Piezoelectric shape meter for detecting flatness of cold and thermal state strip material

A piezoelectric and shape meter technology, which is applied in the field of testing instruments and automatic measurement of metallurgical machinery and equipment to achieve the effect of improving flatness, reducing the influence of electromagnetic interference and temperature changes, and improving accuracy and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

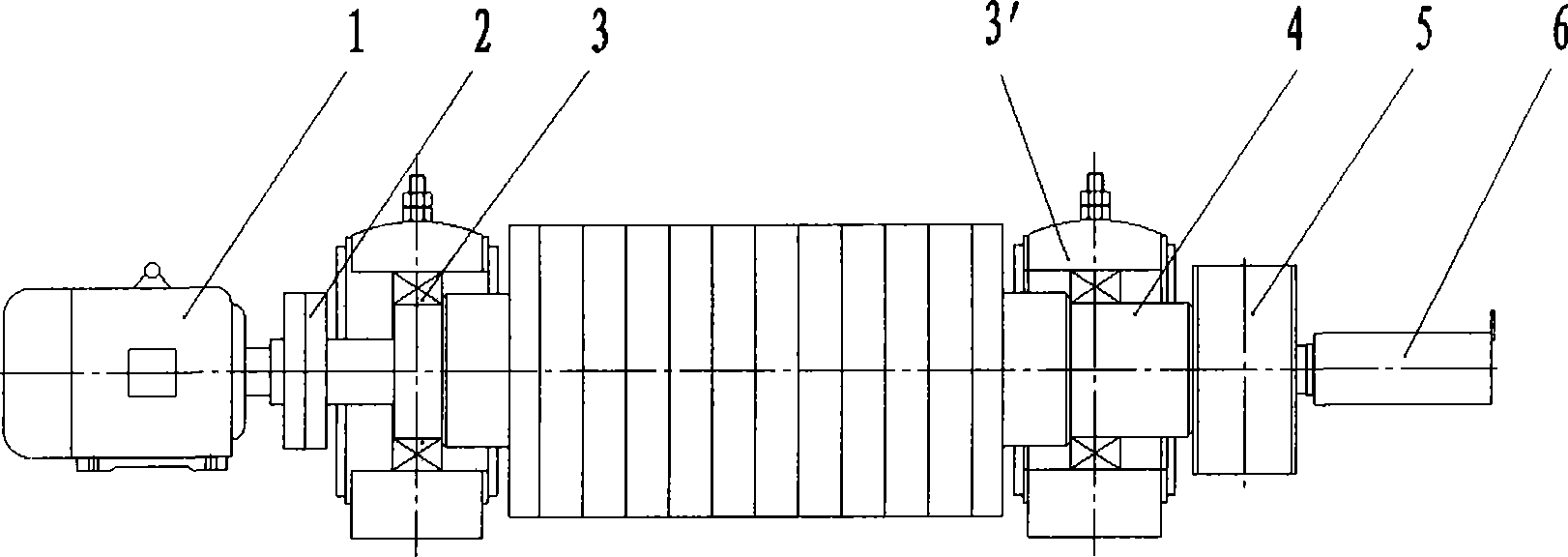

[0012] figure 1 As an embodiment disclosed by the present invention, the shape meter is driven by a stepless speed-regulating motor (1) connected to one end of the detection roller (4) through a coupling or directly driven by the strip steel to be detected. An angular displacement sensor is installed at the end of the roller body to detect the rotational speed, and to ensure that the rotational speed of the detection roller (4) is synchronized with the speed of the rolled plate and strip. The other end of the detection roller (4) is equipped with a power distributor (5), and the signal of the piezoelectric sensor (12) is connected to the power distributor (5), and the signal is carried out through the connection of the charge amplifier, the acquisition card, the signal transmission device (6) and the computer. Processing and shape signal display.

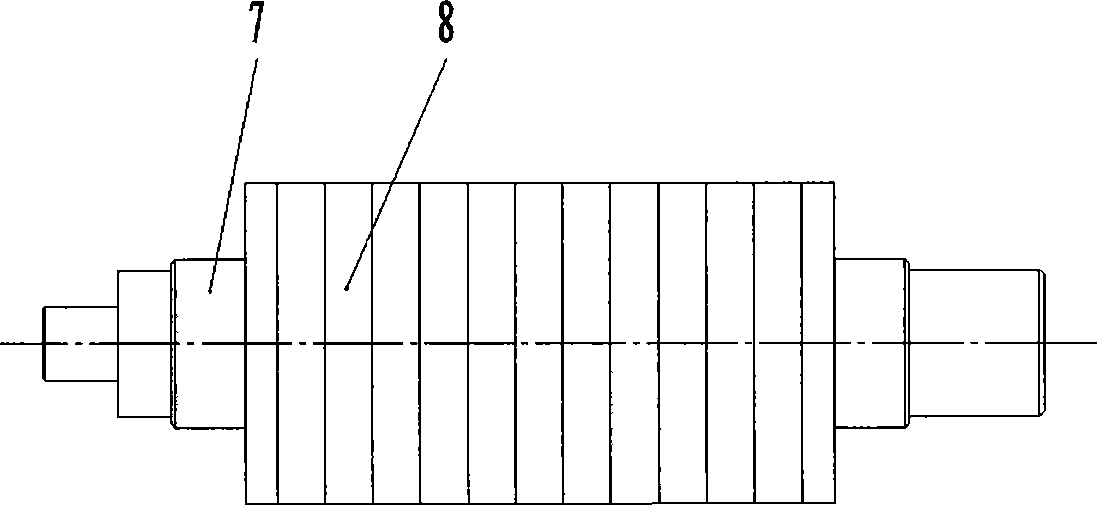

[0013] The roll core (7) of the detection roll (4) is a cylindrical structure (see figure 2 ), the outer surface of which is ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com