Manufacturing process of magnesium metal refining kettle

A manufacturing process and refining pot technology, applied in the field of manufacturing process of magnesium metal refining pot, can solve the problems of low qualification rate and difficulty in manufacturing the magnesium metal refining pot, and achieve the effects of reducing raw materials, improving the manufacturing qualification rate, and reducing the amount of air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

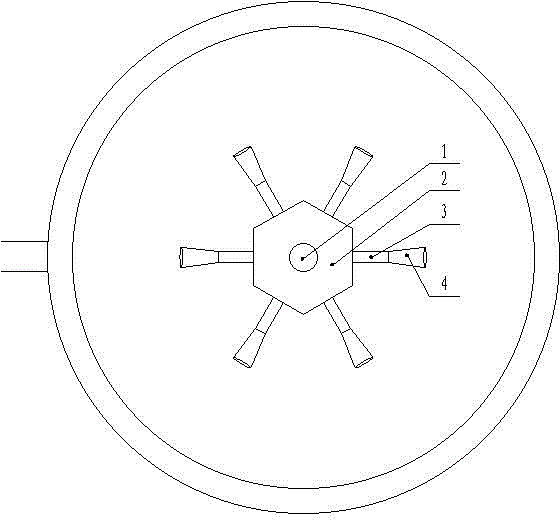

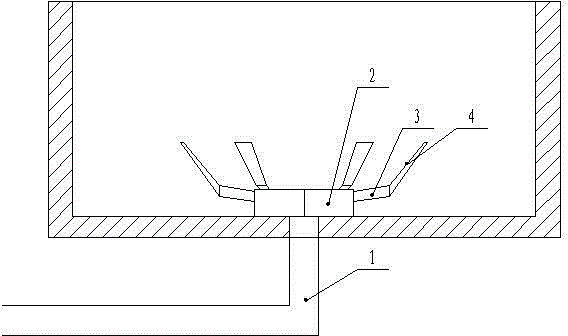

[0016] A metal magnesium refining pot manufacturing process, including the steps of metal magnesium refining pot manufacturing process, before casting, the sand mold of the lower box is built, put into the lost foam, and the upper box and the lower box are connected by bolts , Then pump out the gas in the box, vacuumize the box, start casting from the gate at the center of the lower box, melt the lost foam, continue vacuuming at the same time, pull out the air in the casting liquid, and cool and form. The present invention creatively adopts a duckbill sprue device for casting, and the duckbill sprue device includes a runner 1, a distribution pool 2, an inner runner 3 and a duckbill runner 4, and the end of the runner 1 The distribution pool 2 is connected and the runner 1 is perpendicular to the bottom surface of the distribution pool 2. The distribution pool 2 is a flat cylindrical or flat hexagonal cavity, and the side walls of the distribution pool 2 are evenly distributed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com