Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

104results about How to "Reduce the amount of air bubbles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid container, liquid delivering device equipped therewith and liquid delivering method

ActiveCN102050248AImprove qualityAvoid breakingClosuresLiquid transferring devicesEngineeringElectrical and Electronics engineering

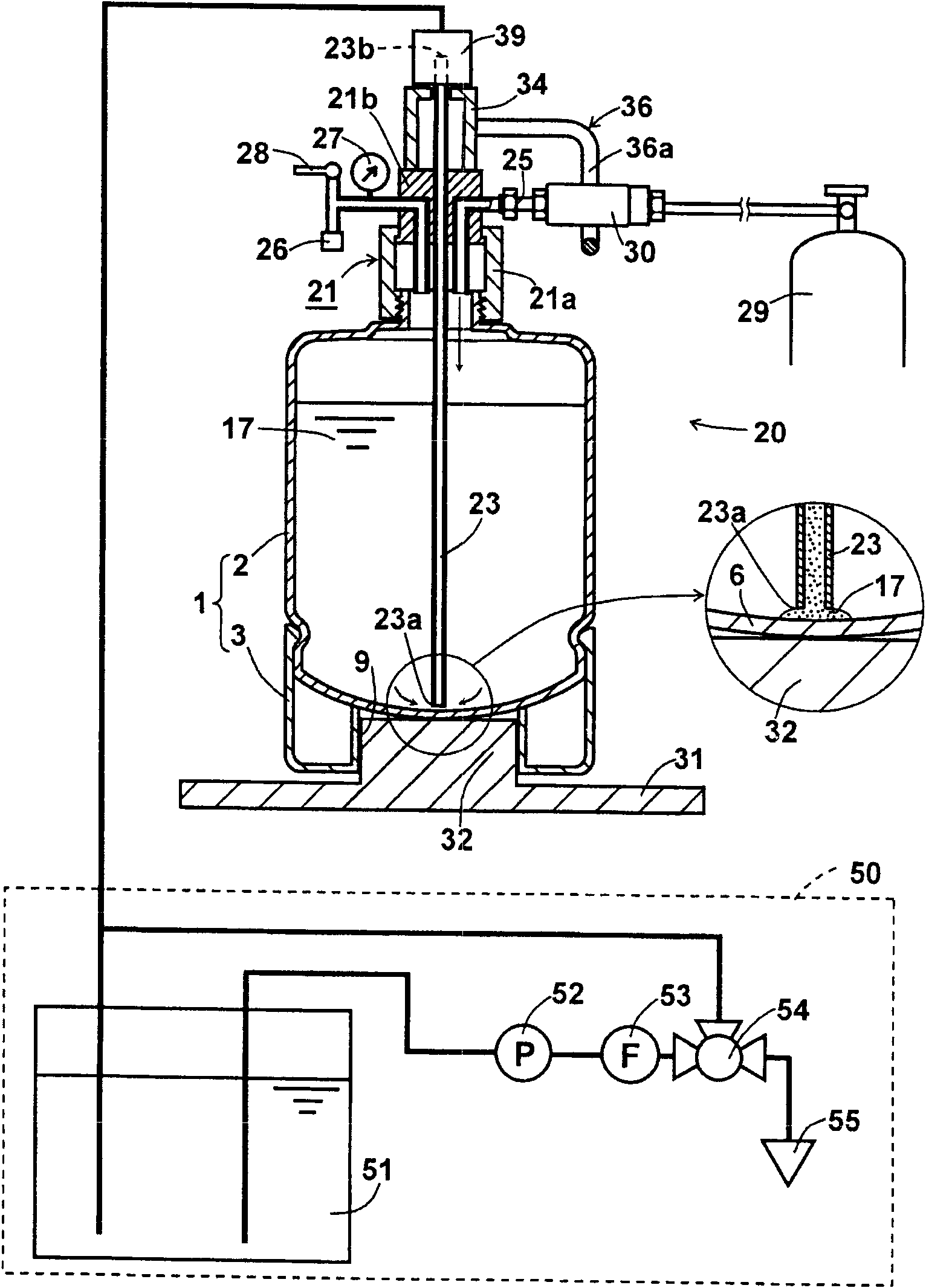

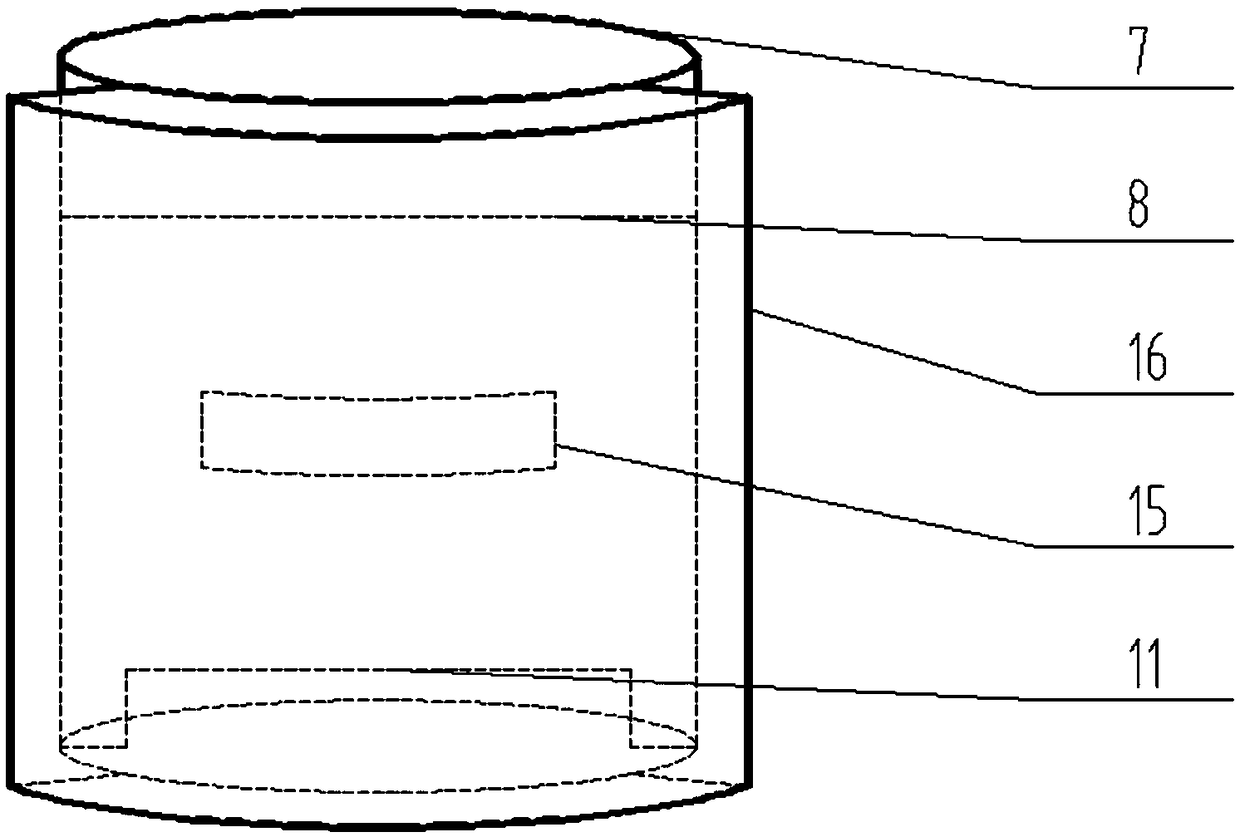

The invention discloses a liquid container, a liquid delivering device equipped therewith and a liquid delivering method. The liquid container can maintain the filled liquid with high quality, wherein the space is saved for storing liquid and the residual liquid is reduced to the minimal amount when the liquid is discharged. According to the liquid delivering device and the liquid delivering method, the installation and replacement operation of the liquid container is operated conveniently, which is simple in structure and low in cost. Meanwhile, the amount of the residual liquid in the container is largely reduced and the liquid is discharged safely. The liquid container (1) comprises a round-bottomed main body (2) and a supporting platform (3) made of thermoplastic resin with a bending elastic rate of at least 700 MPa. The inner surface of the main body (2) is made of thermoplastic resin of high purity and the supporting platform (3) is equipped with a through part (9). According to the liquid delivering device (20) arranged on the liquid container (1), the end (23a) of a liquid feeding pipe (23) is inserted to the round bottom (6) of the container. The upper end and the lower end of the main body (2) are respectively clamped by a protrusion part (32) and a pressing member (34). When gas with a pressure of 200 kPa is supplied, the liquid in the container is discharged.

Owner:AICELLO

Reflow-soldering die bonding process

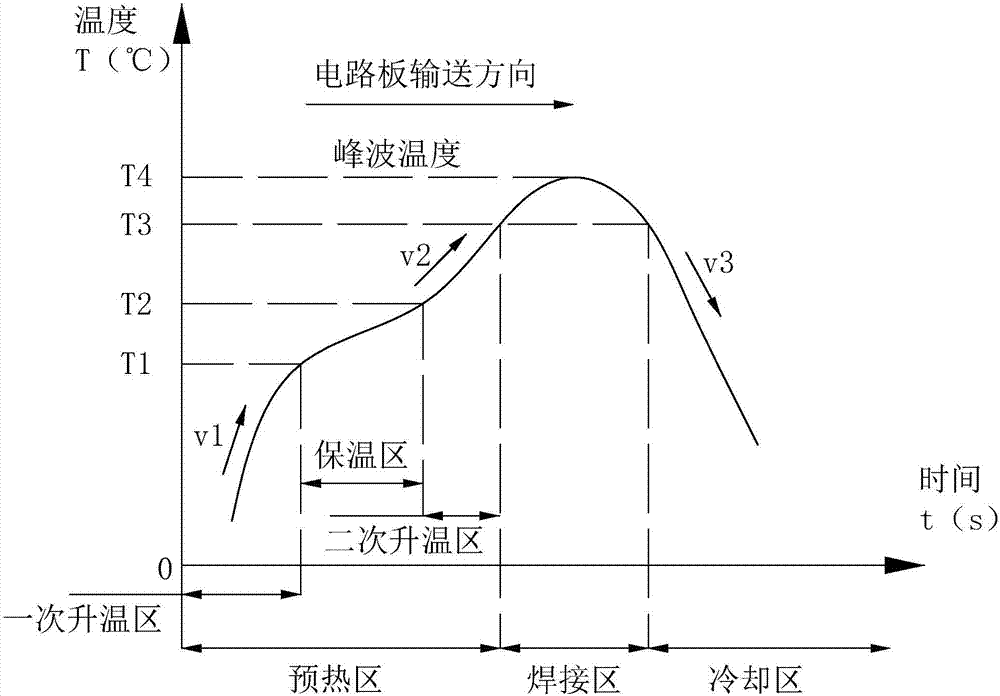

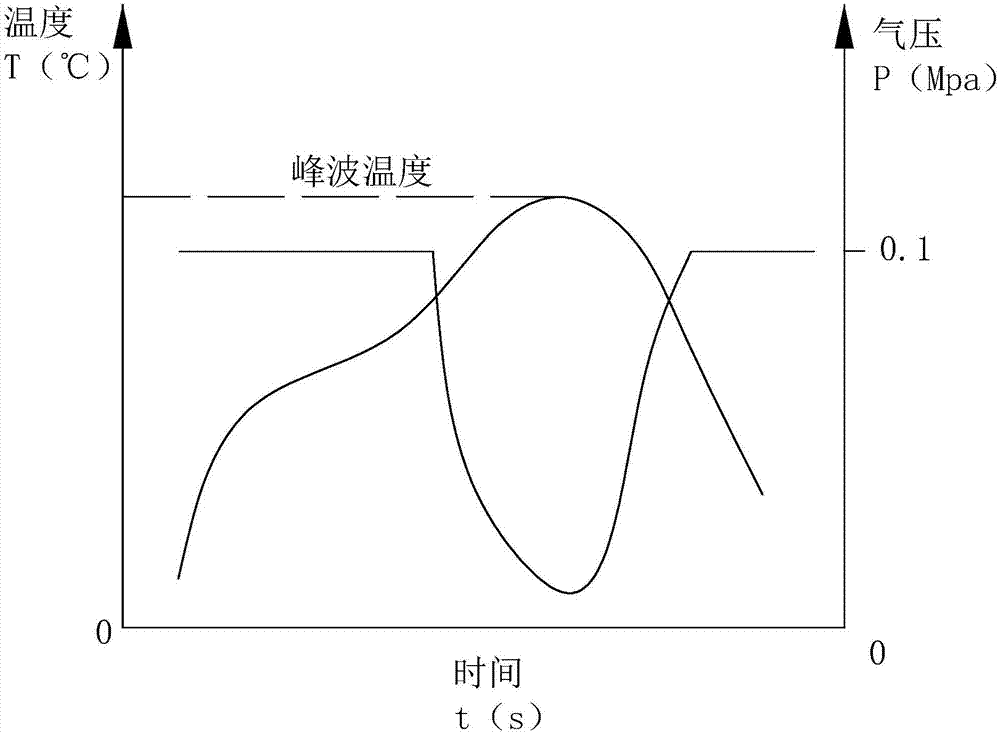

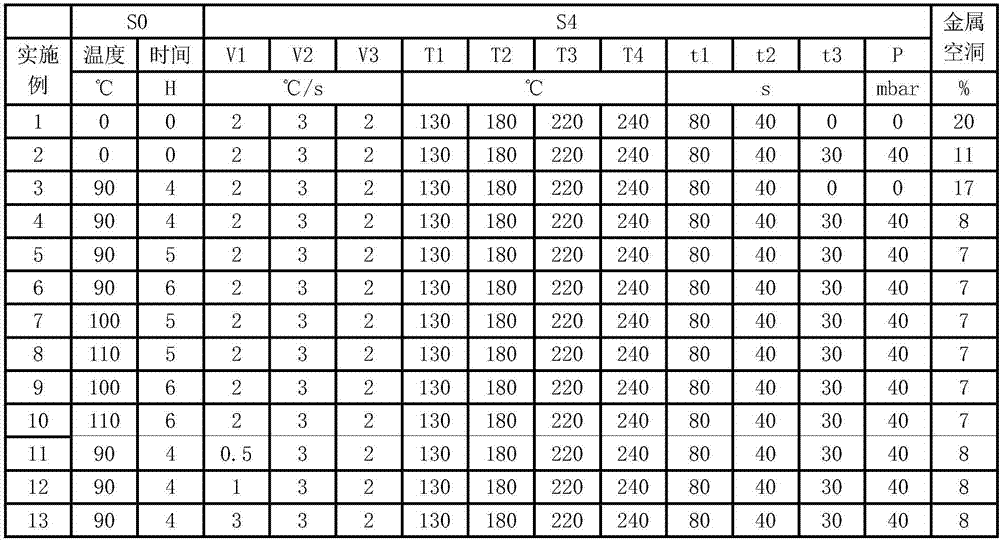

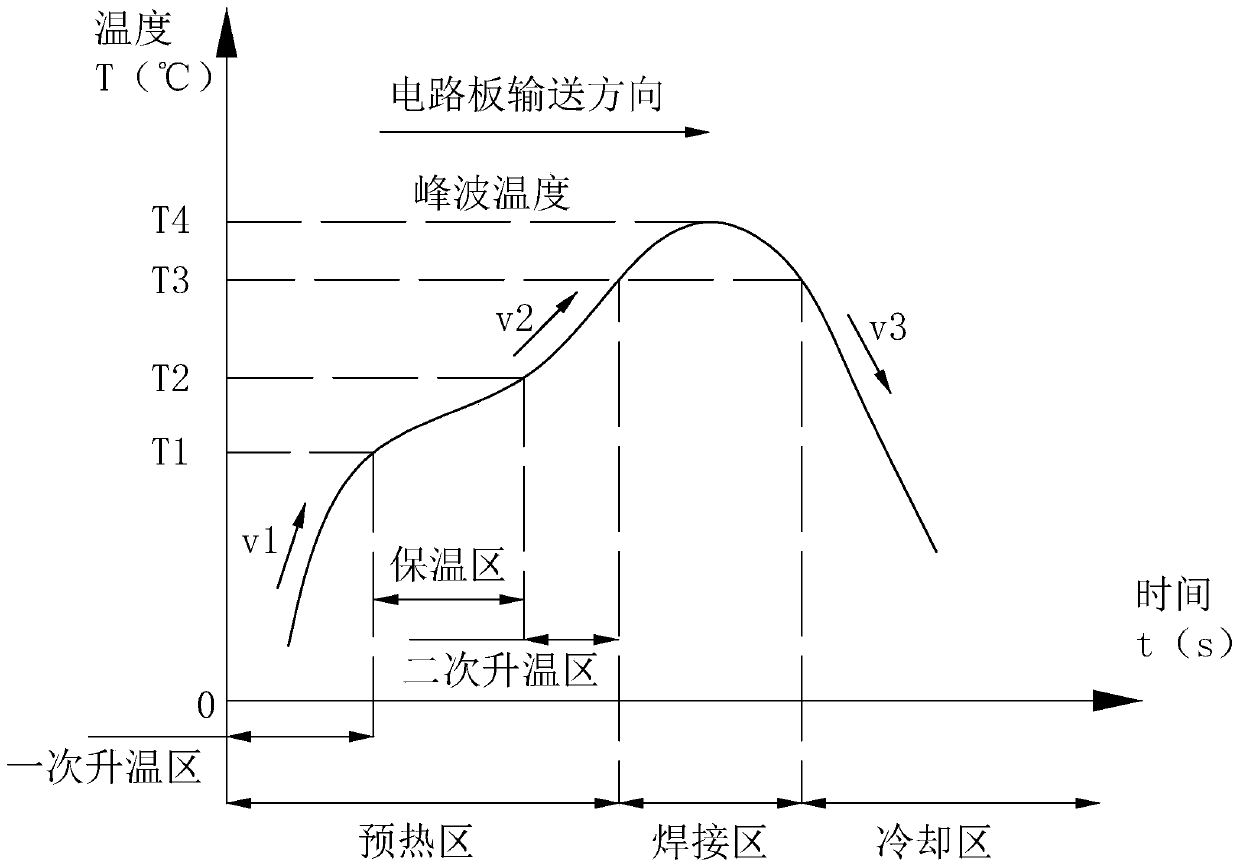

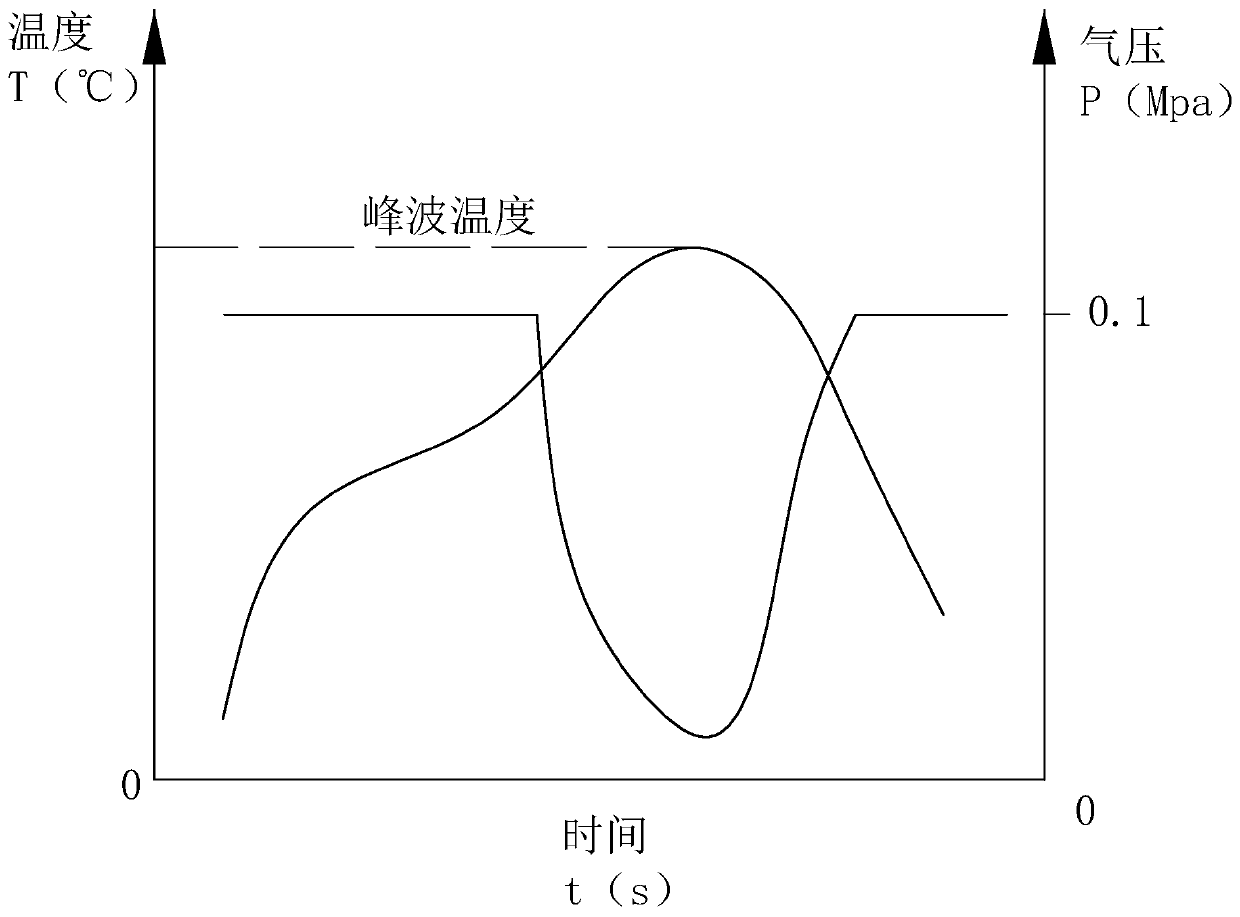

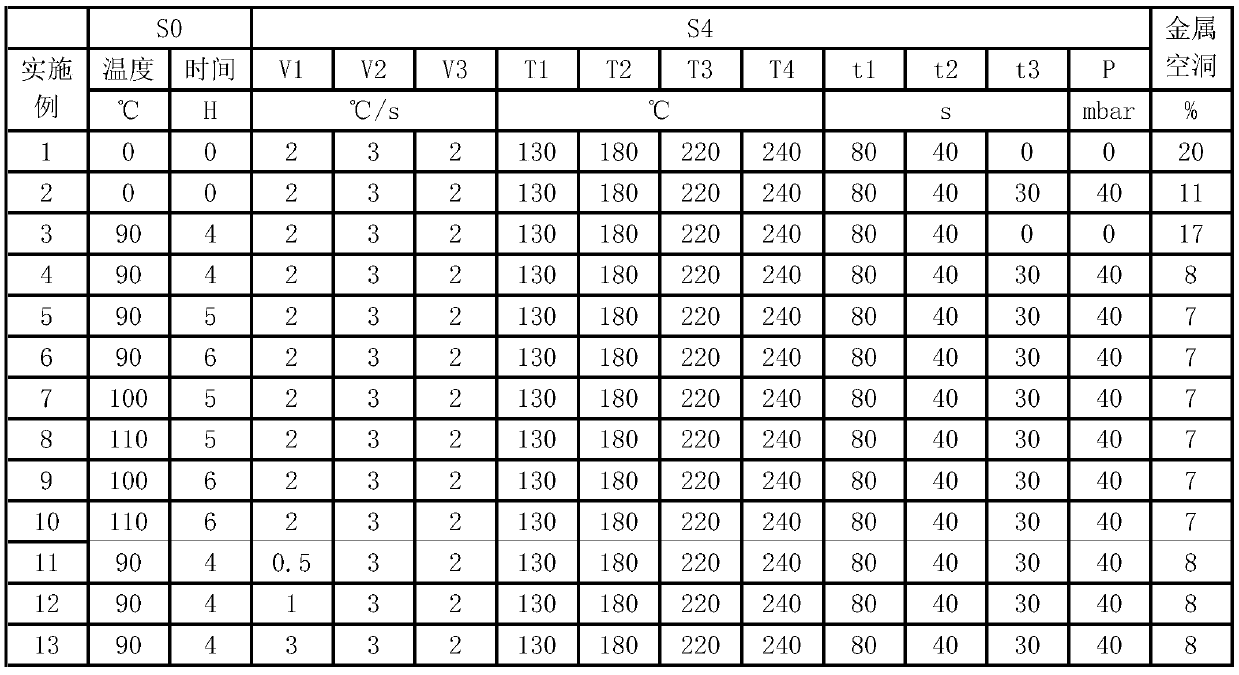

ActiveCN107124835AReduce generationReduce the amount of air bubblesPrinted circuit assemblingPressure reductionSolder paste

The invention discloses a reflow-soldering die bonding process. The process comprises the following steps of printing a solder paste, patching, intermediate inspection, reflow soldering and inspection after soldering. During the reflow soldering step, the pressure reduction treatment is conducted. In this way, the formation of cavities, due to the generation of huge air bubbles during the welding process, can be avoided. The formation of explosive exhausts, caused by the escaping of huge air bubbles, is also avoided. Since many fine tin beads are escaped, the negative pressure is formed in a welding zone through the pressure reduction treatment. Therefore, small air bubbles escape easily during the welding process, and huge air bubbles are not easily formed. The phenomenon of bead splashing is avoided.

