Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Small residual current" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

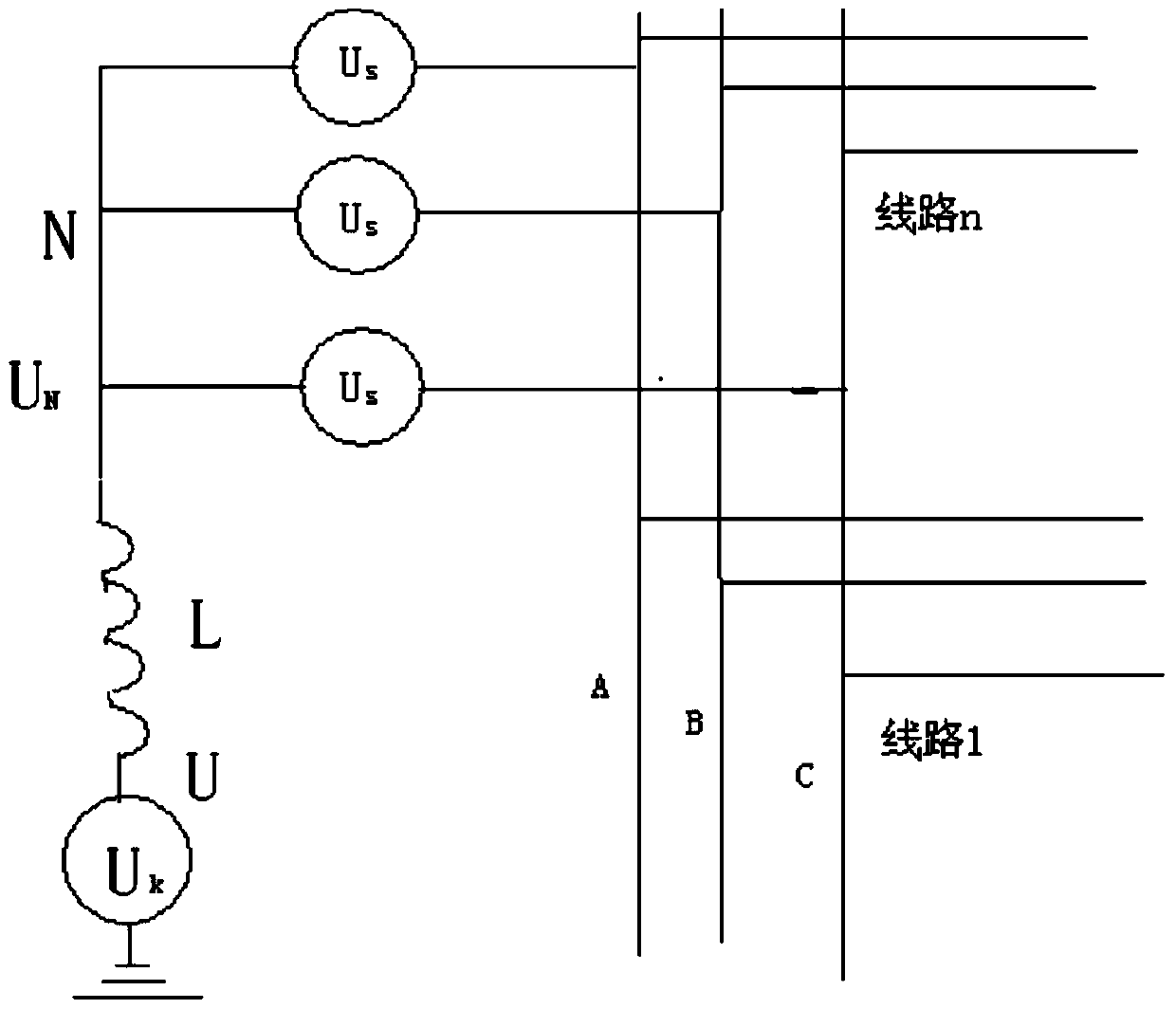

Arc-suppression method of ground fault in neutral non-grounding system and apparatus thereof

