Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

452results about How to "Meet assembly requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

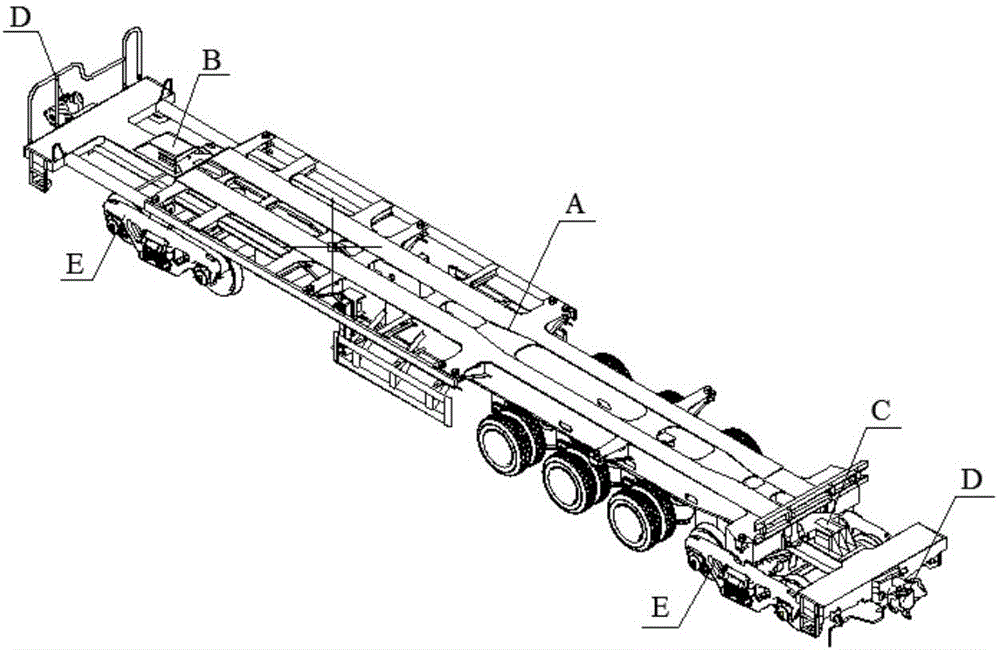

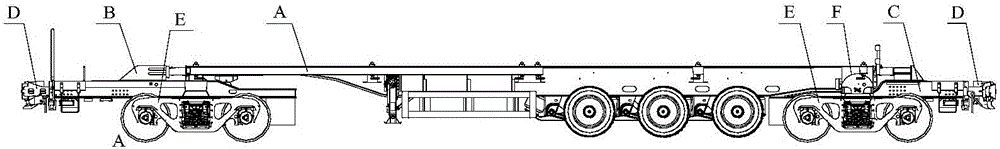

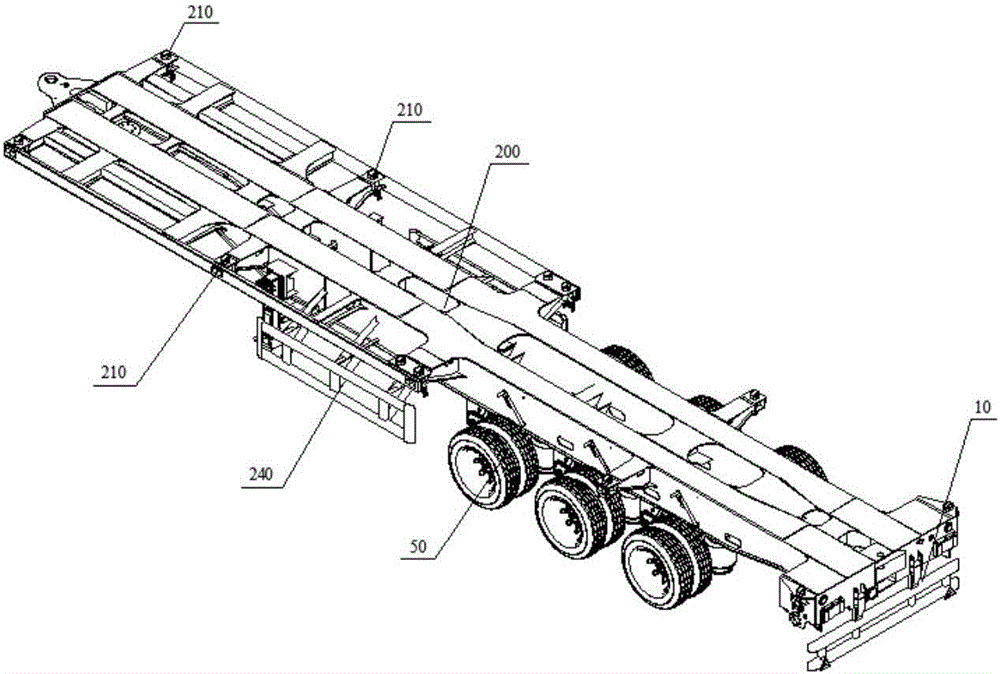

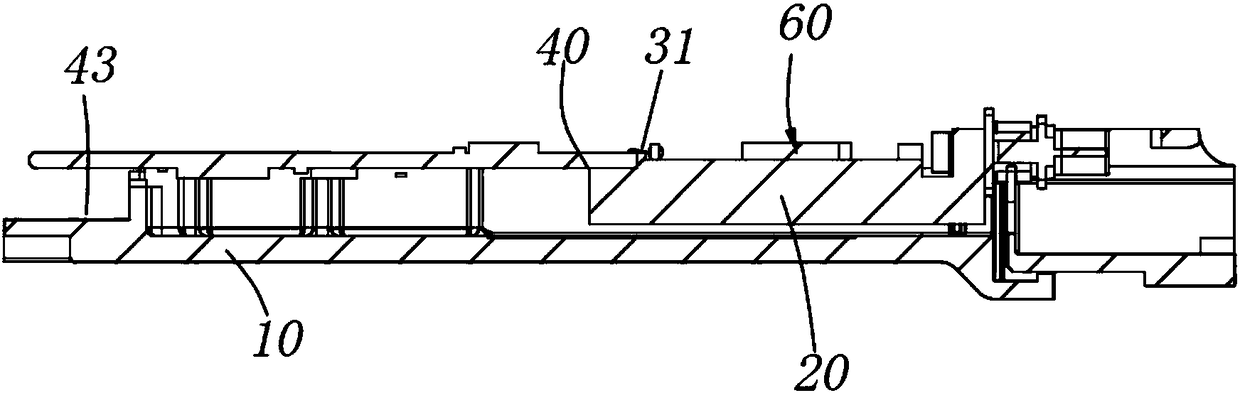

Highway-railway convertible car

ActiveCN106394681AMeet the requirements of transport tractionPrevent and block accessUnderstructuresVehicular safety arrangmentsRotational axisBogie

The invention discloses a highway-railway convertible car, comprising a highway container semi-trailer, a one-position traction bolster assembly, a two-position traction bolster assembly, a coupler buffer device, a bogie and an air and manual brake device. The highway container semi-trailer comprises a frame, container locks, ground jacks, a suspension damping system and protective devices. Two parallel centre sill assemblies are welded by adopting connection plate assemblies, to form the main part for bearing the railway longitudinal force; a secondary hook and a primary hook serve as the connectors and are connected with traction bolster assemblies at the head and the tail, so that the highway-railway convertible car can meet the requirement of railway transportation; when the highway-railway convertible car is used for railway transportation, a rear protective device is overturned upwards from the outside of the car around a rotating shaft, so that the requirements of assembling the railway bogie and the car body are met; and the suspension damping system adopts vibration damping gasbag and lifting gasbag structures, so that the matching of the highway container semi-trailer, a highway semi-trailer tractor and the bogie of the highway-railway convertible car during the conversion between highways and railways and the requirement of the gap between the road tire and the lower margin during railway transportation are met.

Owner:CRRC YANGTZE CO LTD

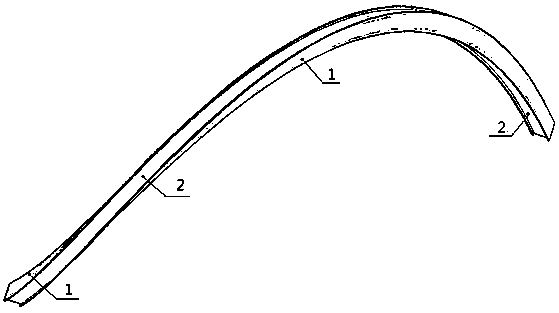

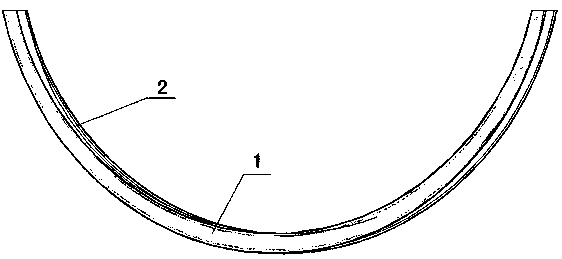

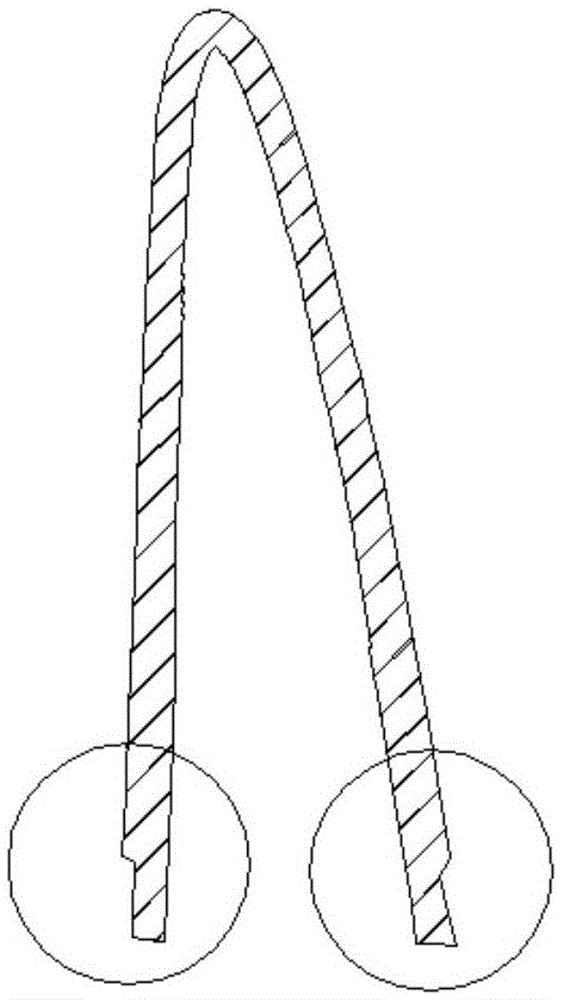

Integral forming method for thin-walled titanium alloy part with irregularly-shaped curved surface and die

InactiveCN102672435AOvercoming shape constraintsOvercome the processShaping toolsLaser beam welding apparatusTitanium alloyMetal

The invention belongs to the field of sheet metal and welding processing, and relates to an integral forming method for a thin-walled titanium alloy part with an irregularly-shaped curved surface. The integral forming method aims at overcoming the defects that the shape of parts processed through the prior art is limited or the procedure and the cost are higher, and effectively ensuring the precision forming of a thin-walled component with an irregular shape. The integral forming method comprises the steps as follows: a parting surface is determined; blanking is carried out; in the preforming step, a plate is bent from a flat into a circular arc through a bending die or a bending machine; welding is carried out; in the hot shaping step, a hot shaping die is put in the inner part of a part that is processed through the assembly welding under the ordinary temperature, and the part is supported tightly due to the dead weight of the die and is heated in a hot shaping machine; and in addition, a pressing machine applies pressure to the hot shaping die when the part is heated until material is softened, so as to enable the part to reach the needed size. The integral forming method comprehensively utilizes the advantages of various processes, can obtain the large-sized thin-walled titanium alloy part with the irregularly-shaped curved surface through only two weld joints, and achieves higher surface quality of the part.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

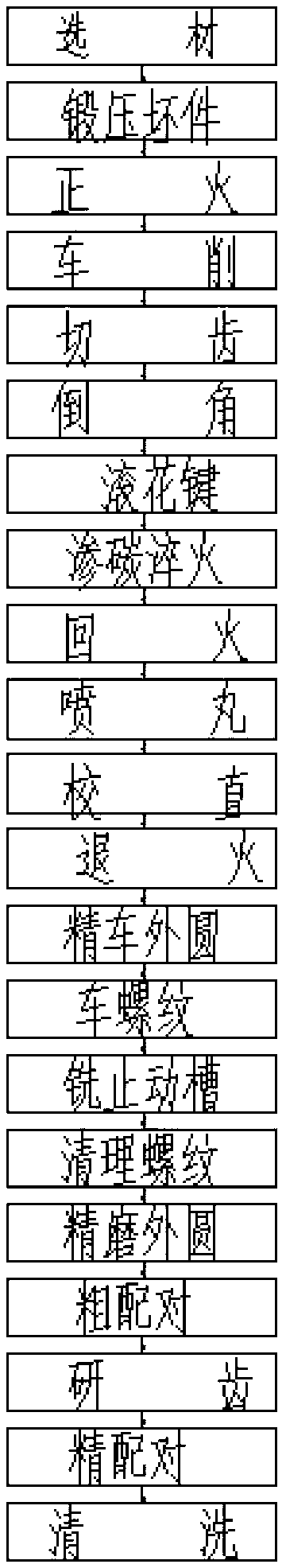

Processing technology for rear axle drive bevel gear

ActiveCN103286533AImprove manufacturing precisionImprove bevel gear accuracyCarbon layerInternal pressure

The invention discloses a processing technology for a rear axle drive bevel gear which is characterized by including steps of selecting raw materials, forging a blank, normalizing, turning, cutting a gear, chamfering, rolling a spline, carburizing and quenching, tempering, blasting shots, straightening, annealing, finely turning an outer circle, threading, milling a locking groove, cleaning a thread, finely grinding an outer circle, roughly matching, shaving the gear, finely matching and rinsing, and obtaining a finished product after rinsing the a workpiece. By the processing technology, machining precision of threads of the rear axle drive bevel gear is improved and reaches a grade of H6; quenching to harden the carbon layer is totally omitted through machining after heat treatment; hardness of a product surface and a core is reduced after annealing, internal pressure of the gear is eliminated, and a metallographic structure of the core of the gear is improved; the processing technology for the gear axle drive bevel gear is high in precision, and requirements of assembling is favorably achieved; service life of the gear axle drive bevel gear is prolonged.

Owner:重庆市綦江区华丰变速箱有限公司

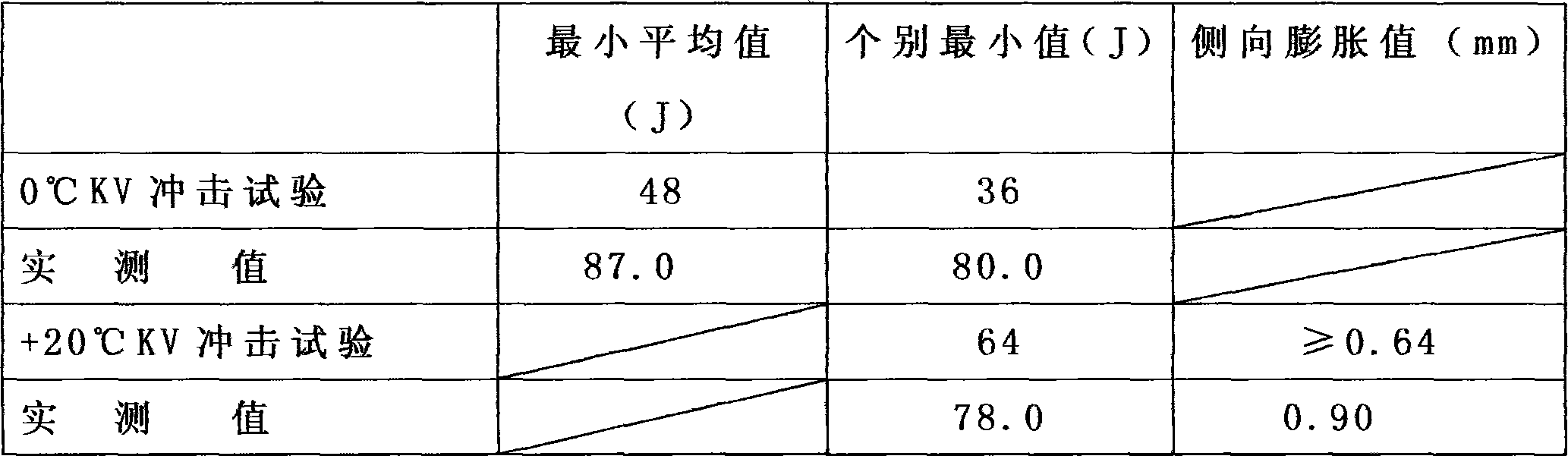

Million - kilowatts class nuclear power station reactor main bolt production process

ActiveCN101169150AUniform tissueFully heatedNuclear energy generationScrewsNuclear engineeringNuclear power

The invention discloses a pile main bolt manufacturing technique of a million kilowatt grade nuclear power station. The manufacturing technique includes material-selecting, melting, heating, forging, cooling, after-forging heat treatment, defect-detecting, and forging capability heat treating. When selecting the material, the microelement content of the materials is controlled, the heat preserving duration in the intermediate temperature stage is prolonged, the heat raising and the heat preserving duration in the high temperature stage are reduced, the distortion volume in the course of the forging is controlled between 30 percent and 70 percent, the forging rate reaches 5 above; after-forging heat treatment, ultrasonic defect detecting, and forging capacity heat treating are conducted when the forging is finished. The main bolt produced according to the manufacturing technique of the invention can improve the impact value under the circumstance that the intensity keeps unchanged, theproduct can meet the RCC-M standard requirements completely, and the reliability and the safety of the pile pressure container using the main bolt of the million kilowatt grade nuclear power station can be ensured.

Owner:GUIZHOU AEROSPACE XINLI CASTINGSAND FORGINGS

Temperature compensation method and system for silicon micro-accelerometer based on improved PSO (Particle Swarm Optimization) optimized neural network

InactiveCN108120451AExpand the search spaceDiversity guaranteedTesting/calibration of speed/acceleration/shock measurement devicesNeural learning methodsAccelerometerEngineering

The invention relates to a temperature compensation method and system for a silicon micro-accelerometer based on an improved PSO (Particle Swarm Optimization) optimized neural network, and the temperature compensation method and the temperature compensation system are designed for improving temperature compensation precision. The method comprises the following steps: acquiring a training sample ofPSO optimization and a BP (Back Propagation) neutral network; constructing the BP neutral network on the basis of the training sample; using an optimal extreme point optimized by an adaptive weight PSO as an initial weight value and a threshold value of a BP neutral network model; introducing mutation operation into a PSO algorithm, updating the particles, then reinitializing the particles at a certain probability and expanding a population search space which is continuously reduced in iteration by the mutation operation; establishing the BP neutral network by calling the parameters, realizing real-time temperature compensation of the silicon micro-accelerometer and outputting a compensation result. The temperature compensation method and the temperature compensation system disclosed by the invention have the advantages that the problems of solving of an optimal compensation result and temperature globality are solved, and finally improved compensation precision and global improvementof the silicon micro-accelerometer are realized.

