Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Shorten the signal transmission distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

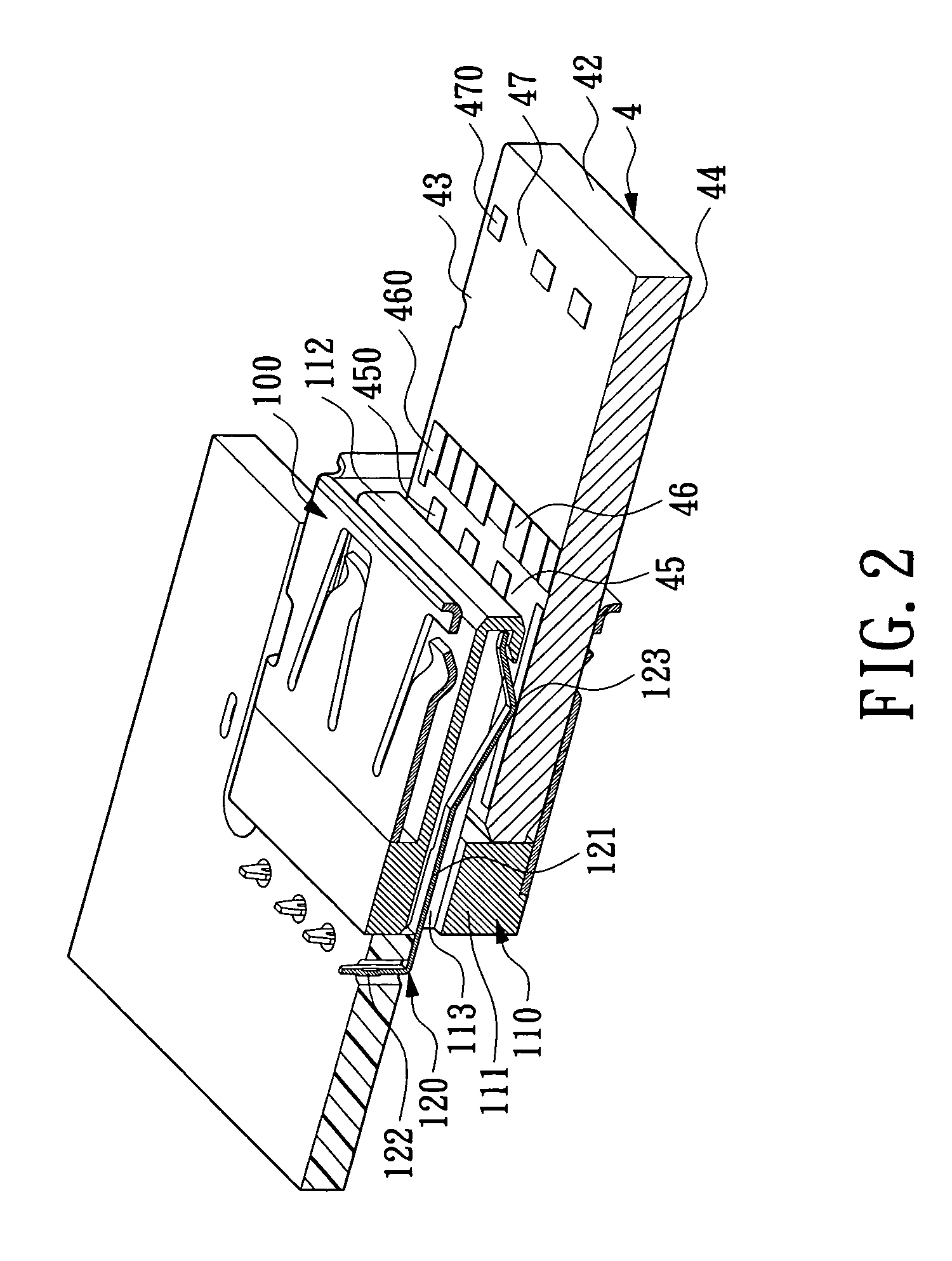

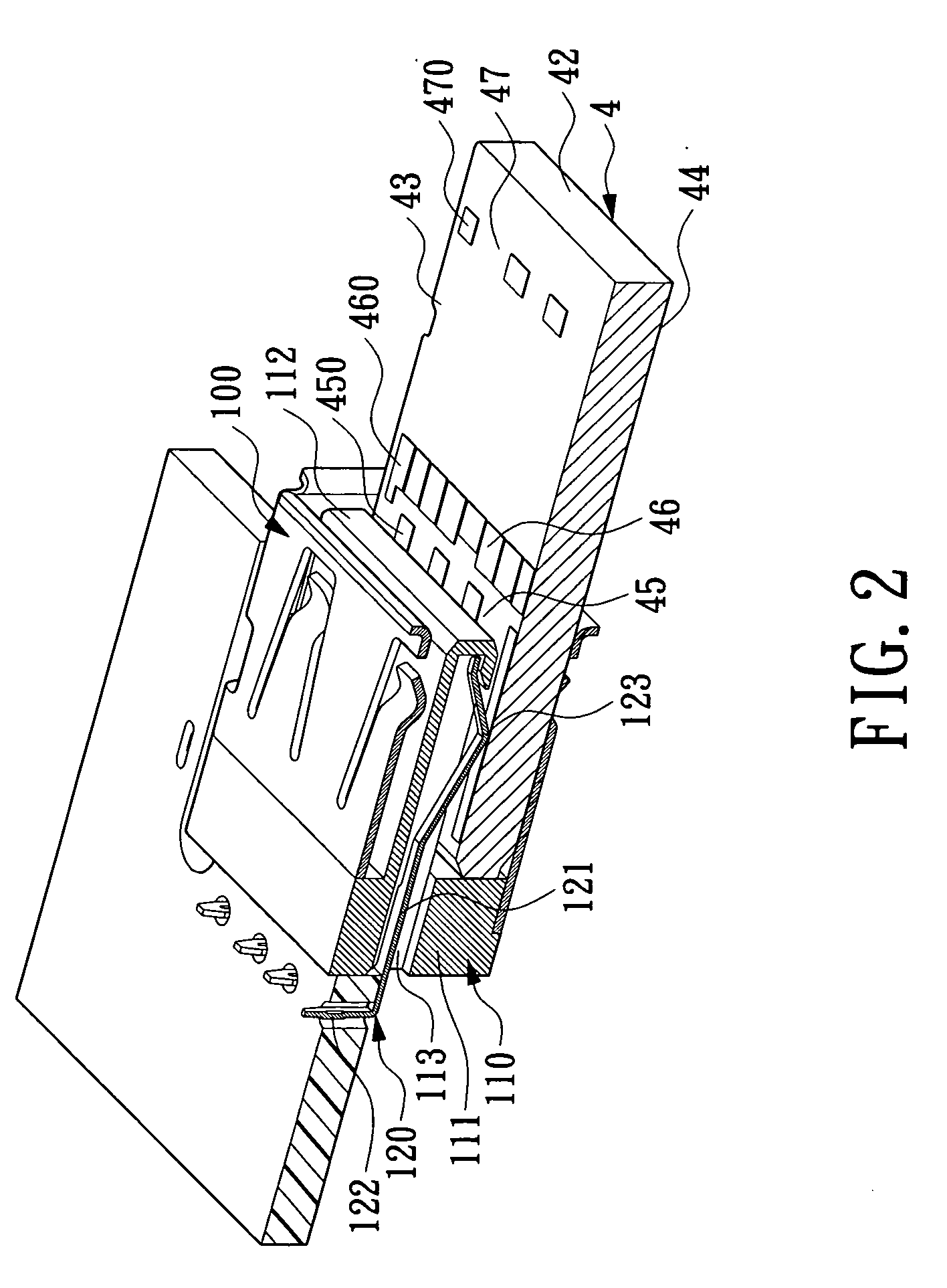

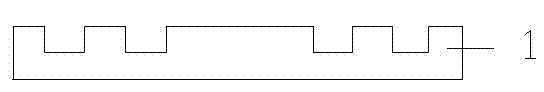

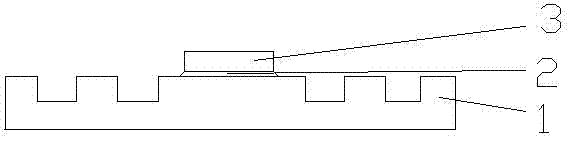

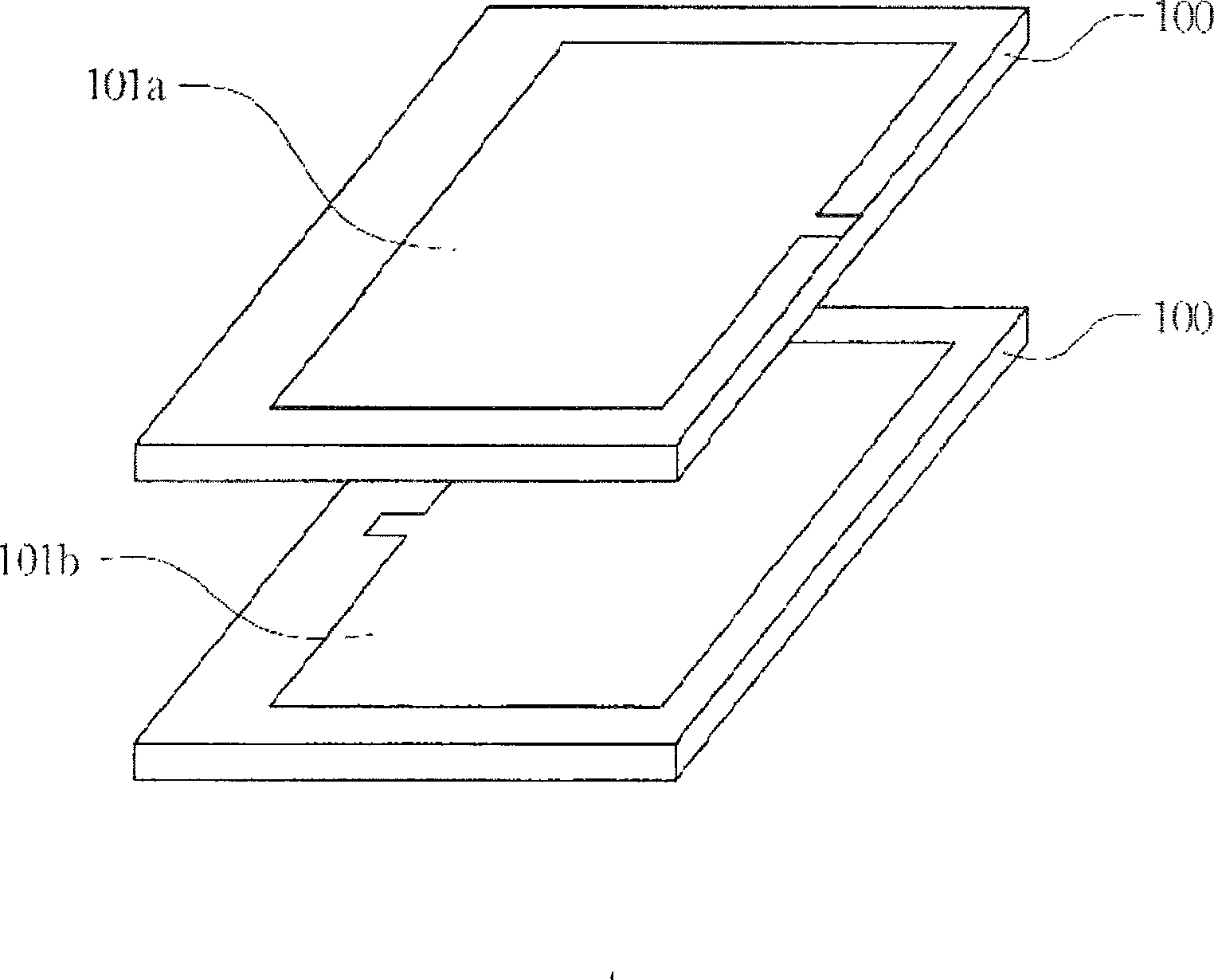

Electrical connector and inserting method thereof

InactiveUS7628655B1The transmission signal is stableConnection securityElectric discharge tubesTwo-part coupling devicesElectrical connectorMemory cards

An electrical connector includes an insulating body with a main body portion in which a first receiving space is concavely formed. Spaced first terminal passages extend in a top surface of the first receiving space. A second receiving space is formed in the front end of the main body portion and connected with the first receiving space. A tongue plate extends forwards from a front end face of the main body portion and has a working surface in which spaced second terminal passages extend. The second receiving space is located above the tongue plate. First and second conductive terminals are respectively correspondingly received in the first and the second terminal passages. When a memory card is inserted into the connector, there is no other in-series disturbed signal noise for stable signal transmission; and when the memory card is inserted to its position, it cannot swing and can be connected stably.