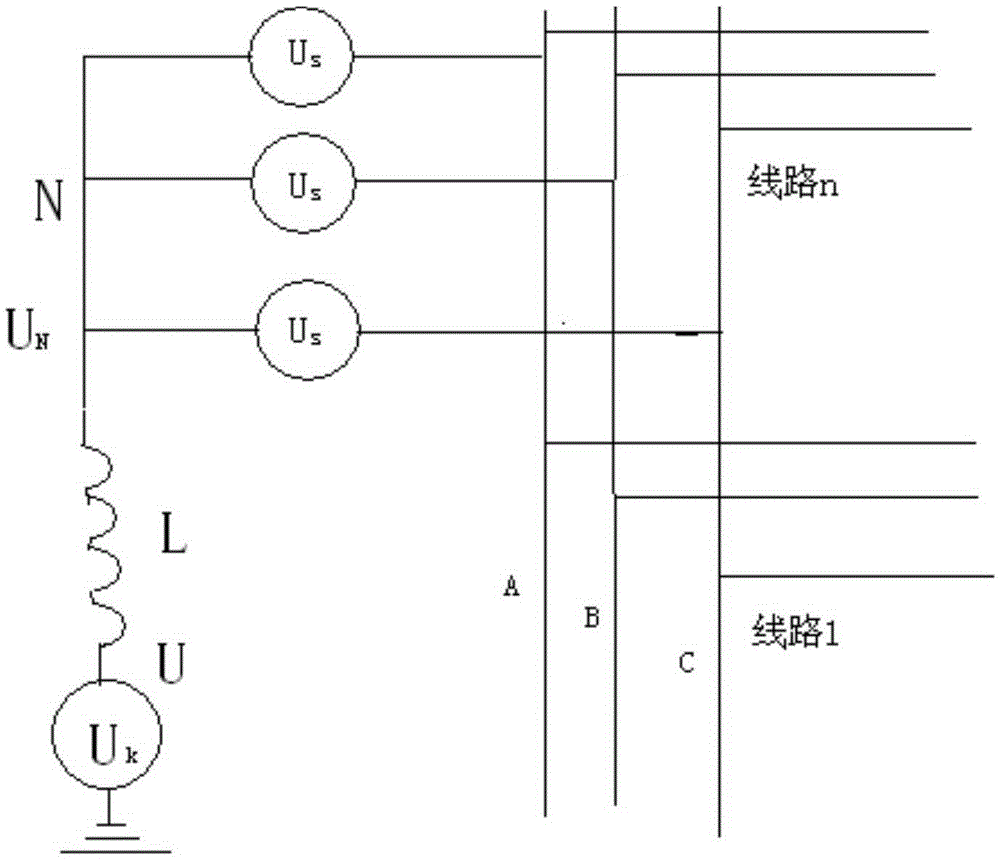

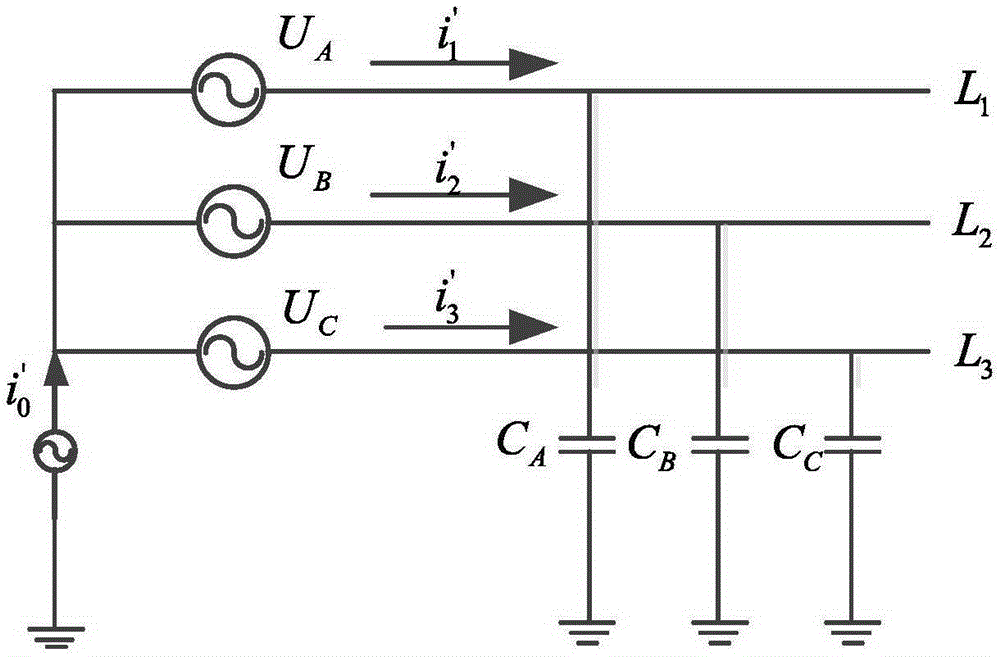

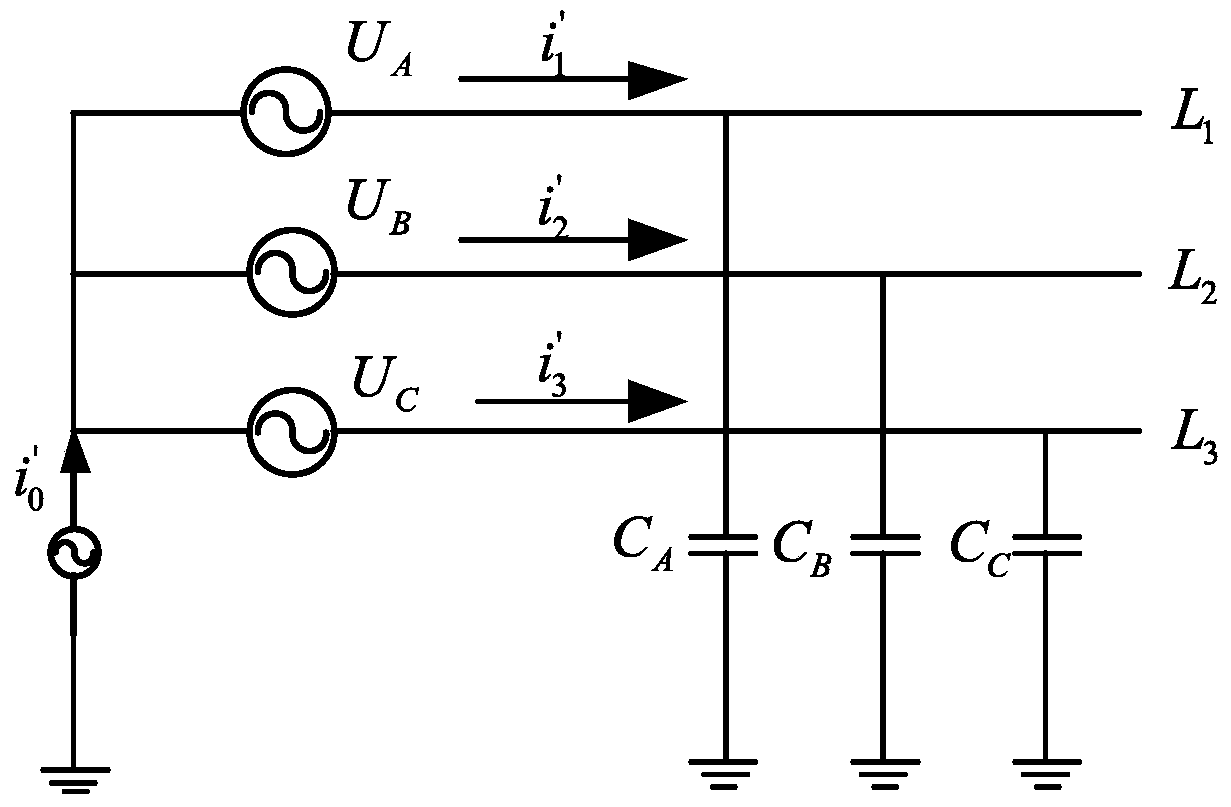

ActiveCN105262076AEasy to run in parallelNovel ideaEmergency protective arrangements for limiting excess voltage/currentNeutral lineOmega

The invention discloses an arc-suppression method of a ground fault in a neutral non-grounding system and an apparatus thereof. A power supply apparatus is connected to a neutral line in the neutral non-grounding system. Through the power supply apparatus, a compensation voltage is output so as to compensate a fault current of the system so that an arc-suppression purpose is reached. An output voltage of the power supply apparatus is defined in the description, wherein omega is a fundamental wave angular frequency; ic, iR and ih are capacitive, resistive and harmonic wave currents respectively; n is a harmonic order; a zero sequence voltage on a neutral point is defined in the description and L is an equivalent inductance of a power supply system. The arc-suppression method of the ground fault in the neutral non-grounding system and the apparatus are easy to carry out and arc suppression can be effectively enforced aiming at a single-phase ground fault.

Owner:STATE GRID CORP OF CHINA +2

Production method and application of nano-platinum doped/enzyme modified carbon paste electrode

InactiveCN105044171AImprove conductivityWide electrochemical windowMaterial electrochemical variablesPlatinumTetrafluoroborate

The invention discloses a production method and an application of a nano-platinum doped / enzyme modified carbon paste electrode. The method is characterized in that a carbon paste electrode is doped with nano-platinum ions, and comprises the following steps: mixing carbon nanotubes with graphite powder with 1-ethyl-3-methylimidazole tetrafluoroborate as an adhesive to prepare a carbon paste electrode, and modifying the carbon paste electrode with methyltransgerase to obtain the nano-platinum doped / enzyme modified carbon paste electrode. Compared with common carbon paste electrodes, the nano-platinum doped / enzyme modified carbon paste electrode has 1-2 times rising conductivity, wide electrochemical window, simple production method, low cost, easy updating of the surface, and small residual current; the electrode can be used to rapidly detect SAM in a sample, so a detection method using the electrode has the advantages of high sensitivity, good selectivity, short response time and less interference, is better than other detection methods, and is a simple, rapid and easy SAM determination method; and an immobilized methyltransgerase electrode sensor made in the invention has the advantages of low cost, simple production process, good specificity and automatic onsite determination realization potential.

Owner:UNIV OF JINAN

Preparation method of nanometer VN/graphene composite paste electrode sensor

InactiveCN108918609AImprove conductivityWide electrochemical windowMaterial nanotechnologyMaterial electrochemical variablesEthyl groupElectrochemical window

The invention discloses a preparation method of a nanometer VN / graphene composite paste electrode sensor. The preparation method comprises following steps: firstly, sulfuric acid is adopted for pre-treatment of oxidized graphene so as to obtain pre-treated oxidized graphene; by mass, 42 to 45% of nanometer VN, 20 to 25% of the pre-treated oxidized graphene, 12 to 18% of N-ethyl-3-methylpyridine hexafluorophosphate, 8 to 12% of liquid paraffin, and 6 to 10% of petroleum ether are introduced into a agate mortar for uniform grinding, an obtained carbon paste is introduced into a glass tube connected with a wire, compressing, drying, polishing with abrasive paper for metallograph, polishing, and deionized water washing are carried out so as to obtain a nanometer VN / graphene composite paste electrode, wherein the internal diameter of the glass tube is 5mm. The electric conductivity of the nanometer VN / graphene composite paste electrode is increased by 2 to 4 times of that of common paste electrode; the electrochemical window is wide; the preparation method is simple; cost is low; surface replacing is convenient; residual current is low; the sensitivity and the selectivity in detection of luteolin are high.