Owner:杭州晶志康电子科技有限公司

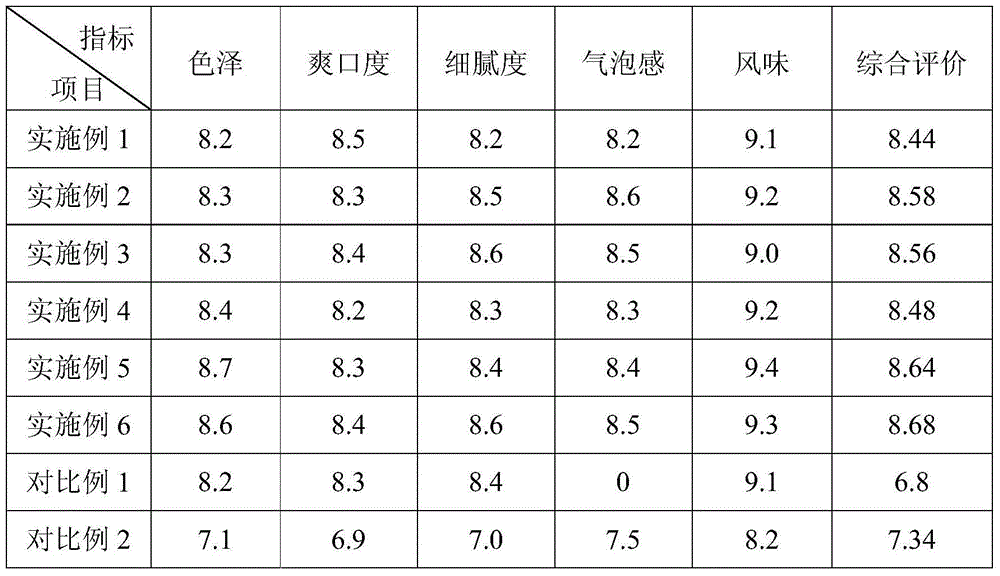

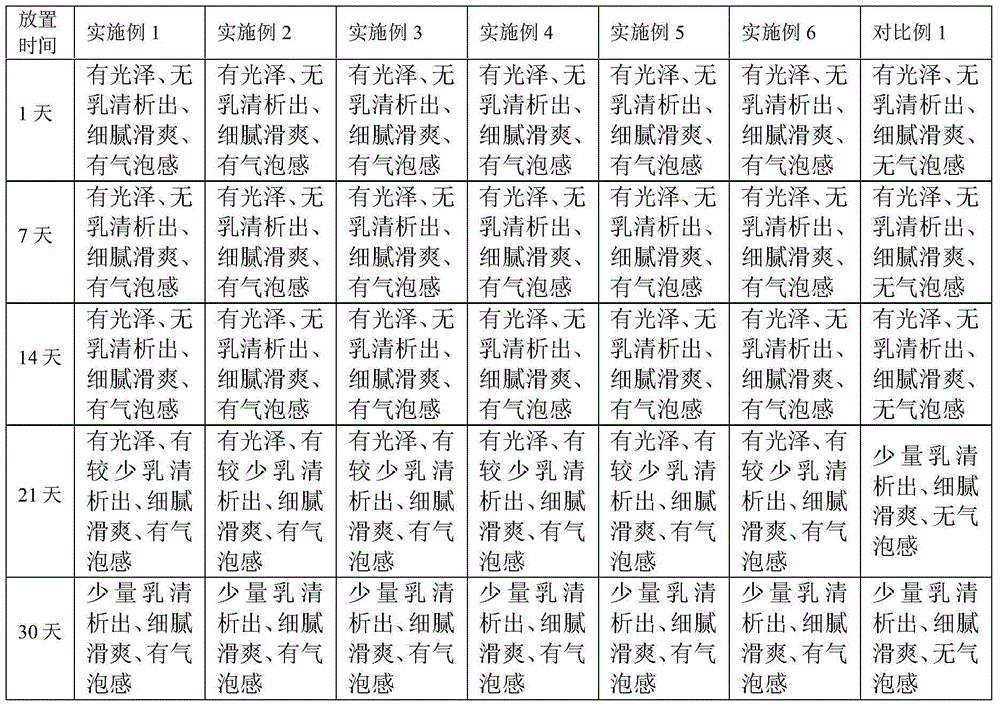

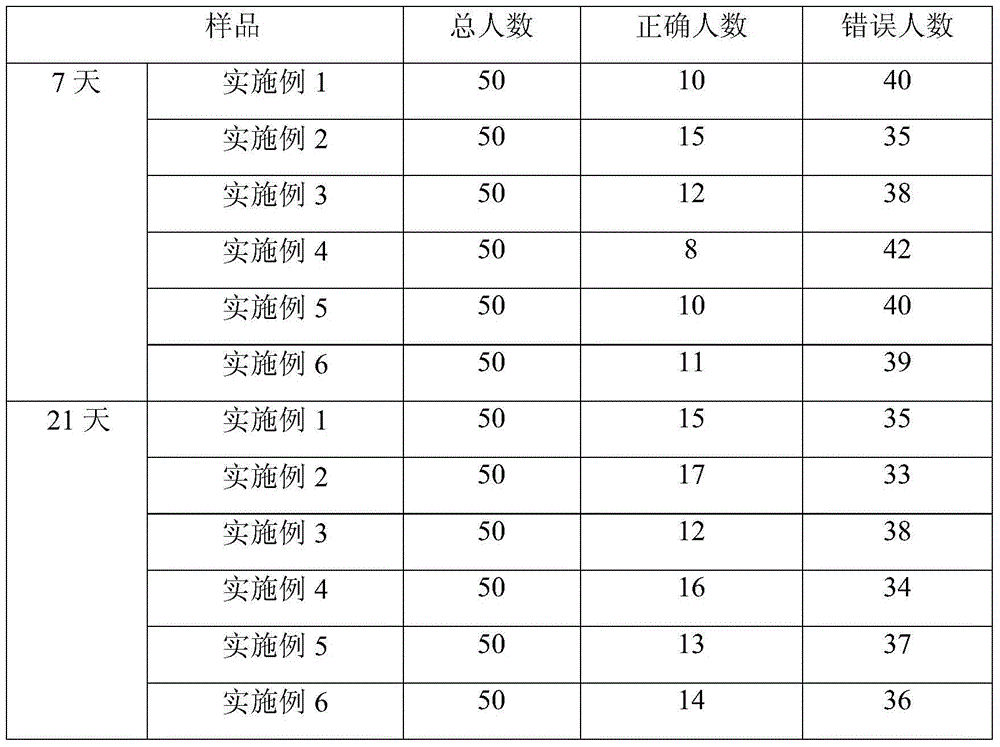

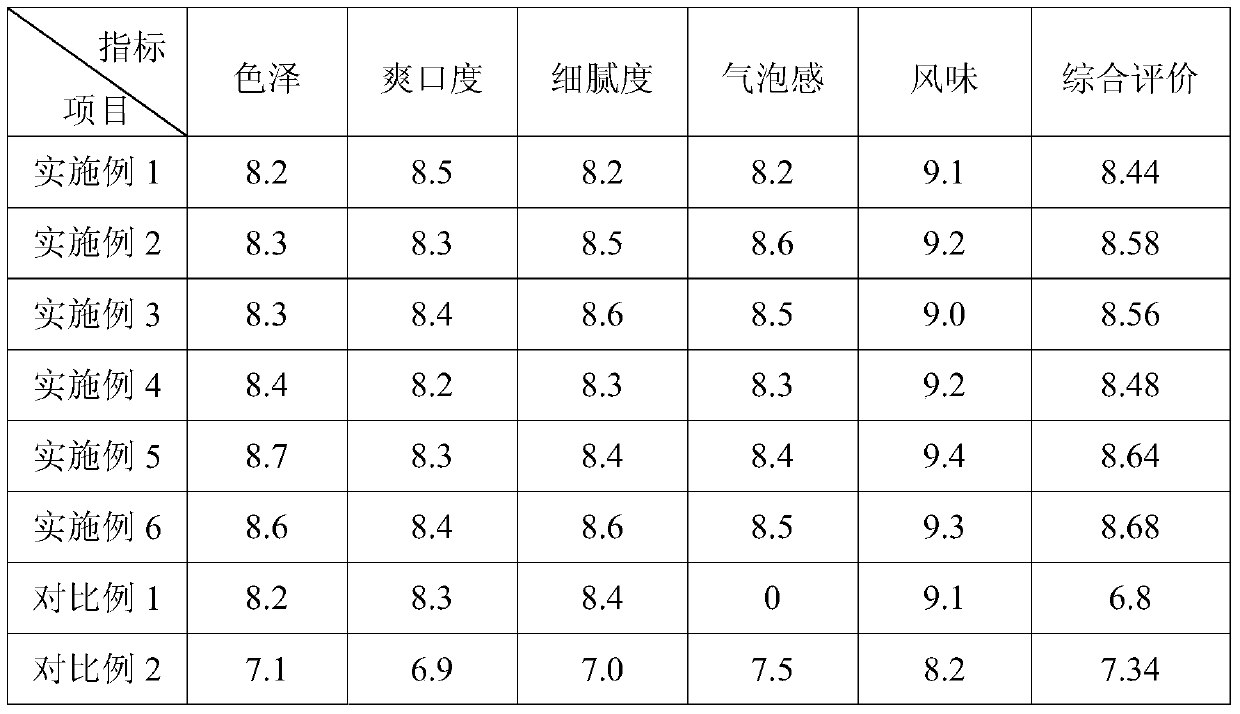

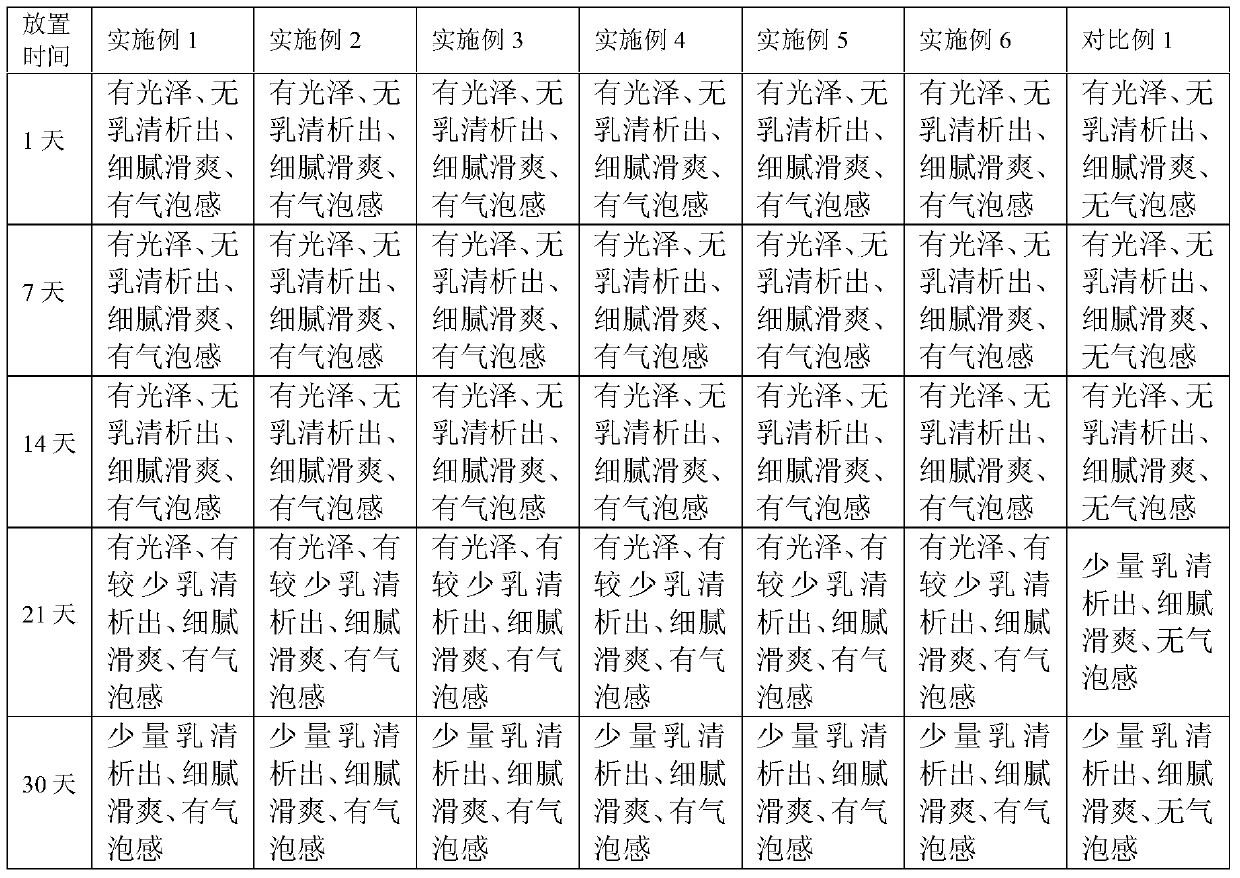

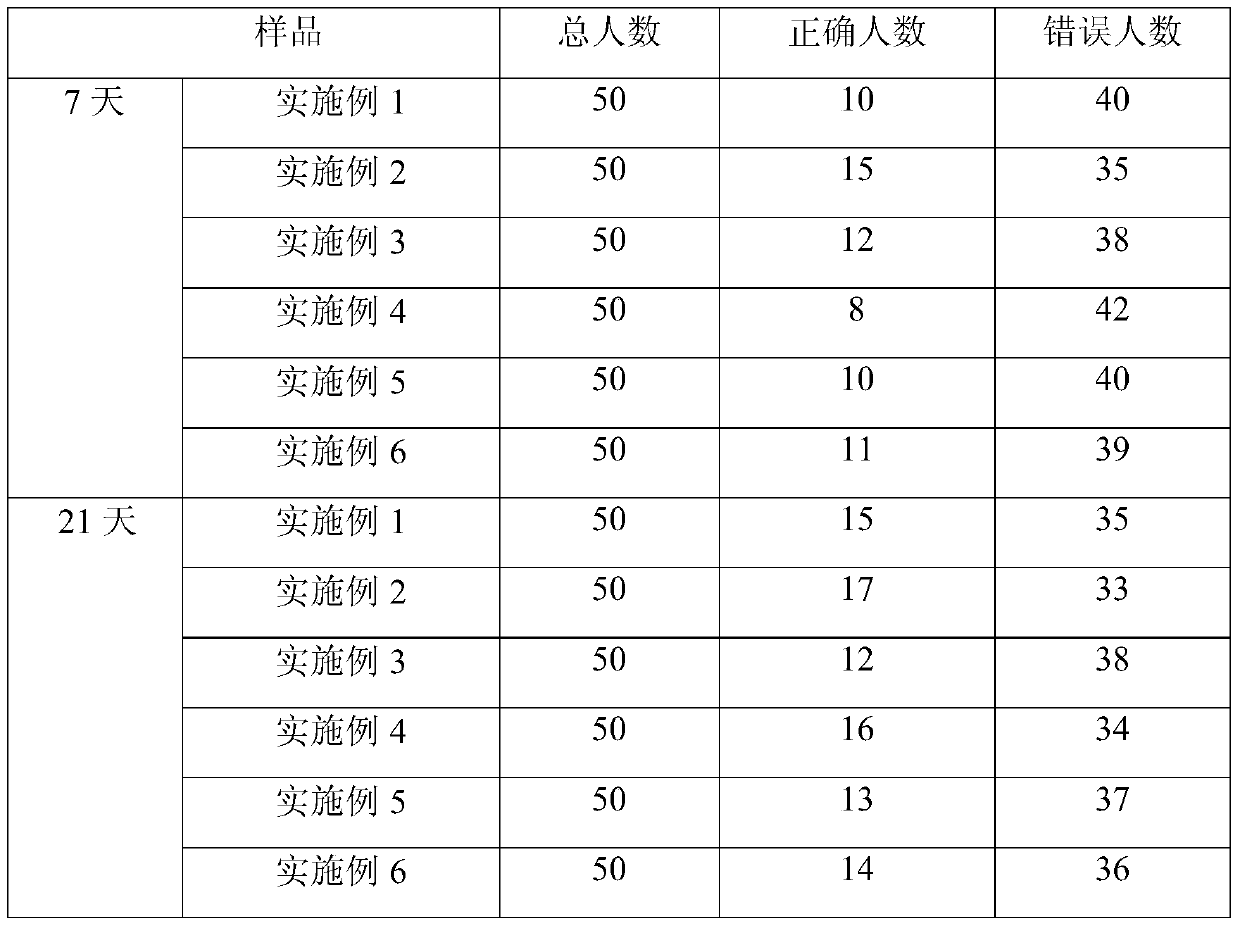

Gas-production fermented milk, flavored fermented milk and preparation methods thereof

ActiveCN104642541AStrong foam holding capacityWon't overflowMilk preparationLactic acid bacteriumFood flavor

The invention provides gas-production fermented milk, flavored fermented milk and preparation methods thereof. The gas-production fermented milk is a product including fine bubbles, which is prepared from fresh raw milk or reconstituted milk as a raw material and through processes of sterilization and inoculation of a fermentation agent comprising lactococcus lactis subsp. cremoris, leuconostoc, lactococcus lactis subsp. diacetylactis and lactococcus lactis subsp. lactis to perform strain fermentation. The gas-production flavored fermented milk is a product including fine bubbles, which is prepared with the fresh raw milk or the reconstituted milk accounting for not less than 80% as a raw material with addition of other raw materials and through the processes of sterilization and inoculation of a fermentation agent comprising lactococcus lactis subsp. cremoris, leuconostoc, lactococcus lactis subsp. diacetylactis and lactococcus lactis subsp. lactis to perform strain fermentation. In the products, special lactococcus lactis is used in fermentation to generate CO2 and special flavors, wherein the majority of gas exists in the form of fine bubbles in the products. The products are refreshing in taste, are unique in texture and are suitable for various people.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

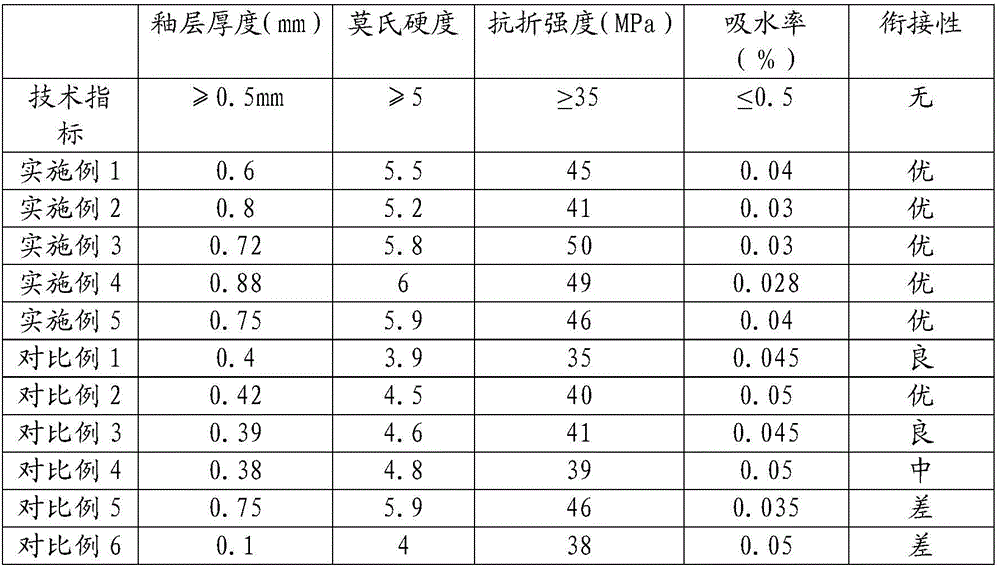

Background wall brick preparing method and background wall preparing method

ActiveCN106007800AGood melting performanceReduce high temperature viscosityCovering/liningsInkjet printingHardness

The invention provides a background wall brick preparing method. The background wall brick preparing method comprises the following steps: 1, forming a green body and drying the green body to obtain the dry green body; 2, applying ground coat enamel on the surface of the dry green body to obtain a first green brick; 3, inkjet printing the ground coat enamel of the first green brick to obtain a second green brick; 4, drying the second green brick to obtain a third green brick; 5, applying cover glaze on the inkjet-printed side of the third green brick to obtain a fourth green brick; 6, drying the fourth green brick to obtain a fifth green brick; 7, roasting the fifth green brick at high temperature to obtain a sixth green brick; 8, polishing the sixth green brick to obtain the background wall brick. The background wall brick is large in moh hardness and breaking strength and low in water absorption. The invention further provides a background wall preparing method, and the background wall is good in link and attractive and elegant in appearance.

