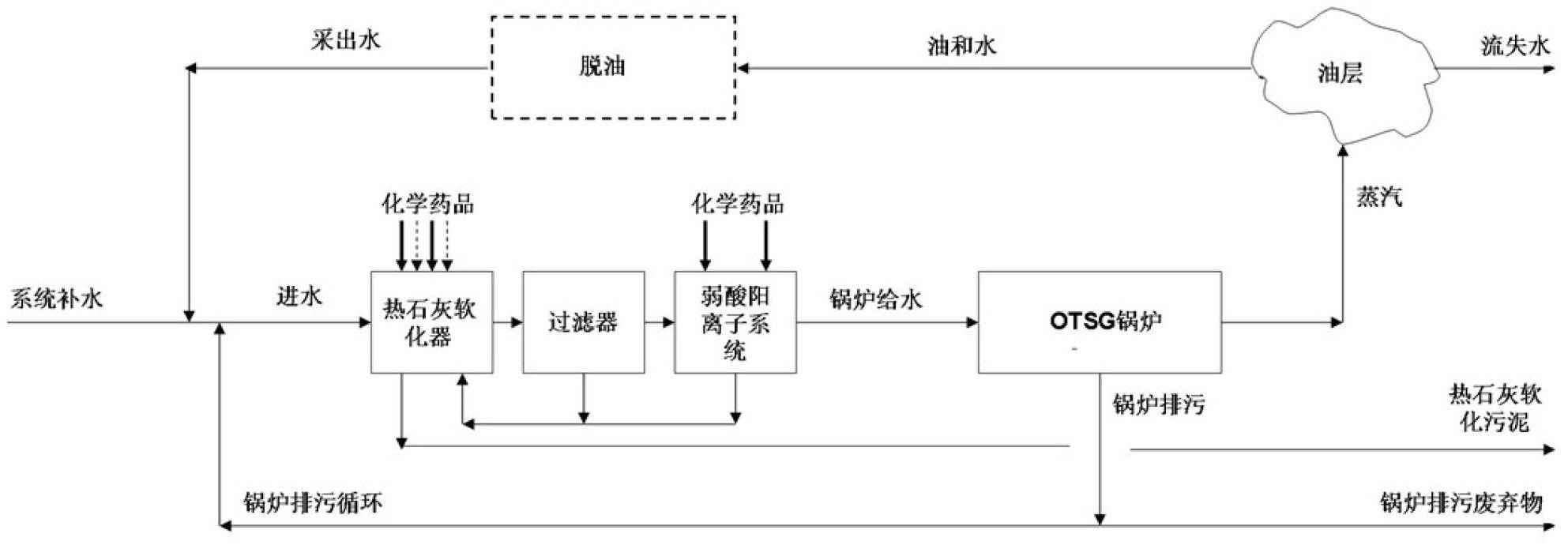

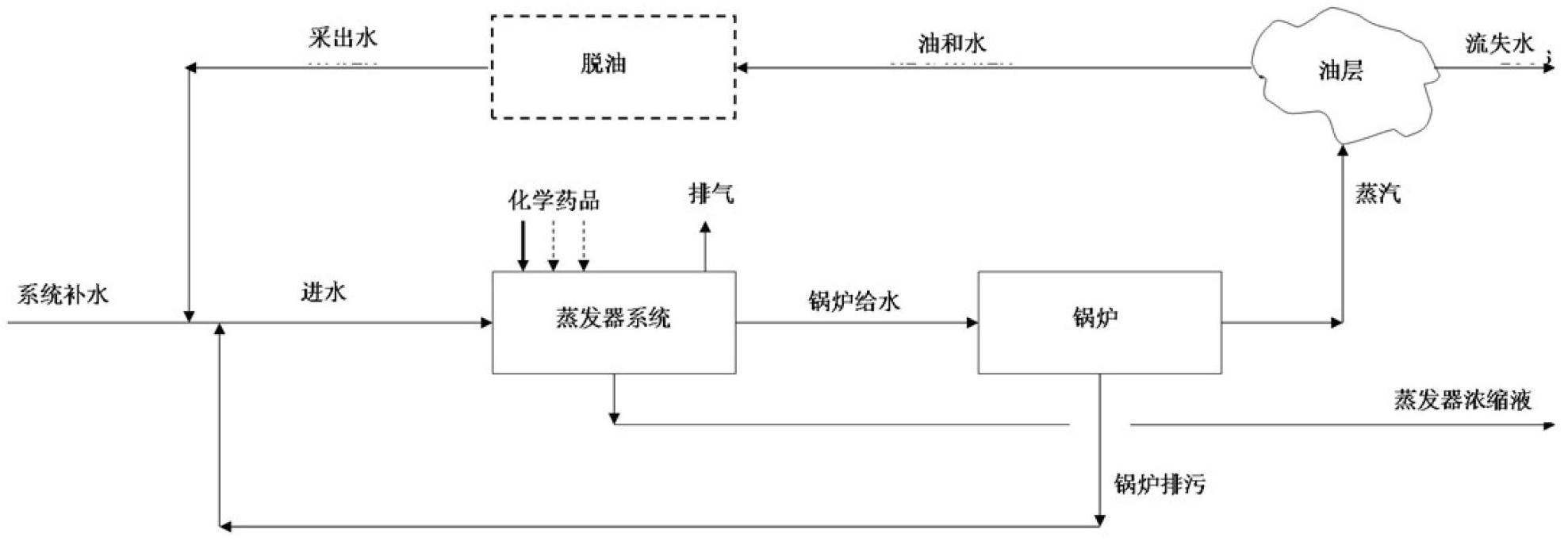

Water treatment process for recovering heavy oil recovery produced water to serve as boiler feed water