Owner:UNIV OF JINAN

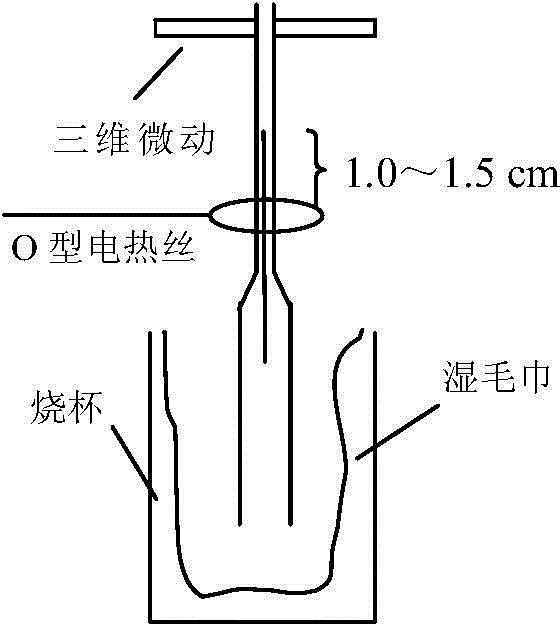

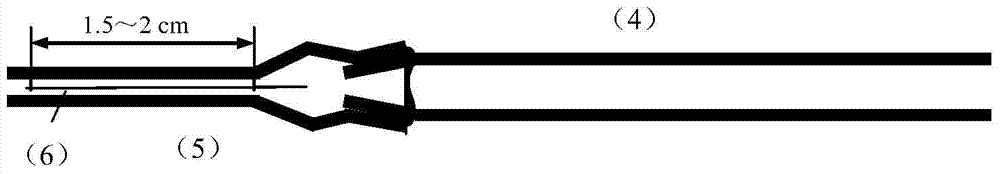

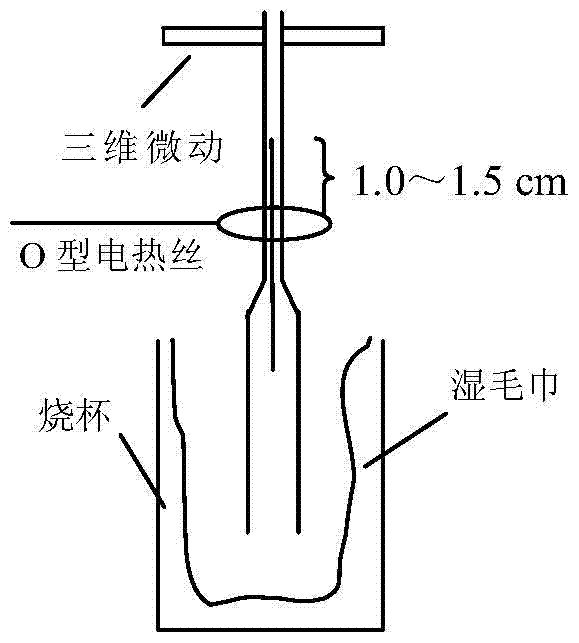

Method for manufacturing nano carbon disk electrode with radius less than 500nm

InactiveCN1789998AOvercome the defect that curing tends to leave small pinholesHigh affinitySemiconductor/solid-state device manufacturingMaterial electrochemical variablesFiberManufacturing technology

The invention discloses a nanometer disc electrode making method of more than 500 nm radius, which comprises the following steps: connecting the micron-size diameter carbon fiber or carbon pipe or carbon rod with the copper wire through the aluminum conductive glue; etching through electrochemical method in the alkali solution; fracturing the detected carbon material on the solution and air boundary part to generate nanometer-size point; depositing the electrophoretic insulation layer on the carbon material surface through direct current stabilized power; solidifying the heat insulating layer until the electrode is complete insulated; drying the insulated electrode in the plastic pipe through sealing glue; sanding and buffing or etching by laser; exposing the point of carbon material; appearing the carbon nanometer disc electrode of 'S' shape limit stabilized volt-ampere curve in the potassium chloride of iron cyanidation chemistry solution.

Owner:YANGZHOU UNIV

PTC thermosensitive resistor based on conducting polymer and application of PTC thermosensitive resistor

InactiveCN106280444AImprove stabilityHigh temperature sensitivityPositive temperature coefficient thermistorsEpoxyTemperature control

The invention discloses a PTC thermosensitive resistor based on a conducting polymer and application of the PTC thermosensitive resistor. The PTC thermosensitive resistor based on the conducting polymer is prepared from polyimide, polyacetylene, phenolic epoxy resin, conductive filler, thermal conducting filler, silicon dioxide, calcium oxide and talcum powder. The PTC thermosensitive resistor based on the conducting polymer has the advantages of being high in temperature sensibility, short in response time, low in residual current and high in stability, has the excellent winding property and fracture resistance, can be widely applied to automatic temperature-control heaters such as a plate-type automatic temperature-control heater, an automatic temperature-control heating band, a tubular automatic temperature-control heater and an automatic temperature-control heating cable which have various shapes and is long in service life.