Owner:HEYUAN DONGYUAN EAGLE CERAMICS CO LTD +2

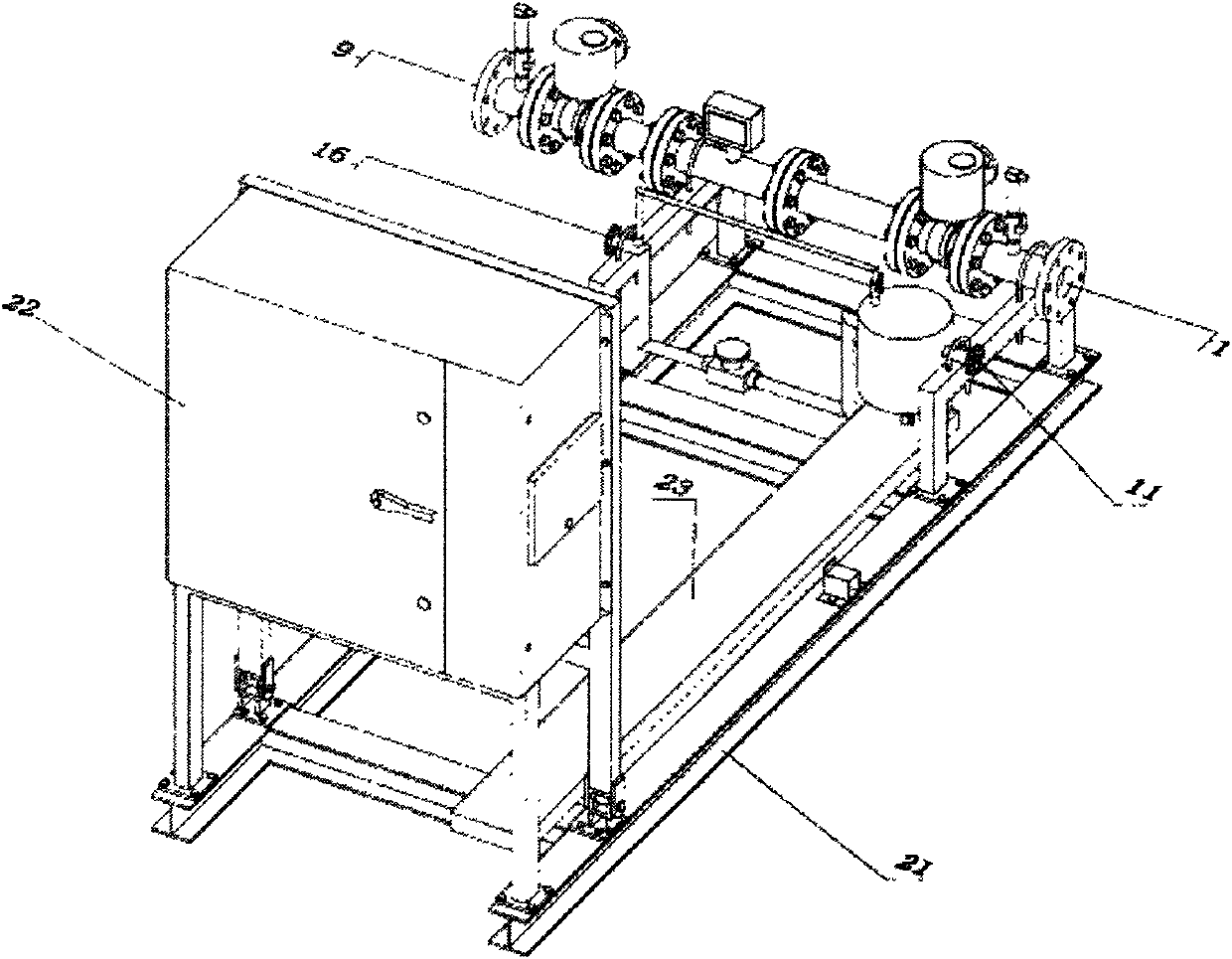

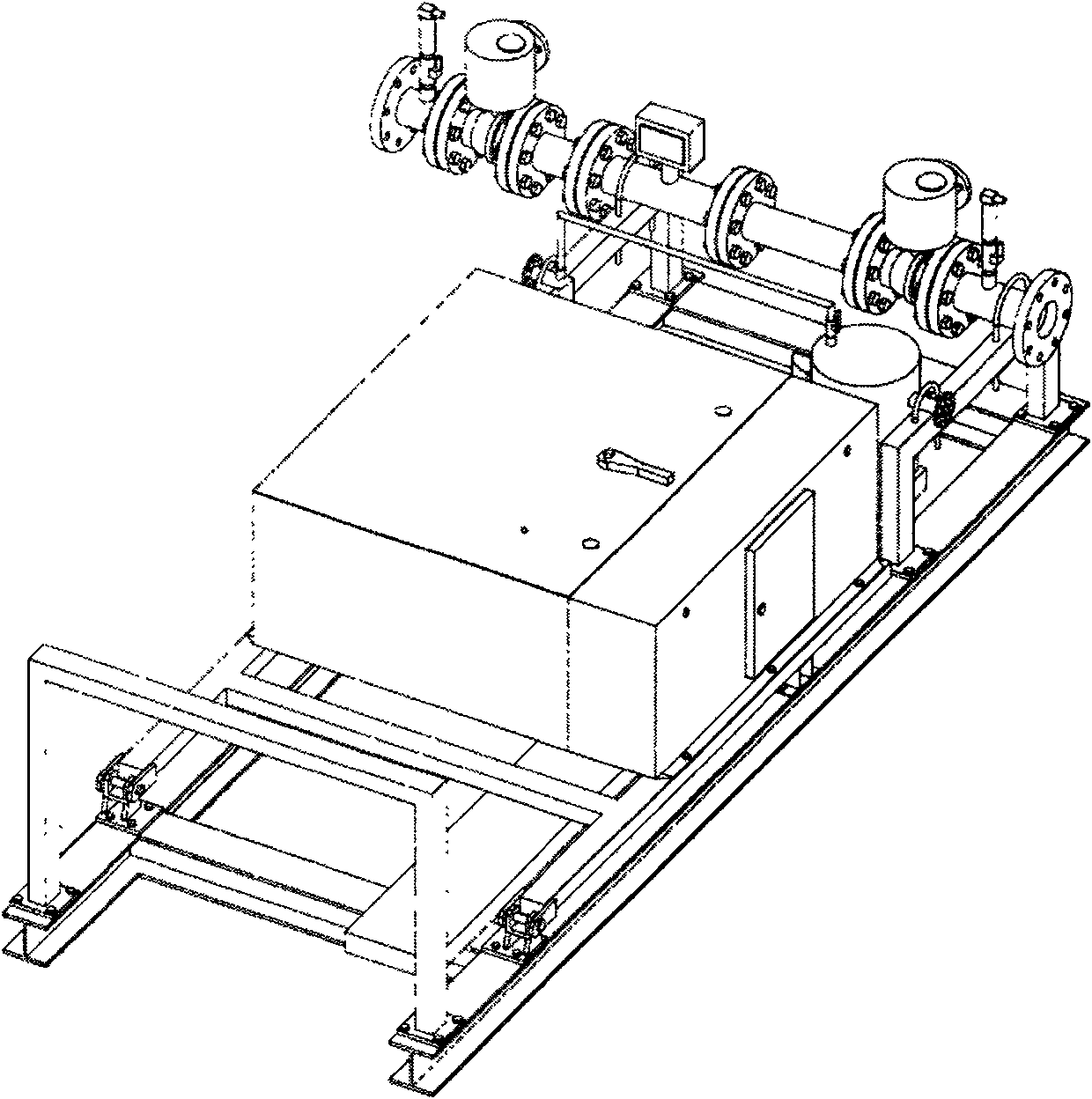

Exploitation measuring device and method of coal bed gas well

ActiveCN102168548AConvenient automatic separationImprove pump efficiencySurveyFluid removalProduction rateVapor–liquid separator

The invention provides an automatic exploitation measuring device and control method of a coal bed gas well. The measuring and control method is used for controlling a working fluid level by controlling the casing pressure of the coal bed gas well so as to stop the using of a traditional gas-liquid separator on the gas well field; requirements on gas production rate measurement can be satisfied by using a gas flowmeter; meanwhile, the liquid is separated from solid-phase coal powder and a gas after produced to the ground and before passing through a liquid flowmeter, thus the measuring accuracy is improved; the measurement is realized and the measuring accuracy is also increased while the liquid production rate is very small. A produced liquid measuring device, a produced gas measuring device and a control box provided by the invention are respectively mounted on a base bracket to form a highly integrated automatic exploitation measuring and control system of the coal bed gas well; therefore, the parameters are measured and field equipments on the well field are also simplified; the device is very simple and convenient to move, mount, operate, use and maintain; moreover, the invention also provides an optimized exploitation control method of a coal bed gas well.

Owner:CHONGQING OPRO ENERGY TECH CO LTD

High stability glass fiber reinforced plastics production device and working method thereof

The invention discloses a high stability glass fiber reinforced plastics production device which comprises a creel, a glue trough, a forming mold and a traction device, wherein an overflow device is matched with a fan to discharge air bubbles on a resin liquid level in the glue trough immediately; the air bubble amount generated when fibers enter the glue trough are reduced through a material guide device; the fibers are prevented from entangling in the glue trough through a roller, so that the skim coating quality is ensured; resins in the glue trough is heated efficiently through a circulator; and the resins are recycled through a transfer cavity. The high stability glass fiber reinforced plastics production device optimizes the impregnating flow fully, so that the defects of a glass fiber reinforced plastics product induced by air bubbles are reduced remarkably, the process stability is improved remarkably, and meanwhile, the resin recycling efficiency is enhanced, and the energy consumption for maintaining constant temperature of the resins is reduced.

Owner:揭阳市金利玻璃钢有限公司

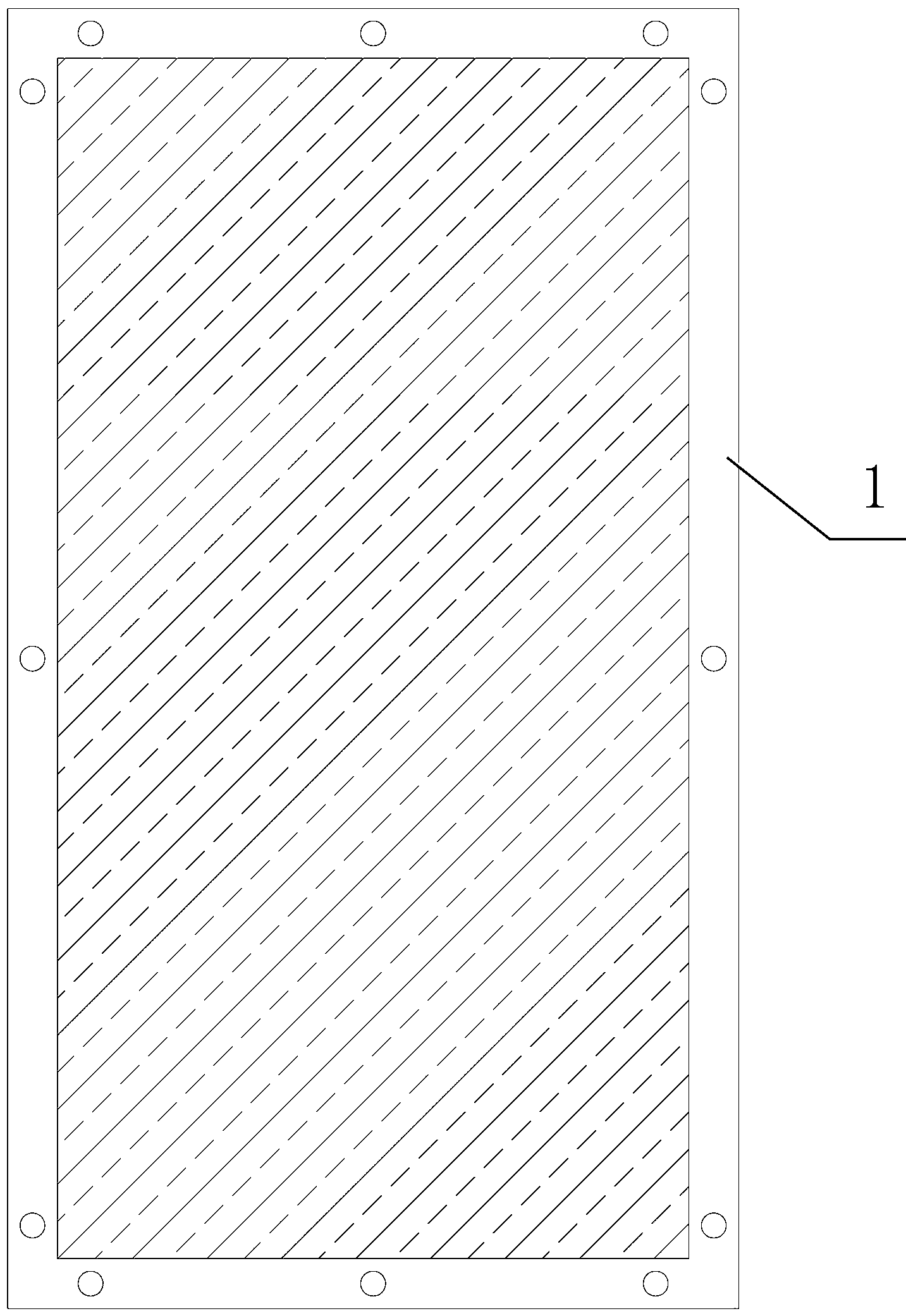

Method for adhering large-scale plane targetto back plate

InactiveCN102699519AReduce the amount of air bubblesReduce in quantityNon-electric welding apparatusElectricityStructure property

The invention relates to a method for adhering large-scale plane target to a back plate. The method comprises the following steps of processing before adhering, pre-coating welding flux, adhering, and processing after adhering in sequence. In the step of pre-coating the welding flux, the two opposite surfaces to be adhered are coated with the welding flux which is uniformly distributed, and then the fishbone welding flux is pre-coated on any adhering surface or fishbone welding flux preformed units are arranged on any adhering surface. The target can be steadily adhered with the back plate in the atmosphere and vacuum environment by using the method, so that the structure property and the size of the target cannot be influenced by adhesion, and the purposes that the adhesion has the properties of high bonding strength, high thermal conductivity and high electricity conductivity can be realized with low cost and easiness of operation.

Owner:YANTAI SHIELD ADVANCED MATERIALS

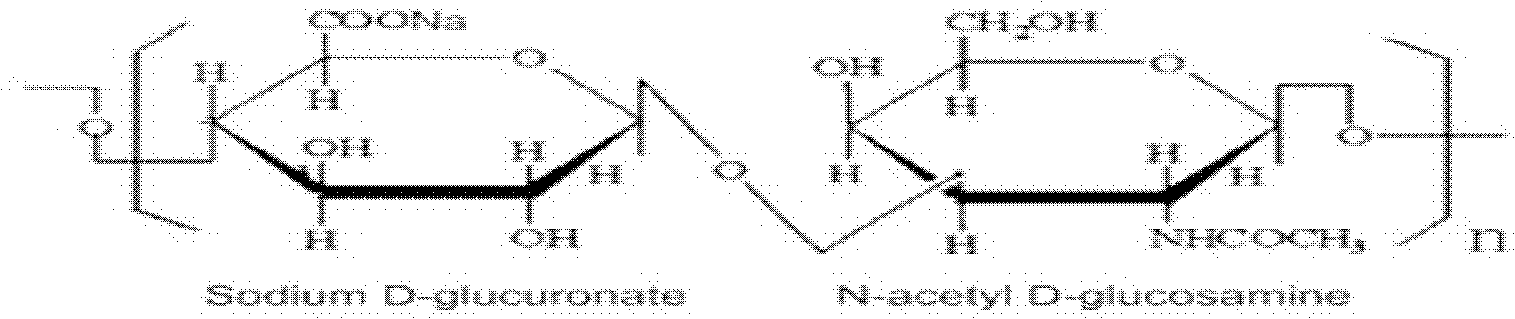

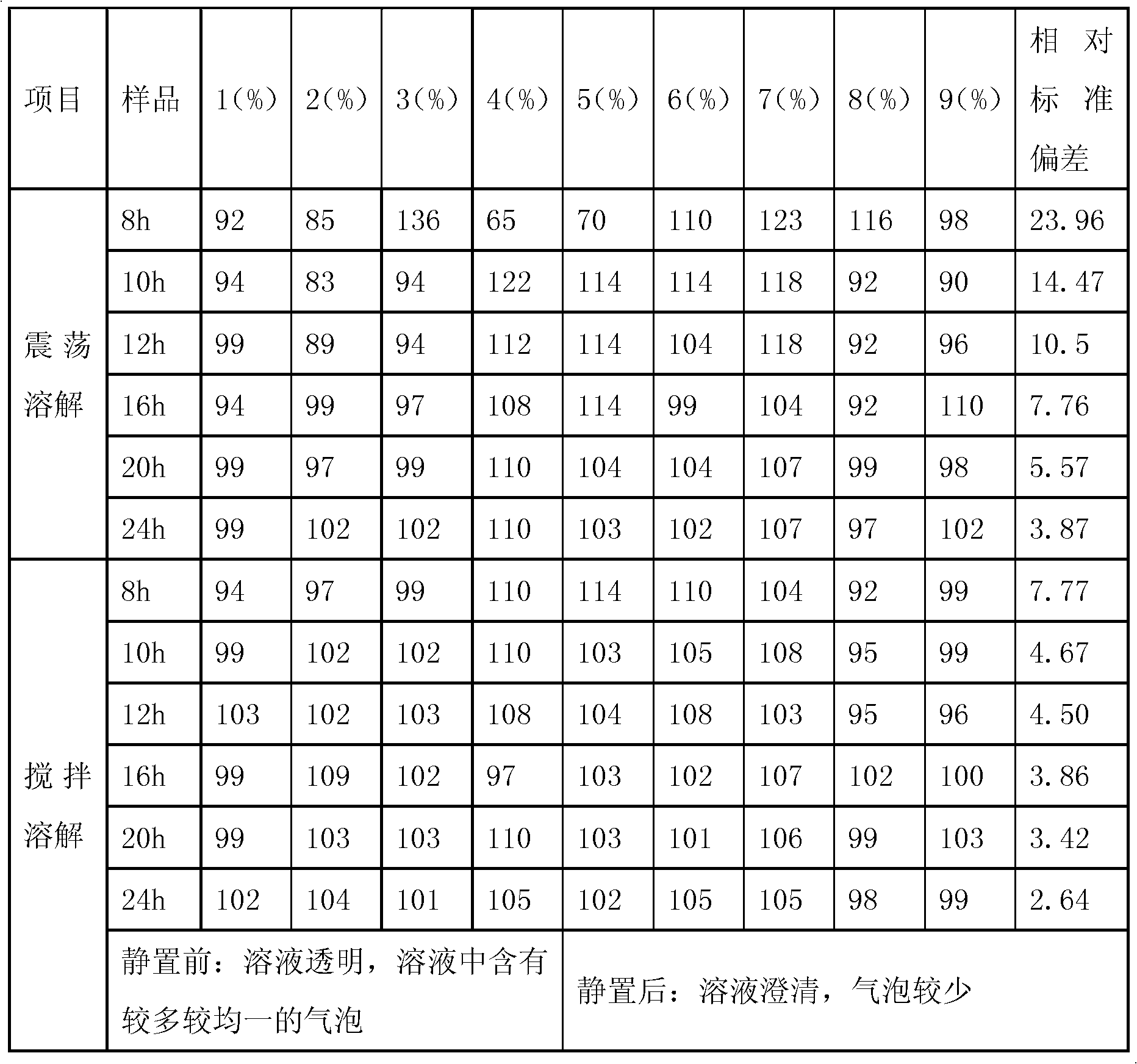

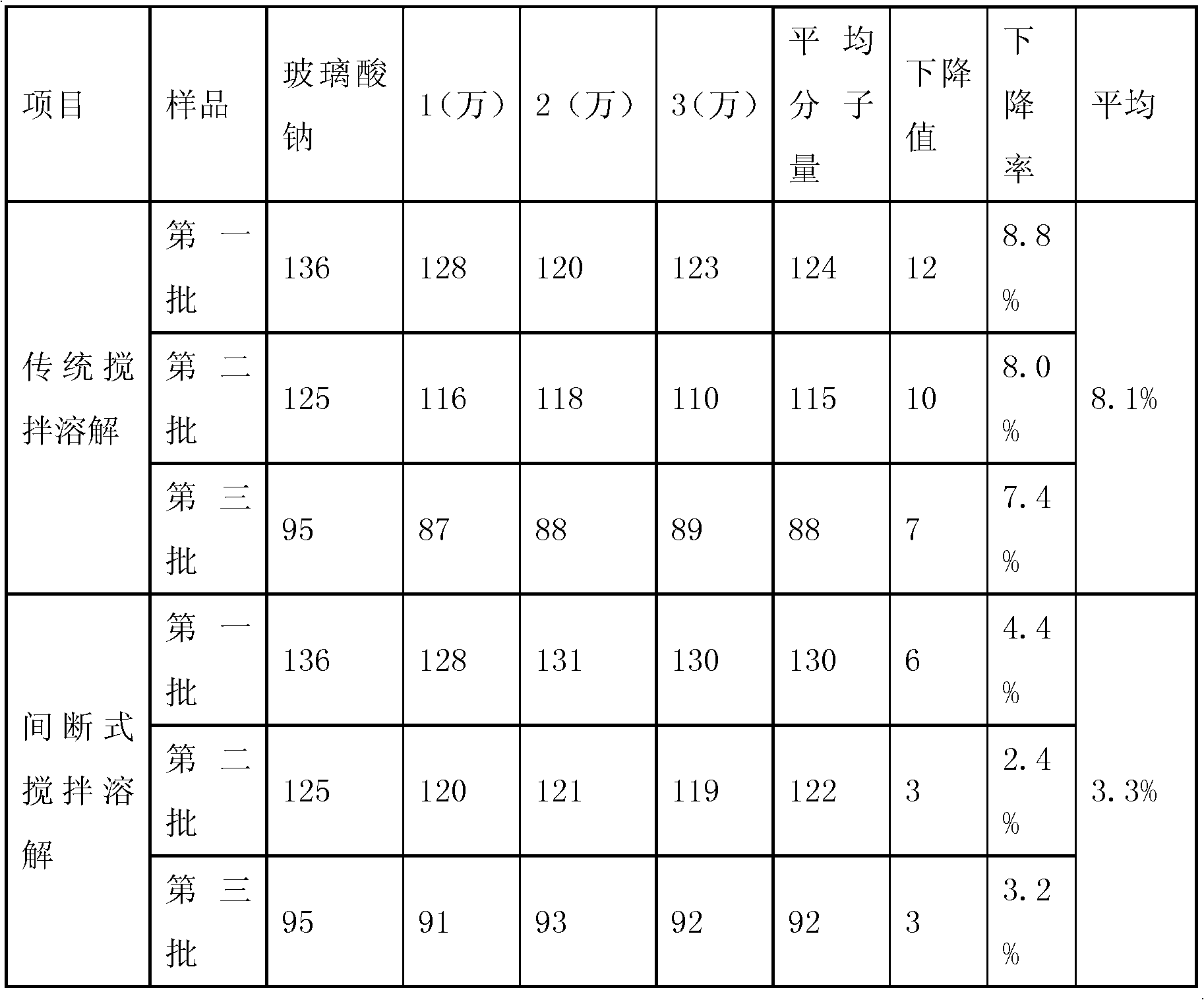

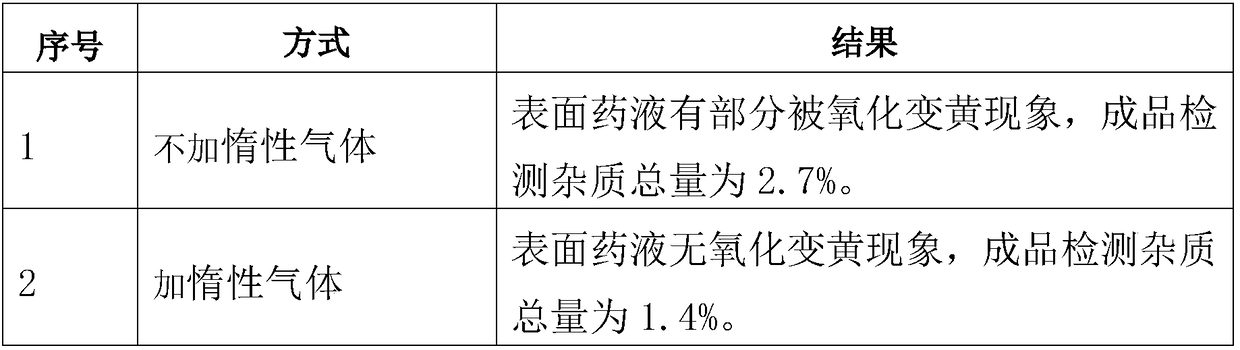

Dissolving method of sodium hyaluronate for solution preparation

ActiveCN102489193AEasy to spreadOvercome the defect of poor uniformityDissolvingHyaluronic acidSodium hyaluronate

The invention relates to a dissolving method of hyaluronic acid for solution preparation. The method comprises the steps of: first adding a PBS solution into a solution preparation tank and starting stirring; adding sodium hyaluronate with a stirring rotating speed less than 150 round / min; closing a feed inlet after addition, filling inert gas in the solution preparation tank, controlling a pressure within a range of from 0 to 0.1MPa, stirring continuously, predissolving for 40-60 min, stopping stirring, carrying out limit swelling for 1-2 h and carrying out intermittent stirring; finally, finishing stirring, protecting the hyaluronic acid solution in inert gas and carrying out standing. The method for dissolving sodium hyaluronate can substantially increase soup dissolving homogeneity, avoid oxidation of product, enhance aseptic guarantee level during product production process and improve product quality; the standing process employs natural sedimentation to reduce bubble amount in an injection; beside, the method substantially shortens a dissolving time during solution preparation, reduces production cost and especially applies to industrialized production.