Owner:LOTES

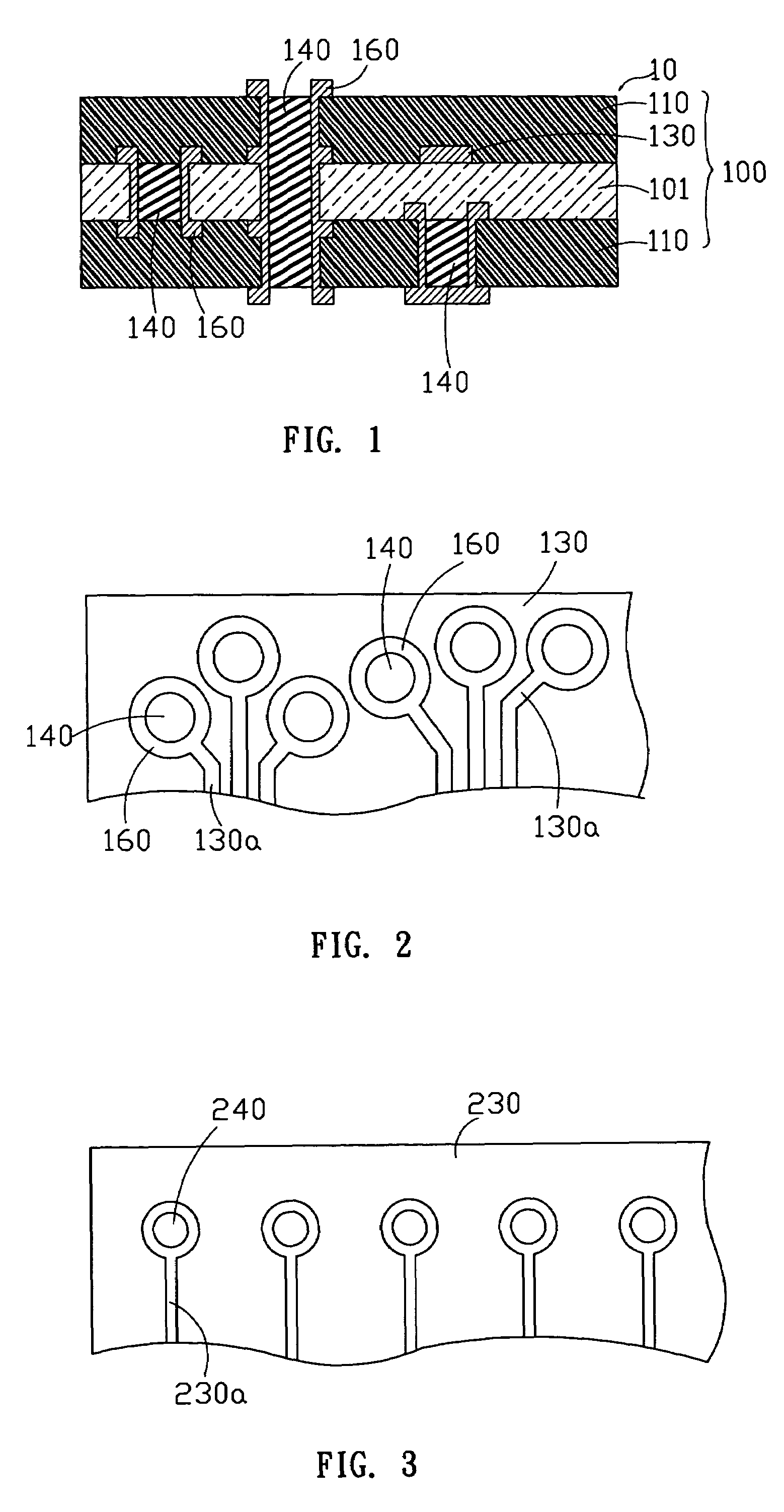

Circuit substrate and fabrication method thereof

ActiveUS7060595B2High densityReduce in quantitySemiconductor/solid-state device detailsPrinted circuit aspectsEngineeringMetal

A circuit substrate includes a board, a plurality of metal layers and an insulator. The board has a plurality of conductive traces layers and a via formed therein. The metal layers are formed on the inner wall of the via and each of the metal layers is electrically connected to its corresponding conductive traces layer. The via is filled with the insulator so that each of the metal layers is electrically isolated from each other. In addition, this invention also provides a fabrication method of the circuit substrate.

Owner:ADVANCED SEMICON ENG INC

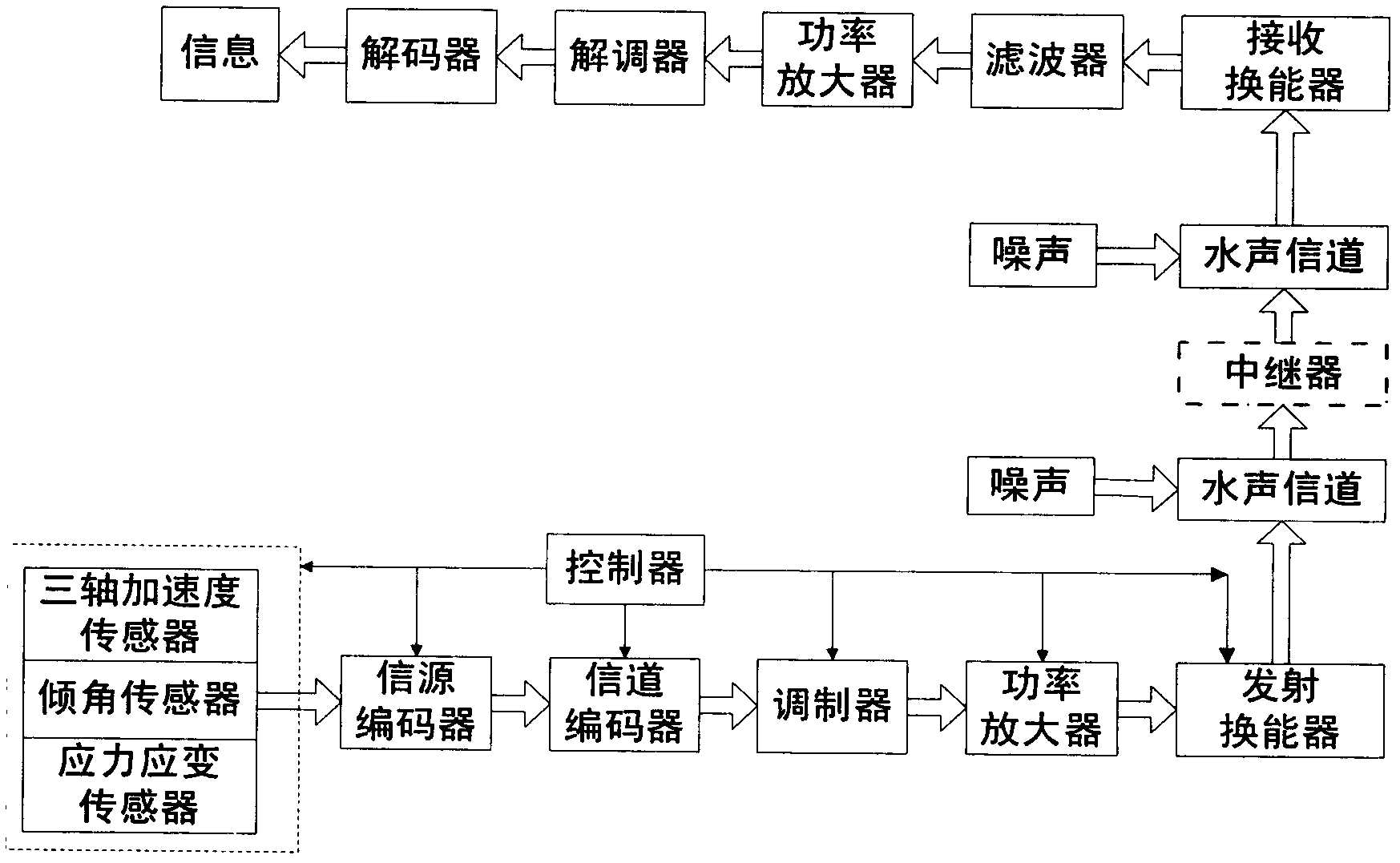

Measurement and transmission apparatus for marine riser fatigue parameter and calculation method of optimal repeater spacing

InactiveCN102426773AReduce transmission power consumptionProlong lifeNon-electrical signal transmission systemsMeasurement devicesEngineeringEnergy consumption

The invention provides a measurement and transmission apparatus for marine riser fatigue parameters and a calculation method of optimal repeater spacing. The apparatus comprises an underwater sound signal receiving device, a plurality of repeaters and a marine riser fatigue monitoring device. The marine riser fatigue monitoring device detects a fatigue signal and transmits the fatigue signal to the repeaters; and after multiple transmissions by the repeaters, the fatigue signal is transmitted to the underwater sound signal receiving device. According to calculation of energy consumption of different repeater spacing single hop links, total transmission energy consumption of employing different repeater spacings is figured out, thereby figuring out the optimal repeater spacing corresponding to a lowest total transmission energy consumption by comparison. The invention employs repeaters to shorten a signal transmission distance, reduce transmission power consumption of a single hop distance; besides, an optimal distance scope exists, so as to realize a lowest total transmission energy consumption.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Encapsulating piece for preventing chip salient point from being short-circuited and manufacturing process thereof

InactiveCN103311205AIncrease the number of I/OsImprove connection efficiencySemiconductor/solid-state device detailsSolid-state devicesEtchingWafer thinning

The invention discloses an encapsulating piece for preventing a chip salient point from being short-circuited and a manufacturing process thereof. The encapsulating piece mainly comprises a copper circuit, an annular copper column, a copper column, a copper plate, a chip salient point, a chip, a molten chip salient point, a plastic package body, a copper column left after back side etching, a green oil layer and a tin ball, wherein the copper circuit, the annular copper column and the copper column are arranged on the copper plate; the molten chip salient point is bonded in the annular copper column; the chip is arranged at the chip salient point; the left copper column is formed after back side etching of the copper plate; the green oil layer is formed on the back side of the copper plate; the tin ball is arranged on the copper column left after back side etching; the plastic package body surrounds the upper surface of the copper plate, the copper circuit, the annular copper column, the copper column and the chip to form an integral circuit; and the chip, the chip salient point on the chip, the annular copper column and the copper column left after back side etching construct a power supply and a signal channel. The process flow comprises wafer thinning, wafer scribing, reserve chip loading, reflow cleaning, plastic package, etching for separating pins, filling green paint, printing and reballing of a steel screen, printing, cutting, packing and delivering. Due to the adoption of the encapsulating piece, short circuit between two chip salient points can be prevented, and the reliability of a product is improved.