Owner:ANHUI NINGGUO TIANCHENG ELECTRICAL APPLIANCES

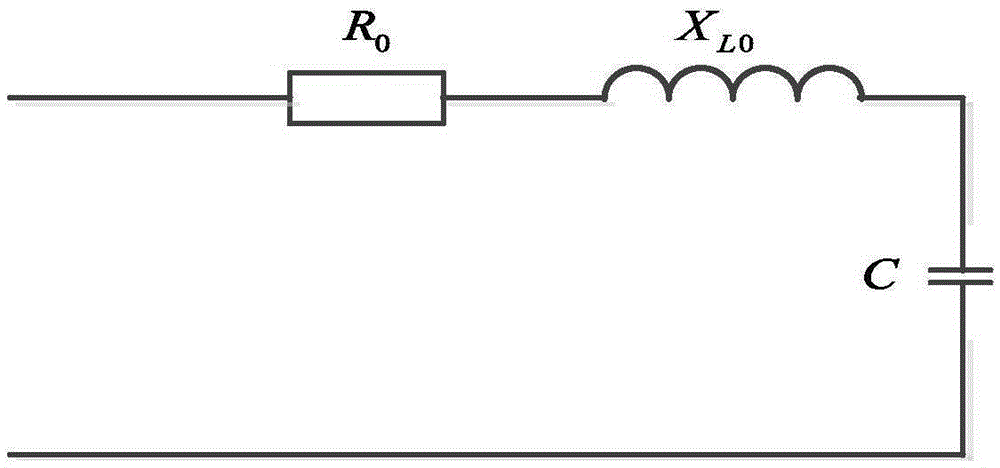

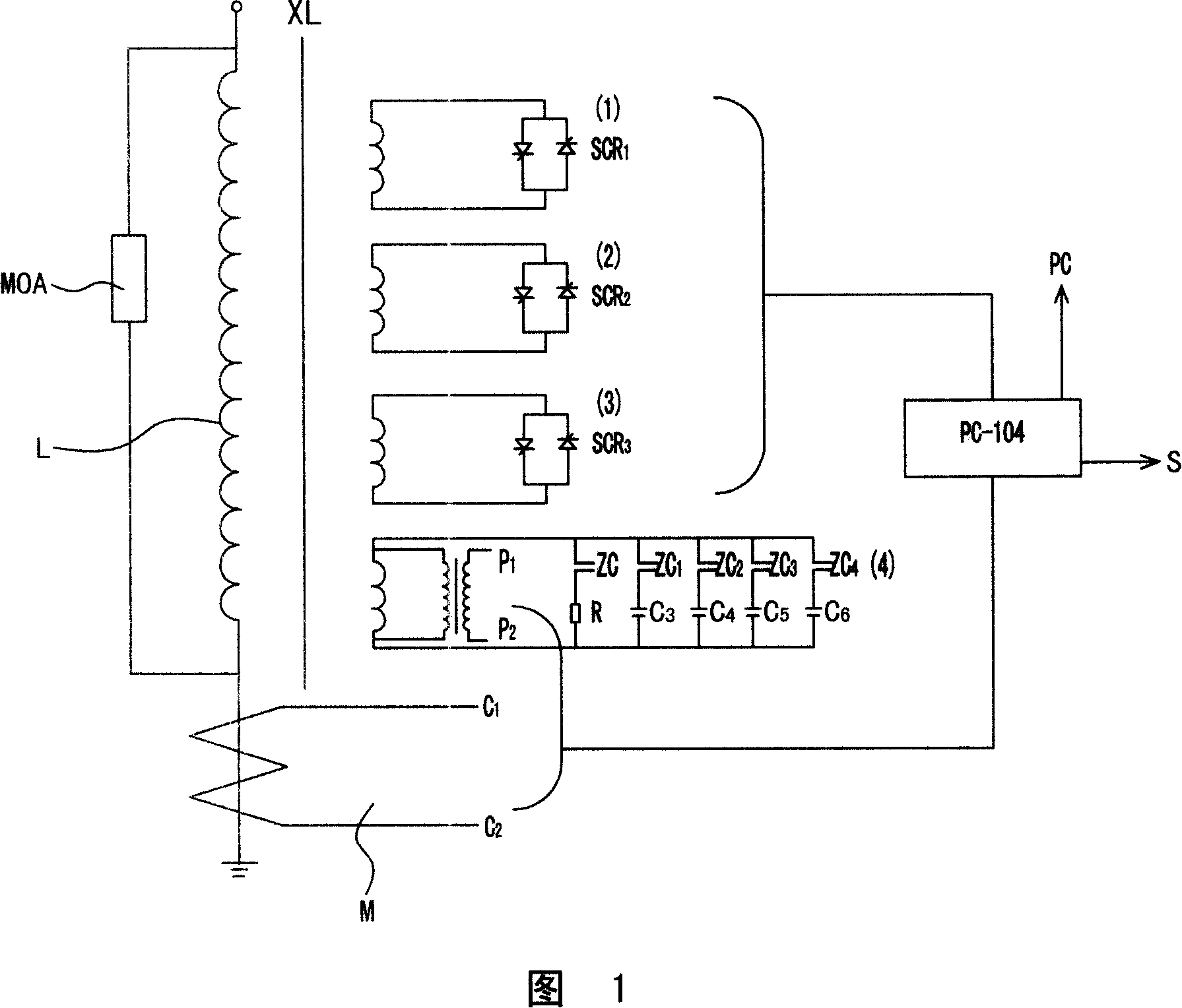

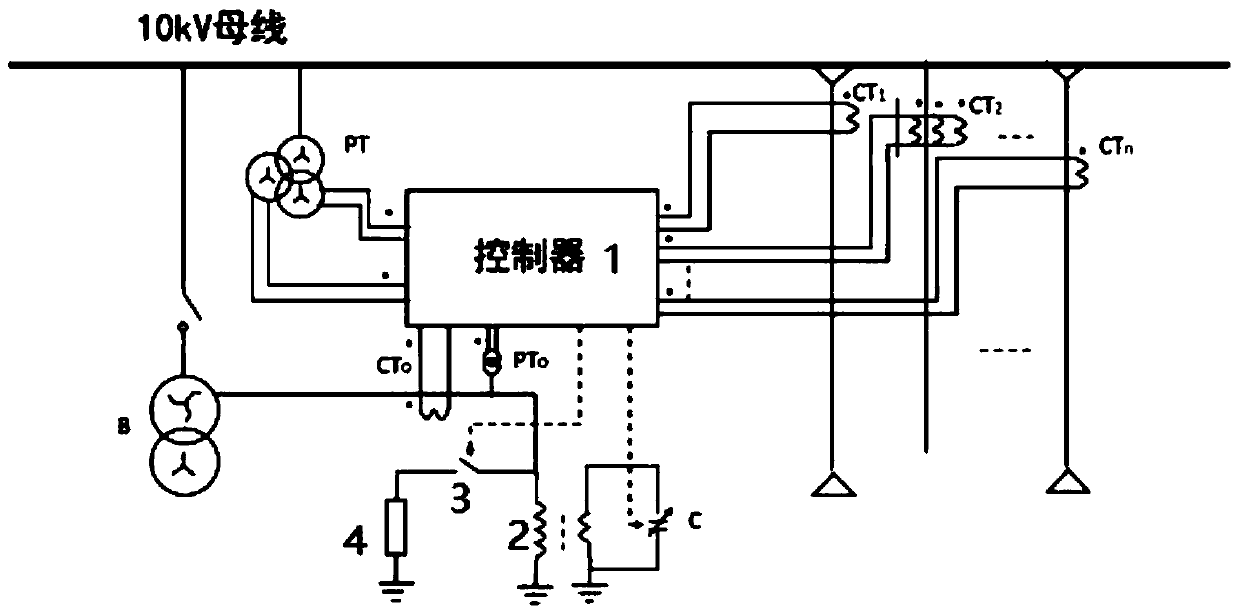

Inductance regulation type self-tuning arc-extinguishing pressure-limiting device

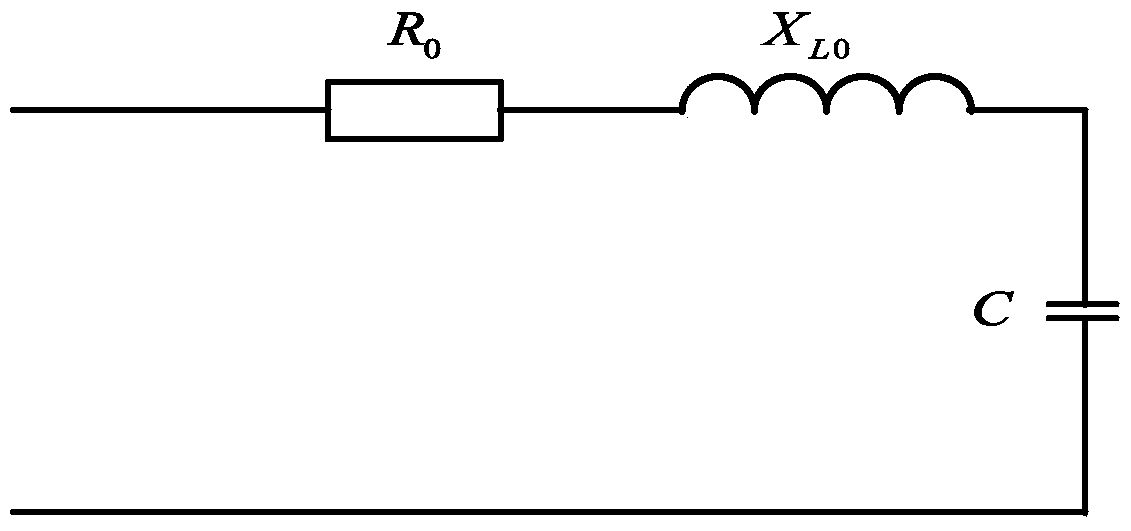

InactiveCN101132131AFast adjustmentEasy to adjustTransformers/inductances coils/windings/connectionsTransformers/inductances circuitsElectric power systemEngineering

This invention relates to an induction-adjustment type automatic tuning, arc-suppression voltage-limiting device, being of a transformer direct connecting neutral point of electric power system. It has earthing type primary coil and two or more than two groups of high impedance secondary coil (with fine turing and coarse tuning); computer signal sources are in the current mutual inductor and voltage mutual inductor of said primary coil; the computer controls the switching of the fine tuning and coarse tuning. In this invention, single-phase transformer is used to realize precompensation and follow-up compensation during the production of capacitive current at primary earthing condition; the embodiment is that: PC-104 computer calculates the capacitive current of the system, and then controls the fine tuning and coarse tuning, proceeds compensation of the capacitive current.

