Welding method for eliminating pore defects of aluminum alloy electron beam weld joint

An electron beam welding seam and welding method technology, which is applied in the welding field of eliminating porosity defects of aluminum alloy electron beam welding seam joints, can solve the problems of unsatisfactory welding seam quality, large tendency of liquid aluminum pinholes, reducing material compactness and the like, Achieve high appearance quality, promote the escape of pores, and prolong the liquid time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

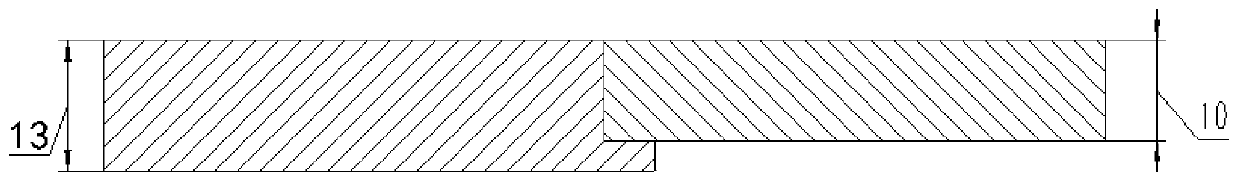

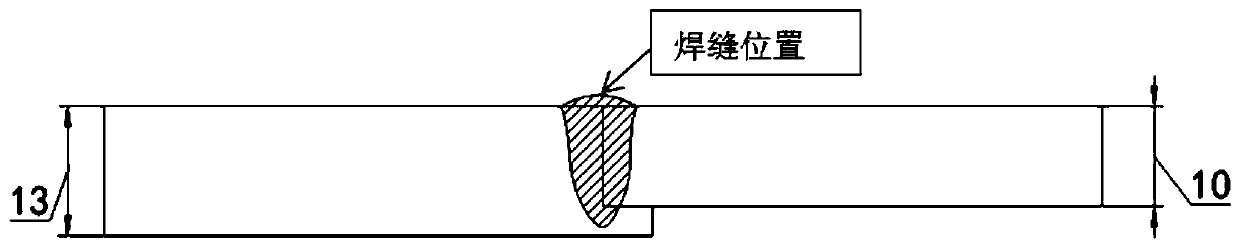

[0053] The ZL114A cast aluminum alloy test plate is selected, and the bottom lock joint is adopted, the thickness of the butt joint is 10mm, and the thickness of the bottom lock is 3mm.

[0054] Before welding, use a scraper to scrape the butt surface of the test plate, and grind the surface of the weld with a width of 10-15mm, grind until the surface shows metallic luster, and clean the parts to be welded;

[0055] Use welding tooling to assemble the test plate to be welded on the tooling frame, send the test plate to be welded into the vacuum chamber, and evacuate to make the vacuum degree reach 6×10 -4 mbar;

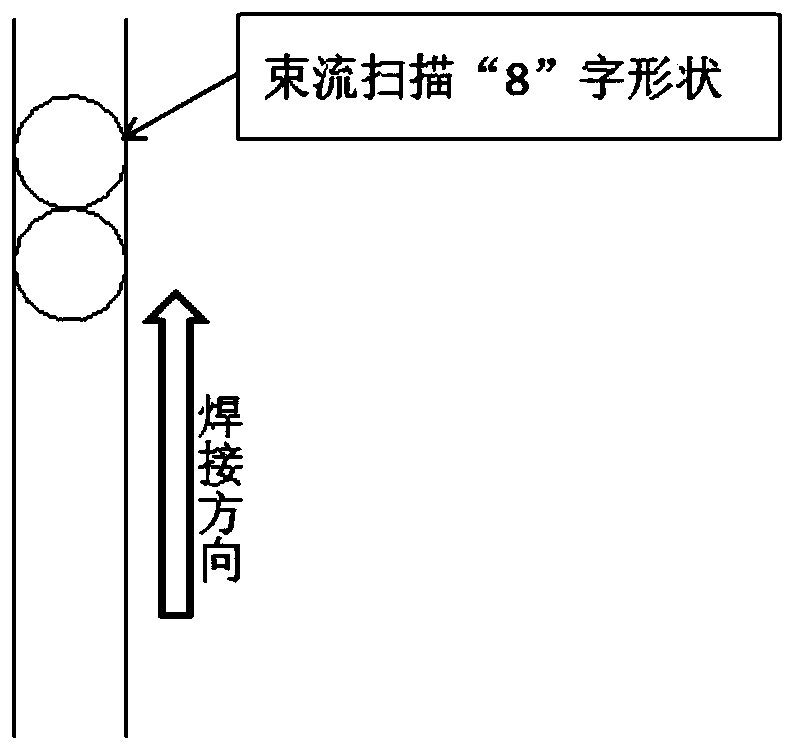

[0056] Vacuum electron beam welding is performed on the test plate, including tack welding, deep penetration welding, remelting welding, and modification welding. The electron beam is welded in the form of "8" swing scanning; the welding parameters are shown in the table:

[0057] Table 1 Vacuum electron beam welding parameters

[0058]

[0059]

[0060] After...

Embodiment 2

[0064] It is implemented on a certain type of fuel tank cylinder. The outer diameter of the welding part is 560mm, and the material is ZL114A cast aluminum alloy with strontium modifier. The cylinder body to be welded is a bottom-lock joint structure, with a butt thickness of 25mm and a bottom-lock thickness of 5mm. The specific welding method is as follows:

[0065] Cleaning of the part to be welded on the cylinder: use a scraper to scrape the butt surface of the test plate before welding, and grind the surface of the weld with a width of 15mm until the surface shows a metallic luster, and then clean the part to be welded with anhydrous alcohol;

[0066] Use aluminum alloy welding tooling to butt and assemble the cylinders together, adjust the working distance between the electron gun and the surface of the weld to be 400mm, the butt step difference during welding is ≤0.3mm, and the butt gap is ≤0.2mm, and the workpiece to be welded is hoisted to the electron beam welding mach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com