Owner:HUATIAN TECH XIAN

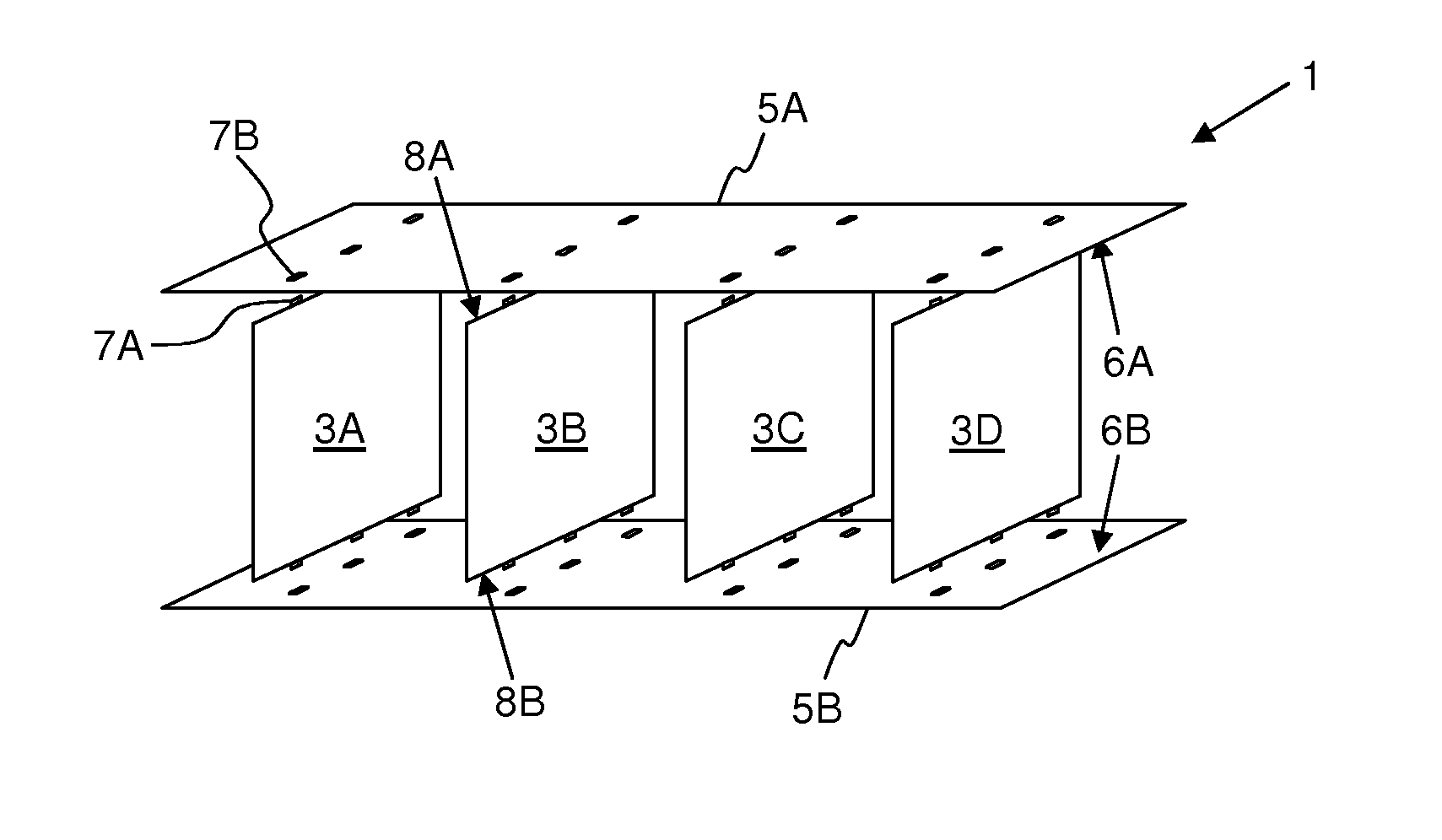

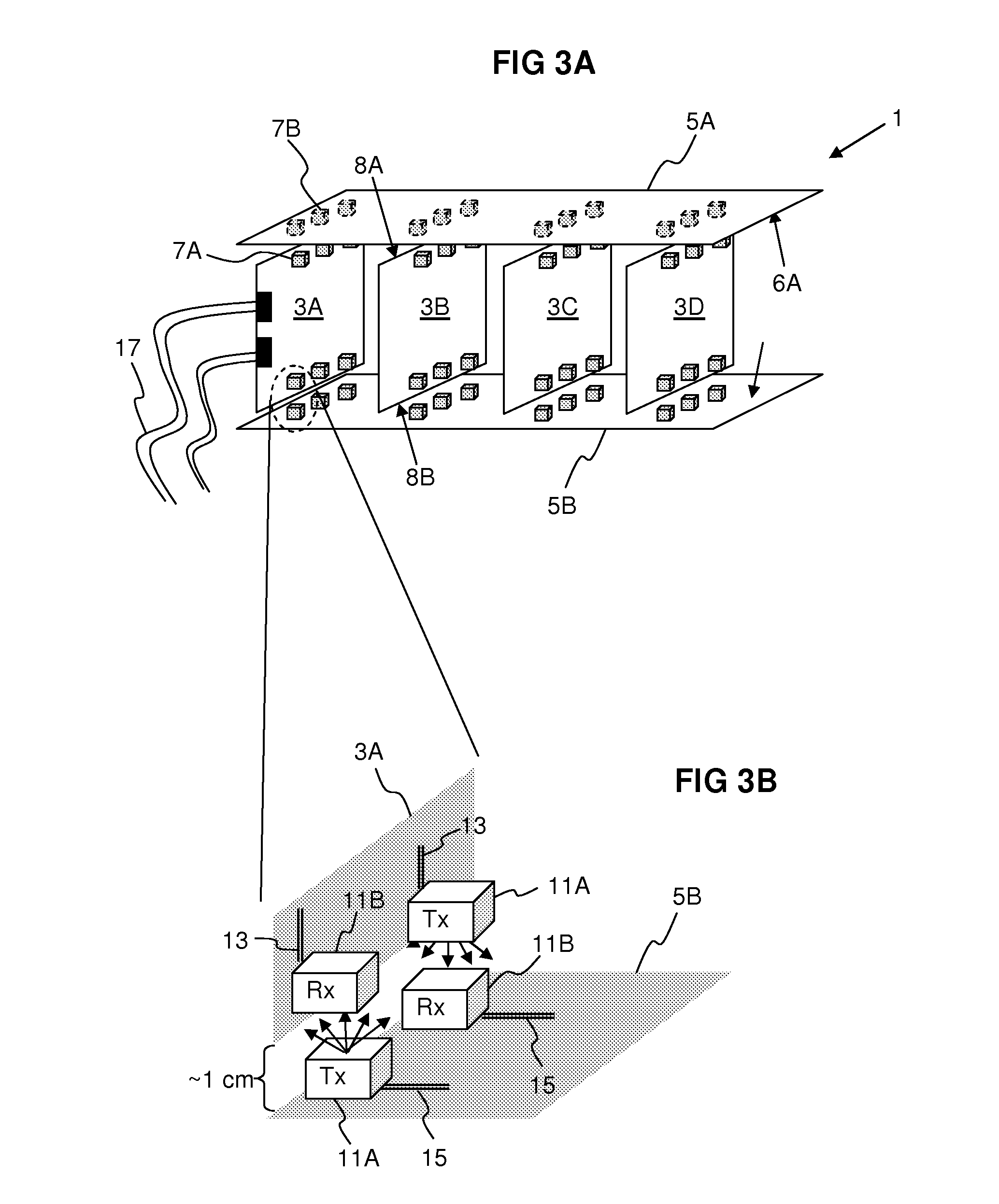

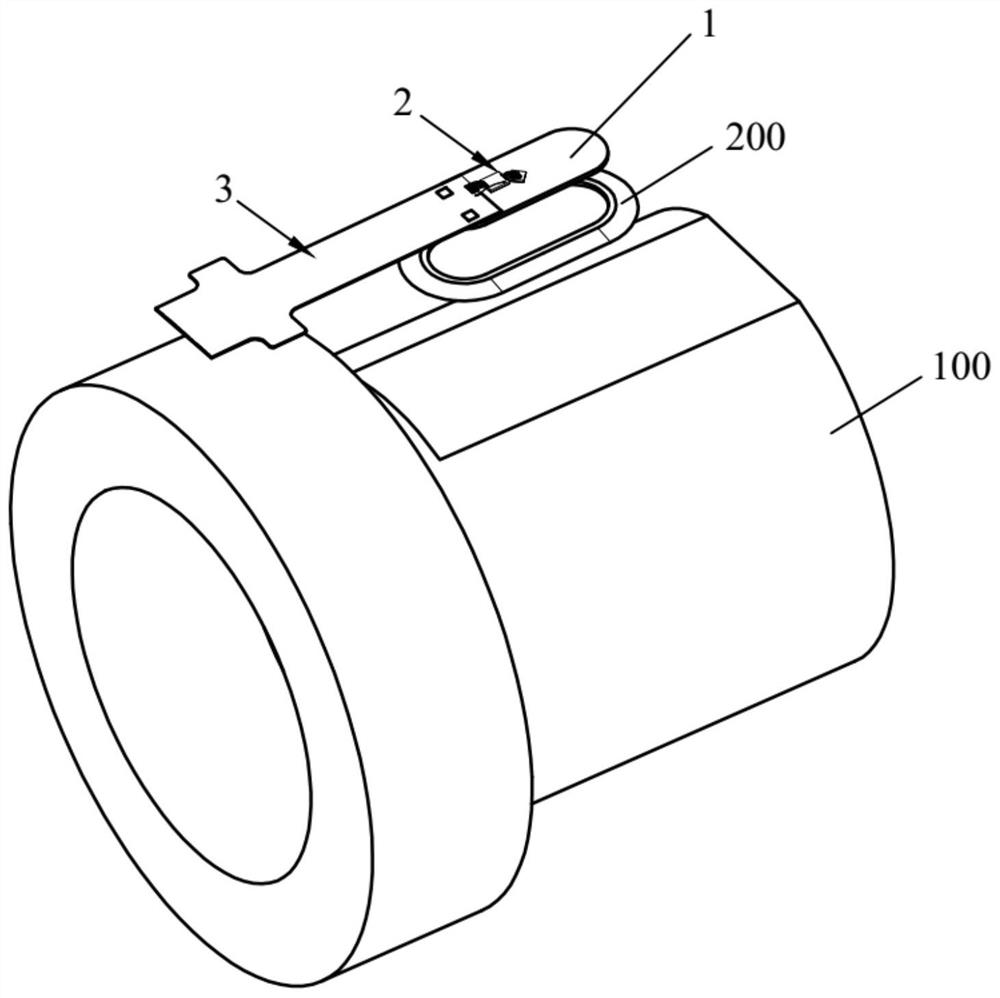

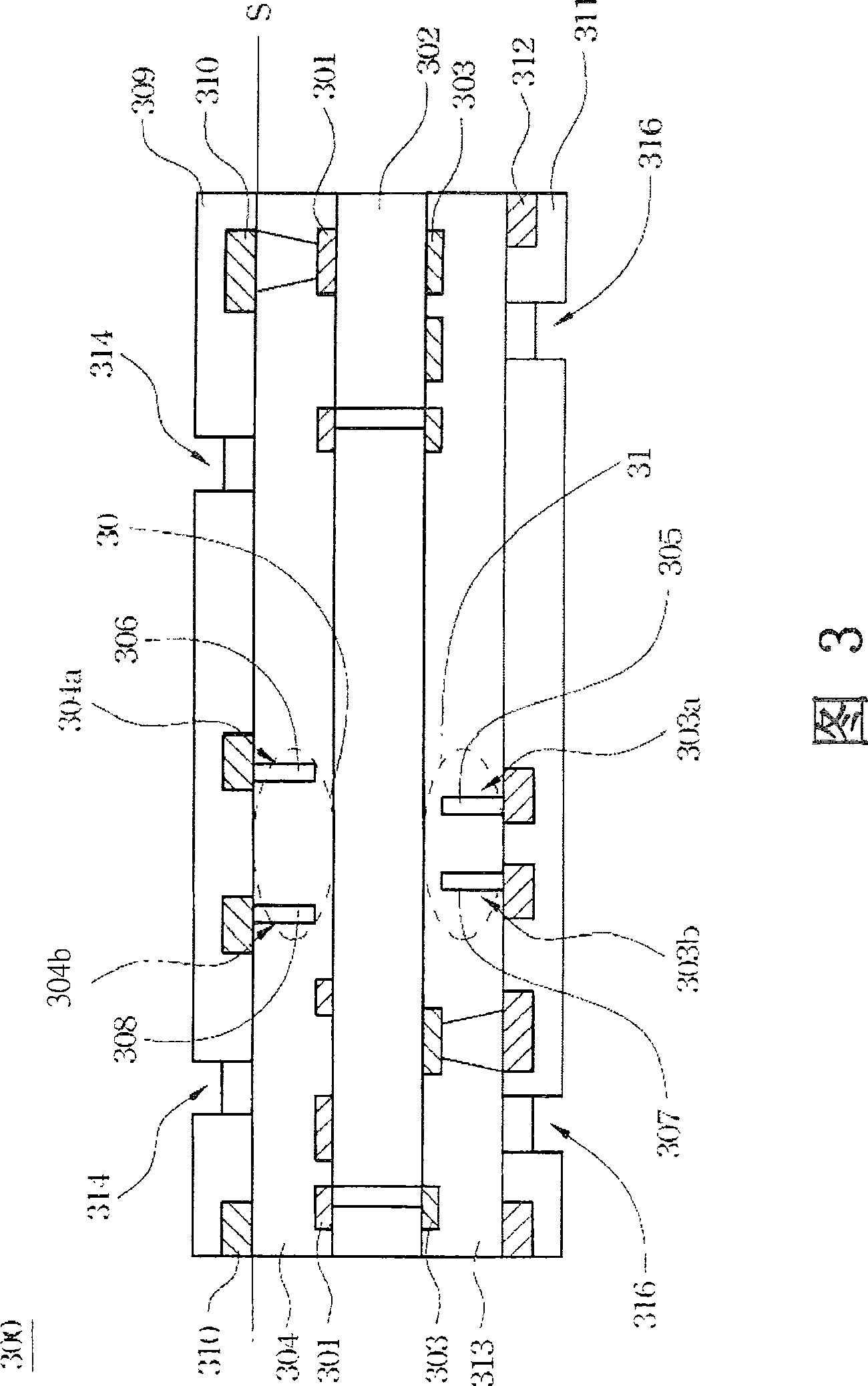

System card architecture for switching device

ActiveUS20110002108A1Directional communicationSmall sizeEnergy efficient ICTRack/frame constructionLine cardInterconnection

It is an object of the present invention to provide switching equipment for communications networks, which switching equipment supports high-speed signalling between switch cards and line cards. Hence, the invention relates to a switching device for communications networks comprising a plurality of line cards and at least one switch card. The line cards comprise connection means arranged on or close to one edge of each line card, and the at least one switch card comprises matching connection means arranged on one flat side of said switch card. In this way, when said switch card is arranged substantially perpendicular to said line cards with said flat side of the switch card facing and at least partially overlapping said edges of the line cards, interconnection is achieved between the connection means of the line cards and the matching connection means of the at least one switch card.

Owner:TELEFON AB LM ERICSSON (PUBL)

