AAQFN package part using electroplating process and manufacture process thereof

An electroplating process and manufacturing process technology, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of cumbersome packaging process and increased packaging costs, so as to improve electrical performance and product reliability, save Package cost, wear prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

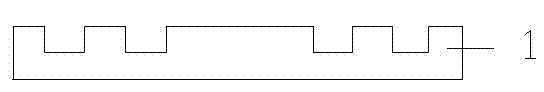

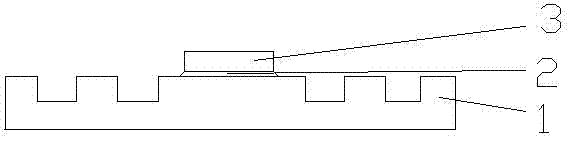

[0022] As shown in the figure, an AAQFN package using an electroplating process is mainly composed of a copper lead frame 1, a die adhesive 2, a chip 3, a bonding wire 4, a molding compound 5, a solder resist layer 6 and a solder ball 7. The copper lead frame 1 is first half-etched, and then the chip 3 and the etched copper lead frame 1 are bonded with the adhesive 2, and the chip 3 and the etched copper frame 1 pin are bonded. The connecting wire 4 is connected, and then plastic-sealed with a plastic encapsulant 5. The copper pin 1 is to etch the bottom of the half-etched copper frame to separate the pins, and then fill the etched pins at the bottom with a solder resist layer 6 The voids are then electroplated with tin balls 7 using an electroplating process, followed by product cutting.

[0023] As shown in the figure, a manufacturing process of an AAQFN p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com