Owner:SUZHOU UNIV

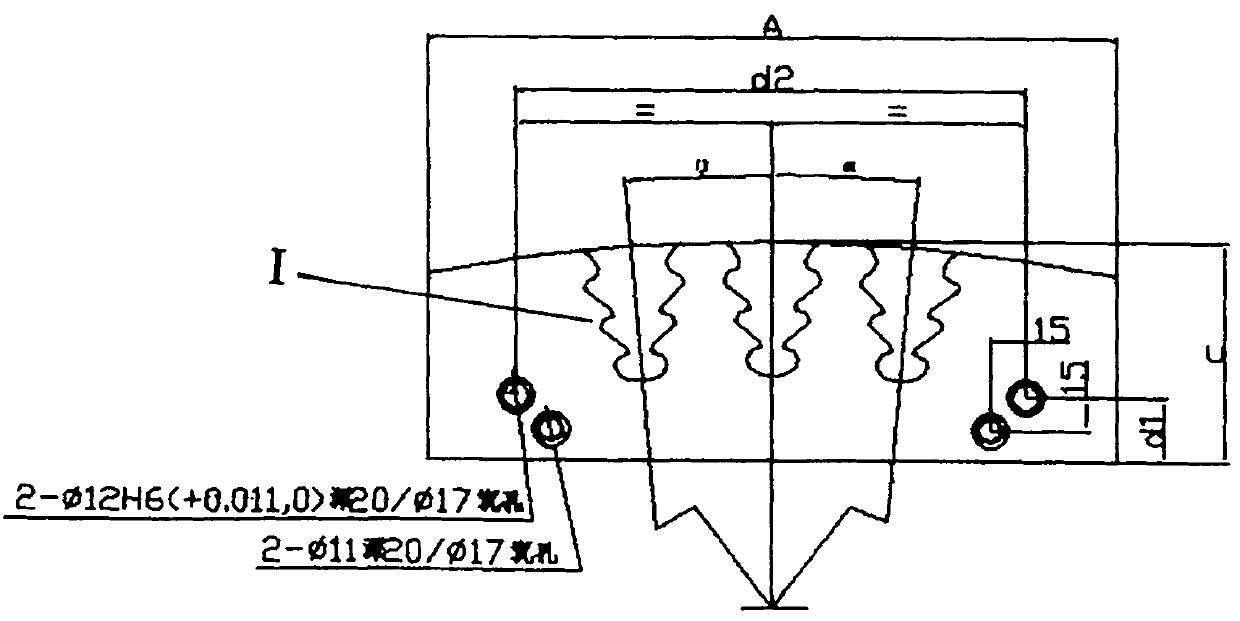

Method for assembling and positioning vertical column array type fuselage wall panel and device thereof

ActiveCN102306207APrecise positioningMeet assembly requirementsSpecial data processing applicationsFuselageThree dimensional model

The invention discloses a method for assembling and positioning a vertical column array type fuselage wall panel and a device thereof. The method comprises the steps of: firstly, establishing a three-dimensional model of a vertical column array type tool and a fuselage wall panel; then, uniformly dividing a positioning region of the wall panel in the three-dimensional model; uniformly arranging positioning points of the wall panel within the range of the wall panel; accurately positioning the model of the wall panel; reading a coordinate; controlling each positioning point of the tool to moveto a specified coordinate; measuring actual coordinate values; computing and generating coordinate compensation values; and controlling for movement. According to the invention, on the basis of completely discarding a template, the wall panel is ensured to be accurately positioned according to a design requirement; and different assembly requirements are satisfied.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Steam turbine blade fitting measuring tool and processing technology thereof

ActiveCN101947723AAvoid Batch Quality IssuesShorten the manufacturing cycleMetal working apparatusImpellerSteam turbine blade

The invention discloses a steam turbine blade fitting measuring tool and a processing technology thereof. The fitting measuring tool is a fake impeller simulating an arc of steam turbine rotor impeller, the fake impeller is provided with a plurality of blade assembling slots distributed in a radial manner, the contour line, the radial radius and the circumferential graduation of the assembling slot are all consistent with those of the assembling slot of real impeller, and the bottom of the slot is provided with a blade locking screw hole and screws. The fitting measuring tool is used for the pre-assembly of blades, in order to inspect the quality indexes of assembly in advance, avoid the quality-related problem of blades in batch, reduce maintenance rate, enable blades to meet the assembly requirement in production workshop, enhance working efficiency, shorten assembly period of unit, and lower economic losses.

Owner:DONGFANG TURBINE CO LTD

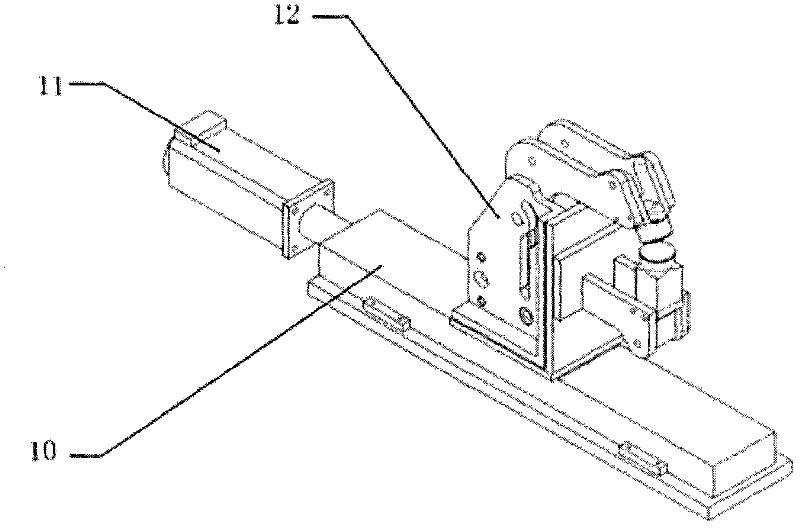

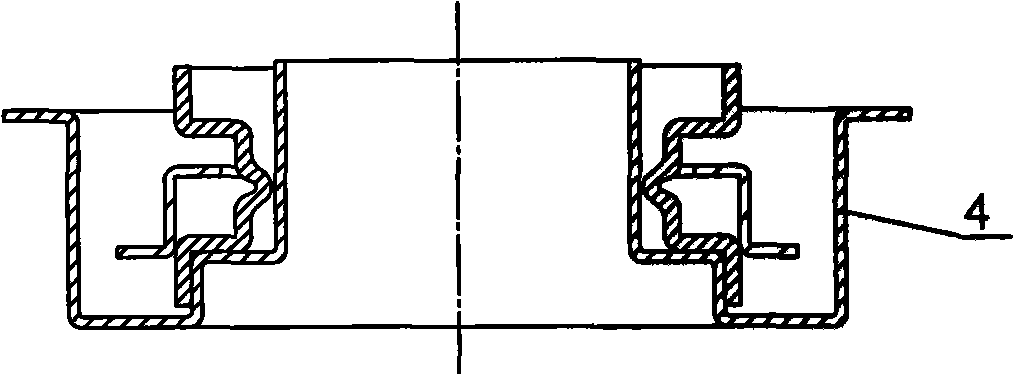

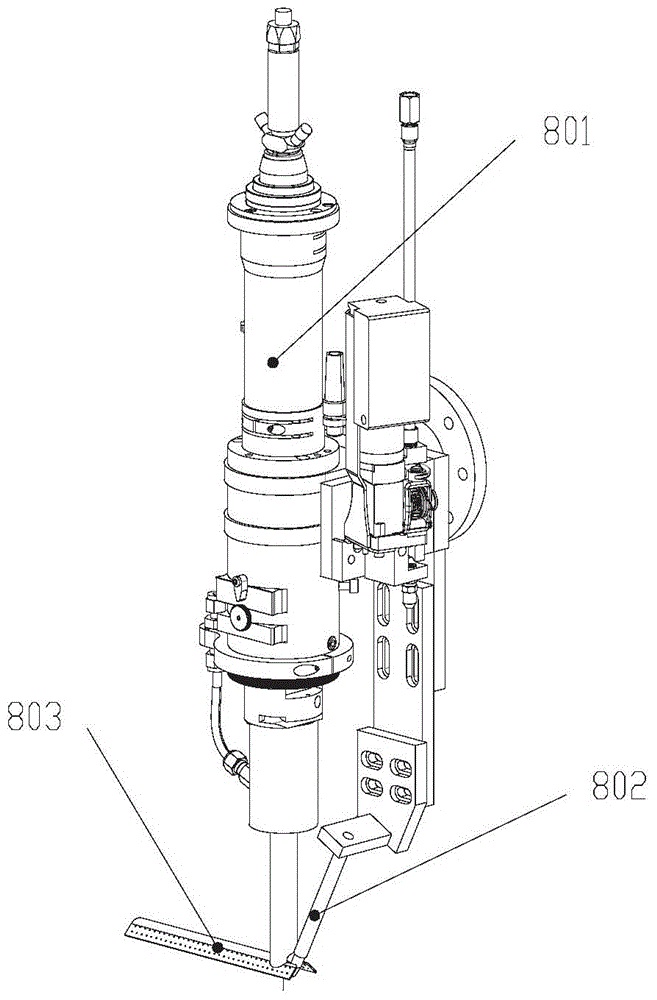

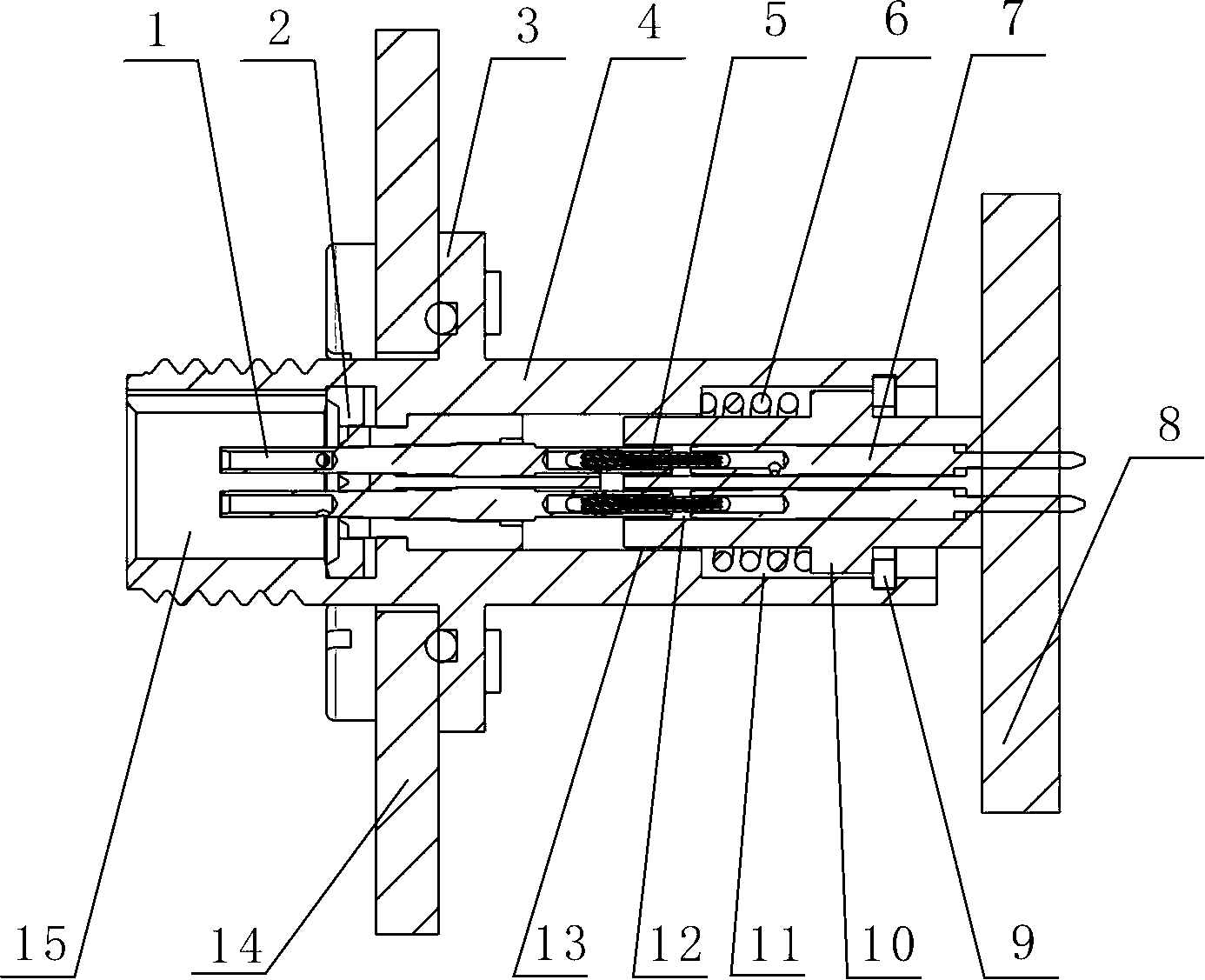

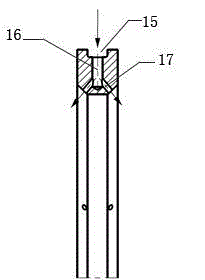

Water sealing stationary ring subgroup assembling machine

ActiveCN101318289AMeet assembly requirementsEasy to put inAssembly machinesMetal working apparatusEngineeringAssembly machine

The invention discloses an assembly machine for water seal static ring components, which mainly comprises a bottom plate (13), a worktable (12), a lead rail (32), an indenter device I, a pressure plate device, a slide carriage device and mechanical grippers matched with the pressure plate device and the slide carriage device; the worktable (12) is arranged above the bottom plate (13); the indenter device I is arranged at one end of the bottom plate (13); the pressure plate device is arranged below the indenter device I and is also arranged on the bottom plate (13); the axis of a through hole (17) of the pressure plate device and the axis of an indenter I (15) of the indenter device I are in the same line; the minimum diameter of the through hole (17) is larger than the external diameter of the indenter I (15); the slide carriage device is matched with the lead rails (32) arranged on the bottom plate (13) in a sliding way. The assembly machine for water seal static ring components is high in assembly precision and efficiency, simple and convenient in operation.

Owner:NINGBO VULCAN TECH CO LTD

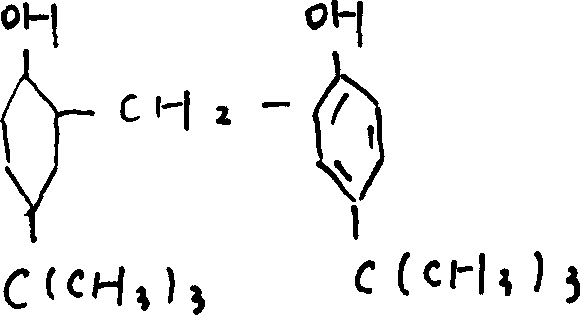

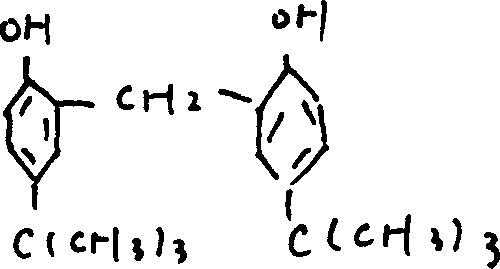

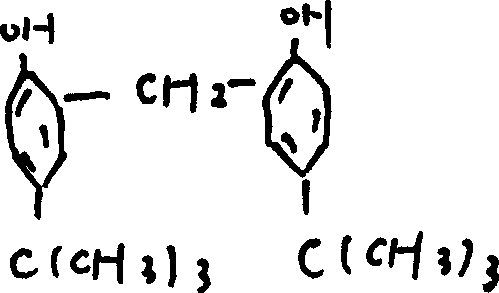

Concentrated sulfuric acid resistant fluoro-rubber sealing spacer

ActiveCN1699463ANo decrease in hardnessMeet assembly requirementsOther chemical processesPolymer scienceBarium sulfate

The invention relates to a concentrated sulfuric acid resistant fluoro-rubber sealing spacer which comprises the following raw material (by weight ratio), terafluoroethylene-propylene rubber 60-65, type 23 fluoro rubber 35-40, dicumyl peroxide 2.5-2.8, triallyl cyanurate 4-4.5, spraying carbon black 15-18, barium sulfate 15-18, lubricating agent 2-2.2.

Owner:蒋惠成

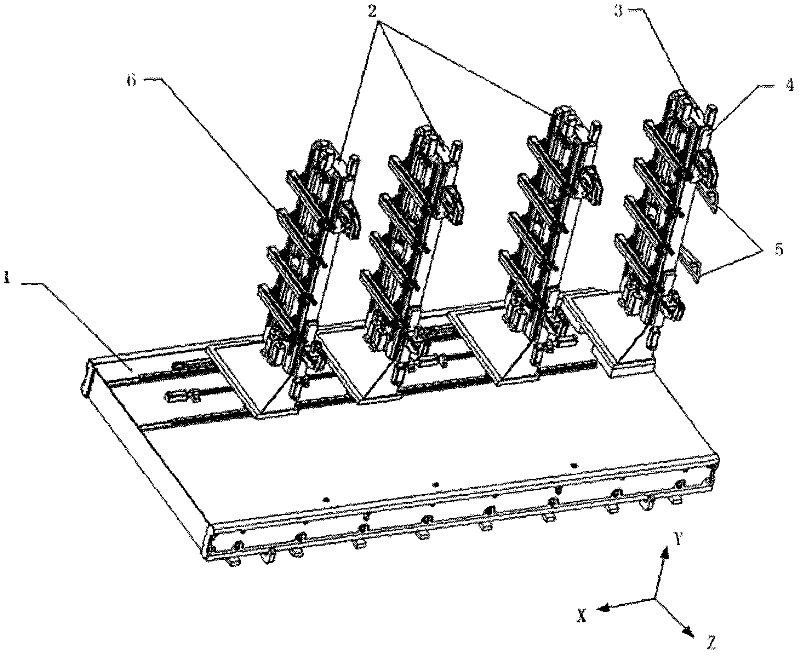

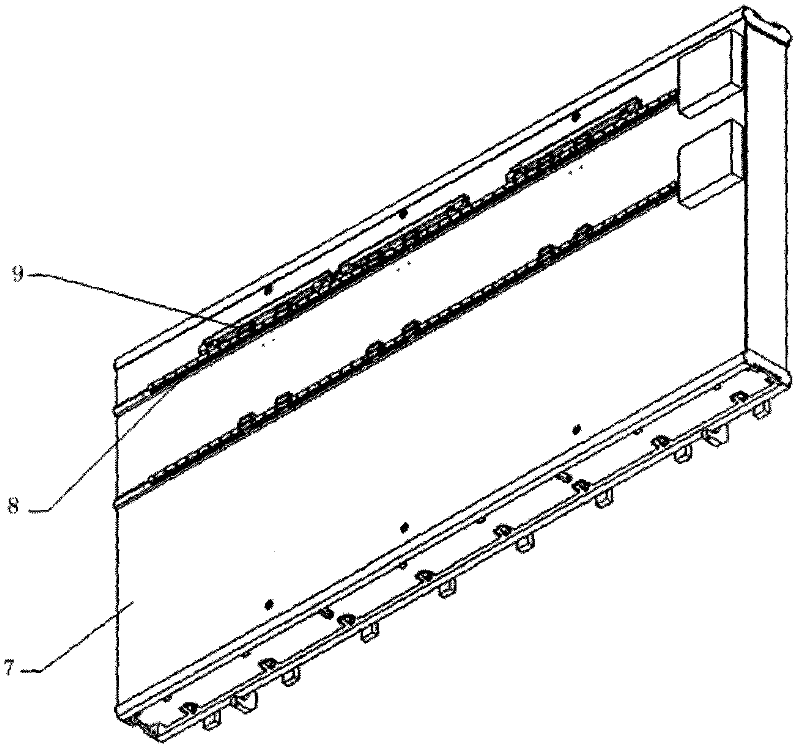

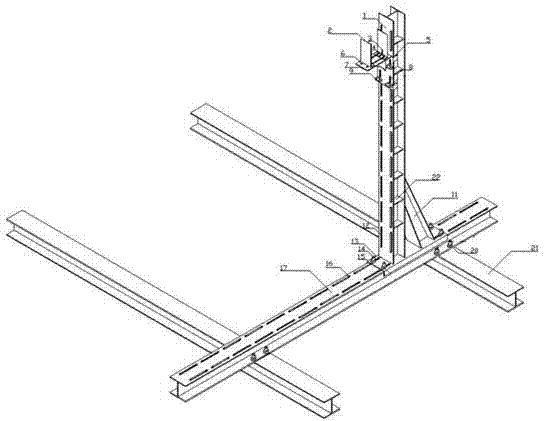

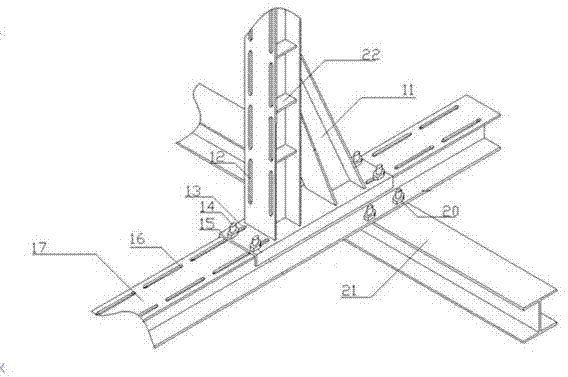

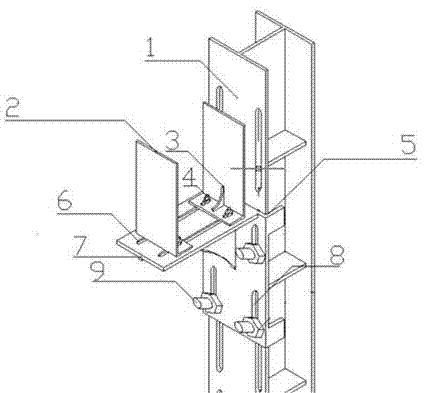

Adjustable splicing mould bed

ActiveCN104259717ASolve the adjustmentSolve usabilityWelding/cutting auxillary devicesAuxillary welding devicesCantileverMaterials science

Provided is an adjustable splicing mould bed. An I steel platform is connected with an I steel cross bar through a bolt, the I steel cross bar is connected with an I steel vertical bar through groove steel I, the back of the groove steel I is welded with the I steel vertical bar, the front of the groove steel I is clamped on the I steel cross bar through a slot, a plurality of long round holes are formed in the I steel cross bar and the groove steel I, a cantilever plate is arranged on one side of the inner side of the I steel vertical bar, the cantilever plate is connected with the I steel vertical bar through groove steel II, the back of the groove steel II is welded with the cantilever plate, the front of the groove steel II is connected with the I steel vertical bar through a bolt, a plurality of long round holes are formed in the I steel vertical bar and the groove steel II, two clamping plates are arranged on the cantilever plate, the bottoms of the clamping plates are connected with the cantilever plate through the bolts, and a plurality of long round holes are formed in the cantilever plate. The size of the mould bed can be changed freely by adjusting the bolts to meet the requirement for assembly of mould beds of different sizes. The mould bed is convenient to disassemble and capable of being used in circulation.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