Owner:SHANGHAI JINGFENG PHARMA

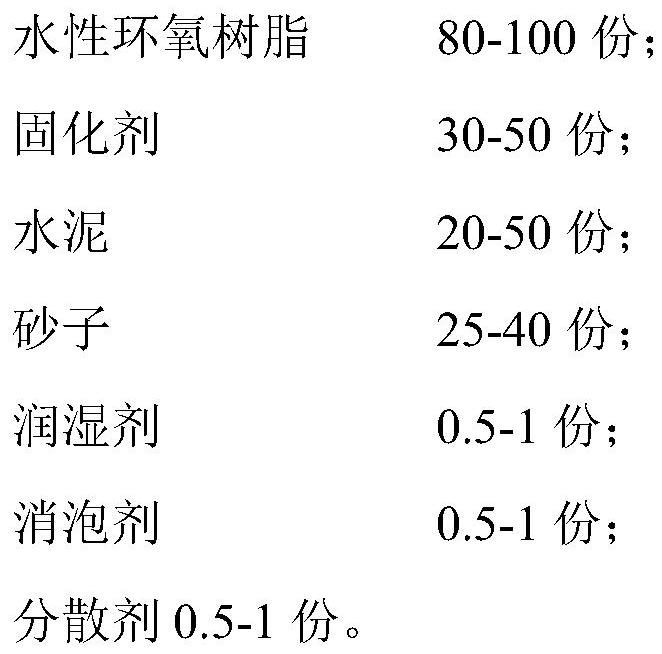

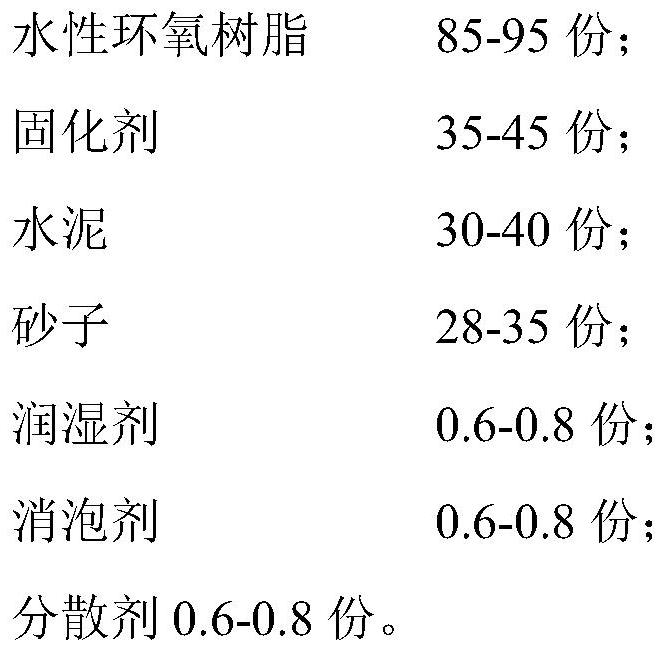

Epoxy polymer modified cement mortar and preparation method thereof

ActiveCN113480268AImprove anti-seepage performanceImprove mechanical propertiesPolymer sciencePolymer modified

The invention provides epoxy polymer modified cement mortar and a preparation method thereof, and belongs to the technical field of building materials. The cement mortar comprises the following components in parts by weight: 80-100 parts of water-borne epoxy resin; 30-50 parts of a curing agent; 20-50 parts of cement; 25-40 parts of sand; 0.5-1 part of a wetting agent; 0.5-1 part of a defoaming agent; and 0.5-1 part of a dispersant. The cement mortar provided by the invention is mainly used for the outer wall of a lining steel pipe, so that the cement mortar has strict requirements on the anti-seepage performance of the cement mortar, and the mechanical property, the adhesive force and the anti-seepage performance of the prepared cement mortar are obviously improved by selecting the specific components of the raw materials in the implementation process.

Owner:GUANGDONG NO 2 HYDROPOWER ENGINEERING COMPANY LTD

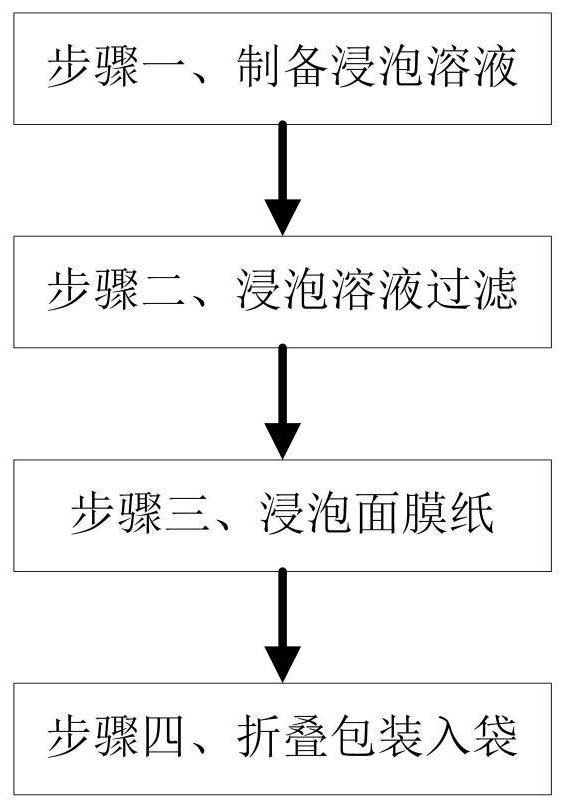

Preparation method of antibacterial emulsion essence mask

ActiveCN112107492ALow wettabilityAvoid cloggingCosmetic preparationsToilet preparationsMaterials scienceW o emulsion

The invention belongs to the technical field of mask manufacturing, and particularly relates to a preparation method of an antibacterial emulsion essence mask, which comprises: 1, preparing a soakingsolution, wherein plant essence components, water, a thickening agent and an emulsifying agent are mixed and stirred to obtain the soaking solution; 2, filtering the soaking solution, namely filteringthe soaking solution prepared in the step 1 to remove fine impurities in the soaking solution; 3, soaking the mask paper: soaking the mask paper into the soaking solution, and fully soaking to obtainthe antibacterial emulsion essence mask; 4, folding, packaging and bagging: taking out the antibacterial emulsion essence mask from the soaking solution, folding, bagging and sealing; wherein the step 2 is completed by cooperation of an antibacterial emulsion essence mask preparation machine. Bubbles in the soaking solution are extruded and crushed, the quantity of the bubbles in the soaking solution is reduced, the bubbles are prevented from blocking micropores of a filter bag, and the filtering effect is improved; the soaking solution is ground through a second defoaming mechanism, and bubble residues are avoided.

Owner:广州市碧莹化妆品有限公司

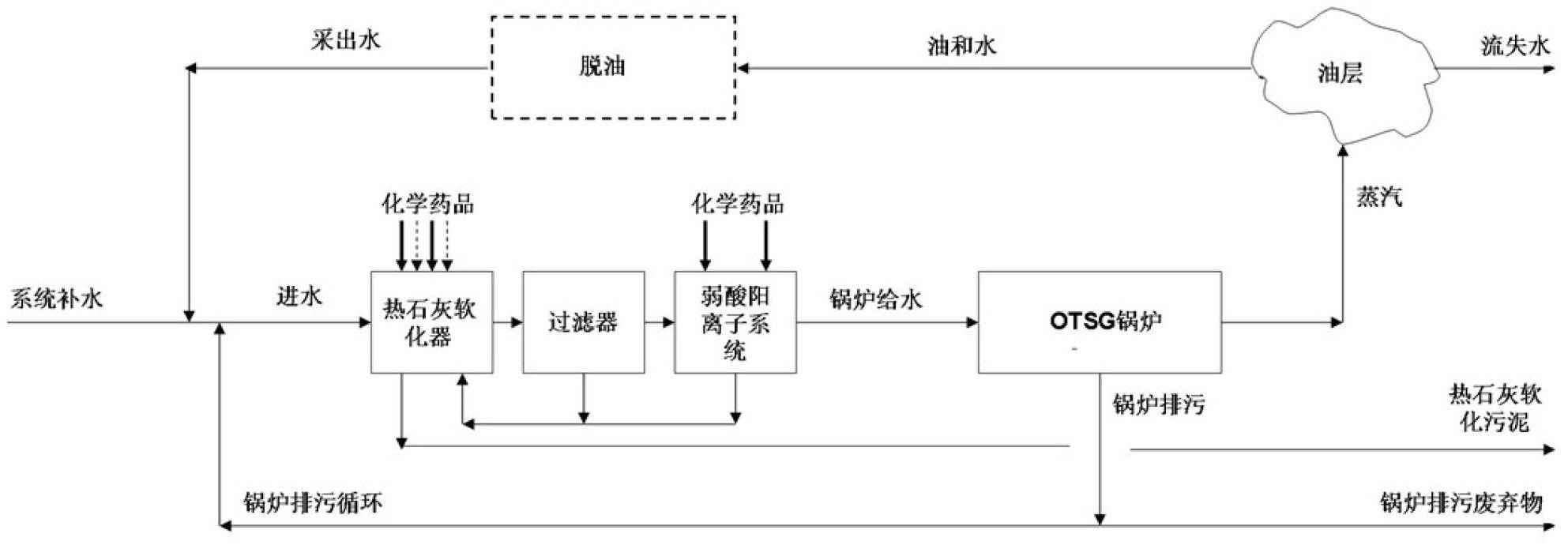

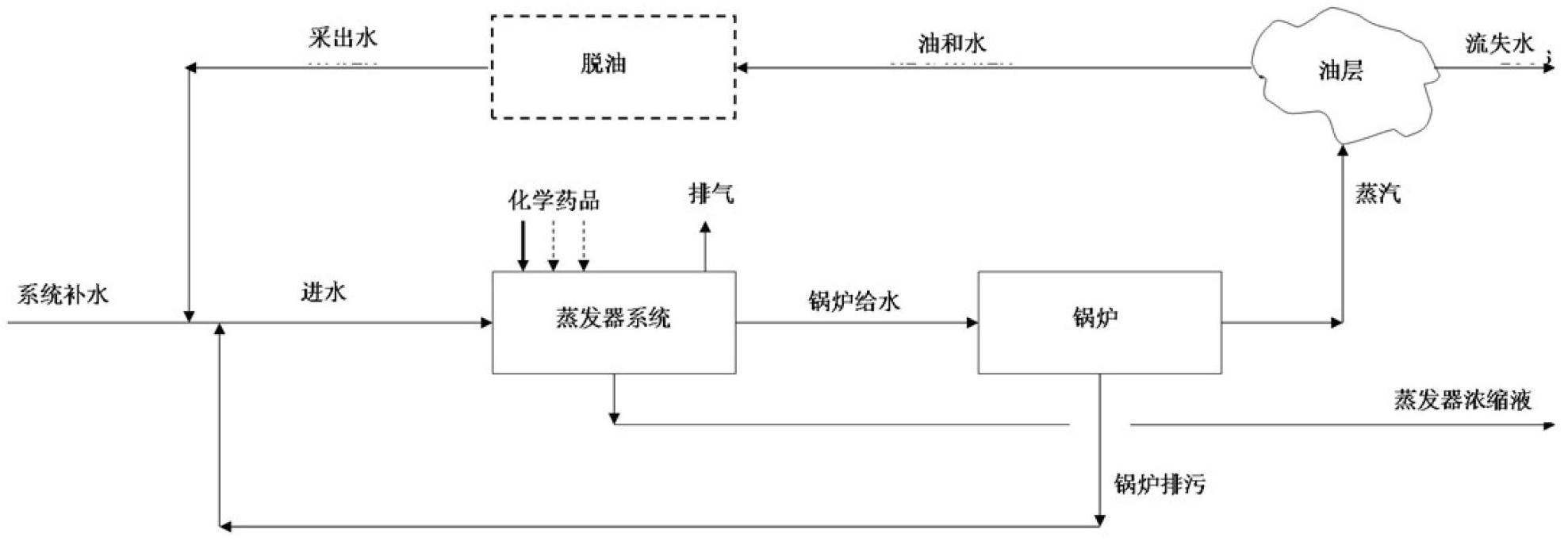

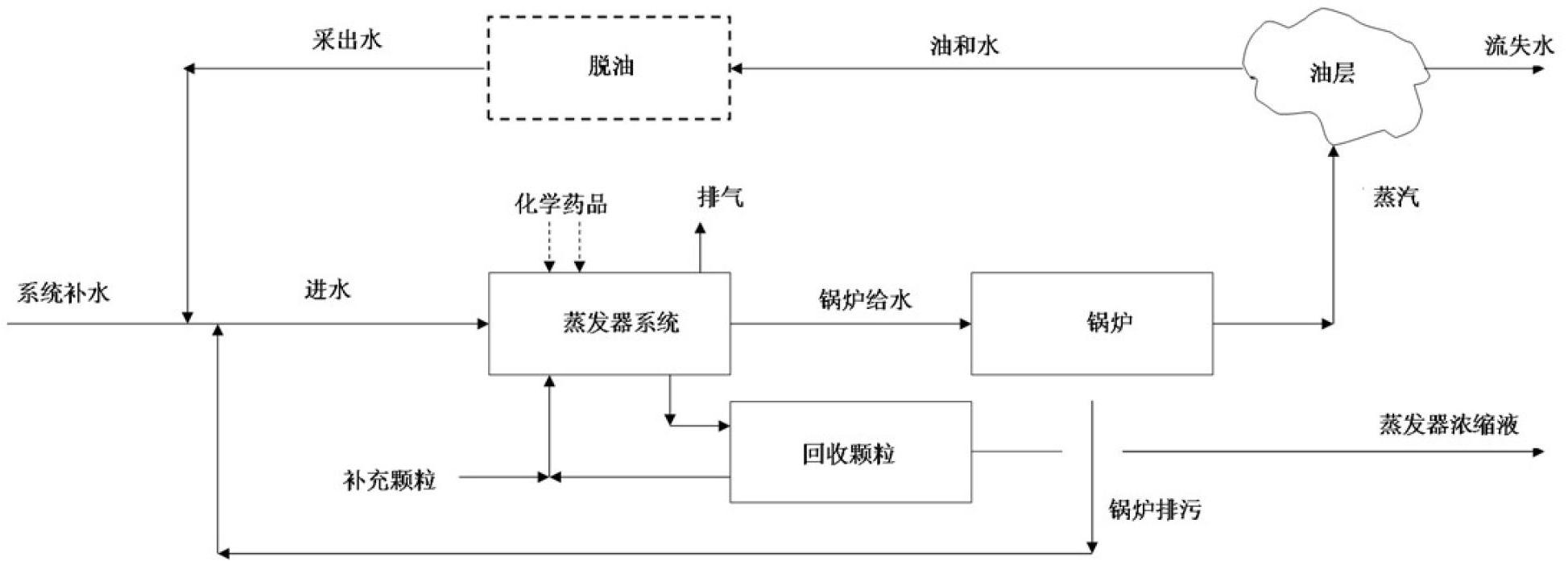

Water treatment process for recovering heavy oil recovery produced water to serve as boiler feed water

ActiveCN102659197AAvoid dirtHigh organic contentEvaporationWater/sewage treatment by heatingWater useChemical treatment

The invention discloses a water treatment process for recovering heavy oil recovery produced water to serve as boiler feed water. Inlet water taking the produced water as the main is conveyed to a vertical falling-film evaporator with a brine distribution device; distilled water used for the boiler feed water is produced through evaporation; scrubbing particles are added to the inlet water taking the produced water as the main or the circulating strong brine of the vertical falling-film evaporator to form size; and when the size is evaporated by the vertical falling-film evaporator, scaling on the heat exchange surface of an evaporator is prevented or reduced by utilizing the solid particles in the size. According to the process, most of produced water is processed into the high-quality distilled water used for a boiler to produce steam to increase the heavy oil recovery rate, and the process can be directly used for treating the produced water; the recovery rate can reach more than 95 percent; and the high-quality boiler feed water used for producing the steam required by heavy oil recovery is produced. The process can also be used for treating boiler blow-off, thus, the discharge of a factory is reduced, the requirement of physicochemical treatment is relieved, and the total water recovery rate of a water treatment plant is increased.

