Method of the encapsulation vertical surface-mount module and base sheet, horse and vertical surface-mount module

A lead frame and pin technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of increasing the size of the substrate, increasing the occupied area, and occupying a large area, so as to increase the number of I/Os and increase the The number of I/O ports and the effect of improving the degree of circuit integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

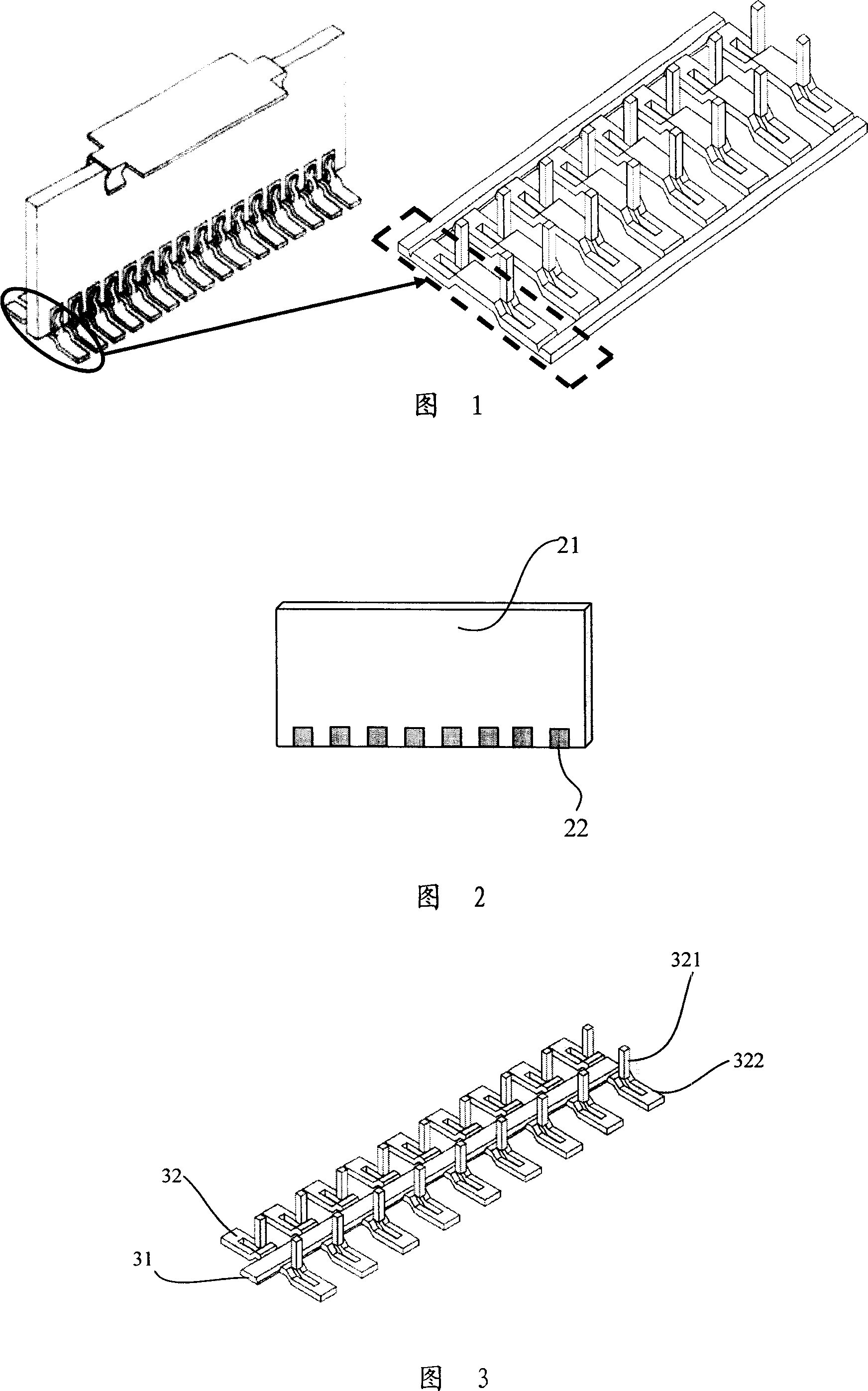

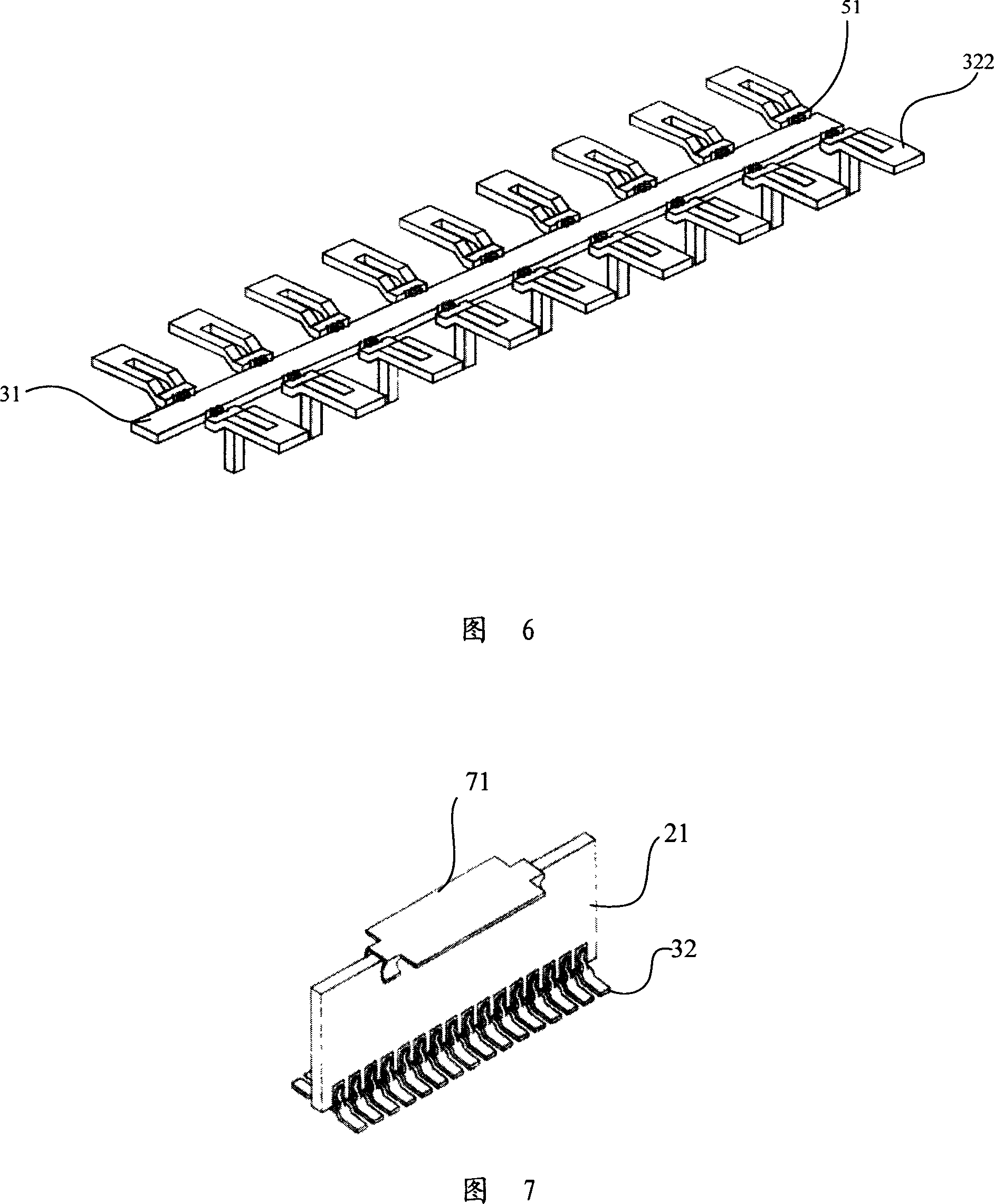

[0027] The embodiment of the present invention provides a method for packaging a vertical surface-mount module and a technical solution for a substrate, a lead frame, and a vertical surface-mount module. One pad of the substrate corresponds to one I / O port, and the corresponding In the process of packaging the vertical surface mount module, the lead frame with the intermediate connection bar structure will be used. After the package is completed, the connection bar will be removed to separate the pins, so that a single pin corresponds to a single pad of the substrate, corresponding to a single I / O port, so as to realize the vertical double list paste module.