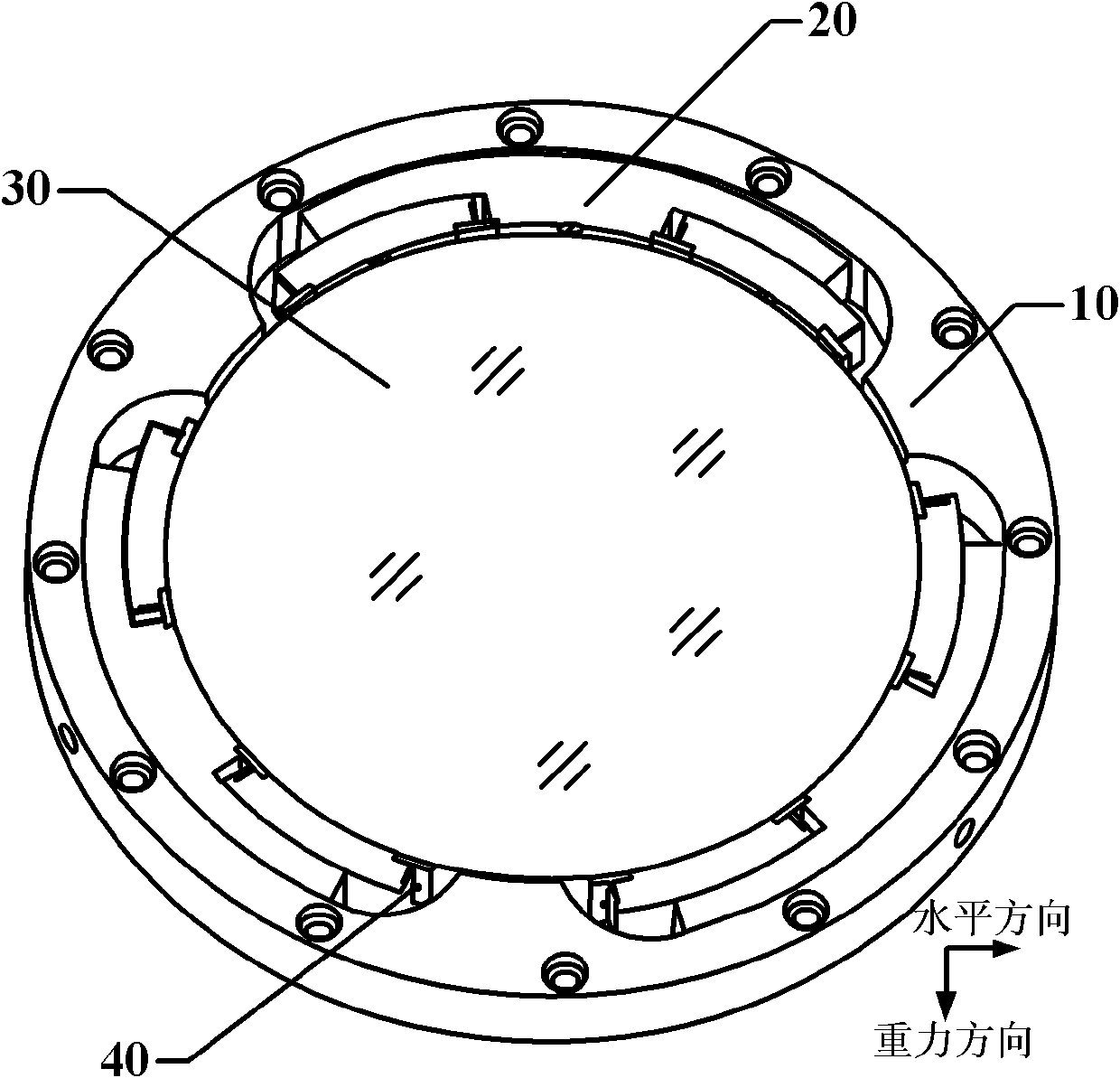

Optical element fixing device and installation method thereof

The invention provides an optical element fixing device and an installation method thereof. The optical element fixing device comprises a microscope base, flexible elements and ball pins, wherein at least three grooves are formed at equal intervals on the inner wall of the microscope base; the flexible elements are arranged in the grooves in a matching way; and the ball pins are used for connecting the flexible elements with the microscope base. The radial force of the fixing device is controlled by controlling the friction coefficient and transition matching way between the ball pins and corresponding conical sleeves as well as the friction coefficient and transition matching way between a cylindrical pin and a corresponding conical sleeve, so that the influences caused by the thermal deformation and assembly stress deformation of an optical element or optical assembly on the surface type of the optical element are controlled; a flexible element multipoint gluing support structure is adopted, so that the influence of gravity on the surface type is reduced, and release of the thermal stress of an annular optical element in a circumferential direction is realized simultaneously by using the low rigidity characteristics of the flexible elements in a direction which is vertical to the optical axis; and the fixing device provided by the invention has the advantages of simple structure, high stability, convenience for installing, accurate positioning, firm and reliable fixing and wide application range.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Super deep-draw fingerprint resistant electro-galvanized plate and manufacturing method thereof

InactiveCN104862592AExcellent deep drawing performanceSolve the technical problems of assembly difficultiesReduction rateChemical composition

The invention discloses a super deep-draw fingerprint resistant electro-galvanized plate and a manufacturing method thereof. The super deep-draw fingerprint resistant electro-galvanized plate comprises the following chemical components in percentage by weight: less than or equal to 0.002 percent of C, less than or equal to 0.01 percent of Si, 0.06-0.12 percent of Mn, less than or equal to 0.012 percent of P, less than or equal to 0.009 percent of S, 0.065-0.085 percent of Ti, 0.02-0.05 percent of sol Al, less than or equal to 0.003 percent of N, and the balance of Fe and inevitable impurities. The manufacturing method comprises the steps of molten iron desulphurization, smelting in a converter, vacuum treatment, continuous casting, hot rolling, cold rolling, continuous annealing and reeling, wherein the heating temperature of the hot rolling is 1,000-1,200 DEG C, the temperature of the final rolling is 800-1,000 DEG C, five times of cold rolling is conducted after the continuous hot rolling, the reduction rate of the cold rolling is controlled to be 73-83%, the temperature of continuous annealing is 810-860 DEG C, the time of the continuous annealing is 15-80 s, and then the electrogalvanizing and fingerprint resisting treatment is conducted after leveling and withdrawal straightening. The electro-galvanized plate has excellent stamping processing and fingerprint resisting performance, and the manufacturing method of steel is simple in process flow and low in production cost.

Owner:武钢集团有限公司

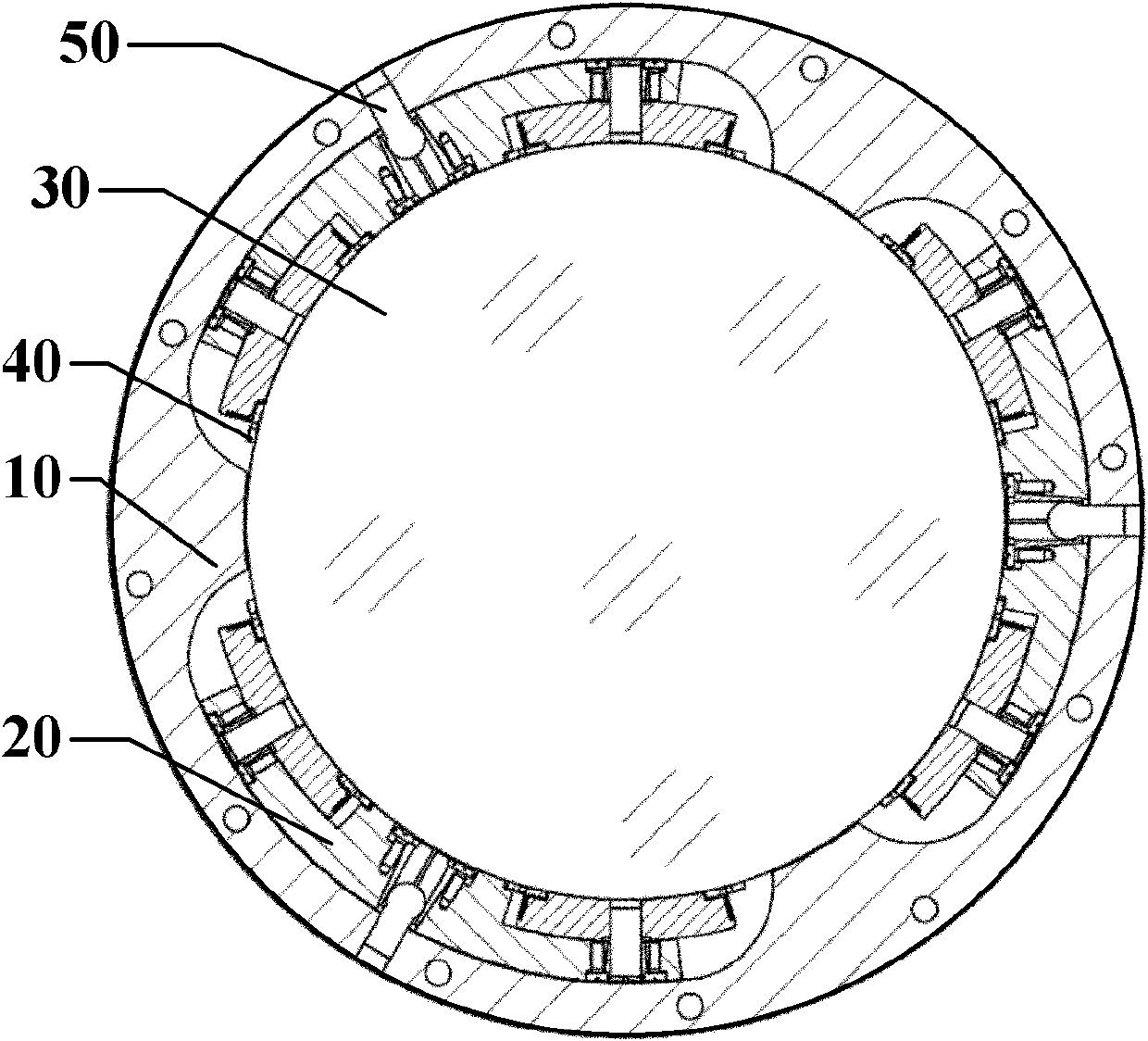

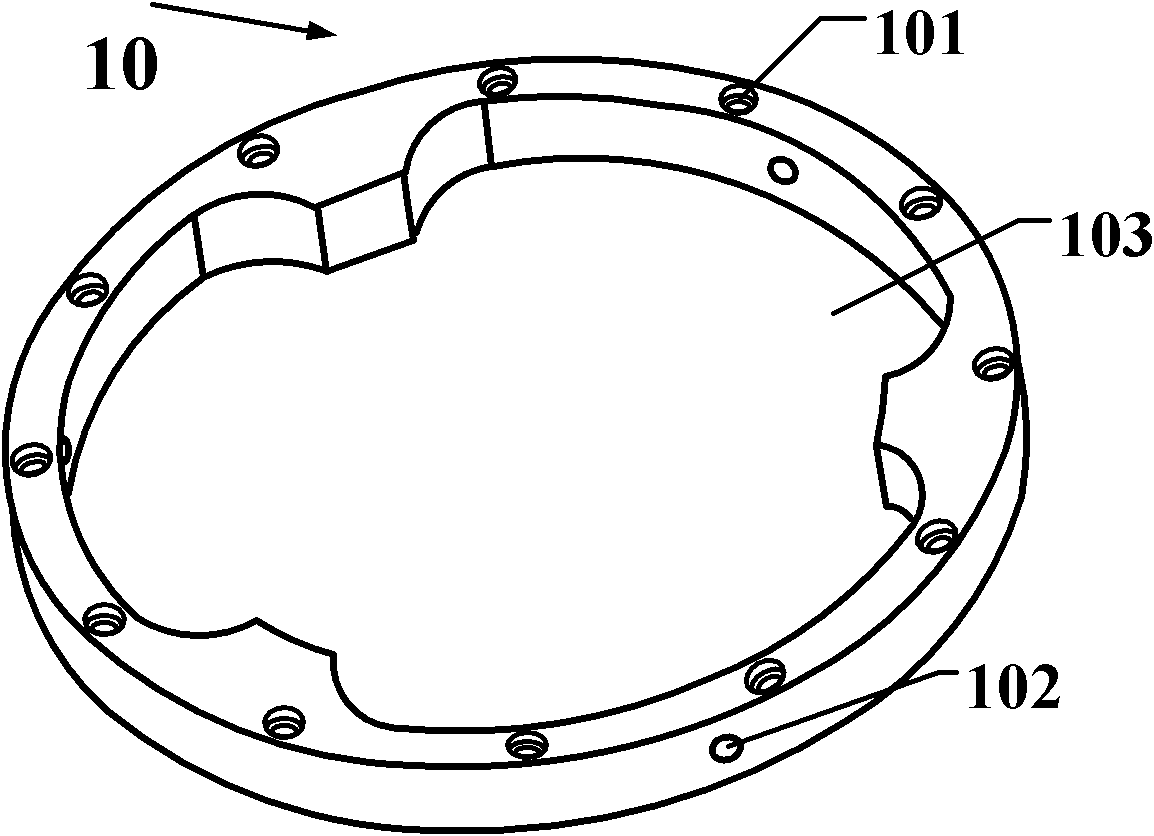

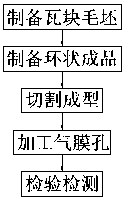

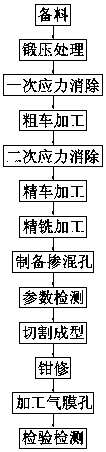

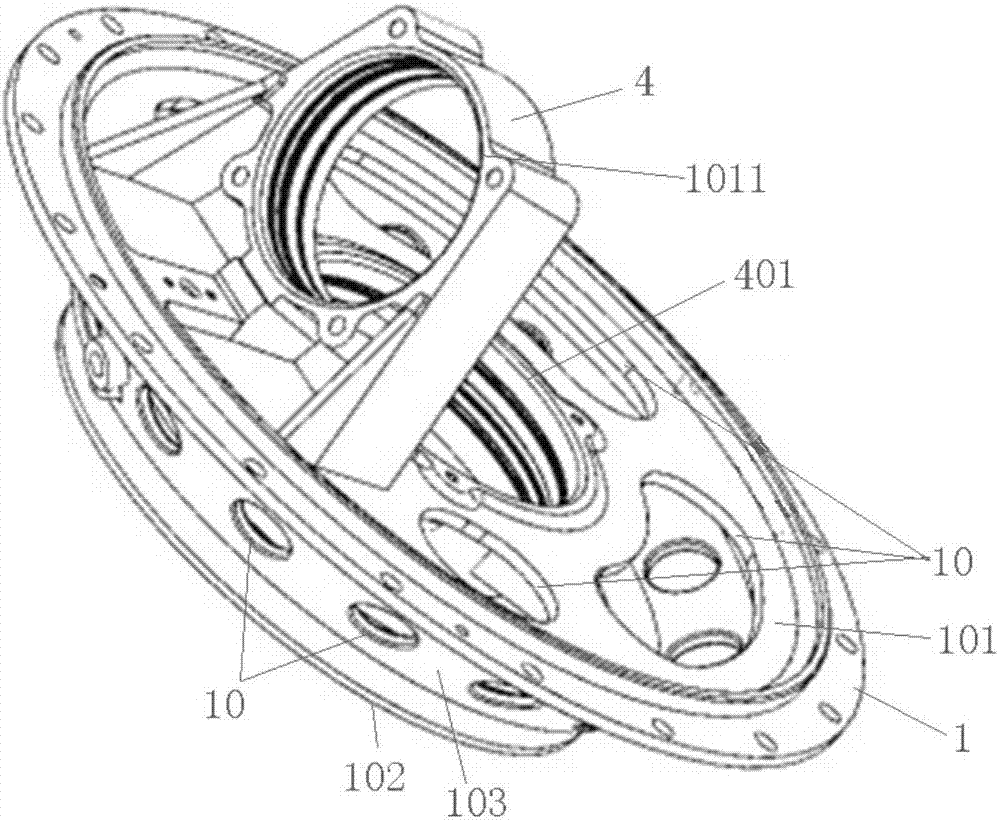

Process for machining flame cylinder floating wall tile blocks by adopting annular forgings

ActiveCN108381122AShort manufacturing cycleIncrease productivityContinuous combustion chamberRoughcastGas turbines

The invention relates to the field of aero-engines and gas turbines, in particular to a process for machining flame cylinder floating wall tile blocks by adopting annular forgings. The process comprises a step of preparing annular finished products and a step of molding by cutting; the step of preparing the annular finished products is to machine tile block blanks to prepare the annular finished products; the sizes of the annular finished products are the same with the sizes of cylindrical structures formed by connecting multiple tile blocks end to end; the step of molding by cutting is to cutthe annular finished products to prepare multiple independent tile block initial finished products, so that multiple floating wall tile blocks can be prepared through once machining flow, and the production efficiency is improved; and meanwhile, correspondingly, approximate location degrees of multiple structures on each floating wall tile block can be easily guaranteed, so that the sizes of themultiple floating wall tile blocks prepared in each process flow are the same, structure-stable floating walls are formed in the same flame cylinder, the module assembly requirements can be preferablymet, and the flame cylinders can stably work for a long time.

Owner:广汉天空动力机械有限责任公司

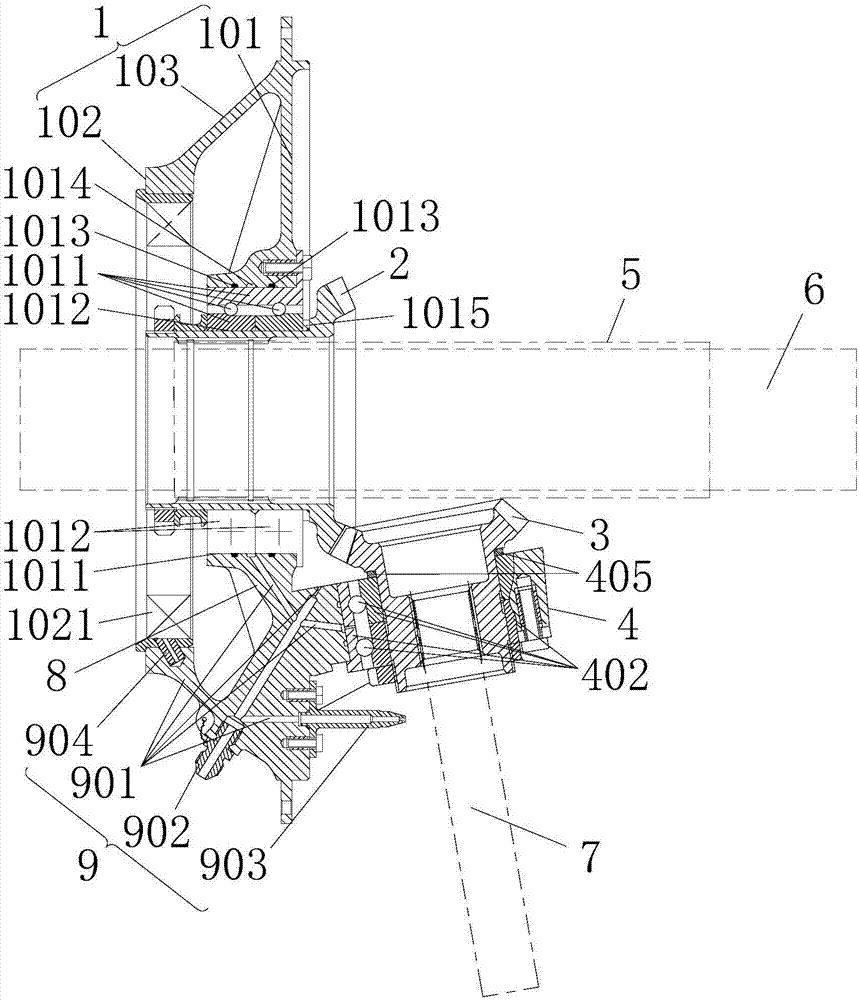

Oblique central transmission frame assembly used for aircraft engine and aircraft engine

ActiveCN107218355AStable deliveryIncrease independenceToothed gearingsGear lubrication/coolingAviationCantilever

The invention discloses an oblique central transmission frame assembly used for an aircraft engine and the aircraft engine. The oblique central transmission frame assembly used for the aircraft engine comprises a conical basin-shaped support. The conical basin-shaped support comprises a large end surface, a small end surface and an oblique side surface. A hollow inner cavity is formed in the conical basin-shaped support. A first bearing pedestal hole used for assembling a drive bevel gear along the conical basin-shaped support is formed in the axial center of the large end surface of the conical basin-shaped support. The large end surface of the conical basin-shaped support is provided with a cantilever bearing pedestal used for assembling a driven circular-arc bevel gear in conical tooth engagement with the drive bevel gear. The cantilever bearing pedestal inclines towards the central axis of the conical basin-shaped support and overhangs on the large end surface of the conical basin-shaped support. The cantilever bearing pedestal is provided with a second bearing pedestal hole used for assembling the driven circular-arc bevel gear. The bearing hole in the cantilever bearing pedestal is small in stress, and stress of all components of the oblique central transmission frame assembly should meet strength requirements. By adoption of the form of the oblique transmission assembly, the output power of the oblique central transmission frame assembly approximately triples that of up-down vertical transmission.

