Safety automatic pouring system

A gating system, safe and automatic technology, applied in the direction of equipment that sends molten metal into molds, metal processing equipment, casting equipment, etc., can solve the problem of affecting the health of operators and production efficiency, without protective equipment and protective measures, staff Safety hazards and other issues, to achieve the effect of saving resources, saving operation time, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

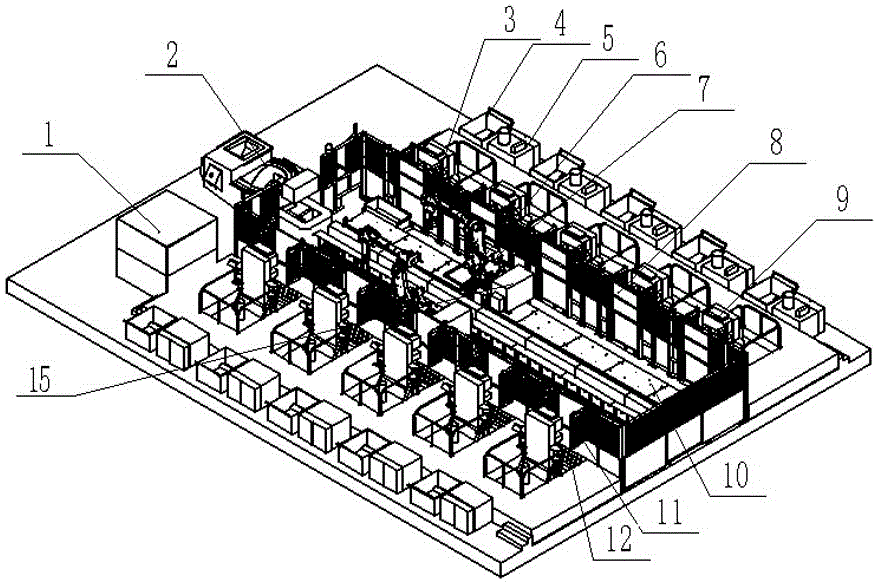

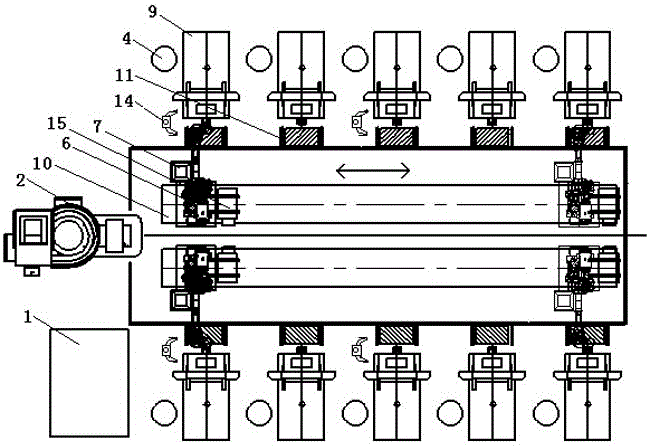

[0024] Such as figure 1 and figure 2 As shown, a safe automatic pouring system includes a mobile platform 10 and a pouring robot 6 set on the mobile platform 10 (in this embodiment, the pouring robot 6 is a six-axis joint robot, and the transmission end of the pouring robot 6 is installed through a clamp 3 There are pouring ladles 16 for picking and placing molten metal), a smelting furnace 2 arranged at one end of the mobile platform 10, a fence 8 surrounding the mobile platform 10, and four casting machines 9 arranged along the mobile platform 10 and located outside the fence 8 ( The number of casting machines 9 is not limited to 4, and can be appropriately increased or decreased according to actual production requirements and site constraints), openings are provided at the corresponding positions of the melting furnace 2 on the fence 8, and double ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com