Sensor assembly shell, leadless thermopile sensor and manufacturing method

A thermopile sensor, sensor technology, applied in instruments, measuring devices, scientific instruments, etc., can solve the problems of hindering epidemic prevention work, poor shock resistance, inaccurate body temperature parameters, etc., to save binding lead space and lead connection. Process, the effect of reducing the overall size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

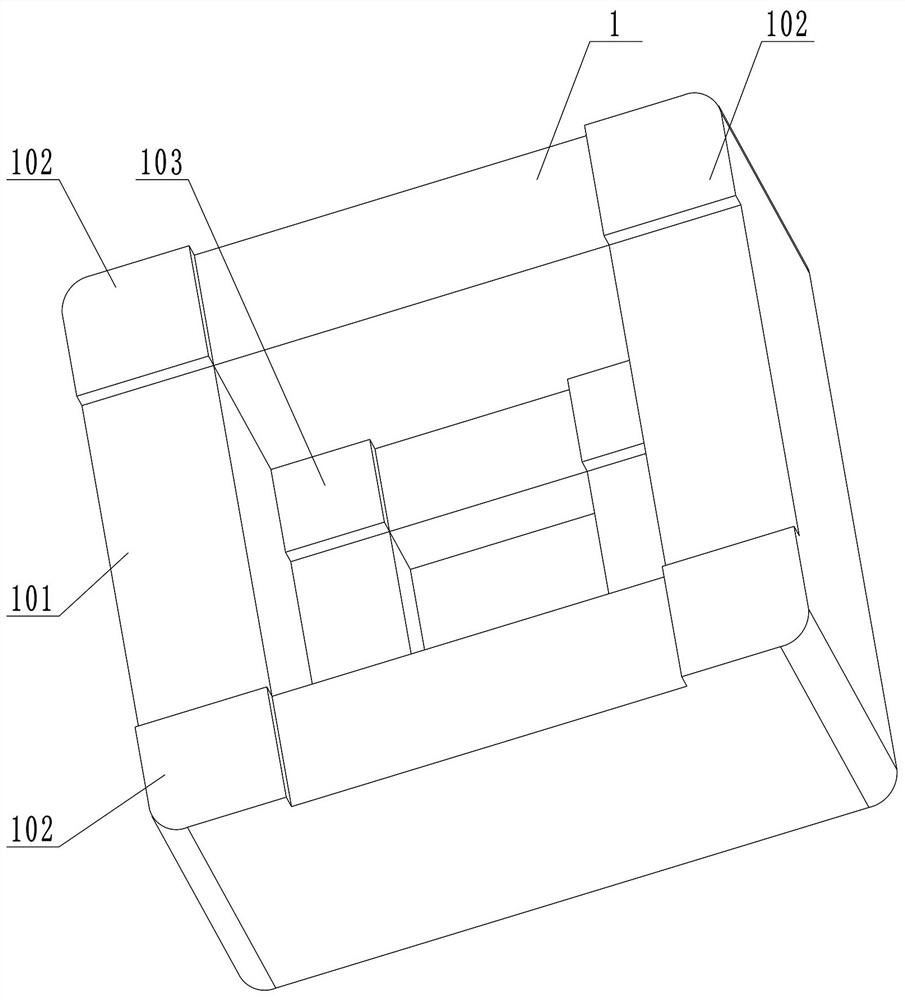

[0044] attached Figures 2 to 4 A sensor assembly housing is shown, the sensor assembly housing 1 is provided with a detection chamber for accommodating at least one thermopile sensitive chip, and the top of the detection chamber is provided with an internal conductive wire for electrically connecting the thermopile sensitive chip. Bump 103, the outer wall of the sensor assembly housing 1 is provided with an external pin 102 for outputting a detection signal; the external pin 102 is connected to the internal conductive bump 103 to detect the thermopile sensitive chip 2 The signal is output via the external pin. The inner conductive bump is an inner pad.

[0045] In this embodiment, the optical filter 4 is mounted in the window 104 opened on the top of the detection chamber; the bottom plate 3 is covered above the installation port of the bottom 101 of the detection chamber, and the housing is assembled with the sensor 1 is sealed and connected, and the bottom plate 3, the op...

Embodiment 2

[0053] This embodiment provides a specific implementation of a single-channel leadless thermopile sensor, as attached figure 1 And attached Figure 6 shown.

[0054] The leadless thermopile sensor comprises the above-mentioned sensor assembly housing, thermopile sensitive chip 2 and optical filter 4; The surface is set corresponding to the filter 4; the detection surface of the thermopile sensitive chip 2 is provided with electrode pads 201 on the same side, and the electrode pads 201 of at least one thermopile sensitive chip are electrically conductive with the inside of the top of the detection chamber. The bumps 103 are contacted and connected to realize the electrical connection between the thermopile sensitive chip 2 and the sensor assembly housing.

[0055] This embodiment provides a specific implementation of a sensor assembly housing, the sensor assembly housing includes a sensor assembly housing 1 and a bottom plate 3, the sensor assembly housing 1 is provided with ...

Embodiment 3

[0063] On the basis of the above-mentioned leadless thermopile sensor, the present invention also provides a manufacturing method of the leadless thermopile sensor.

[0064] The manufacturing method of the leadless thermopile sensor includes the following steps: attaching the optical filter 4 in the window 104 on the top of the detection chamber through epoxy resin glue, so as to ensure the airtight connection between the optical filter and the sensor assembly housing , to avoid light leakage; turn the above-mentioned sensor assembly housing 1 upside down, apply conductive glue on the internal conductive bump 103 on the top of the detection chamber through a glue dispenser, and place the thermopile sensitive chip 2 into the sensor assembly housing 1 In the detection chamber, wherein, the detection surface of the thermopile sensitive chip 2 is set corresponding to the optical filter 4, so that the electrode pad 201 of the thermopile sensitive chip is in contact with the internal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com