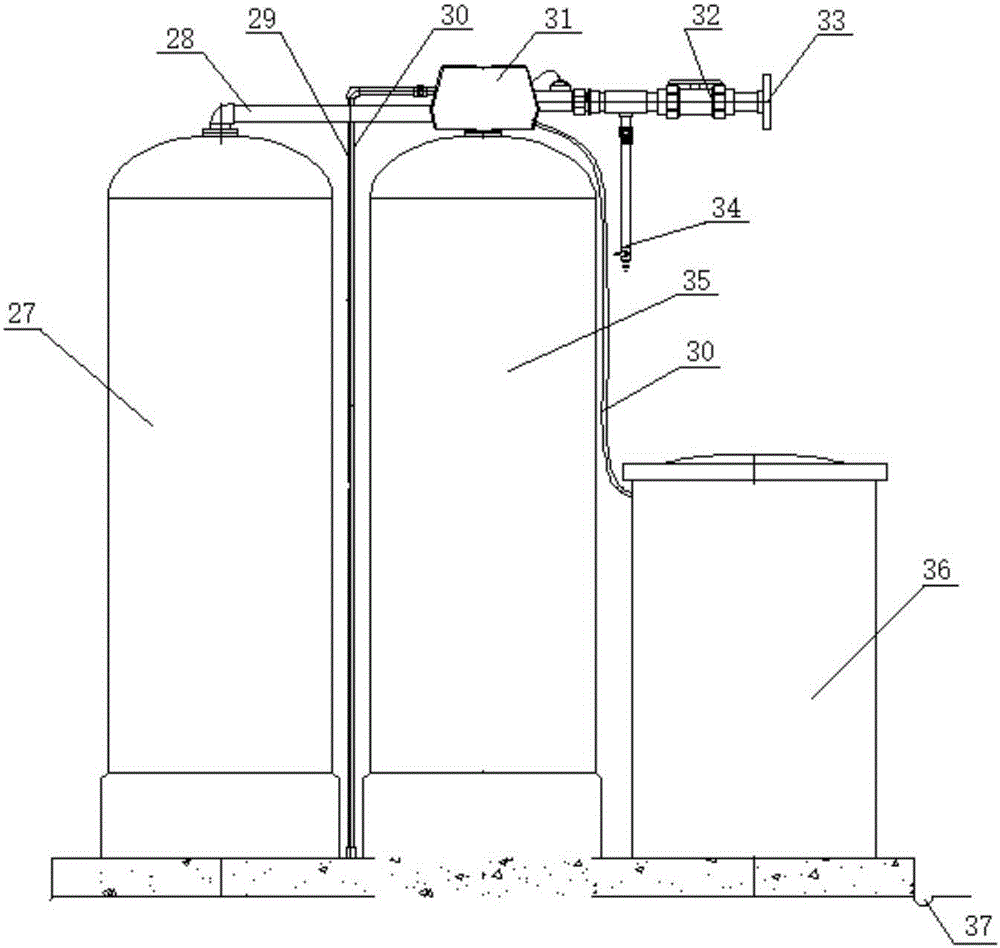

System and method for treating oil and gas field station industrial boiler water and domestic drinking water

InactiveCN106673260AAddress different processing requirementsImprove qualitySpecific water treatment objectivesTreatment involving filtrationFiberWater softening

Owner:PETROCHINA CO LTD

Method and apparatus for producing natural gas through combination of smashed coal pressurized gasification and dry-process entrained-bed gasification

InactiveCN105273785AIncrease gas productionImprove thermal efficiencyGaseous fuelsGas compositionTar

The invention provides a method and apparatus for producing natural gas through combination of smashed coal pressurized gasification and dry-process entrained-bed gasification. Smashed coal pressurized gasification and dry-process entrained-bed gasification technologies are organically combined, low-heat raw gas generated by a smashed-coal gasification furnace is utilized to chill a high-heat coal gas generated by a dry-process entrained-bed gasification furnace, tar, phenols and other substances in raw gas are gasified and are converted into raw-gas compositions. The wastewater processing problem of the smashed-coal pressurized gasification technology is essentially solved, also disposition of residual pulverized coal in the smashed-coal pressurized gasification technology is solved. Under the premise of not increasing the investment, the coal-made natural gas output is improved, wastewater investment and running cost are reduced, and the method is an optimized technological route for coal-made natural gas.

Owner:辽宁大唐国际阜新煤制天然气有限责任公司

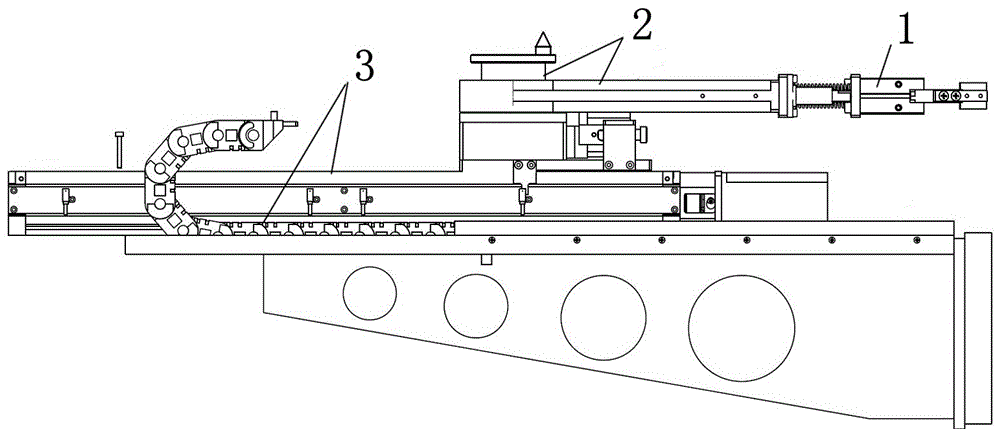

Curing barrel surface dose rate detection device and detection method thereof

ActiveCN106443751AHigh degree of automationReduce manual operationsDosimetersWithdrawing sample devicesProblem of timeDose rate