Owner:CHINA HANGFA SOUTH IND CO LTD

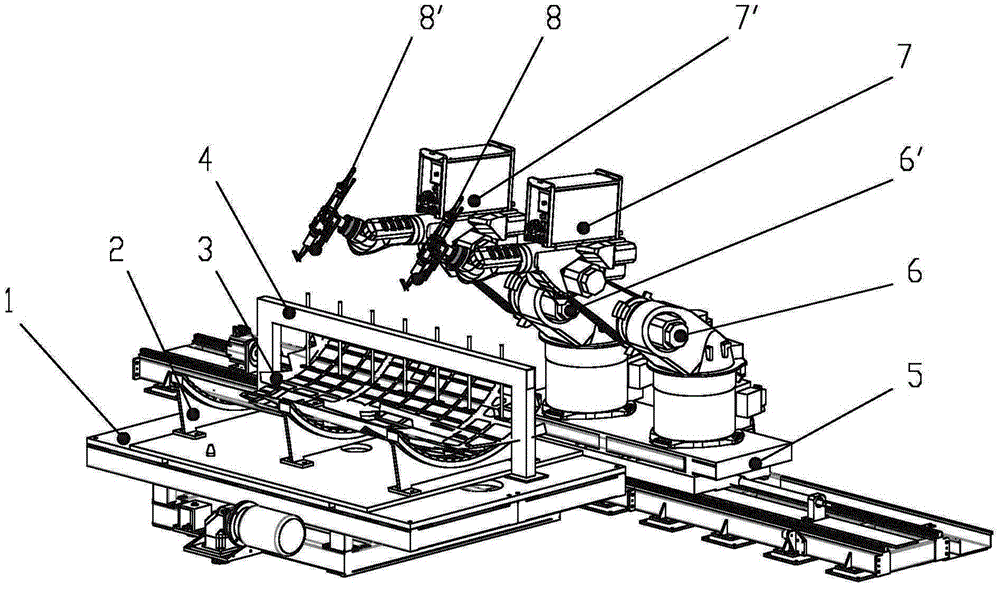

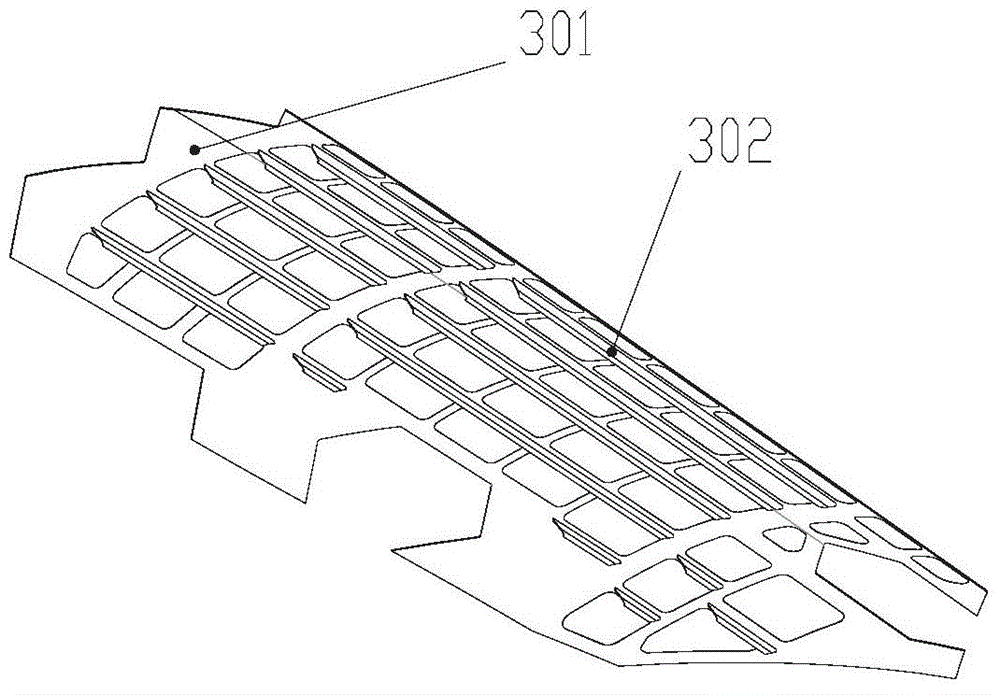

Double-beam laser synchronous welding method for titanium alloy wallboard and rib strip through T-shaped joint

InactiveCN104690425AImprove welding efficiencyTo achieve the purpose of one-time moldingWelding/soldering/cutting articlesLaser beam welding apparatusLaser processingTitanium alloy

The invention relates to a laser processing method and in particular to a double-beam laser synchronous welding method for a titanium alloy wallboard and a rib strip through a T-shaped joint. The titanium alloy wallboard is fixed on a movable worktable through a positioning and supporting seat, wherein the rib strip is perpendicularly arranged on the titanium alloy wallboard and is tightly pressed through a tooling fixture; the T-shaped joint is formed by the rib strip and the titanium alloy wallboard; two sides of the T-shaped joint are synchronous welded through a first laser welding device and a second laser welding device. By virtue of the method, the two sides of the T-shaped joint can be synchronously welded by using two beams of laser; the welding efficiency is improved; the purpose of molding at a time can be achieved.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

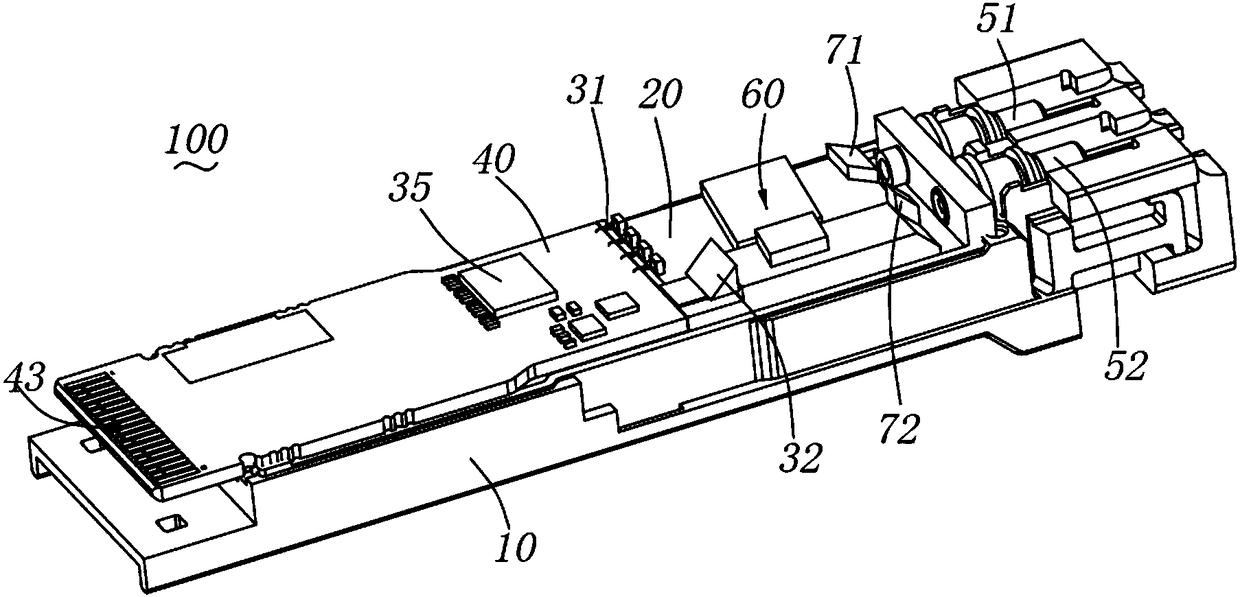

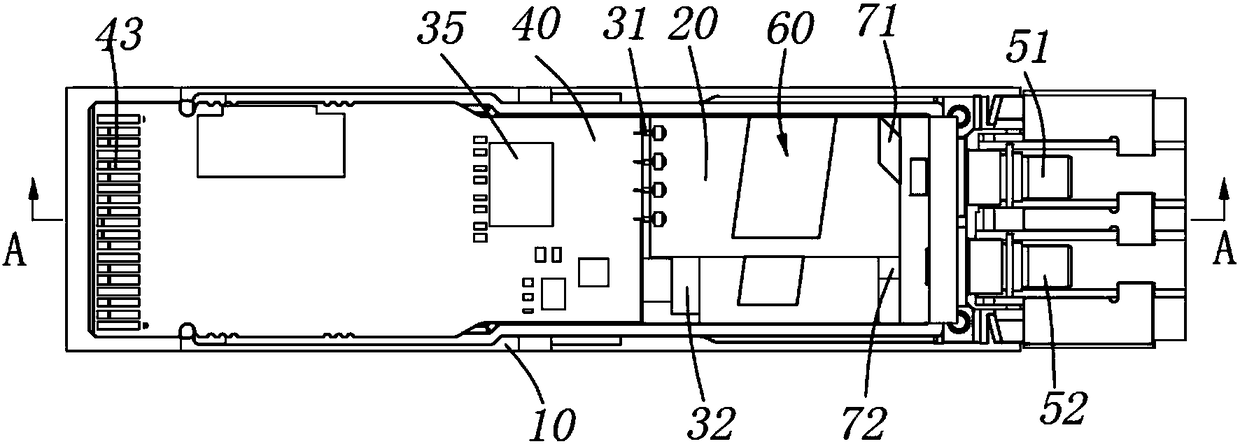

Optical module

ActiveCN109283632AMeet assembly requirementsExcellent high-speed electrical signal transmission performanceCoupling light guidesElectricityOptical Module

The invention discloses an optical module which comprises a housing, a heat sink arranged in the housing, a plurality of lasers arranged on the heat sink, a PCB which is partially arranged on the heatsink, and an optical system arranged in the housing. One end of the optical module is provided with an optical interface, and the other end is provided with an electric interface. The optical systemis arranged between the plurality of lasers and the optical interface. The optical system comprises a wavelength division multiplexer. The PCB is a hard board. The plurality of sets of laser are electrically connected with the PCB. One end of the PCB is fixed to the heat sink, and the other end is constructed to be provided with the electric interface. The optical system guides an optical wave transmitted from the laser to the optical interface. The optical module is a whole hard PCB and supplies better high-speed electric signal transmission performance.

Owner:INNOLIGHT TECHNOLOGY (SUZHOU) LTD

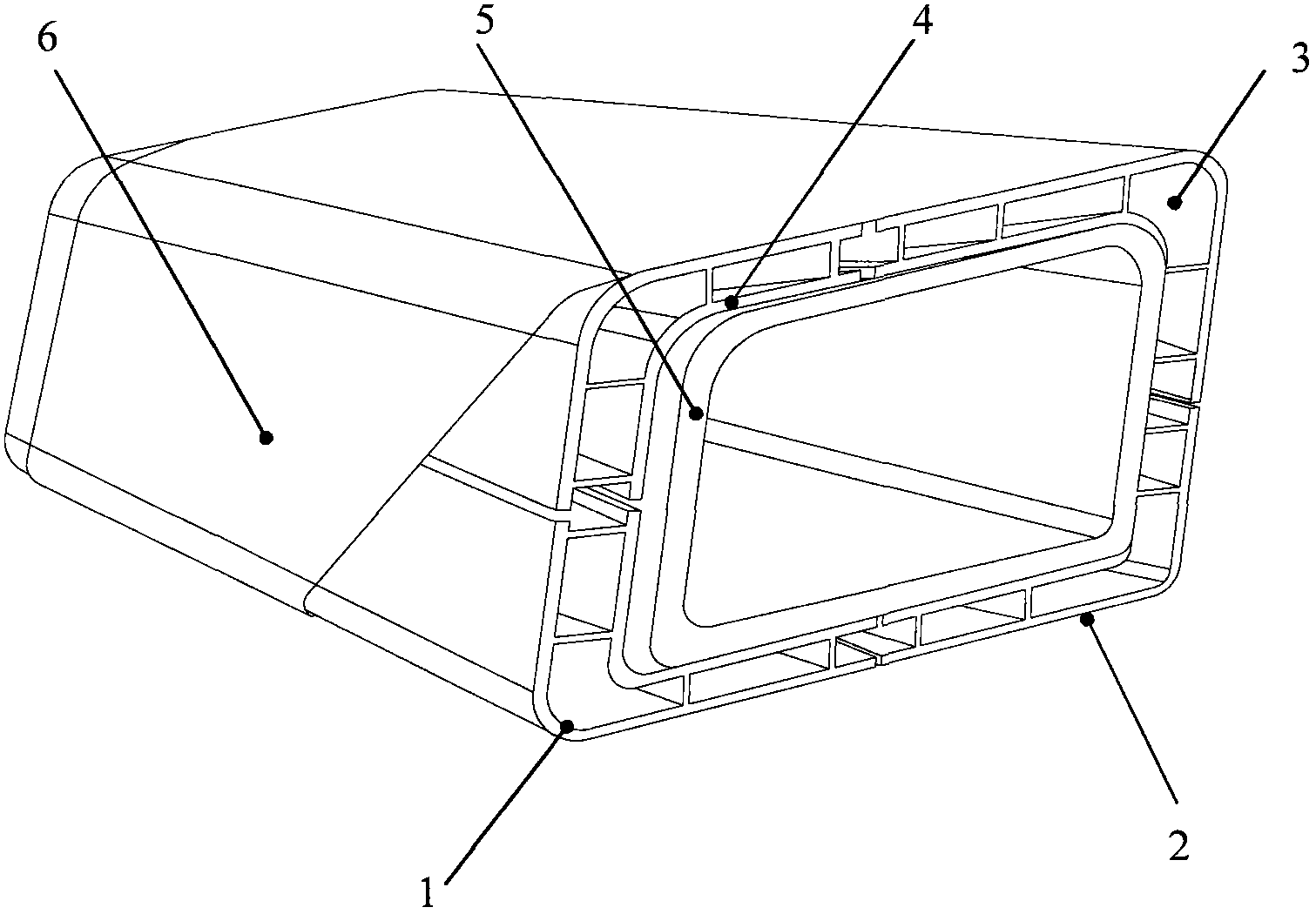

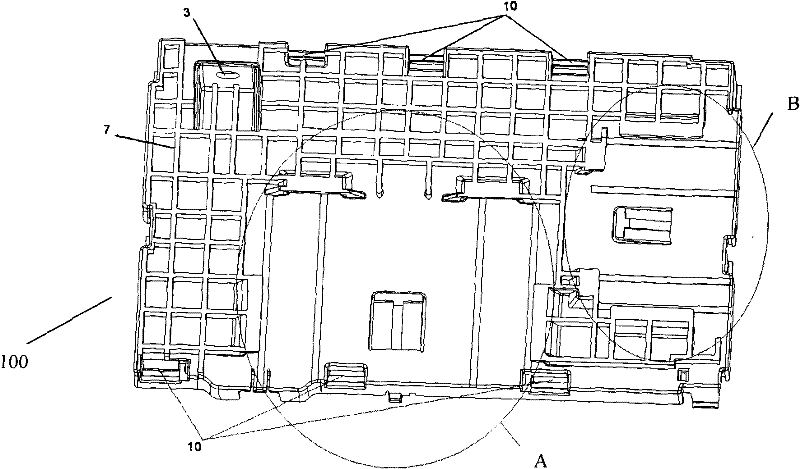

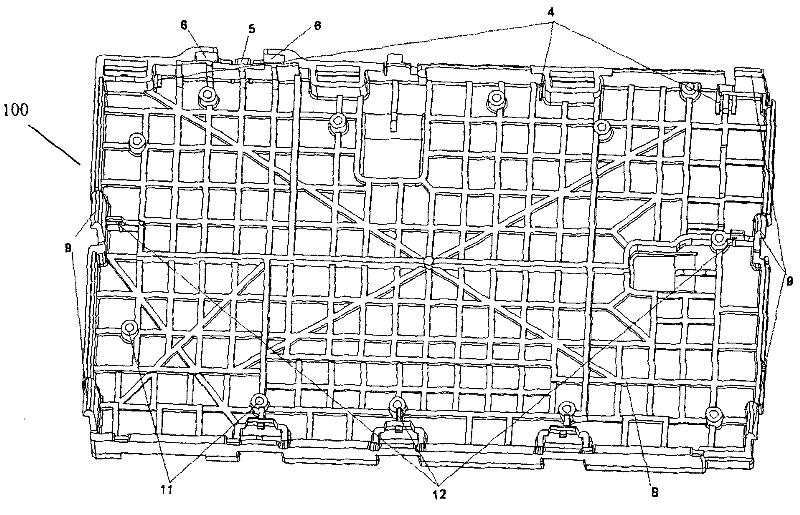

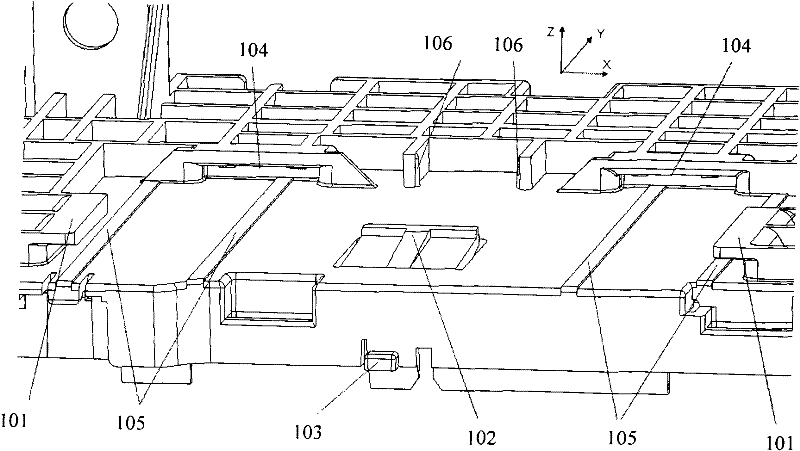

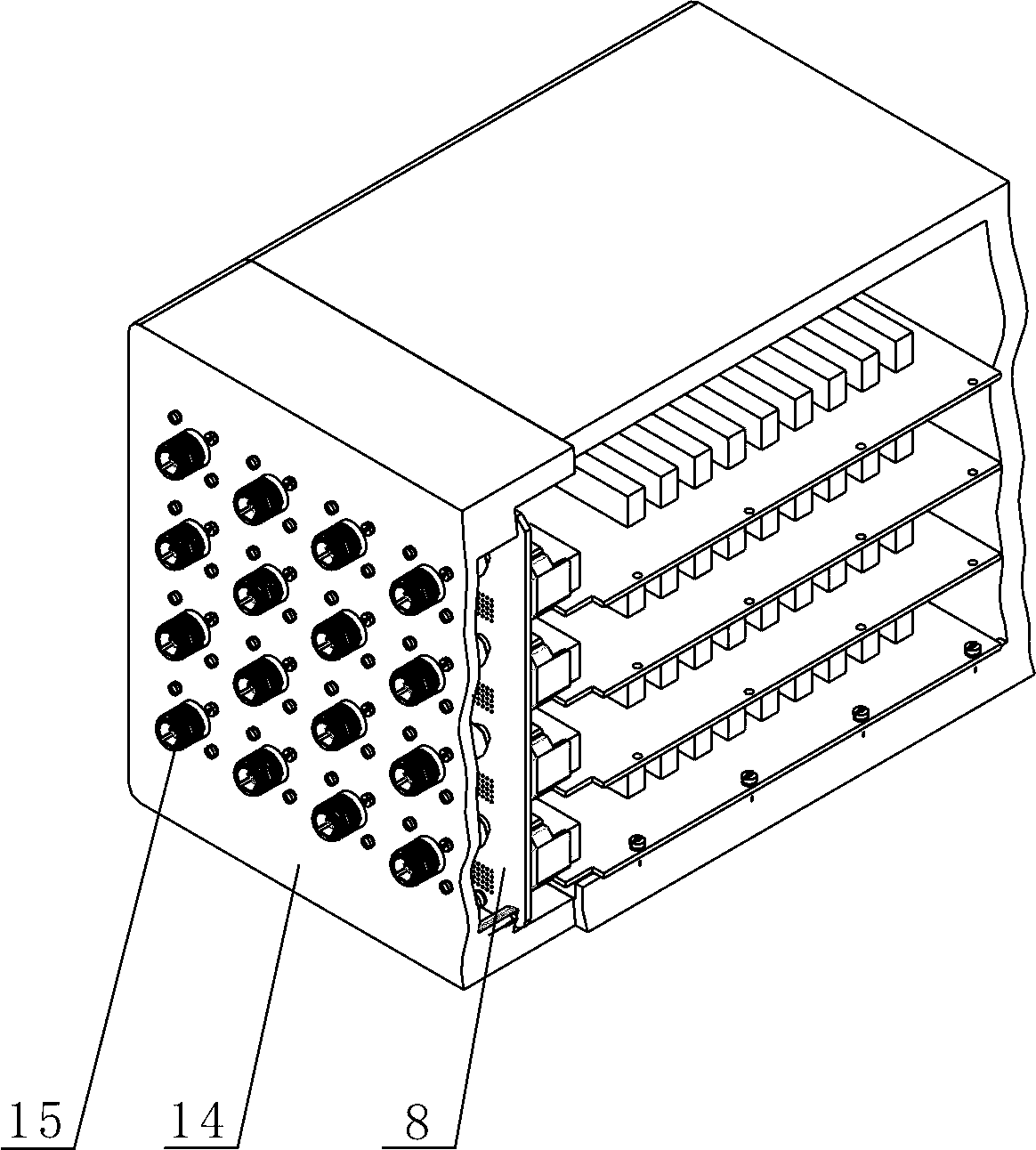

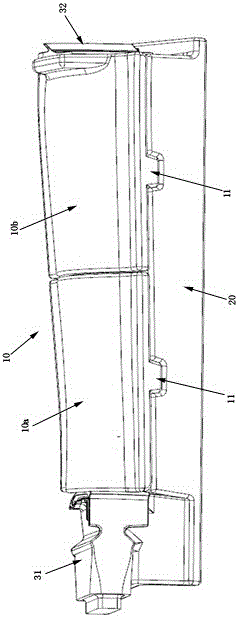

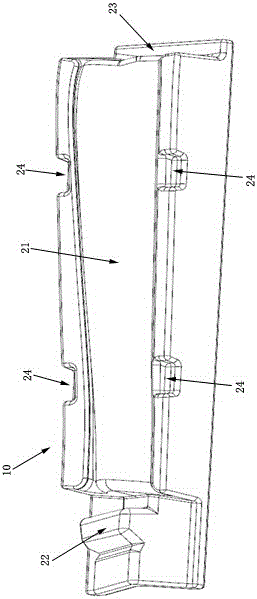

Shell structure of automobile body control module (BCM)