Owner:ZHEJIANG GUANGTIAN TRANSFORMER

Preparation method of hyaluronidase modified vanadium nitride paste electrode sensor

InactiveCN108414600ASelectivityImprove conductivityMaterial electrochemical variablesSilanesPolyvinyl alcohol

The invention discloses a preparation method of a hyaluronidase modified vanadium nitride paste electrode sensor. The preparation method is characterized by comprising the following steps: preparing anano VN / graphene composite paste electrode from nano VN, graphene oxide, N-ethyl-3-methylpyridine hexafluorophosphate; then, modifying the nano VN / graphene composite paste electrode with gamma-glycidyl ether oxopropyl trimethoxy silane to obtain a gamma-glycidyl ether oxopropyl trimethoxy silane modified nano VN / graphene composite paste electrode; preparing hyaluronidase stationary liquid from deionized water, bovine serum albumin, hyaluronidase and polyvinyl alcohol; finally, dropwise applying the hyaluronidase stationary liquid to the gamma-glycidyl ether oxopropyl trimethoxy silane modified nano VN / graphene composite paste electrode, and drying to obtain the hyaluronidase modified vanadium nitride paste electrode sensor. With higher electrical conductivity than a common carbon paste electrode, the electrode sensor is specific to hyaluronic acid and has high sensitivity.

Owner:UNIV OF JINAN

Preparation method of quantum dot/enzyme compounded carbon paste electrode for detecting SAM (S-Adenosylmethionine)

InactiveCN104965014AImprove conductivityEasy to prepareMaterial electrochemical variablesAdhesiveCarbon nanotube

The invention discloses a preparation method of a quantum dot / enzyme compounded carbon paste electrode for detecting SAM (S-Adenosylmethionine). The preparation method is characterized by comprising the following steps of doping water-soluble CdZnTe quantum dots and transmethylase in a carbon paste electrode; by taking 1-ethyl-3--methylimidazolium hexafluorophosphate as an adhesive, mixing a carbon nano-tube with graphite powder to prepare the carbon electrode, so as to obtain the quantum dot / enzyme compounded carbon paste electrode; compared with an ordinary carbon paste electrode, the quantum dot / enzyme compounded carbon paste electrode has the advantages of conducting property improved by 1 to 2 times, wide electrochemical window, simple preparation method, low cost, easy update for surface, low residual current and the like; the eelctrode can be used for quickly detecting the SAM in a sample; the method has the characteristics of high sensitivity, good selectivity, short response time and low interference, is superior to other detection methods, and is a determination method with simpleness, quickness, convenience and feasibility for the SAM. A fixed methyltransferase electrode sensor prepared by the preparation method disclosed by the invention is low in cost, simple in preparation process and good in specificity, and has the possibility of realizing automated field determination.

Owner:UNIV OF JINAN

Preparation of nano-TiC/graphene composite paste electrode sensor

InactiveCN108663421AImprove conductivityEasy to prepareMaterial electrochemical variablesTetrafluoroborateCarbon paste electrode

The invention discloses a preparation method of a nano-TiC / graphene composite paste electrode sensor. The preparation method of the nano-TiC / graphene composite paste electrode sensor is characterizedby comprising the following steps: treating graphene by using concentrated sulfuric acid and ammonium persulfate to obtain pretreated graphene; then adding 42 to 46% of nano-TiC, 21 to 25% of pretreated graphene, 20 to 25% of N-ethyl-3-methylpyridine tetrafluoroborate and 8 to 12% of silicone oil respectively in an agate mortar, and uniformly grinding to obtain a mixture of carbon paste; placing the carbon paste of the mixture in a glass tube connected with a wire and of which the inner diameter is Phi 5mm, performing compaction, drying, sanding with metallographic sandpaper, polishing, and washing with deionized water, thereby obtaining the nano-TiC / graphene composite paste electrode sensor. The carbon paste electrode prepared by the application has the advantages of having 4 to 5 times higher conductivity than that of the ordinary carbon paste electrode, wide electrochemical window, simple preparation method, low cost, easy surface renewal, small residual current and the like, and isfurther high in detection sensitivity of cefoxitin and good in selectivity.

Owner:UNIV OF JINAN

Preparation method of titanium nitride/carbon nano tube composite paste electrode sensor

InactiveCN110441363AImprove conductivityWide electrochemical windowMaterial electrochemical variablesAdhesiveTitanium nitride

The invention discloses a preparation method of a titanium nitride / carbon nano tube composite paste electrode sensor. The preparation method is characterized by comprising the steps of: processing a carbon nano tube by using sulphuric acid and periodate potassium, so that a pre-processed carbon nano tube is obtained; preparing a composite adhesive by adopting 1-butyl-1-methyl pyrrole trifluoromethylsulfonate and cellulose; and then, adding the following components into an agate mortar in percentage by weight: 36-42% of nano titanium nitride, 28-32% of the pre-processed carbon nano tube, 12-16%of the composite adhesive, and 15-18% of liquid paraffin, uniformly grinding to form a carbon paste, putting the carbon paste into a glass tube, wherein the glass tube is connected to a conducting wire; the inside diameter of the glass tube is phi5 mm; and thus, the titanium nitride / carbon nano tube composite paste electrode sensor is prepared. Compared with the ordinary carbon paste electrode, the electrical conductivity of the carbon paste electrode prepared in the invention is increased by 6-8 times; the carbon paste electrode prepared in the invention has the advantages of being wide in electrochemical window, simple in preparation method, low in cost, easy to update the surface, low in residual current, high in paracetamol detection sensivity, good in selectivity and the like.