The invention discloses a curing barrel surface dose rate detection device, and aims at solving the problems of time waste, labor waste and low automatic degree for detecting an existing curing barrel surface dose rate. The device comprises a wiping sampling device and a dose detection device, and is characterized in that the wiping sampling device comprises a flexible grip (1), a rotation mechanism (2) for rotating the flexible grip (1) and a linear moving mechanism (3) for linearly moving the flexible grip (1). The device and method have the advantages of effectively improving the automatic degree during wiping sampling, reducing labor operation and further reducing labor and material sources.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

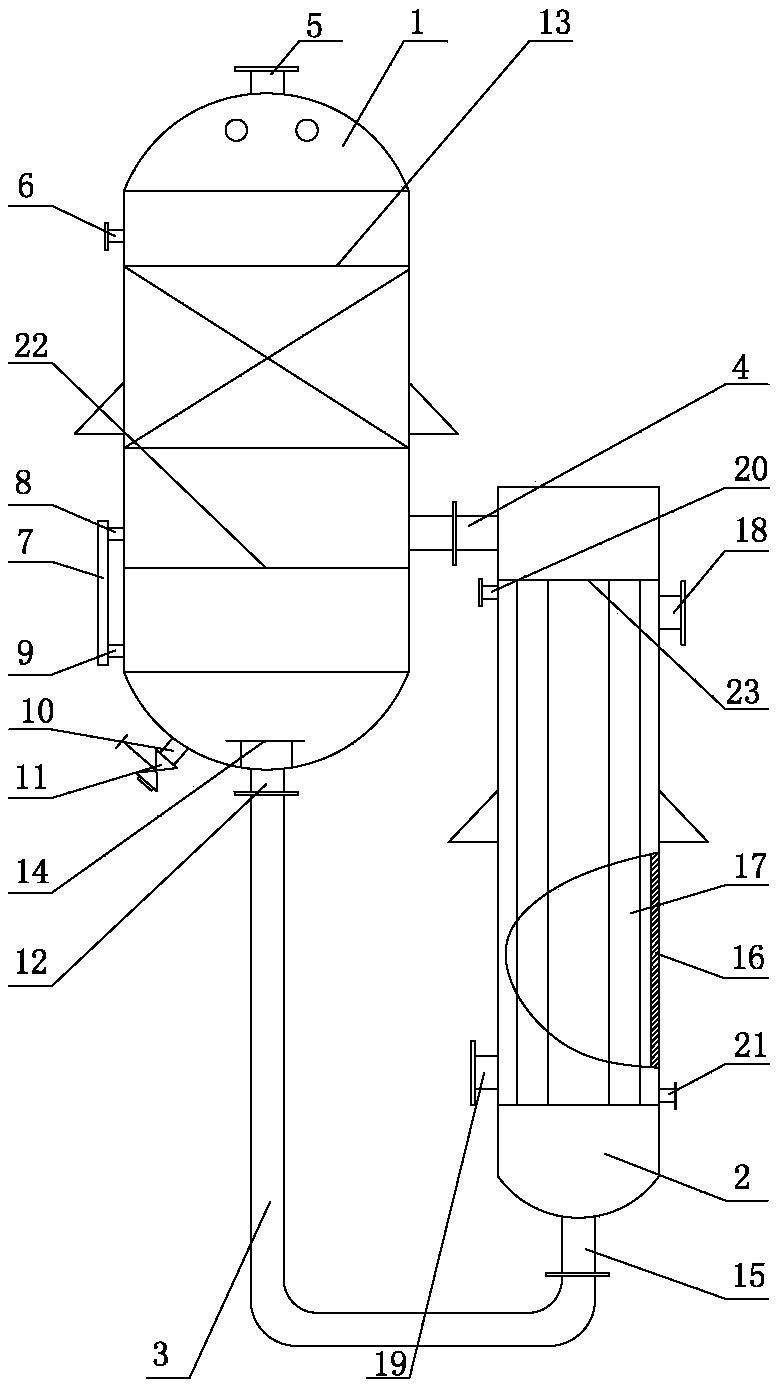

Naphthalene evaporation device used in preparation process of phthalic anhydride

The invention relates to a naphthalene evaporation device used in the preparation process of phthalic anhydride. The naphthalene evaporation device comprises a naphthalene evaporator, the naphthaleneevaporator comprises an upper end enclosure, a cylinder body and a lower end enclosure, the lower part of the cylinder body is connected to the lower part of a naphthalene reboiler through a pipeline,the upper part of the naphthalene reboiler is connected to the middle-upper part of the cylinder body, a heavy component discharge port is formed in the bottom part of the naphthalene reboiler, highpressure steam is introduced into the naphthalene reboiler to indirectly heat the liquid naphthalene; a heavy component discharge port is formed in the bottom part of the lower end enclosure, angle iron is evenly distributed outside the cylinder body, a steam inlet channel encircling the cylinder body is connected to the upper end of the angle iron, a steam outlet channel encircling the cylinder body is connected to the lower end of the angle iron, a closed steam channel is formed among the steam inlet channel, the steam outlet channel, the angle iron and the cylinder body, and a demister is arranged at the upper part of the interior of the cylinder body. The naphthalene reboiler is added to use together with the naphthalene evaporator, the liquid naphthalene is heated, the yielding capacity of the naphthalene is increased, the liquid naphthalene is completely transformed into gas naphthalene, the separation effect is good, and the production and the operation are stable.

Owner:河南庆安化工高科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com