FCQFN encapsulation part preventing solder balls from collapsing and manufacturing process of FCQFN encapsulation part

A manufacturing process and packaging technology, used in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as chip and frame reduction, plastic packaging voids, and impact on product reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

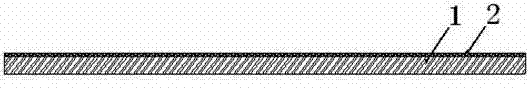

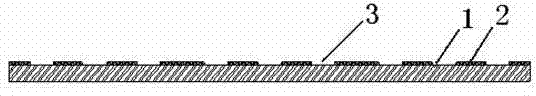

[0029] The specific implementation method is: the first layer of green paint 2 (photosensitive resist material) is coated on a specific area of the copper lead frame 1 by screen printing, exposed and developed after drying, and formed as image 3 The green paint groove 3 shown has a groove depth of about 30 μm, an opening of about 0.22 mm, and a copper lead frame thickness defined as 0.127 mm. Then, the tin-silver-copper bump 5 is dipped in flux, and the tin-silver-copper bump 5 is combined with the copper surface in the corresponding green paint groove 3 through a flip-chip machine, and an effective solder joint is formed under the action of reflow soldering, and the chip The diameter of the bump is 0.2mm, the height of the tin-silver-copper bump 5 is 0.13mm, and the material is Sn96.5%Ag3.0%Cu0.5%. Finally, the residual flux on the tin-silver-copper bumps 5 is cleaned with plasma water having a resistivity of 1.0 m / Ω.mm or more. The reflux temperature is 260°C, the reflux...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com