ActiveCN102413651AHigh strengthSmall amount of deformationCasings/cabinets/drawers detailsElectric/fluid circuitInterference fitVehicle frame

The invention provides a shell structure of an automobile body control module (BCM). The shell structure consists of an upper cover and a lower cover, wherein a circuit board is arranged between the upper cover and the lower cover; the upper cover is fixed on an automobile frame through a fixing support; the upper cover is in interference fit with the fixing support, thus connecting fastener components and assembly processes thereof are omitted; notches of electrical couplers on a shell achieve common mode through additionally arranging embedded lumps on a plastic mould, thereby meeting different circuit board assembly requirements; reinforcing ribs in the upper and lower covers can be used for enhancing the integrated intensity of the shell, reducing the shell deformation caused by high temperature, low temperature, vibration and impact, eliminating the resonance vibration brought by deformation, reducing the automobile noise, prolonging the service lives of the shell parts of the BCM, improving the reliability of electron components in the MCM and prolonging the service life of the BCM; drain holes are arranged in the shell and are used for preventing water accumulated in the shell from causing the function invalidity of the BCM; under the condition that a certain distance exists between an automobile body fixing point and a BCM placement position, through assembling different installing supports, the installation reliability of the BCM and an automobile body also can be ensured.

Owner:YANFENG VISTEON AUTOMOTIVE ELECTRONICS

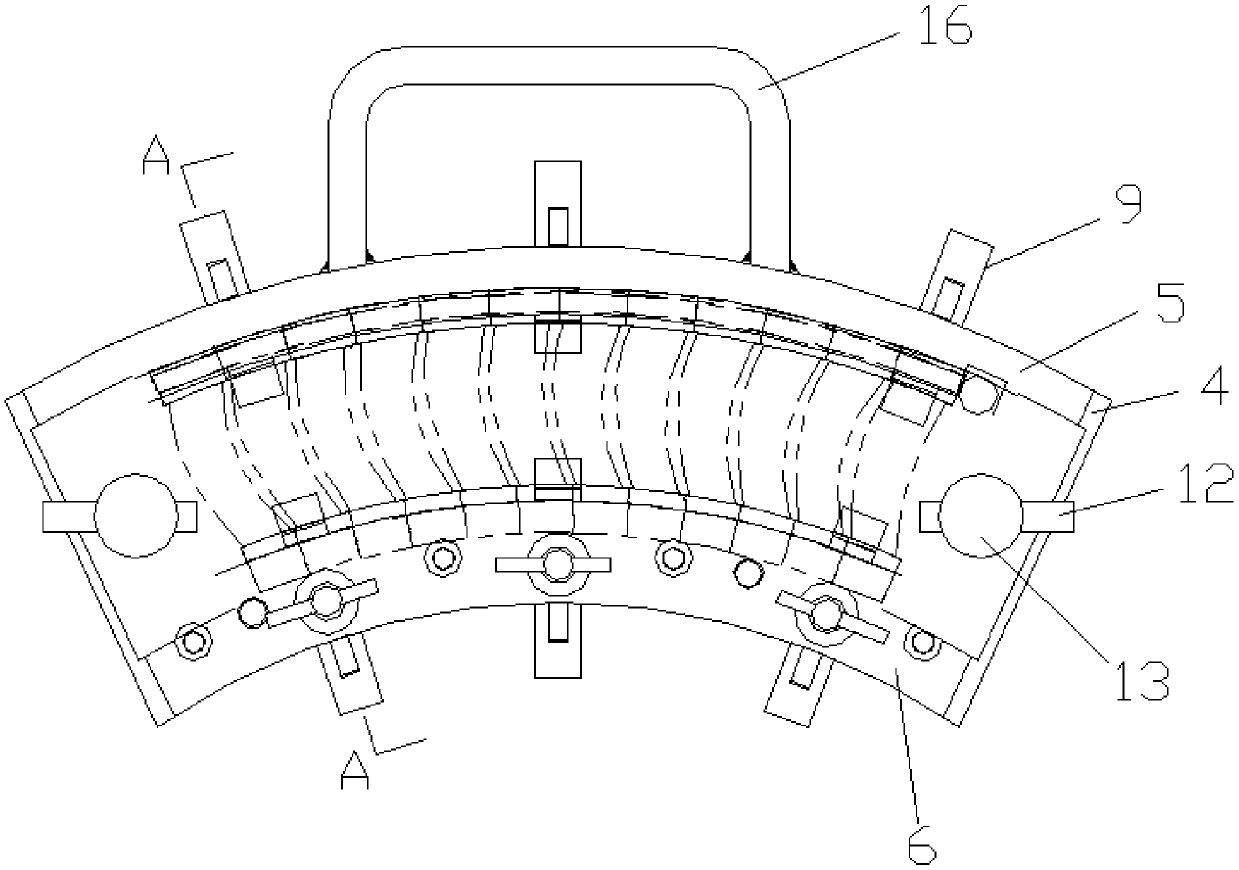

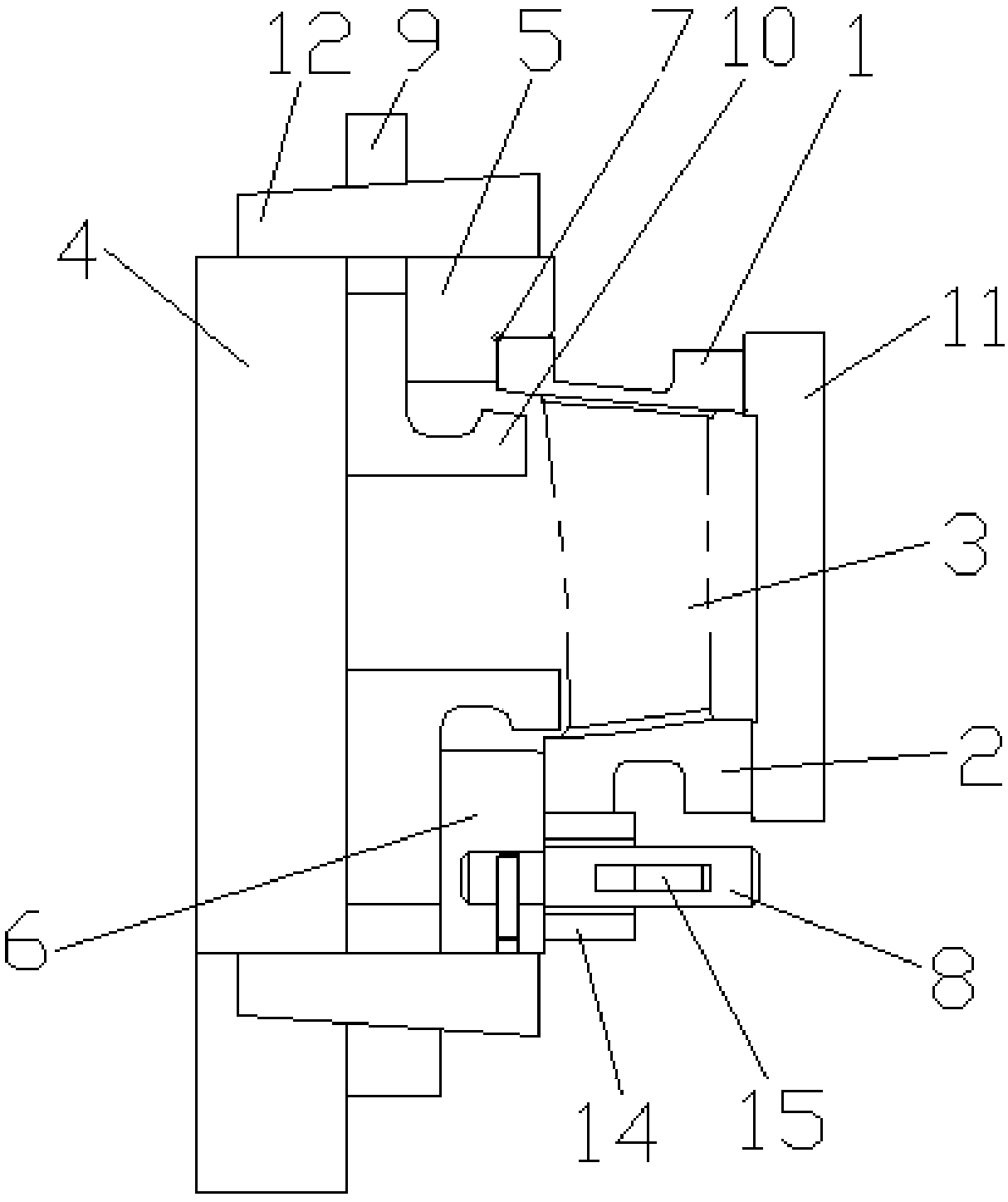

Fan-shaped clamp and method for reducing blade assembly welding deformation

ActiveCN108031944AReduce the influence of welding deformationNo deformationSoldering auxillary devicesEngineeringMechanical engineering

The invention relates to a fan-shaped clamp and method for reducing blade assembly welding deformation. The clamp comprises a base plate, the base plate is provided with an upper edge plate positioning block and a lower edge plate positioning block, a positioning pin is arranged on the lower edge plate positioning block, circumferential pressing blocks are inserted into the upper edge plate positioning block and the lower edge plate positioning block, hook-type parts are arranged at one ends of the circumferential pressing blocks, first locking devices are arranged on the circumferential pressing blocks, an upper pressing block is arranged at the upper end of the base plate, and a second locking device is arranged on the upper pressing block. After welding is carried out through the clampand method, the welding deformation influences are greatly reduced, a reference surface formed after welding is used for appropriately grinding treatment, a good standard is machined through a fan-shaped section assembly edge plate part, the deformation condition does not exist after a fan-shaped section assembly edge plate is machined, the assembly quality is better guaranteed, the position accuracy of a runner part better meets the assembly requirement, and the yield of a welded assembly is greatly improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

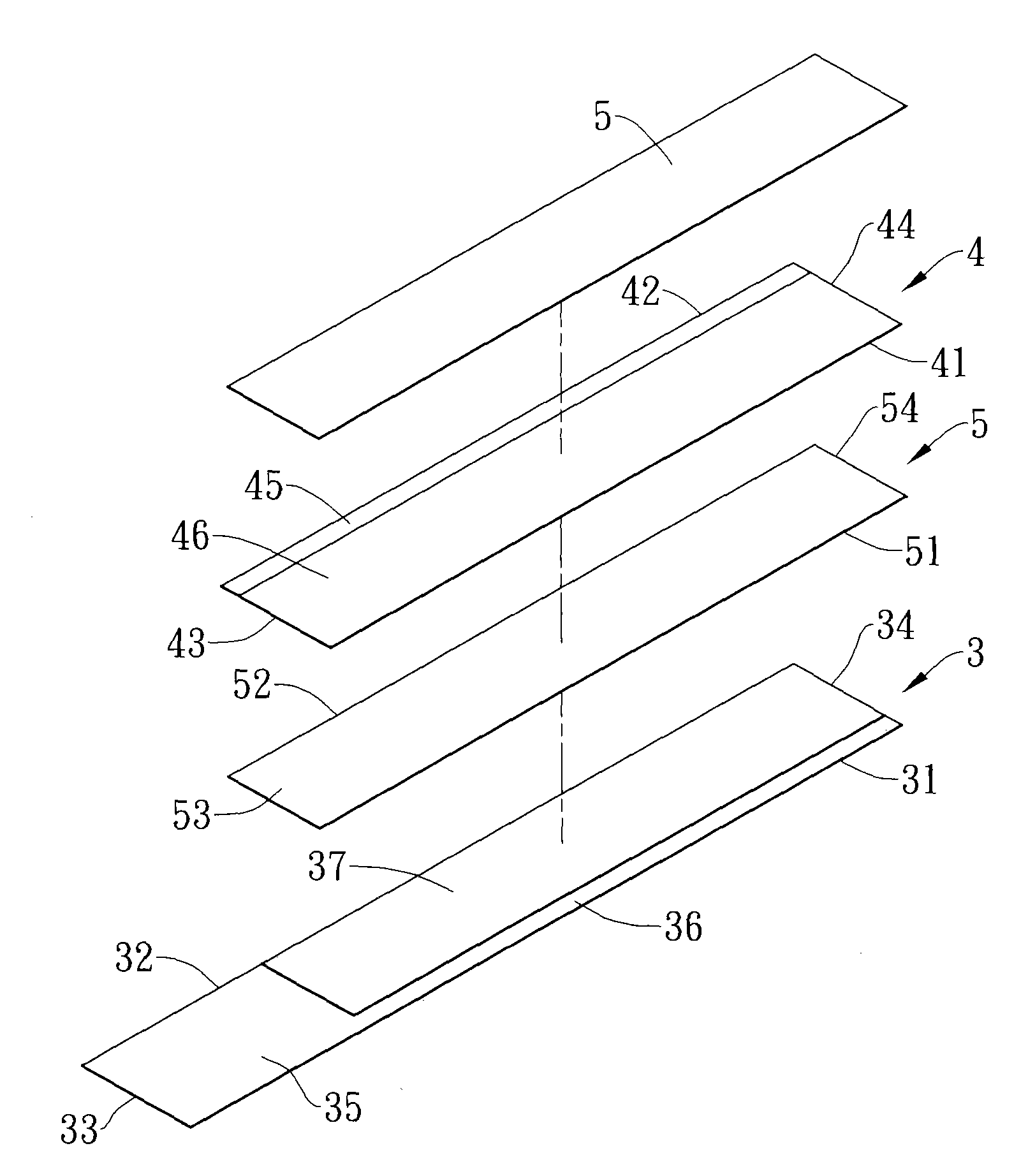

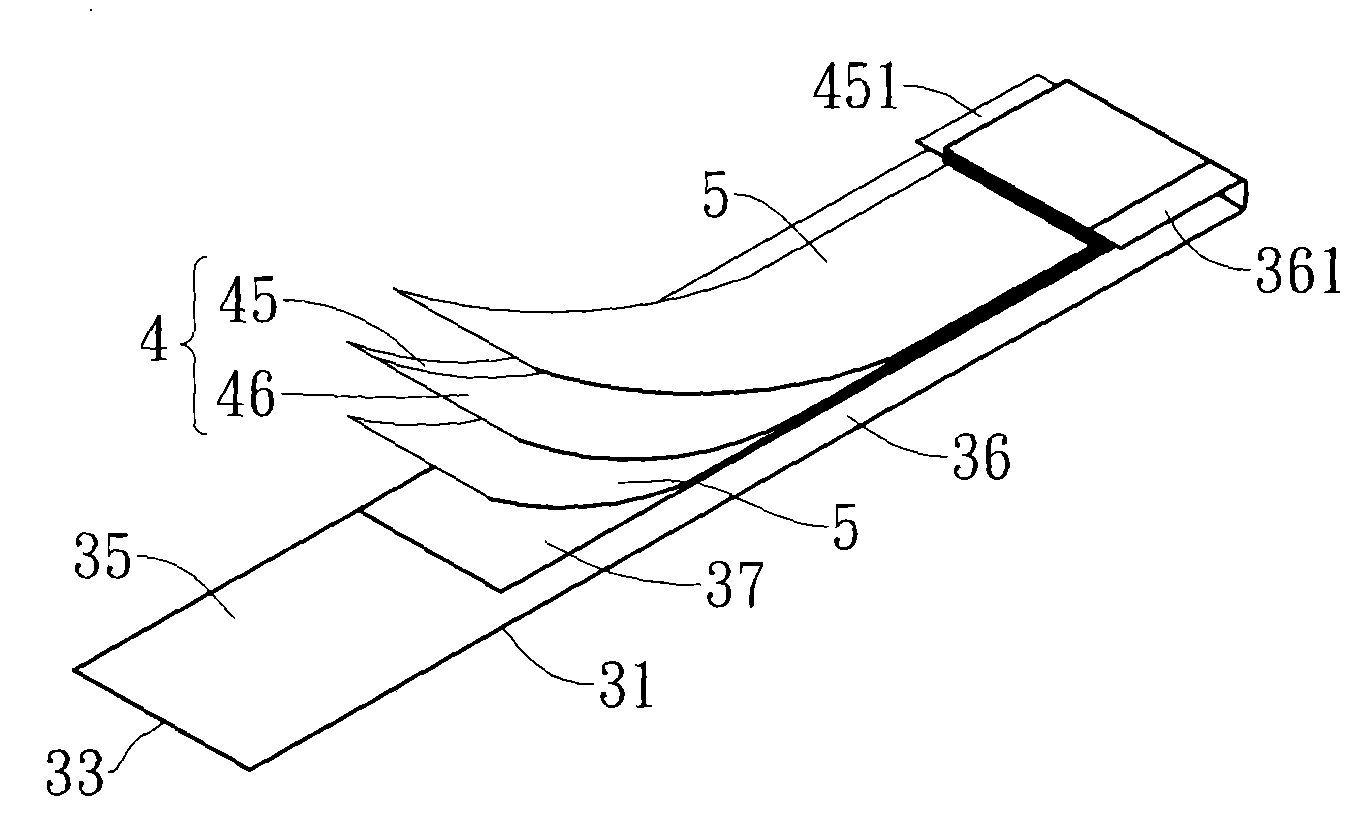

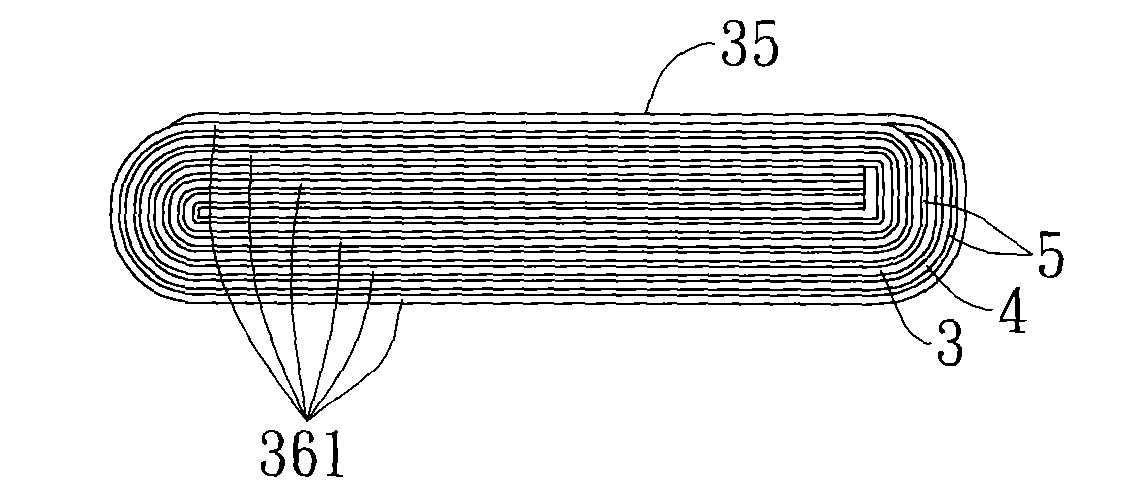

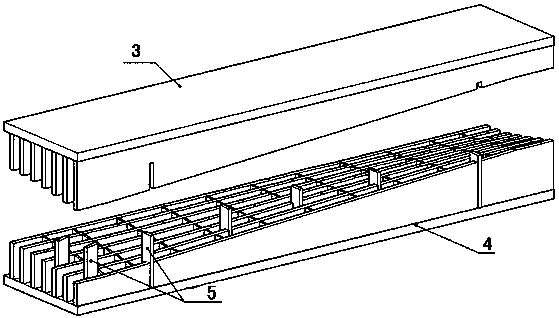

High-capacity lithium battery

InactiveCN102760905AMeet assembly requirementsLow costLi-accumulatorsCell component detailsHigh rateEngineering

The invention discloses a high-capacity lithium battery which is in a package structure covering an anode plate, a cathode plate, an isolation film and electrolyte solution. The anode plate, the cathode plate and the isolation film are elongated respectively and are respectively provided with first long sides and second long sides parallel to the first long sides. The first long side of the anode plate forms an anode welding area, and other parts of the anode plate form an anode area. The second long side of the cathode plate forms a cathode welding area, and other parts of the cathode plate form a cathode area. The isolation film is sandwiched between the anode area and the cathode area. When the anode plate, the isolation film and the cathode plate are wound simultaneously, multiple layers of wound anode lugs are formed in the anode welding area, and multiple layers of wound cathode lugs are formed in the cathode welding area. Therefore, requirements for a high-capacity and high-rate battery pack can be met, and automatic production can be achieved so as to reduce cost.