Owner:江苏中圣清洁能源有限公司

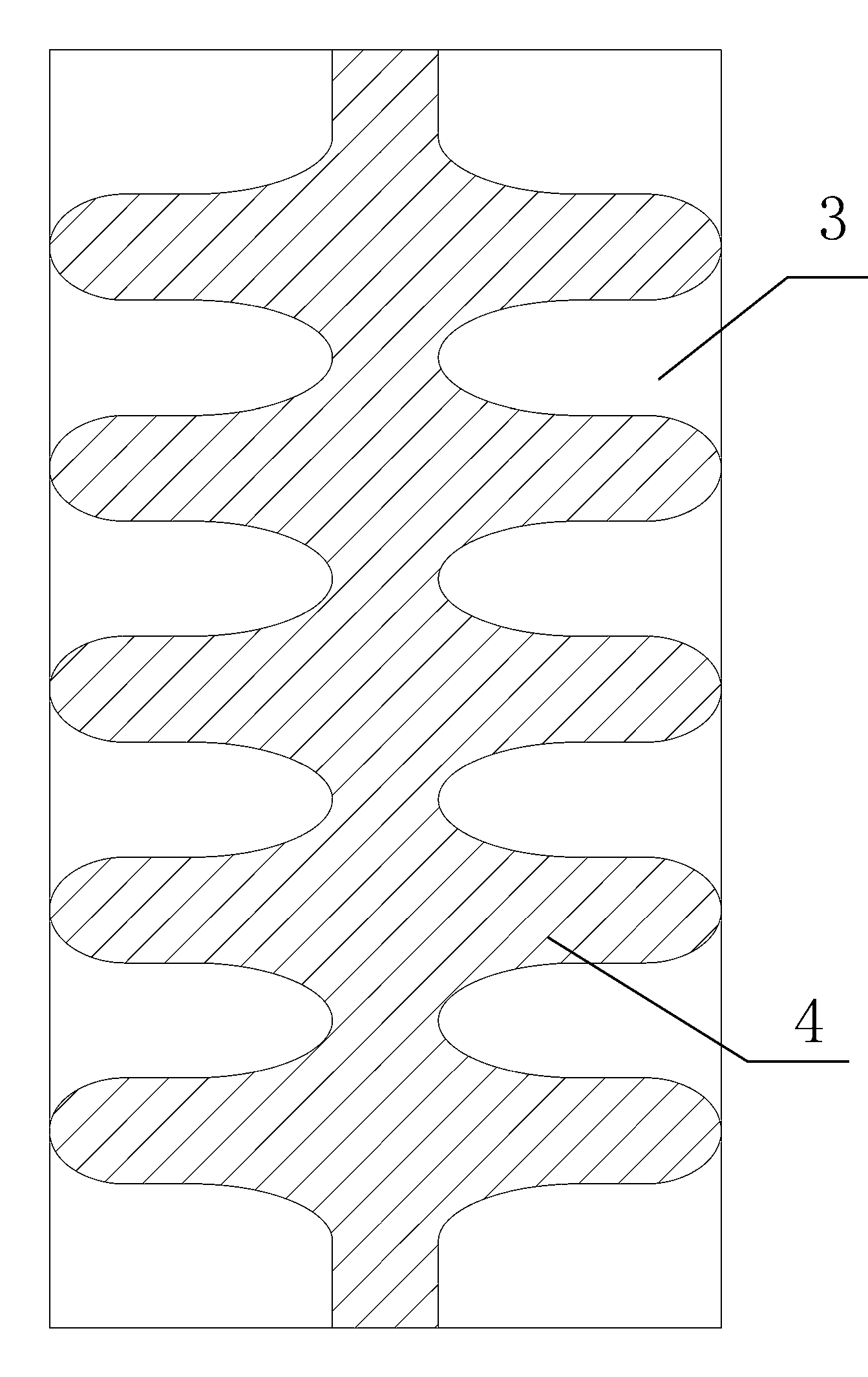

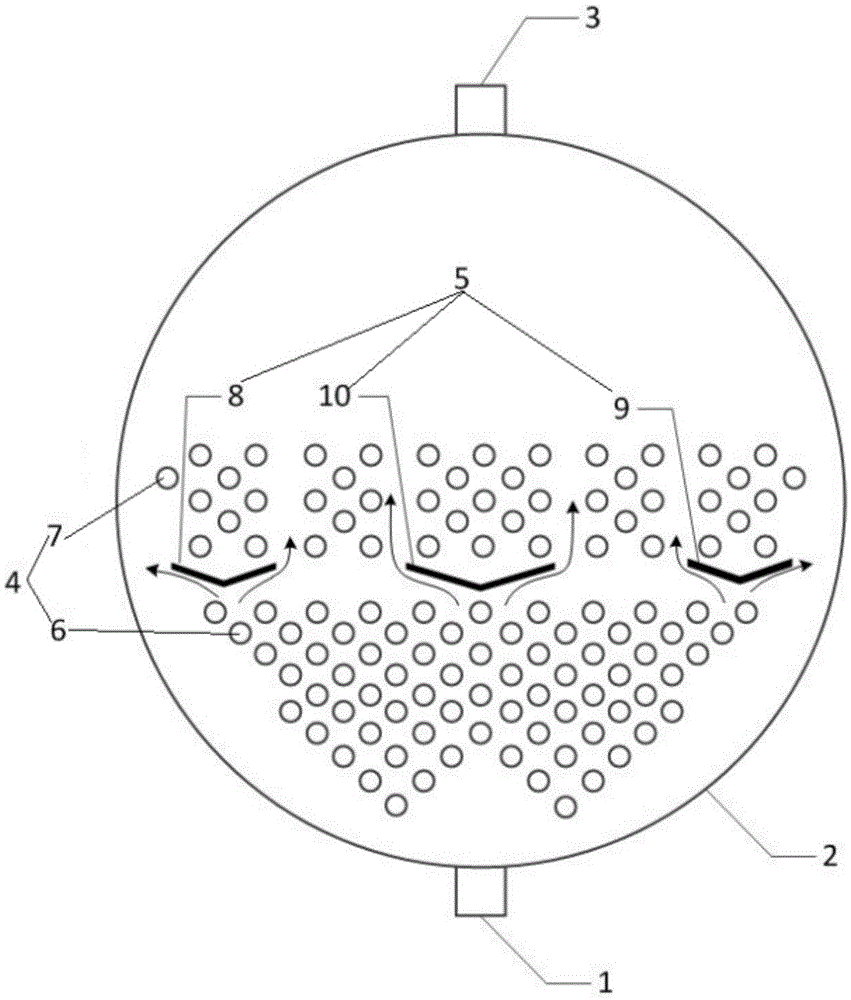

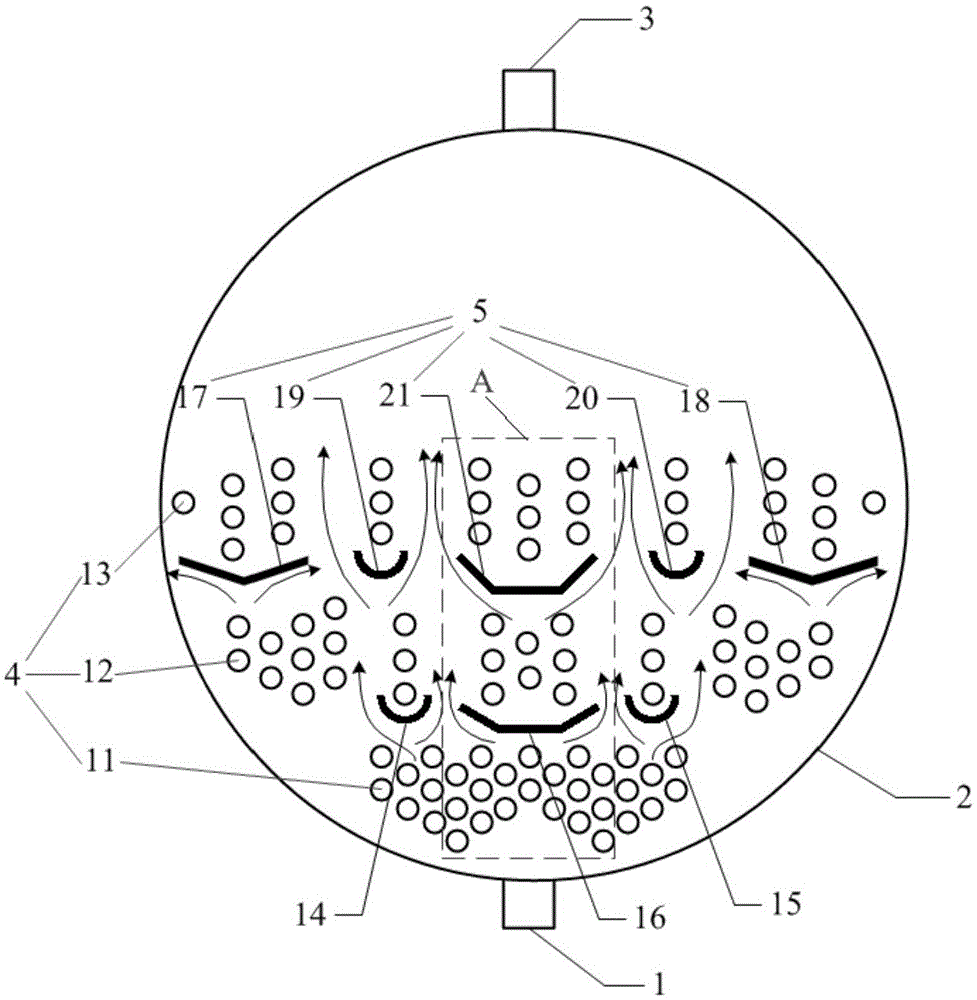

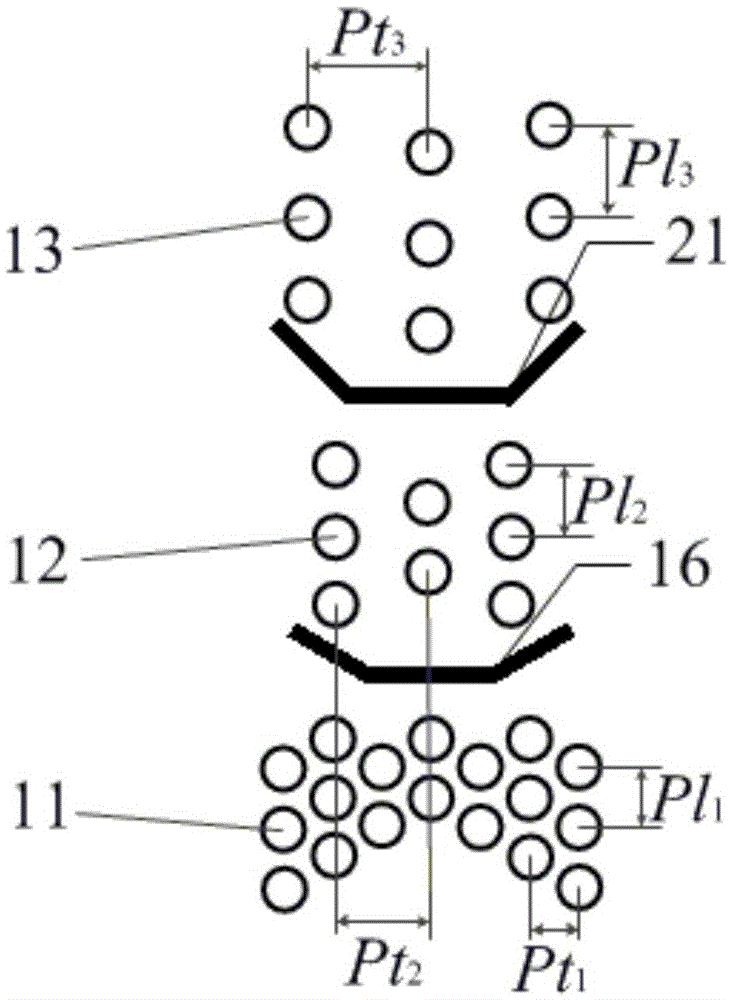

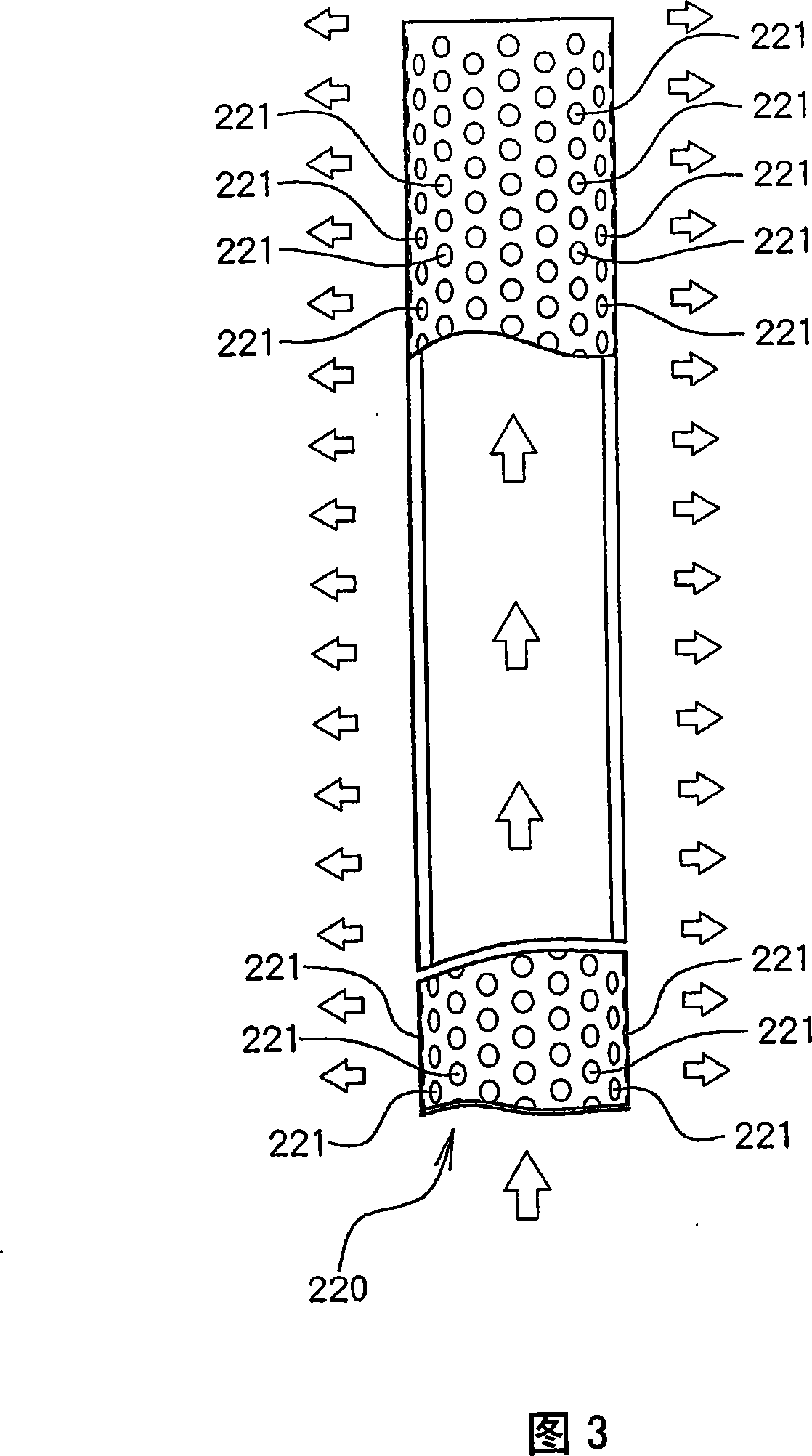

Bubble flow guide full-liquid type shell tube evaporator

ActiveCN105546881AReduce the amount of air bubblesImprove overall heat transfer performanceEvaporators/condensersFlueEvaporator

A bubble flow guide full-liquid type shell tube evaporator comprises heat exchange tubes and bubble flow guide plates arranged in a shell. The heat exchange tubes are arranged on the upper portions and the lower portions of the bubble flow guide plates; longitudinal air flues are formed on the two sides of the bubble flow guide plates; bubbles are exhausted out of the area where the heat exchange tubes are placed through the air flues; the bubble flow guide plates are in a V shape or a U shape or a trapezoid shape; and the convex faces of the bubble flow guide plates face to the rising direction of the bubbles. The bubble flow guide full-liquid type shell tube evaporator obviously reduces the quantity of the bubbles attached to the heat exchange tubes, prevents the bubbles from forming an air film outside the heat exchange tubes, fully performs the performance of the heat exchange tubes, and improves the overall heat exchange performance of the evaporator.

Owner:SHANGHAI JIAO TONG UNIV +1

Quick defoaming method of washing product

InactiveCN107185276AFast defoamingReduce crackingLiquid degasification regulation/controlWarming processAtmosphere

The invention provides a defoaming method of a washing product. The method comprises the following steps: mixing raw materials of the washing product; increasing the temperature to be 72-76 DEG C with continuous stirring; maintaining the temperature and stirring, wherein vacuumizing is carried out in at least two times during stirring, and the vacuum degree in each vacuumizing reaches -60 to -80kPa; maintaining the pressure for 3-7min; then recovering to the atmosphere pressure; decreasing the temperature to be 45-49 DEG C with continuous stirring; repeating step 2. According to the method, a mode of alternatively changing the vacuum degree is adopted, so that the purposes of effectively removing foam and quickly decreasing foam quantity can be achieved, and as a result, the foam of the washing product can be quickly removed.

Owner:PERFECT CHINA +1

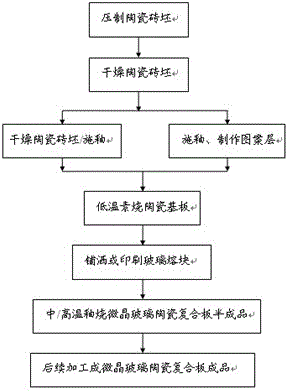

Production process of ultrathin microcrystalline layer microcrystalline glass ceramic composite board

The invention provides a production process of an ultrathin microcrystalline layer microcrystalline glass ceramic composite board, comprising the following steps: 1, preparing a low-temperature biscuiting high-water-absorption ceramic substrate; 2, printing or spraying a fixing agent on the ceramic substrate and then paving or printing a transparent glass smelting block, a semitransparent glass smelting block or an emulsion opal glass smelting block with the thickness of 1.0-3.5 mm; and pre-pressing and fixing; 3, carrying out glaze firing through a kiln to smelt the glass smelting block, and annealing and cooling to obtain a microcrystalline glass ceramic composite board semi-finished product; and 4, polishing, milling, checking and packaging the microcrystalline glass ceramic composite board semi-finished product to obtain a finished product. Compared with the prior art, preferable special microcrystalline glass smelting block cloth production process and sintering process are obtained through many times of optimized experiments; and the surface of the prepared ultrathin microcrystalline layer microcrystalline glass ceramic composite board has no air bubbles by visual contact and the crystallization degree is high, so that the microcrystalline glass ceramic composite board is more attractive. The production process has the advantages of low production cost, large capacity, high product quality, good appearance effect and the like, and has very strong market competitiveness.

Owner:恩平市一箭陶瓷有限公司

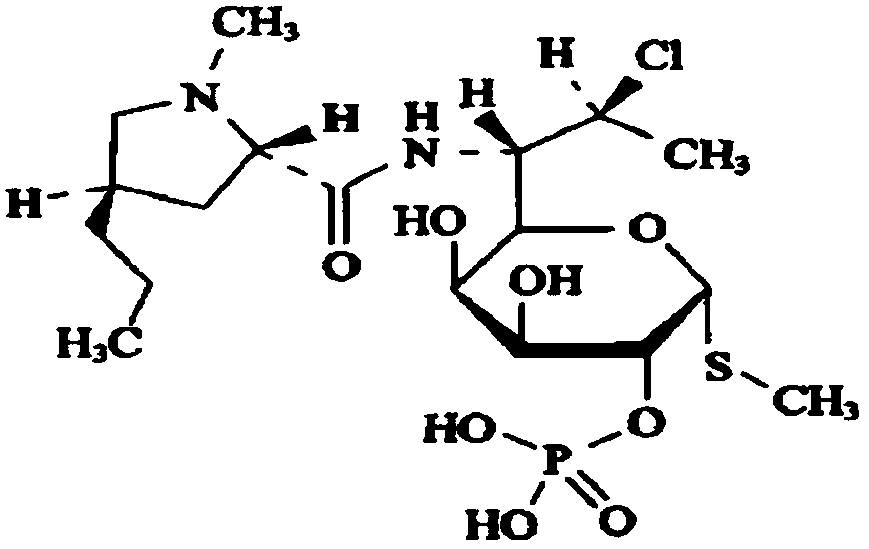

Clindamycin phosphate compound liquid and preparation method thereof

ActiveCN109498564AIncrease temperatureShorten the dissolution timeAntibacterial agentsOrganic active ingredientsActivated carbonFiltration

The invention discloses a clindamycin phosphate compound liquid and a preparation method thereof. The clindamycin phosphate compound liquid is prepared from the following components in proportions: 500-700 parts of clindamycin phosphate, 35-55 parts of sodium hydroxide, 1700-3000 parts of water for injection and 2-10 parts of activated carbon; the clindamycin phosphate dose is prepared by adding raw materials and a PH regulator gradually according to the proportions, dissolving and other processes. By adopting the preparation method, the uniformity of medicinal liquid dissolution is greatly improved, the oxidation process of a product is eliminated, the sterility assurance level in the production process of the product is improved, and the amount of air bubbles in an injection is reduced;in addition, the dissolution time and the filtration time in the liquid preparation process are greatly shortened and the production cost is reduced; therefore, the preparation method is especially suitable for industrial production; the dissolution method is not only applicable to the liquid preparation process of the clindamycin phosphate for injection, but also applicable to the liquid preparation process of other products using the clindamycin phosphate as a raw material and sodium hydroxide as the pH regulator.

Owner:GUIZHOU JINGFENG INJECTION

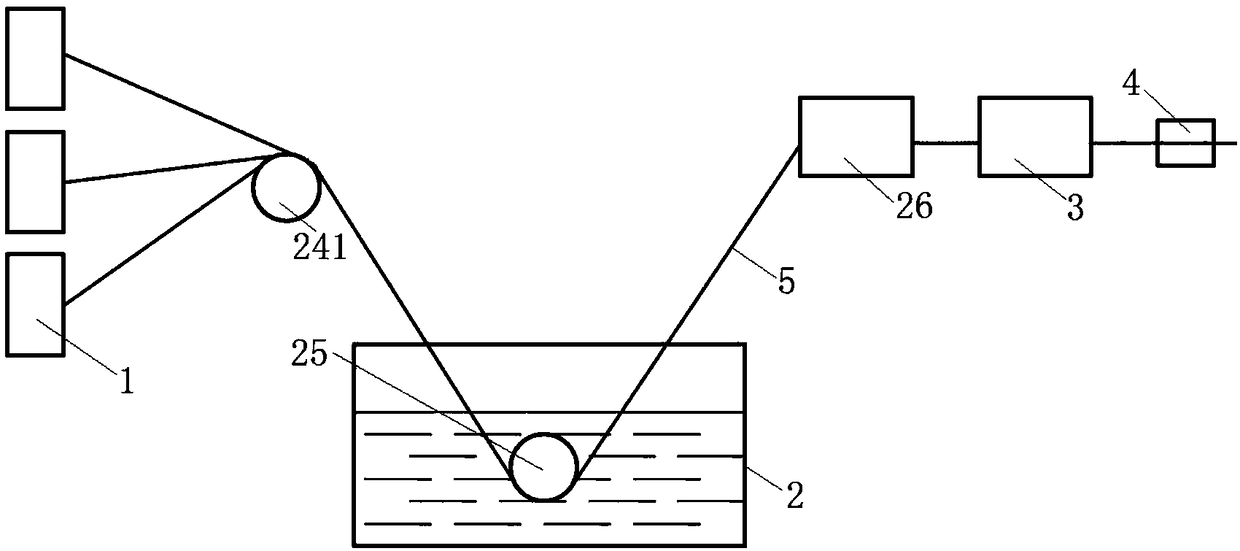

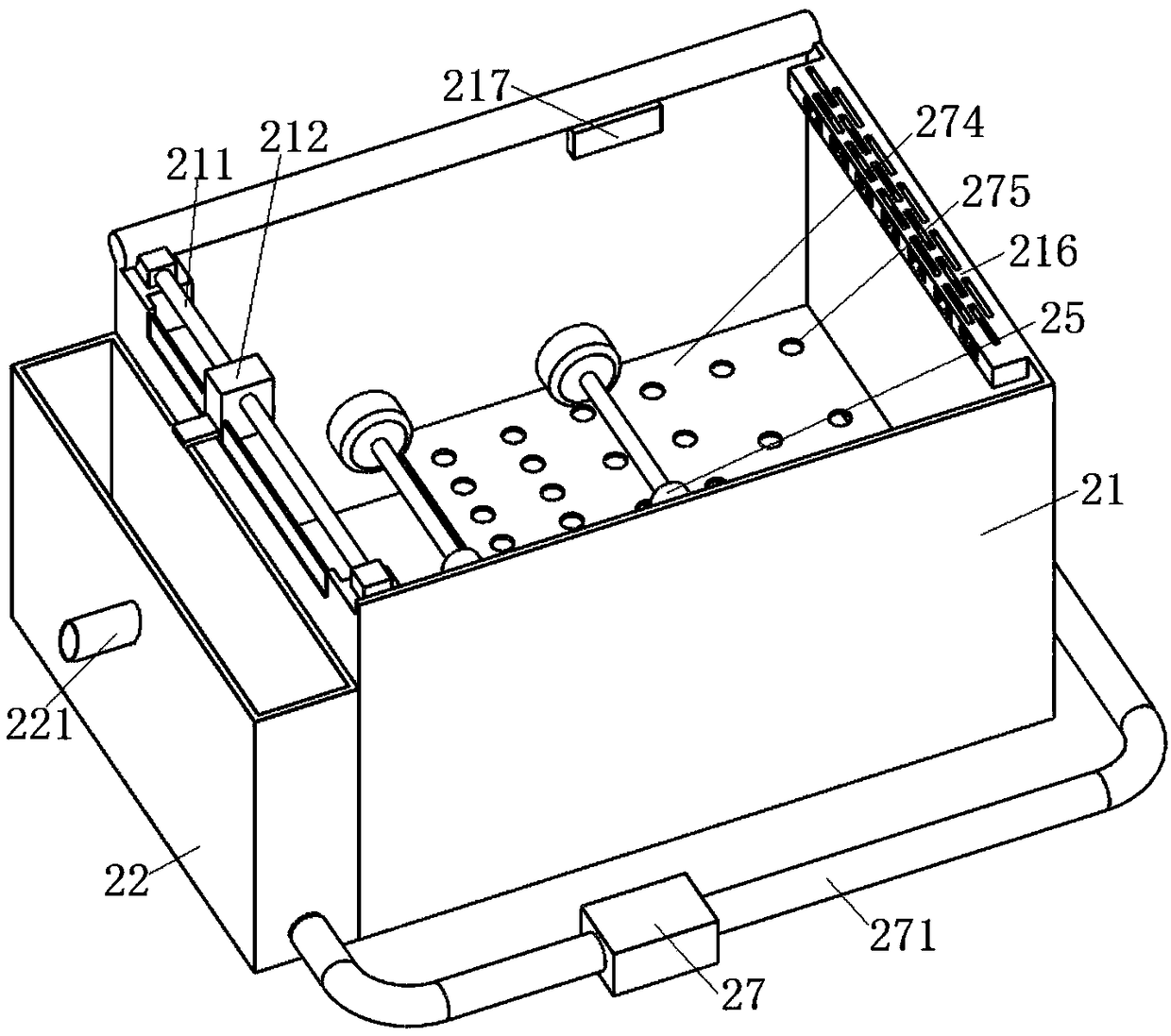

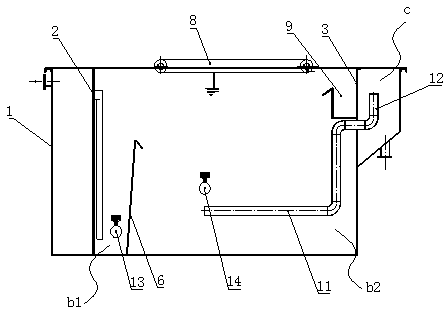

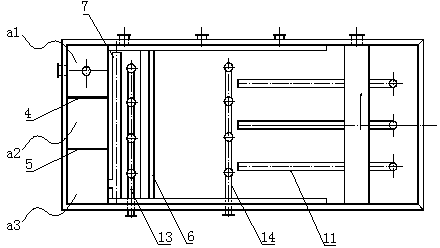

Flotation device

ActiveCN103739155AReduce the amount of air bubblesEasy to handleMultistage water/sewage treatmentSewageTherapeutic effect

The invention relates to a flotation device which is characterized by comprising a box body and a gas dissolved water release system, wherein the box body is sequentially divided into a pretreatment area, a flotation water collecting area and a clear water area; the flotation water collecting area is divided into a flotation area and a water collecting area by a flashing plate; the gas dissolved water release system comprises a first gas dissolved water release pipeline positioned at the bottom of the flotation area and a second gas dissolved water release pipeline positioned in the water collecting area. The flotation device disclosed by the invention has the advantages that in the flotation area, the gas dissolved water released by the first gas dissolved water release pipeline adsorbs tiny particles in sewage, the tiny particles move upwards along with bubbles and float to the liquid surface, a residue scraping machine is used for scraping floating matters into a residue collecting tank, and the water subjected to flotation enters the water collecting area for secondary flotation, then enters the clear water area through a communicating pipe consisting of a water collecting pipe and a water outlet pipe, and then is discharged. The water is subjected to secondary flotation in the water collecting area, the amount of the bubbles of the secondary flotation is greatly reduced compared with that of the primary flotation, so that the energy consumption is basically not increased and the normal water connection can not be influenced while the treatment effect is improved.

Owner:NANTONG BEICHEN MACHINERY EQUIP MFGCO

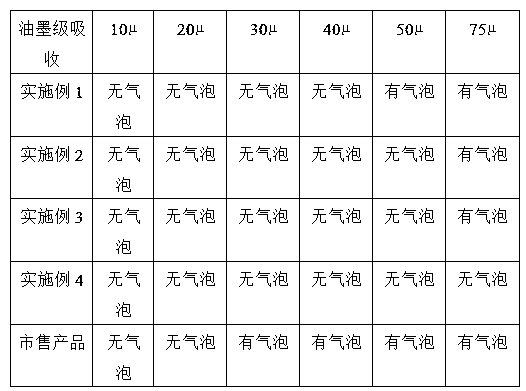

OCA optical adhesive easy to attach

InactiveCN110819241AReduce surface tensionHigh affinityNon-macromolecular adhesive additivesMacromolecular adhesive additivesIsooctyl acrylatePolymer science

The invention discloses an OCA optical adhesive easy to attach. The OCA optical adhesive comprises the following components in parts by mass: 20 parts to 45 parts of hydroxypropyl methacrylate, 40 parts to 50 parts of glycidyl methacrylate, 6 parts to 20 parts of 2-ethylhexyl acrylate, 2 parts-6 parts of benzene polyacid ester, 1 part-4 parts of hydroxybenzophenone, 1 part-5 parts of phthalic acidester, 1 part-5 parts of hydroquinone, 1 part-5 parts of ethyl acetate, 0.5 part-1 part of an initiator, 0.2 part-0.5 part of polyethylene glycol dimethacrylate, 0.2 part-0.5 part of a sensitizer, 0.5 part-1 part of a crosslinking agent, 1 part-3 parts of a surface modifier and 1 part-5 parts of polysiloxane. According to the OCA optical adhesive easy to attach, the surface of a screen is comprehensively filled with 2-ethylhexyl acrylate, and bubbles generated when an OCA optical adhesive product is attached are eliminated; moreover, by adding the surface modifier and polysiloxane, the surface tension of the OCA optical adhesive is reduced, air between the OCA optical adhesive and the screen can be extruded during OCA optical adhesive pasting, the bubble amount is reduced, and the productquality is improved.

