Manufacturing method for spiral twisted box type

A production method and spiral technology are applied in the production field of spiral twisted box shapes, which can solve the problems of high production requirements, low production efficiency, and difficult installation, and achieve the effects of ensuring production quality, improving production efficiency, and meeting assembly precision requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

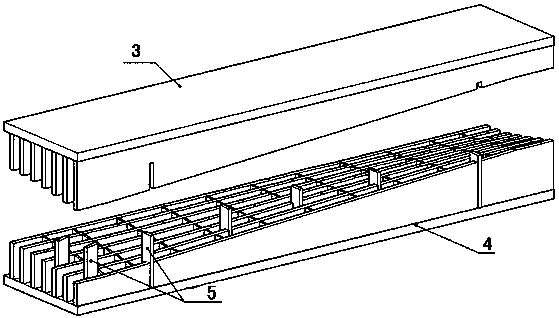

[0035] see figure 1 , one A manufacturing method of a spiral twisted box type is carried out according to the following steps:

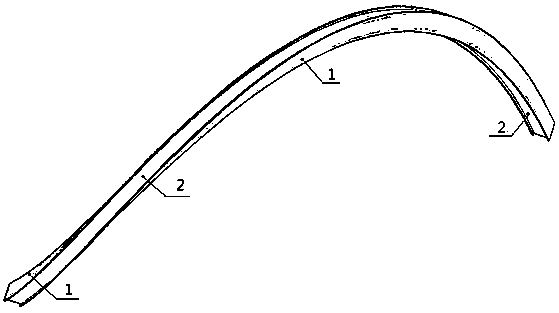

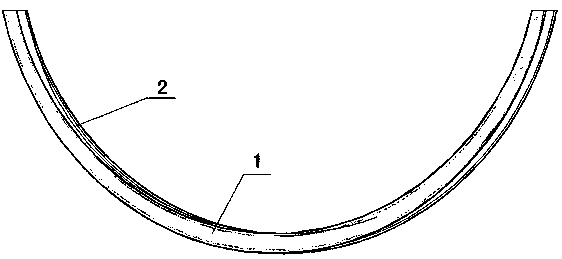

[0036] Step 1: With the aid of CAD, Tekla Structures and other 3D drawing software, establish models of all helically twisted box-shaped members of the whole bridge, and classify and number all helically twisted box-shaped structural members of the whole bridge. The edge plate 1 and the web plate 2 are unfolded respectively.

[0037] Step 2, according to the capacity of the processing equipment, the expanded flange plate 1 and web plate 2 are cut into sections, and the length of the sections is equally divided to ensure the versatility of the flange plate and web plate, and each sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com