Owner:UNIV OF JINAN

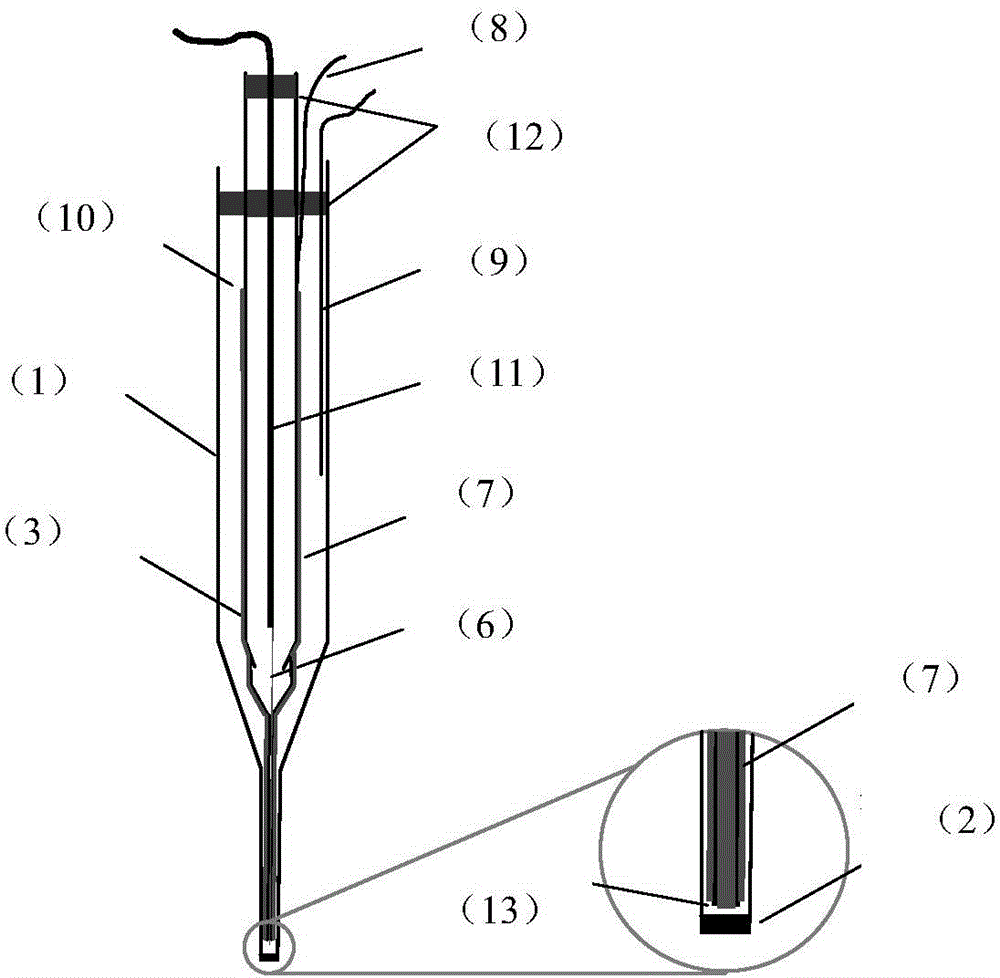

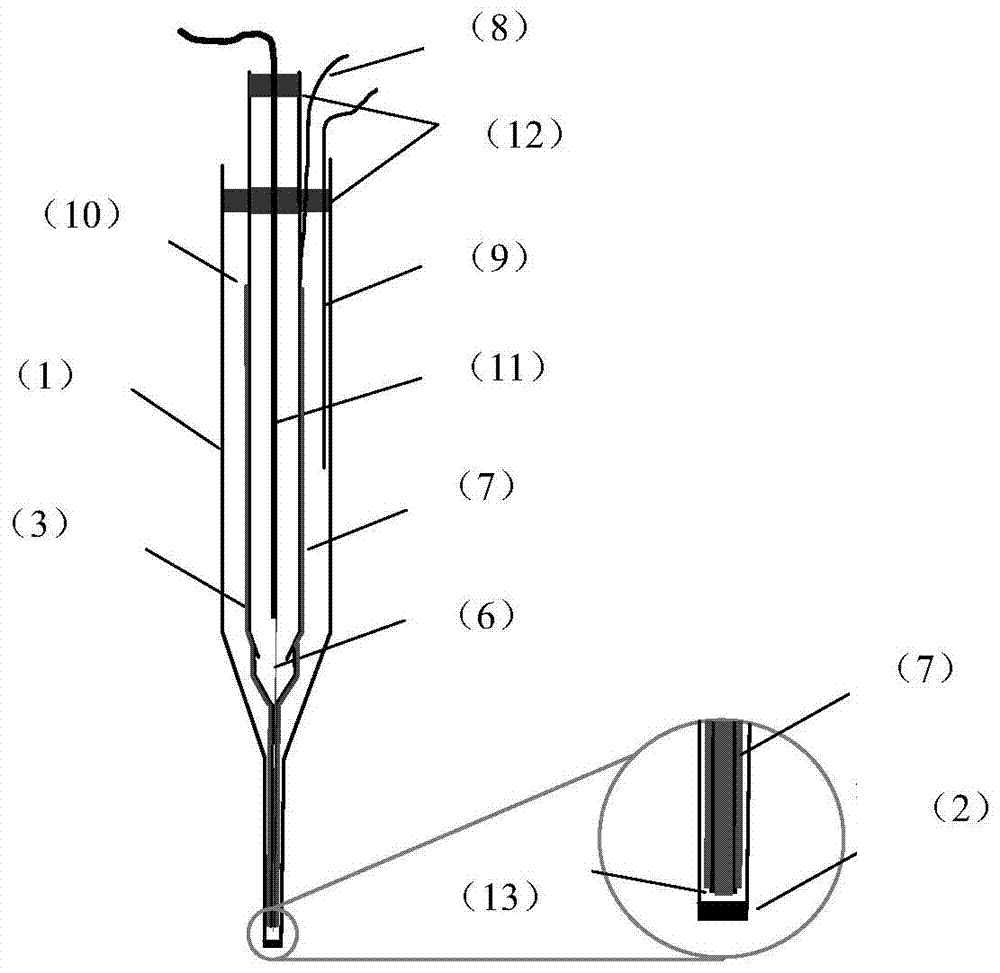

Coaxial compound oxygen microelectrode and preparation method thereof

ActiveCN104865301AEasy to manufactureIncreased drawing efficiencyMaterial electrochemical variablesCathode

The invention discloses a coaxial compound oxygen microelectrode and a preparation method thereof. The oxygen microelectrode includes an external casing, a working cathode column located at the central part, and a reference electrode located between the external casing and the working cathode column, the central part of the working cathode column is provided with a platinum wire, an electrolyte solution is filled between the external casing and the working cathode column, the outer wall of the working cathode column or the inner wall of the external casing is plated with a layer of silver layer, and the upper end surface of the silver layer is welded with a conductive metal wire to form a protection cathode. The electrode making process is simple, and high in control success rate, the results show that the protection cathode switches on to reduce residual current of the coaxial compound oxygen microelectrode by about 80%, dissolved oxygen response linear dependence R2 is more than 0.99, and the dissolved oxygen resolution is about 0.03 mg O2 / L.

Owner:TSINGHUA UNIV

Neutral point grounding mode switching device and method

InactiveCN110247382ASmall residual currentMonitor Capacitor CurrentEmergency protective circuit arrangementsCapacitancePower grid

The embodiment of the application discloses a neutral point grounding mode switching device and method. When a distribution network is in normal operation, a controller turns off a control switch of a grounding resistor, simultaneously monitors the grid capacitance current, and determines the combination state of an adjustable capacitor bank of an arc suppression coil. When a single-phase ground fault occurs in the distribution network, the controller adjusts the arc suppression coil to an over-compensation state according to the combination state of the adjustable capacitor bank, and gives full scope to the effect that the low residual current of a fault point slows down the recovery voltage rise speed of the fault phase under an arc suppression coil grounding mode so that the transient fault automatically disappears. When the duration of the single-phase ground fault occurring in the distribution network is greater than a preset duration, the control switch is turned on in order that the neutral point is grounded through the arc suppression coil and is grounded through the grounding resistor.

Owner:云南电力技术有限责任公司 +1

Production method of molecularly imprinted composite paste electrode sensor for detecting ribavirin

ActiveCN112362705AImprove conductivityWide electrochemical windowMaterial electrochemical variablesStrontium titanateFunctional monomer

The invention relates to a production method of a molecularly imprinted composite paste electrode sensor for detecting ribavirin. The production method comprises the following steps: producing a nanodysprosium nitride / nano strontium titanate / graphene oxide composite paste electrode; preparing a ribavirin molecularly imprinted polymer: in an oxygen-free atmosphere, taking aconitic acid as a functional monomer, taking methylene bisacrylamide as a cross-linking agent, taking azobisisoheptonitrile as an initiator and taking ribavirin as a template to carry out a cross-linking polymerization reaction to prepare the ribavirin molecularly imprinted polymer; and producing a composite paste electrode sensor: dropwise adding a ribavirin molecularly imprinted polymer modification liquid into the nano dysprosium nitride / nano strontium titanate / graphene oxide composite paste electrode by adopting a dispensing method, volatilizing a solvent, and removing template molecules to obtain the composite paste electrode sensor. According to the method, a molecular imprinting technology, a layer-by-layer self-assembly method and a dispensing method are combined, and the produced molecular imprinting composite paste electrode sensor is good in response performance, good in selectivity and high in sensitivity.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Fabrication method of bismuth-doped nanometer SiC/carbon nanotube paste electrode sensor

InactiveCN110297021AImprove conductivityWide electrochemical windowMaterial electrochemical variablesCelluloseViscous liquid

The invention discloses a fabrication method of a bismuth-doped nanometer SiC / carbon nanotube paste electrode sensor. The fabrication method is characterized by comprising the steps of dissolving bismuth citrate and cellulose by employing 1-butyl-3-methylimidazole chlorine salt to prepare faint yellow viscous liquid being a bismuth-doped carbon quantum dot-containing adhesive; uniformly grinding 45-48wt% of nanometer SiC, 25-28wt% of carbon oxide nanotube, 10-14wt% of bismuth-doped carbon quantum dot-containing adhesive, 4-6wt% of polyethylene glycol and 8-12wt% of ethyl alcohol in an agate mortar, thereby obtaining nanometer SiC / carbon nanotube / bismuth-doped carbon quantum dot mixture carbon paste; and loading the mixture carbon paste in a glass tube connected with a wire having inner radius being 5 millimeters, thereby obtaining the bismuth-doped nanometer SiC / carbon nanotube paste electrode sensor. Conductivity of the electrode fabricated by the method is improved by 4-6 times compared with a conventional carbon paste electrode, the electrode has the advantages of wide electrochemical window, simple fabrication method, small residual current, high detection sensitivity and goodselectivity and the like, and a surface is easy to update.