Owner:DIJIYA ENERGY SAVING TECH

Manufacturing method for spiral twisted box type

ActiveCN108723630AIncrease productivityGuarantee the quality of productionWelding/cutting auxillary devicesAuxillary welding devicesHot pressingHelix

The invention relates to a manufacturing method for a spiral twisted box type. The method comprises that the entire engineering model diagram is drawn, the same components are classified, flange plates and web plates of the different members are respectively extended and sampled, the extended flange plates and web plates are discharged in a segmented mode, the upper and lower flange plates are hot-pressed and molded by using a die made according to the box-type member twisted shape size, the web plates are rolled by using a plate rolling machine, an shape-imitation assembly tread is made according to the different members, the segmented pressed-molded flange plates are placed on the special assembly tread for splicing, welding, repairing so as to be tightly attach to the tread, and then the web plates and internal partition plates are assembled; and the internal partition plates are welded, the assembly accuracy is controlled by the assembly tread and the fit gap of the tread, the boxflange plates and the web plates, finally, the additional flange plates are assembled, and by combining with the trimming, the assembly detecting, welding of the box type main seam, post-welding detecting, member rust removal, and member coating are conducted. By means of the manufacturing method, the production efficiency can be improved, the production quality is ensured, and the requirements ofthe assembly accuracy are met.

Owner:二十二冶集团装备制造有限公司

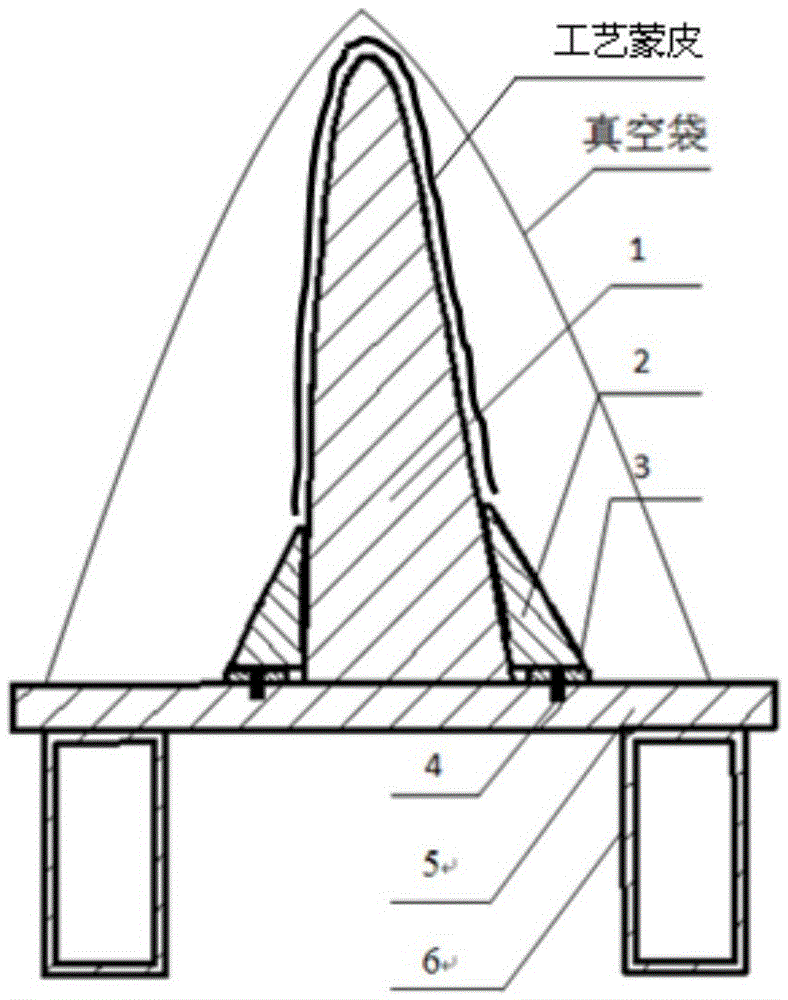

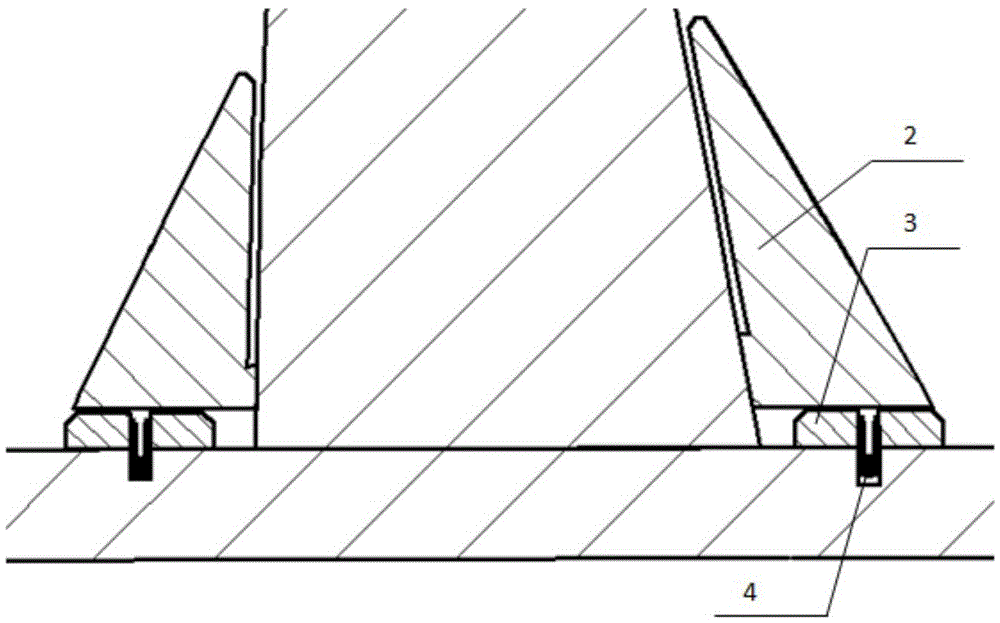

Mould and method for forming partial special-shape surface of large composite material workpiece in autoclave

ActiveCN105538746AAccurate internal and external profilesReliable internal qualityAbnormal shapedInternal bonding

The invention belongs to a composite material thermal forming technology, and particularly relates to a mould and a method for forming a partial special-shape surface of a large composite material workpiece in an autoclave. The mould is characterized in that a mould mode of a main body male die and special-shape position partial female and male die match is adopted for forming the large composite material special-shape workpiece in the autoclave. The main body male die is adopted, so that the forming precision of the inner surface of the workpiece is ensured, and the inner surface of the workpiece is applicable to internal bonding; for a partial special-shape position of the outer surface of the workpiece, the female and male die match is adopted, so that the size and the position precision of a special-shape moulding surface at an assembling part of the outer surface of the special-shape workpiece are ensured, and the internal quality of the workpiece can be ensured.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST +1

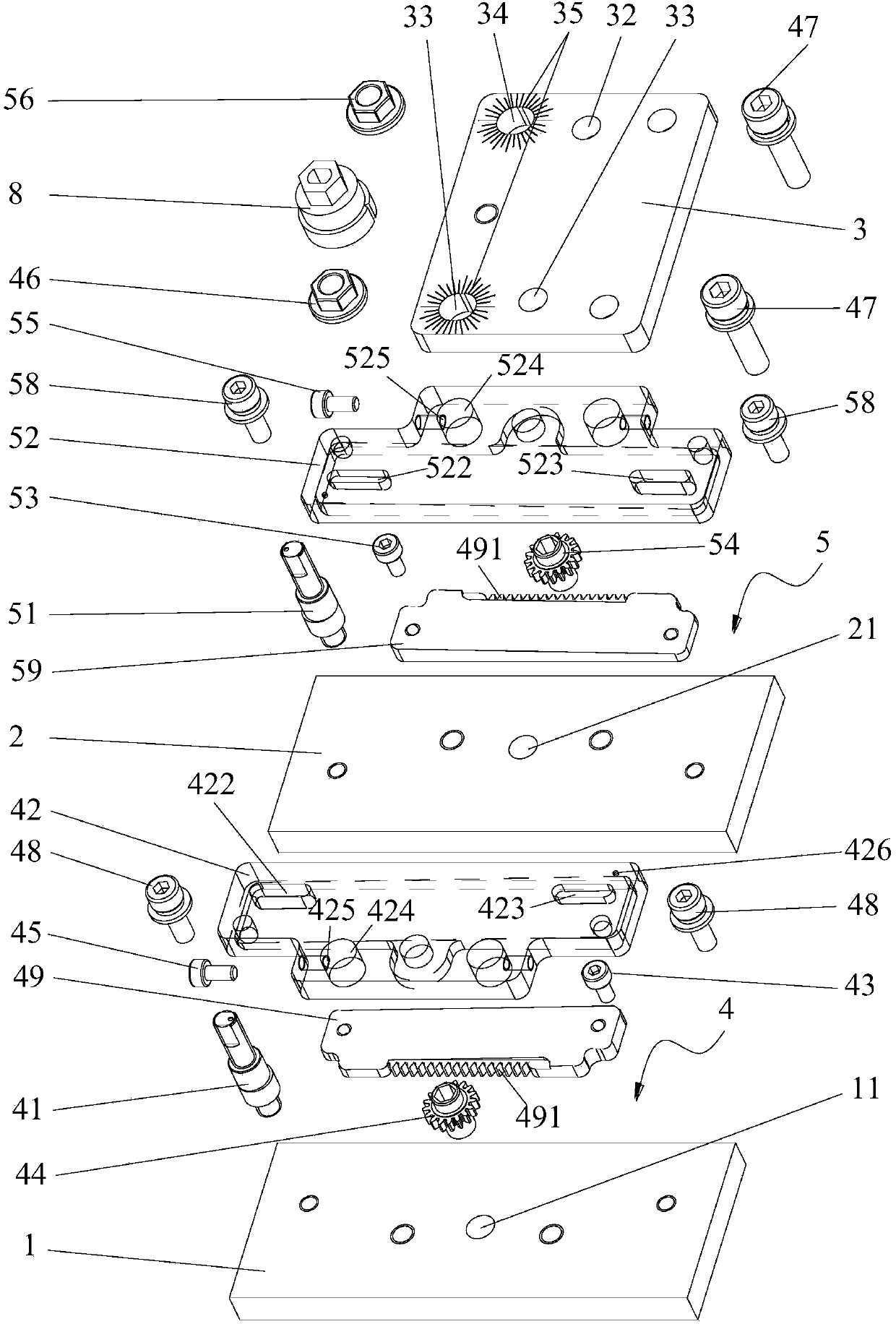

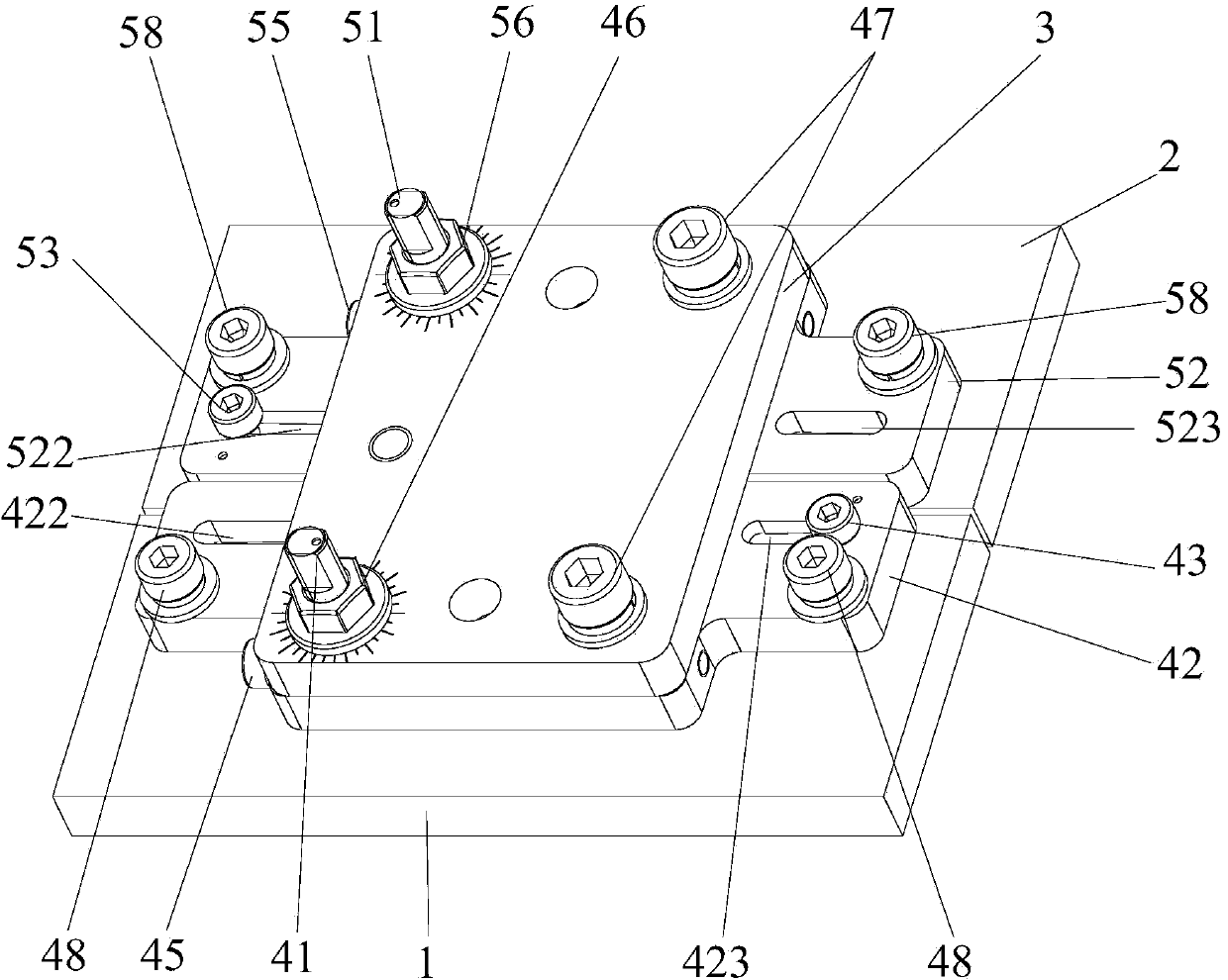

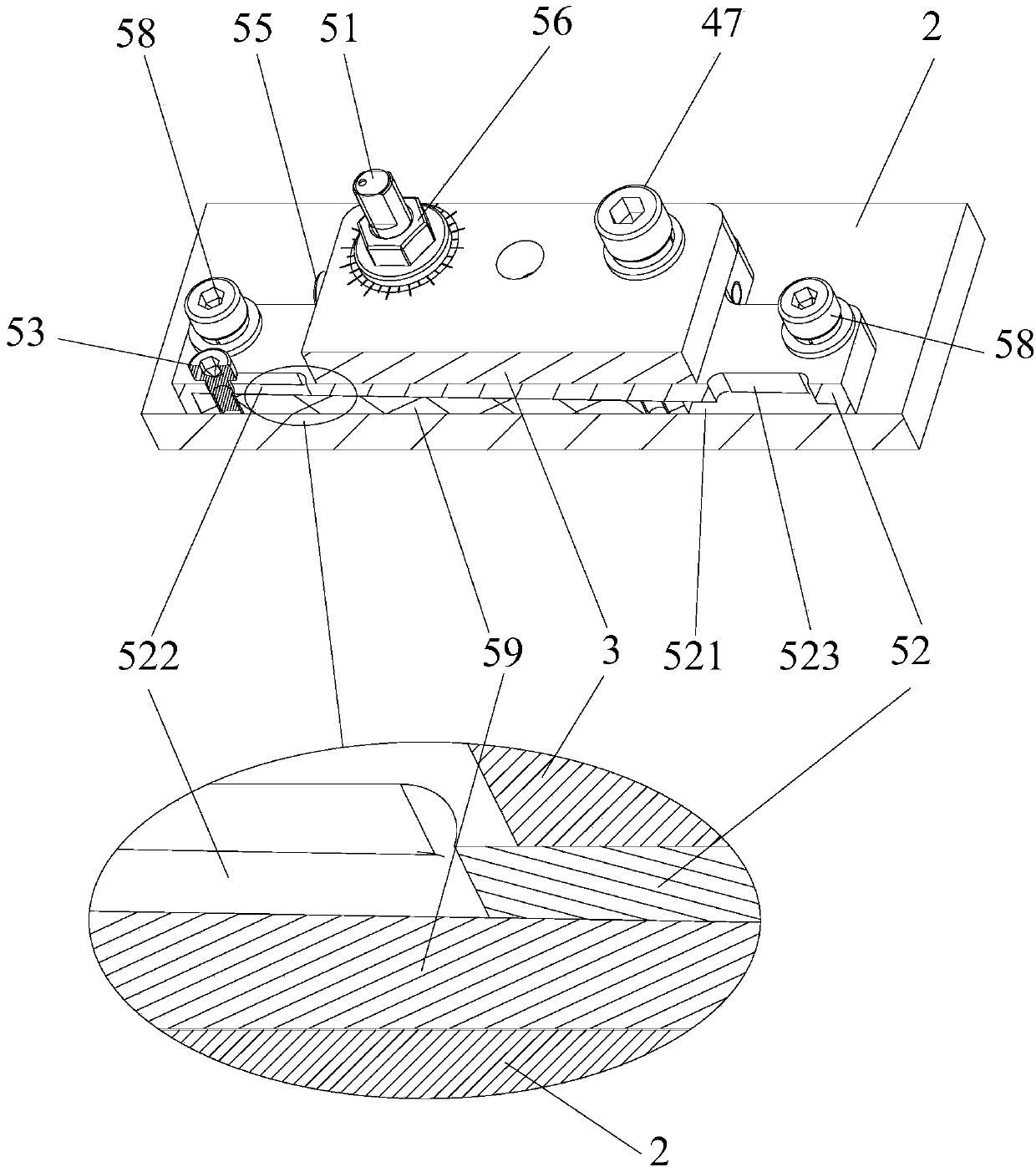

LED display system, gap adjusting device for fixing and assembling screen bodies and adjusting method

ActiveCN104175116ACompensation for machining errorsRealize high-precision stitchingMetal working apparatusIdentification meansCushionEngineering

The invention belongs to the technical field of assembly and aims to provide a gap adjusting device for fixing and assembling screen bodies. The gap adjusting device comprises a first adjusting component, a second adjusting component and a connecting plate which is used for connecting a first screen body unit with a second screen body unit; the invention also aims to provide an LED display system and an adjusting method of the gap adjusting device. According to the invention, a first adjusting cushion block and a second adjusting cushion block are respectively arranged on the back surfaces of two adjacent screen body units, and movable blocks respectively corresponding to the first adjusting cushion block and the second adjusting cushion block can move in respective slide ways with the same inclination, so that the front sides of the two adjacent LED screen body units are flush with each other through stepless fine adjustment; through the rotation of a first eccentric shaft and / or a second eccentric shaft, the distance between the matching center of each eccentric shaft and the connecting plate, and that of the respective opposite eccentric shaft and the connecting plate can be adjusted, so that gaps between the two adjacent screen body units in the vertical and horizontal directions can be subjected to stepless fine adjustment, and further, the requirement for small space assembly is satisfied and the display effect of the high density LED display system is improved.

