Antenna-integrated package structure and manufacturing method thereof

A technology of packaging structure and manufacturing method, which is applied in the direction of antenna support/mounting device, radiation element structure, etc., can solve the problems of substrate shrinkage manufacturing process efficiency, low assembly yield, and insufficient, so as to avoid high-frequency parasitic effects, Effect of reducing signal transmission loss and reducing signal transmission distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

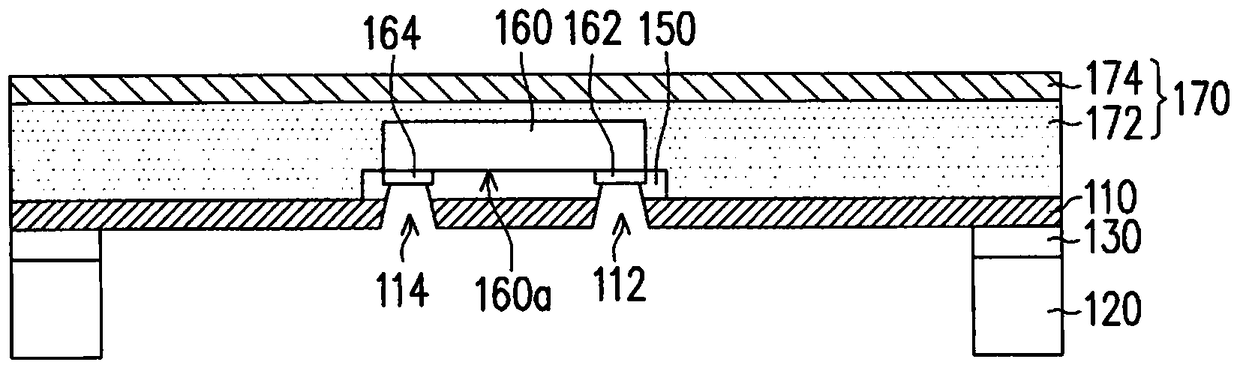

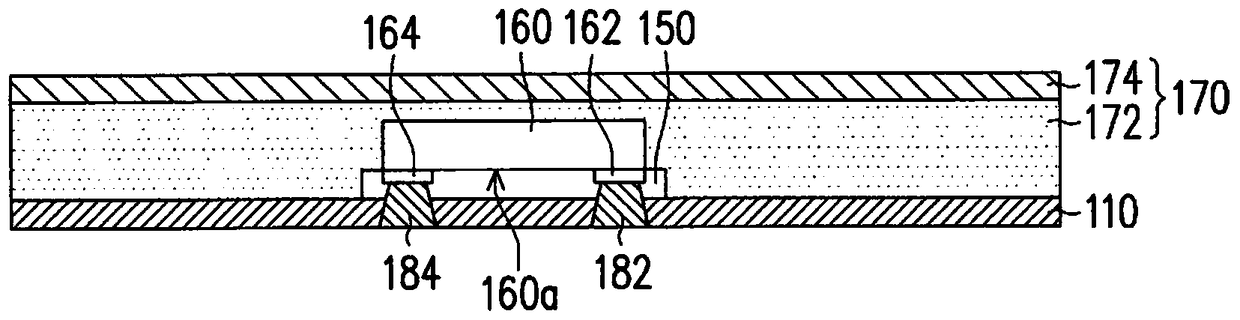

[0057] Figure 1 to Figure 6 It is a cross-sectional flowchart of a method for manufacturing an antenna-integrated package structure according to an embodiment of the present invention.

[0058] refer to figure 1 , first provide a carrier board 120 . Next, the first metal layer 110 is bonded to the carrier 120 , and the first metal layer 110 is bonded to the carrier 120 through the adhesive layer 130 . The bonding surface of the first metal layer 110 may have a release layer 140, the release layer 140 only partially covers the bonding surface, and in some areas the first metal layer 110 is bonded to the bonding surface through the release layer 140 and the adhesive layer 130. carrier plate 120 .

[0059] see figure 1, and then, a primer 150 is formed on the first metal layer 110 . A chip 160 is disposed on the primer 150 so that the chip 160 is attached to the first metal layer 110 through the primer 150 . The chip 160 has an active surface 160a, a first contact pad 162...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com