Owner:UNIV OF JINAN

Method for preparing nano TiB2/carbon nano tube composite paste electrode sensor

InactiveCN108490050AImprove conductivityEasy to prepareMaterial electrochemical variablesTetrafluoroboratePower flow

The invention discloses a method for preparing a nano TiB2 / carbon nano tube composite paste electrode sensor. The method is characterized by comprising the following steps: pre-treating carbon nano tubes with concentrated sulfuric acid and ammonium persulfate to obtain pretreated carbon nano tubes; respectively 38-42% of nano TiB2, 23-26% of pretreated carbon nano tubes, 25-30% of 1-allyl-3-methylimidazolium tetrafluoroborate and 6-10% of glycerin into an agate mortar, and uniformly grinding to obtain the mixture carbon paste; and filling the carbon paste into a glass tube which is connected with a wire and has an inner diameter of Phi 5 mm, compacting, drying, polishing by abrasive paper for metallograph, polishing, and washing with deionized water, thereby obtaining the nano TiB2 / carbonnano tube composite paste electrode. Compared with that of an ordinary carbon paste electrode, the conductivity of the carbon paste electrode prepared in the invention is improved by 4-5 times, and the carbon paste electrode has the advantages of being wide in electrochemical window, simple in preparation method, low in cost, easy for surface renewal, low in residual current and the like. The cefixime detection sensitivity is high, and the selectivity is excellent.

Owner:UNIV OF JINAN

Preparation method of sulfoaminobiotin modified indium nitride paste electrode sensor

ActiveCN111551619ASelectivityImprove conductivityNanosensorsBiological testingCarbon paste electrodePhysical chemistry

The invention discloses a preparation method of a sulfoaminobiotin modified indium nitride paste electrode sensor, and the method is characterized in that the method comprises the steps: preparing a indium nitride paste electrode sensor from nano indium nitride, graphene oxide, 1-aminopropyl-3-methylimidazolium bromide, mineral oil and pentanol; modifying the indium nitride paste electrode by adopting triethylenetetramine and carbon quantum dots to prepare a triethylenetetramine / quantum dot modified indium nitride paste electrode; adding 92-96% of phosphate buffer solution and 4-8% of sulfoaminobiotin into a reactor, performing dissolving, putting the triethylenetetramine / quantum dot modified indium nitride paste electrode into the solution, performing stirring and soaking for 2 hours at room temperature, taking out the electrode, and performing washing and drying to obtain the sulfoaminobiotin modified indium nitride paste electrode sensor. Compared with a common carbon paste electrode, the electrode sensor is higher in conductivity, has specific recognition performance on protein and is high in sensitivity.

Owner:UNIV OF JINAN

A preparation method of uricase-modified titanium diboride composite paste electrode sensor

InactiveCN108896362BSelectivityImprove conductivityPreparing sample for investigationMaterial electrochemical variablesTetrafluoroborateCarbon nanotube

Owner:山东政和产业大数据技术研究院

Preparation method of uricase-modified titanium diboride composite paste electrode sensor

InactiveCN108896362ASelectivityImprove conductivityPreparing sample for investigationMaterial electrochemical variablesTetrafluoroborateCarbon nanotube

The invention discloses a preparation method of a uricase-modified titanium diboride composite paste electrode sensor. The preparation method is characterized by comprising the following steps: firstly preparing a nano-TiB2 / carbon nanotube composite paste electrode from nano-TiB2, oxidized carbon nanotubes and 1-propenyl-3-methylimidazolium tetrafluoroborate; carrying out surface modification on the nano-TiB2 / carbon nanotube composite paste electrode by virtue of 3-chloropropyltrimethoxysilane, so as to obtain a 3-chloropropyltrimethoxysilane-modified nano-TiB2 / carbon nanotube composite pasteelectrode; and modifying the 3-chloropropyltrimethoxysilane-modified nano-TiB2 / carbon nanotube composite paste electrode by virtue of uricase stationary liquid prepared from a Tris buffer solution, gelatin and bovine serum albumin, so as to obtain the uricase-modified titanium diboride composite paste electrode sensor, wherein the pH value of the Tris buffer solution is 8.5. The electrode sensor prepared by virtue of the preparation method has higher conductivity than a common carbon paste electrode, has specific recognition ability to uric acid and is high in sensitivity.

Owner:山东政和产业大数据技术研究院

Preparation method of biomarker modified semiconductor paste electrode sensor

InactiveCN111551620ASelectivityImprove conductivityNanosensorsMaterial electrochemical variablesGallium arsenateConductive materials

The invention discloses a preparation method of a biomarker modified semiconductor paste electrode sensor, and the method is characterized in that the method comprises the steps: preparing a gallium arsenide paste electrode sensor by using nano gallium arsenide, graphene oxide and carbon quantum dots as conductive materials and using 1-aminoethyl-3-methylimidazole to modify a nitrate adhesive; modifying a gallium arsenide paste electrode by adopting gamma-aminopropyl methyl diethoxysilane as a coupling agent; in a reactor, adding the following components by the mass percentage concentration: 90-94%of buffer solution, the preparation method comprises the following steps: dissolving 6-10% of Sulfo-NHS-SS-Biotin, putting a gamma-aminopropylmethyldiethoxysilane modified gallium arsenide pasteelectrode into a solution, performing stirring and reacting at room temperature for 6 hours, taking out the electrode, washing with a phosphate buffer solution and absolute ethyl alcohol respectively,and drying to obtain the biomarker modified semiconductor paste electrode sensor. The electrode sensor has higher conductivity than a common carbon paste electrode, has specific recognition on aminoacid, and is high in sensitivity.

Owner:UNIV OF JINAN

Arc suppression method and device for ground fault in neutral point ungrounded system

ActiveCN105262076BEasy to run in parallelNovel ideaEmergency protective arrangements for limiting excess voltage/currentNeutral lineControl theory

The invention discloses an arc-suppression method of a ground fault in a neutral non-grounding system and an apparatus thereof. A power supply apparatus is connected to a neutral line in the neutral non-grounding system. Through the power supply apparatus, a compensation voltage is output so as to compensate a fault current of the system so that an arc-suppression purpose is reached. An output voltage of the power supply apparatus is defined in the description, wherein omega is a fundamental wave angular frequency; ic, iR and ih are capacitive, resistive and harmonic wave currents respectively; n is a harmonic order; a zero sequence voltage on a neutral point is defined in the description and L is an equivalent inductance of a power supply system. The arc-suppression method of the ground fault in the neutral non-grounding system and the apparatus are easy to carry out and arc suppression can be effectively enforced aiming at a single-phase ground fault.

Owner:STATE GRID CORP OF CHINA +2

Preparation method of quantum dot/enzyme composite carbon paste electrode for detection of SAM

InactiveCN104965014BImprove conductivityEasy to prepareMaterial electrochemical variablesAdhesiveCarbon nanotube

The invention discloses a method for preparing a quantum dot / enzyme composite carbon paste electrode for detecting SAM, which is characterized in that: carbon paste electrodes are doped with water-soluble CdZnTe quantum dots and methyltransferase, and 1-ethyl ‑3‑Methylimidazole hexafluorophosphate is used as an adhesive to prepare a carbon paste electrode by mixing carbon nanotubes and graphite powder, which is a quantum dot / enzyme composite carbon paste electrode. Compared with ordinary carbon paste electrodes, the conductivity is improved by 1~2 times, and the electrochemical window is wide, the preparation method is simple, the cost is low, the surface is easy to renew, and the residual current is small; the electrode is used to quickly detect SAM in the sample, and the method has high sensitivity. Good selectivity, short response time, less interference, superior to other detection methods, is a simple, fast, convenient and easy SAM determination method, the fixed methyltransferase electrode sensor prepared by the application has low cost, simple preparation process, specific It has good performance and has the possibility of realizing automatic on-site determination.