Owner:惠州市加韵新材料有限公司

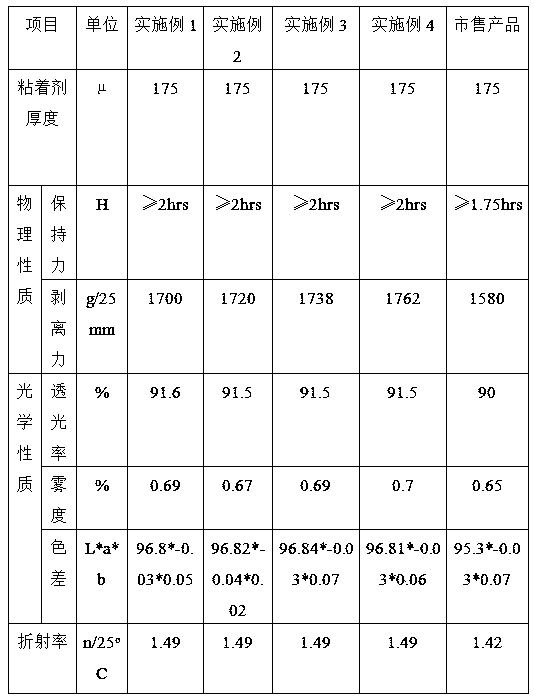

Cell culture reactor

PendingCN108048319AAvoid damageImprove cultivation efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsBiochemical engineeringBioreactor

The invention discloses a cell culture reactor, which includes a tank, an air inlet pipe and a sampling pipe. The tank is provided with a reaction chamber and an air inlet, an air outlet, a sample adding port and a sampling port that communicate with the reaction chamber. The size of the reaction chamber is gradually reduced from the bottom to top, and the undersurface of the reaction chamber is provided with a tapered projection. One end of the air inlet pipe is located outside the tank and communicates with a bioreactor, and the other end of the air inlet pipe is extended to the bottom of the tapered projection via the air inlet. One end of the sampling pipe is located outside the tank and communicates with the bioreactor, and the other end of the sampling pipe is extended to the bottomof the tapered projection via the sampling port. The air outlet and the sample adding port communicate with the bioreactor, respectively. The cell culture reactor is good in oxygen supply performance,uniform in oxygen distribution, reduced in damaged cells, improved in cell culture efficiency, and low in production cost.

Owner:FOSHAN CANTON BIOLOGICS CO LTD +1

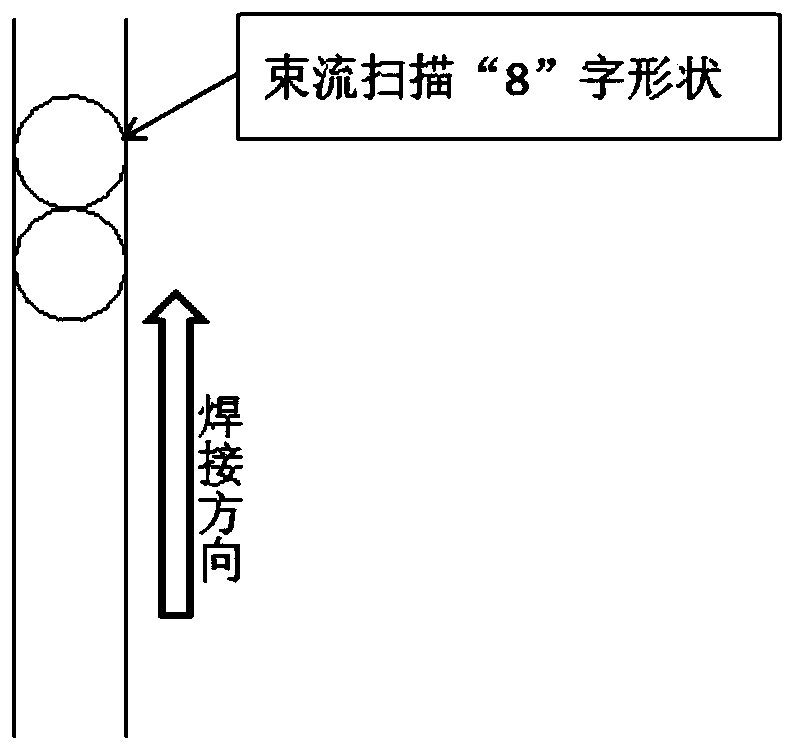

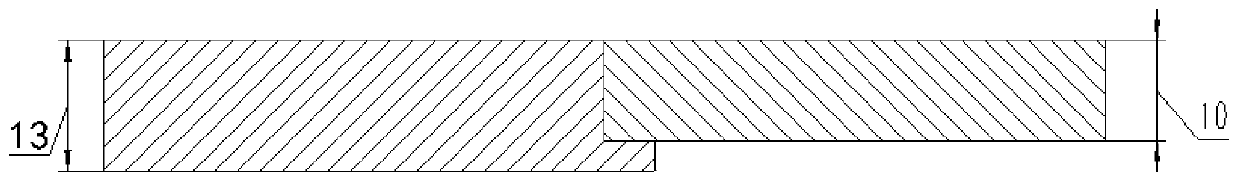

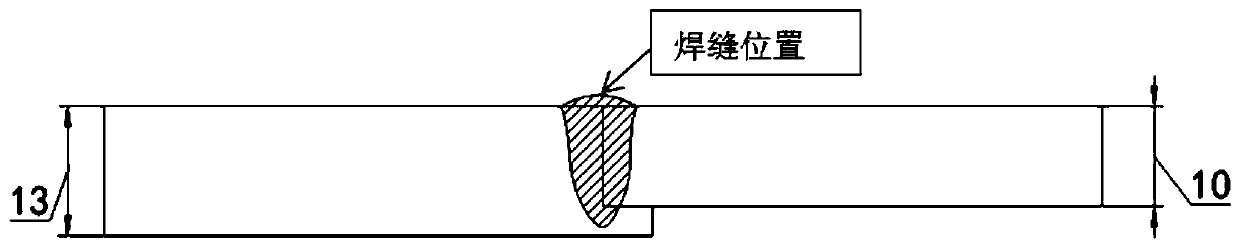

Welding method for eliminating pore defects of aluminum alloy electron beam weld joint

PendingCN111014927AReduce defectsWide applicabilityElectron beam welding apparatusWelding/soldering/cutting articlesElectron bunchesAluminium alloy

The invention provides a welding method for eliminating pore defects of an aluminum alloy electron beam weld joint. The vacuum electron beam welding method is applied to the welding method, welding isperformed through electron beams in the form of swing scanning, an 8-shaped scanning trace serves as a repeating unit in a scanning trajectory formed through swing scanning, and the scanning trajectory is formed by arraying the 8-shaped scanning traces in a staggered mode, wherein the longitudinal direction of the 8-shaped scanning traces is the direction of the weld joint, and the transverse direction of the 8-shaped scanning traces is perpendicular to the direction of the weld joint. The welding method is suitable for materials with large pinhole inclination and poor compactness caused whencast aluminum alloy absorbs hydrogen due to the addition of a strontium alterant, can also be suitable for welding ordinary cast aluminum alloy, is wide in application range, has a magnificent effectof eliminating pores, and greatly enhances the tensile strength of the weld joint.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

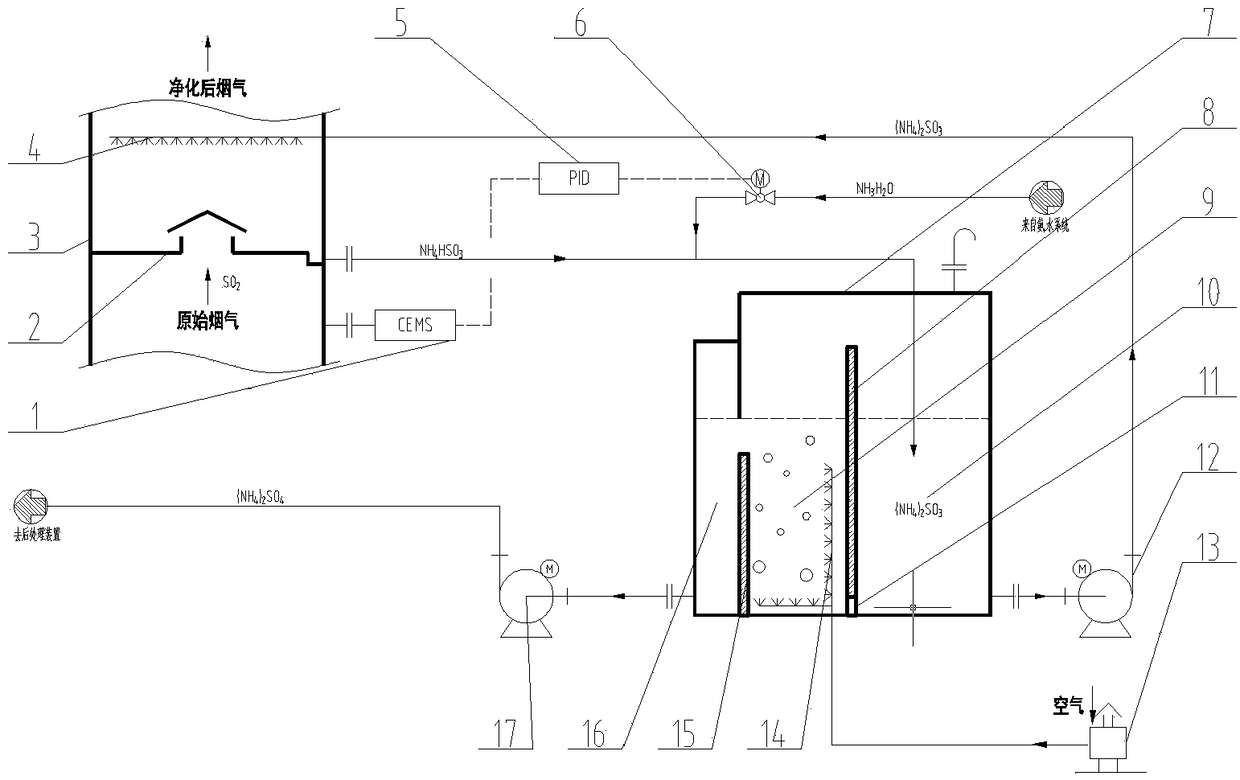

Function guidance product partition ammonia process desulfurization oxidation circulation tank device and method

PendingCN109260895AImprove desulfurization effectWon't happenGas treatmentDispersed particle separationOxidation zoneSlurry

The invention belongs to the technical field of ammonia process smoke gas desulfurization, and particularly relates to a function guidance product partition ammonia process desulfurization oxidation circulation tank device and method. The device comprises a desulfurization tower absorption section and an oxidation circulation tank, wherein the desulfurization tower absorption section and the oxidation circulation tank are connected through a pipeline; the oxidation circulation tank is separated into three regions including a single phase liquid region, an oxidation region and a reduction region by tank wall plates and separation plates; one side of the reduction region is communicated with the oxidation region; the other side of the reduction region is communicated with a desulfurization circulation pump through a pipeline; the oxidation region is communicated with the single phase liquid region; the single phase liquid region is communicated with an ammonium sulfate material transferpump through a pipeline; an oxidation aeration layer is arranged inside the oxidation region, and is communicated with an oxidation fan through a pipeline. The absorbing capacity of absorption slurryon SO2 is greatly improved; the smoke gas desulfurization effect is enhanced; the field operation environment is greatly improved; the continuous and stable discharging of ammonium sulfate by-productsis ensured.

Owner:XIAN AEROSPACE SOURCE POWER ENG CO LTD

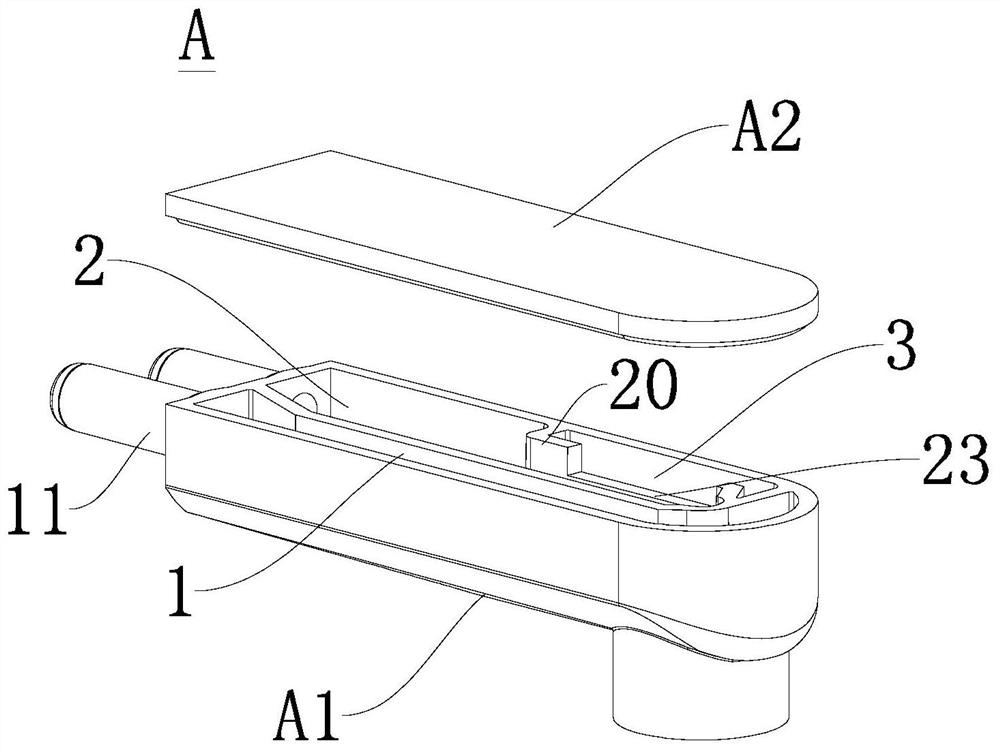

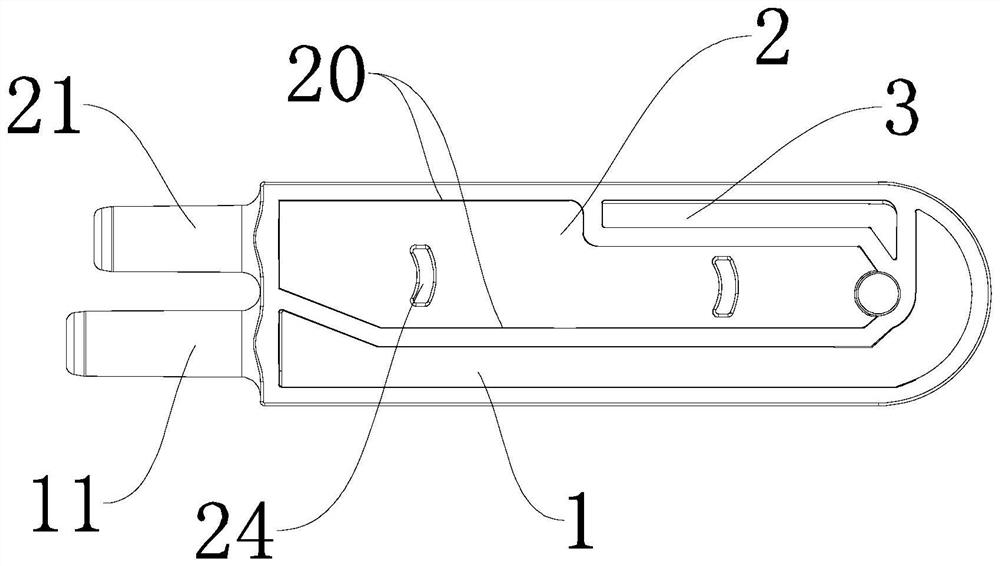

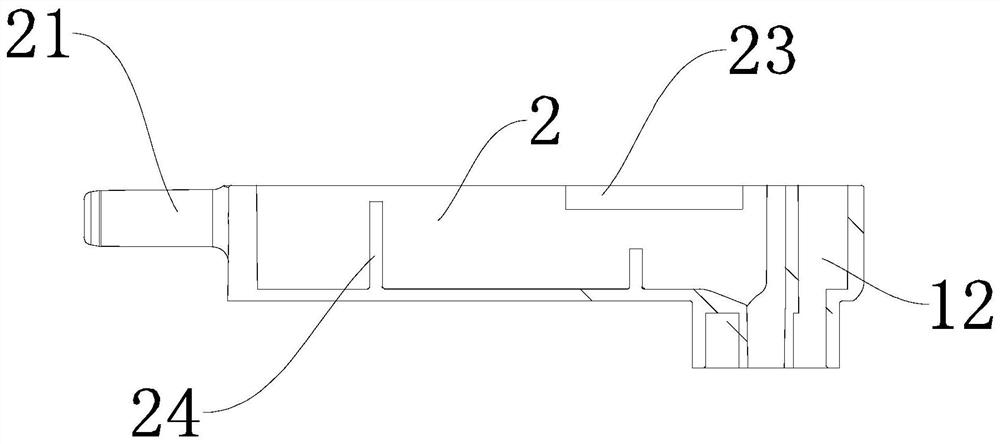

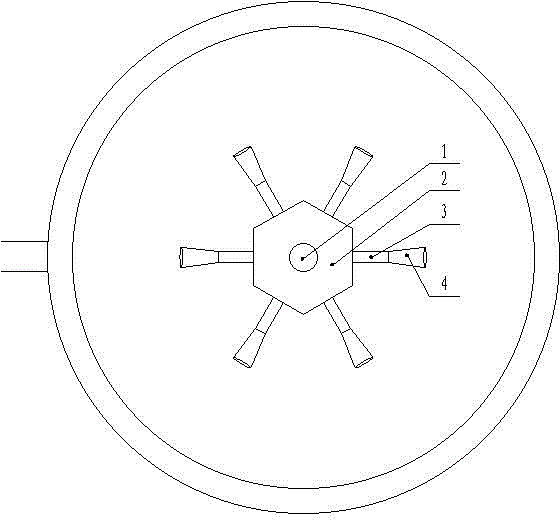

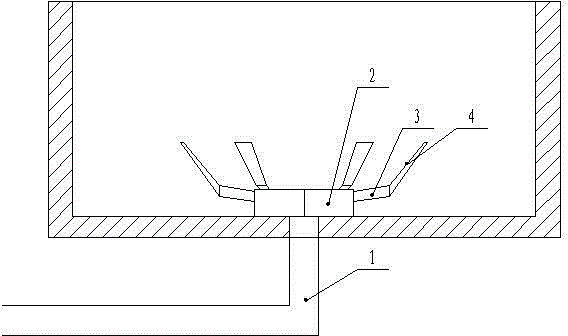

High-temperature faucet with water-gas separation device

PendingCN111998122AReduce the amount of air bubblesGood water and gas separation effectValve arrangementsLiquid degasificationGas separationEnvironmental geology

The invention discloses a high-temperature faucet with a water-gas separation device. The high-temperature faucet comprises the water-gas separation device and a faucet main body, the water outlet tail end of the faucet main body is provided with an accommodating space, and the water-gas separation device is arranged in the accommodating space; a cold water inlet pipe and a hot water inlet pipe are in communication with a cold water inlet and a hot water inlet of the water-gas separation device, the water-gas separation device comprises a hot water cavity and an exhaust runner, the water passing area of the hot water cavity is larger than that of the hot water inlet, and at least one water baffle is arranged in the hot water cavity; and an exhaust window is formed in the side wall of the hot water cavity, and the hot water cavity communicates with the exhaust channel through the exhaust window. According to the high-temperature faucet, the water-gas separation device is integrated in the water outlet tail end of the faucet body, the structure is simple, the occupied space is small, the water-gas separation effect is good, water flow is soft, the water outlet effect is good, and a user can be prevented from being scalded.

Owner:XIAMEN EASO CO LTD

Stone plastic board and processing method thereof

PendingCN109897302AReduce mutual disengagementImprove surface strengthSynthetic resin layered productsLaminationColor filmLubricant

The invention relates to the technical field of building materials, and specifically relates to a stone plastic board, which comprises a substrate layer, a color film layer, and a UV layer from bottomto top. The substrate layer is prepared from following raw materials in percentage by weight: 52.5 to 72.5% of calcium powder, 20 to 30% of PVC powder, 2.5 to 8.5% of a lubricant, and 5 to 9% of a reinforcing agent. The color film layer is prepared from PVC. The stone plastic board is nontoxic and environmentally friendly, and is harmless to the environment and humans. The substrate layer mainlymade of PVC powder and the color film layer made of PVC can be better combined.

