Coaxial compound oxygen microelectrode and preparation method thereof

An oxygen microelectrode and a composite technology, which are applied in the field of coaxial composite oxygen microelectrodes and their preparation, can solve the problems of difficulty in obtaining the diameter of the microelectrode tip, limited application range of the microelectrode, complicated and difficult control process, and the like. The effect of simplifying the electrode fabrication process, increasing electrode drawing power, and high spatial resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Example 1. Preparation of coaxial composite oxygen microelectrode and its performance test:

[0058] 1. Preparation of coaxial composite oxygen microelectrodes:

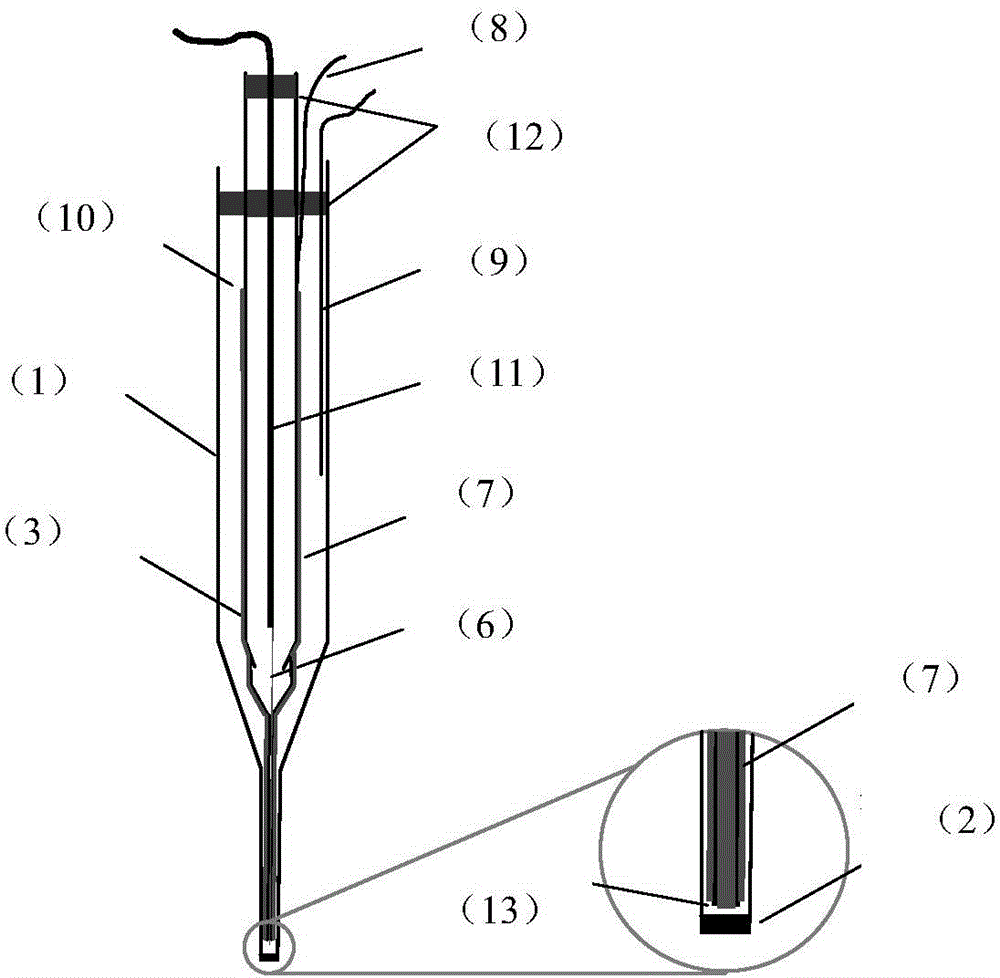

[0059] according to figure 1 The schematic diagram of the structure is shown to prepare the coaxial composite oxygen microelectrode:

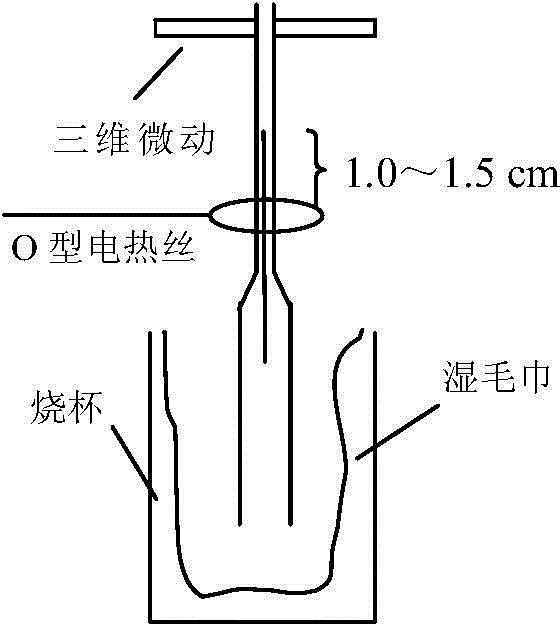

[0060] 1) Making a working cathode: using boiling aqua regia (H 2 O:HNO 3 :HCl=4:1:3, volume ratio) corrode the tip of a platinum wire with a diameter of 0.1mm (purity 99.95%, purchased from China Pharmaceutical (Group) Shanghai Chemical Pharmacy Company) to 5-10 μm, specifically, put aqua regia Put it in a 100mL beaker and raise the temperature in a water bath, then insert the platinum wire into aqua regia 2cm, and corrode for 90min, the tip of the platinum wire can be corroded to 5μm.

[0061] Take a white glass tube (hard neutral glass, with an outer diameter of 3.33 mm and an inner diameter of 2.69 mm, purchased from Beijing Aote Glass Tube Research Institute) and a gre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com