Owner:UNIV OF JINAN

PTC (Positive Temperature Coefficient) ceramic thermistor

InactiveCN102354591AHigh pressureSmall residual currentPositive temperature coefficient thermistorsManganese oxideComposite material

The invention relates to a PTC ceramic thermistor, which is produced with barium carbonate as base material, the purity of the barium carbonate is 99.5 to 99.99 percent, the granularity of the barium carbonate is 0.1 to 2 microns, and the percentages of materials by weight are as follows: 57.53 percent of electron-level barium carbonate; 11.83 percent of electron-level strontium carbonate; 0.4321 percent of electron-level yttrium oxide; 0.4013 percent of electron-level silicon oxide; 30.41 percent of electron-level titanium oxide; and 0.417 percent of electron-level manganese oxide. The PTC ceramic thermistor has the characteristics of high voltage withstanding, low aftercurrent, low power, high reliability, long service life and the like, and is safe to use.

Owner:DONGGUAN YUCHI ELECTRONICS

A kind of preparation method of sulfabiotin modified indium nitride paste electrode sensor

ActiveCN111551619BSelectivityImprove conductivityNanosensorsBiological testingCarbon paste electrodeAmyl alcohol

The invention discloses a preparation method of a sulfonamide-biotin modified indium nitride paste electrode sensor, which is characterized in that nano-indium nitride, graphene oxide, 1-aminopropyl-3-methylimidazolium bromide, mineral oil and amyl alcohol to prepare indium nitride paste electrode sensor; using triethylenetetramine and carbon quantum dots to modify indium nitride paste electrode, to prepare triethylenetetramine / quantum dot modified indium nitride paste electrode; then, In the reactor, add, phosphate buffer solution: 92~96%, sulfabiotin: 4~8%, dissolve, put triethylenetetramine / quantum dot modified indium nitride paste electrode into the solution, room temperature Stir and soak for 2 hours, take out the electrode, wash, and dry to obtain the sulfonamide-biotin-modified indium nitride paste electrode sensor. The electrode sensor has higher electrical conductivity than ordinary carbon paste electrodes, has specific recognition for proteins, and has high sensitivity.

Owner:UNIV OF JINAN

Preparation method and application of a nano-platinum doped/enzyme-modified carbon paste electrode

InactiveCN105044171BImprove conductivityWide electrochemical windowMaterial electrochemical variablesTetrafluoroborateAdhesive

Owner:UNIV OF JINAN

Preparation of a superoxide dismutase modified vanadium nitride paste electrode sensor

InactiveCN108896636BImprove conductivityWide electrochemical windowMaterial electrochemical variablesBovine serum albuminElectrochemical window

Owner:UNIV OF JINAN

A kind of preparation method of calcium-doped silicon nitride graphene paste electrode sensor

ActiveCN110297020BImprove conductivityEasy to prepareMaterial electrochemical variablesViscous liquidMeth-

The invention discloses a preparation method of a calcium-doped silicon nitride graphene paste electrode sensor, which is characterized in that, firstly, 1-butyl-3-methylimidazole p-toluenesulfonate is used to dissolve calcium gluconate and absorbent cotton to prepare The light yellow viscous liquid obtained is calcium-doped carbon-containing quantum dot adhesive; in an agate mortar, gold-modified silicon nitride: 34-38%, graphene oxide: 28-32%, calcium-doped carbon-containing Quantum dot adhesive: 10~14%, ammonium polyacrylate: 3~5%, ethanol: 14~20%, grind evenly, put it into a glass tube with an inner diameter of Φ5mm connected with a wire, and then get calcium doped nitriding Silicon graphene paste electrode sensor. The electrode prepared by this application has the advantages of 4-6 times higher conductivity than ordinary carbon paste electrodes, wide electrochemical window, simple preparation method, easy surface renewal, and small residual current. High detection sensitivity and good selectivity.

Owner:UNIV OF JINAN

Fast-response thermistor and application thereof

InactiveCN106280365AShort action timeSmall residual currentPositive temperature coefficient thermistorsThermistorCorrosion

The invention discloses a fast-response thermistor and application thereof and relates to the technical field of PTC thermistors and application thereof. The fast-response thermistor is composed of polysiloxane, polycarbonate, epoxy resin, PVP, a carbon-based material, metal fibers, silicon dioxide, a fire retardant, an antioxidant, an anti-ultraviolet agent and lubricant. PVP is prepared into flaky xerogel, and a carbon skeleton penetrating through the whole thermistor is obtained after carbonization. The actuation time is effectively shortened, rapid response can be achieved, residual current is reduced, the safety of the thermistor is improved, excellent mechanical performance and corrosion resistance are achieved, and the application range is wide.

Owner:ANHUI NINGGUO TIANCHENG ELECTRICAL APPLIANCES

A kind of coaxial type composite oxygen microelectrode and preparation method thereof

ActiveCN104865301BEasy to manufactureIncreased drawing efficiencyMaterial electrochemical variablesLinear correlationSilver plate

The invention discloses a coaxial composite oxygen microelectrode and a preparation method thereof. The oxygen microelectrode comprises an outer casing, a working cathode column at its center and a reference electrode between the two. An electrolyte solution is injected between them; the outer wall of the working cathode column or the inner wall of the outer casing is plated with a silver layer, and a conductive wire is welded on the upper surface of the silver layer to form a protective cathode. The electrode manufacturing process is simple, and the drawing efficiency is high. The results show that: the connection of the protective cathode reduces the residual current of the coaxial composite oxygen microelectrode by about 80%, and the linear correlation R2 of the response to dissolved oxygen is above 0.99. The resolution of dissolved oxygen is about 0.03mg O2 / L.

Owner:TSINGHUA UNIV

Thermistor medium material and preparation method thereof

InactiveCN106278249AHigh pressureSmall residual currentNegative temperature coefficient thermistorsChromium sesquioxideIron oxide

The invention discloses thermistor medium material and a preparation method thereof. The thermistor medium material is prepared from the following raw materials in parts by weight: 80 to 85 parts of BaTiO3 (barium titanate), 10 to 20 parts of Sb2O3 (antimonous oxide), 5 to 12 parts of Co2O3 (cobalt sesquioxide), 1 to 9 parts of SrCO3 (strontium carbonate), 2 to 6 parts of MnO2 (manganese dioxide), 2 to 8 parts of Cr2O3 (chromium sesquioxide), 3 to 5 parts of SnO2 (stannic oxide), 2 to 10 parts of SiO2 (silicon dioxide), 2 to 10 parts of CeO2 (cerium dioxide), 2 to 8 parts of ZrO2 (zirconium oxide), and 3 to 10 parts of Y2O3 (yttrium oxide). The thermistor medium material has the advantages that the service life is prolonged, the cost is low, the preparation cost is simple, the material cost is greatly reduced, and the energy-saving and environment-friendly requirements are met.

Owner:ANHUI NINGGUO TIANCHENG ELECTRICAL APPLIANCES

Preparation method of nano NbN/graphite composite paste electrode sensor

InactiveCN110441362AImprove conductivityWide electrochemical windowMaterial electrochemical variablesParaffin waxAdhesive

The invention discloses a preparation method of a nano NbN / graphite composite paste electrode sensor. The preparation method is characterized by comprising the following steps: carrying out pretreatment on nano graphite powder by adopting sulfuric acid and potassium periodate to obtain pretreated nano graphite powder; adopting 1-vinyl-3-butyl imidazolium trifluoromethanesulfonate for dissolving loofah sponge to prepare a composite adhesive; and then, in an agate mortar, adding, in percentage by mass, 42-46% of nano niobium nitride, 22-26% of the pretreated nano graphite powder, 14-18% of the composite adhesive and 16-20% of liquid paraffin, uniformly grinding the components to form carbon paste, and then putting the carbon paste into a glass tube with the inner diameter of phi 6 mm, connected with a lead wire, so as to obtain the nano NbN / graphite composite paste electrode sensor. Compared with a common carbon paste electrode, a prepared carbon paste electrode has the advantages that the conductivity can be improved by 6-8 times, an electrochemical window is wide, the preparation method is simple, the cost is low, the surface is easy to update, the residual current is small, and the like. The astaxanthin detection sensitivity is high and the selectivity is high.

Owner:UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com