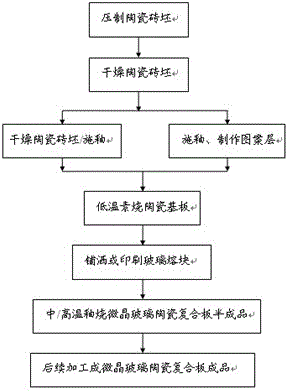

Production process of ultrathin microcrystalline layer microcrystalline glass ceramic composite board

A technology of glass-ceramic ceramics and production process, which is applied in the field of inorganic material production, can solve the problems of long production cycle, low production capacity, high cost of microcrystalline frit layer, etc., and achieves low raw material cost, short production cycle and less bubbles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment includes the following steps:

[0041] (1) This step is the process of preparing ceramic tiles with conventional ceramic manufacturing technology:

[0042] Using potassium and sodium feldspar, potassium and sodium sand, clay, kaolin, talc, wollastonite, spodumene, nepheline, etc., plus an appropriate amount of debonding agent and strengthening agent as raw materials, the raw material formula meets (quality ratio): 63 to 75 parts of silica, 14 to 25 parts of alumina, 0 to 3.5 parts of calcium oxide, 0 to 4 parts of magnesium oxide, 2 to 5 parts of potassium oxide, 1 to 5 parts of sodium oxide, 0 to 1 part of titanium dioxide, oxide Iron 0-2 parts, ignition loss: 4-7 parts. After weighing the raw materials, put them into a ball mill and wet ball mill; spray drying granulation, the powder moisture content is 5-8%; the powder material is pressed into a ceramic brick press and dried in a drying kiln to obtain moisture It is 0.1~1.5% dry ceramic tiles.

[0043] (2...

Embodiment 2

[0055] This embodiment includes the following steps:

[0056] (1) This step is the process of preparing ceramic tiles with conventional ceramic manufacturing technology:

[0057] Using potassium and sodium feldspar, potassium and sodium sand, clay, kaolin, talc, wollastonite, spodumene, nepheline, etc., plus an appropriate amount of debonding agent and strengthening agent as raw materials, the raw material formula meets (quality ratio): 63 to 75 parts of silica, 14 to 25 parts of alumina, 0 to 3.5 parts of calcium oxide, 0 to 4 parts of magnesium oxide, 1 to 5 parts of potassium oxide, 2 to 5 parts of sodium oxide, 0 to 1 part of titanium dioxide, oxide Loss on ignition of 0 to 2 parts of iron: 4 to 7 parts. After weighing the raw materials, put them into a ball mill and wet ball mill; spray drying granulation, the powder moisture content is 5-8%; the powder material is pressed into a ceramic brick press and dried in a drying kiln to obtain moisture It is 0.1~1.5% dry ceramic til...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com