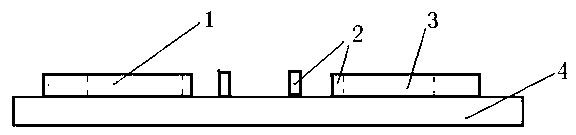

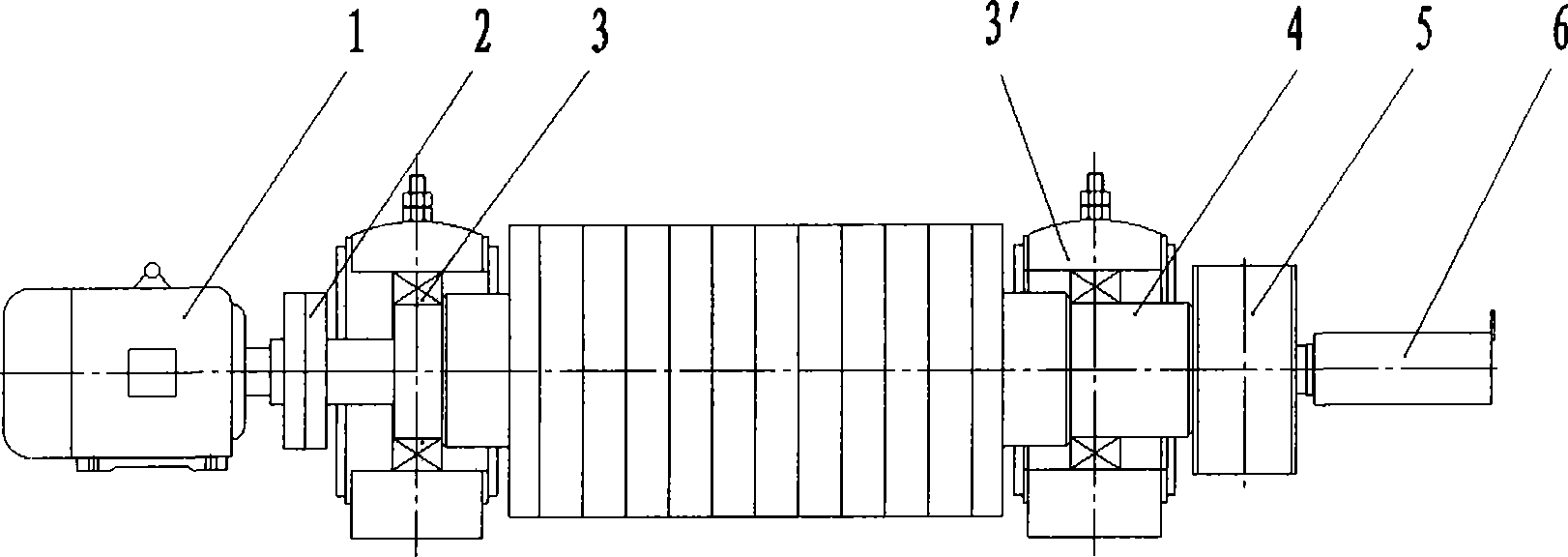

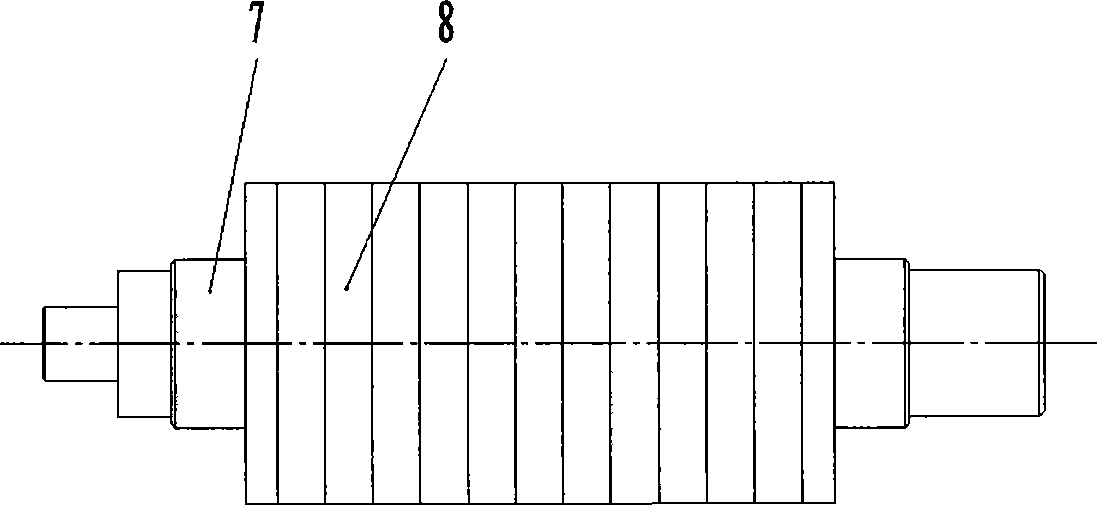

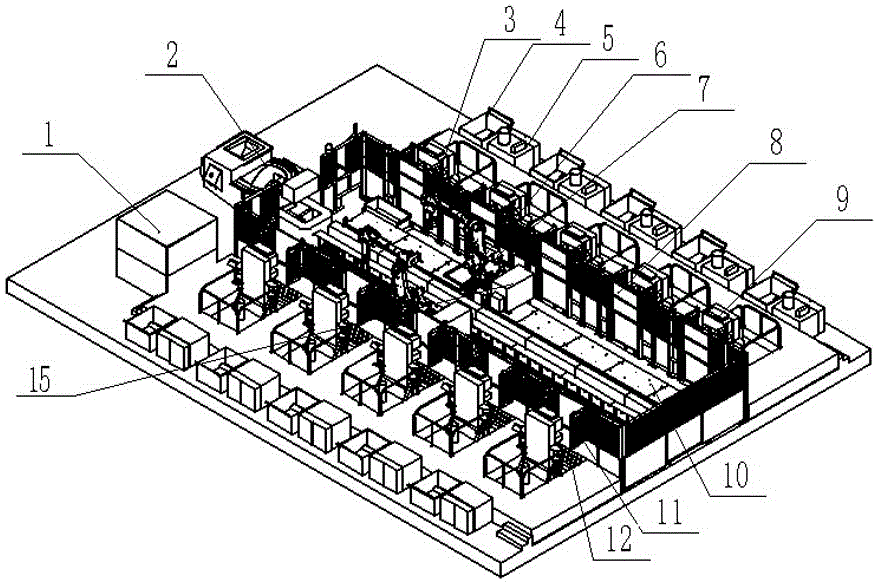

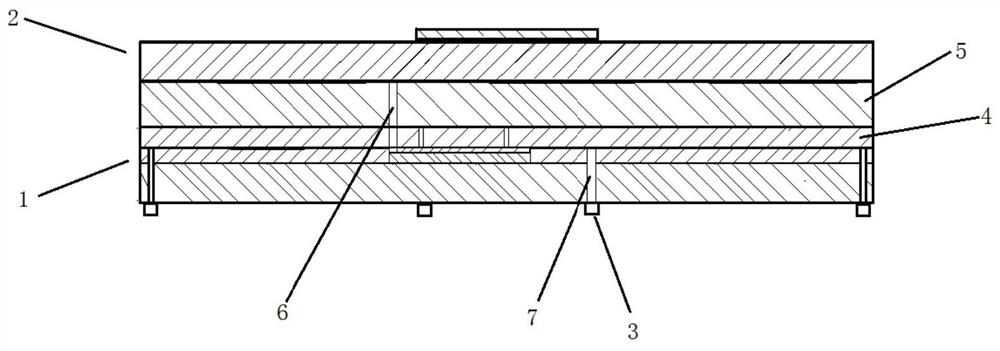

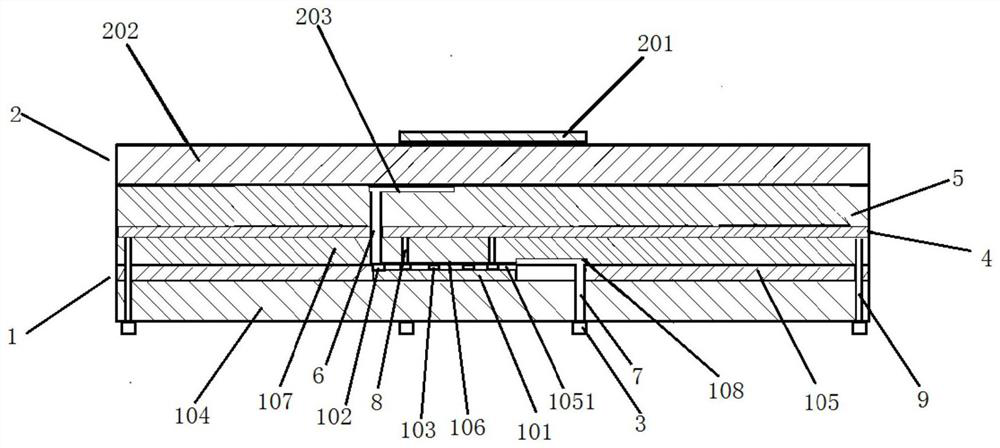

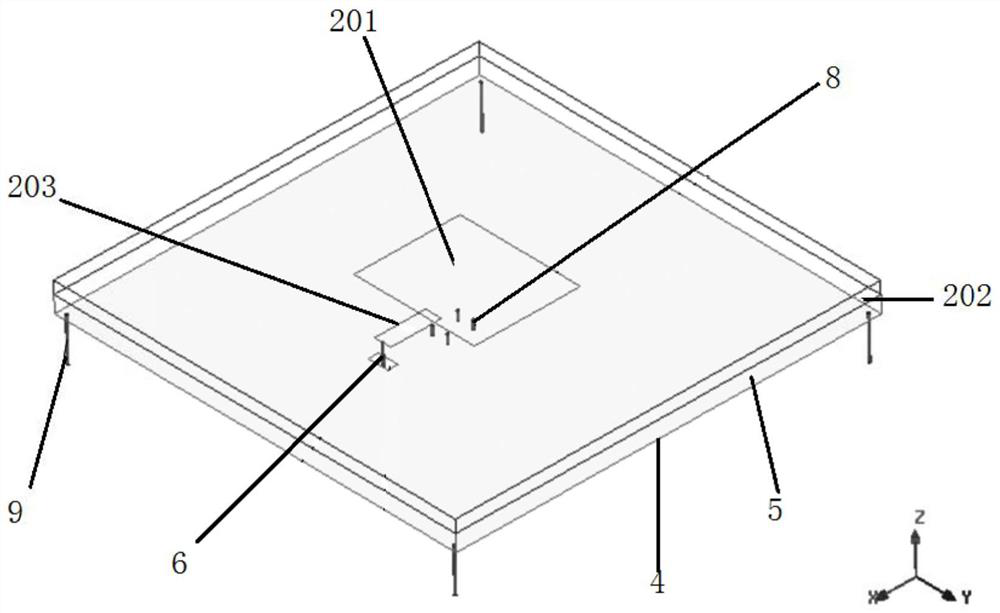

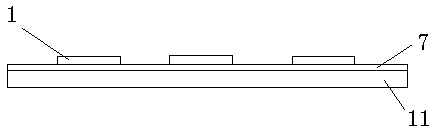

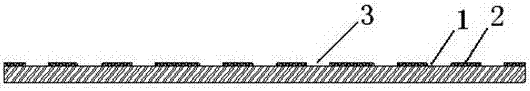

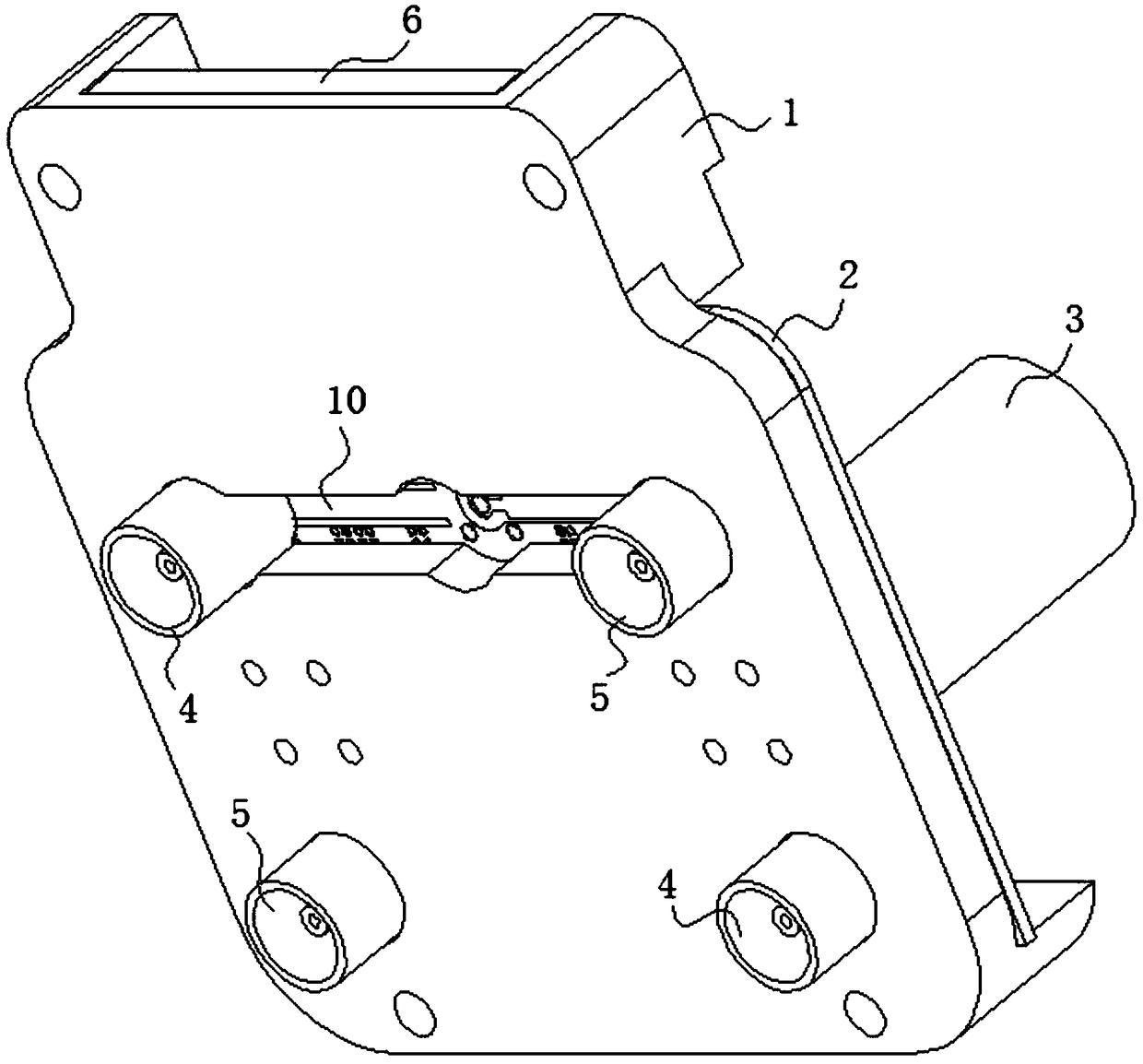

Piezoelectric shape meter for detecting flatness of cold and thermal state strip material

InactiveCN101497084AShorten the signal transmission distanceReduces the effects of electromagnetic interference and temperature changesMeasuring devicesMetal rolling arrangementsThermal stateArray data structure

The invention belongs to the technical field of automatic testing of slab band rolling lines, and relates to a detection device for automatically detecting the flatness (strip shape) of cold and hot rolled strips on line. The detection device is characterized in that a detecting roller (4) is arranged on bearing seats (3) and (3'); a stepless speed regulating motor (1) which can drive or be driven is connected with the detection roller (4) through a shaft coupling (2); the other end of the detection roller (4) is provided with a distributor (5) and a signal transmission device (6); the outer surface of a roller core (7) of the detection roller (4) is provided with 1 to 6 concave through grooves along the axial direction; and a plurality of sets of piezoelectric sensors (12) are arranged in the through grooves and in combined assembly with an integral elastic press plate (11) and a roller sleeve (8). The detection roller (4) adopts a fully sealing structure, and can perform water cooling so as to adapt to the cold and hot rolled working conditions; and pressure signals are transmitted in wired and wireless modes, so high-speed on-line detection can be achieved. A strip shape instrument has high rigidity, quick response and high adapting speed; and the signals are not intervened by static load and the temperature. Therefore, the detection device has the advantages of stable signal, high detection precision, quick detection, adaptation to high-speed cold and hot rolling, long service life, and the like, and has important practical value for improving the flatness of the strips and achieving the high-speed rolling.

Owner:YANSHAN UNIV

Electrical connector and inserting method thereof

InactiveUS20090311895A1Save crafting materialsLow production costElectric discharge tubesTwo-part coupling devicesElectrical connectorMemory cards

Owner:LOTES

Extension pin Fan-out Panel Level ball grid array (BGA) package part and manufacture process thereof

ActiveCN103094234AFlexible wiring positionSolve cross problemsSemiconductor/solid-state device detailsSolid-state devicesInsulation layerPunching

The invention discloses an extension pin Fan-out Panel Level ball grid array (BGA) package part and manufacture process thereof. The package part is mainly composed of a chip, a plastic package material, an insulation layer, metal copper, nickel porpezite, a solder ball, a soldering disk, a second insulation layer, a reversely-bonded chip, secondary metal copper distribution wires and a third insulation layer. The manufacture process comprises the following steps of thinning a wafer, scratching a wafer, reversely bonding a chip, plastically packing, tearing a film, turning, carrying out primary insulation treatment, punching holes first time, distributing copper wires first time, carrying out secondary insulation treatment, punching holes second time, distributing copper wires second time, carrying out third insulation treatment, punching holes third time, plating nickel porpezite, printing, reflow soldering and cutting. The manufacture process solve the wire cross problem, saves cost and improve electric performance and reliability of products.

Owner:HUATIAN TECH XIAN

Substrate structure for an integrated circuit package and method for manufacturing the same

InactiveUS6489572B2Effective contactImprove transmission performanceSemiconductor/solid-state device detailsSolid-state devicesElectrical connectionAdhesive glue

A substrate structure for an integrated circuit package. The substrate is electrically connected to a circuit board and an integrated circuit. The substrate includes a plurality of metal sheets and glue. The metal sheets are arranged opposite to each other. Each of the metal sheets includes a first surface and a second surface. The glue is used for sealing the plurality of metal sheet to form the substrate. The first surfaces and second surfaces of the metal sheets are exposed to the outside of the glue so as to form a plurality of signal input terminals for electrically connecting to the integrated circuit and a plurality of signal output terminals for electrically connecting to the circuit board. Thus, the signal output terminals of the metal sheets can be electrically connected to the circuit board smoothly. Furthermore, the signal transmission distance between the integrated circuit and the circuit board can be shortened so that better signal transmission effect can be obtained. A method for manufacturing the substrate is also disclosed.

