Bubble flow guide full-liquid type shell tube evaporator

A flooded, evaporator technology, used in evaporator/condenser, refrigeration and liquefaction, refrigeration components, etc., can solve the problems of blockage of heat exchange tube channels, high reliability requirements, complex structure, etc., to reduce the number of, The effect of improving the overall heat transfer performance and reducing the amount of air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

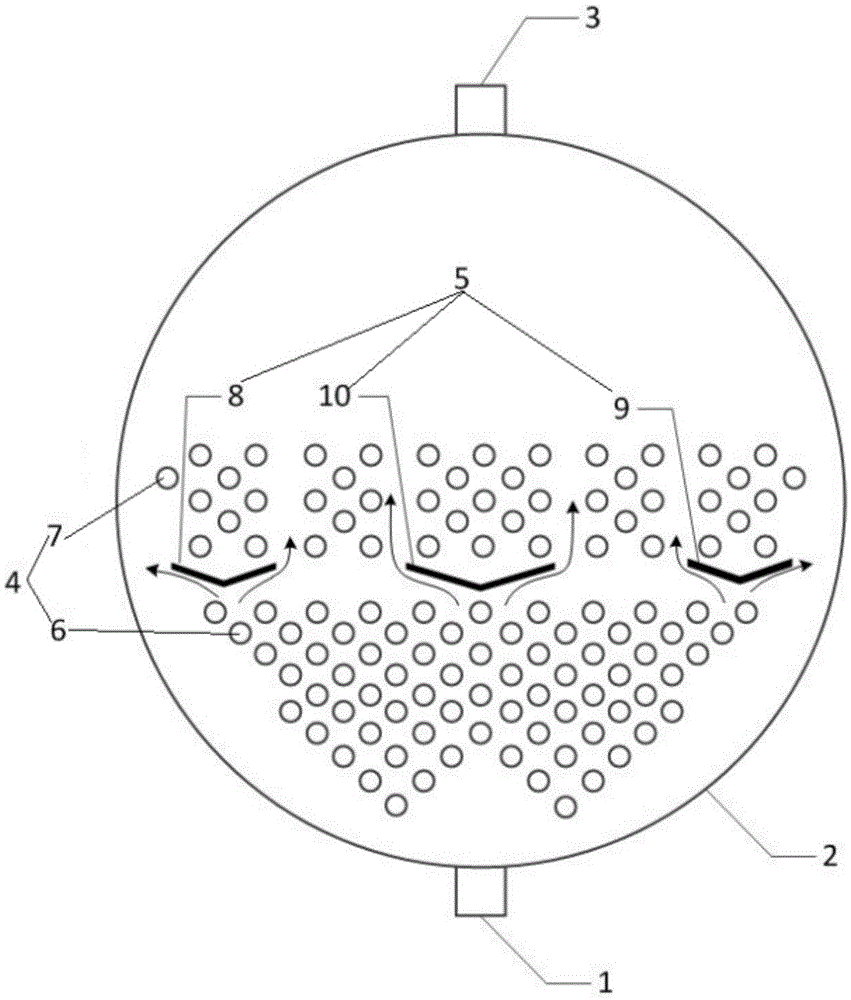

[0021] Such as figure 1 As shown, this embodiment includes: a shell 2, a heat exchange tube 4 and a bubble deflector 5, wherein: the upper part of the shell 2 is provided with a shell-side outlet 3, and the lower part is provided with a shell-side inlet 1. The heat exchange tubes 4 arranged in the casing 2 include: bottom heat exchange tubes 6 and upper layer heat exchange tubes 7 . The air bubble deflector 5 is V-shaped, including: a left V-shaped deflector 8, a right V-shaped deflector 9, and a middle V-shaped deflector 10, which are arranged in rows on the bottom heat exchange tubes 6 in sequence. And between the upper layer heat exchange tube 7.

[0022] The bottom heat exchange tubes 6 are arranged in a conventional tight and equidistant equidistant triangle. In this area, the refrigerant with a certain degree of subcooling enters the shell 2 from the shell side inlet 1, and the temperature of the refrigerant rises from the subcooling temperature to the evaporation temp...

