A/B siro spinning slub yarn produced from cotton fiber, viscose fiber and polyester fiber and its blending process

A viscose fiber and polyester fiber technology is applied in the field of A/B siro spinning slub yarn and its blending process. precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

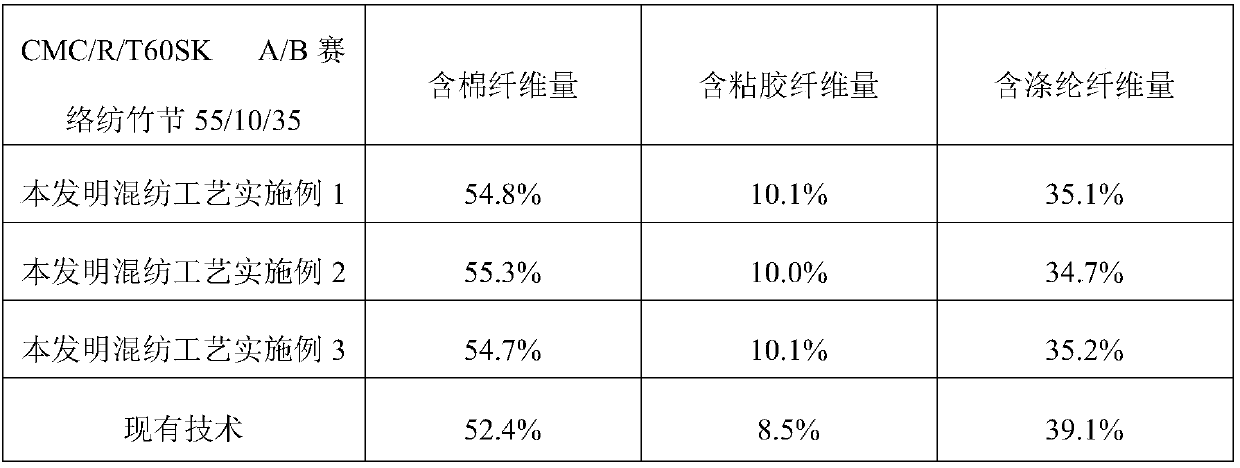

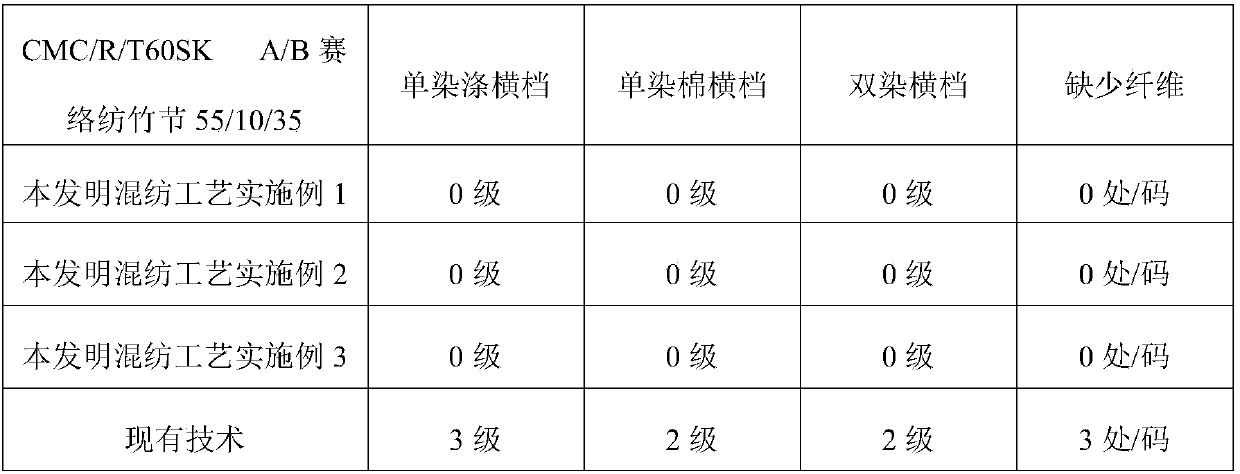

Embodiment 1

[0034] Embodiment 1: the present invention provides a kind of A / B siro spinning slub yarn and its blending process produced by cotton fiber, viscose fiber and polyester fiber, in this A / B siro spinning slub yarn, Cotton fiber is 54.8%, viscose fiber is 10.1%, polyester fiber is 35.1%.

[0035] The method for controlling the blending ratio of A / B siro spinning slub yarns includes: cotton fibers are pre-drawn after cleaning, carding, pre-drawing, sliver winding, combing, and one pre-combination; After the viscose fiber is cleaned, carded, pre-drawn in one pass, and pre-drawn in the second pass, the viscose fiber pre-drawing is obtained; the cotton fiber pre-drawing is mixed with the viscose fiber pre-drawing, and the two fibers are mixed evenly The cooked sliver is then fed into the roving frame to produce A roving; the polyester fiber is fed into the roving frame to produce B roving after cleaning, carding, one-stage drawing, and two-stage drawing; the A roving is combined with...

Embodiment 2

[0044] Embodiment 2: the present invention provides a kind of A / B siro spinning slub yarn and its blending process produced by cotton fiber, viscose fiber and polyester fiber, in this A / B siro spinning slub yarn, Cotton fiber is 55.3%, viscose fiber is 10.0%, and polyester fiber is 34.7%.

[0045] The method for controlling the blending ratio of A / B siro spinning slub yarns includes: cotton fibers are pre-drawn after cleaning, carding, pre-drawing, sliver winding, combing, and one pre-combination; After the viscose fiber is cleaned, carded, pre-drawn in one pass, and pre-drawn in the second pass, the viscose fiber pre-drawing is obtained; the cotton fiber pre-drawing is mixed with the viscose fiber pre-drawing, and the two fibers are mixed evenly The cooked sliver is then fed into the roving frame to produce A roving; the polyester fiber is fed into the roving frame to produce B roving after cleaning, carding, one-stage drawing, and two-stage drawing; the A roving is combined ...

Embodiment 3

[0054] Embodiment 3: the present invention provides a kind of A / B siro spinning slub yarn and its blending process produced by cotton fiber, viscose fiber and polyester fiber, in this A / B siro spinning slub yarn, Cotton fiber is 54.7%, viscose fiber is 10.1%, and polyester fiber is 35.2%.

[0055] The method for controlling the blending ratio of A / B siro spinning slub yarns includes: cotton fibers are pre-drawn after cleaning, carding, pre-drawing, sliver winding, combing, and one pre-combination; After the viscose fiber is cleaned, carded, pre-drawn in one pass, and pre-drawn in the second pass, the viscose fiber pre-drawing is obtained; the cotton fiber pre-drawing is mixed with the viscose fiber pre-drawing, and the two fibers are mixed evenly The cooked sliver is then fed into the roving frame to produce A roving; the polyester fiber is fed into the roving frame to produce B roving after cleaning, carding, one-stage drawing, and two-stage drawing; the A roving is combined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com