Owner:KINGPAK TECH INC

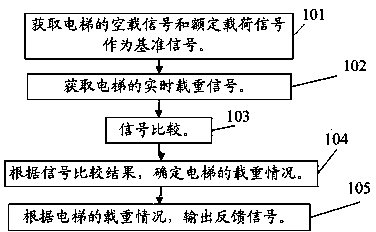

Detection method and system for elevator load

ActiveCN103387165AImprove operational safetyAccurate signal acquisitionElevatorsControl engineeringControl theory

The invention discloses a detection method and system for an elevator load. The method comprises the steps of taking a no-load signal and a rated load signal of an elevator as reference signals; obtaining the real-time load signal of the elevator; respectively comparing the values of the reference signals and the ream-time load signal; and determining the load condition of the elevator according to the comparing result of the reference signals and the real-time load signal of the elevator. The system comprises a storage unit, a real-time load signal acquiring unit, a comparing unit, an analysis unit and an output unit; the storage unit and the real-time signal acquiring unit are electrically connected with the comparing unit respectively; the comparing unit is electrically connected with the analysis unit electrically connected with the output unit. By adopting the detection method and system for the elevator load, the real-time load signal of the elevator is more accurate, the load condition of the elevator judged according to a logic operation result by comparing the elevator real-time load signal, the elevator no-load signal and the elevator rated load signal more accords with real condition, and the safety of the elevator operation is higher.

Owner:GUANGDONG HUANYU ELECTRONICS TECH CO LTD

AAQFN package part using electroplating process and manufacture process thereof

InactiveCN103094235AEliminate reflow soldering processReduce consumptionElectrolytic coatingsSemiconductor/solid-state device detailsSolder maskSolder ball

The invention discloses an AAQFN package part using an electroplating process and a manufacture process thereof. The package part is mainly composed of a copper lead framework, adhesive tape glue, a chip, a bonding wire, a plastic package material, a solder mask layer and a solder ball. The copper lead is etched to be adhered with the chip through the adhesive tape glue, the chip is connected with a pin of the copper lead framework through the bonding line and plastically packed by the plastic package materials, the solder mask layer is filled in a pin gap etched at the bottom of the copper lead framework, and the solder ball is electroplated on the pin. The manufacture process mainly comprises the following steps of semi etching a copper framework, thinning a wafer, scratching a wafer, bonding the chip, press soldering, plastically packing, framing, etching at the back, brushing the solder mask layer at the back, electroplating the solder ball and cutting. The manufacture process saves package cost and improves electric performance and product reliability.

Owner:HUATIAN TECH XIAN

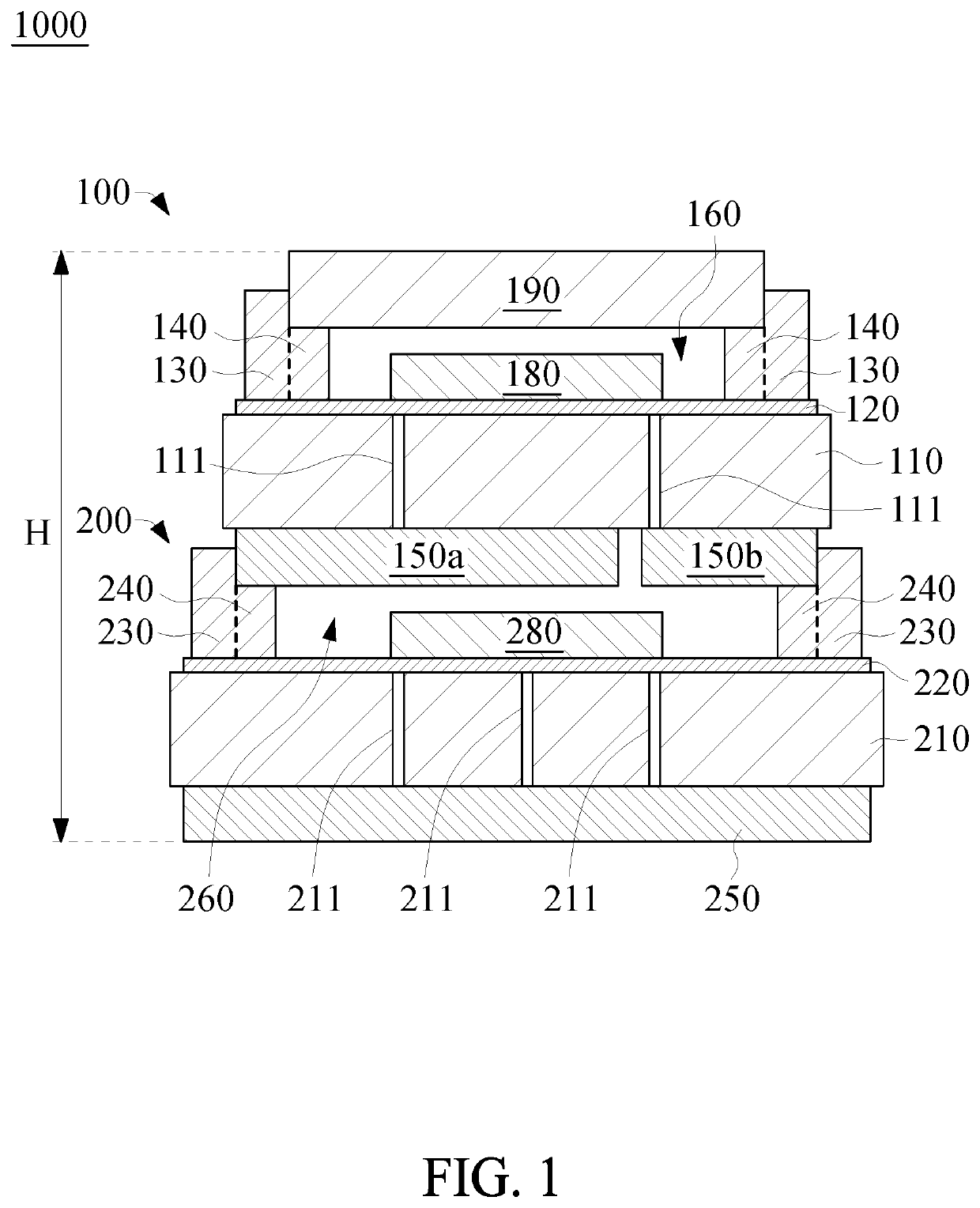

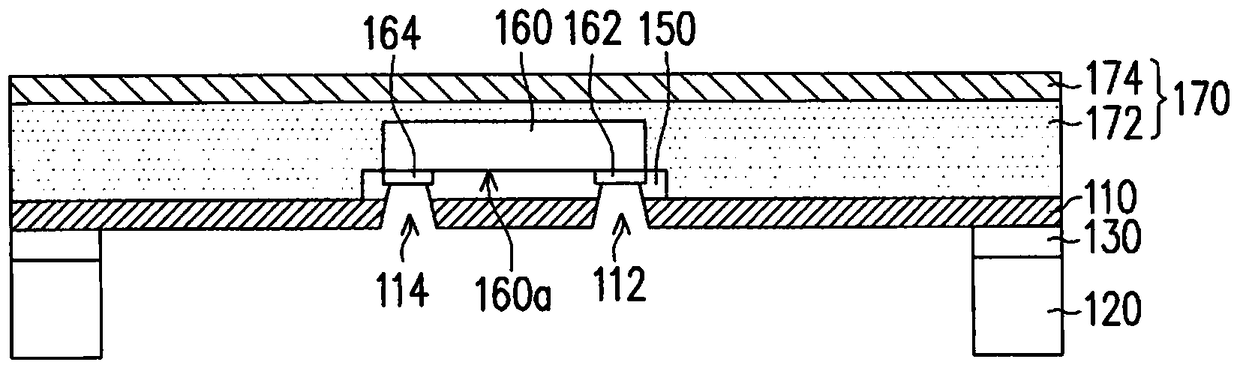

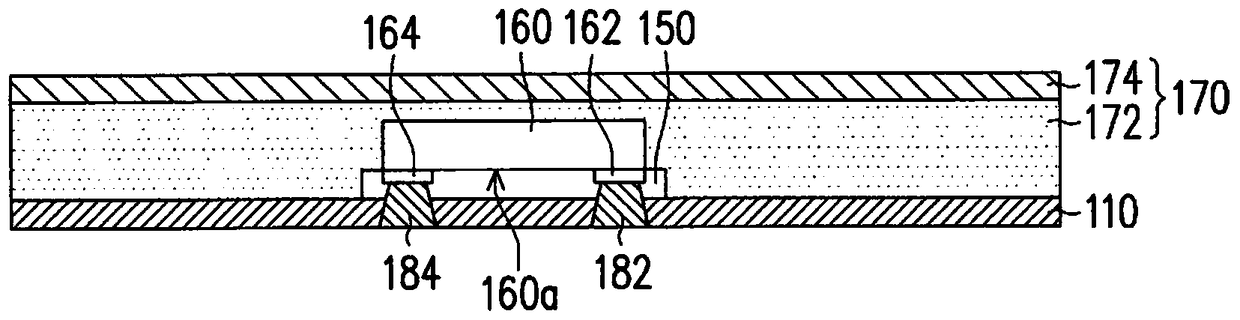

Electro-optical module

ActiveUS9058971B2Small sizeShorten the signal transmission distanceLaser detailsSemiconductor/solid-state device detailsOptical ModuleInterposer

An electro-optical module is provided, which includes: a substrate having a first surface with a groove and an opposite second surface; a plurality of support members disposed on the first surface of the substrate; at least an electro-optical element having opposite active and non-active surfaces and disposed in the groove of the substrate via the non-active surface thereof; an interposer disposed on the first surface of the substrate and the electro-optical element for electrically connecting the electro-optical element to the substrate, wherein the interposer has a through hole corresponding in position to the active surface of the electro-optical element; and a transparent plate disposed over the first surface of the substrate and the interposer through the support members and having a lens portion corresponding in position to the through hole of the interposer, thereby reducing signal losses, improving alignment precision, and achieving preferred thermal dissipation and EMI shielding effects.

Owner:SILICONWARE PRECISION IND CO LTD

FCQFN encapsulation part preventing solder balls from collapsing and manufacturing process of FCQFN encapsulation part

ActiveCN103325758AIncrease the number of I/OsImprove connection efficiencySemiconductor/solid-state device detailsSolid-state devicesEtchingPlastic packaging

The invention discloses an FCQFN encapsulation part preventing solder balls from collapsing and a manufacturing process of the FCQFN encapsulation part. The encapsulation part is mainly composed of a copper lead frame, a first green paint layer, green paint grooves, chips, tin-silver-copper protruded points, a plastic packaging body, etched pins, a second green paint layer and the solder balls. The first green paint layer coats the copper lead frame and is provided with the green paint grooves, and the chips and the tin-silver-copper protruded points are adhered to the green paint grooves. The plastic packaging body wraps the upper surface of the copper lead frame, the first green paint layer, the green paint grooves, the chips and the tin-silver-copper protruded points to form an overall circuit. The etched pins are formed by the etched copper lead frame, the etched copper lead frame comprises an etching thinning area, the second green paint layer coats the inside of the etching thinning area, and the solder balls are located on the etched pins. The manufacturing process comprises the following steps of wafer thinning, wafer scribing, green paint coating of the frame, exposure development, inverse chip assembly, backflow cleaning, plastic packaging, thinning of the back face of the frame, etching and separation of the pins, green paint filling, steel mesh printing and ball mounting, cutting, packaging and delivery. According to the FCQFN encapsulation part preventing the solder balls from collapsing and the manufacturing process of the FCQFN encapsulation part, short circuit is prevented, filling performance of plastic packaging materials is improved, and therefore product reliability is promoted.

Owner:HUATIAN TECH XIAN

Fan-out Panel Level ball grid array (BGA) package part manufacture process

InactiveCN103094128ALow warpageLow costSolid-state devicesSemiconductor/solid-state device manufacturingHigh densityCopper wire

The invention discloses a Fan-out Panel Level ball grid array (BGA) package part manufacture process. The manufacture process comprises the following steps of thinning a wafer, scratching a wafer, reversely bonding a chip, plastically packing, tearing a film, turning, carrying out primary insulation treatment, punching holes, distributing copper wires, carrying out secondary insulation treatment, punching holes, plating nickel porpezite, printing, reflow soldering and cutting. Compared with traditional package technique, the manufacture process saves cost, can achieve multi-pin, high-density, small and thin package and has the advantages of being good in radiation, electric performance and coplanarity and the like.