Embodiment 2

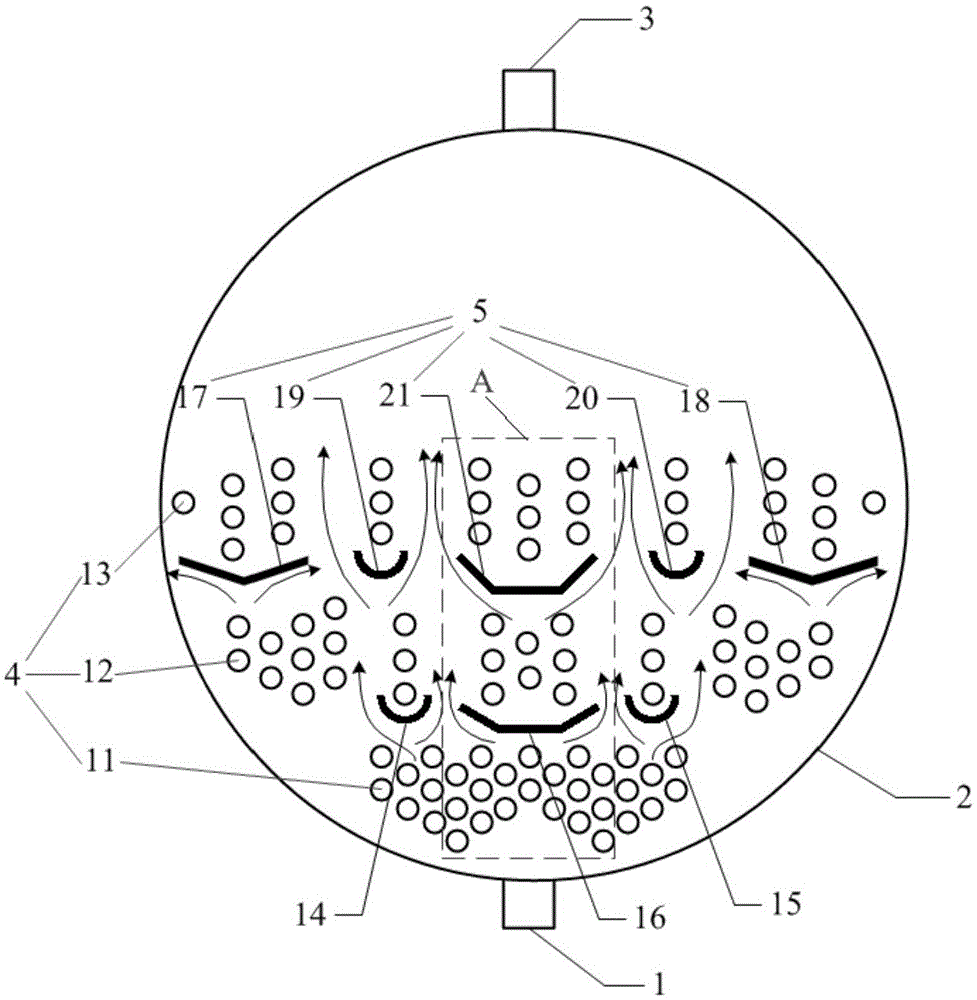

[0026] Such as figure 2 As shown, this embodiment includes: a shell 2, a heat exchange tube 4 and a bubble deflector 5, wherein: the upper part of the shell 2 is provided with a shell-side outlet 3, and the lower part is provided with a shell-side inlet 1.

[0027] The difference between this embodiment and embodiment 1 is:

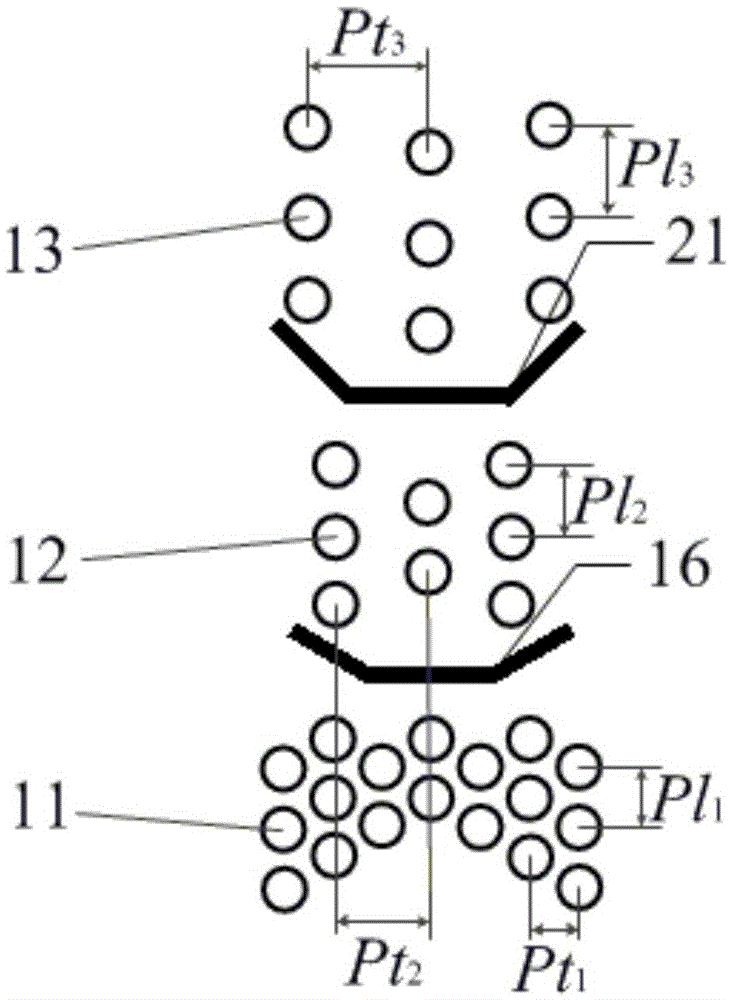

[0028] The heat exchange tube 4 includes: a bottom heat exchange tube 11 , a middle layer heat exchange tube 12 and an upper layer heat exchange tube 13 . Between the bottom heat exchange tubes 11 and the middle heat exchange tubes 12, the lower left U-shaped deflector 14, the lower middle trapezoidal deflector 16, and the lower right U-shaped deflector 15 are arranged in rows in sequence; Between the heat exchange tubes 13 and the middle heat exchange tubes 12, the upper left V-shaped deflector 17, the upper left U-shaped deflector 19, the upper middle trapezoidal deflector 21, and the upper right U-shaped deflector are arranged in rows. The font defl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com