[0028] The specific technical solutions of the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

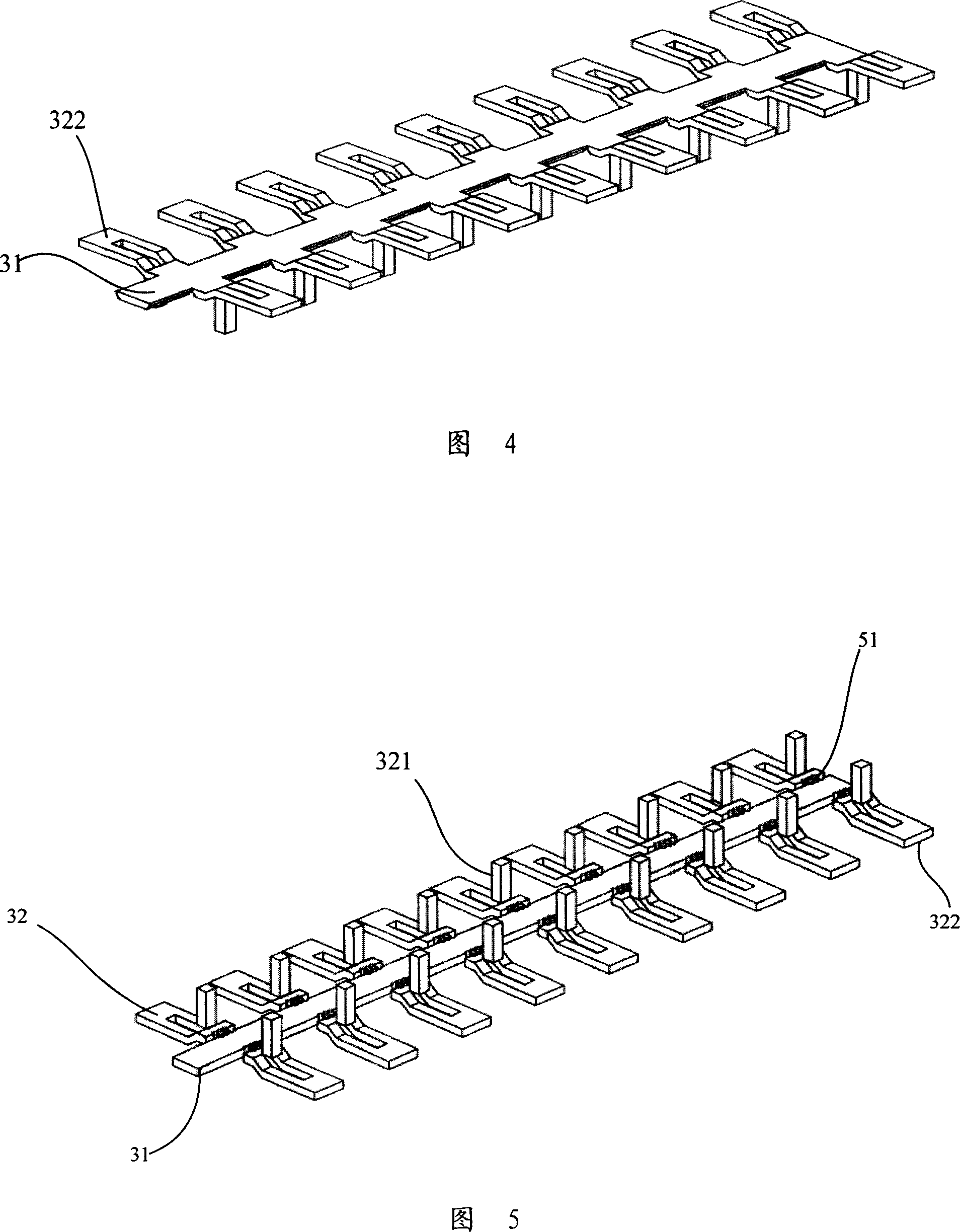

[0029] Referring to FIG. 2 , it is a schematic structural diagram of a specific embodiment of a substrate provided by the present invention. It can be seen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com