Owner:上海普濡建材科技有限公司

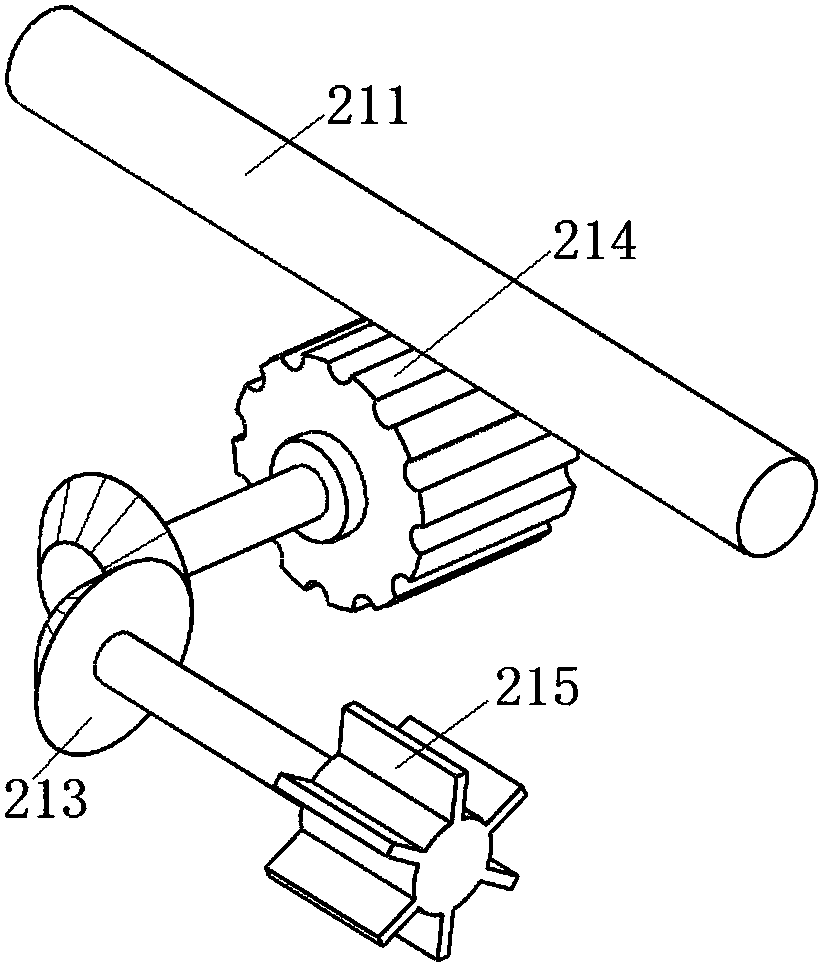

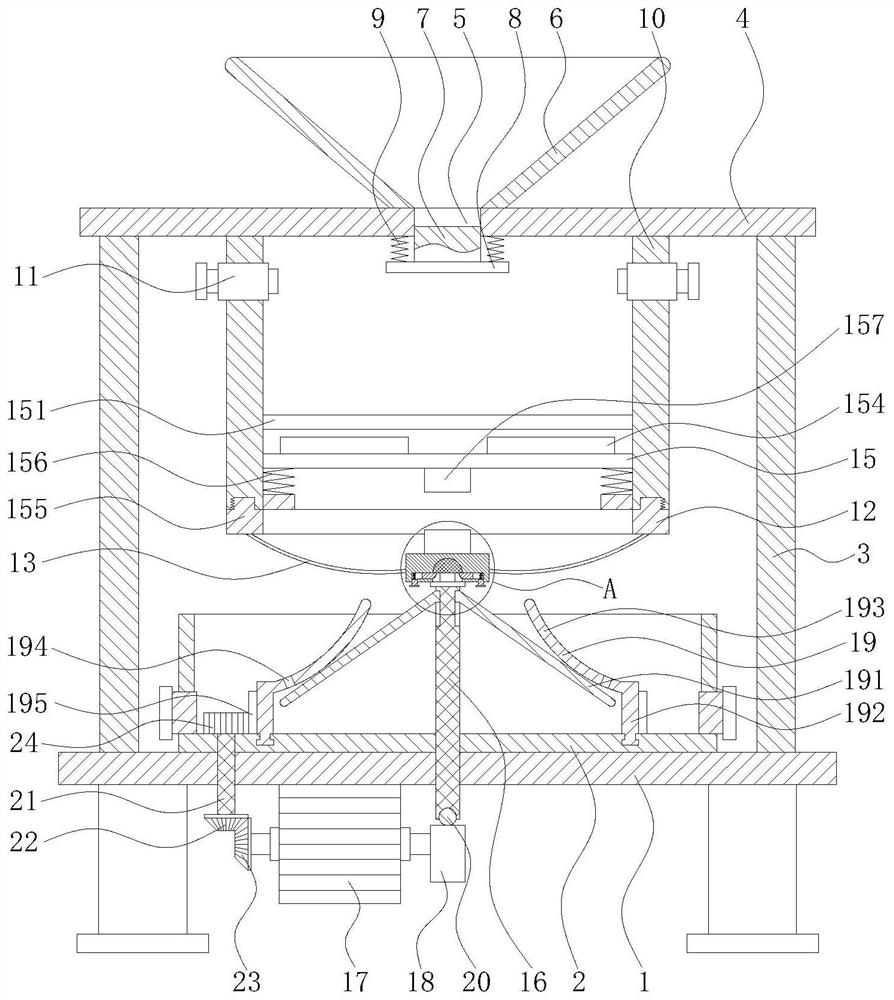

Hydraulic casting equipment with bubble removing function for metal product

InactiveCN111001786AReduce the presence of air bubblesEvenly distributedHydraulic cylinderElectric machinery

The invention relates to hydraulic casting equipment with a bubble removing function for a metal product. The equipment comprises a base, a bottom plate, a top plate, a top mold, a bottom mold, a supporting plate, a fixing box, a first hose, two supporting rods and two hydraulic cylinders. The equipment further comprises a bubble removing mechanism and a shaking mechanism. The bubble removing mechanism comprises a stirring assembly and two air exhaust assemblies. The stirring assembly comprises a motor, a rotating shaft, a first bearing, a transmission unit and a plurality of stirring blades.The shaking mechanism comprises a moving assembly and a connecting assembly. The moving assembly comprises a lead screw, a sliding block and two second bearings. According to the hydraulic casting equipment with the bubble removing function for the metal product, a bubble removing function can be realized through the bubble removing mechanism, and an influence on quality of a cast finished productdue to residual bubbles in a casting liquid is avoided; and the top mold and the bottom mold can be driven to shake through the shaking mechanism so that the casting liquid can be uniformly distributed in the top mold and the bottom mold, the casting finished product is prevented from being uneven, and quality of the casting finished product is improved.

Owner:科曼空气技术(深圳)有限公司

Gas-producing fermented milk and flavored fermented milk and production method thereof

The invention provides aerated fermented milk and flavored fermented milk and a preparation method thereof. The gas-producing fermented milk is made from raw fresh milk or reconstituted milk, which is sterilized and inoculated, including the fermentation of Lactococcus lactis subsp. It is a product containing fine air bubbles made by fermenting agent strains. The gas-producing flavored fermented milk is made from more than 80% raw fresh milk or reconstituted milk, and other raw materials are added, sterilized and inoculated including Lactococcus lactis subsp. Lactococcus lactis subspecies lactic acid starter culture fermented products containing fine air bubbles. The product of the present invention uses special lactic acid bacteria to ferment to produce carbon dioxide and special flavor. Most of the gas in the product exists in the form of microbubbles, has a refreshing taste and unique texture, and is suitable for drinking by various people.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

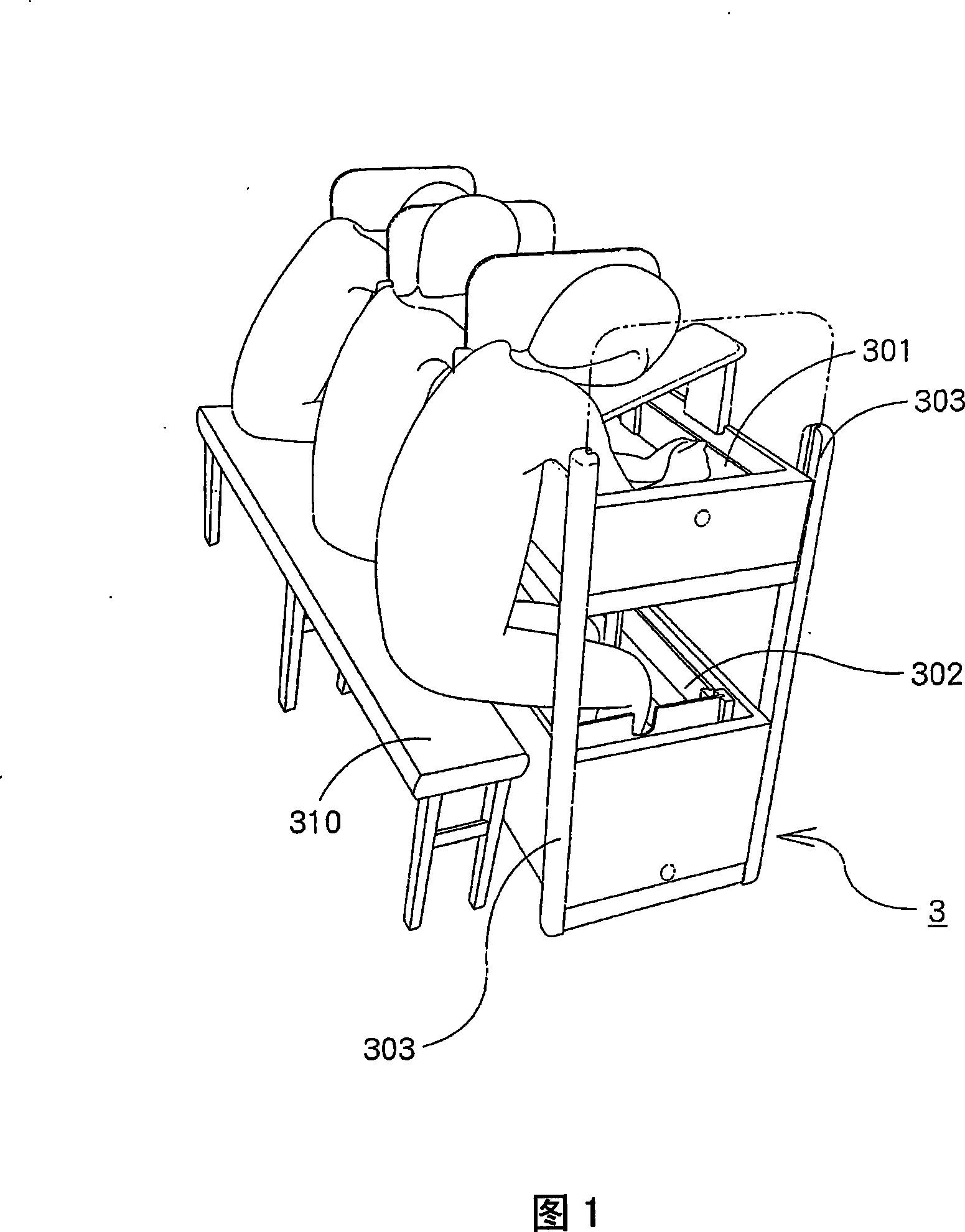

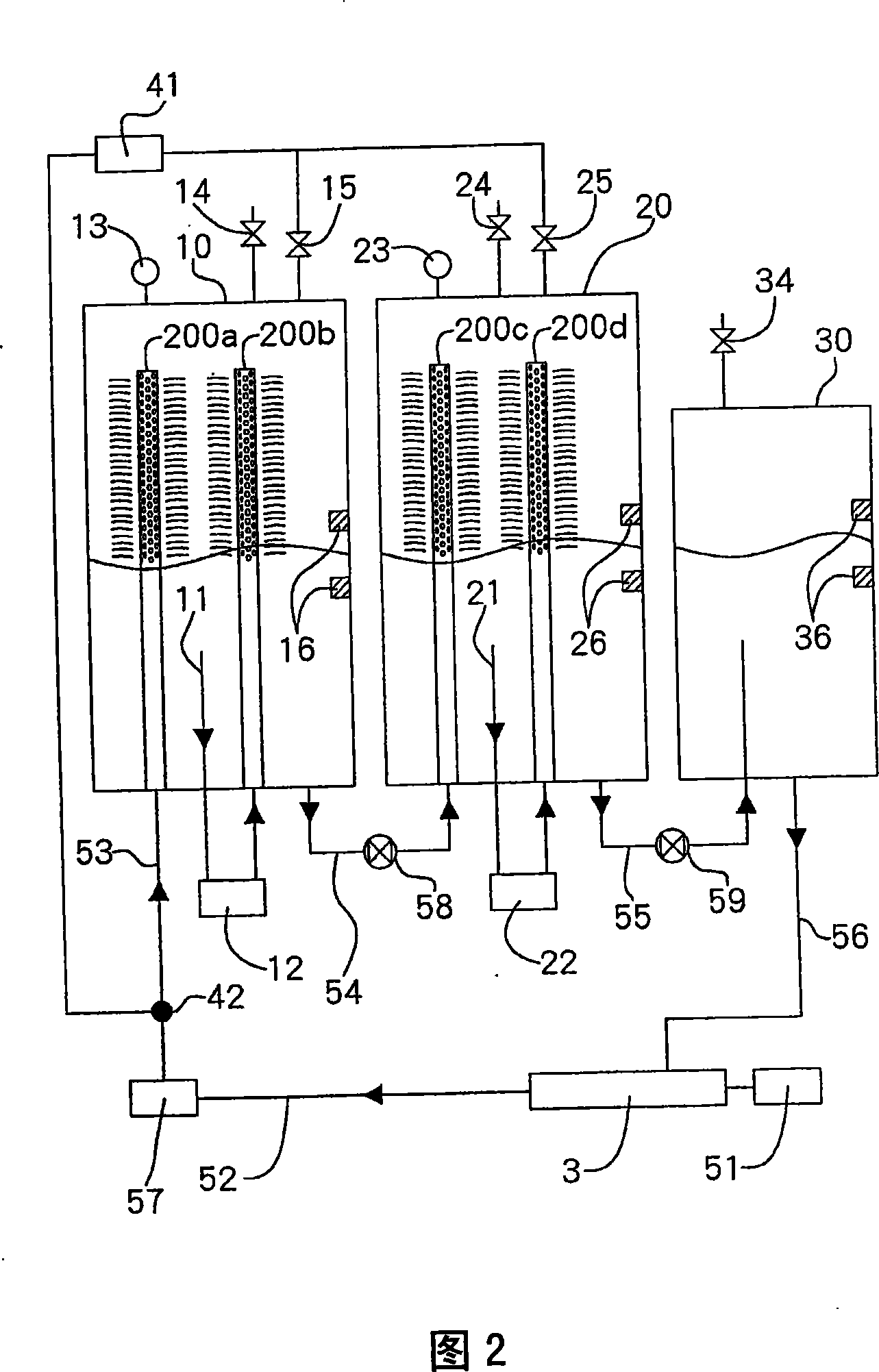

Mixing device for tub

A fluid mixing apparatus configured to be connected to a tub, a liquid supply, and a gas supply, includes: a 1st pressurable liquid-storing chamber for storing liquid and mixing gas into liquid; a 2nd pressurable liquid-storing chamber for storing liquid and mixing gas into liquid; and a connection path connecting the 1st and 2nd liquid-storing chamber for supplying liquid from the 1st liquid-storing chamber to the 2nd liquid-storing chamber where the pressure inside the 2nd liquid-storing chamber is lower than the pressure inside the 1st liquid-storing chamber. The 2nd liquid-storing chamber is disposed downstream of the 1st liquid-storing chamber with respect to liquid flow.

Owner:增田胜利

Manufacturing process of magnesium metal refining kettle

InactiveCN104874741AReduce the amount of air bubblesImprove pass rateFoundry mouldsFoundry coresSteelmakingMaterials science

The invention discloses a manufacturing process of a magnesium metal refining kettle, and belongs to the technical field of casting, so as to solve the technical problems that the magnesium metal refining kettle is difficult to manufacture and the percent of pass is low. In order to solve the technical problems above, according to the technical scheme adopted for the manufacturing process of the magnesium metal refining kettle, the manufacturing process of the magnesium metal refining kettle comprises the step of the manufacturing process of the magnesium metal refining kettle: before pouring, constructing a sand mold of a lower box body, putting the sand mold into lost foam, connecting an upper box body with the lower box body through a bolt, and then exhausting gases in a box body, after the box body is vacuumized, pouring from a pouring gate at the central position of the lower box body, melting the lost foam, meanwhile, continuously vacuumizing, exhausting air in a pouring liquid, cooling and molding. A duckbilled running channel device is particularly adopted for pouring; in the condition that steelmaking procedures are the same, the manufacturing percent of pass of the magnesium metal refining kettles is increased to above 85 percent from below 50 percent by adopting the design of the duckbilled running channel device for the manufacturing process of the magnesium metal refining kettle.