Owner:HUATIAN TECH XIAN

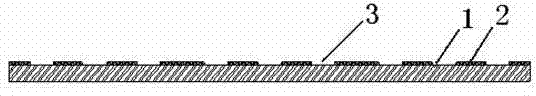

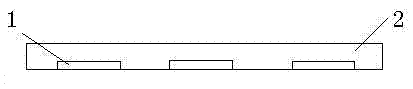

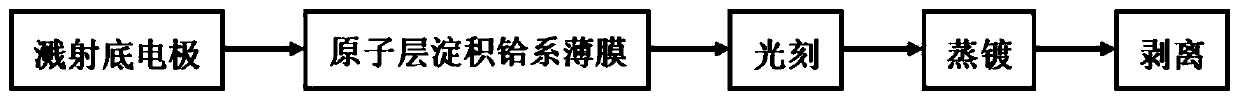

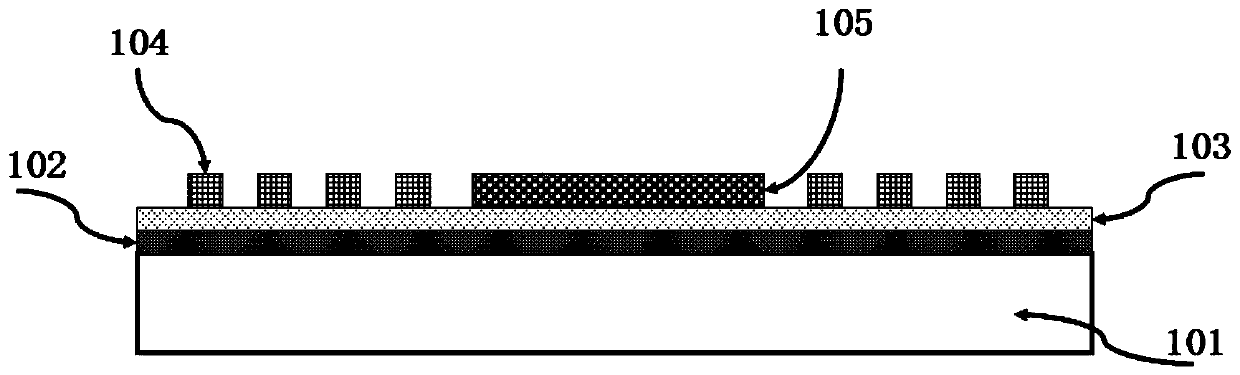

Surface acoustic wave device based on hafnium ferroelectric film and film bulk acoustic wave device

ActiveCN110601673AHighly integratedImprove portabilityImpedence networksResonanceEnvironmental perception

The invention discloses a surface acoustic wave device based on a hafnium ferroelectric film and a film bulk acoustic wave device, the surface acoustic wave device comprises any one or two of a resonance / filtering assembly and a sensing assembly which are integrated on a substrate, and each assembly comprises a bottom electrode layer, a piezoelectric layer and a top electrode layer which are stacked in sequence; the film bulk acoustic wave device comprises any one or two of a resonance / filtering assembly and a sensing assembly which are integrated on a substrate, and each assembly comprises abottom electrode layer, a piezoelectric layer and a top electrode layer which are stacked in sequence; the piezoelectric layers in the two types of acoustic wave devices are respectively prepared fromhafnium ferroelectric films doped with zirconium, aluminum or silicon by using an atomic layer deposition process. Two types of sound wave devices and storage devices can be prepared on the hafnium ferroelectric film, environmental perception, signal processing and storage can be integrated, and the integration degree and the working speed of electronic equipment can be improved.

