Extension pin Fan-out Panel Level ball grid array (BGA) package part and manufacture process thereof

A manufacturing process and packaging technology, used in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of reducing package size, reducing packaging cost, shortening current and signal transmission distance, and achieving low warpage. , The effect of improving product reliability, shortening current and signal transmission distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

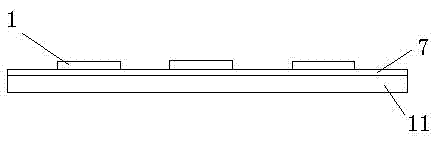

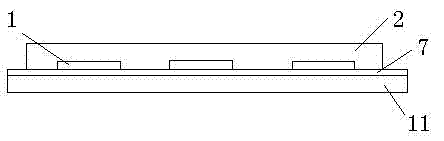

[0028] As shown in the figure, a Fan-out Panel Level BGA package with extended pins is mainly composed of chip 1, plastic compound 2, insulating layer 3, metal copper 4, nickel palladium gold 5, solder ball 6, pad 8, The second insulating layer 9 , the secondary metal copper wiring 12 , and the third insulating layer 13 are composed. The chip 1 is bonded to the double-sided adhesive film 7 by flip-chip bonding, wherein the other side of the double-sided adhesive film 7 is bonded to the high-temperature-resistant glass 11, and the chip 1 is then plastic-sealed with a plastic sealing compound 2, Then manually tear off the double-sided adhesive film 7 together with the high-temperature-resistant glass 11, and then turn the plastic-encapsulated chip 180 degrees as a whole, so that the chip 1 is facing upwards, and lay an insulating layer 3 on the plastic-encapsul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com