Construction method for integrally hoisting large-size multi-edge-and-corner overhanging truss

A technology of overall hoisting and construction methods, applied in the processing of building materials, roofs, building components, etc., can solve the problems of increasing the visual aesthetics of buildings, high hoisting safety risks, and difficult construction, etc., and achieve easy assurance of project quality and construction safety. High performance, reducing installation and construction costs and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention takes the main project of the first bid section of the first phase of the first phase of Shishi International Textile City as the specific implementation site, and provides the following specific examples.

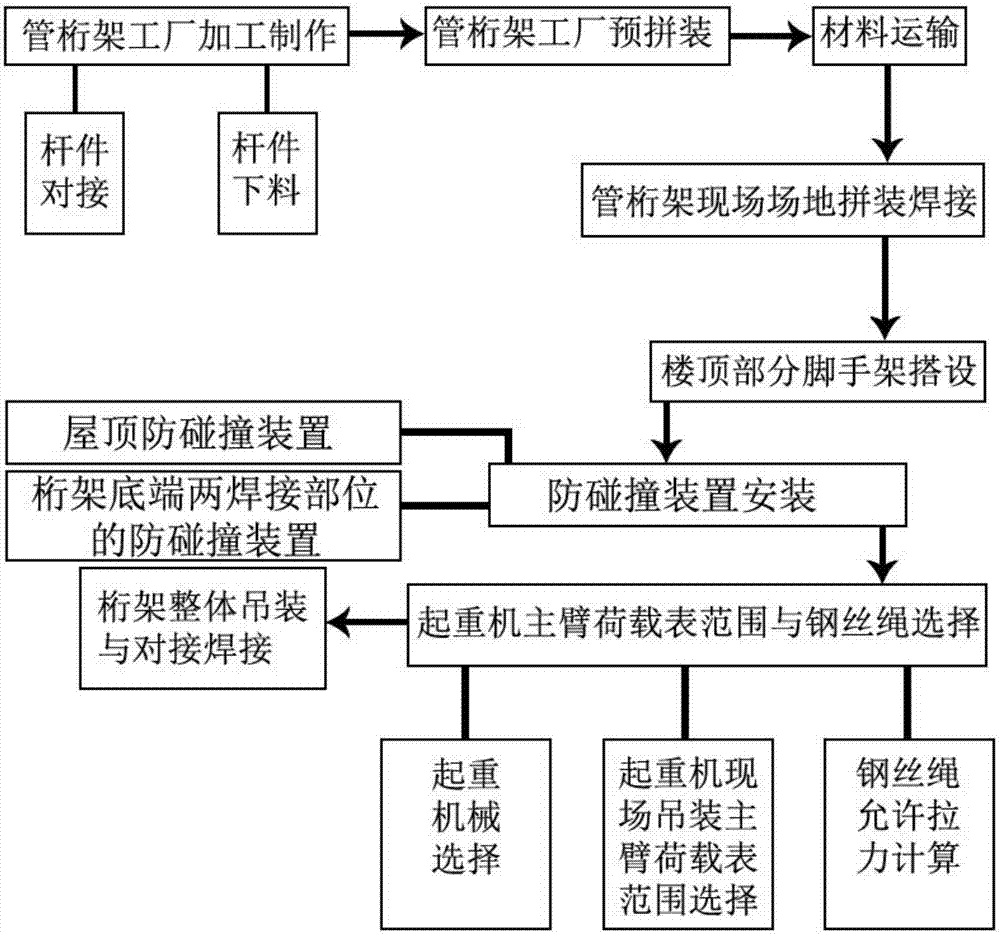

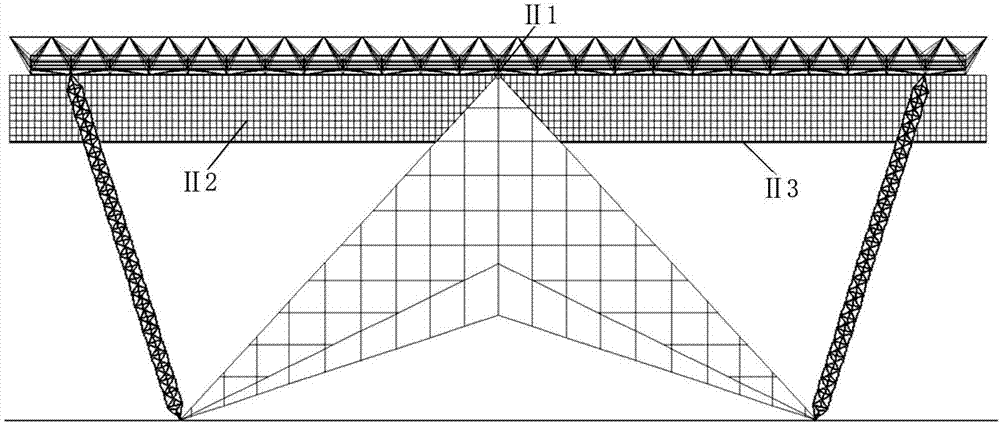

[0073] Such as figure 1 As shown, a construction method for overall hoisting of large multi-angular cantilevered trusses is characterized in that,

[0074] The steel pipe truss is assembled on site as a whole, and the overall hoisting is carried out after the assembly is completed; after the three welding positions of the truss are connected, they are welded firmly; Hoisting;

[0075] The construction method specifically includes the following steps:

[0076] 1) Pipe truss factory processing and production

[0077] ① Rod butt joint

[0078] Before butt jointing, the steel pipes should be cut on the pipe lathe, and then the rods should be butt welded on the special tire frame. The quality of the butt welding seam should meet the first-class ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Breaking force | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com