Owner:TSINGHUA UNIV

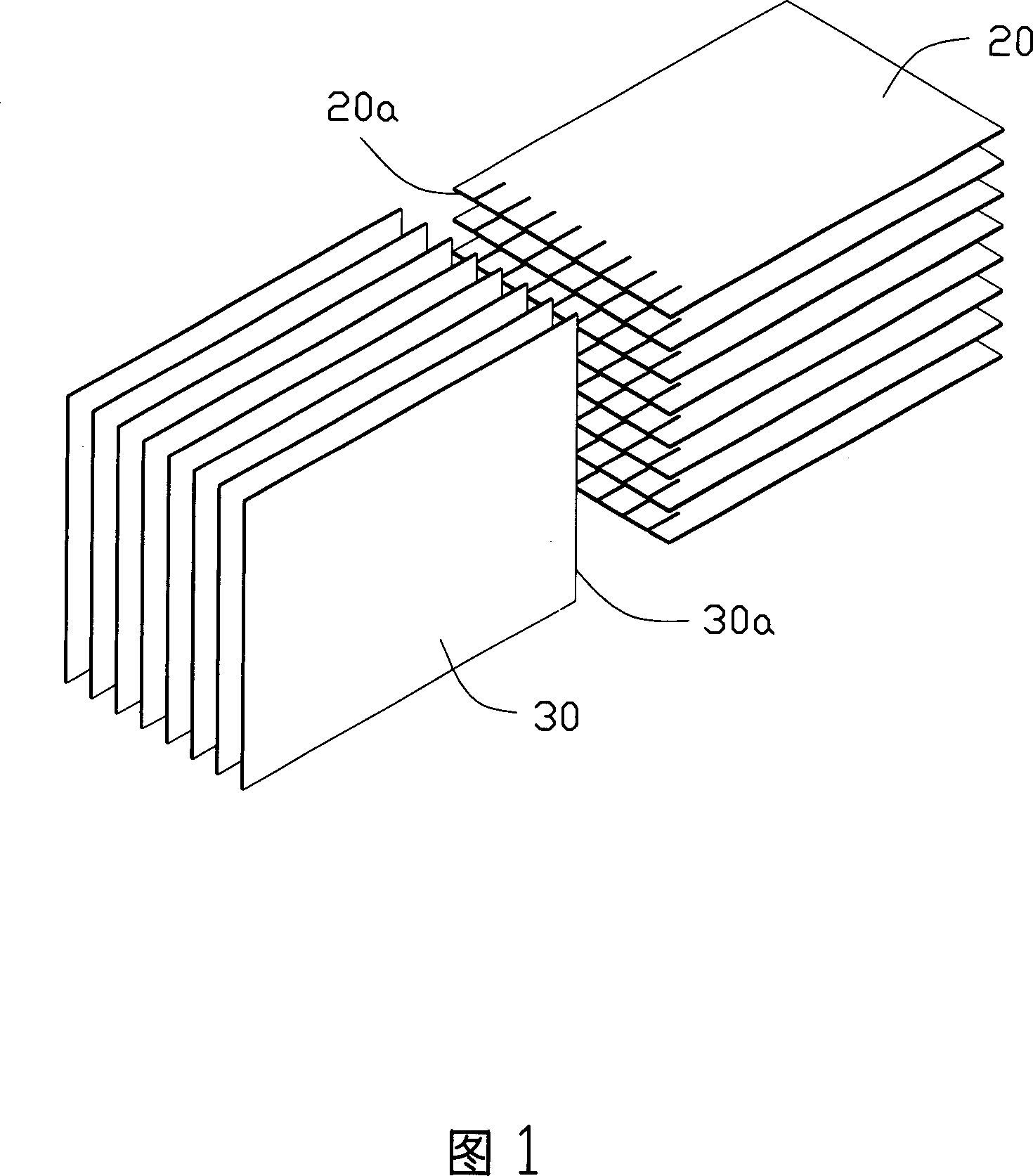

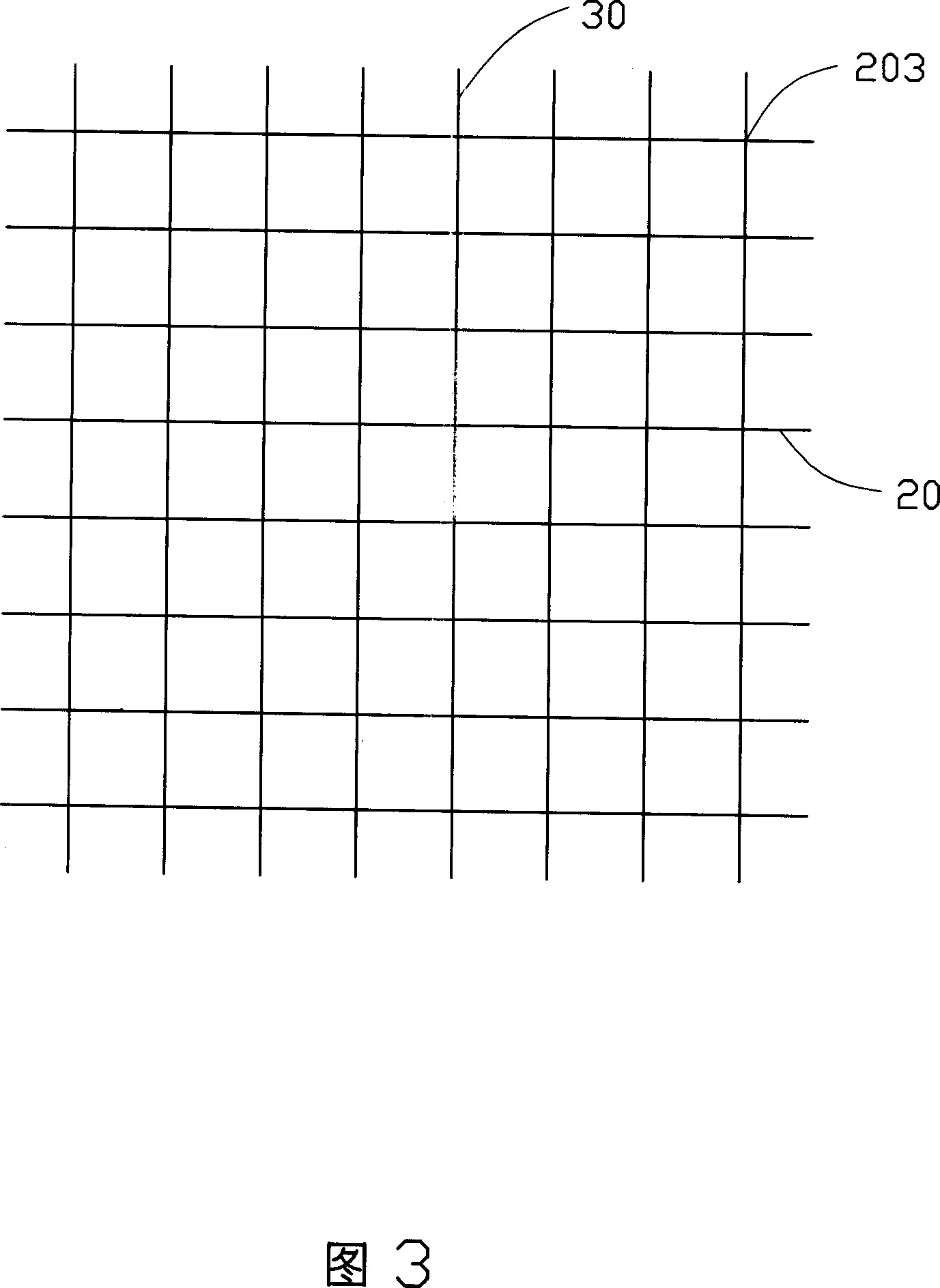

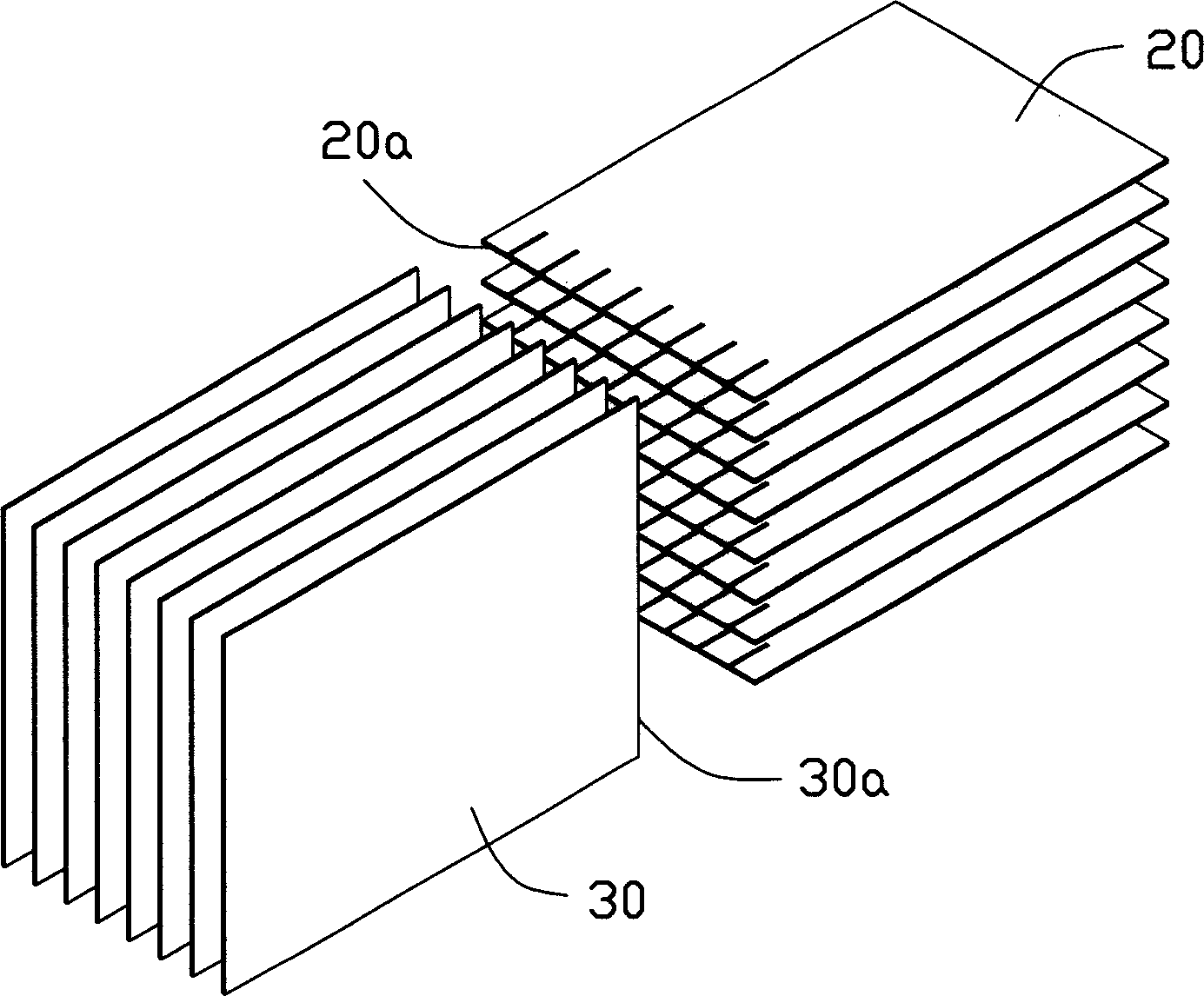

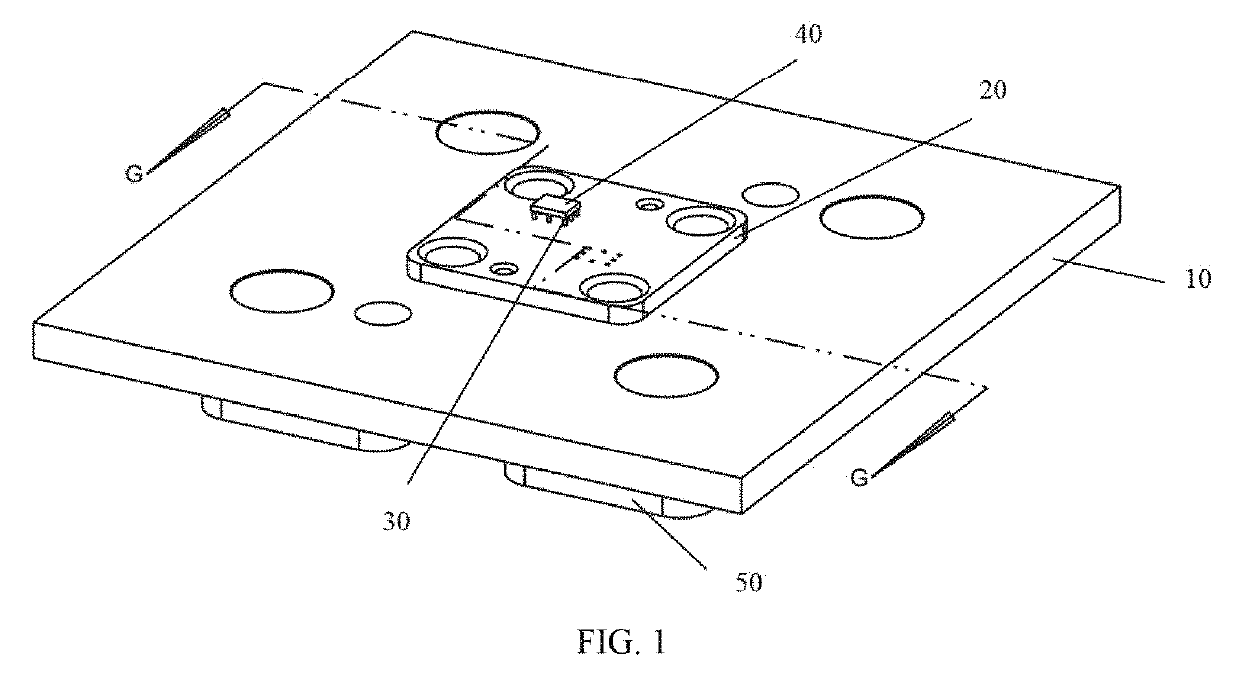

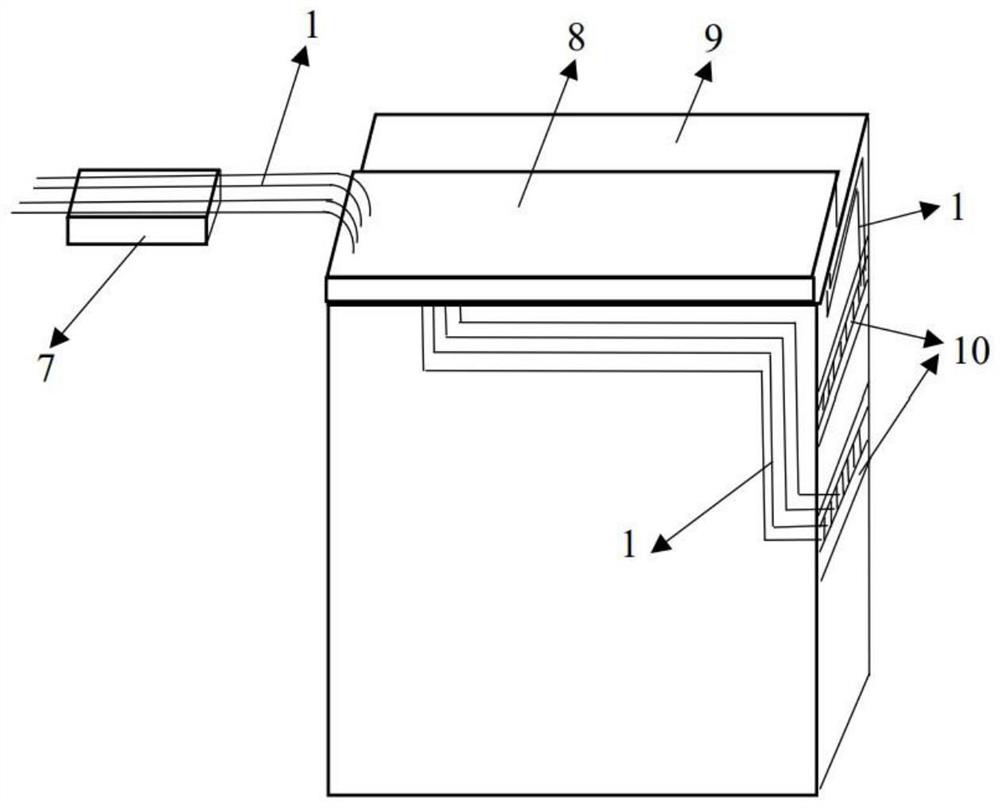

Backboard connector combination

InactiveCN101009406AShorten the signal transmission distancePrinted circuit manufacturePrinted circuits structural associationsElectrical connectionEngineering

A method for electrically interconnecting two printed circuit boards includes the steps of: providing a first printed circuit board (20); providing a second printed circuit board (30); providing a receiving slot (22) in one of the first and the second printed circuit boards such that the first and the second printed circuit boards are orthogonally intersected with each other; and providing at least one electrical connector (1) adjacent the receiving slot and in electrical connection with the first and the second printed circuit boards.

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD +1

Method for interconnecting multiple printed circuit boards

InactiveCN1661860AShorten the signal transmission distanceCoupling device connectionsPrinted circuit manufactureElectrical connectionEngineering

A method for electrically interconnecting two printed circuit boards includes the steps of: providing a first printed circuit board (20); providing a second printed circuit board (30); providing a receiving slot (22) in one of the first and the second printed circuit boards such that the first and the second printed circuit boards are orthogonally intersected with each other; and providing at least one electrical connector (1) adjacent the receiving slot and in electrical connection with the first and the second printed circuit boards.

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD +1

Strain detection device and strain detection method

InactiveCN111928771AHigh precisionImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesElectrical connectionEngineering

The invention relates to the technical field of mechanical quantity detection, in particular to a strain detection device and a strain detection method. The strain detection device comprises a substrate, a detection assembly and an output terminal, wherein the substrate is configured to be mounted on a detected carrier, the detection assembly is fixed on the substrate, the detection assembly comprises a strain sensing module and a signal processing module which are arranged at an interval, and the strain sensing module is electrically connected with the signal processing module; one end of theoutput terminal is fixed on the substrate and is electrically connected with the signal processing module, and the other end of the output terminal is configured to be electrically connected with anexternal controller. According to the strain detection device, the strain sensing module and the signal processing module are both installed on the detected carrier, so that the signal transmission distance between the strain sensing module and the signal processing module is shortened, and attenuation and interference in the signal transmission process are reduced; the strain sensing modules andthe signal processing modules are arranged at intervals, so that the influence of heat generated by the signal processing modules on the strain sensing modules is reduced, and the accuracy and reliability of detection results are improved.

Owner:GUANGDONG GOBAO ELECTRONICS TECH CO LTD +1

Sensor assembly shell, leadless thermopile sensor and manufacturing method

PendingCN111735546AReduce connectionsMeet assembly requirementsPyrometry using electric radation detectorsElectrical connectionMaterials science

The invention provides a sensor assembly shell, a leadless thermopile sensor and a manufacturing method. The leadless thermopile sensor comprises the sensor assembly shell and a thermopile sensitive chip; the detection surface of the thermopile sensitive chip is correspondingly arranged below the top of the inner wall of the detection cavity of the sensor assembly shell; and an electrode bonding pad of at least one thermopile sensitive chip is in contact connection with an internal conductive convex block at the top of the detection cavity, so that the thermopile sensitive chip is electricallyconnected with the sensor assembly shell. According to the invention, the assembly process of the lead is reduced, the operation difficulty of the assembly process is greatly simplified, the assemblyefficiency is improved, and the technical problem of complex process of the existing thermopile sensor is solved; meanwhile, in terms of structural design, a lead binding space is omitted, the overall size of the leadless thermopile sensor is greatly reduced, and the problem that application of a thermopile sensor in the prior art is limited in electronic products due to the fact that the size ofthe thermopile sensor is too large is effectively solved.

Owner:HENAN HANWEI ELECTRONICS

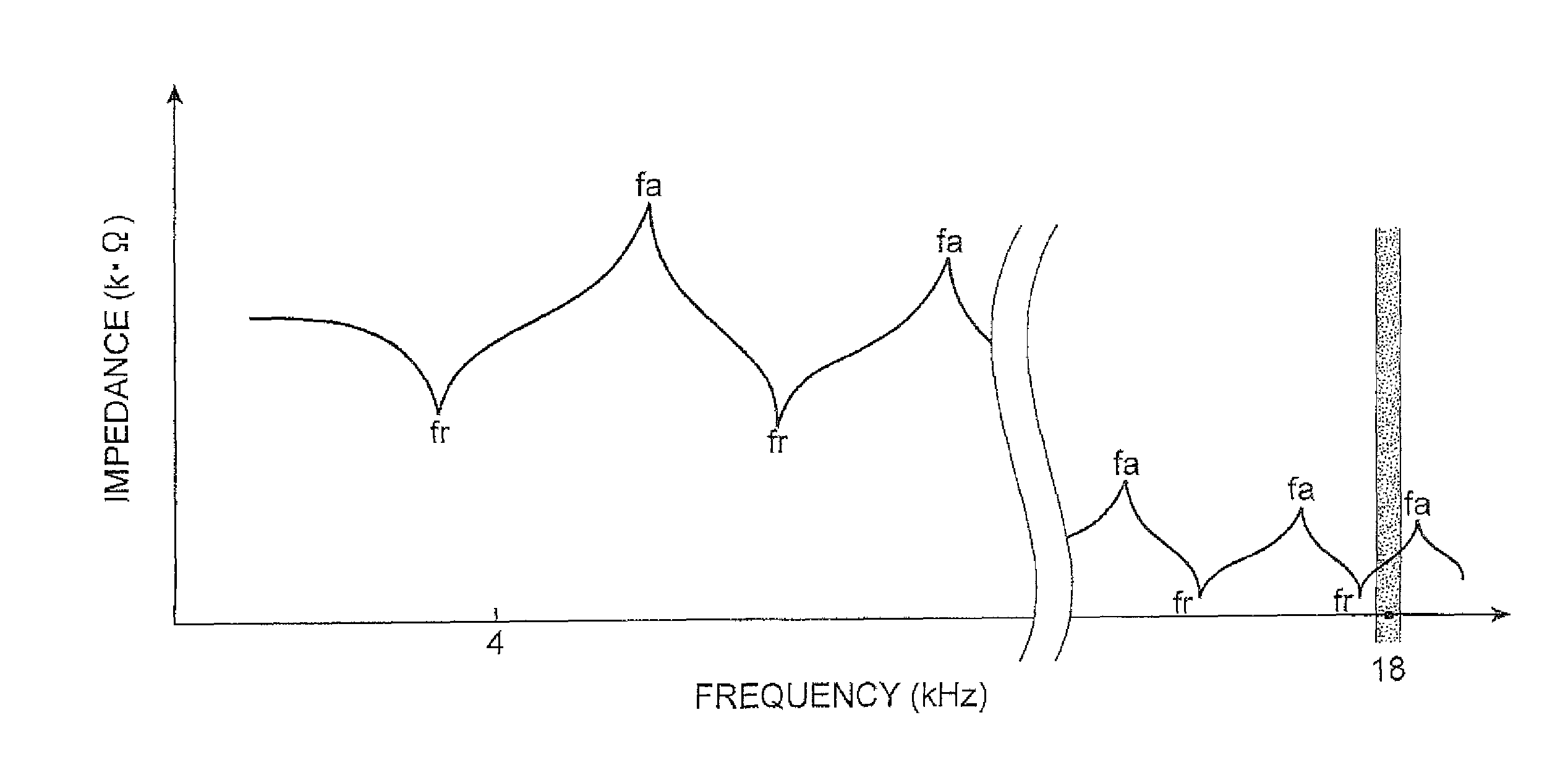

Piezoelectric sounder

ActiveUS9055373B2Improve stabilityShorten the signal transmission distancePiezoelectric/electrostrictive resonant transducersLoudspeakersAcoustic transmissionMetal sheet

A piezoelectric sounder for transmitting a signal by using a sound comprises a piezoelectric diaphragm constructed by attaching a piezoelectric element to a metal sheet, a ease containing the piezoelectric diaphragm and having a resonance space defined therewithin and adapted to resonate as the piezoelectric diaphragm vibrates, a pair of terminals electrically connected to the metal sheet and piezoelectric element of the piezoelectric diaphragm, while the piezoelectric sounder has no resonance points fr, fa in a frequency range of the signal. Thus removing the resonance points fr, fa from the frequency band of the signal to be transmitted prevents the signal transmission distance from shortening at the resonance points, thereby improving the stability in communications.

Owner:TDK CORPARATION

Vertical probe card

ActiveUS20190250190A1Shorten the signal transmission distanceReduce signal lossElectrical measurement instrument detailsPrinted circuit aspectsProbe cardElectrical conductor

Provided is a vertical probe card, the vertical probe card includes: a printed circuit board (PCB) including a bottom hole and a PCB pad surrounding the bottom hole; a cover plate disposed on the PCB and including a cover hole, where the cover hole and the bottom hole are disposed coaxial with each other and form a receiving space; and a probe received in the receiving space. The probe includes a probe head passing through the cover hole to extend out of the cover plate and to contact with a chip, where an end, which is provided with the probe head, of the probe is a first end; and a protruding portion disposed in the mid-portion of the probe and in contact with the PCB pad, where a part between the probe head and the protruding portion of the probe and the protruding portion are conductors.

Owner:SUZHOU TAOSHENG ELECTRONICS TECH CO LTD

Base plate with buried passive element and its producing method

ActiveCN100501952CReduce layoutReduce the number of stacksPrinted circuit assemblingSemiconductor/solid-state device detailsEngineeringDielectric layer

The disclosed base plate includes interlaid circuit board of possessing first conducting circuit, dielectric layer, first electrode, second electrode, and second conducting circuit. Being setup on the interlaid circuit board, the dielectric layer possesses first concave hole and second concave hole. First electrode is setup in the first concave hole, and the second electrode is setup in the second concave hole. The first and second electrodes as well as the dielectric layer located between first electrode and second electrode constitute an embedded passive element jointly. Second conducting circuit connects first electrode and second electrode electrically.