Owner:LINFEN PENGTAI WEIYE

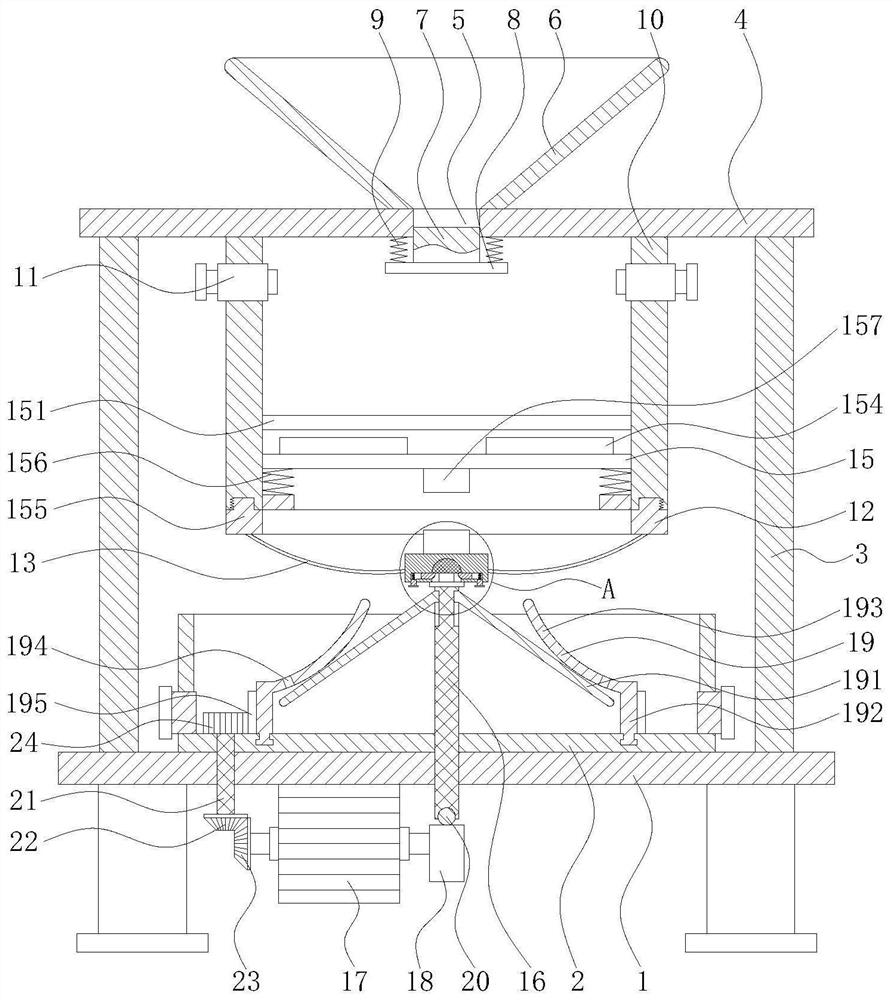

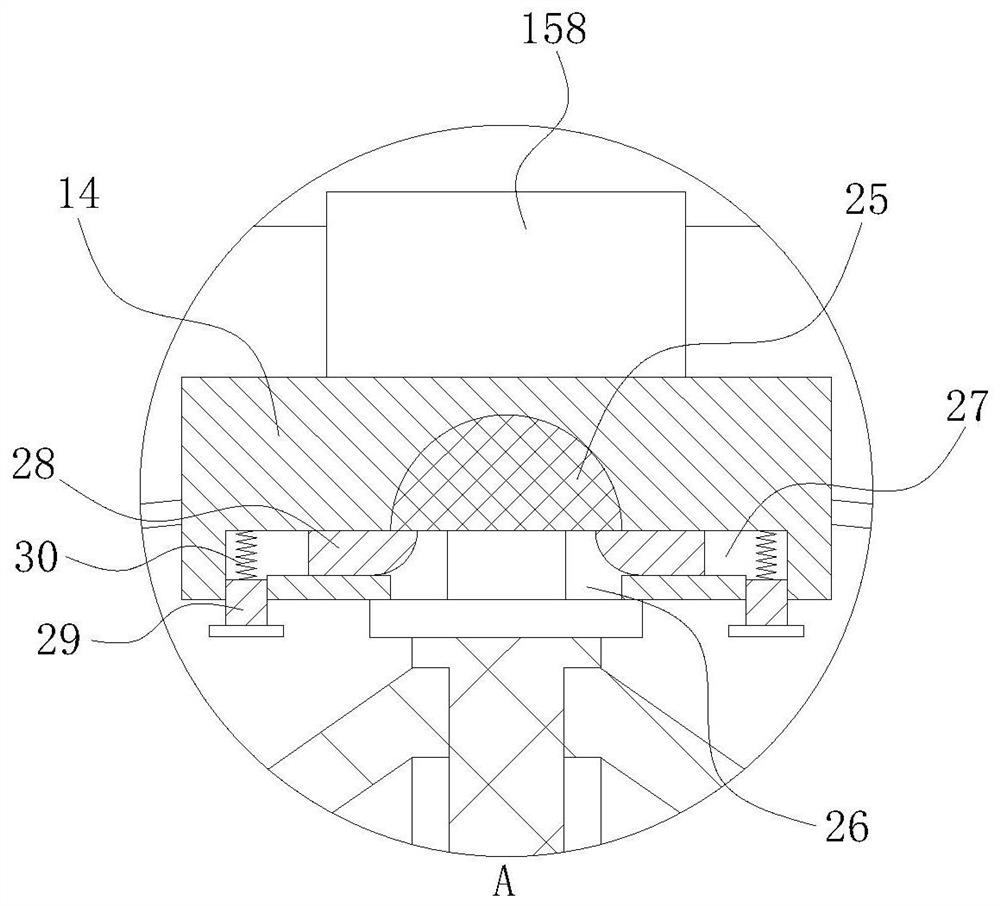

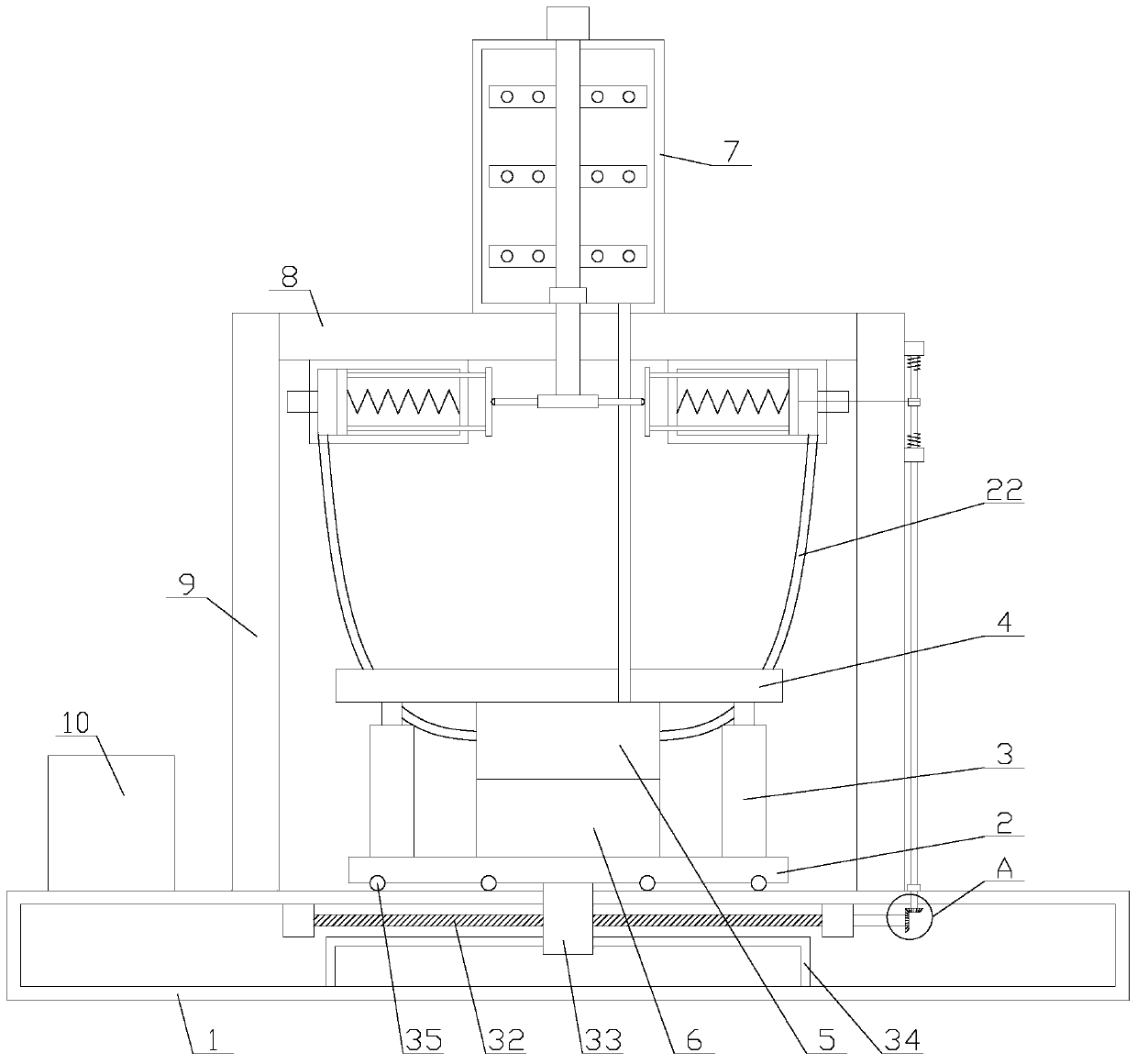

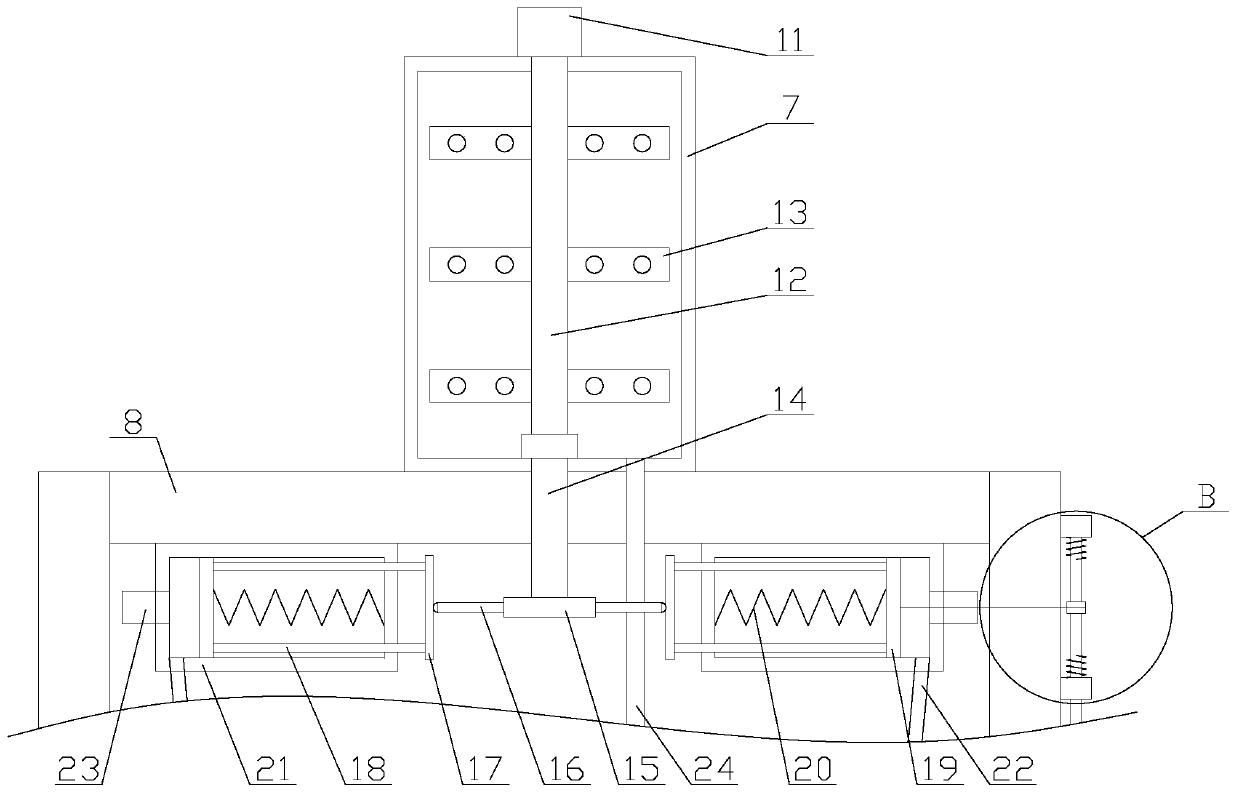

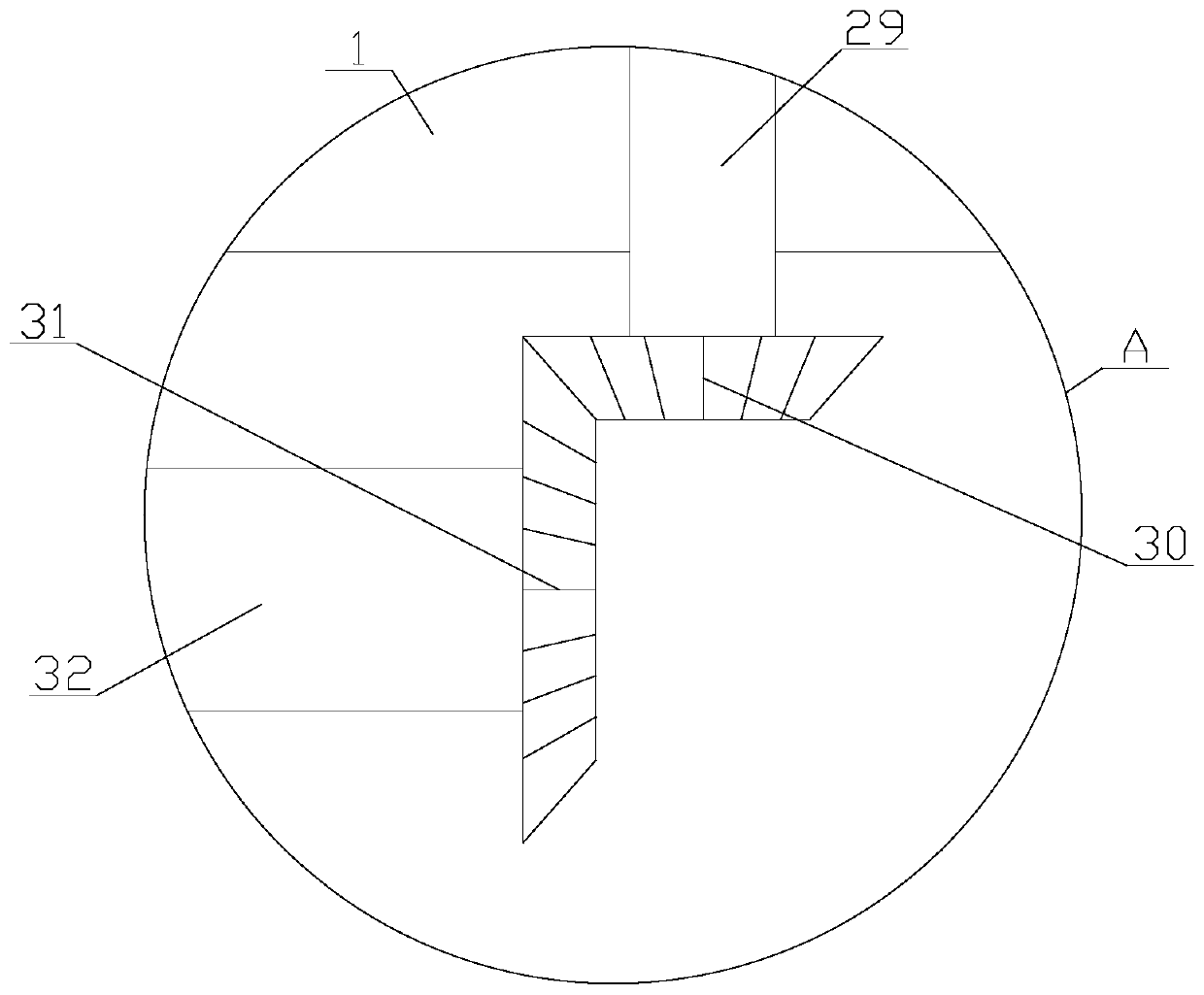

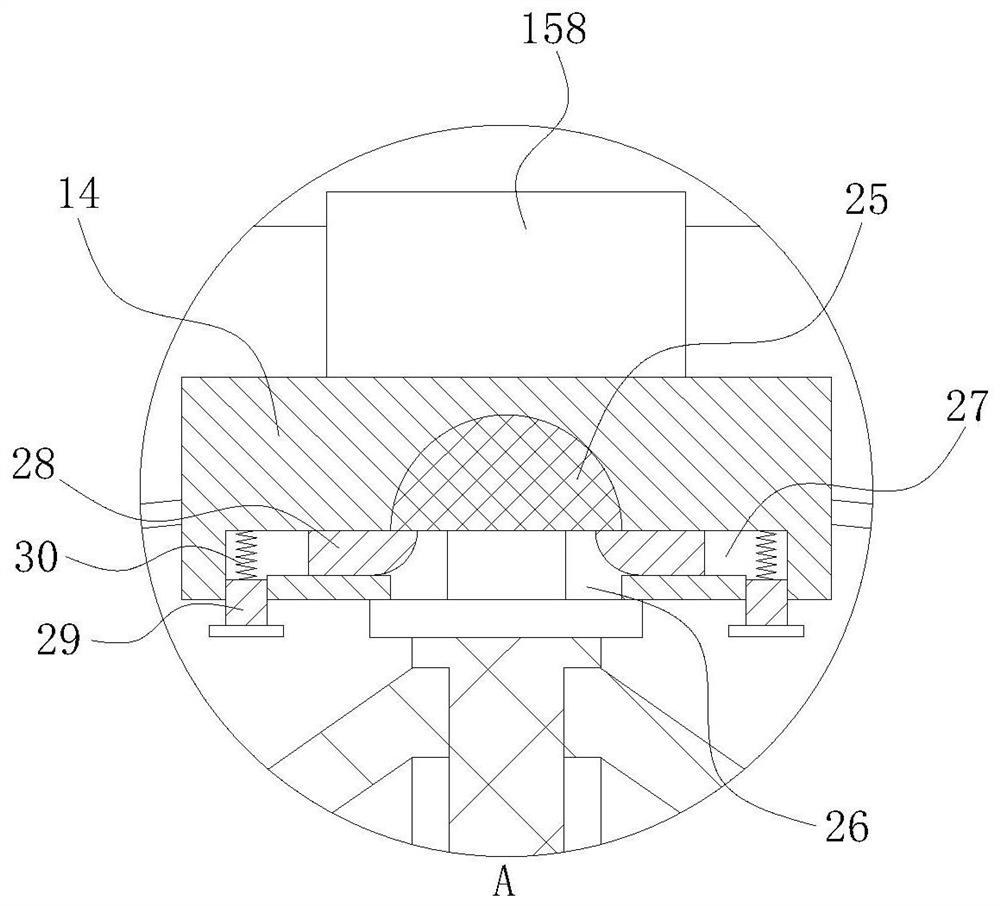

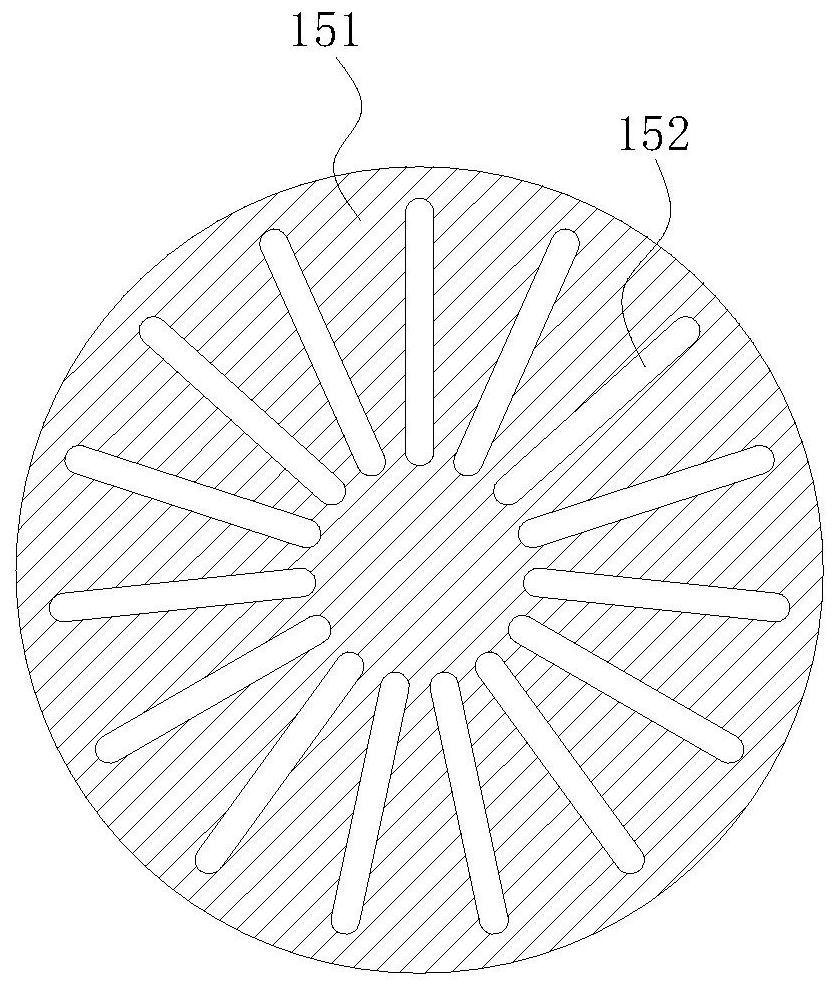

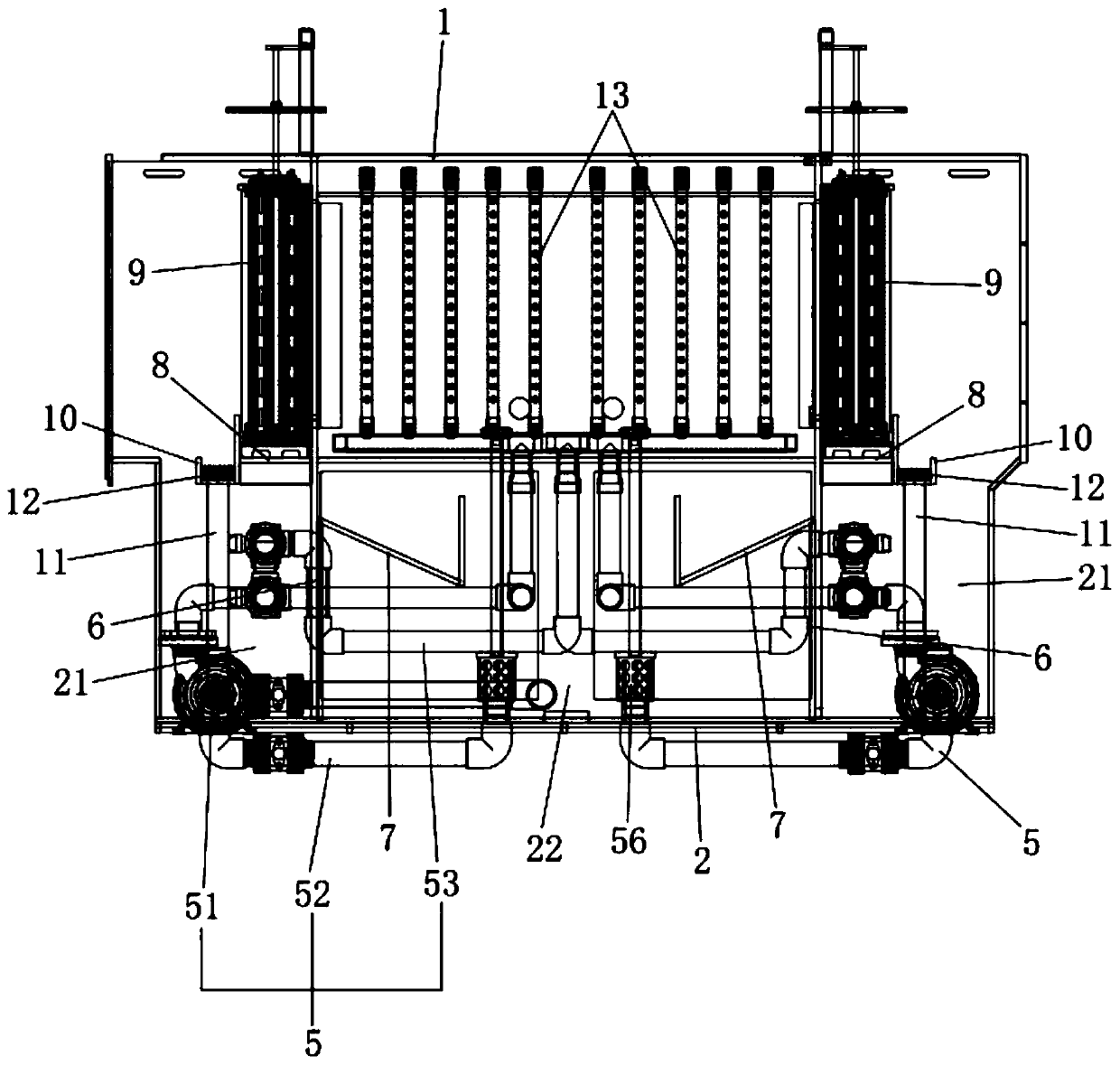

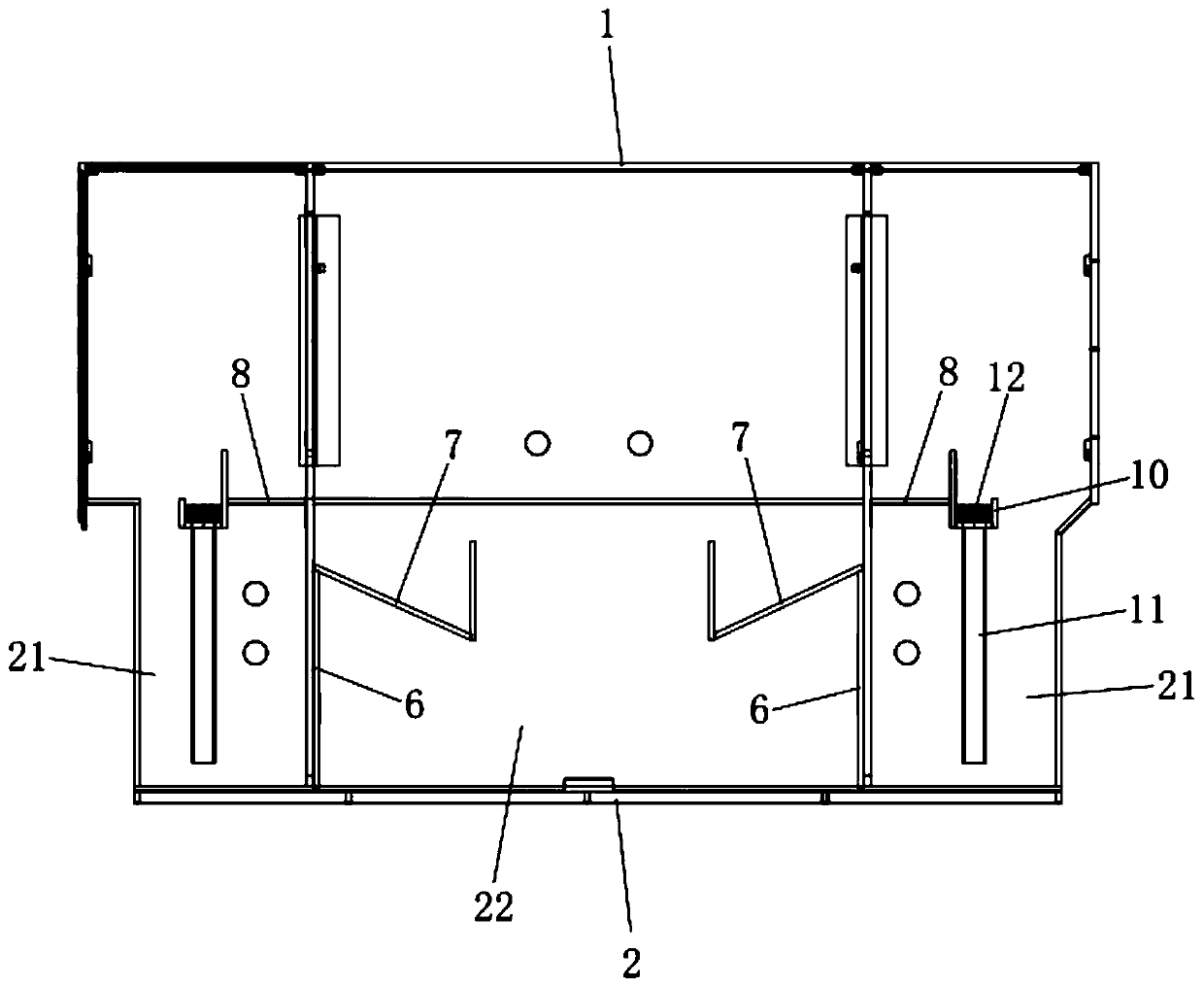

Processing and preparing system for antibacterial emulsion essence mask

InactiveCN112138432ALow wettabilityAvoid cloggingCosmetic preparationsLiquid degasificationPolymer scienceEngineering

The invention belongs to the technical field of mask manufacturing, and particularly relates to a processing and preparing system for an antibacterial emulsion essence mask. The system comprises a horizontal bottom plate, and a plurality of supporting legs are vertically and fixedly mounted on the bottom surface of the bottom plate. A receiving box with an opening in the top and a liquid outlet inthe side face is fixedly installed on the top face of the bottom plate. A connecting rod is fixedly installed on the top face of the bottom plate around the receiving box, and a horizontal top plateis fixedly installed at the top of the connecting rod. Bubbles in the soaking solution are extruded and crushed, so that the quantity of the bubbles in the soaking solution is reduced, the bubbles areprevented from blocking micropores of a filter bag, and the filtering effect is improved; and the soaking solution is ground through the second defoaming mechanism, and bubble residues are avoided.

Owner:南京科艺通化工科技有限公司

Reflow defoaming system of electroplating process tank

The invention discloses a reflow defoaming system of an electroplating process tank. The system involves an upper tank body, a flow guiding tank body, a lower tank body, a overflow box and a defoamingdevice, wherein the upper tank body is provided with a through port for allowing a to-be-plated board to pass through, the flow guiding body is arranged on one side of the upper tank body and communicates with the upper tank body through the through port, the lower tank body is located below the upper tank body, the bottom of the lower tank body is provided with a partition plate for partitioningthe interior space of the lower tank body into a reflow area and a defoaming area, a bubble layer above the electroplating liquid or cleaning liquid in the reflow area overflows from the top of the partition plate and enters the defoaming area, the overflow box communicates with a plate passing liquid discharging port at the side, opposite to the upper tank body, of the flow guiding tank body, the lower part of the overflow box communicates with a drainage pipe leading to the reflow area, the defoaming device is located above the defoaming area, and a negative pressure area is formed above the defoaming area to suck air bubbles in the reflow area and perform shear elimination on the bubbles. According to the system, a overflow pipe is arranged between the upper tank body and the lower tank body, the partition board and the defoaming device are arranged in the lower tank body, bubbles in the electroplating solution or cleaning liquid obtained by reflow can be eliminated, and the influence of bubbles on the electroplating quality of the product is reduced.

Owner:广德东威科技有限公司

Reflow SMT Process

ActiveCN107124835BReduce generationReduce the amount of air bubblesPrinted circuit assemblingEngineeringSolder paste

The invention discloses a reflow-soldering die bonding process. The process comprises the following steps of printing a solder paste, patching, intermediate inspection, reflow soldering and inspection after soldering. During the reflow soldering step, the pressure reduction treatment is conducted. In this way, the formation of cavities, due to the generation of huge air bubbles during the welding process, can be avoided. The formation of explosive exhausts, caused by the escaping of huge air bubbles, is also avoided. Since many fine tin beads are escaped, the negative pressure is formed in a welding zone through the pressure reduction treatment. Therefore, small air bubbles escape easily during the welding process, and huge air bubbles are not easily formed. The phenomenon of bead splashing is avoided.

Owner:杭州晶志康电子科技有限公司

Technique for producing calcium oxide E glass

The invention relates to the production of E glass and provides a production technique to produce E glass with quicklime instead of limestone. The specific method of the invention is that: the limestone is sintered outside the kiln at a temperature about 950-1050 DEG C for 20-25h and the preferential sintering temperature is 1000-1020 DEG C for 24-25h; then the object obtained from the sintering is put into the kiln according to prescription ratio. The technique of the invention greatly improves the quality of the E glass and reduces production cost, and energy consumption can be greatly reduced compared with directly applying limestone; the discharge of CO2 generated from most of raw materials is controlled, thereby reducing environmental pollution.

Owner:TAISHAN FIBERGLASS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com