Reflow-soldering die bonding process

A reflow soldering and reflow soldering technology, which is applied in the direction of assembling printed circuits with electric components, can solve the problems of reducing device reliability, increasing the thermal resistance of power MOS tubes, and increasing the on-resistance RDS, so as to reduce the generation of water vapor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-56

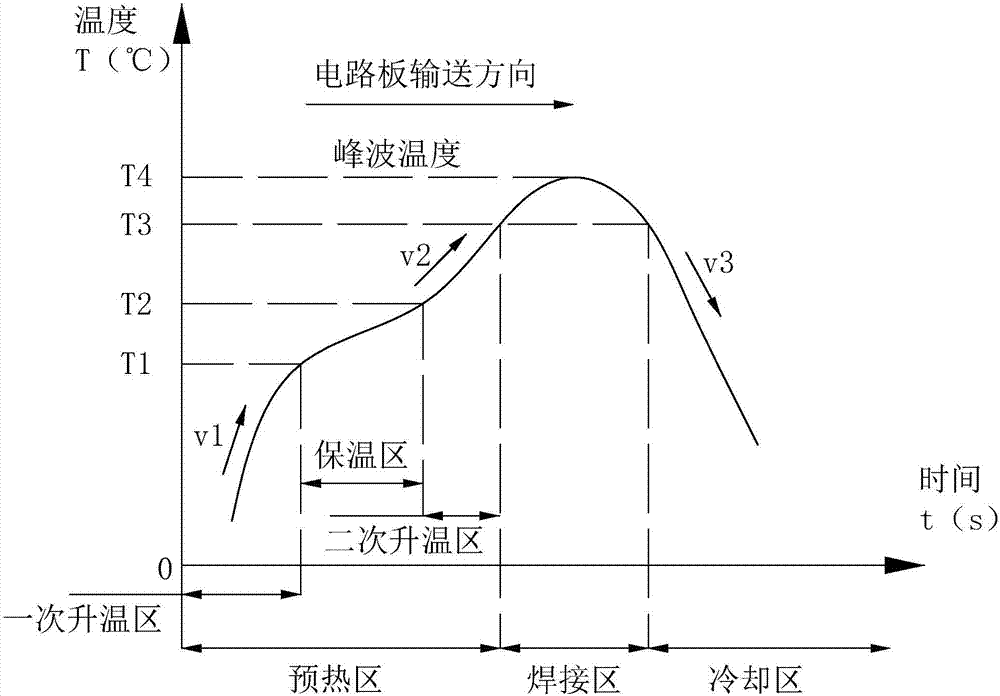

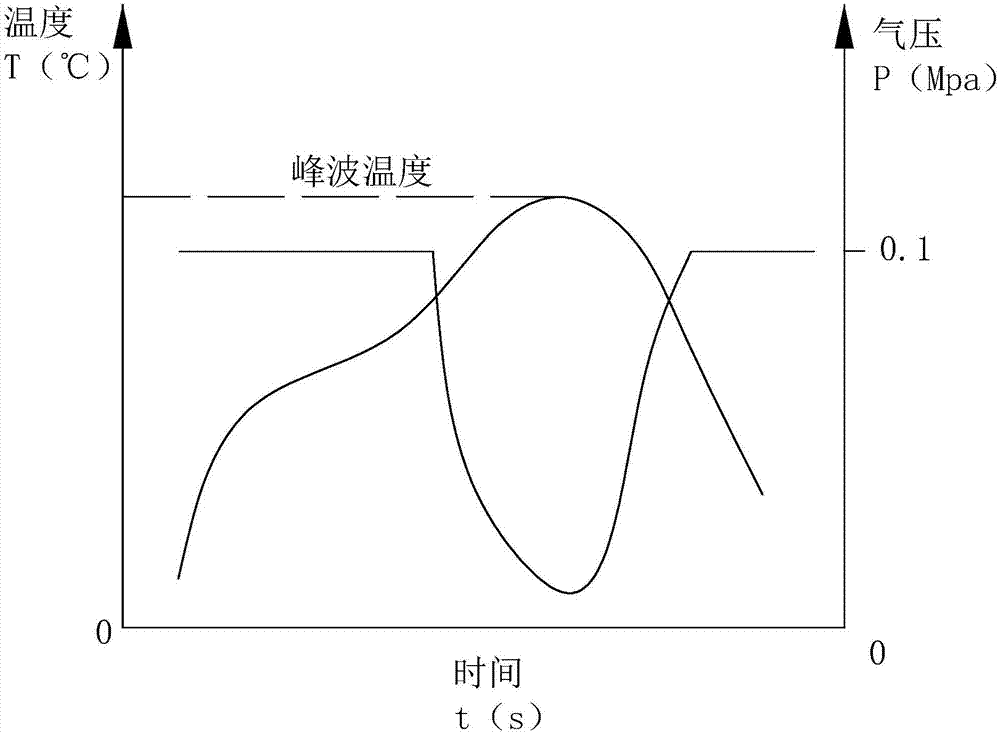

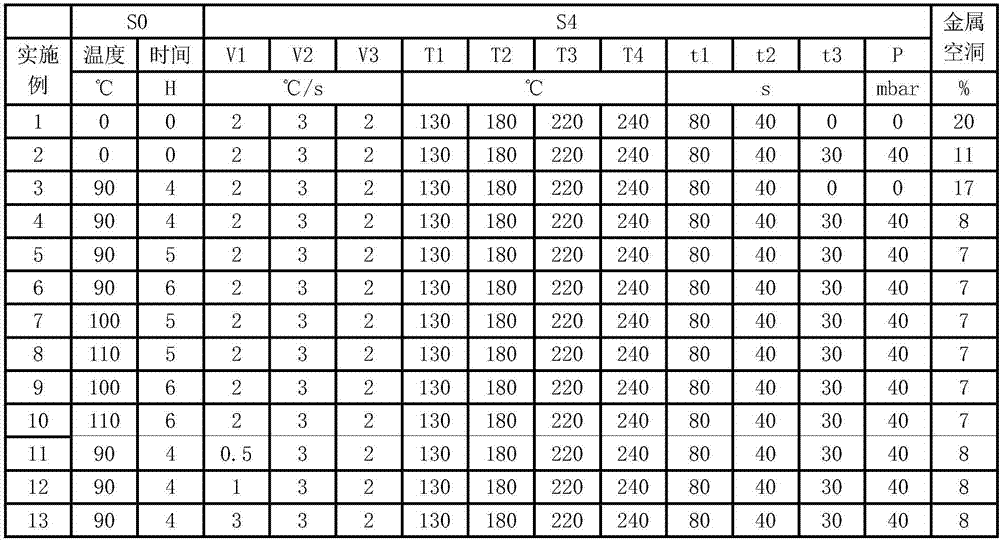

[0036] Embodiment 1-56: A reflow soldering patch process, including the following steps:

[0037] S0. Drying, put the circuit board to be soldered into the oven for pre-bake 4-6H, the drying temperature is 90-110℃; S1, print the solder paste, check the circuit board with the optical camera, then put the circuit The board is pasted under the stencil, and while the lead-free scraper is moved above the stencil, the solder paste is printed on the circuit board through the mesh on the stencil. The solder paste is Sn-Ag-Cu series Alloy solder, in which the mesh holes of the steel mesh board are inverted tapered round holes to increase the surface area of the solder paste printed on the circuit board;

[0038] S2, placement, send the circuit board after step S1 to the placement machine for placement;

[0039] S3. Intermediate inspection, check whether the polarity of the component is reversed, whether the mounting is offset, whether there is a short circuit, whether there are few or more...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com