Owner:ADVANCED SEMICON ENG INC

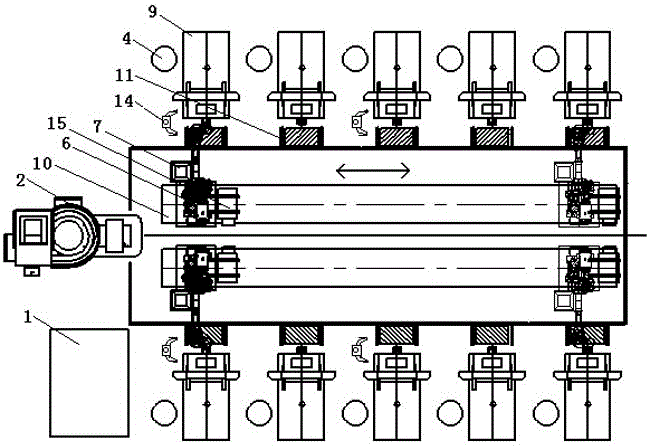

Safety automatic pouring system

InactiveCN106424677AImprove efficiencyEasy to operateMolten metal conveying equipmentsEngineeringElectrical and Electronics engineering

The invention relates to a safety automatic pouring system comprising a mobile platform, pouring robots arranged on the mobile platform, a melting furnace arranged on one end of the mobile platform, a fence surrounding the mobile platform, and a plurality of casting machines arranged along the mobile platform and outside the fence; a position, corresponding to the melting furnace, on the fence is provided with an opening; positions, corresponding to the casting machines, on the fence are provided with double doors; a gravity sensor is arranged below a worker operation area of the casting machine; when the gravity sensor detects a person in the worker operation area, the double door is closed, and the pouring robot pouring signal is locked. The safety automatic pouring system is high in pouring efficiency, easy in operations, and safe.

Owner:WUHAN FENJIN INTELLIGENT MACHINE CO LTD

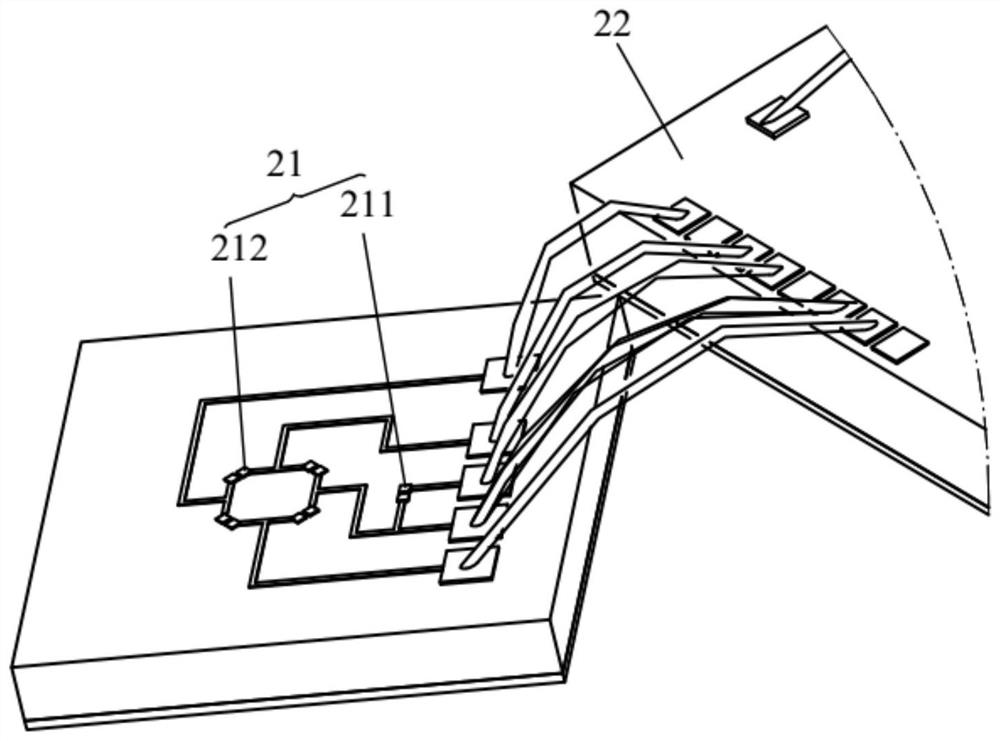

Millimeter wave packaging antenna based on fan-out packaging technology

PendingCN114122674AShorten the signal transmission distanceReduce attenuation and lossAntenna supports/mountingsSemiconductor/solid-state device detailsPhysicsAntenna radiation

The invention provides a millimeter wave packaging antenna based on a fan-out packaging technology. The millimeter wave packaging antenna comprises a chip packaging layer, an antenna radiation structure, an external substrate bonding pad, a reflection metal layer and a first passivation layer. The external substrate bonding pad is arranged below the chip packaging layer, and the reflective metal layer is arranged above the chip packaging layer; the first passivation layer is arranged above the reflective metal layer, and the antenna radiation structure is arranged above the first passivation layer; the antenna radiation structure carries out signal transmission with the chip packaging layer through the conductor. And the chip packaging layer performs signal transmission with the external substrate bonding pad through the conductor. According to the antenna structure, signal transmission is directly carried out through the conductor and the chip packaging layer, and the chip packaging layer is longitudinally and electrically connected with the bonding pad of the external substrate, so that the signal transmission distance between the antenna and the chip is greatly shortened, attenuation and loss of signals in the transmission process are effectively reduced, and the transmission performance of the antenna is improved.

Owner:GUANGDONG UNIV OF TECH

A fan-out panel-level BGA package with extended pins and its manufacturing process

ActiveCN103094234BLow warpageFlexible wiring positionSemiconductor/solid-state device detailsSolid-state devicesWafer dicingSolder ball

The invention discloses a Fan-out Panel Level BGA package with extended pins and its manufacturing process. The second insulating layer, the second metal copper wiring, and the third insulating layer are composed. The manufacturing process is carried out according to the following steps: wafer thinning, wafer dicing, flip chip mounting, plastic packaging, film tearing and flipping, first insulation treatment, first drilling and copper wiring, second insulation Processing, the second punching and copper wiring, the third insulation treatment, the third punching and nickel-palladium-gold plating, printing and reflow soldering, cutting. The invention solves the problem of line crossover, saves cost, and improves electrical performance and product reliability.

Owner:HUATIAN TECH XIAN

Laser diode device

ActiveUS10707644B1Lower drive strengthIncrease laser diode driving speedLaser detailsSemiconductor laser structural detailsMaterials scienceLaser diode

A laser diode device includes a laser diode component, a lens, a first carrying element, a driving chip and a second carrying element. The first carrying element receives the laser diode component and the lens. The second carrying element receives the driving chip and is disposed below the first carrying element to carry the first carrying element and electrically connected to the first carrying element.

Owner:SHANGHAI ORIENT CHIP TECH CO LTD

Antenna-integrated package structure and manufacturing method thereof

ActiveCN105789847BShorten the signal transmission distanceReduce signal transmission lossAntenna supports/mountingsRadiating elements structural formsEngineeringMetal

The invention discloses an antenna integrated packaging structure and a manufacturing method thereof. The packaging structure includes a stacked structure and a multi-layer substrate. The stacked structure includes at least one chip embedded in the stacked structure and at least one plated through hole structure penetrating the stacked structure. The multi-layer substrate is laminated on the stacked structure. The multi-layer substrate at least includes a metal layer located on a side of the multi-layer substrate away from the stacked structure and includes at least one antenna pattern. The antenna pattern is located above the chip. The multi-layer substrate includes an electroplated via hole structure that penetrates the multi-layer substrate and is connected to the electroplated via hole structure to electrically connect the antenna pattern and the chip. The present invention also provides a method for manufacturing the aforementioned antenna integrated packaging structure.

Owner:IND TECH RES INST

Modular network wiring management system based on Internet of Things

PendingCN114679638AReduce usageImprove construction efficiencyTransmissionSelection arrangementsSystems managementThe Internet

The invention discloses a modularized network distribution management system based on the Internet of Things, which comprises a distribution system management software end, a cabinet, a switch, a metal distribution box, an information acquisition server, a main control module mounted in the metal distribution box, a double-sided cable plug circuit board, at least one group of plug units and a plug judgment circuit module, on the basis of the Internet of Things technology, the connection condition of wiring ports and the upstream and downstream relationship of cable links are identified, the access position and equipment information of each cable and the use condition of the network port number are recorded and identified, and network management personnel can conveniently configure and maintain network line resources.

Owner:NANJING UNIV OF POSTS & TELECOMM

A kind of fcqfn package for preventing solder ball from collapsing and its manufacturing process

ActiveCN103325758BIncrease the number of I/OsImprove connection efficiencySemiconductor/solid-state device detailsSolid-state devicesEtchingPlastic packaging

The invention discloses an FCQFN encapsulation part preventing solder balls from collapsing and a manufacturing process of the FCQFN encapsulation part. The encapsulation part is mainly composed of a copper lead frame, a first green paint layer, green paint grooves, chips, tin-silver-copper protruded points, a plastic packaging body, etched pins, a second green paint layer and the solder balls. The first green paint layer coats the copper lead frame and is provided with the green paint grooves, and the chips and the tin-silver-copper protruded points are adhered to the green paint grooves. The plastic packaging body wraps the upper surface of the copper lead frame, the first green paint layer, the green paint grooves, the chips and the tin-silver-copper protruded points to form an overall circuit. The etched pins are formed by the etched copper lead frame, the etched copper lead frame comprises an etching thinning area, the second green paint layer coats the inside of the etching thinning area, and the solder balls are located on the etched pins. The manufacturing process comprises the following steps of wafer thinning, wafer scribing, green paint coating of the frame, exposure development, inverse chip assembly, backflow cleaning, plastic packaging, thinning of the back face of the frame, etching and separation of the pins, green paint filling, steel mesh printing and ball mounting, cutting, packaging and delivery. According to the FCQFN encapsulation part preventing the solder balls from collapsing and the manufacturing process of the FCQFN encapsulation part, short circuit is prevented, filling performance of plastic packaging materials is improved, and therefore product reliability is promoted.

Owner:HUATIAN TECH XIAN

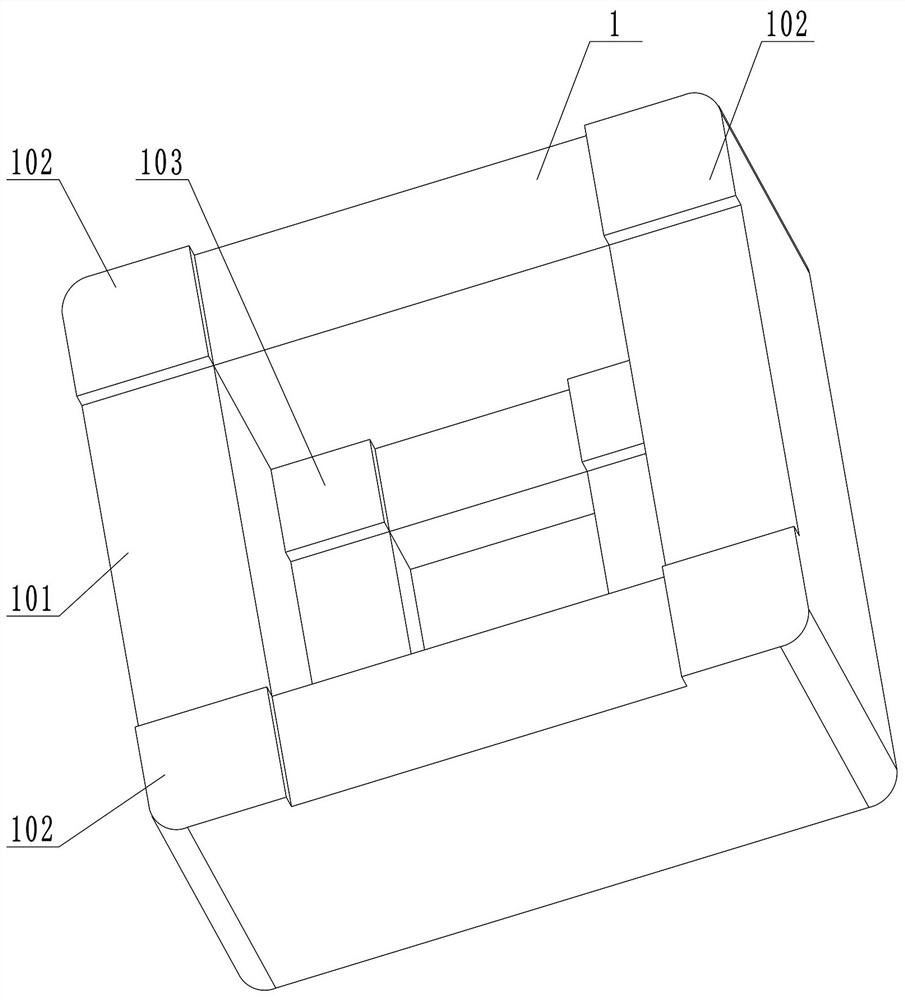

Vertically interconnected microwave polarized synthesis circulation assembly

ActiveCN108183296AReduce consumptionSimple structureWaveguide type devicesRadio frequencyAntenna feeder

The invention discloses a vertically interconnected microwave polarized synthesis circulation assembly. The vertically interconnected microwave polarized synthesis circulation assembly comprises a base, a double-surface microstrip circuit board, antenna feeder radio frequency coaxial connectors, reception radio frequency coaxial connectors, emission radio frequency coaxial connectors and a circulator, the double-surface microstrip circuit board is arranged on the base, the numbers of the antenna feeder radio frequency coaxial connectors, the reception radio frequency coaxial connectors and theemission radio frequency coaxial connectors are all two, the antenna feeder radio frequency coaxial connectors, the reception radio frequency coaxial connectors and the emission radio frequency coaxial connectors are vertically arranged on the double-surface microstrip circuit board, the front surface and the rear surface of the double-surface microstrip circuit board are both provided with microstrip lines, the antenna feeder radio frequency coaxial connectors, the reception radio frequency coaxial connectors, the emission radio frequency coaxial connectors and the circulator are separatelyconnected with the microstrip lines of the double-surface microstrip circuit board, and the circulator is arranged on the base and connected with the microstrip lines of the double-surface microstripcircuit board. The vertically interconnected microwave polarized synthesis circulation assembly is advantageous in that the structure is simple, the size and the weight of the polarized synthesis circulation assembly are reduced, and the cost is lowered.

Owner:BEIJING INST OF RADIO MEASUREMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com