A technology for boiler feed water and produced water, which is applied in water/sewage treatment, heating water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problem of easy scaling of silicon components and hard components and affect the operation of the evaporation system , High boiler blowdown, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0116] a kind of like Figure 6 The liquid distributor 10 for the vertical falling film evaporator shown is mainly composed of a guide body 9 with a concave surface around the main body 6 and a bottom area of the top cover 1 larger than the area of the heat exchange tube 8 of the vertical falling film evaporator, and the The diversion body 9 is movably supported at the corresponding position in the upper part of the heat exchange tube 8 of the vertical falling film evaporator, so that the edge of the bottom surface of the top cover 1 of the diversion body 9 and the upper surface of the upper tube sheet 7 of the vertical falling film evaporator are separated by a certain gap to form a gap. The support part 5 of the liquid channel is composed. The guide body 9 is symmetrically distributed along the central axis of the heat exchange tube of the vertical falling film evaporator, and consists of a main body 6 and a top cover 1 . The top cover 1 is in the shape of a hat, and it...

Embodiment 2

[0120] a kind of like Figure 9 The liquid distributor 10 for the vertical falling film evaporator shown is mainly composed of a guide body 9 with a concave surface around the main body 6 and a bottom area of the top cover 1 larger than the area of the heat exchange tube 8 of the vertical falling film evaporator, and the The diversion body 9 is movably supported on the corresponding upper part of the heat exchange tube 8 of the vertical falling film evaporator, so that the edge of the bottom surface of the top cover 1 of the diversion body 9 and the top surface of the upper tube plate 7 of the vertical falling film evaporator are separated by a certain gap to form The support part 5 of the liquid inlet channel is composed. The guide body 9 is symmetrically distributed along the central axis of the heat exchange tube of the vertical falling film evaporator, and the diameter of the bottom surface of the guide body 9 is 0.6 times the inner diameter of the heat exchange tube 8...

Embodiment 3

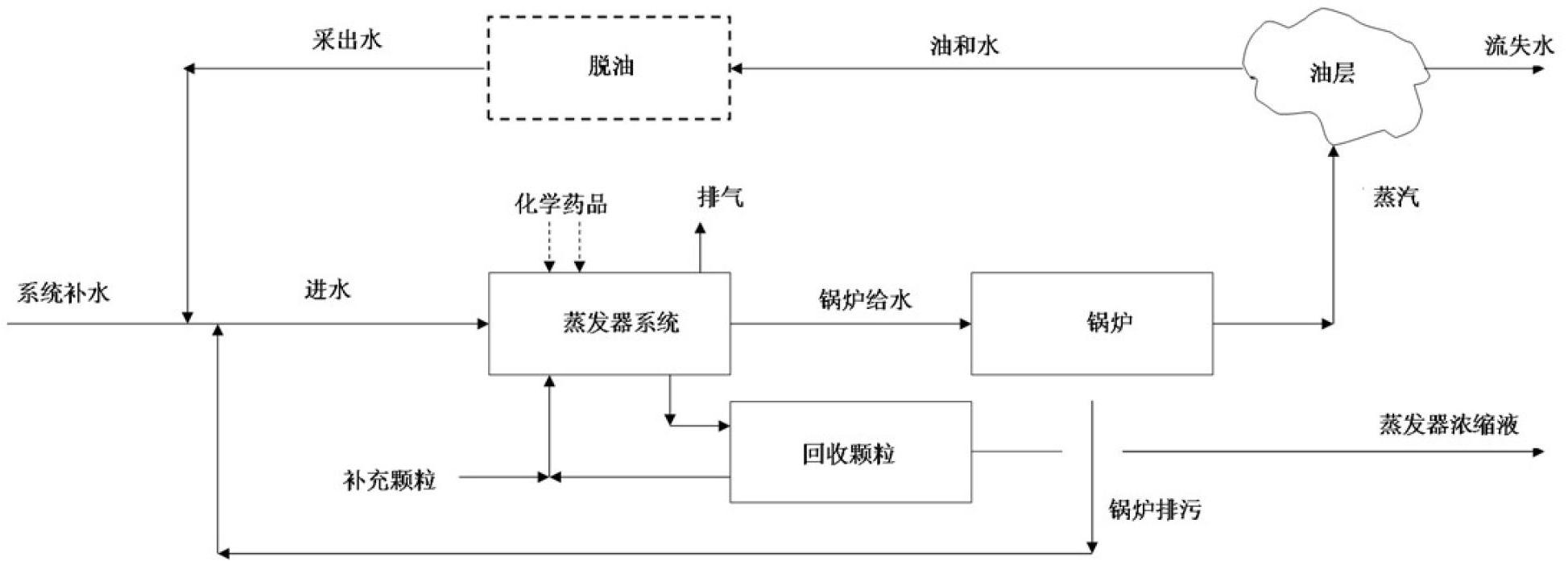

[0124] A water treatment system for recovering heavy oil production water as boiler feed water, including a water inflow pretreatment system, an evaporation system, a supplementary particle system, and a particle recovery system.

[0125] The water pre-treatment system includes the water pre-treatment system, including a chemical treatment device, a water preheater and a degasser. The chemical treatment device is composed of dosing equipment 11-1, 11-2, water inlet tank mixer 12, and water inlet tank 13. The water inlet tank and the water inlet preheater are connected by a water inlet pump 14 . The incoming water mainly produced water enters the water inlet tank, and the chemical treatment agent is added to the water inlet tank 13 through the dosing equipment 11 - 1 and 11 - 2 , and reacts under the stirring of the water inlet tank mixer 12 . The chemically treated water is pumped into the water preheater 15 by the water pump 14 for preheating, and then enters the degasser fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com