Owner:SHENZHEN AOTO ELECTRONICS

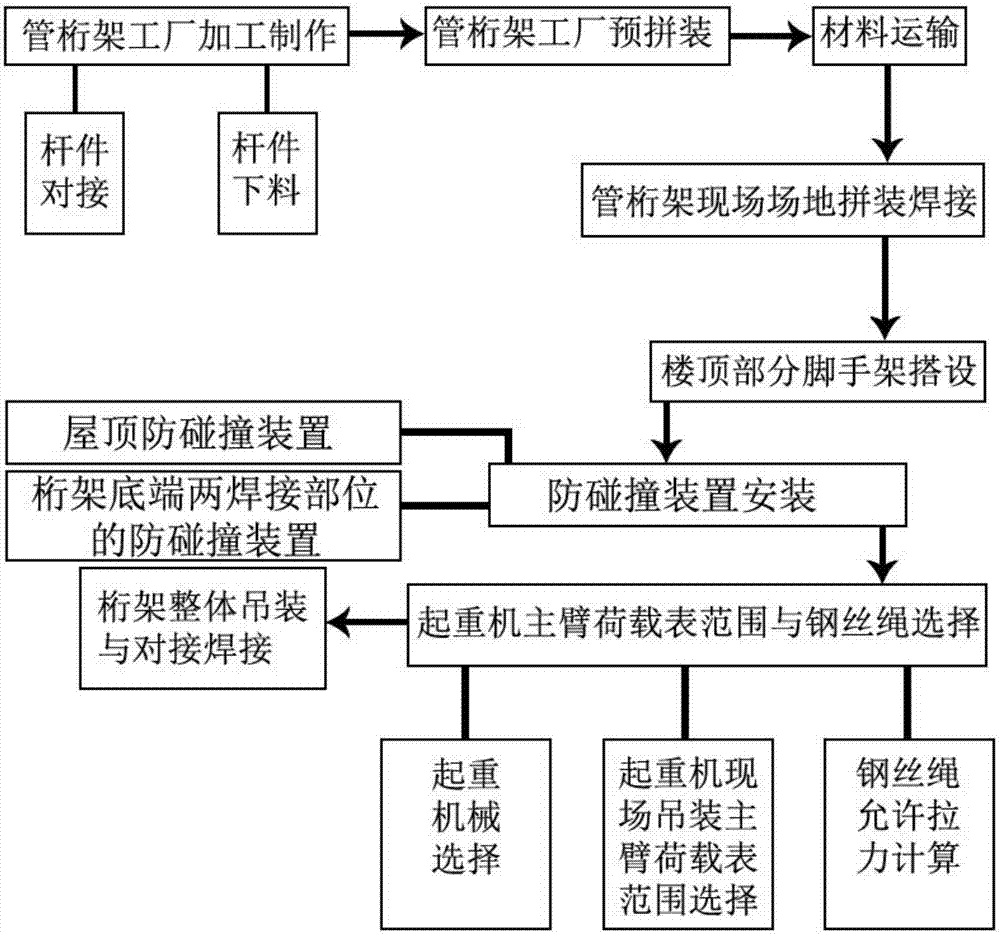

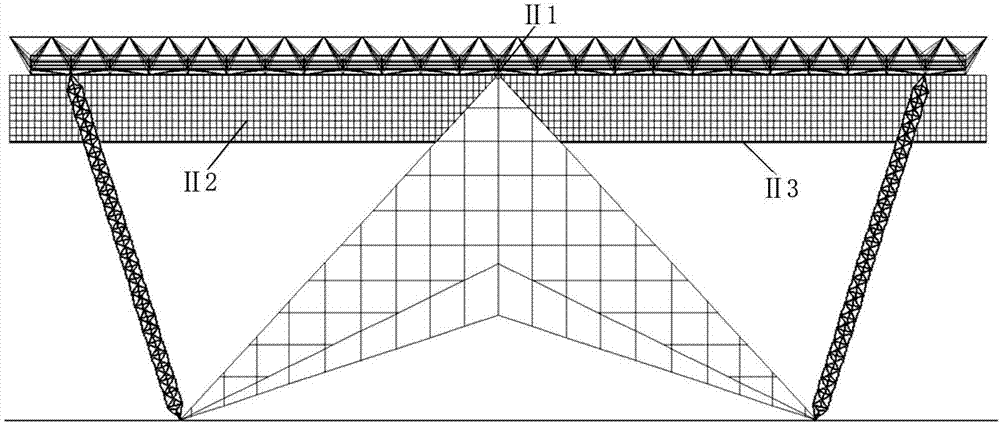

Construction method for integrally hoisting large-size multi-edge-and-corner overhanging truss

ActiveCN107100309AImprove assembly efficiencyEasy constructionBuilding roofsBuilding material handlingTerrainButt welding

A construction method for integrally hoisting a large-size multi-edge-and-corner overhanging truss is disclosed. Integral assembling of a steel pipe truss is conducted on site, and integral hoisting is conducted after assembling is completed; the truss is connected with three welding positions in a butt-joint mode and then is welded firmly; two 500 t all-terrain cranes and a 350 t all-terrain crane are adopted to hoist the whole truss simultaneously, and step-by-step hoisting is conducted from south to north; the truss is totally provided with three main stress support joints which are all fixed by adopting butt welding, a third calibration point support is located at the top of the truss, a welded ball joint at the position of the third calibration point is a support point of a steel rainshed grid frame actually, a first calibration point support and a second calibration point support are located on both the left and right sides of the bottom of the truss correspondingly, and the first calibration point support and the second calibration point support are global stress supporting points of the truss. The construction method for integrally hoisting the large-size multi-edge-and-corner overhanging truss has the characteristics that the construction safety is high, the construction period is short, the engineering quality is easy to guarantee, the ground integral assembling efficiency is high, and the construction cost is reduced greatly.

Owner:FUJIAN MINNAN CONSTR ENG

Rubber pad for automobile radiator

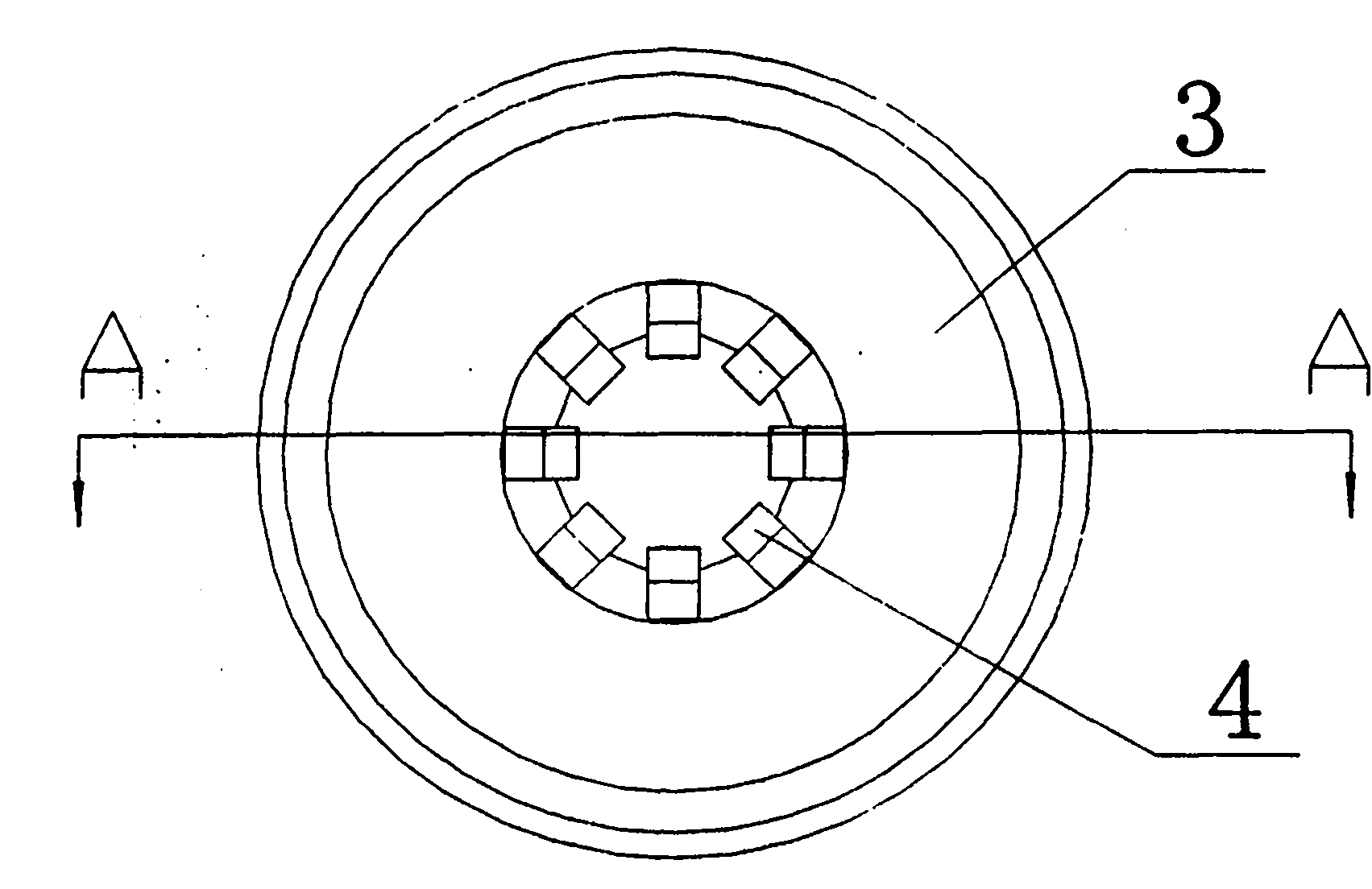

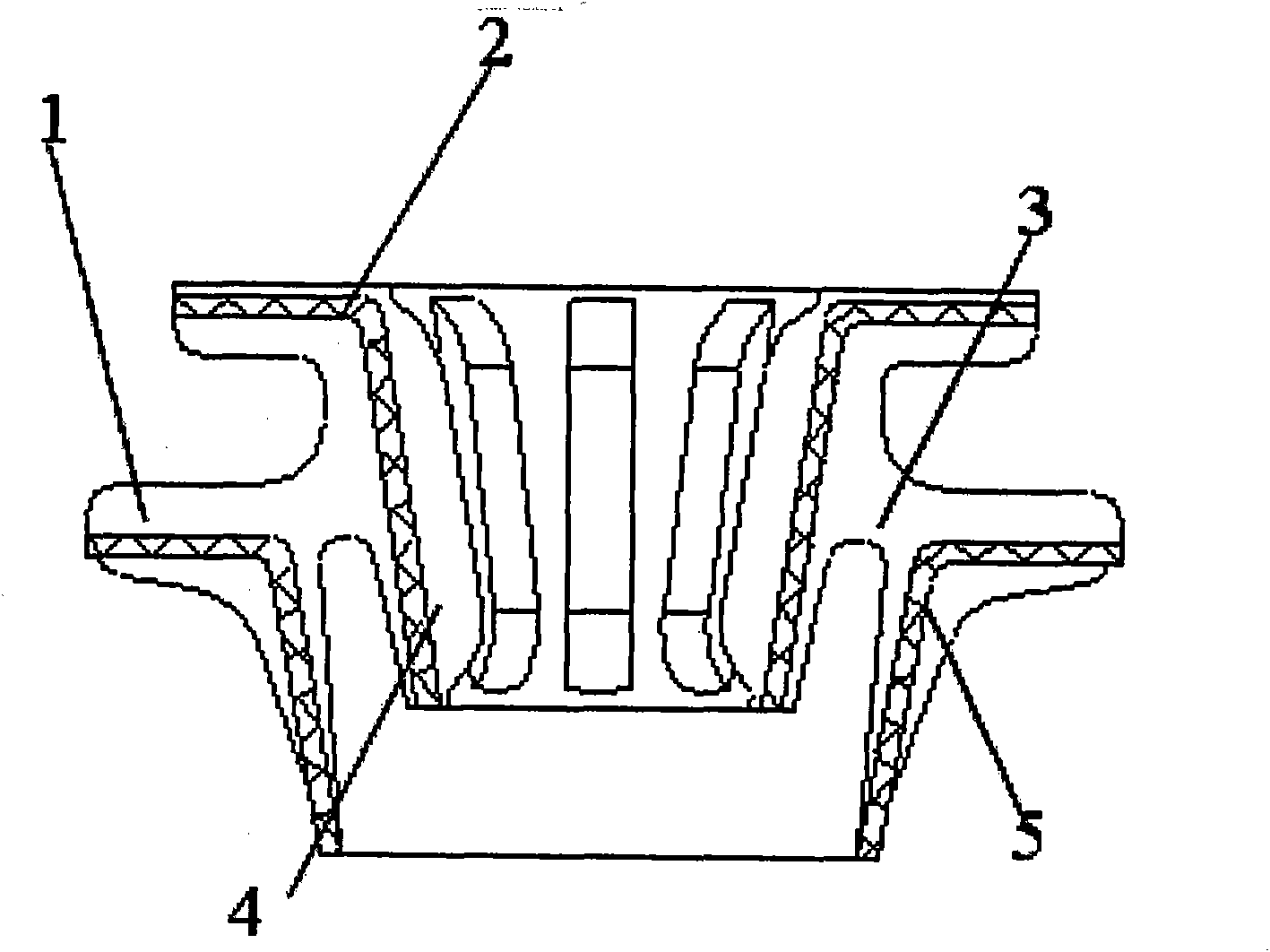

InactiveCN101865240AAvoid deformationReduce vibrationNon-rotating vibration suppressionPropulsion coolingEngineeringRelative motion

The invention discloses a rubber pad for an automobile radiator. The rubber pad comprises a shock absorbing ferrule body with two turned edges and is characterized in that an upper rigid ferrule with the turned edge is embedded into the upper part of the shock absorbing ferrule body; the inner wall on the upper part of the shock absorbing ferrule body is provided with a plurality of upper corrugates with inclination angles; a lower rigid ferrule with the turned edge is embedded into the lower part of the shock absorbing ferrule body; and the outer wall on the lower part of the shock absorbing ferrule body is provided with a plurality of lower corrugates with inclination angles. The rubber pad has the following advantages that: because the upper rigid ferrule and the lower rigid ferrule are connected through the shock absorbing ferrule body, the vibration transferred by a fan and an engine to the radiator is reduced by the relative motion of the upper rigid ferrule and the lower rigid ferrule in the shock absorbing ferrule body so as to reduce the vibration transferred by the radiator to the automobile body in the entire driving process, the rubber pad meets the requirements of the entire automobile on the bearing capacity, the shock absorption and the assembly, ensures reliable positioning of the radiator on the entire automobile and improves the comfort of the riding.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Floating connection mechanism used between hard face plate and printed board

ActiveCN103022757AMeet the requirements for assemblyIncrease contactCoupling device detailsInstallation ErrorSurface plate

Owner:SICHUAN HUAFENG ENTERPRISE GRP

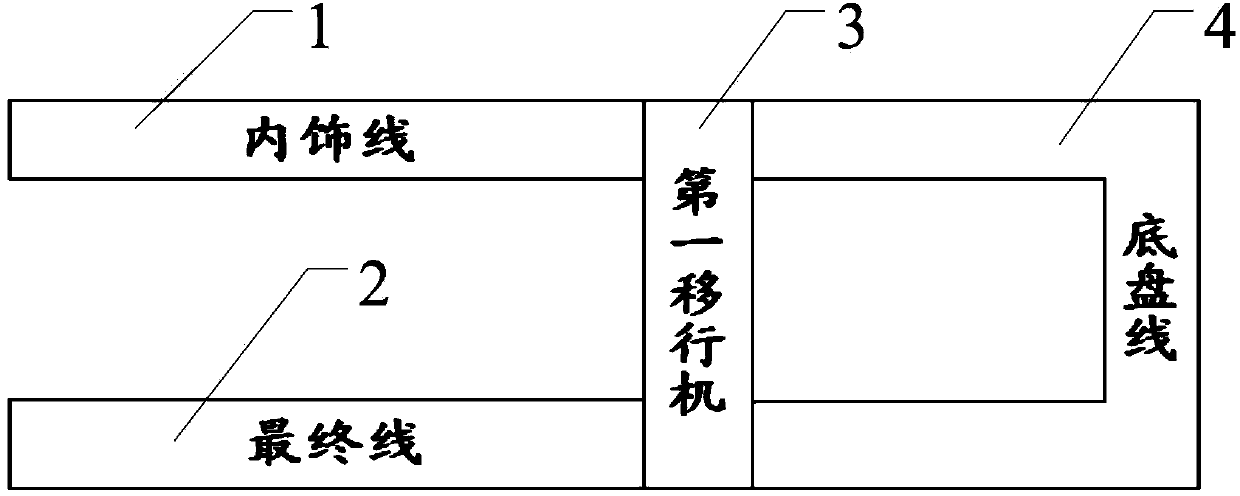

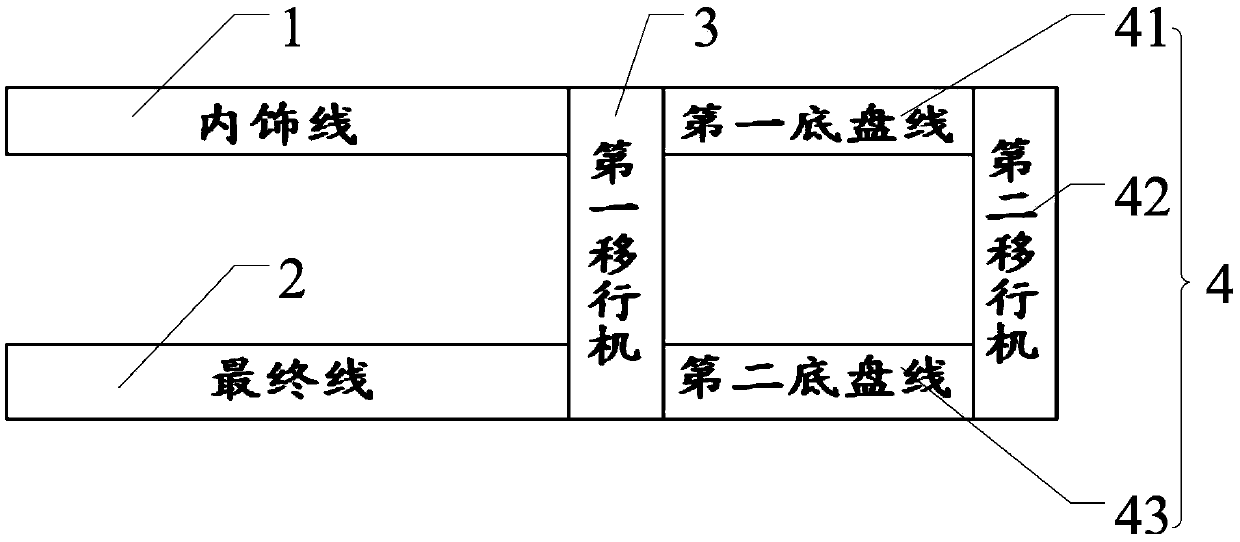

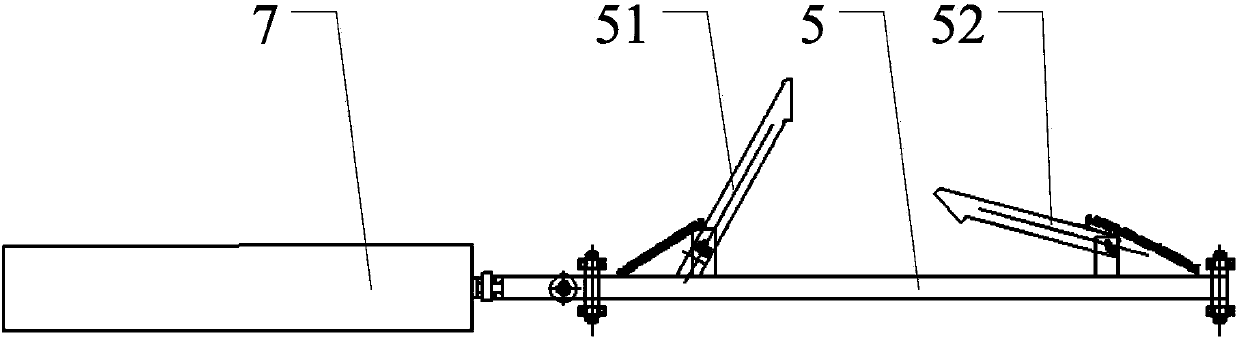

Automobile flexible assembly line

The invention discloses an automobile flexible assembly line which comprises an inner decoration line, an ultimate line, a chassis line and a first transitional machine, wherein the ultimate line and the inner decoration line are arranged side by side, one end of the first transitional machine is respectively connected with the end of the inner decoration line and one end of the chassis line, the other end of the first transitional line is respectively connected with the end of the ultimate line and the other end of the chassis line, and the first transitional line is provided with a first bidirectional cart device. The transitional machine is added to enable the assembly line to have various combining forms, for example, a production line formed by the inner decoration line, the chassis line and the ultimate line or a production lien formed by the inner decoration line, the first transitional machine and the ultimate line or the like, regulation can be carried out on the production line according to market requirements, redundant loss is eliminated, meanwhile assembling requirements of half loading trucks, full loading trucks and the like are met, performance is reliable, cost is low, and regulation is facilitated; under the action of the bidirectional cart device and a cart machine on the production line, all lifting device trolley sets can be moved in and be moved out of the transitional machine, and products can conveniently move among various components of the production line.

