OCA optical adhesive easy to attach

A technology of optical glue and bonding, which is applied in the field of optical glue, and can solve problems such as difficult bonding of OCA products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

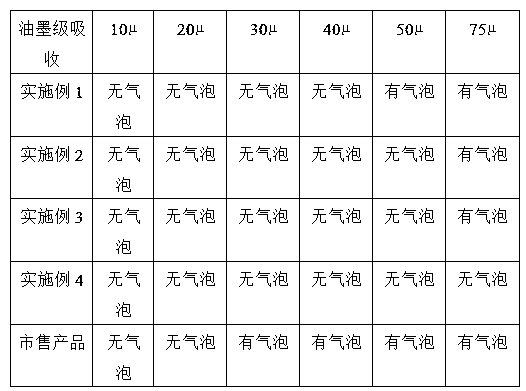

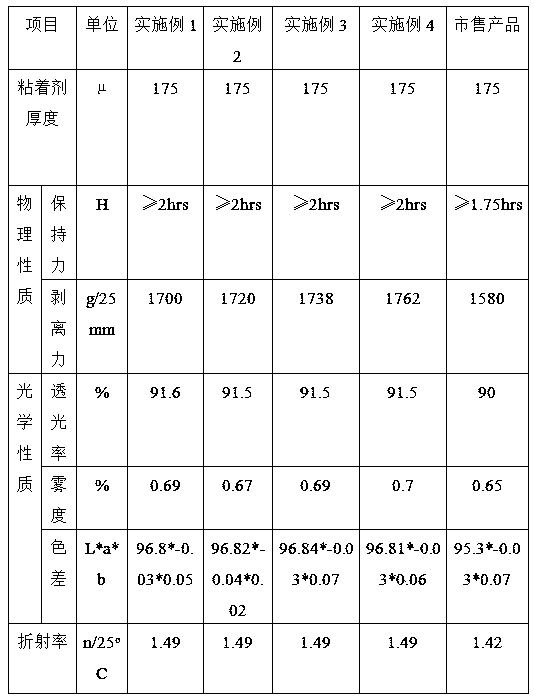

Examples

Embodiment 1

[0018] The invention provides an easy-to-laminate OCA optical adhesive, which includes the following components in parts by mass: 20 parts of hydroxypropyl methacrylate, 40 parts of glycidyl methacrylate, 6 parts of isooctyl acrylate, benzene polyacrylate 2 parts of acid ester, 1 part of hydroxybenzophenone, 1 part of phthalate, 1 part of hydroquinone, 1 part of ethyl acetate, 0.5 part of initiator, 0.2 part of sensitizer, 0.5 part of crosslinking agent 1 part, 1 part of surface modifier and 1 part of polysiloxane.

[0019] The above-mentioned easy-to-laminate OCA optical glue is made of UV semi-cured OCA by combining soft materials with strong fluidity such as isooctyl acrylate and hard materials with low fluidity such as hydroxypropyl methacrylate. Optical glue, in this way, the more fluid isooctyl acrylate will fully fill the surface of the screen, which is beneficial to eliminate the bubbles generated in the process of bonding OCA optical glue products to the screen; moreo...

Embodiment 2

[0032] The invention provides an easy-to-laminate OCA optical adhesive, which includes the following components in parts by mass: 30 parts of hydroxypropyl methacrylate, 43 parts of glycidyl methacrylate, 11 parts of isooctyl acrylate, benzene polyacrylate 3 parts of acid ester, 2 parts of hydroxybenzophenone, 2 parts of phthalate, 2 parts of hydroquinone, 2 parts of ethyl acetate, 0.62 parts of initiator, 0.3 parts of sensitizer, 0.7 parts of crosslinking agent 1.5 parts of surface modifier, 2 parts of polysiloxane and 3 parts of di-n-octyltin dilaurate.

[0033]The above-mentioned easy-to-laminate OCA optical glue is made of UV semi-cured OCA by combining soft materials with strong fluidity such as isooctyl acrylate and hard materials with low fluidity such as hydroxypropyl methacrylate. Optical glue, in this way, the more fluid isooctyl acrylate will fully fill the surface of the screen, which is beneficial to eliminate the bubbles generated in the process of bonding OCA op...

Embodiment 3

[0038] The invention provides an easy-to-laminate OCA optical adhesive, which includes the following components in parts by mass: 40 parts of hydroxypropyl methacrylate, 46 parts of glycidyl methacrylate, 18 parts of isooctyl acrylate, benzene polyacrylate 5 parts of acid ester, 3 parts of hydroxybenzophenone, 4 parts of phthalate, 4 parts of hydroquinone, 4 parts of ethyl acetate, 0.9 part of initiator, 0.4 part of sensitizer, 0.8 part of crosslinking agent 2.5 parts of surface modifier, 4 parts of polysiloxane and 5 parts of di-n-octyltin dilaurate.

[0039] The above-mentioned easy-to-laminate OCA optical glue is made of UV semi-cured OCA by combining soft materials with strong fluidity such as isooctyl acrylate and hard materials with low fluidity such as hydroxypropyl methacrylate. Optical glue, in this way, the more fluid isooctyl acrylate will fully fill the surface of the screen, which is beneficial to eliminate the bubbles generated in the process of bonding OCA optic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com