Reflow SMT Process

A reflow soldering and reflow soldering technology, applied in the direction of assembling printed circuits with electrical components, can solve the problems of reducing the reliability of the device, excessive contact resistance, and reducing the safe working area of the device, and achieve the effect of reducing the generation of water vapor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-56

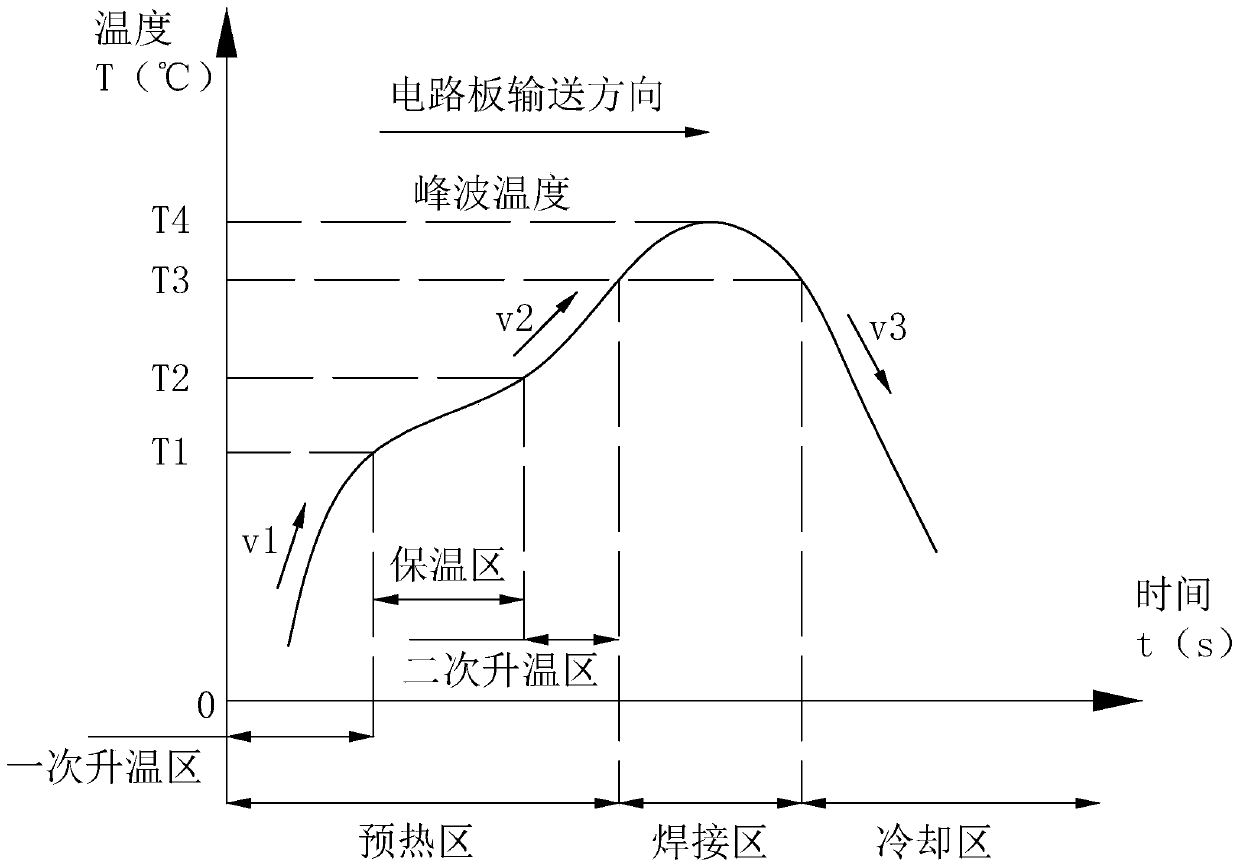

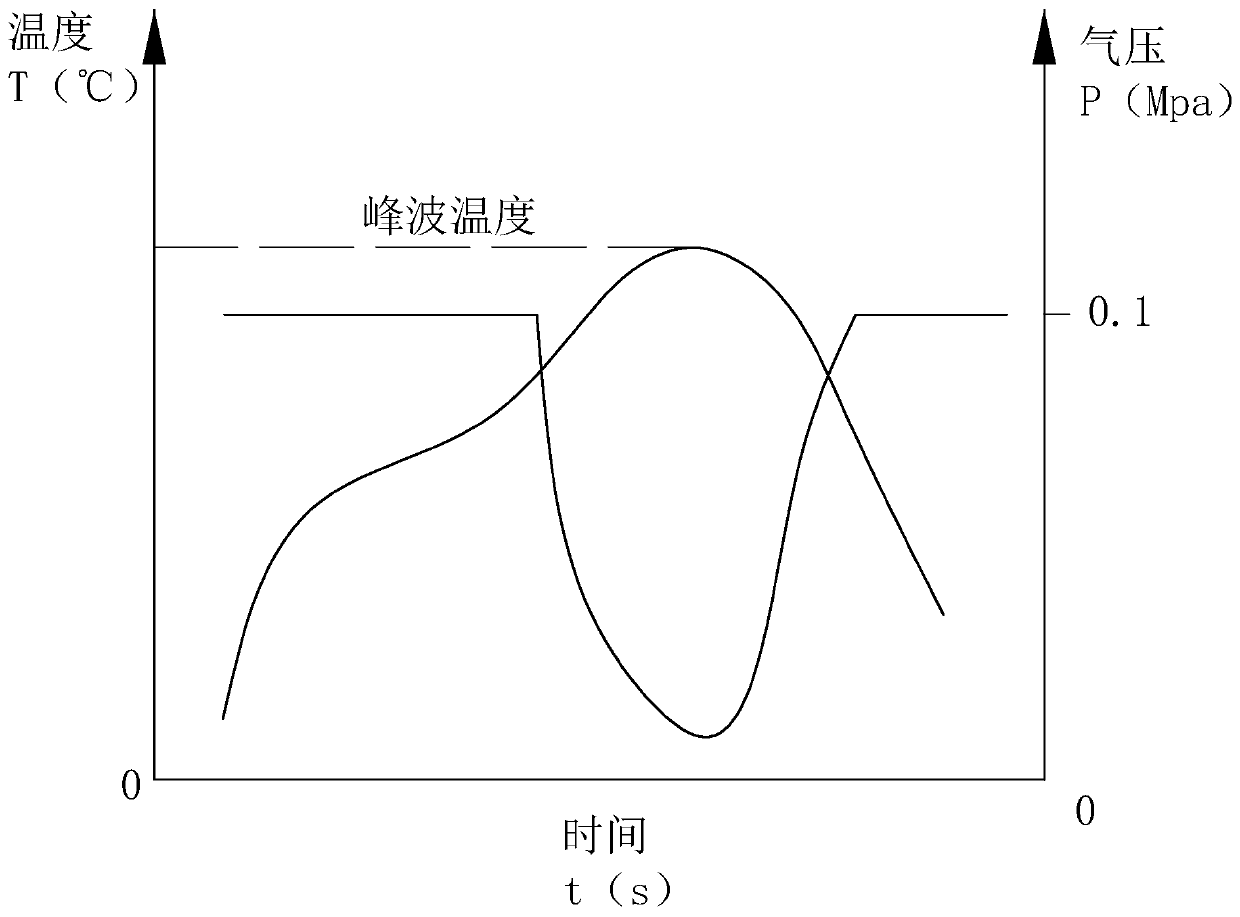

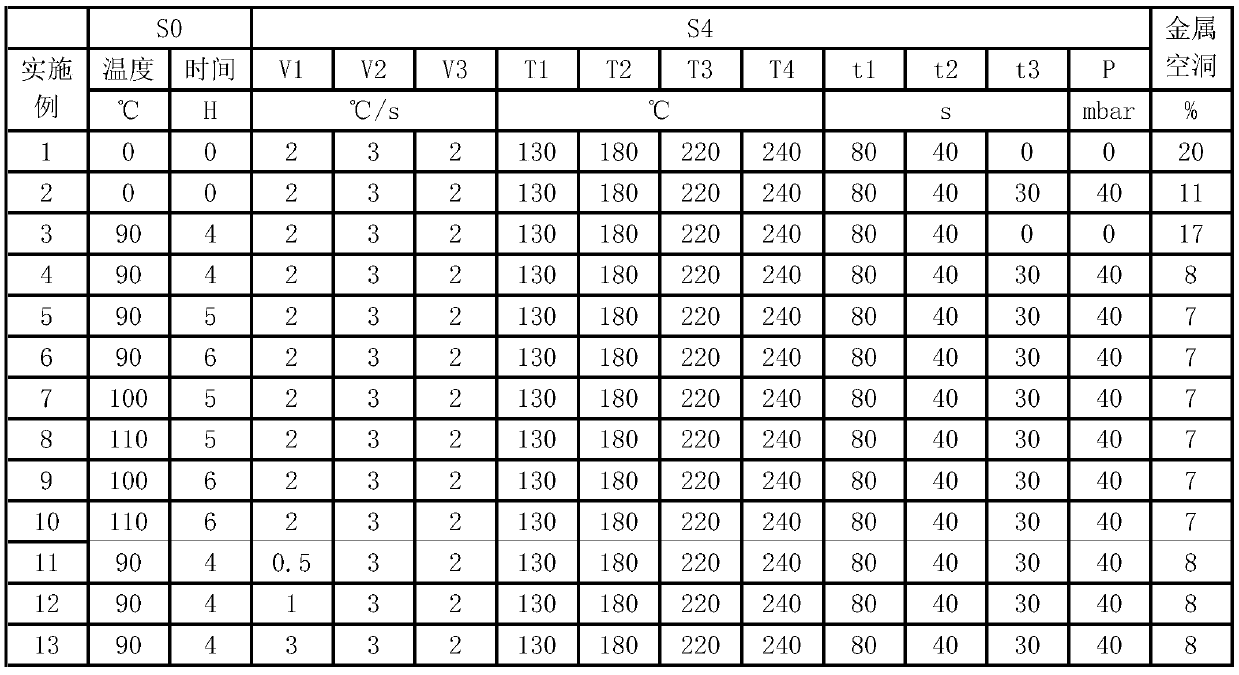

[0036] Embodiment 1-56: a reflow soldering patch process, comprising the following steps:

[0037] S0, drying, sending the circuit board to be soldered into an oven for pre-baking for 4-6H, and the drying temperature is 90-110°C;

[0038] S1. Printing solder paste. After the circuit board is detected correctly by the optical camera, the circuit board is pasted under the stencil, and the solder paste is passed through the mesh on the stencil while the lead-free scraper is moving above the stencil. The solder paste is printed on the circuit board through the hole, and the solder paste is Sn-Ag-Cu alloy solder. The mesh on the stencil is an inverted tapered round hole to increase the surface area of the solder paste printed on the circuit board. ;

[0039] S2, placement, sending the circuit board after step S1 into the placement machine for placement;

[0040] S3. Intermediate inspection, check whether the polarity of the component is reversed, whether the mounting is offset,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com