Owner:LIUZHOU WULING MOTORS +1

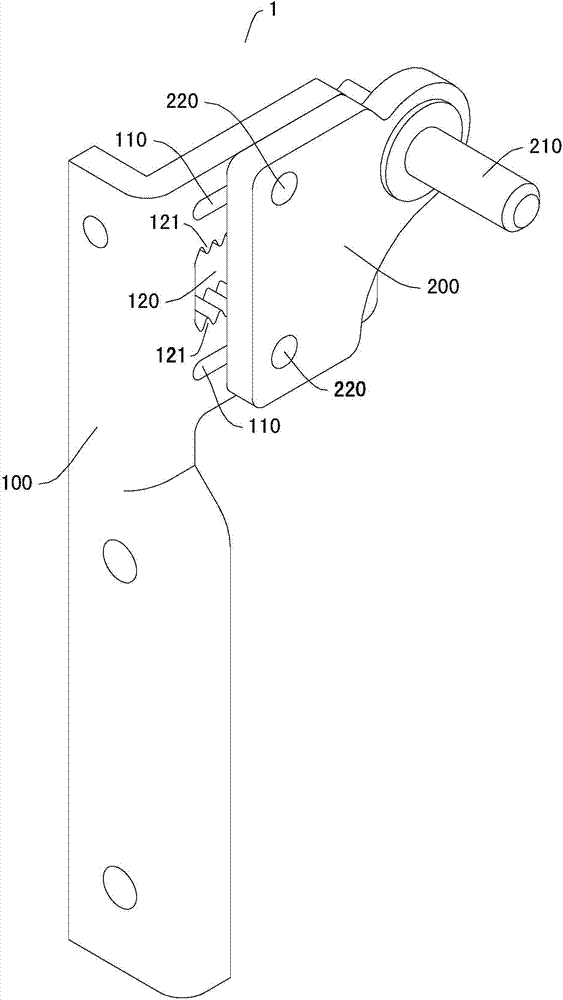

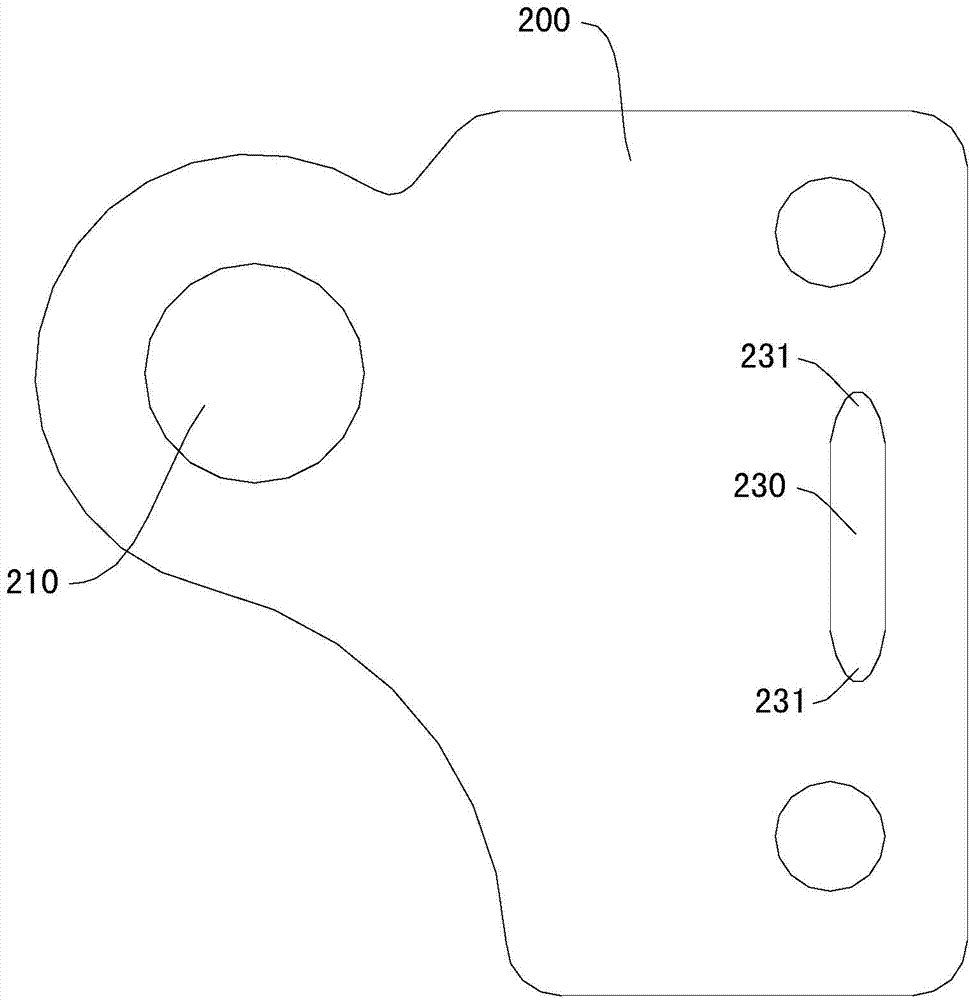

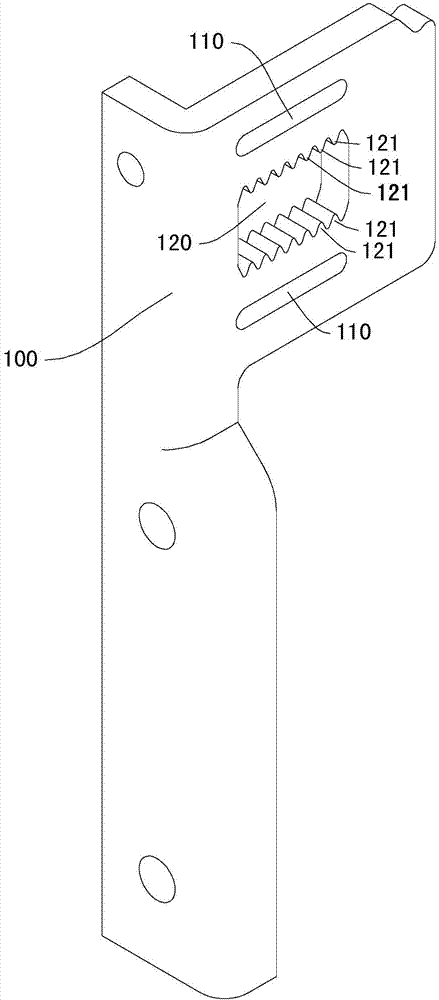

Hinge and refrigerator with hinge

ActiveCN103670094AImprove applicabilityEasy to standardize managementHingesFastenerAerospace engineering

The invention discloses a hinge and a refrigerator with the hinge. The hinge comprises a hinge base, a hinge frame and a fastening part. A central shaft is arranged on the hinge frame, the hinge frame is movably arranged on the hinge base, and the fastening part is used for fixing the hinge frame on the hinge base. The hinge which can meet the assembly requirements of different refrigerators has the advantages of facilitating standardization management, being low in mold development cost and the like.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

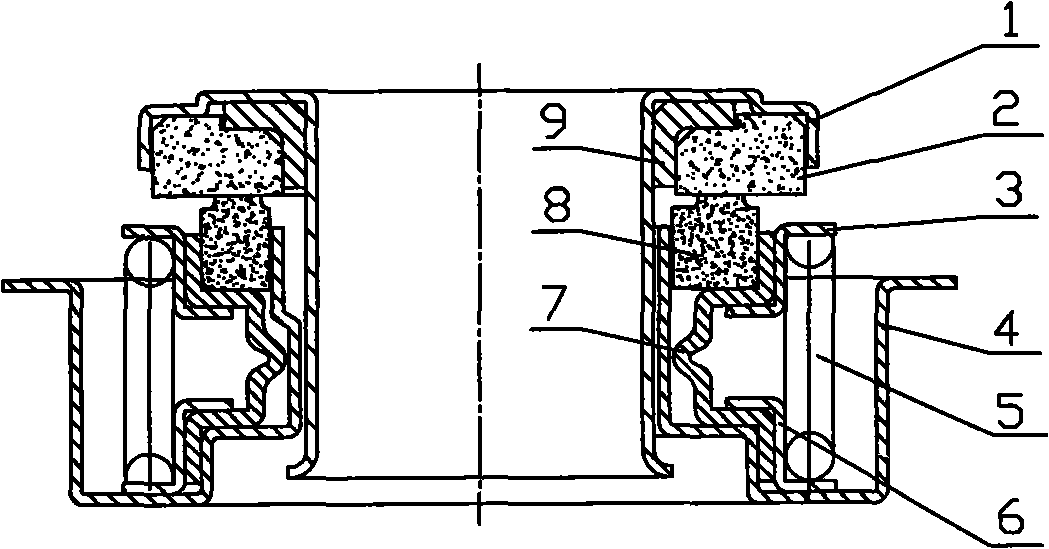

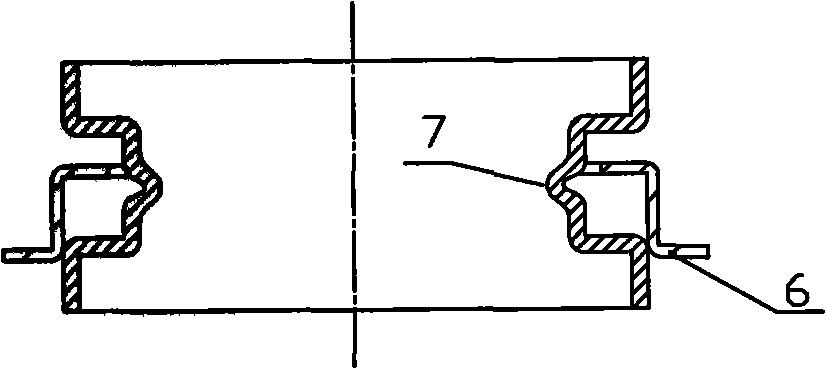

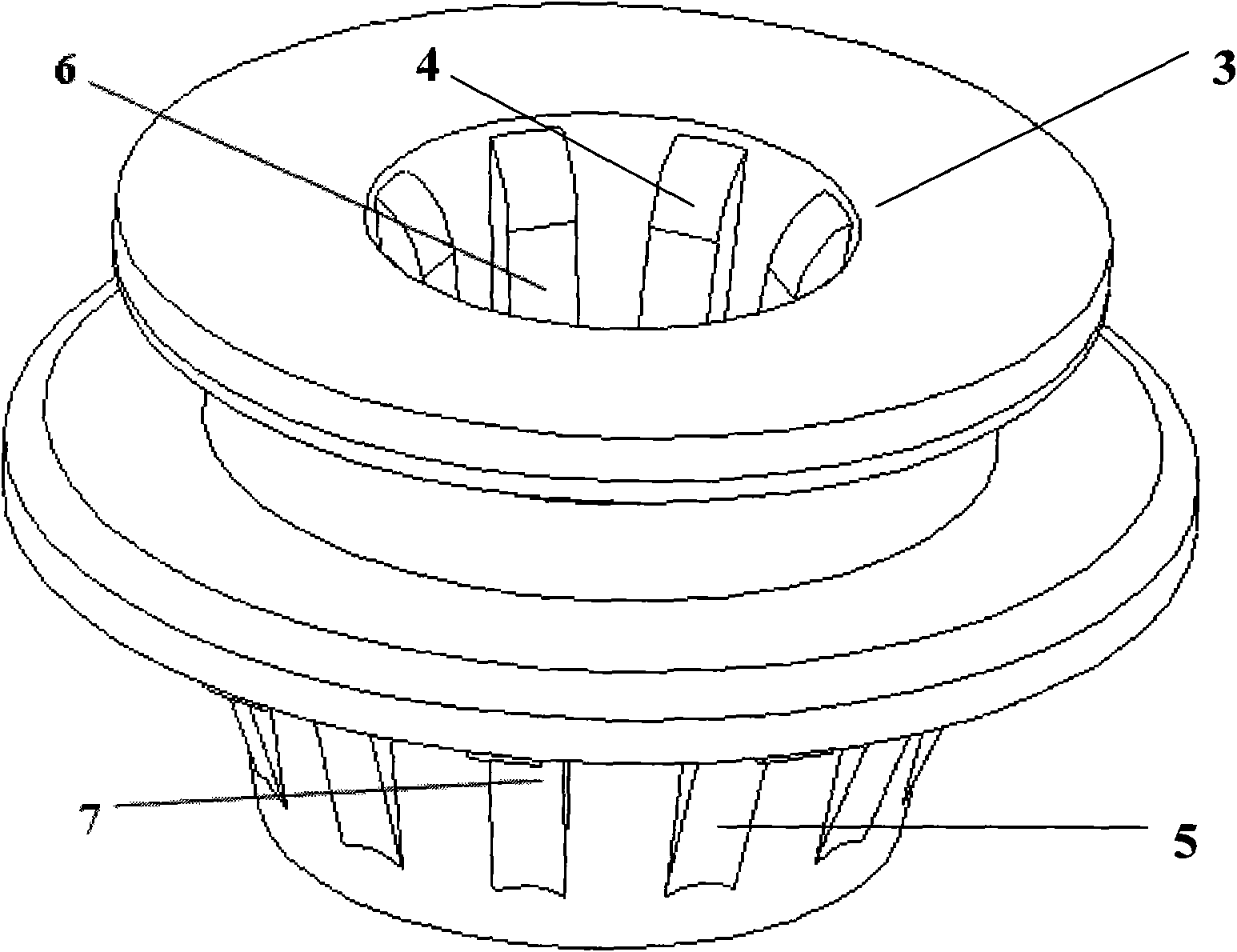

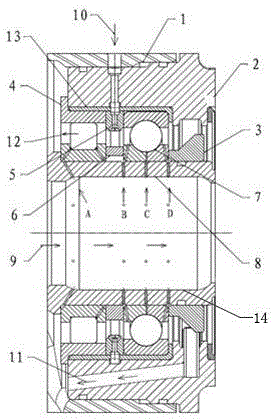

Novel bearing lubricating structure

ActiveCN104963942ANovel structureImprove the lubrication effectRolling contact bearingsBearing componentsRotational axisEngineering

The invention provides a novel bearing lubricating structure. The novel bearing lubricating structure comprises an upper annular lubrication part and a lower annular lubrication part; the upper annular lubrication part mainly enables lubrication oil to be sprayed on a rolling element through an oil path of a casing and an end cover so as to lubricate a bearing. The lower annular lubrication part mainly stores oil through an oil storage structure of an inner cavity of a rotary shaft, and then the lubrication oil enters an inner bearing ring and a retainer through four rows of annular oil holes in the rotary shaft to lubricate the bearing. The double-channel bearing lubrication mode of the upper annular lubrication part and the lower annular lubrication part is adopted, so that the bearing lubrication effect is good, and the technical problem of a large bearing heating amount under the high-speed heavy-load condition is solved well. The novel bearing lubricating structure is novel; the lubrication effect is good; the two paths of lubrication modes do not interfere with each other and operate independently; reliability of bearing lubrication is improved; at the same time, the heating amount of a bearing is reduced and the service life of the bearing is prolonged by increasing the lubrication amount of lubrication oil.

Owner:CHINA AVIATION POWER MACHINE INST

Pattern correction method of investment casting engine blade and pattern correction mould of method

InactiveCN105964739AAchieve hot isostatic pressingImprove production pass rateShaping toolsInvestment castingCorrection method

The invention provides a pattern correction method of an investment casting engine blade. The problem that in the casting process of an existing investment casting engine blade, casting deformation cannot be prejudged, and consequently, the size of a casting cannot meet the requirement is solved. A special pattern correction mould is machined and manufactured according to the design size of an engine blade casting, a pattern correction cavity matched with the design profile of the engine blade casting is machined in the dedicated pattern correction mould, then the engine blade casting is put into the pattern correction cavity of the dedicated pattern correction mould, the engine blade casting is put into a hot isostatic pressing treatment furnace along with the dedicated pattern correction mould to be subject to hot isostatic pressing treatment, and the dedicated pattern correction mould carries out pattern correction on the engine blade casting while the engine blade casting is subject to hot isostatic pressing treatment. Therefore, the invention further provides the dedicated pattern correction mould used for the pattern correction method.

Owner:FALCON AEROTECH LTD

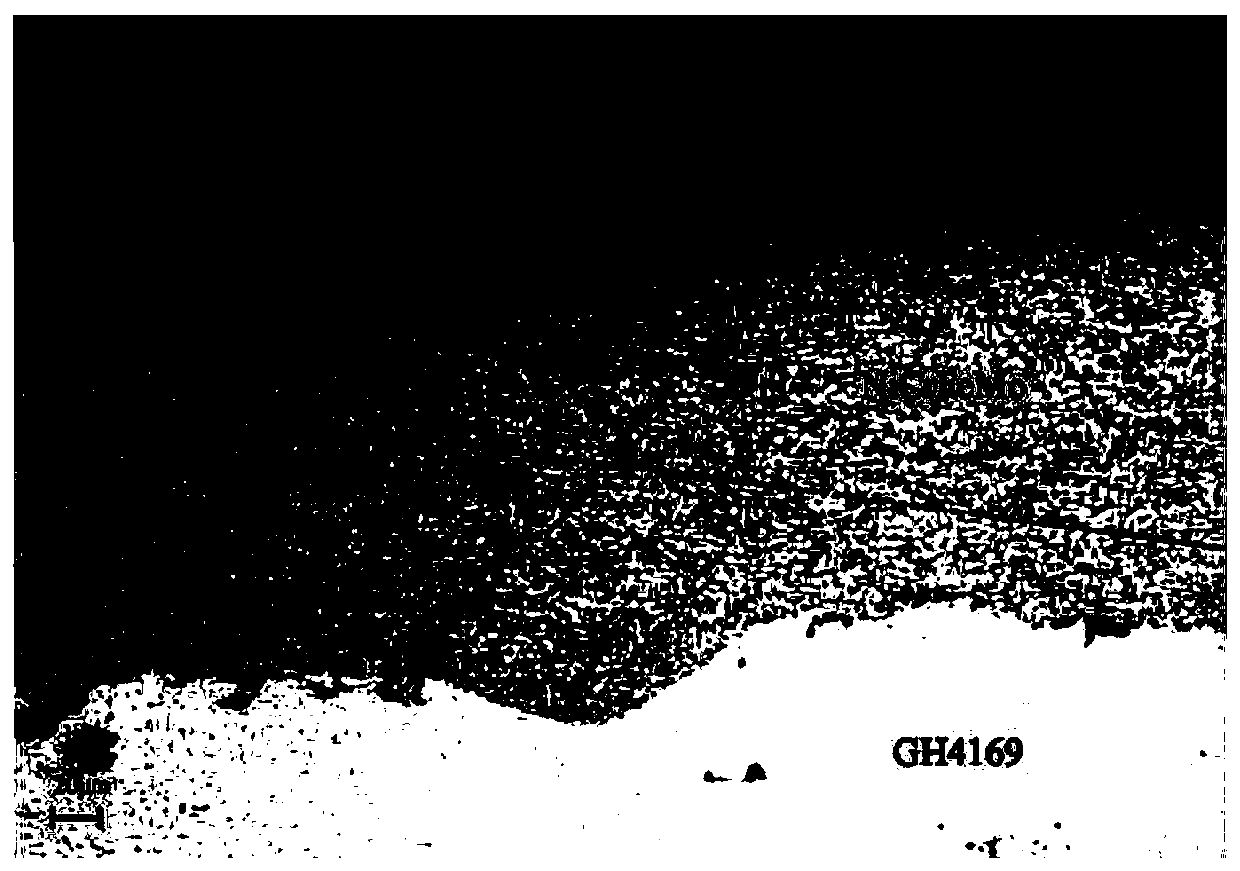

Size correcting method for aeroengine high-temperature alloy disc shaft abrasion

The invention discloses a size correcting method for aeroengine high-temperature alloy disc shaft abrasion, in particular to a thermal spraying size correcting coating technology for an aeroengine nickel-base alloy disc shaft part. The method comprises the specific steps that (1) before a coating is sprayed, the part is subjected to oil removing treatment; (2) the non-coating area of the part is protected; (3) the part is subjected to sand blowing treatment; (4) ultrasonic spraying of a NiCrFeMo coating is carried out on an area after sand blowing; and (5) the sprayed coating is subjected to machining, so that the surface roughness of the coating is consistent with the surface roughness of the part. The bonding strength of the size correcting coating prepared by the method and the base alloy is greater than 69 MPa, the porosity of the size correcting coating is less than 1%, the oxygen content is less than 0.5%, and the hardness is HV0.3435.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com